Choosing Your Forging Machine: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for forging machine

In an increasingly competitive global market, sourcing the right forging machine can be a daunting task for international B2B buyers. The demand for precision and efficiency in manufacturing processes is at an all-time high, and companies must navigate various challenges, including technological advancements, compliance with international standards, and fluctuating costs. This comprehensive guide addresses these challenges head-on, providing insights into the diverse types of forging machines available, their specific applications across industries, and strategic advice on supplier vetting and cost considerations.

Whether you are an automotive manufacturer in Germany, a metal fabricator in Nigeria, or an industrial engineer in Saudi Arabia, understanding the nuances of forging machinery is crucial for making informed purchasing decisions. This guide empowers you with the knowledge to select the most suitable equipment, ensuring that your operations remain competitive and efficient. With detailed sections on the latest innovations, industry best practices, and expert recommendations, you will be well-equipped to navigate the complexities of the forging machine market.

By focusing on critical factors such as durability, automation capabilities, and customization options, this guide serves as a valuable resource for businesses seeking to optimize their production processes and enhance their operational performance. Embrace the opportunity to leverage this knowledge, transforming the way you approach sourcing forging machines in today’s dynamic marketplace.

Understanding forging machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Press | Utilizes hydraulic force for metal shaping | Aerospace, automotive, heavy equipment | Pros: High precision, suitable for complex shapes. Cons: Higher initial cost and maintenance. |

| Mechanical Press | Operates using mechanical force; often more compact | Mass production, automotive parts | Pros: Faster cycle times, robust for high-volume production. Cons: Limited flexibility for custom shapes. |

| Power Hammer | Uses a hammering action to shape metal | Artistic forging, custom parts fabrication | Pros: Versatile for various shapes, relatively low cost. Cons: Requires skilled operators, less efficient for mass production. |

| Induction Forge | Employs electromagnetic induction to heat metal | Tool manufacturing, small parts production | Pros: Energy-efficient, quick heating. Cons: Limited to smaller parts, higher setup costs. |

| Upsetter Machine | Specializes in increasing the diameter of metal bars | Oil and gas, aerospace components | Pros: Excellent for forging large diameters, efficient material use. Cons: Limited to specific applications, requires specialized tooling. |

What Are the Key Characteristics of Hydraulic Presses in Forging?

Hydraulic presses are renowned for their ability to apply significant force through hydraulic systems, making them ideal for precise metal shaping. These machines excel in applications requiring intricate designs, such as aerospace and automotive parts. Buyers should consider factors like tonnage requirements and the complexity of the components they intend to produce, as hydraulic presses can accommodate a wide range of materials and geometries. However, the initial investment and ongoing maintenance costs can be higher compared to other types.

How Do Mechanical Presses Benefit High-Volume Production?

Mechanical presses operate through a mechanical force mechanism, making them particularly suited for high-volume production scenarios. They are commonly used in automotive manufacturing for stamping and forming parts rapidly. The advantages of mechanical presses include faster cycle times and robustness, which contribute to lower production costs over time. However, their inflexibility in handling custom shapes can be a drawback for businesses that require diverse product offerings.

Why Are Power Hammers Popular for Custom Forging?

Power hammers are versatile machines that use a hammering action to shape metal, making them popular in artistic forging and custom fabrication. They are particularly beneficial for manufacturers looking to create unique designs or small production runs. While power hammers are relatively inexpensive and flexible, they require skilled operators to achieve the desired results. Their efficiency may not match that of hydraulic or mechanical presses in mass production contexts, so businesses must assess their specific needs before investing.

What Are the Advantages of Using Induction Forges?

Induction forges utilize electromagnetic induction to heat metal, offering a quick and energy-efficient heating solution. This makes them ideal for small parts manufacturing and tool production, where precision is critical. Buyers should consider their production volume and the types of materials they will be working with, as induction forges excel in specific applications. However, the limitations on part size and higher setup costs could deter some businesses from choosing this option.

How Do Upsetter Machines Enhance Forging Processes?

Upsetter machines are designed to increase the diameter of metal bars and are particularly useful in industries like oil and gas and aerospace. These machines optimize material usage and are efficient for creating larger components. When considering an upsetter machine, businesses should evaluate their specific production needs and the types of parts they intend to forge. While upsetters provide significant advantages in terms of efficiency and material utilization, they may require specialized tooling and are limited to specific applications.

Key Industrial Applications of forging machine

| Industry/Sector | Specific Application of forging machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of crankshafts and connecting rods | Enhanced strength and durability of components | Supplier reliability, machine precision, and capacity |

| Aerospace | Manufacturing of structural components | Lightweight, high-strength parts for aircraft | Compliance with aviation standards, material quality |

| Oil and Gas | Production of valves and fittings | High resistance to extreme conditions | Material specifications, customization options |

| Defense | Forging of weapon components | Precision and reliability in critical applications | Certifications, lead times, and service support |

| Heavy Machinery | Production of gears and drive shafts | Improved performance and lifespan of machinery | Technical support, maintenance services, and cost |

How Is Forging Machinery Used in the Automotive Sector?

In the automotive industry, forging machines are crucial for producing high-strength components like crankshafts and connecting rods. These parts require exceptional durability to withstand the stresses of engine operation. By using forging techniques, manufacturers can create components with superior mechanical properties compared to those made through casting. International buyers should prioritize suppliers that offer precise machine specifications and reliable service to ensure consistent quality and production efficiency.

What Role Does Forging Machinery Play in Aerospace Manufacturing?

