Choosing Your Gasket Exhaust Material: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for gasket exhaust material

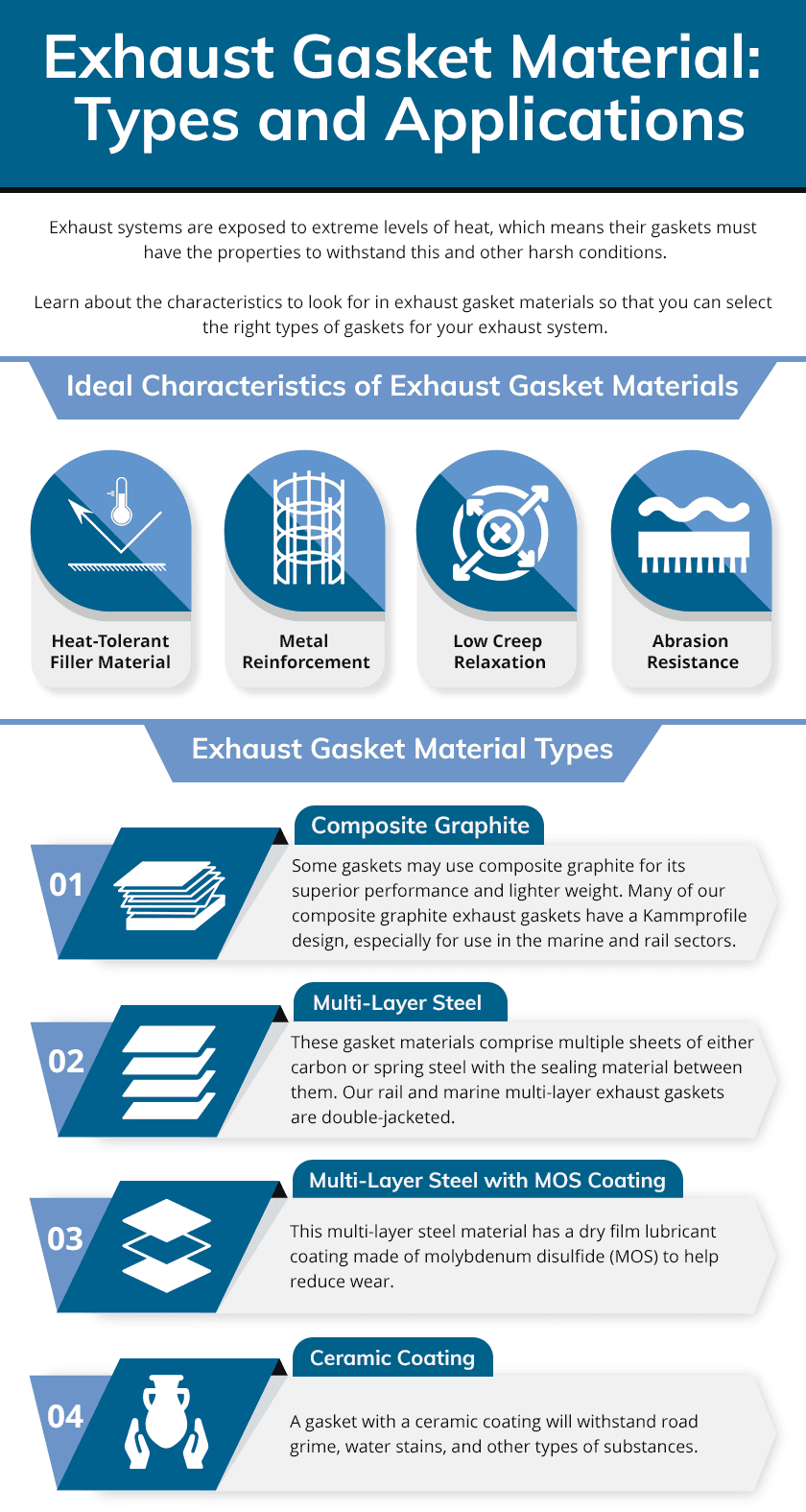

In the ever-evolving landscape of global commerce, sourcing high-quality gasket exhaust material poses a significant challenge for international B2B buyers. With the growing demand for durable and heat-resistant sealing solutions, particularly in regions like Africa, South America, the Middle East, and Europe, businesses must navigate a complex array of options to ensure optimal performance and compliance with industry standards. This guide serves as a comprehensive resource for understanding the diverse types of gasket exhaust materials available, their specific applications across various sectors, and effective strategies for supplier vetting.

As you explore the nuances of gasket materials—ranging from composite graphite to multi-layer steel—you’ll gain insights into the essential characteristics that dictate their functionality, such as heat tolerance and abrasion resistance. Additionally, this guide will delve into critical factors influencing costs, helping you to make informed purchasing decisions that align with your operational needs and budget constraints. By equipping international buyers with the knowledge to evaluate suppliers and products effectively, this guide empowers you to secure reliable gasket exhaust solutions that enhance your automotive or industrial applications. Whether you’re based in Nigeria, Saudi Arabia, or elsewhere, understanding these dynamics will position your business for success in the global market.

Understanding gasket exhaust material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Composite Graphite | High-temperature tolerance, lightweight, low creep relaxation | Marine, rail, and automotive sectors | Pros: Excellent sealing, lightweight. Cons: May require specialized handling. |

| Multi-layer Steel | Multiple sheets with sealing material, enhanced durability | Heavy machinery, automotive exhaust systems | Pros: Strong, reliable under pressure. Cons: Heavier than alternatives. |

| Multi-layer Steel with MOS Coating | Dry film lubricant reduces wear and friction | High-performance automotive and industrial applications | Pros: Extended lifespan, reduced maintenance. Cons: Higher initial cost. |

| Ceramic Coated | Resistant to road grime and high temperatures | Automotive and industrial applications | Pros: Durable, easy to clean. Cons: Can be brittle under extreme conditions. |

| Sandwich Type | Combination of metal layers with a graphite core | Diesel engines, performance vehicles | Pros: Excellent heat resistance, flexible. Cons: Complexity in installation. |

What are the characteristics and suitability of Composite Graphite gaskets?

Composite graphite gaskets are designed to withstand extreme temperatures while maintaining structural integrity. Their lightweight nature makes them ideal for applications where weight is a critical factor, such as in marine and rail sectors. Buyers should consider their high sealing performance and low creep relaxation, which helps maintain flange loading over time. However, they may require specialized handling during installation, making it essential to ensure proper training for staff.

How does Multi-layer Steel enhance durability in exhaust systems?

Multi-layer steel gaskets consist of several sheets of steel with sealing material sandwiched in between. This design enhances durability and strength, making them suitable for heavy machinery and automotive exhaust systems that experience significant pressure. B2B buyers can benefit from their reliable sealing capabilities, but they should also note that these gaskets are heavier than other options, which could impact overall system weight and performance.

What advantages does Multi-layer Steel with MOS Coating offer for industrial applications?

