Choosing Your Golf Bag Cart Rubber Mat: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for golf bag cart rubber mat

In the competitive landscape of the golf industry, sourcing high-quality golf bag cart rubber mats poses a significant challenge for B2B buyers. These essential accessories not only enhance the functionality of golf carts but also contribute to the overall customer experience by providing durability and comfort. This guide serves as a comprehensive resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil.

Within this guide, you will find an in-depth exploration of the various types of rubber mats available, their applications across different golf cart models, and crucial factors for supplier vetting. We will also cover cost considerations, ensuring that you can make informed purchasing decisions that align with your budget and quality expectations.

By equipping you with actionable insights and best practices, this guide empowers you to navigate the global market effectively. It aims to streamline your sourcing process and enhance your competitive edge, ensuring that you not only meet but exceed customer expectations in the ever-evolving golf market. Whether you are a retailer, distributor, or manufacturer, understanding the nuances of golf bag cart rubber mats can be the key to unlocking new business opportunities and fostering long-term partnerships.

Understanding golf bag cart rubber mat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rubber Mats | Basic grip and water resistance; fits most cart models. | General golf cart use; budget-conscious buyers. | Pros: Cost-effective, easy to clean. Cons: Limited customization, less durability. |

| Heavy-Duty Mats | Enhanced thickness and durability; often custom-fit. | Commercial golf courses, frequent use settings. | Pros: Long-lasting, excellent grip. Cons: Higher upfront cost, may be heavier. |

| Diamond Plate Mats | Textured surface for superior traction; aesthetic appeal. | Premium golf carts, luxury applications. | Pros: Stylish, enhanced safety. Cons: Higher price, potential for wear over time. |

| Custom-Fit Mats | Tailored to specific cart models; varied materials available. | OEM replacements, specialty carts. | Pros: Perfect fit, tailored features. Cons: Longer lead times, potential for higher costs. |

| Eco-Friendly Mats | Made from recycled materials; sustainable options available. | Environmentally conscious brands, green initiatives. | Pros: Sustainable choice, appealing to eco-conscious buyers. Cons: May lack durability compared to traditional materials. |

What are the characteristics of Standard Rubber Mats and their suitability for buyers?

Standard rubber mats are the most basic type of golf bag cart mats. They provide adequate grip and water resistance, making them suitable for everyday use. These mats typically fit a wide range of golf cart models, appealing to budget-conscious buyers or those who require a simple solution for general use. When considering this option, B2B buyers should evaluate the balance between cost and performance, as these mats may not offer the longevity or customization of more premium options.

How do Heavy-Duty Mats stand out in terms of durability and application?

Heavy-duty mats are designed for rigorous use, featuring increased thickness and durability compared to standard options. They are ideal for commercial golf courses or settings where carts are used frequently. B2B buyers in these environments should consider the long-term investment, as these mats provide excellent grip and can withstand wear and tear. The higher upfront cost is often justified by their longevity and performance, making them a preferred choice for businesses prioritizing durability.

What advantages do Diamond Plate Mats provide for premium applications?

Diamond plate mats are characterized by their textured surface, which offers superior traction and an aesthetically pleasing design. These mats cater to premium golf carts and luxury applications, enhancing both safety and style. B2B buyers looking to elevate the image of their golf cart fleet or provide a more luxurious experience for customers should consider these mats. However, the price point may be higher, and buyers should be aware of potential wear over time.

Why are Custom-Fit Mats essential for specific cart models?

Custom-fit mats are tailored to specific golf cart models, ensuring a perfect fit and often incorporating varied materials based on client needs. This type of mat is vital for OEM replacements or specialty carts that require unique specifications. B2B buyers should factor in the lead times associated with custom orders and the potential for increased costs. The benefits of a tailored fit can significantly enhance user experience and functionality.

How do Eco-Friendly Mats appeal to environmentally conscious buyers?

Eco-friendly mats are made from recycled materials, making them a sustainable option for businesses looking to align with green initiatives. These mats cater to environmentally conscious brands and can enhance a company’s reputation in sustainability. While they may not always match the durability of traditional materials, their appeal lies in their sustainable nature. B2B buyers should assess the trade-off between environmental benefits and long-term performance when considering eco-friendly mats for their golf cart fleets.