Aerospace manufacturers leverage forging machines to create lightweight yet strong structural components, such as landing gear and turbine disks. The forging process allows for complex geometries that are essential for performance while meeting stringent safety standards. Buyers from regions with emerging aerospace sectors, such as Africa and South America, need to ensure their suppliers comply with aviation regulations and provide materials that meet high-performance criteria to ensure safety and reliability.

How Is Forging Machinery Utilized in the Oil and Gas Industry?

In the oil and gas sector, forging machines are used to produce critical components like valves, fittings, and flanges that must withstand extreme temperatures and pressures. The forging process enhances the material’s integrity, making it ideal for challenging environments. Buyers in this industry should focus on sourcing from manufacturers that can meet specific material requirements and offer customization options to fit unique project needs.

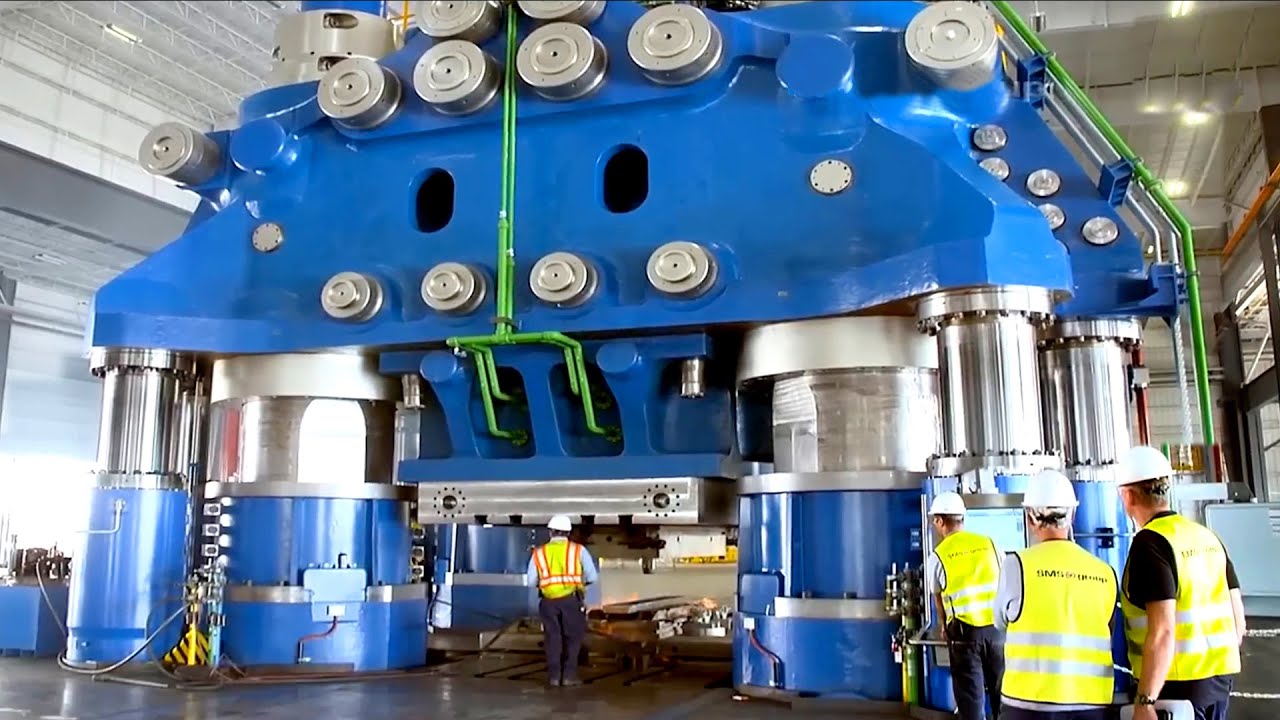

Illustrative image related to forging machine

Why Is Forging Machinery Important for the Defense Industry?

The defense sector relies on forging machinery to produce weapon components and other critical parts that require high precision and reliability. The forging process ensures that these components can perform under demanding conditions, which is vital for national security applications. B2B buyers in this sector must consider suppliers with the necessary certifications and proven track records in delivering high-quality, durable products on time.

How Does Forging Machinery Benefit Heavy Machinery Production?

Forging machines are essential in producing gears and drive shafts for heavy machinery, where durability and performance are paramount. The forging process improves the material’s structural integrity, leading to longer-lasting components that can operate under heavy loads. Buyers looking for forging solutions in this field should evaluate suppliers based on their technical support capabilities, maintenance services, and overall cost-effectiveness to optimize their production processes.

3 Common User Pain Points for ‘forging machine’ & Their Solutions

Scenario 1: Overcoming Production Inefficiencies in Forging Operations

The Problem: Many manufacturers face significant production inefficiencies due to outdated or improperly configured forging machines. These inefficiencies can manifest as increased cycle times, higher scrap rates, and an inability to meet production demands, ultimately affecting the bottom line. For instance, a company in Nigeria may struggle to keep up with growing orders due to a lack of advanced automation features in their existing machinery. This not only leads to missed opportunities but also impacts customer satisfaction.

Illustrative image related to forging machine

The Solution: To address these challenges, it is crucial to invest in modern forging equipment that integrates advanced automation and precision engineering. Buyers should conduct a thorough needs assessment to identify specific production requirements and gaps in their current operations. Collaborating with reputable manufacturers like Ajax/CECO/Erie Press or Coal Iron Works can provide insights into the latest technologies available, such as programmable hammers and automated presses. Furthermore, it is essential to consider machinery that offers scalability and customization options to adapt to fluctuating market demands. By upgrading to high-speed, durable machines that offer better control and consistency, manufacturers can enhance their productivity and reduce waste.