Multi-layer steel gaskets with a molybdenum disulfide (MOS) coating provide an additional layer of protection against wear and friction. This feature makes them particularly advantageous for high-performance automotive and industrial applications where maintenance is a concern. While they offer a longer lifespan and reduced maintenance needs, buyers should consider the higher initial cost, which may affect budget allocations for gasket procurement.

Why choose Ceramic Coated gaskets for exhaust systems?

Ceramic-coated gaskets are specifically designed to resist road grime, water stains, and other contaminants while withstanding high temperatures. This makes them ideal for automotive and industrial applications where cleanliness and durability are paramount. Their ease of cleaning can reduce long-term maintenance efforts. However, it is important for buyers to be aware that ceramic materials can be brittle under extreme conditions, which may limit their use in high-stress environments.

What makes Sandwich Type gaskets suitable for diesel engines?

Sandwich type gaskets consist of thin metal layers surrounding a graphite core, providing excellent heat resistance and flexibility. They are particularly suited for diesel engines and performance vehicles that require reliable sealing under varying temperature conditions. Buyers should appreciate their adaptability; however, the complexity of installation may necessitate skilled labor, which could increase overall project costs.

Key Industrial Applications of gasket exhaust material

| Industry/Sector | Specific Application of gasket exhaust material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Sealing exhaust systems in vehicles | Enhances vehicle performance and reduces emissions | Look for materials that withstand high temperatures and vibrations. |

| Marine Engineering | Exhaust systems for marine vessels | Ensures reliable operation in harsh marine environments | Consider corrosion resistance and compatibility with marine fuels. |

| Heavy Equipment | Sealing exhaust components in construction machinery | Improves durability and reduces maintenance costs | Evaluate tensile strength and resistance to thermal cycling. |

| Power Generation | Gaskets for exhaust systems in generators | Ensures efficient operation and compliance with emissions standards | Focus on high-temperature tolerance and long service life. |

| Oil & Gas | Sealing exhaust for drilling and processing equipment | Prevents leaks and enhances safety in high-pressure environments | Assess compatibility with various chemicals and extreme conditions. |

How is Gasket Exhaust Material Used in Automotive Manufacturing?

In the automotive sector, gasket exhaust materials are essential for sealing exhaust systems, ensuring that exhaust gases are contained and do not leak into the vehicle’s cabin. This application not only enhances vehicle performance but also plays a crucial role in reducing harmful emissions, thus helping manufacturers meet stringent environmental regulations. Buyers should prioritize materials that can withstand high temperatures and vibrations, as these are common in automotive applications, particularly in regions with variable climates like Nigeria or Saudi Arabia.

What Role Does Gasket Exhaust Material Play in Marine Engineering?

In marine engineering, gasket exhaust materials are critical for ensuring the integrity of exhaust systems on vessels. These materials must withstand the corrosive effects of saltwater and other harsh conditions typical of marine environments. By using high-quality gasket materials, operators can ensure reliable engine performance and compliance with maritime emission standards. When sourcing for marine applications, buyers should consider materials that offer corrosion resistance and compatibility with various marine fuels, especially in regions like South America where maritime activities are prominent.

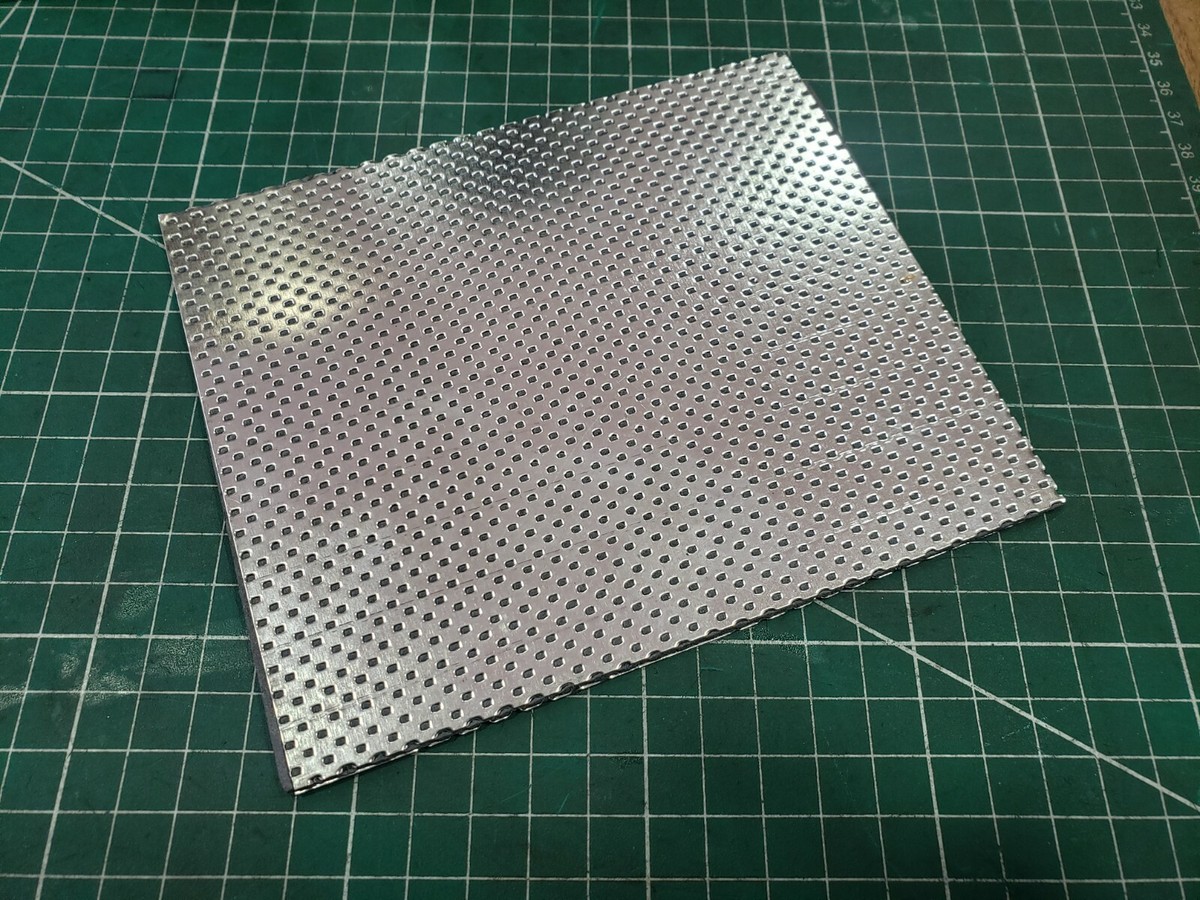

Illustrative image related to gasket exhaust material

How is Gasket Exhaust Material Applied in Heavy Equipment?

Heavy equipment relies on robust gasket exhaust materials to seal exhaust components in machinery such as bulldozers and excavators. These gaskets must endure extreme conditions, including high temperatures and pressures, while also providing excellent durability to minimize maintenance costs. For international buyers in regions with extensive construction activities, such as the Middle East, sourcing materials with high tensile strength and resistance to thermal cycling is vital to ensure long-lasting performance.

