Choosing Your Fish Griller: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for fish griller

The global market for fish grillers presents a unique set of challenges for B2B buyers seeking to enhance their culinary offerings. Sourcing high-quality fish grillers that cater to diverse culinary styles and requirements is essential for businesses operating in the seafood sector. This guide aims to navigate the complexities of this market by providing insights into various types of fish grillers, their applications in both commercial and residential settings, and strategies for supplier vetting. With a focus on cost considerations and quality assurance, this resource is tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany.

Understanding the nuances of selecting the right fish griller can empower businesses to make informed purchasing decisions that align with their operational needs and budget constraints. By exploring the different grill types—from electric to gas and charcoal—and their specific advantages, buyers can tailor their choices to suit their target markets. Additionally, the guide will delve into essential factors such as supplier reputation, product warranties, and after-sales support, ensuring that buyers are equipped with the knowledge to forge successful partnerships. Ultimately, this comprehensive guide serves as a crucial tool for B2B buyers aiming to elevate their seafood offerings and stay competitive in a dynamic global marketplace.

Understanding fish griller Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Fish Grill | Uses electric heat for even cooking; portable | Restaurants, food trucks | Pros: Easy to use, consistent heat; Cons: Limited to indoor use, requires power supply. |

| Charcoal Fish Grill | Utilizes charcoal for a smoky flavor; high heat | Catering, outdoor events | Pros: Unique flavor, high-temperature cooking; Cons: Longer setup time, requires more maintenance. |

| Gas Fish Grill | Burns propane or natural gas; quick heat-up | Commercial kitchens, outdoor dining | Pros: Fast heating, precise temperature control; Cons: Initial cost can be high, requires gas supply. |

| Infrared Fish Grill | Uses infrared radiation for rapid cooking | High-end restaurants, catering | Pros: Cooks food quickly and evenly; Cons: Higher price point, may require special training. |

| Pellet Fish Grill | Burns wood pellets for flavor; versatile | Specialty seafood restaurants | Pros: Unique wood-smoked flavor; Cons: Requires pellet supply, more complex operation. |

What are the Key Characteristics of Electric Fish Grills for B2B Buyers?

Electric fish grills are designed for consistent cooking using electric heat, making them ideal for establishments with limited space or power availability. Their portability allows for easy relocation, which is beneficial for food trucks and small kitchens. When considering an electric fish grill, B2B buyers should evaluate wattage for heating efficiency, ease of cleaning, and safety features. These grills are particularly suited for indoor use, but their reliance on electricity can limit outdoor applications.

How Do Charcoal Fish Grills Stand Out in the Market?

Charcoal fish grills are favored for imparting a unique smoky flavor to seafood, appealing to restaurants aiming to differentiate their menu. They can reach high temperatures quickly, making them suitable for grilling delicate fish like salmon. However, B2B buyers should be aware of the longer setup time and the need for regular maintenance, including ash disposal. These grills are ideal for outdoor events and catering services, where the flavor enhancement is a key selling point.

Why Choose Gas Fish Grills for Commercial Use?

Gas fish grills are known for their quick heat-up times and precise temperature control, which are essential for busy commercial kitchens. They can accommodate various cooking styles and are suitable for outdoor dining setups. Buyers should consider the initial investment and ongoing gas supply costs when selecting a gas grill. Their efficiency makes them a popular choice for restaurants that prioritize speed without sacrificing quality.

What Makes Infrared Fish Grills a Premium Choice?

Infrared fish grills utilize radiation to cook food quickly and evenly, making them ideal for high-end restaurants that demand precision. They often come with advanced features that allow chefs to experiment with various cooking techniques. B2B buyers should weigh the benefits of faster cooking times against the higher price point and potential need for specialized training. These grills are particularly effective in environments where time is critical, and presentation matters.

How Do Pellet Fish Grills Enhance Flavor Profiles in Seafood?

Pellet fish grills are a unique option that burns wood pellets to infuse food with rich flavors. They offer versatility, allowing chefs to adjust the type of wood for different flavor profiles, which can enhance the dining experience. Buyers should consider the complexity of operation and the requirement for a consistent pellet supply. These grills are well-suited for specialty seafood restaurants looking to provide a unique culinary experience that stands out in a competitive market.