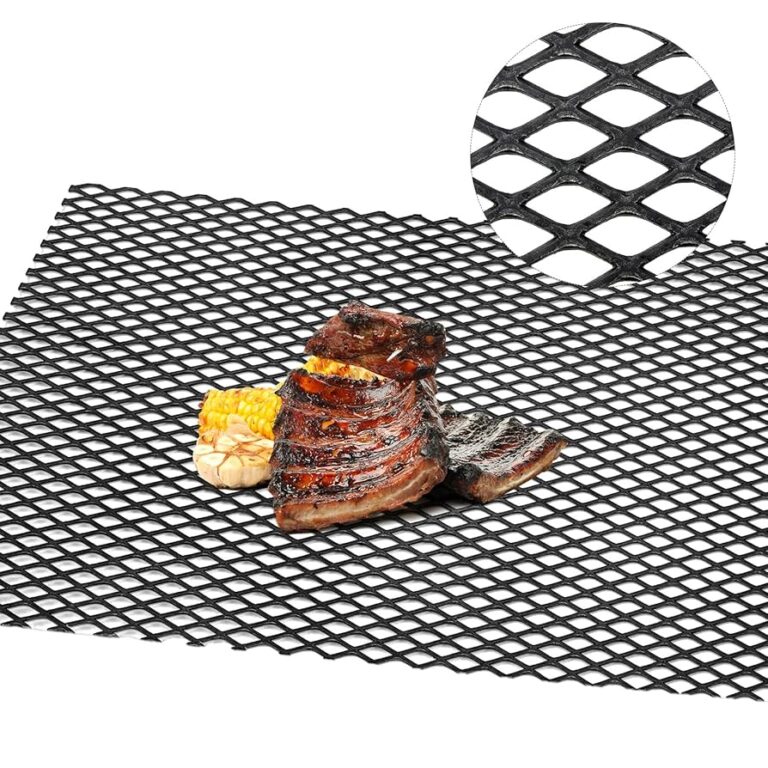

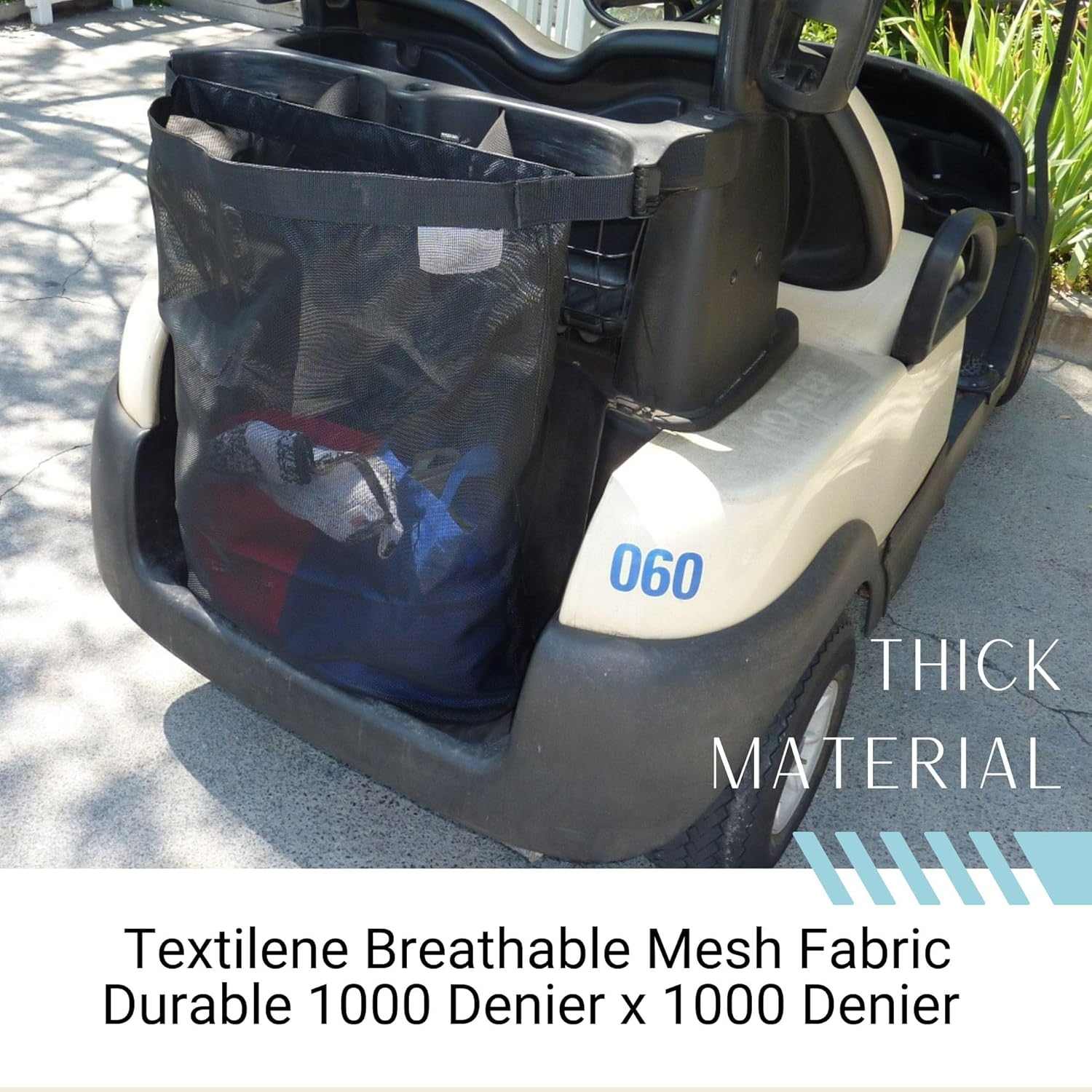

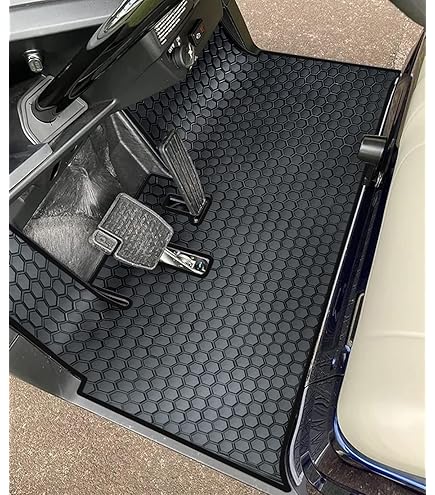

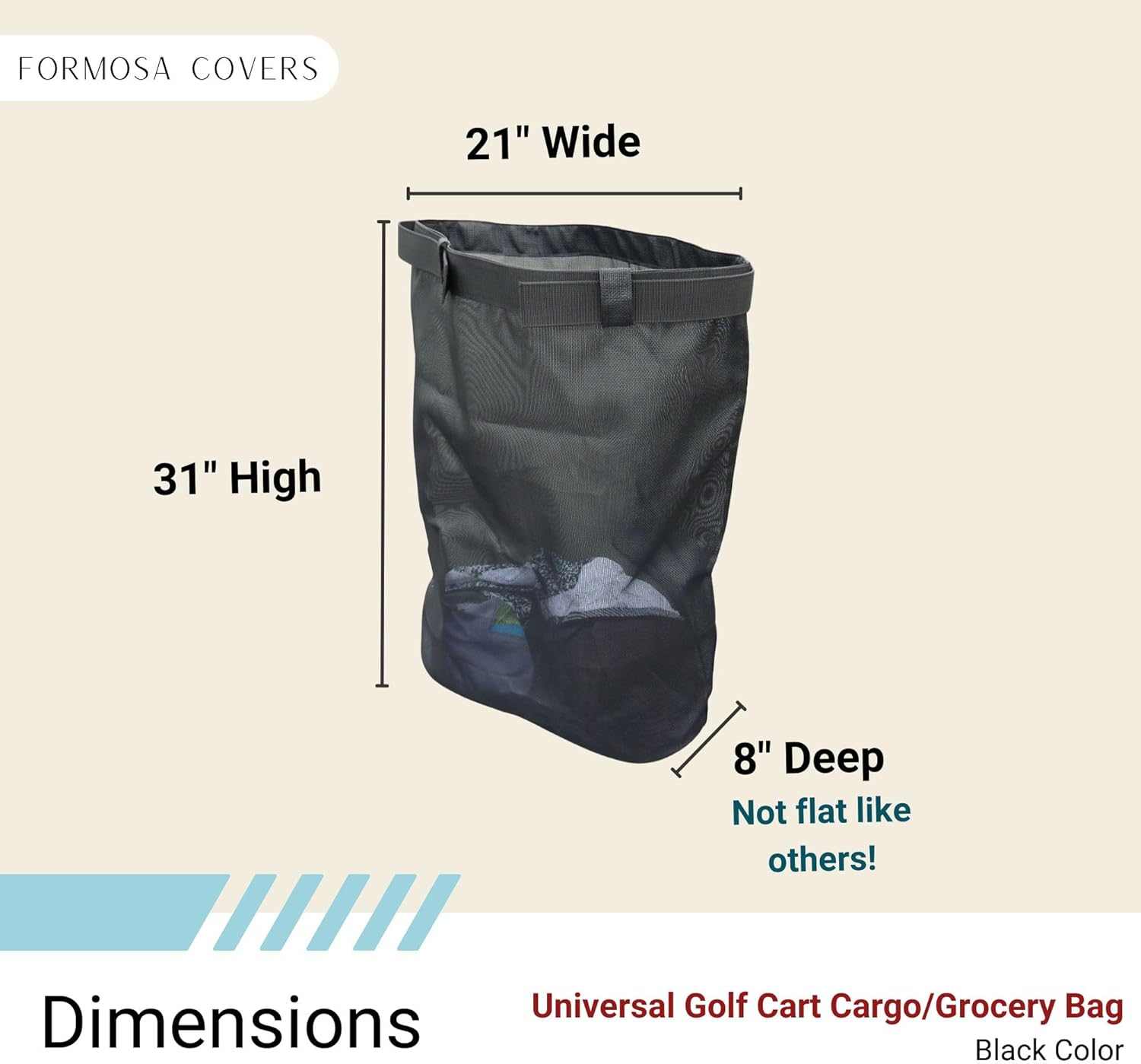

Illustrative image related to golf bag cart rubber mat

Key Industrial Applications of golf bag cart rubber mat

| Industry/Sector | Specific Application of golf bag cart rubber mat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Golf Course Management | Enhancing golfer experience with improved cart interiors | Increases customer satisfaction and retention | Custom fit for various cart models; durability in various climates |

| Sporting Goods Retail | Display and demo of golf carts | Attracts customers by showcasing quality and functionality | Non-slip surfaces; aesthetic appeal; easy maintenance |

| Event Management | Temporary golf events and tournaments | Provides a professional appearance and protects carts | Lightweight for easy transport; weather resistance |

| Hospitality Industry | Golf resorts and hotels utilizing golf carts | Enhances guest experience while maintaining cart longevity | Custom branding options; resistance to wear and tear |

| Rental Services | Rental fleets for golf carts | Reduces maintenance costs and extends the lifespan of carts | Availability of bulk orders; compatibility with various models |

How is the Golf Bag Cart Rubber Mat Used in Golf Course Management?

In golf course management, rubber mats are employed to enhance the interiors of golf carts, providing a non-slip surface for players and their equipment. These mats improve the overall user experience by ensuring that golfers can easily enter and exit the carts without slipping, especially in wet conditions. For international buyers, particularly in regions with diverse climates such as Africa and the Middle East, sourcing mats that are durable and resistant to wear is essential. Custom-fit mats tailored to specific cart models can further enhance functionality.

What Role Does the Golf Bag Cart Rubber Mat Play in Sporting Goods Retail?

In sporting goods retail, golf bag cart rubber mats serve as an effective display tool for showcasing golf carts. By providing a clean, attractive, and functional surface, these mats can draw customers’ attention and demonstrate the quality of the carts. Retailers should consider mats that not only offer aesthetic appeal but also feature non-slip surfaces to enhance safety during demonstrations. For buyers in Europe, where competition is high, investing in high-quality mats can be a differentiator in a crowded marketplace.

How Can Golf Bag Cart Rubber Mats Benefit Event Management?