Why is Gasket Exhaust Material Important for Power Generation?

In power generation, gasket exhaust materials are used in exhaust systems of generators to maintain efficient operation and ensure compliance with emissions regulations. These materials help prevent exhaust leaks, which can lead to safety hazards and operational inefficiencies. Buyers should focus on sourcing high-temperature tolerant materials that offer long service life, particularly in areas with high energy demands like Europe, where energy efficiency is a priority.

How is Gasket Exhaust Material Utilized in the Oil & Gas Industry?

In the oil and gas sector, gasket exhaust materials are crucial for sealing exhaust systems in drilling and processing equipment. This application helps prevent leaks, which can pose significant safety risks in high-pressure environments. Buyers in this industry should evaluate gasket materials based on their compatibility with various chemicals and their ability to withstand extreme conditions. This is particularly relevant for international operations in regions like Africa, where oil extraction activities are prevalent.

3 Common User Pain Points for ‘gasket exhaust material’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Gasket Material

The Problem:

For B2B buyers in industries such as automotive or manufacturing, choosing the correct gasket exhaust material can be a daunting task. With various options available—like composite graphite, multi-layer steel, and ceramic-coated gaskets—buyers often struggle to understand which material will perform best under specific conditions. This challenge is compounded by the need to consider factors like temperature tolerance, chemical exposure, and mechanical stress. Making the wrong choice can lead to premature gasket failure, resulting in costly downtime and repairs.

The Solution:

To effectively select the appropriate gasket exhaust material, buyers should conduct a thorough assessment of their operational environment. Start by compiling a list of the specific conditions the gasket will face, such as maximum temperatures, exposure to corrosive substances, and the types of metals involved in the exhaust system. Utilize this information to consult with suppliers who can provide detailed product specifications and recommendations. When sourcing materials, prioritize those with proven performance in similar applications. Additionally, consider investing in samples to test in real-world conditions before finalizing a bulk order. By approaching the selection process methodically and relying on expert guidance, buyers can significantly mitigate the risk of gasket failure.

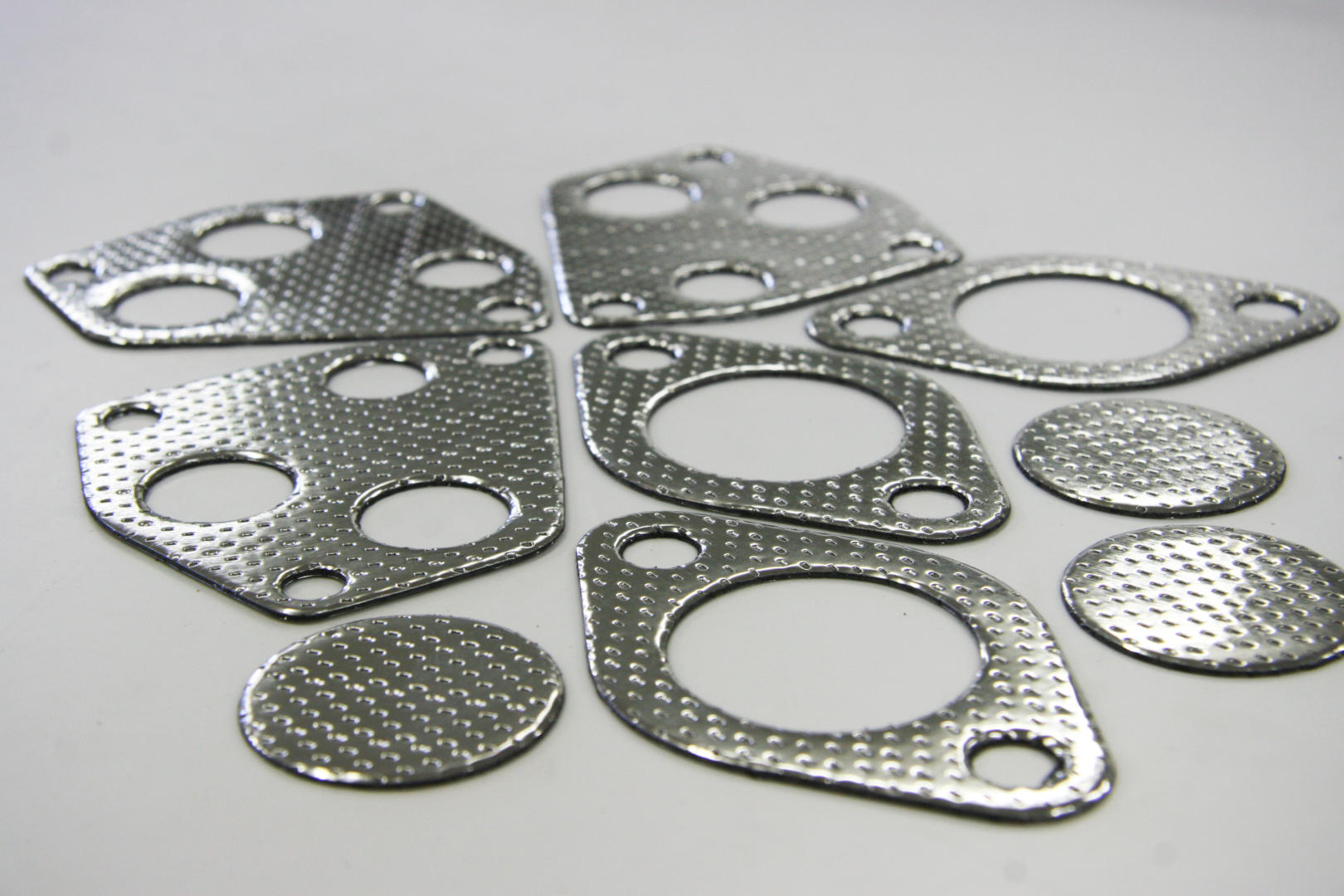

Illustrative image related to gasket exhaust material

Scenario 2: Inconsistent Gasket Performance Across Different Regions

The Problem:

International B2B buyers often face challenges related to inconsistent gasket performance due to varying regional environmental conditions. For instance, gaskets that perform well in temperate climates may fail prematurely in high-humidity or extreme heat environments found in parts of Africa or the Middle East. This inconsistency can lead to increased maintenance costs and operational delays, as companies may find themselves frequently replacing gaskets that were expected to last longer.

The Solution:

To address this issue, buyers should engage in a comprehensive evaluation of their gasket materials, specifically tailored to the environmental conditions of their operational regions. When sourcing gasket exhaust materials, seek suppliers who understand local climates and can recommend materials specifically designed for those conditions. For example, consider gaskets with enhanced abrasion resistance for areas with significant thermal cycling or those with moisture-resistant properties for humid environments. Additionally, maintaining an open line of communication with local distributors can provide insights into performance trends and common issues faced in specific regions. This proactive approach will ensure that the selected materials are well-suited to local conditions, enhancing overall performance and longevity.