Key Industrial Applications of fish griller

| Industry/Sector | Specific Application of fish griller | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Restaurants & Cafés | Grilling fish for menu items | Enhances menu diversity and attracts health-conscious customers | Durability, size, and energy efficiency of the grill |

| Catering Services | On-site fish grilling for events | Provides fresh, customized seafood dishes for large gatherings | Portability, ease of use, and maintenance requirements |

| Food Processing | Pre-cooking fish products for packaging | Improves product quality and shelf-life for retail distribution | Consistency in cooking times and temperature control |

| Hospitality Sector | Seafood grilling in hotels and resorts | Elevates dining experience and enhances guest satisfaction | Aesthetic design and integration with kitchen space |

| Seafood Retailers | Preparing grilled fish for sale | Adds value to fresh fish offerings and attracts more customers | Compliance with food safety standards and grilling speed |

How Are Fish Griller Applications Beneficial in the Restaurant and Café Sector?

In the restaurant and café sector, fish grillers are essential for creating a variety of grilled fish dishes that cater to health-conscious diners. By offering grilled options, establishments can enhance their menu diversity, appealing to customers seeking nutritious meals. Buyers should consider the durability and energy efficiency of the grill, as these factors directly impact operational costs and the quality of the food served.

What Role Do Fish Grillers Play in Catering Services?

Catering services utilize fish grillers to prepare fresh seafood dishes at events, providing clients with customized menus that meet specific dietary requirements. This on-site grilling capability not only ensures the freshness of the food but also enhances the overall dining experience. When sourcing fish grillers, caterers should prioritize portability and ease of use to facilitate quick setup and operation in various venues.

How Do Fish Grillers Enhance Food Processing Operations?

In food processing, fish grillers are used to pre-cook fish products before packaging, significantly improving product quality and extending shelf life. This application is particularly crucial for businesses aiming to maintain high standards in retail distribution. Key considerations for buyers in this sector include consistency in cooking times and precise temperature control to ensure product safety and quality.

Why Are Fish Grillers Important in the Hospitality Sector?

Hotels and resorts often incorporate fish grillers into their kitchens to elevate the guest dining experience. Grilled seafood can be a highlight of the culinary offerings, attracting guests looking for unique and high-quality meals. Buyers in this sector should focus on the aesthetic design of the grill and how well it integrates into existing kitchen spaces to enhance operational efficiency and customer satisfaction.

How Do Seafood Retailers Benefit from Using Fish Grillers?

Seafood retailers can increase their sales by offering grilled fish as part of their fresh offerings, appealing to customers looking for ready-to-eat options. This not only adds value to their products but also attracts a broader customer base. Compliance with food safety standards is crucial when sourcing fish grills, as maintaining high hygiene levels is essential for customer trust and satisfaction.

Illustrative image related to fish griller

3 Common User Pain Points for ‘fish griller’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Cooking Results

The Problem: B2B buyers often face challenges in achieving uniform cooking results when grilling fish, especially in commercial settings like restaurants or catering services. Variability in temperature control, grill design, and the type of fish being cooked can lead to overcooked or undercooked meals. This inconsistency can compromise food quality, negatively impact customer satisfaction, and increase food waste, ultimately affecting the bottom line.

The Solution: To ensure consistent cooking results, buyers should prioritize investing in high-quality fish grillers equipped with precise temperature controls and even heat distribution systems. Opt for models that feature digital thermostats and programmable settings, allowing for specific temperature adjustments based on the type of fish being grilled. Additionally, utilizing temperature probes can provide real-time feedback, ensuring that the fish is cooked to the desired doneness without guesswork. Regular maintenance of the grill, including cleaning and calibration, is also essential to maintain optimal performance and achieve consistent results.

Scenario 2: Limited Knowledge of Fish Varieties and Cooking Techniques

The Problem: Many B2B buyers lack comprehensive knowledge about different fish varieties and the specific grilling techniques required for each. This gap can lead to poor menu choices, ineffective marketing of seafood dishes, and ultimately, dissatisfied customers. In regions where seafood consumption is growing, such as Africa and South America, understanding local preferences and sourcing options is crucial for success.

The Solution: To overcome this challenge, buyers should invest in training for their culinary teams that focuses on fish species, sourcing strategies, and effective grilling methods. Workshops led by seafood experts can provide valuable insights into the best practices for grilling various types of fish, including marinating techniques and complementary side dishes. Furthermore, establishing partnerships with local fish suppliers can enhance knowledge about seasonal fish varieties and ensure a fresh, appealing menu. Leveraging this knowledge can also facilitate effective marketing campaigns that highlight unique seafood offerings, enhancing customer interest and loyalty.