Scenario 2: Navigating Maintenance and Downtime Challenges

The Problem: Unplanned machine downtime due to maintenance issues is a common pain point for B2B buyers in the forging industry. For example, a forging operation in Saudi Arabia may experience unexpected failures in their presses, leading to costly production halts and delayed deliveries. These interruptions not only disrupt workflow but also strain relationships with clients who rely on timely service.

The Solution: Implementing a proactive maintenance strategy can significantly mitigate these challenges. Buyers should establish a preventative maintenance program that includes regular inspections, lubrication, and part replacements based on usage patterns. Partnering with manufacturers that offer comprehensive support services, including training for in-house technicians, can be invaluable. Utilizing data analytics and IoT-enabled machinery can also help predict maintenance needs before failures occur, thereby minimizing downtime. By investing in robust, high-quality forging machines designed for longevity and ease of maintenance, companies can ensure smoother operations and maintain production schedules.

Illustrative image related to forging machine

Scenario 3: Ensuring Compliance with Industry Standards and Safety Regulations

The Problem: Compliance with industry standards and safety regulations is a critical concern for forging companies, especially those operating in regions with stringent requirements. For instance, a manufacturer in Europe may grapple with ensuring that their forging machines meet ISO standards while also adhering to local safety regulations. Non-compliance can lead to hefty fines, legal issues, and damage to reputation.

The Solution: To navigate these complexities, it is essential for B2B buyers to work closely with suppliers who understand the regulatory landscape of their industry. When sourcing forging machines, buyers should prioritize manufacturers that maintain ISO 9001 certification and can provide documentation of compliance with relevant safety standards. Conducting a thorough review of machinery specifications and seeking equipment designed with safety features—such as emergency stops, safety guards, and user-friendly interfaces—can significantly reduce risks. Additionally, investing in training programs for employees on safe operational practices can further enhance compliance efforts. By fostering a culture of safety and accountability, companies can protect their workforce and ensure adherence to industry regulations, thus safeguarding their operations.

Strategic Material Selection Guide for forging machine

When selecting materials for forging machines, understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and ensuring compliance with industry standards. Below, we analyze four common materials used in forging machines, focusing on their key properties, pros and cons, and specific considerations for international B2B buyers.

What are the Key Properties of Steel in Forging Machines?

Steel is the most widely used material in forging machines due to its excellent mechanical properties. Key properties include high tensile strength, good ductility, and the ability to withstand high temperatures and pressures. Steel grades such as carbon steel and alloy steel are common, with varying compositions that enhance specific characteristics like hardness and toughness.

Pros: Steel’s durability and strength make it suitable for heavy-duty applications. It is relatively cost-effective and can be easily machined and welded, allowing for complex designs.

Illustrative image related to forging machine

Cons: Steel can be susceptible to corrosion if not properly treated, and its weight may increase the overall mass of the machinery, potentially affecting transport and installation.

Impact on Application: Steel’s compatibility with various forging processes, including hot and cold forging, makes it ideal for producing components in industries such as automotive and aerospace.

Considerations for International Buyers: Buyers should ensure that the steel grades comply with international standards such as ASTM or DIN. Additionally, understanding local corrosion conditions is vital for selecting appropriate surface treatments.

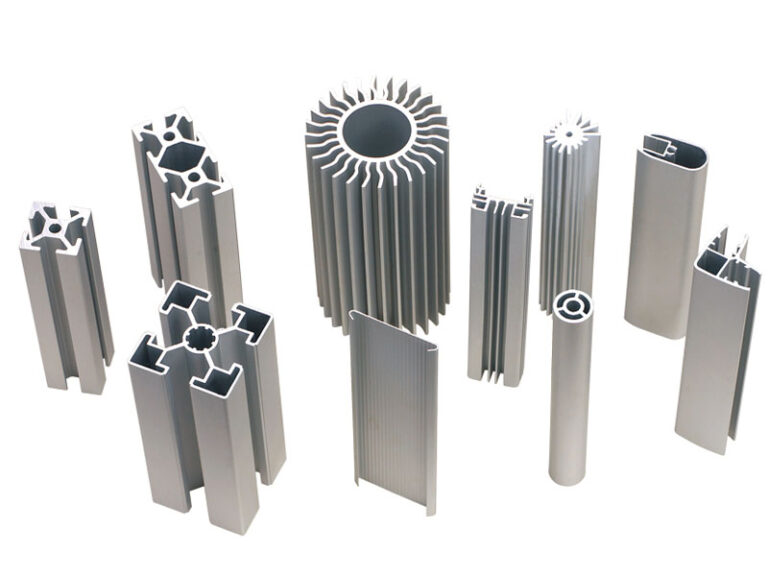

How Does Aluminum Perform in Forging Applications?

Aluminum is increasingly used in forging machines, particularly in applications requiring lightweight components. Key properties include low density, excellent corrosion resistance, and good thermal conductivity. Aluminum alloys can be tailored to enhance strength and formability.

Pros: The lightweight nature of aluminum reduces energy consumption during operation and transport. Its corrosion resistance extends the lifespan of components, making it suitable for outdoor applications.

Illustrative image related to forging machine

Cons: Aluminum has lower tensile strength compared to steel, which may limit its use in high-load applications. It is also more expensive than some steel grades, which can affect overall project budgets.

Impact on Application: Aluminum is ideal for applications in the automotive and aerospace sectors, where weight reduction is critical. It is also used in marine environments due to its corrosion resistance.

Considerations for International Buyers: Compliance with standards such as JIS for aluminum alloys is essential. Buyers should also consider the availability of specific alloys in their regions, as this can impact lead times and costs.