Scenario 3: Overlooking Installation Best Practices

The Problem:

Even with high-quality gasket exhaust materials, improper installation can lead to catastrophic failures and inefficiencies. B2B buyers often overlook installation best practices, leading to issues such as uneven torque application, misalignment, or contamination during installation. These mistakes can result in leaks, increased emissions, and compromised engine performance, creating a ripple effect of operational challenges.

Illustrative image related to gasket exhaust material

The Solution:

To prevent installation-related issues, it is crucial for buyers to invest in training and resources for their installation teams. Begin by providing detailed installation guidelines for the specific gasket materials being used, which should include torque specifications, recommended tools, and steps to ensure proper alignment. Additionally, consider hosting workshops or training sessions with suppliers who can share best practices and common pitfalls to avoid. Implementing a checklist for installation can also be beneficial, ensuring that every step is followed meticulously. By prioritizing installation quality, buyers can enhance the durability and effectiveness of their gasket exhaust materials, reducing the likelihood of failure and the associated costs.

Strategic Material Selection Guide for gasket exhaust material

What Are the Key Properties of Common Gasket Exhaust Materials?

When selecting gasket exhaust materials, it’s essential to understand the properties that will influence performance in various applications. Here are four common materials used in gasket exhaust applications, along with their characteristics, advantages, and limitations.

1. Composite Graphite Gasket Material

Key Properties:

Composite graphite gaskets are known for their excellent heat resistance, typically rated up to 650°C (1200°F). They exhibit low creep relaxation, which helps maintain sealing pressure over time.

Pros & Cons:

These gaskets are lightweight and provide superior sealing capabilities, making them suitable for high-performance applications. However, they can be more expensive than traditional materials and may require precise manufacturing processes to achieve the desired thickness and shape.

Impact on Application:

Composite graphite gaskets are ideal for applications involving high-temperature exhaust systems, such as automotive and industrial engines. They are compatible with a variety of media, including exhaust gases and oils.

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, to guarantee performance and safety. The availability of composite materials may vary, so it’s crucial to work with reliable suppliers.

2. Multi-layer Steel Gasket Material

Key Properties:

Multi-layer steel gaskets consist of several layers of steel with a sealing material in between, providing excellent strength and durability. They can withstand high pressures and temperatures, typically rated around 500°C (932°F).

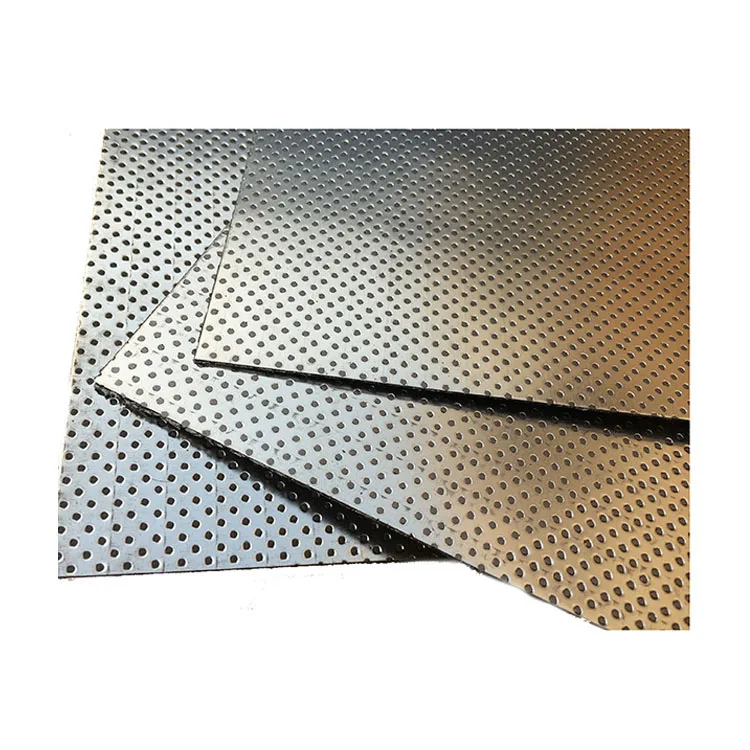

Illustrative image related to gasket exhaust material

Pros & Cons:

These gaskets offer superior sealing performance and are highly resistant to blowouts. However, they can be heavier and more complex to manufacture, which may increase costs.

Impact on Application:

Multi-layer steel gaskets are widely used in heavy-duty applications, such as diesel engines and industrial machinery. They are particularly effective in environments with fluctuating temperatures and pressures.

Considerations for International Buyers:

For buyers in Europe and South America, it’s vital to verify that the gaskets meet local compliance standards. The manufacturing process may require specific certifications, which should be confirmed with suppliers.

3. Ceramic Coated Gasket Material

Key Properties:

Ceramic-coated gaskets are designed to withstand extreme temperatures and are resistant to corrosion and wear. They can handle temperatures exceeding 800°C (1472°F).

Pros & Cons:

These gaskets provide excellent durability and are suitable for harsh environments. However, they can be more costly due to the specialized manufacturing process and materials used.

Impact on Application:

Ceramic-coated gaskets are ideal for high-performance racing engines and industrial applications where exposure to contaminants is common. They are particularly effective in preventing leaks in aggressive media.

Considerations for International Buyers:

Buyers should be aware of the specific requirements for ceramic materials in their regions, as some countries may have restrictions or standards that need to be met.

4. Sandwich Type Gasket Material

Key Properties:

Sandwich gaskets consist of layers of metal, such as aluminum or copper, with a core of graphite. They are designed to provide excellent sealing under varying thermal conditions.

Pros & Cons:

These gaskets are relatively easy to manufacture and offer good performance in terms of sealing and durability. However, they may not perform as well under extreme conditions compared to other materials.