Event management companies utilize golf bag cart rubber mats during temporary golf events and tournaments to provide a professional appearance and protect rental carts. These mats can be easily transported and installed, making them ideal for short-term use. Buyers in regions such as South America, where events may be held in varying weather conditions, should prioritize mats that are weather-resistant and lightweight for easy setup and teardown. This ensures a seamless experience for both organizers and participants.

Illustrative image related to golf bag cart rubber mat

Why Are Golf Bag Cart Rubber Mats Important in the Hospitality Industry?

For the hospitality industry, particularly golf resorts and hotels, rubber mats are crucial for enhancing the guest experience. They provide a comfortable and safe environment for guests using golf carts, while also contributing to the longevity of the carts themselves. International buyers should look for mats that can be customized with branding options, allowing resorts to promote their identity while maintaining functionality. Additionally, mats that resist wear and tear from frequent use are essential for minimizing replacement costs.

How Do Rental Services Benefit from Golf Bag Cart Rubber Mats?

Rental services that offer golf carts can significantly benefit from the use of golf bag cart rubber mats. These mats help reduce maintenance costs by protecting the cart floors from wear and damage, thus extending the lifespan of the equipment. When sourcing mats, rental service providers should consider bulk order options to reduce costs and ensure compatibility with various cart models. This is particularly relevant for buyers in regions with burgeoning golf tourism, where demand for rental carts is high.

3 Common User Pain Points for ‘golf bag cart rubber mat’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Fit for Golf Bag Carts

The Problem: Many B2B buyers face the challenge of sourcing golf bag cart rubber mats that fit specific models of golf carts. With a variety of brands and models in the market, buyers often purchase mats that do not align with the dimensions or features of their carts, leading to wasted time, resources, and increased returns. This issue can be especially frustrating when dealing with multiple suppliers or when trying to cater to diverse customer needs across different regions, such as Africa or Europe, where specifications may vary widely.

Illustrative image related to golf bag cart rubber mat

The Solution: To ensure the proper fit, B2B buyers should prioritize sourcing from manufacturers that offer custom solutions tailored to specific golf cart models. When evaluating suppliers, request detailed specifications, including dimensions, compatibility, and installation instructions. Engage in open communication with manufacturers to discuss your specific needs and consider requesting samples before placing bulk orders. By investing time in understanding the precise requirements of each golf cart model, you can mitigate the risk of purchasing incorrect mats and enhance customer satisfaction.