What Role Does Cast Iron Play in Forging Machinery?

Cast iron is known for its excellent wear resistance and ability to dampen vibrations, making it a popular choice for machine bases and components. Key properties include high compressive strength and good machinability.

Pros: Cast iron’s durability and vibration-damping properties enhance the stability and longevity of forging machines. It is also generally more cost-effective than steel and aluminum.

Cons: Cast iron is brittle and can fracture under high tensile loads, limiting its application in high-stress components. Its weight can also be a disadvantage in terms of mobility.

Impact on Application: Cast iron is often used in the construction of machine frames and bases, where stability is more critical than weight. It is less suitable for components that experience high tensile forces.

Considerations for International Buyers: Buyers should check for compliance with relevant standards such as ASTM A48 for cast iron. Understanding local manufacturing capabilities for cast iron components is also important.

How Does Titanium Compare in Forging Machinery Applications?

Titanium is a high-performance material known for its exceptional strength-to-weight ratio and corrosion resistance. Key properties include high tensile strength, low density, and excellent resistance to oxidation at elevated temperatures.

Pros: Titanium’s lightweight nature and strength make it ideal for high-performance applications, particularly in aerospace and defense. Its corrosion resistance extends the lifespan of components in harsh environments.

Cons: The high cost of titanium can be a significant barrier for many projects. Additionally, its machining can be complex and requires specialized tools, increasing manufacturing costs.

Impact on Application: Titanium is particularly suited for applications in the aerospace and medical industries, where performance and reliability are paramount.

Illustrative image related to forging machine

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B348 for titanium. Understanding the availability of titanium alloys in local markets is crucial for project planning.

Summary Table of Material Selection for Forging Machines

| Material | Typical Use Case for forging machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty components in automotive and aerospace | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight components in automotive and aerospace | Excellent corrosion resistance | Lower tensile strength | High |

| Cast Iron | Machine bases and frames | Good wear resistance and stability | Brittle under tensile loads | Low |

| Titanium | High-performance aerospace components | Exceptional strength-to-weight ratio | High cost and complex machining | High |

This guide provides a comprehensive overview of material selection for forging machines, emphasizing the importance of understanding the unique properties and implications of each material for international B2B buyers. By aligning material choices with operational needs and compliance standards, buyers can enhance the performance and longevity of their forging machinery.

In-depth Look: Manufacturing Processes and Quality Assurance for forging machine

What Are the Main Stages in the Manufacturing Process of Forging Machines?

The manufacturing process of forging machines is intricate, involving multiple stages that ensure precision and durability. Understanding these stages helps B2B buyers make informed decisions when sourcing equipment.

Material Preparation: How Is Raw Material Selected and Processed?

The first stage in manufacturing forging machines is material preparation. High-quality raw materials, such as alloy steel and cast iron, are selected based on the intended application of the machine. The materials undergo processes like cutting, grinding, and heat treatment to enhance their mechanical properties. This preparation is crucial, as the strength and durability of the forging machine heavily depend on the quality of the raw materials used.

Forming: What Techniques Are Employed in the Forging Process?

Once the materials are prepared, the next stage is forming. This involves shaping the raw materials into the desired configurations through various forging techniques. Common methods include:

- Open Die Forging: This technique uses flat dies to shape the material, allowing for larger components.

- Closed Die Forging: In this method, the material is placed in a die cavity, which shapes it into the desired form under high pressure.

- Roll Forging: This process involves passing the material through a pair of rolls to achieve the desired shape, often used for long components like bars and rods.

These techniques are selected based on factors such as the size and complexity of the components being produced, as well as the production volume required.

Assembly: How Are Forging Machines Assembled for Optimal Performance?

After forming, the components are assembled. This stage involves precision alignment and integration of various parts, such as the hydraulic systems, control panels, and safety mechanisms. The assembly process may include welding, bolting, and the application of adhesives to ensure structural integrity. Each component must meet strict specifications to ensure the machine operates efficiently and safely.

Finishing: What Are the Final Steps to Ensure Quality and Functionality?

The final stage of manufacturing involves finishing processes that enhance the machine’s performance and longevity. This includes surface treatments such as coating, polishing, and heat treatment. These processes protect against wear and corrosion, ensuring that the forging machine can withstand the rigors of continuous operation. Quality checks are integral at this stage, ensuring that every machine meets the required operational standards.

Illustrative image related to forging machine

What Quality Control Measures Are Implemented in Forging Machine Manufacturing?

Quality assurance is a vital component of the manufacturing process for forging machines. B2B buyers need to be aware of the standards and practices that ensure the machinery meets international quality benchmarks.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of forging machines often adhere to several international standards to guarantee quality and safety. The most notable include:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Certification: Relevant for manufacturers in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: For buyers in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial for ensuring equipment reliability and safety.

Understanding these certifications can help buyers from regions such as Africa, South America, the Middle East, and Europe evaluate the credibility of potential suppliers.

Illustrative image related to forging machine

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is typically segmented into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor the quality of the components being produced.

- Final Quality Control (FQC): Before the machines leave the manufacturing facility, a comprehensive inspection is conducted to ensure that all specifications are met.

These checkpoints help identify issues early in the production process, minimizing waste and ensuring that only high-quality machines are delivered to buyers.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure the integrity and functionality of forging machines. Common methods include:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle testing, and dye penetrant testing are used to identify flaws in materials without causing damage.

- Load Testing: This simulates operational conditions to ensure that the machine can handle the specified loads without failure.