Scenario 3: High Operational Costs Due to Inefficient Equipment

The Problem: A common pain point for B2B buyers is the high operational costs associated with inefficient fish grilling equipment. Poorly designed grills can consume excessive energy, require frequent repairs, and lead to longer cooking times, all of which contribute to inflated operating expenses. For businesses, particularly in competitive markets, managing costs while maintaining quality is essential for sustainability.

The Solution: Buyers should consider investing in energy-efficient fish grillers that are designed to reduce operational costs. Look for models that carry energy certifications and are built with materials that promote better heat retention and distribution. Features such as rapid pre-heating, built-in timers, and automatic shut-off functions can further enhance energy efficiency. Conducting a cost-benefit analysis before purchasing new equipment can help identify options that offer the best return on investment over time. Additionally, developing a regular maintenance schedule can prevent costly breakdowns and extend the lifespan of the equipment, ensuring that businesses can operate smoothly and efficiently.

Strategic Material Selection Guide for fish griller

What Are the Key Materials Used in Fish Griller Manufacturing?

When selecting materials for fish grillers, manufacturers must consider various factors such as durability, cost, and performance under specific conditions. Here, we analyze four common materials used in fish grillers: stainless steel, cast iron, aluminum, and ceramic. Each material has distinct properties that influence its suitability for different applications.

How Does Stainless Steel Perform in Fish Griller Applications?

Stainless steel is a popular choice for fish grillers due to its excellent corrosion resistance and high-temperature tolerance. It typically has a temperature rating of up to 1,200°F (649°C), making it suitable for high-heat cooking. The alloy’s chromium content provides a protective layer that resists rust and staining, which is crucial in humid environments often found in regions like Southeast Asia and coastal areas.

Pros: Stainless steel is durable, easy to clean, and maintains its appearance over time. It is also compliant with international standards such as ASTM and DIN, making it a reliable choice for B2B buyers.

Cons: The primary downside is its cost, which can be higher than other materials. Additionally, while it is resistant to corrosion, it can still be susceptible to pitting in chloride-rich environments, common in coastal areas.

What Advantages Does Cast Iron Offer for Fish Grilling?

Cast iron is renowned for its heat retention and even cooking properties, making it ideal for grilling fish. It can withstand high temperatures and provides a non-stick surface when properly seasoned. Cast iron grillers can reach temperatures up to 1,500°F (815°C), suitable for searing fish quickly.

Pros: The material is highly durable and can last for generations with proper care. It is also relatively inexpensive compared to stainless steel, making it an attractive option for budget-conscious buyers.

Cons: However, cast iron is heavy and requires regular maintenance to prevent rust. It is also not as corrosion-resistant as stainless steel, which could be a concern in humid or salty environments.

How Does Aluminum Compare in Fish Griller Manufacturing?

Aluminum is lightweight and has excellent thermal conductivity, allowing for quick heating and even cooking. It can reach temperatures of around 1,200°F (649°C) and is often anodized for improved corrosion resistance. This makes aluminum a good option for portable grillers or those requiring frequent transport.

Pros: The lightweight nature of aluminum makes it easy to handle and transport, which is beneficial for catering businesses or outdoor events. It is also cost-effective and can be molded into various shapes.

Cons: On the downside, aluminum is not as durable as stainless steel or cast iron and can warp under extreme heat. It may also react with acidic foods, which could affect the flavor of grilled fish.

Illustrative image related to fish griller

What Role Does Ceramic Play in Fish Grilling Applications?

Ceramic materials are increasingly used in high-end fish grillers due to their ability to retain heat and provide a non-stick surface. They can withstand high temperatures, typically up to 1,500°F (815°C), and are often used in combination with other materials for enhanced performance.

Pros: Ceramic grillers are easy to clean and provide excellent heat retention, ensuring even cooking. They are also aesthetically pleasing, which can enhance the presentation of the grill.

Cons: However, ceramic can be fragile and may crack if subjected to thermal shock. It is also generally more expensive than metal options, which could be a limiting factor for some buyers.