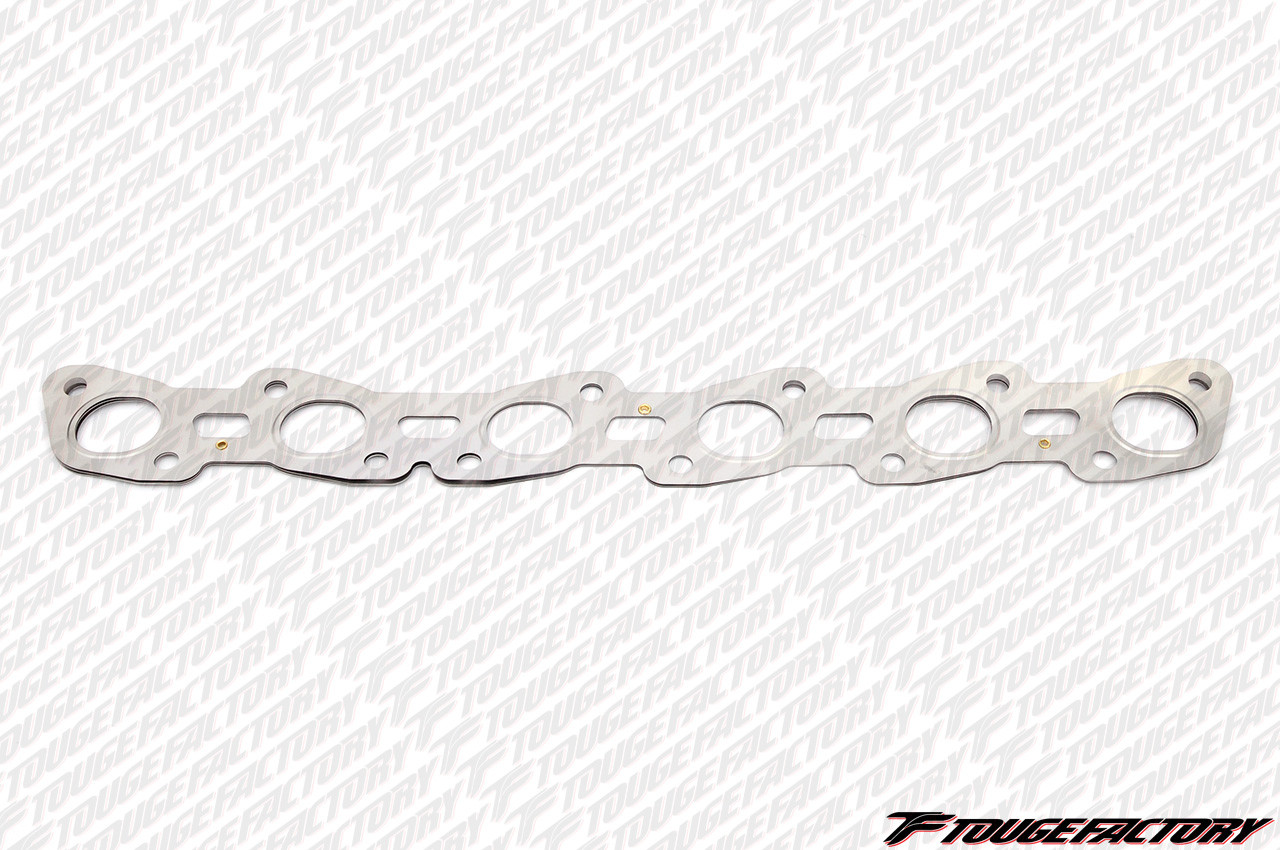

Illustrative image related to gasket exhaust material

Impact on Application:

Sandwich gaskets are commonly used in automotive exhaust systems and can handle moderate pressure and temperature fluctuations effectively.

Considerations for International Buyers:

International buyers should ensure that sandwich gaskets meet the necessary quality standards for their specific applications, particularly in regions with stringent automotive regulations.

Summary Table of Gasket Exhaust Materials

| Material | Typical Use Case for gasket exhaust material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Composite Graphite | High-performance automotive engines | Lightweight with superior sealing | Higher cost, complex manufacturing | High |

| Multi-layer Steel | Heavy-duty diesel engines | Excellent strength and durability | Heavier, complex to manufacture | Medium |

| Ceramic Coated | Racing engines, industrial applications | High temperature and corrosion resistance | Higher cost, specialized manufacturing | High |

| Sandwich Type | Automotive exhaust systems | Easy to manufacture, good sealing | Moderate performance under extremes | Medium |

This strategic material selection guide provides essential insights for international B2B buyers when considering gasket exhaust materials. Understanding the properties, advantages, and limitations of each material will facilitate informed decision-making tailored to specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gasket exhaust material

What Are the Key Stages in the Manufacturing Process of Gasket Exhaust Material?

The manufacturing of gasket exhaust material involves several critical stages that ensure the final product meets the stringent requirements of various applications. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process is selecting high-quality materials that can withstand extreme temperatures and harsh exhaust conditions. Common materials include composite graphite, multi-layer steel, and metal-reinforced gaskets. Once selected, these materials undergo thorough cleaning and inspection to eliminate contaminants that could compromise the gasket’s integrity.

-

Forming: In this stage, the prepared materials are shaped into gaskets using various techniques. Common methods include die-cutting, where sheets of material are cut into specific shapes using precise dies, and compression molding, which involves placing the material into a mold and applying heat and pressure. This ensures uniformity and consistency in thickness and shape, which are crucial for effective sealing.

-

Assembly: For multi-layer gaskets, assembly involves layering the materials together, ensuring that the sealing material is positioned correctly between the metal sheets. This step may include the application of adhesives or coatings to enhance performance, such as adding a molybdenum disulfide (MOS) coating to reduce wear in multi-layer steel gaskets.

-

Finishing: The final stage includes trimming excess material, surface treatment, and final inspections. Surface treatments may involve coatings that improve resistance to corrosion and abrasion. The gaskets are then packaged for shipment, ensuring they remain undamaged during transit.

How Is Quality Assurance Implemented in Gasket Exhaust Material Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the gaskets meet both international standards and customer expectations. Various international standards, such as ISO 9001, provide frameworks for quality management systems that manufacturers must adhere to.

Illustrative image related to gasket exhaust material

-

International Standards: Compliance with ISO 9001 ensures that manufacturers maintain consistent quality in their products through systematic processes. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) validate that the gaskets meet specific safety and performance requirements for various applications.

-

Quality Control Checkpoints: Manufacturers implement a multi-tiered quality control system comprising:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. Techniques include visual inspections and measurements at various stages of production.

– Final Quality Control (FQC): Before packaging, final inspections are conducted to ensure that the gaskets meet all dimensional and performance specifications. -

Common Testing Methods: Various testing methods are employed to verify the performance of gasket materials, including:

– Tensile Strength Testing: Measures the material’s strength and elasticity under stress.

– Heat Resistance Testing: Assesses how well the gasket withstands high temperatures.

– Leak Testing: Ensures that the gasket maintains a proper seal under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control procedures is crucial for ensuring product reliability.

-

Supplier Audits: Conducting regular audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control practices. This can include on-site visits to assess their facilities, equipment, and adherence to quality standards.

-

Reviewing Quality Reports: Requesting access to quality control reports can help buyers understand the supplier’s compliance with international standards. These reports should detail inspection results, testing outcomes, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections often include detailed reports and certifications that can serve as a quality assurance measure.

What Are the Specific Quality Control Nuances for International Buyers?

International buyers face unique challenges when sourcing gasket exhaust materials. Understanding these nuances can help mitigate risks and ensure that the products meet their operational needs.

-

Regulatory Compliance: Different regions may have varying regulations regarding materials used in exhaust systems. Buyers must ensure that the gaskets comply with local environmental regulations, especially in regions with stringent emissions standards.

-

Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother negotiations and foster stronger supplier relationships. For instance, communication styles and negotiation tactics may differ significantly between regions.