Scenario 2: Inadequate Durability and Performance Under Various Conditions

The Problem: Another significant pain point is the durability of rubber mats under different weather and usage conditions. Buyers often receive complaints from customers about mats that wear out quickly, especially in regions with extreme temperatures or heavy rainfall. This can lead to reputational damage and increased costs related to returns and replacements.

The Solution: To address durability concerns, buyers should seek rubber mats made from high-quality, weather-resistant materials. Look for suppliers that provide performance guarantees and detailed information on material composition, such as UV resistance and water absorption rates. Conduct thorough research on suppliers’ reputations and read customer reviews to assess the long-term performance of their products. Additionally, consider investing in mats that feature anti-slip surfaces to improve safety and user experience, especially in wet conditions. By prioritizing quality over cost, you can reduce long-term expenses associated with replacements and enhance brand loyalty.

Scenario 3: Limited Customization Options for Branding

The Problem: B2B buyers often encounter challenges in finding rubber mats that can be customized for branding purposes. In a competitive market, having branded golf bag cart mats can significantly enhance visibility and market differentiation. However, many suppliers offer limited options for customization, which can hinder promotional efforts and diminish the perceived value of the product.

Illustrative image related to golf bag cart rubber mat

The Solution: To overcome this limitation, buyers should look for manufacturers that specialize in custom branding options for golf bag cart rubber mats. Engage in discussions about personalized designs, including logos, colors, and textures that align with your brand identity. It may also be beneficial to collaborate with suppliers who can accommodate small batch orders for customized mats, allowing for flexibility in inventory management. Additionally, consider leveraging digital printing technologies that can provide high-quality branding without compromising the mat’s durability. By investing in customized mats, you can create a unique selling proposition that resonates with your target audience and enhances brand recognition.

Strategic Material Selection Guide for golf bag cart rubber mat

When selecting materials for golf bag cart rubber mats, it is essential to consider various properties that impact performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in the production of these mats, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Natural Rubber for Golf Bag Cart Mats?

Natural rubber is a popular choice for golf bag cart mats due to its excellent elasticity and grip. It can withstand a wide range of temperatures, making it suitable for various climates. Natural rubber also has good abrasion resistance, which helps maintain the mat’s integrity even under heavy use. However, it is less resistant to UV light and ozone, which can lead to degradation over time.

Pros and Cons:

– Pros: High elasticity, excellent grip, good abrasion resistance.

– Cons: Limited UV and ozone resistance, potentially higher cost.

Impact on Application:

Natural rubber mats are ideal for environments where high traction is necessary, particularly in wet conditions. However, their susceptibility to UV damage means they may require replacement more frequently in sunny regions.

Considerations for International Buyers:

Buyers should ensure compliance with local environmental regulations regarding natural rubber sourcing. Standards such as ASTM D2000 can guide quality expectations.

How Does Synthetic Rubber Compare for Golf Bag Cart Mats?

Synthetic rubber, such as EPDM (Ethylene Propylene Diene Monomer), offers excellent weather resistance and durability. It can withstand extreme temperatures and is highly resistant to UV radiation and ozone, making it suitable for outdoor applications. This material is also less prone to degradation compared to natural rubber.

Pros and Cons:

– Pros: Superior weather resistance, long lifespan, lower maintenance.

– Cons: Generally higher manufacturing complexity, which can increase costs.

Impact on Application:

Synthetic rubber mats are well-suited for regions with extreme weather conditions, ensuring longevity and performance. They are particularly beneficial in areas with high UV exposure, such as parts of Africa and South America.

Considerations for International Buyers:

Buyers should be aware of the specific grades of synthetic rubber that meet local standards, such as DIN 53505 for abrasion resistance.

What Role Does PVC Play in Golf Bag Cart Mat Production?

Polyvinyl Chloride (PVC) is another common material used for golf bag cart mats. Known for its excellent chemical resistance, PVC can withstand various substances without degrading. It is also relatively inexpensive and easy to manufacture, making it a cost-effective option for many businesses.

Pros and Cons:

– Pros: Cost-effective, good chemical resistance, easy to mold.

– Cons: Lower durability compared to rubber, can be slippery when wet.

Impact on Application:

PVC mats are suitable for indoor use or in controlled environments where exposure to harsh conditions is limited. However, their lower durability may lead to more frequent replacements.

Considerations for International Buyers:

Buyers should ensure that the PVC used complies with safety standards such as REACH in Europe, which regulates chemicals in consumer products.

How Does Foam Rubber Enhance Comfort in Golf Bag Cart Mats?

Foam rubber is often used in golf bag cart mats for its cushioning properties. It provides a comfortable surface for users while also offering good insulation against temperature fluctuations. However, foam rubber typically has lower durability and may not withstand heavy loads as effectively as other materials.

Pros and Cons:

– Pros: Excellent comfort, good insulation, lightweight.

– Cons: Limited durability, can compress under heavy weight.

Illustrative image related to golf bag cart rubber mat

Impact on Application:

Foam rubber mats are best suited for recreational environments where comfort is prioritized over heavy-duty use. They may be ideal for regions with milder climates.

Considerations for International Buyers:

Buyers should check for compliance with international safety standards, particularly regarding flammability and chemical emissions.

Summary Table of Material Selection for Golf Bag Cart Rubber Mats

| Material | Typical Use Case for golf bag cart rubber mat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | High-traction environments, wet conditions | Excellent grip and elasticity | Limited UV resistance | Medium |

| Synthetic Rubber | Extreme weather conditions, outdoor use | Superior weather and UV resistance | Higher manufacturing complexity | High |

| PVC | Indoor use, controlled environments | Cost-effective and easy to mold | Lower durability, slippery when wet | Low |

| Foam Rubber | Recreational environments, comfort-focused | Excellent cushioning and insulation | Limited durability | Medium |

This guide provides valuable insights for B2B buyers looking to select the most suitable material for golf bag cart rubber mats, ensuring that they meet performance requirements while adhering to regional standards and preferences.

Illustrative image related to golf bag cart rubber mat

In-depth Look: Manufacturing Processes and Quality Assurance for golf bag cart rubber mat

What Are the Key Stages in the Manufacturing Process of Golf Bag Cart Rubber Mats?

The manufacturing process of golf bag cart rubber mats involves several critical stages that ensure both functionality and quality. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step involves selecting high-quality rubber compounds that are durable and resistant to wear and tear. Common materials include EPDM (Ethylene Propylene Diene Monomer) and natural rubber, known for their excellent grip and weather resistance.