Summary Table of Material Selection for Fish Grillers

| Material | Typical Use Case for fish griller | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Commercial fish grillers | Corrosion resistant and durable | Higher cost and susceptible to pitting | High |

| Cast Iron | Heavy-duty grillers | Excellent heat retention | Heavy and requires maintenance | Medium |

| Aluminum | Portable or lightweight grillers | Lightweight and cost-effective | Less durable and may warp | Low |

| Ceramic | High-end grillers | Non-stick and aesthetically pleasing | Fragile and higher cost | High |

This guide provides essential insights into the materials used in fish grillers, helping international B2B buyers make informed decisions based on their specific needs and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for fish griller

What Are the Key Manufacturing Processes for Fish Grillers?

The manufacturing of fish grillers involves several critical stages that ensure the final product meets the required performance, durability, and safety standards. Understanding these processes can help B2B buyers make informed decisions when sourcing equipment.

What Are the Main Stages of Fish Griller Manufacturing?

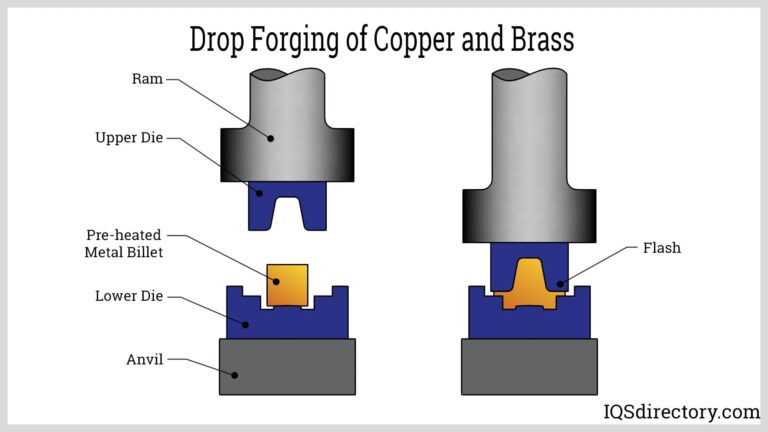

-

Material Preparation

The initial stage of manufacturing involves selecting high-quality materials. Stainless steel is commonly used due to its corrosion resistance and durability, while aluminum may be chosen for its lightweight properties. Manufacturers often undergo a rigorous material inspection process to ensure the materials meet industry standards before proceeding to the next step. -

Forming

The forming process typically employs techniques such as stamping, bending, and welding. These methods shape the metal into the desired components of the fish griller, including the cooking surface, body, and framework. Advanced technologies like CNC machining are increasingly used for precision and efficiency. -

Assembly

After individual components are formed, the assembly stage begins. This involves integrating the various parts, including heating elements, gas lines, and electronic controls. Skilled technicians conduct this process, ensuring that all components fit together correctly and function as intended. -

Finishing

The finishing stage includes surface treatments like powder coating or anodizing, which enhance the aesthetic appeal and protect against corrosion. This step is vital for maintaining hygiene and ensuring the grillers are easy to clean. Final inspections are conducted to verify that the finish meets quality standards.

How Is Quality Assurance Implemented in Fish Griller Manufacturing?

Quality assurance (QA) is critical in the manufacturing of fish grillers to ensure reliability, safety, and compliance with international standards. B2B buyers should be aware of the various QA practices and certifications that manufacturers may utilize.

What International Standards Are Relevant for Fish Grillers?

-

ISO 9001

This international standard focuses on quality management systems and is applicable across various industries, including manufacturing. Certification indicates that a company adheres to consistent quality practices, which can enhance buyer confidence. -

CE Marking

In Europe, CE marking signifies that the product meets EU safety, health, and environmental protection requirements. B2B buyers in Europe should look for this certification to ensure compliance with local regulations. -

API Standards

For manufacturers involved in gas or electric grillers, the American Petroleum Institute (API) standards may apply. These ensure that products are safe for use with gas fuels, which is crucial for operational safety.

What Are the Key Quality Control Checkpoints in Fish Griller Manufacturing?

Quality control (QC) involves systematic processes to monitor and verify the quality of the fish grillers at various stages of production. B2B buyers should understand these checkpoints to assess supplier reliability.