- Performance Testing: Assessing the machine’s operational efficiency under real-world conditions to verify that it meets performance standards.

These testing methods ensure that the machines not only meet design specifications but also function effectively in demanding industrial environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those from diverse regions, verifying the quality control practices of potential suppliers is crucial. Here are some effective strategies:

Illustrative image related to forging machine

What Steps Can Be Taken to Conduct Supplier Audits?

Conducting audits is one of the most effective ways to assess a supplier’s quality control practices. Buyers can:

- Request Documentation: Ask for quality assurance documentation, including certifications, inspection reports, and testing results.

- On-Site Audits: If feasible, visiting the manufacturing facility allows buyers to observe the quality control processes in action and evaluate the production environment.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control systems and practices.

What Are the Benefits of Quality Reports and Certifications?

Quality reports and certifications serve as vital indicators of a supplier’s commitment to quality. Buyers should look for:

- Traceability: Certifications should be traceable to specific products or batches, providing assurance of quality consistency.

- Reputation: Researching the supplier’s reputation in the industry can provide insights into their reliability and adherence to quality standards.

- Customer Testimonials: Feedback from other customers can highlight the supplier’s strengths and any potential weaknesses in their quality control practices.

By understanding these aspects of the manufacturing and quality assurance processes for forging machines, B2B buyers can make informed decisions that align with their operational needs and standards. This knowledge not only helps in selecting high-quality suppliers but also ensures that investments in forging machinery yield long-term benefits.

Illustrative image related to forging machine

Practical Sourcing Guide: A Step-by-Step Checklist for ‘forging machine’

In today’s competitive manufacturing landscape, acquiring the right forging machine is essential for optimizing production efficiency and ensuring product quality. This practical sourcing guide outlines the critical steps B2B buyers should follow when procuring forging machines, particularly for industries in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for matching the right machine to your production needs. Consider factors such as tonnage capacity, material types, and specific forging processes required. Understanding these parameters will streamline your search and help you communicate effectively with suppliers.

Step 2: Assess Your Production Volume Needs

Determine the volume of parts you plan to produce and the expected production rates. This step is crucial as different machines cater to varying production scales—some may be designed for high-speed continuous operations, while others may be better suited for lower volume, specialized tasks. Knowing your production needs can prevent overspending on unnecessary capabilities.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Request company profiles, case studies, and references from other buyers in similar industries or regions. A supplier’s reputation and history of reliability can significantly influence your operational success, so don’t rely solely on their website claims.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the forging machines meet international standards and certifications, such as ISO 9001. This verification is essential not only for quality assurance but also for compliance with safety and operational regulations in your region. Machines that adhere to these standards often reflect a commitment to quality and reliability.

Step 5: Request Customization Options

Many suppliers offer customizable solutions tailored to specific production layouts and part specifications. Discuss your unique requirements with potential suppliers to explore options for machine configuration, automation integration, and other enhancements. Customization can lead to improved efficiency and better alignment with your production goals.

Step 6: Analyze Total Cost of Ownership (TCO)

Consider the total cost of ownership, including initial purchase price, maintenance costs, and operational expenses. A lower upfront cost may lead to higher long-term expenses due to inefficiency or frequent repairs. Evaluate warranties and service agreements to ensure you understand the long-term financial implications of your investment.

Step 7: Plan for Training and Support

Finally, assess the training and support services that suppliers offer. Effective training ensures that your team can operate the machines safely and efficiently, maximizing productivity from day one. Additionally, inquire about ongoing support, such as maintenance services or troubleshooting assistance, to ensure you have the resources necessary for sustained operation.

Illustrative image related to forging machine

By following these steps, B2B buyers can make informed decisions when sourcing forging machines, ultimately leading to enhanced productivity and operational efficiency.

Comprehensive Cost and Pricing Analysis for forging machine Sourcing

What Are the Key Cost Components in Sourcing Forging Machines?

When sourcing forging machines, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The raw materials used in manufacturing forging machines significantly influence costs. High-quality steels and alloys can raise the price but also enhance durability and performance. Buyers should assess the material specifications required for their intended applications to ensure they are investing in the right products.

-

Labor: Labor costs vary by region and can be a significant factor in the overall pricing of forging machines. Skilled labor is often necessary for both assembly and maintenance, impacting the total cost. Understanding local labor market conditions in your sourcing region can provide insights into potential cost savings.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment used in the manufacturing process. Overhead costs can vary widely depending on the manufacturer’s location and operational efficiency. Buyers should inquire about the manufacturer’s production capabilities and facility standards to gauge quality and efficiency.

-

Tooling: Specialized tooling may be required for the production of custom forging machines, which can add to the initial costs. This is particularly relevant for buyers needing specific machine configurations or capabilities. Understanding tooling costs can help buyers budget more accurately.

-

Quality Control (QC): Implementing strict QC measures ensures the reliability and performance of forging machines. The associated costs of QC processes should be factored into the total price. Buyers should look for certifications like ISO 9001, which indicate adherence to quality standards.

-

Logistics: Shipping costs are a vital consideration, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect the final cost. Negotiating Incoterms that minimize logistical risks can help manage these expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on competition, demand, and the supplier’s market position. Understanding typical margins in the forging machine market can help buyers identify fair pricing.

What Influences the Pricing of Forging Machines?

Several factors can influence the pricing of forging machines:

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate volume discounts, especially if planning to source multiple machines.

-

Specifications and Customization: Custom-built machines tailored to specific production needs can significantly increase costs. Buyers should clearly define their requirements upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and compliance with international certifications can elevate costs but also ensure better performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a history of quality may charge a premium, but their products often come with greater assurance of performance.