-

Logistics and Supply Chain Challenges: International shipping can introduce delays and potential damage to products. Buyers should work closely with suppliers to implement robust packaging solutions and logistics plans that ensure the safe delivery of gasket materials.

-

Performance Expectations: Different markets may have varying performance expectations for gasket materials. Buyers should clearly communicate their requirements and specifications to suppliers to ensure that the products delivered meet their operational demands.

By focusing on these aspects, B2B buyers can navigate the complexities of sourcing gasket exhaust materials more effectively, ensuring that they partner with reliable suppliers who prioritize quality and performance.

Illustrative image related to gasket exhaust material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gasket exhaust material’

Introduction

When sourcing gasket exhaust materials, particularly for industries requiring high-performance specifications, a structured approach is essential. This checklist serves as a practical guide for B2B buyers, ensuring that all critical factors are considered to procure the right material for your specific applications.

-

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the gasket exhaust material. Consider factors such as temperature tolerance, chemical resistance, and application-specific needs. This step is vital as it directly influences the performance and longevity of the gaskets you will be sourcing. -

Step 2: Research Material Types

Familiarize yourself with the different types of gasket materials available, such as composite graphite, multi-layer steel, and sandwich types. Understanding the advantages and limitations of each type will help you select the best option for your application, ensuring optimal sealing and durability under extreme conditions. -

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers before making a commitment. Look for company profiles, product catalogs, and customer testimonials. It’s crucial to assess their reputation in the market and ensure they have experience with the specific types of gasket materials you require.

- Sub-bullet: Request references from existing customers in similar industries to gauge reliability and quality.

- Sub-bullet: Check for certifications such as ISO 9001 or industry-specific standards to verify quality assurance practices.

-

Step 4: Request Product Samples

Before finalizing your order, request samples of the gasket materials you are considering. Testing samples in your specific application can reveal how well the materials perform under real-world conditions. This step minimizes risks associated with poor performance and helps ensure compatibility with your existing systems. -

Step 5: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and compliance with international standards. Certifications like ISO or ASTM can indicate that the supplier adheres to strict quality control measures, providing you with confidence in their products. -

Step 6: Assess Pricing and Terms

Compare pricing structures from multiple suppliers, but don’t focus solely on cost. Evaluate the total cost of ownership, including shipping, taxes, and potential import duties. Understanding the payment terms and return policies is also essential for maintaining smooth transactions. -

Step 7: Establish Long-term Relationships

After selecting a supplier, focus on building a strong partnership. Regular communication and feedback can lead to better service and product improvements over time. A long-term relationship can also provide you with advantages such as priority support and customized solutions tailored to your evolving needs.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for gasket exhaust materials, ensuring they make informed decisions that align with their operational requirements.

Comprehensive Cost and Pricing Analysis for gasket exhaust material Sourcing

What Are the Key Cost Components in Sourcing Gasket Exhaust Materials?

When analyzing the cost structure for gasket exhaust material sourcing, several components contribute to the overall pricing. These include:

Illustrative image related to gasket exhaust material

-

Materials: The primary cost driver in gasket production is the raw materials used. Common materials include composite graphite, multi-layer steel, and ceramic coatings, each varying in cost based on performance characteristics and market availability. High-quality materials generally command a premium due to their superior heat resistance and durability.

-

Labor: Labor costs can fluctuate significantly depending on the region and the complexity of the manufacturing process. Skilled labor is often required to ensure precision in gasket fabrication, especially for customized solutions.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, equipment maintenance, and factory management. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The initial investment in tooling can be substantial, especially for custom gasket designs. This cost should be amortized over the expected production volume to achieve more favorable pricing.

-

Quality Control (QC): Ensuring the gaskets meet stringent industry standards incurs additional costs. QC processes are critical, especially for applications in high-performance or safety-sensitive environments, as they prevent costly failures and warranty claims.

-

Logistics: Transportation and handling fees can significantly impact the total cost, especially for international shipments. This includes freight costs, customs duties, and insurance.

-

Margin: Suppliers will add their profit margin to cover operational costs and ensure sustainability. This margin can vary widely based on market competition and supplier reputation.

What Factors Influence Pricing for Gasket Exhaust Materials?

Several elements can influence the pricing of gasket exhaust materials:

-

Volume/MOQ: Bulk orders often attract discounts, making it essential for buyers to assess their needs and negotiate minimum order quantities (MOQ) effectively.

-

Specifications and Customization: Custom gaskets tailored to specific applications may incur higher costs due to additional engineering and production requirements.

-

Material Quality and Certifications: Gaskets that meet industry certifications or use premium materials will be priced higher. Buyers should weigh the cost against the benefits of enhanced performance and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: The terms of shipping can affect pricing significantly. Buyers should understand the implications of different Incoterms on their total landed costs.

How Can Buyers Optimize Costs in Gasket Exhaust Material Sourcing?

-

Effective Negotiation: Engage suppliers in discussions about pricing structures and be prepared to negotiate based on order size and commitment to future purchases.

-

Total Cost of Ownership (TCO): Consider not just the purchase price, but the entire lifecycle cost of the gaskets, including installation, maintenance, and potential downtime due to failures. This comprehensive view can lead to better purchasing decisions.

-

Leverage Technology: Utilize digital tools for sourcing and procurement to streamline processes, reduce administrative costs, and enhance supplier communication.

-

Understand Pricing Nuances: International buyers, particularly from regions like Africa, South America, and the Middle East, should be aware of currency fluctuations, import tariffs, and local market dynamics that can affect pricing.

-

Build Long-term Relationships: Establishing strong partnerships with suppliers can lead to better pricing, improved service, and priority access to new products.

Conclusion

In the competitive landscape of gasket exhaust material sourcing, understanding the intricacies of cost components and pricing influencers is crucial for B2B buyers. By leveraging negotiation strategies and considering the total cost of ownership, international buyers can make informed decisions that enhance their supply chain efficiency and cost-effectiveness. As the market continues to evolve, staying abreast of these dynamics will ensure that buyers can navigate the complexities of sourcing effectively.

Alternatives Analysis: Comparing gasket exhaust material With Other Solutions

Understanding Alternatives to Gasket Exhaust Material

When considering solutions for exhaust systems, gasket exhaust materials are just one option among several. B2B buyers must evaluate various alternatives to find the best fit for their specific applications, particularly in regions with diverse operational challenges such as Africa, South America, the Middle East, and Europe. Each alternative presents unique benefits and drawbacks, influencing performance, cost, and maintenance needs.