Once the materials are selected, they undergo a preparation phase where they are mixed with various additives to enhance properties such as elasticity and UV resistance. This mixture is then processed into sheets or rolls, ready for the next stage of production.

Illustrative image related to golf bag cart rubber mat

Forming: What Techniques Are Used to Shape the Mats?

The forming stage utilizes various techniques to shape the rubber into the desired mat configuration. Common methods include:

-

Compression Molding: This technique involves placing the rubber mixture into a mold, where heat and pressure are applied to form the mat. It is suitable for producing mats with complex shapes and designs.

-

Extrusion: For mats with a continuous profile, extrusion is used. The rubber is forced through a die to create long strips that can be cut to size.

-

Die Cutting: After forming, mats may undergo die cutting for precise dimensions, ensuring they fit specific golf cart models perfectly.

These techniques ensure that the mats are both aesthetically pleasing and functional, offering optimal grip and comfort.

Assembly: How Are Different Components Integrated?

In some cases, golf bag cart rubber mats may require assembly with other components, such as backing materials or anti-slip layers. This assembly process ensures that the mats not only provide comfort but also enhance safety for users.

Illustrative image related to golf bag cart rubber mat

Manufacturers may use adhesives or mechanical fastening methods to ensure that all components are securely attached. Quality control checks are often performed at this stage to ensure that the assembly meets design specifications.

Finishing: What Are the Final Touches Applied to the Mats?

The finishing stage involves applying surface treatments that enhance the aesthetic and functional properties of the mats. This could include:

-

Texturing: To improve grip and prevent slipping, mats may have textured surfaces.

-

Coating: A protective coating may be applied to enhance durability and resistance to environmental factors.

-

Inspection: Final inspection is crucial to ensure that the mats meet quality standards before packaging and shipping.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for golf bag cart rubber mats. It ensures that the final products meet international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding international quality standards is essential. Key certifications include:

-

ISO 9001: This standard focuses on quality management systems and continuous improvement. Suppliers adhering to ISO 9001 demonstrate their commitment to quality and customer satisfaction.

-

CE Marking: Particularly relevant for buyers in Europe, CE marking indicates that products comply with EU safety, health, and environmental protection standards.

-

API Standards: For suppliers targeting markets in the Middle East or specific industrial applications, adherence to American Petroleum Institute (API) standards can be critical.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before production begins.

-

In-Process Quality Control (IPQC): Ongoing inspections during manufacturing ensure that any deviations from standards are addressed promptly.

-

Final Quality Control (FQC): This final inspection phase assesses the finished products for adherence to design and performance specifications before they are packaged for shipment.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods are crucial for verifying the performance and durability of the mats. Common tests include:

-

Tensile Strength Testing: Measures the material’s resistance to breaking under tension, ensuring durability.

-

Slip Resistance Testing: Assesses how well the mats perform under wet and dry conditions, which is vital for user safety.

-

Weathering Tests: Evaluate how well the mats can withstand UV exposure and extreme temperatures, essential for outdoor use.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is vital to ensure they are making a sound investment.

What Steps Can Buyers Take to Conduct Supplier Audits?

-

Request Documentation: Buyers should ask for quality assurance documentation, including ISO certifications, test reports, and compliance statements.

-

On-Site Audits: Conducting on-site audits can provide invaluable insights into a supplier’s manufacturing processes and quality control measures.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices, ensuring they meet international standards.

What Are the Nuances of Quality Control for International Markets?

Understanding regional regulations and standards is crucial for international B2B buyers. For example:

-

European Standards: In Europe, compliance with CE marking is essential, while in regions like Africa and South America, local regulations may vary significantly.

-

Cultural Considerations: Different markets may have varying expectations regarding quality and durability, which should be factored into the supplier selection process.

By paying attention to these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing golf bag cart rubber mats, ensuring they receive products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘golf bag cart rubber mat’

In the competitive landscape of golf accessories, sourcing high-quality golf bag cart rubber mats requires careful consideration and strategic planning. This guide offers a step-by-step checklist to streamline your procurement process, ensuring you select the best products and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for effective sourcing. Consider factors such as size, material composition (e.g., rubber, foam), and design features like drainage systems or anti-slip surfaces. Having precise requirements helps you communicate your needs to suppliers and ensures compatibility with various golf cart models.

Step 2: Research Supplier Marketplaces

Begin your search by exploring reputable online marketplaces and industry-specific platforms. Look for suppliers with a strong track record in the golf accessory sector and positive customer reviews. Utilize filters to narrow down options based on product ratings, delivery capabilities, and geographical reach to ensure you find suitable candidates for your region.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is essential to conduct a thorough evaluation of potential suppliers. Request detailed company profiles, including years in business, product lines, and production capacities. Additionally, ask for case studies or testimonials from other B2B buyers in your industry to gauge their reliability and quality.

Step 4: Request Samples

Always request samples before finalizing your order. This step allows you to assess the quality, durability, and overall design of the mats firsthand. Pay attention to factors such as texture, weight, and flexibility, as these attributes directly impact user experience and satisfaction.

Step 5: Verify Compliance and Certifications

Confirm that suppliers meet industry standards and safety regulations applicable to your market. Look for certifications related to materials used, such as non-toxic or eco-friendly claims, which can enhance your brand’s credibility. Ensure that the supplier can provide necessary documentation to support their compliance.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms to find a mutually beneficial arrangement. Inquire about bulk purchase discounts, shipping costs, and lead times. Understanding the full cost of procurement helps you budget effectively and avoid unexpected expenses.

Step 7: Establish a Long-Term Relationship

Once you have chosen a supplier, focus on building a strong partnership. Regular communication and feedback can lead to better service, tailored offerings, and potential discounts for future orders. A long-term relationship can also facilitate quicker responses to market changes or product innovations.

Illustrative image related to golf bag cart rubber mat

By following this checklist, B2B buyers can streamline their sourcing process for golf bag cart rubber mats, ensuring they procure high-quality products that meet both their operational needs and customer expectations.

Comprehensive Cost and Pricing Analysis for golf bag cart rubber mat Sourcing

Analyzing the cost structure and pricing for sourcing golf bag cart rubber mats is essential for international B2B buyers looking to make informed purchasing decisions. This section delves into the various cost components, price influencers, and valuable tips for buyers in regions such as Africa, South America, the Middle East, and Europe, specifically Germany and Brazil.