-

Incoming Quality Control (IQC)

IQC is the first line of defense in quality assurance. It involves inspecting raw materials and components upon arrival at the manufacturing facility. This step ensures that only materials that meet specified standards are used in production. -

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC monitors various parameters, such as dimensions, weight, and functionality, at different stages. This ongoing assessment helps identify defects early, minimizing waste and rework. -

Final Quality Control (FQC)

At the end of the production line, FQC involves comprehensive testing of the finished product. This includes functionality tests, safety checks, and visual inspections to ensure that the fish griller meets all specifications and standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying the quality control processes of potential suppliers is essential to ensure the reliability of the products. Here are effective methods to accomplish this:

-

Conducting Audits

Regular audits of suppliers can provide insights into their manufacturing practices and quality control measures. Buyers can request to review the supplier’s quality management system and any certifications they hold. -

Requesting Quality Reports

Suppliers should be willing to provide documentation that outlines their quality control processes, including test results and compliance certificates. This transparency is crucial for building trust and ensuring product reliability. -

Engaging Third-party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s manufacturing processes and quality control practices. This step is especially important for buyers in regions with less stringent regulatory environments.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing fish grillers from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should consider several nuances:

Illustrative image related to fish griller

-

Cultural and Regulatory Differences

Different regions have varying standards and regulations governing manufacturing practices. Buyers should familiarize themselves with local compliance requirements to avoid potential legal issues. -

Supply Chain Considerations

International logistics can impact the quality of products. Buyers should work with suppliers who have robust supply chain management practices to mitigate risks associated with shipping and handling. -

Communication and Transparency

Clear communication regarding quality expectations and standards is vital. B2B buyers should establish strong relationships with suppliers to ensure mutual understanding and adherence to quality benchmarks.

Conclusion

Understanding the manufacturing processes and quality assurance practices for fish grillers is essential for B2B buyers. By familiarizing themselves with the key stages of production, relevant international standards, and effective QC methods, buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fish griller’

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for fish grillers, ensuring they make informed decisions that align with their business needs. The following checklist outlines essential steps to streamline sourcing and ensure quality, reliability, and compliance.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the fish grillers you wish to procure. This includes determining the desired cooking capacity, size, fuel type (electric, gas, or charcoal), and any specific features such as adjustable grates or integrated thermometers. Having a precise specification helps avoid miscommunication with suppliers and ensures that the equipment meets your operational needs.

Illustrative image related to fish griller

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers within the fish grilling industry. Look for companies that specialize in commercial kitchen equipment and have a proven track record in your target markets (Africa, South America, the Middle East, and Europe). Utilize trade shows, industry publications, and online directories to compile a list of potential candidates.

Step 3: Evaluate Supplier Certifications and Compliance

Before making a decision, verify that suppliers possess the necessary certifications and comply with relevant safety and quality standards. This may include certifications such as ISO 9001 or CE marking, which indicate adherence to international quality management standards. Ensuring compliance minimizes the risk of purchasing substandard equipment that could jeopardize your operations.

Step 4: Request Samples or Demonstrations

Whenever possible, request product samples or arrange for demonstrations of the fish grillers. This step allows you to evaluate the equipment’s performance, build quality, and user-friendliness firsthand. Pay close attention to the grilling capabilities and features that align with your menu offerings, ensuring they meet your culinary expectations.

Step 5: Assess Warranty and After-Sales Support

Investigate the warranty terms and after-sales support offered by potential suppliers. A comprehensive warranty not only protects your investment but also indicates the supplier’s confidence in their product. Additionally, reliable after-sales support, including maintenance services and spare parts availability, is crucial for minimizing downtime in your operations.

Step 6: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Look beyond the initial cost; consider total cost of ownership, including maintenance and operational costs. Negotiate favorable payment terms that align with your cash flow and procurement strategy, ensuring that you maintain a healthy financial position.

Step 7: Make an Informed Decision

After completing the previous steps, analyze all gathered information to make an informed decision. Consider factors such as supplier reputation, product quality, pricing, and support services. Engaging in discussions with other businesses in your network can provide additional insights and confidence in your final choice.

By following this checklist, B2B buyers can efficiently source fish grillers that meet their operational requirements while ensuring quality, compliance, and value for money.

Comprehensive Cost and Pricing Analysis for fish griller Sourcing

What Are the Key Cost Components in Sourcing a Fish Griller?

When sourcing a fish griller, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The type of materials used significantly impacts the overall cost. Stainless steel, for example, is durable and corrosion-resistant but may be more expensive than other materials. Buyers should evaluate the material’s suitability for their operational environment, especially in regions with high humidity or saline conditions.

-

Labor: Labor costs vary by region and are influenced by local wage standards. Skilled labor is essential for manufacturing high-quality grills, which can also affect lead times. In countries with lower labor costs, buyers might find more competitive pricing, but this may come at the expense of quality control.