Comparison of Gasket Exhaust Material and Alternatives

| Comparison Aspect | Gasket Exhaust Material | Alternative 1: Multi-layer Steel Gaskets | Alternative 2: Composite Graphite Gaskets |

|---|---|---|---|

| Performance | Excellent heat resistance and sealing | High durability; withstands thermal motion | Lightweight with good sealing properties |

| Cost | Moderate cost; varies by material type | Higher cost due to manufacturing complexity | Generally lower cost; good for various applications |

| Ease of Implementation | Easy to cut and fit in various applications | Requires precision installation | Flexible; easy to mold into specific shapes |

| Maintenance | Low maintenance; high longevity | Moderate; may require periodic checks | Low maintenance; good lifespan |

| Best Use Case | General automotive and industrial use | Heavy-duty applications with high thermal cycling | Light to medium-duty applications; ideal for marine and rail |

In-Depth Look at Alternative Solutions

Multi-layer Steel Gaskets:

These gaskets consist of multiple sheets of steel, providing enhanced durability and thermal resistance. Their design allows them to handle extreme temperatures and pressures, making them suitable for heavy-duty applications such as industrial engines and high-performance vehicles. However, they can be more expensive and require precise installation to ensure effective sealing. This complexity can be a drawback for operations with limited technical resources.

Composite Graphite Gaskets:

Composite graphite gaskets are known for their lightweight nature and excellent sealing capabilities. They are particularly beneficial in applications where weight reduction is critical, such as in marine and rail industries. These gaskets can withstand high temperatures and provide reliable performance with minimal maintenance. However, their performance may diminish in extremely harsh conditions compared to metal alternatives, making them less suitable for some heavy-duty industrial applications.

Making the Right Choice for Your Business Needs

When selecting the right exhaust solution, B2B buyers should consider factors such as operational conditions, budget constraints, and maintenance capabilities. Each alternative to gasket exhaust material offers distinct advantages, and the optimal choice will depend on specific application requirements. By thoroughly evaluating the performance, cost, ease of implementation, and maintenance needs of each option, buyers can make informed decisions that enhance their operational efficiency and longevity of their exhaust systems. This strategic approach ensures that the selected solution aligns with both immediate and long-term business goals.

Essential Technical Properties and Trade Terminology for gasket exhaust material

What Are the Key Technical Properties of Gasket Exhaust Material?

When sourcing gasket exhaust materials, understanding their technical specifications is crucial for ensuring optimal performance in demanding environments. Here are some essential properties to consider:

1. Material Grade

The material grade refers to the classification of the gasket based on its composition and performance capabilities. Common materials include composite graphite, multi-layer steel, and ceramic-coated options. Selecting the appropriate grade is vital for ensuring the gasket can withstand the specific thermal and pressure conditions of your exhaust system, preventing premature failures and costly downtime.

2. Thickness

The thickness of the gasket material impacts its sealing capability and durability. Standard thicknesses often range from 1/16 inch to 1/4 inch. Thicker gaskets may provide better sealing under high-pressure conditions but can also lead to misalignment if not properly installed. Understanding the required thickness for your application is crucial for maintaining system integrity.

3. Temperature Resistance

Gasket exhaust materials must exhibit high-temperature resistance to cope with the extreme heat generated by exhaust systems. Materials should be able to maintain their structural integrity at temperatures often exceeding 500°F (260°C). Selecting materials with high-temperature resistance helps ensure longevity and reliability, particularly in heavy-duty applications such as industrial machinery and commercial vehicles.

4. Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. For gasket exhaust materials, high tensile strength is critical to prevent deformation and maintain a tight seal under varying operational conditions. This property is particularly important in applications with frequent thermal cycling, where expansion and contraction can lead to gasket failure.

5. Creep Relaxation

Creep relaxation refers to the tendency of a material to deform over time under constant stress. Low creep relaxation in gasket materials is essential for maintaining flange loading and ensuring a reliable seal. Gaskets made from materials like graphite tend to exhibit low creep relaxation, making them suitable for high-performance applications where pressure retention is critical.

6. Abrasion Resistance

Abrasion resistance is the ability of a material to withstand wear and tear from physical contact. In exhaust systems, gaskets may be exposed to various factors that contribute to abrasion, such as thermal movement between dissimilar metals. Choosing materials with high abrasion resistance helps extend the lifespan of the gasket and prevents leaks that can compromise system efficiency.

What Are the Common Trade Terminology and Jargon Used in Gasket Exhaust Material?

Navigating the world of gasket exhaust materials requires familiarity with specific trade terms. Here are some key terms that every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial when sourcing gaskets that fit specific engines or exhaust systems, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively, especially when dealing with custom gasket materials or bulk orders.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. This process allows buyers to compare costs and terms from multiple suppliers, ensuring they obtain the best value for their gasket exhaust materials.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping logistics, cost allocation, and liability in cross-border trade.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is critical for inventory management and ensuring that production schedules are met without delays.

6. Testing Standards

Testing standards encompass the protocols and benchmarks used to evaluate the performance and reliability of gasket materials. Compliance with recognized testing standards is vital for ensuring that the gaskets meet industry requirements and can perform under expected operating conditions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing gasket exhaust materials, ultimately enhancing the performance and reliability of their applications.

Illustrative image related to gasket exhaust material

Navigating Market Dynamics and Sourcing Trends in the gasket exhaust material Sector

What Are the Key Market Trends Affecting Gasket Exhaust Material Sourcing?

The global market for gasket exhaust materials is influenced by several key drivers, including rising vehicle production, advancements in automotive technology, and increasing regulations related to emissions. The push for more efficient exhaust systems has led to a growing demand for high-performance gasket materials that can withstand extreme temperatures and provide superior sealing capabilities. Notably, markets in Africa, South America, the Middle East, and Europe are witnessing a surge in demand due to urbanization and increasing vehicle ownership rates.

Emerging technologies are reshaping sourcing strategies in this sector. Innovations in material science, such as the development of composite and multi-layer steel gaskets, are gaining traction. These materials offer enhanced durability and reliability, essential for maintaining optimal exhaust system performance. Additionally, digital sourcing platforms and e-commerce are becoming increasingly popular among B2B buyers, enabling them to streamline procurement processes and access a wider range of suppliers.

Furthermore, the market dynamics are heavily influenced by geopolitical factors and trade policies. Buyers in regions like Nigeria and Saudi Arabia should remain vigilant about potential tariffs or import restrictions that could affect pricing and availability. Establishing relationships with local distributors or manufacturers can mitigate risks associated with international sourcing.

Illustrative image related to gasket exhaust material

How Is Sustainability Shaping Gasket Exhaust Material Procurement?

Sustainability is becoming a critical consideration for B2B buyers in the gasket exhaust material sector. As global awareness of environmental issues rises, companies are under pressure to adopt sustainable practices in their supply chains. The extraction and processing of traditional gasket materials can have significant environmental impacts, prompting a shift toward eco-friendly alternatives.

Buyers are increasingly prioritizing suppliers that offer ‘green’ certifications or materials, such as those derived from recycled or sustainably sourced components. For instance, gasket materials that comply with environmental standards like ISO 14001 or are certified by organizations like the Forest Stewardship Council (FSC) are gaining popularity. This trend not only helps reduce the ecological footprint but can also enhance brand reputation and customer loyalty.