-

Incoterms: The terms of sale can impact total costs. Buyers should understand the implications of Incoterms on shipping responsibilities, duties, and insurance to optimize their purchasing strategy.

How Can Buyers Negotiate for Better Pricing on Forging Machines?

Effective negotiation can lead to significant savings. Here are some strategies for buyers:

-

Do Your Homework: Research market prices and supplier offerings to establish a baseline for negotiations. Understanding the competitive landscape can empower buyers during discussions.

-

Leverage Volume: If purchasing multiple machines, use this as leverage to negotiate better terms or discounts. Suppliers are often willing to provide better pricing for larger orders.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate the long-term costs associated with maintenance, energy consumption, and potential downtime. This holistic view can justify higher upfront investments in more reliable machinery.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can enhance bargaining power. This process can also provide insights into pricing trends and options available in the market.

-

Be Flexible with Payment Terms: Offering to pay upfront or negotiating favorable payment terms can sometimes lead to discounts or better pricing.

What Pricing Nuances Should International Buyers Be Aware Of?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several nuances can affect pricing:

-

Currency Fluctuations: Exchange rates can impact the final cost. Buyers should consider the timing of their purchases relative to currency trends.

-

Import Tariffs and Duties: Understanding local tariffs and import duties is crucial, as these can significantly inflate costs upon arrival.

-

Cultural Considerations: Familiarizing oneself with local business practices and negotiation styles can enhance communication and lead to more favorable outcomes.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding the cost and pricing dynamics of forging machines, actual prices may vary based on specific requirements, supplier negotiations, and market conditions. Always consult with suppliers for precise quotations tailored to your needs.

Alternatives Analysis: Comparing forging machine With Other Solutions

Understanding Alternatives to Forging Machines

In the competitive landscape of metalworking, businesses often seek various solutions for forming and shaping materials. Forging machines are a popular choice due to their efficiency and precision. However, alternative methods may also provide viable options depending on specific operational needs, budget constraints, and production goals. This section explores several alternatives to forging machines, comparing their performance, costs, ease of implementation, maintenance requirements, and best use cases.

| Comparison Aspect | Forging Machine | CNC Machining | Casting | 3D Printing |

|---|---|---|---|---|

| Performance | High durability and precision | Excellent precision, versatile | High-volume production | Complex geometries, rapid prototyping |

| Cost | Moderate to high initial investment | High setup costs | Lower initial costs | Varies widely based on material |

| Ease of Implementation | Requires skilled setup | High learning curve | Simple for large batches | Requires specialized software |

| Maintenance | Regular maintenance required | Low maintenance | Minimal after setup | Low, but technology-dependent |

| Best Use Case | Aerospace, automotive parts | Custom parts, intricate designs | High-volume, less intricate | Prototyping, complex designs |

What Are the Advantages and Disadvantages of CNC Machining?

CNC (Computer Numerical Control) machining utilizes computer software to control machine tools for precision manufacturing. This method excels in producing intricate designs and custom parts. However, it typically involves higher initial setup costs and requires skilled operators to manage the software and machinery. CNC machining is ideal for businesses needing detailed components but may not be cost-effective for high-volume production runs, where forging machines could be more advantageous.

How Does Casting Compare to Forging Machines?

Casting is a process that involves pouring molten metal into a mold to create parts. It can be more cost-effective for producing large quantities of simpler shapes. The initial costs for casting can be lower than forging machines, particularly for high-volume production. However, casting may not achieve the same level of strength or precision as forged components. It is best suited for applications where intricate details are not critical, such as in certain automotive and industrial applications.

Illustrative image related to forging machine

What Are the Benefits of 3D Printing in Metalworking?

3D printing, or additive manufacturing, offers unique advantages, particularly in creating complex geometries that traditional methods may struggle with. It allows for rapid prototyping and customization, making it suitable for low-volume, high-complexity applications. However, the cost of materials can vary significantly, and the technology requires specialized knowledge to operate efficiently. While 3D printing is transformative for design and prototyping, it may not replace the need for traditional forging machines in high-volume production scenarios.

How Should B2B Buyers Choose the Right Solution?

When evaluating the right metalworking solution, B2B buyers should consider their specific operational requirements, production volume, and budget. Forging machines offer durability and precision for high-demand industries like aerospace and automotive. In contrast, CNC machining may be more suitable for custom or intricate components, while casting can be ideal for simpler, high-volume parts. 3D printing stands out for rapid prototyping and complex designs. Ultimately, understanding the strengths and limitations of each method will empower buyers to make informed decisions tailored to their unique manufacturing needs.

Essential Technical Properties and Trade Terminology for forging machine

What Are the Key Technical Properties of Forging Machines?

Understanding the technical specifications of forging machines is essential for B2B buyers looking to invest in high-performance equipment. Here are critical specifications that impact the functionality and suitability of forging machines for various industrial applications.

1. Material Grade

The material grade of a forging machine refers to the quality and type of materials used in its construction, such as high-strength steel or specialized alloys. This property directly influences the machine’s durability, performance under stress, and resistance to wear and tear. For B2B buyers, selecting machines made from superior material grades ensures longevity and reduces maintenance costs, contributing to a better return on investment.

Illustrative image related to forging machine

2. Tonnage Capacity

Tonnage capacity is a critical specification that indicates the maximum weight the machine can handle during forging operations. This is typically expressed in tons and can range from small presses to those capable of handling thousands of tons. Understanding tonnage requirements is vital for manufacturers to ensure they can meet production demands without overloading equipment, which can lead to costly downtime and repairs.