What Are the Key Cost Components for Golf Bag Cart Rubber Mats?

When evaluating the cost of golf bag cart rubber mats, several components contribute to the overall price:

-

Materials: The type and quality of materials significantly impact costs. High-density rubber or synthetic materials that provide durability and weather resistance are often preferred, but they may increase the price. Buyers should consider sourcing from suppliers that offer a balance between quality and cost.

-

Labor: Labor costs vary by region and supplier. In areas with higher labor costs, such as parts of Europe, the manufacturing price may be elevated. Understanding labor market conditions in the supplier’s location can provide insight into pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Suppliers with efficient production processes may offer more competitive pricing.

-

Tooling: Custom molds and tooling for specific designs can add significant costs. Buyers should be aware that one-time tooling fees may apply for custom orders, impacting initial pricing.

-

Quality Control (QC): Investing in quality control processes ensures that the mats meet specified standards, affecting overall costs. Suppliers who prioritize QC may charge more but can provide greater assurance of product quality.

-

Logistics: Shipping and handling costs can be substantial, especially for international shipments. Factors like distance, shipping method, and freight charges should be factored into the total cost.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. Understanding typical margins in the industry can help buyers assess whether a price is fair.

What Influences the Pricing of Golf Bag Cart Rubber Mats?

Several factors can influence the pricing of golf bag cart rubber mats:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often attract discounts. Buyers should negotiate MOQs to optimize cost efficiency.

-

Specifications and Customization: Custom designs and specifications can drive up costs. It’s essential to clarify needs upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO standards) often come at a premium. Buyers should assess whether these certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but provide better service and assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define responsibilities and costs between buyers and sellers, impacting the total cost.

How Can Buyers Negotiate for Better Prices on Rubber Mats?

To secure favorable pricing, buyers should consider the following tips:

-

Research and Compare: Gather quotes from multiple suppliers. Understanding the market rates can provide leverage during negotiations.

-

Build Relationships: Developing a rapport with suppliers can lead to better terms and pricing. Long-term partnerships often yield cost benefits.

-

Highlight Volume Commitments: If planning to order in bulk, communicate potential volume commitments to negotiate better pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price, but also the durability, maintenance, and potential replacement costs associated with different rubber mats.

-

Stay Informed on Pricing Nuances: Be aware of regional pricing trends and economic factors affecting supply chains in Africa, South America, the Middle East, and Europe. This knowledge can empower buyers during negotiations.

Conclusion

Understanding the cost structure and pricing dynamics of golf bag cart rubber mats is crucial for making informed B2B purchasing decisions. By considering the outlined cost components, price influencers, and negotiation strategies, buyers from diverse regions can optimize their sourcing efforts and achieve better value for their investments. Always keep in mind that prices may vary and should be treated as indicative, as fluctuations in material costs and market conditions can influence final quotes.

Alternatives Analysis: Comparing golf bag cart rubber mat With Other Solutions

Exploring Alternative Solutions to Golf Bag Cart Rubber Mats

When considering the best flooring solutions for golf carts, it’s essential to evaluate various options available in the market. While the golf bag cart rubber mat is a popular choice, alternative products also provide unique benefits that may better suit specific operational needs. This analysis compares the golf bag cart rubber mat against two viable alternatives: synthetic turf mats and custom-fit vinyl mats. Each solution has distinct characteristics that can influence a B2B buyer’s decision.

| Comparison Aspect | Golf Bag Cart Rubber Mat | Synthetic Turf Mats | Custom-Fit Vinyl Mats |

|---|---|---|---|

| Performance | Excellent grip and durability, water-resistant | Provides a natural look and feel, moderate grip | Easy to clean, less grip in wet conditions |

| Cost | Moderate ($90-$150) | Moderate ($100-$160) | Higher ($150-$250) |

| Ease of Implementation | Simple installation, fits most models | Requires more effort to install | Usually pre-cut for specific models |

| Maintenance | Low maintenance; easy to clean | Moderate; requires regular upkeep | Low; generally easy to clean |

| Best Use Case | Ideal for varied weather conditions and heavy use | Best for aesthetics and light use | Suitable for custom-fit carts needing protection |

What Are the Advantages and Disadvantages of Synthetic Turf Mats?

Synthetic turf mats offer an appealing alternative for golf carts, especially for those prioritizing aesthetics. These mats mimic the look of natural grass, enhancing the overall visual appeal of the cart. They provide moderate grip, which can be beneficial in dry conditions. However, their performance may diminish in wet conditions, posing a slip hazard. Additionally, maintenance can be more demanding as they require regular cleaning to avoid dirt accumulation. The initial investment can be comparable to rubber mats, but the aesthetic value might justify the cost for some buyers.

How Do Custom-Fit Vinyl Mats Compare?

Custom-fit vinyl mats are designed to perfectly align with specific golf cart models, providing an excellent fit that protects the cart’s flooring from wear and tear. They are relatively easy to clean and maintain, making them a practical choice for busy golf courses. However, the cost tends to be higher than rubber mats, which might deter some buyers. While they offer great protection, the vinyl material may not provide the same level of grip in wet conditions, which could be a concern for users in regions with frequent rain.

Making the Right Choice for Your Golf Cart Needs

When selecting the best flooring solution for golf carts, B2B buyers must consider various factors, including performance, cost, and specific use cases. The golf bag cart rubber mat is a reliable choice for its durability and grip, making it suitable for various weather conditions. However, for businesses focused on aesthetics or specific fit, synthetic turf or custom-fit vinyl mats may offer compelling benefits. Ultimately, the decision should align with operational needs, budget constraints, and desired functionality to ensure a satisfactory investment for the long term.

Essential Technical Properties and Trade Terminology for golf bag cart rubber mat

What Are the Key Technical Properties of Golf Bag Cart Rubber Mats?

When sourcing golf bag cart rubber mats, understanding their technical properties is crucial for ensuring product quality and compatibility. Here are some essential specifications to consider:

1. Material Grade

The material used in rubber mats typically includes high-density polyethylene (HDPE) or thermoplastic rubber (TPR). These materials are known for their durability, flexibility, and resistance to wear and tear. In B2B transactions, specifying material grades ensures that buyers receive products that can withstand heavy usage and adverse weather conditions, ultimately leading to longer product lifespans.