Moreover, ethical sourcing is paramount. Buyers should evaluate their suppliers based on transparency in their supply chains and adherence to fair labor practices. Engaging with suppliers that demonstrate a commitment to social responsibility ensures a more sustainable and ethical procurement process, which is increasingly important to consumers and stakeholders alike.

What Is the Historical Context of Gasket Exhaust Material Development?

The evolution of gasket exhaust materials can be traced back to the early automotive industry, where simple fiber-based materials were predominantly used. As vehicles became more advanced, the need for materials that could withstand higher temperatures and pressures led to the development of composite and metal-reinforced gaskets. Over the decades, innovations in material science, such as the introduction of graphite and multi-layer steel gaskets, have significantly improved the performance and longevity of exhaust systems.

Illustrative image related to gasket exhaust material

Today, the gasket exhaust material sector continues to evolve, driven by technological advancements and the increasing emphasis on sustainability. Understanding this historical context is crucial for B2B buyers as it highlights the importance of choosing materials that not only meet current performance standards but also align with future industry trends.

Frequently Asked Questions (FAQs) for B2B Buyers of gasket exhaust material

-

How do I solve issues with exhaust gasket leaks?

To address exhaust gasket leaks, first identify the source by inspecting the exhaust system for visible damage or wear. Look for signs of soot or exhaust smoke around the gasket area. Replace any damaged gaskets with high-quality materials that can withstand extreme temperatures and pressures. Consider using composite graphite or multi-layer steel gaskets, which offer superior sealing capabilities. Ensure proper installation and torque specifications are followed to maintain a reliable seal and prevent future leaks. -

What is the best gasket material for high-temperature exhaust applications?

For high-temperature exhaust applications, composite graphite and multi-layer steel gaskets are among the best options. Composite graphite gaskets provide excellent thermal resistance and flexibility, making them suitable for various engine types. Multi-layer steel gaskets, especially those with a molybdenum disulfide coating, offer enhanced durability and sealing performance under extreme conditions. Always select a material that meets the specific temperature and pressure requirements of your exhaust system to ensure optimal performance. -

How can I verify the reliability of an exhaust gasket supplier?

To verify the reliability of an exhaust gasket supplier, start by checking their industry certifications, such as ISO 9001, which indicates adherence to quality management standards. Request references or case studies from previous clients to gauge their service quality. Additionally, assess their responsiveness to inquiries and willingness to provide product samples. Review their manufacturing capabilities and product range to ensure they can meet your specific needs. A supplier with a solid reputation and a history of on-time deliveries is crucial for long-term partnerships. -

What customization options are available for exhaust gaskets?

Customization options for exhaust gaskets often include variations in size, thickness, and material composition to suit specific applications. Many suppliers offer tailored designs, such as Kammprofile or clad-style gaskets, which can enhance performance in high-stress environments. You can also request specific coatings for added durability or resistance to chemicals. Communicate your requirements clearly to the supplier, as many are willing to work with clients to develop bespoke solutions that align with unique operational needs. -

What are the typical minimum order quantities (MOQs) for gasket materials?

Minimum order quantities (MOQs) for gasket materials can vary significantly between suppliers and depend on the type of material and complexity of the design. Standard materials may have lower MOQs, often starting from 100 to 500 units, while custom gaskets may require larger orders, sometimes exceeding 1,000 units. It’s essential to discuss your project scope with potential suppliers to understand their MOQ policies and negotiate terms that align with your budget and inventory needs. -

What payment terms should I expect when sourcing exhaust gaskets internationally?

Payment terms for international sourcing of exhaust gaskets typically vary by supplier and the nature of the transaction. Common terms include net 30, net 60, or payment in advance, especially for first-time orders. Some suppliers may offer letter of credit options for larger transactions. Be sure to clarify payment methods, such as wire transfers or credit terms, and discuss any potential currency exchange fees or international banking charges that may apply to your order. -

How do I ensure quality assurance for exhaust gasket materials?

To ensure quality assurance for exhaust gasket materials, request detailed specifications and compliance documents from your supplier. Look for suppliers who perform rigorous testing, including temperature and pressure tolerance tests, to validate their products. Consider conducting your own quality checks upon receipt of the materials, such as visual inspections and dimensional checks. Establishing a solid communication channel with your supplier can also facilitate timely updates on quality control processes and any adjustments needed for future orders. -

What logistics considerations should I keep in mind when importing exhaust gaskets?

When importing exhaust gaskets, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with the import/export requirements of your destination country. Understand the potential tariffs and duties that may apply to your shipment and ensure all documentation is accurate to avoid delays. Additionally, establish clear communication with your supplier regarding shipping schedules and tracking to ensure timely delivery and proper inventory management.

Top 5 Gasket Exhaust Material Manufacturers & Suppliers List

1. Custom Downpipe – BGA Metal Gasket Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom downpipe for car, BGA metal gasket material used, leak detected after 200 miles, flanges made from 10mm mild steel, consideration of high temp silicone sealant and alternative gasket materials suggested.

2. McMaster – Exhaust Gasket Material

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Exhaust Gasket Material, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Pitstop USA – Gasket Material

4. Holley – Gasket Materials

Domain: holley.com

Registered: 1995 (30 years)

Introduction: Holley offers a variety of gasket materials suitable for different applications. The materials include rubber, cork, paper, and composite options, each designed to provide reliable sealing for automotive and performance applications. These gaskets are engineered to withstand high temperatures and pressures, ensuring durability and performance in demanding environments. Holley’s gasket materials ar…

5. Advance Auto Parts – High-Temperature Composite Exhaust Gasket

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: {“Part No.”: “77”, “Warranty”: “90 DAY REPLACEMENT IF DEFECTIVE”, “Material”: “High-temperature composite exhaust material”, “Features”: [“Maximum torque retention to eliminate gasket failure”, “Can be trimmed for modified port applications”, “Precision die cut for an excellent fit”, “OE replacement, high-performance street, drag race and oval track compatible”, “Rated to 1200°F”], “Specifications…

Strategic Sourcing Conclusion and Outlook for gasket exhaust material

In the competitive landscape of gasket exhaust materials, strategic sourcing is paramount for international B2B buyers. By prioritizing high-quality materials that exhibit exceptional heat resistance, tensile strength, and durability, businesses can significantly enhance the performance and longevity of their exhaust systems. Gaskets with features like metal reinforcement and low creep relaxation can ensure reliable sealing under extreme conditions, reducing maintenance costs and improving operational efficiency.

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local market dynamics and supplier capabilities is crucial. Establishing partnerships with reputable manufacturers who can provide tailored solutions will foster resilience in supply chains and mitigate risks associated with fluctuating material availability.

Looking ahead, it is essential for B2B buyers to embrace innovation in gasket technology, such as composite graphite and multi-layer steel options, which are increasingly being adopted in various applications. By proactively engaging with suppliers and exploring new product developments, companies can position themselves at the forefront of the industry. Take the next step in your strategic sourcing journey and connect with leading gasket material suppliers to ensure your business thrives in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.