3. Stroke Length

Stroke length refers to the distance the ram or hammer travels during a forging cycle. This property affects the type and size of parts that can be produced. A longer stroke can accommodate larger or more complex shapes, making it essential for buyers to align this specification with their product requirements. Selecting the appropriate stroke length can optimize production efficiency and part quality.

4. Speed of Operation

The speed of operation, often measured in strokes per minute (SPM), determines how quickly the forging machine can complete cycles. A higher speed can lead to increased productivity, making it crucial for high-volume production environments. Buyers must consider the balance between speed and the quality of the finished product to avoid sacrificing precision for efficiency.

5. Control Systems

Advanced control systems enhance the precision and automation of forging machines. These systems can include programmable features that allow for adjustments in speed, force, and timing, which are essential for complex or variable production requirements. For B2B buyers, investing in machines with sophisticated control systems can lead to greater flexibility and adaptability in manufacturing processes.

Which Common Trade Terms Should B2B Buyers Understand in the Forging Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in the forging machine market. Here are some essential trade terms every buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the forging industry, understanding OEM relationships helps buyers identify trusted suppliers and ensure they are purchasing quality equipment that meets industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. This term is crucial for buyers to understand as it affects inventory costs and cash flow management. Knowing the MOQ can help companies plan their purchases effectively, particularly in regions with tight supply chains.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is a strategic way to gather competitive bids and negotiate better deals, ensuring they receive the best value for their investment.

Illustrative image related to forging machine

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping transactions. Familiarity with Incoterms is essential for B2B buyers, especially in international dealings, as they define who is responsible for shipping costs, insurance, and risks during transportation.

5. Lead Time

Lead time refers to the period between placing an order and receiving the equipment. Understanding lead times is vital for B2B buyers to ensure that production schedules align with delivery timelines, preventing delays in manufacturing operations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when investing in forging machines, ultimately enhancing their operational efficiency and competitiveness in the market.

Illustrative image related to forging machine

Navigating Market Dynamics and Sourcing Trends in the forging machine Sector

What Are the Key Market Dynamics and Trends in the Forging Machine Sector?

The forging machine sector is experiencing significant transformation driven by globalization, technological advancements, and evolving market demands. As industries increasingly prioritize efficiency and precision, key trends include the adoption of automation and smart manufacturing solutions. With the rise of Industry 4.0, manufacturers are integrating IoT and AI technologies into forging processes, enabling real-time monitoring and enhanced operational efficiency. This shift is particularly relevant for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, where the demand for high-quality, reliable machinery is growing.

Emerging markets are also seeing a surge in demand for customized forging solutions that cater to specific industry requirements, such as aerospace, automotive, and energy sectors. Notably, buyers from Nigeria and Saudi Arabia are increasingly looking for equipment that offers not only high performance but also the capability to integrate with existing production lines. Furthermore, sustainability is becoming a critical factor, with companies seeking machines that minimize environmental impact while maintaining productivity.

Additionally, the current supply chain dynamics pose both challenges and opportunities. Disruptions caused by global events necessitate a reevaluation of sourcing strategies. Buyers are encouraged to establish relationships with multiple suppliers to mitigate risks and ensure a steady supply of forging machinery. By staying informed about market trends and leveraging technological advancements, international buyers can make strategic sourcing decisions that enhance their competitive edge.

How Are Sustainability and Ethical Sourcing Influencing the Forging Machine Sector?

Sustainability has emerged as a crucial consideration for B2B buyers in the forging machine sector. The environmental impact of manufacturing processes is under increasing scrutiny, prompting companies to seek machines that comply with stringent environmental regulations. This trend is particularly relevant in regions such as Europe, where the push for greener manufacturing practices is strong. Buyers are increasingly interested in suppliers that offer ‘green’ certifications, such as ISO 14001, which indicates a commitment to environmental management.

Ethical sourcing is another vital aspect, as companies aim to establish transparent supply chains. By prioritizing suppliers that adhere to ethical labor practices and sustainable materials, businesses not only mitigate risks associated with reputational damage but also align with the growing consumer demand for responsible manufacturing. This is especially pertinent for buyers in Africa and South America, where local regulations may be evolving to emphasize sustainable practices.

Moreover, the integration of recycled materials in forging processes is gaining traction. Manufacturers are exploring innovative ways to reduce waste and utilize sustainable materials, which can enhance their market appeal. Ultimately, prioritizing sustainability and ethical sourcing in the procurement of forging machines not only fulfills regulatory obligations but also positions companies as leaders in responsible manufacturing.

What Is the Historical Context of the Forging Machine Sector?

The forging machine sector has evolved significantly since its inception, with roots tracing back to ancient metalworking techniques. The industrial revolution marked a turning point, introducing steam power and mechanization, which transformed forging from a manual craft into a large-scale industrial process. Over the decades, advancements in metallurgy and engineering led to the development of more sophisticated machinery capable of producing high-precision components.