Illustrative image related to golf bag cart rubber mat

2. Tolerance Levels

Tolerance refers to the allowable variation in dimensions during manufacturing. For rubber mats, maintaining tight tolerances (e.g., ±0.5 mm) is essential for ensuring a snug fit in various golf cart models. This precision reduces the risk of movement during use, enhancing safety and comfort for users. Buyers should seek suppliers who can consistently meet these tolerance levels.

3. Thickness

The thickness of the rubber mat directly affects its performance and comfort. Standard thickness ranges from 5 mm to 12 mm, with thicker mats providing better cushioning and shock absorption. In the B2B context, thicker mats may come at a higher cost but offer greater durability, making them a worthwhile investment for frequent users.

4. Grip and Traction

The surface texture of the mat plays a critical role in providing grip, particularly in wet conditions. Mats with anti-slip surfaces ensure that golf bags and passengers remain stable, reducing the risk of accidents. Buyers should inquire about the grip ratings or test results from suppliers to ensure that the mats meet safety standards.

Illustrative image related to golf bag cart rubber mat

5. Customization Options

Many manufacturers offer customization options, such as logo imprints or specific dimensions tailored to particular golf cart models. Customization can enhance brand visibility and ensure a perfect fit. B2B buyers should discuss these options with suppliers to align product offerings with their branding strategies.

What Are Common Trade Terminology and Jargon Related to Golf Bag Cart Rubber Mats?

Familiarity with industry-specific terminology can facilitate smoother negotiations and transactions. Here are some key terms to understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rubber mats, understanding whether a product is OEM can indicate quality and compatibility with specific golf cart brands. B2B buyers should verify OEM status to ensure they are sourcing reliable products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory levels and cost efficiency. Understanding the MOQ can help businesses plan their procurement strategies effectively and avoid overstock situations.

Illustrative image related to golf bag cart rubber mat

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. In the context of golf bag cart rubber mats, an RFQ allows buyers to compare pricing, terms, and conditions from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to mitigate risks and ensure clarity in transactions, especially in cross-border dealings.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. In the rubber mat industry, understanding lead times can help businesses manage inventory and meet customer demands effectively. Buyers should communicate their timelines with suppliers to ensure timely delivery.

Understanding these properties and terms will empower B2B buyers to make informed decisions, optimize their procurement processes, and ultimately enhance customer satisfaction in the golf cart accessory market.

Navigating Market Dynamics and Sourcing Trends in the golf bag cart rubber mat Sector

What Are the Key Market Dynamics and Trends Influencing the Golf Bag Cart Rubber Mat Sector?

The global golf bag cart rubber mat market is experiencing significant growth, driven by increasing participation in golf and a rising demand for high-quality, durable accessories. Key trends influencing this sector include customization and technological advancements in materials. B2B buyers are increasingly seeking mats that provide enhanced grip, weather resistance, and tailored designs that fit specific golf cart models. The demand for lightweight yet robust mats, which can withstand varying climates, is particularly strong in regions like Africa and South America, where outdoor activities are prevalent.

Emerging technologies, such as the use of advanced rubber compounds and eco-friendly materials, are becoming crucial in the sourcing process. International buyers, especially from Europe and the Middle East, are placing a greater emphasis on suppliers who can provide innovative solutions that enhance user experience while ensuring long-term durability. Additionally, e-commerce platforms are making it easier for B2B buyers to access a diverse range of products, thus broadening their sourcing options.

Understanding regional preferences is essential. For instance, in Germany and Brazil, consumers may prioritize sustainability and local sourcing, while buyers in the Middle East might focus on luxury and aesthetics. This variance necessitates that suppliers adapt their offerings to meet the specific needs of different markets.

How Does Sustainability and Ethical Sourcing Impact the Golf Bag Cart Rubber Mat Industry?

Sustainability is a significant concern for B2B buyers in the golf bag cart rubber mat sector. The environmental impact of rubber production, coupled with increasing regulatory pressures, is prompting companies to seek ethically sourced materials. This shift is not only about compliance but also about aligning with consumer expectations for environmentally responsible products.

Illustrative image related to golf bag cart rubber mat

B2B buyers are increasingly interested in suppliers who utilize ‘green’ certifications and sustainable materials, such as recycled rubber or biodegradable alternatives. These certifications serve as a mark of quality and responsibility, making products more appealing in competitive markets. For international buyers, particularly in Europe, demonstrating a commitment to sustainability can enhance brand reputation and marketability.

Additionally, ethical supply chains are becoming a focal point. Buyers are looking for transparency in sourcing practices to ensure that materials are obtained without exploiting labor or harming the environment. This trend is especially pronounced in markets where consumers are more informed and passionate about ethical consumption, such as in Germany and parts of South America.

What Is the Historical Context of the Golf Bag Cart Rubber Mat Market?

The evolution of the golf bag cart rubber mat market can be traced back to the early days of golf cart usage. Initially, mats were simple accessories designed primarily for protection against wear and tear. Over time, as the golf industry grew, so did the demand for specialized products that enhanced both functionality and aesthetics.

With advancements in material technology, manufacturers began to experiment with various rubber compounds, leading to the development of mats that offered superior grip, durability, and customization options. This evolution reflects broader trends in consumer preferences, emphasizing quality and personalized experiences. Today, the golf bag cart rubber mat sector is characterized by innovation and a growing commitment to sustainability, shaping how products are designed, manufactured, and marketed to B2B buyers worldwide.

In conclusion, the golf bag cart rubber mat market is poised for continued growth, driven by evolving consumer demands, technological advancements, and a shift towards sustainable practices. B2B buyers should stay informed about these trends to make strategic sourcing decisions that align with their business goals and customer expectations.

Illustrative image related to golf bag cart rubber mat

Frequently Asked Questions (FAQs) for B2B Buyers of golf bag cart rubber mat

-

How do I ensure the quality of golf bag cart rubber mats from suppliers?

To ensure quality, request samples from potential suppliers before placing large orders. Look for certifications that meet international standards, such as ISO or ASTM, which indicate reliable manufacturing processes. Additionally, consider implementing a quality assurance (QA) plan that includes inspections during production and upon delivery. Engaging third-party inspection services can also provide an unbiased evaluation of product quality, ensuring that the mats meet your specifications. -

What is the best material for golf bag cart rubber mats?