In the latter half of the 20th century, the introduction of computer-controlled systems revolutionized forging operations, allowing for greater accuracy and efficiency. Today, modern forging machines are equipped with advanced automation features, enabling manufacturers to meet the demands of diverse industries while maintaining high production rates and quality standards. This historical evolution underscores the sector’s adaptability and commitment to continuous improvement, making it a vital component of modern manufacturing across various global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of forging machine

-

1. How do I solve challenges related to sourcing forging machines internationally?

To effectively source forging machines from international suppliers, start by conducting thorough market research to identify reputable manufacturers. Evaluate their certifications, such as ISO 9001, to ensure compliance with international quality standards. Engage in direct communication with suppliers to discuss your specific needs, including machine specifications and production capacities. It’s also wise to request customer testimonials or case studies that demonstrate the supplier’s reliability. Finally, consider using third-party services for supplier verification to mitigate risks. -

2. What is the best forging machine for high-volume production?

The best forging machine for high-volume production typically includes hydraulic or mechanical presses, which can handle significant tonnage and ensure consistent part quality. Look for machines that offer programmable features for flexibility and efficiency, such as programmable hammers or upsetters. The choice also depends on the material you are working with and the specific geometry of the parts. Consulting with a supplier’s engineering team can help you determine the most suitable machine based on your production goals and material specifications. -

3. What are the key factors to consider when customizing a forging machine?

Customizing a forging machine requires careful consideration of several factors, including production volume, part geometry, and specific material requirements. Discuss your needs with the manufacturer to ensure they can accommodate your desired modifications, such as stroke length, ram speed, and control systems. Additionally, evaluate the compatibility of the customized machine with existing production lines and automation systems. Clear communication about your specifications will ensure the final product meets your operational needs. -

4. What is the minimum order quantity (MOQ) for forging machines?

The minimum order quantity for forging machines can vary significantly between manufacturers. Some may offer individual machines, while others may require bulk orders to optimize production and reduce costs. It’s essential to discuss your specific requirements with potential suppliers to understand their MOQ policies. Additionally, consider the impact of MOQ on your budget and inventory management, especially if you are a smaller operation or just starting. -

5. What payment terms should I expect when purchasing forging machines internationally?

Payment terms for international purchases of forging machines typically include options like upfront deposits, progress payments, or letters of credit. Most suppliers will require a deposit (often 30-50%) before production begins, with the balance due upon completion or before shipment. It’s crucial to clarify these terms during negotiations to avoid misunderstandings. Be mindful of potential currency fluctuations and associated bank fees when dealing with international transactions. -

6. How do I ensure quality assurance when sourcing forging machines?

To ensure quality assurance, verify that the supplier adheres to recognized international quality standards, such as ISO 9001. Request detailed documentation of their quality control processes, including inspection reports and certification of materials used. Additionally, consider arranging for factory visits or third-party inspections before shipment to assess the machinery firsthand. Establishing clear communication regarding your quality expectations will also help maintain standards throughout the manufacturing process. -

7. What logistics considerations should I keep in mind when importing forging machines?

Importing forging machines involves several logistics considerations, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling heavy machinery to navigate international shipping regulations efficiently. Be aware of potential customs duties and tariffs that may apply to your shipment. Planning for adequate insurance coverage during transit is also essential to protect your investment against damages or losses. -

8. How can I evaluate the reliability of a forging machine supplier?

Evaluating the reliability of a forging machine supplier involves assessing their industry reputation, years of experience, and customer reviews. Request references from previous clients to gain insights into their satisfaction levels. Review case studies that showcase the supplier’s ability to deliver on time and meet quality standards. Additionally, consider their after-sales support and warranty offerings, as these factors can significantly influence your long-term satisfaction with the supplier.

Top 3 Forging Machine Manufacturers & Suppliers List

1. Ajax/CECO/Erie Press – Precision Forging Machinery

Domain: ajaxerie.com

Registered: 2021 (4 years)

Introduction: Ajax/CECO/Erie Press builds precision forging machinery for industrial manufacturers, offering a range of products including upsetters, programmable hammers, presses, wire and bar drawers, forging rolls, and automation solutions. Key features include:

– Upsetters: Robust machines for solid-die ball forging and tube upsetting.

– Programmable Hammers: Customized solutions for unique forging needs….

2. Ficep Group – Forging and Shearing Solutions

Domain: ficepgroup.com

Registered: 2009 (16 years)

Introduction: Presses: DD Direct drive forging, MF Mechanical forging, HF Hydraulic forging, HF 4C 4-columns hydraulic forging, HF X Triple action hydraulic forging, PVX Friction forging. Shearing: CADDY Mechanical cold and warm shearing, CTCH Hydraulic hot shearing, CODEBRASS Mechanical cold and warm shearing. Sawing: S Profiles disc sawing, SP Pipes disc sawing, VS Miscellaneous profiles disc sawing. Automati…

3. ScienceDirect – Forging Machines

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Forging machines are equipment used in the forging process to deform metal through local compressive forces. They include manual or power hammers, presses, and specialized equipment for various forging techniques. The forging process involves shaping metal parts by hammering, pressing, or bending, typically at red heat. Key types of forging include hand forging, drop forging, open-die forging, and…

Strategic Sourcing Conclusion and Outlook for forging machine

In the evolving landscape of forging machinery, strategic sourcing emerges as a crucial pillar for manufacturers aiming to enhance efficiency and productivity. By carefully selecting suppliers and leveraging advanced technologies, companies can optimize their operations while ensuring compliance with international quality standards. Key takeaways from this guide highlight the importance of investing in robust, high-performance forging machines tailored to specific industrial needs, whether in aerospace, automotive, or energy sectors.

As buyers from Africa, South America, the Middle East, and Europe navigate their procurement processes, understanding the unique demands of their respective markets will be essential. The integration of automation and innovative designs not only addresses labor shortages but also enhances product quality and production speed, ultimately driving competitive advantage.

Looking ahead, the demand for advanced forging solutions is set to grow, fueled by globalization and technological advancements. Now is the time for international B2B buyers to engage with leading manufacturers, request customized solutions, and position themselves at the forefront of the forging industry. Take the next step in your strategic sourcing journey—connect with trusted suppliers and explore the possibilities that cutting-edge forging machinery can unlock for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.