The best materials for golf bag cart rubber mats are typically high-density rubber and PVC. These materials offer excellent durability, weather resistance, and grip, making them ideal for various golfing conditions. When selecting a material, consider factors such as the cart’s intended use, exposure to moisture, and the level of wear and tear expected. Custom formulations can also enhance specific properties like UV resistance or anti-slip features, tailored to your market needs. -

What customization options are available for golf bag cart rubber mats?

Many suppliers offer customization options, including size, color, thickness, and design features like logos or branding. When discussing customization, ensure that the supplier has the capability to produce mats that meet your specifications while maintaining quality standards. Request mock-ups or prototypes to visualize the final product before mass production. Custom mats can enhance brand visibility and cater to specific customer preferences, providing a competitive edge in the market. -

What are the minimum order quantities (MOQs) for golf bag cart rubber mats?

Minimum order quantities can vary significantly between suppliers, often ranging from 100 to 1,000 units depending on the customization level and material used. It’s advisable to clarify MOQs upfront to align with your purchasing strategy and budget. If you’re a smaller buyer, discuss the possibility of lower MOQs or consider forming a consortium with other buyers to meet larger order requirements. This approach can help reduce costs while still obtaining quality products. -

What payment terms should I expect when sourcing golf bag cart rubber mats?

Payment terms can vary widely among suppliers but typically include options such as 30% upfront with the balance due upon delivery, or net 30/60 terms. When negotiating payment terms, consider factors like your cash flow and the supplier’s reliability. Be cautious of any requests for full payment upfront, as this can increase risk. Using secure payment methods, such as letters of credit or escrow services, can also help protect your investment in international transactions. -

How can I vet potential suppliers of golf bag cart rubber mats?

Vetting suppliers is crucial to ensure reliability and quality. Start by researching their business credentials, including years in operation and customer reviews. Request references from previous clients and check their production capabilities. Additionally, consider conducting site visits or virtual tours of their manufacturing facilities. Utilize platforms like Alibaba or TradeKey to find verified suppliers and read feedback from other buyers. This thorough vetting process can help mitigate risks associated with international trade. -

What logistics considerations should I keep in mind when importing golf bag cart rubber mats?

Logistics is critical in ensuring timely delivery and cost-effectiveness. Consider factors such as shipping methods (air vs. sea), potential tariffs, and customs clearance processes specific to your country. Engage with freight forwarders who specialize in international trade to navigate these complexities. Additionally, ensure that the supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. -

What are the common issues faced during the import of golf bag cart rubber mats and how can I avoid them?

Common issues include delays in shipping, customs clearance problems, and product quality discrepancies. To avoid these, establish clear communication with suppliers regarding expectations and timelines. Implement a detailed contract that outlines product specifications, delivery schedules, and penalties for non-compliance. Regular updates throughout the production and shipping processes can also help identify potential issues early, allowing for proactive solutions.

Top 5 Golf Bag Cart Rubber Mat Manufacturers & Suppliers List

1. Extreme Mats – Bag Well Mats

Domain: xtrememats.com

Registered: 2012 (13 years)

Introduction: Bag Well Mats – PRO Series: 1. E-Z-GO RXV Bag Well Mat – Fits Most E-Z-GO RXV (2016-2025) – Sale price: $34.99 (Regular price: $39.00) – Available in Red Trim, Grey Trim, All Black, Blue Trim. 2. Yamaha Drive2 Bag Well Mat – Fits Yamaha Drive2 (2017-Current) – Sale price: $34.99 (Regular price: $39.00) – Available in Red Trim, Grey Trim, All Black, Blue Trim. 3. Club Car Bag Well Mat – Fits Preced…

2. Golf Cart Tire Supply – Custom Floor Mats

Domain: golfcarttiresupply.com

Registered: 2014 (11 years)

Introduction: This company, Golf Cart Tire Supply – Custom Floor Mats, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Matworks – Custom Golf Cart Floor Mats

Domain: matworks.com

Registered: 1995 (30 years)

Introduction: Custom Golf Cart Floor Mats with OEM Monogramming Available.

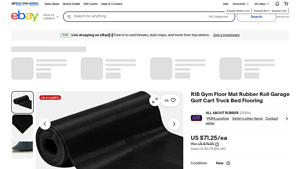

4. RIB – Gym Floor Mat Rubber Roll

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “RIB Gym Floor Mat Rubber Roll Garage Golf Cart Truck Bed Flooring”, “Condition”: “New”, “Price”: “US $71.25”, “Original Price”: “US $75.00”, “Discount”: “5% off”, “Material”: “Rubber”, “Color”: “Black”, “Thickness”: “6.3 mm (1/4 Inch)”, “Available Sizes”: [“4ft x 10ft”, “4ft x 15ft”, “4ft x 4ft”, “4ft x 6ft”, “4ft x 8ft”, “4ft x 5ft”, “4ft x 3ft”], “Quantity Available”: “More tha…

5. 10L0L – Golf Cart Floor Mats

Domain: 10l0l.com

Registered: 2015 (10 years)

Introduction: Golf Cart Floor Mats for EZGO, Club Car, Yamaha – 10L0L. Get 15% off your first order with code 10L0L001 and 30% off golf cart wheels with code WHEELS30! Free shipping on orders of $80 or more in the US. Premium quality, designed for durability and comfort.

Strategic Sourcing Conclusion and Outlook for golf bag cart rubber mat

In conclusion, the strategic sourcing of golf bag cart rubber mats represents a pivotal opportunity for B2B buyers aiming to enhance their product offerings and customer satisfaction. By prioritizing high-quality materials, durability, and custom-fit designs, businesses can significantly improve user experience while minimizing maintenance costs. The global demand for these mats is on the rise, particularly in regions such as Africa, South America, the Middle East, and Europe, where golf culture is flourishing.

Investing in robust sourcing strategies will not only help in securing competitive pricing but also foster long-term relationships with reliable suppliers. As the market evolves, staying attuned to emerging trends and consumer preferences will be essential for sustaining growth and capturing market share.

International buyers are encouraged to leverage these insights and initiate conversations with manufacturers and suppliers who can meet their specific needs. By doing so, they can position themselves advantageously in a dynamic marketplace. Embrace the future of golf accessories by making informed sourcing decisions today—your customers will appreciate the quality, and your business will thrive.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.