-

Manufacturing Overhead: This includes expenses related to the production process, such as utilities, rent, and equipment maintenance. Understanding how these costs are allocated can provide insights into the supplier’s pricing strategy.

-

Tooling: Initial setup costs for manufacturing equipment can be significant. Buyers should inquire whether these costs are included in the quoted price or if they are an additional charge, especially when custom designs are requested.

-

Quality Control (QC): Ensuring that the products meet specific standards is crucial. This can involve additional costs for testing and certification. Buyers should consider suppliers with robust QC processes to minimize potential issues post-purchase.

-

Logistics: Shipping costs, including freight charges and tariffs, can add significantly to the final price. Understanding the logistics involved, especially for international shipping, is vital for accurate cost assessment.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary significantly based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Fish Griller Sourcing?

Several factors can influence the pricing of fish grillers:

-

Volume/MOQ: Bulk orders often lead to reduced unit costs. Establishing a minimum order quantity (MOQ) can yield better pricing structures, making it advantageous for buyers with larger operational needs.

-

Specifications and Customization: Custom features or specific specifications can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Material Quality and Certifications: Higher quality materials and industry certifications (like ISO or CE) can raise costs but may provide long-term savings through durability and compliance with safety standards.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can influence pricing. Well-established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The terms of trade, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), can affect total costs. Understanding these terms helps buyers anticipate additional charges and make informed decisions.

What Tips Can Help Buyers Negotiate Better Pricing for Fish Griller Sourcing?

B2B buyers should consider the following strategies for effective negotiation:

-

Research Market Prices: Understanding the average market pricing for fish grillers can provide leverage during negotiations.

-

Leverage Total Cost of Ownership (TCO): Highlighting the long-term savings associated with higher-quality products can justify a higher initial investment. This includes factors like energy efficiency, maintenance costs, and longevity.

-

Build Relationships: Establishing a strong relationship with suppliers can facilitate better pricing and terms. Long-term partnerships often lead to preferential pricing and improved service.

-

Be Transparent About Needs: Clearly communicate your requirements and constraints to suppliers. This transparency can foster trust and lead to more favorable terms.

-

Consider Regional Variations: When sourcing internationally, be aware of regional pricing variations. Factors such as local demand, economic conditions, and currency fluctuations can affect costs.

Disclaimer on Pricing

All prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. It’s crucial for B2B buyers to conduct thorough due diligence before finalizing any sourcing agreements.

Alternatives Analysis: Comparing fish griller With Other Solutions

In the competitive landscape of food preparation, particularly in the seafood sector, businesses often seek efficient solutions for grilling fish. While fish grillers offer a specialized approach, alternative methods exist that can also deliver high-quality results. Understanding these options can help B2B buyers make informed decisions tailored to their operational needs.

| Comparison Aspect | Fish Griller | Electric Grill | Traditional Charcoal Grill |

|---|---|---|---|

| Performance | High, consistent heat distribution; ideal for delicate fish. | Moderate, may require time to heat; good for various foods. | High, authentic flavor but inconsistent heat. |

| Cost | Moderate initial investment; low operating costs. | Generally lower initial cost; higher electricity costs. | Low initial cost; variable fuel costs. |

| Ease of Implementation | Simple setup; requires minimal training. | Easy to use; plug-and-play design. | Requires more preparation; skill needed for optimal use. |

| Maintenance | Low; typically requires regular cleaning. | Moderate; occasional cleaning and part replacements. | High; requires ash disposal and more frequent upkeep. |

| Best Use Case | Ideal for restaurants focusing on seafood quality and consistency. | Suitable for casual dining or varied menu offerings. | Best for outdoor settings and specialty barbecue events. |

What are the Advantages and Disadvantages of Using an Electric Grill?

Electric grills are a popular alternative for businesses seeking convenience and versatility. They offer a quick setup and can easily be used indoors or outdoors, making them ideal for varied dining experiences. However, while they are user-friendly and generally lower in initial cost, they may not achieve the same level of flavor as traditional grilling methods. Additionally, the operating costs can rise due to electricity consumption, particularly in high-volume settings.

How Does a Traditional Charcoal Grill Compare?

Traditional charcoal grills provide an authentic flavor profile that many chefs and diners appreciate. The high heat from charcoal can create a perfect sear on fish, enhancing its taste. However, this method requires more effort, including the need for skill in managing the heat and disposing of ash. Furthermore, the cooking time can be longer, which may not align with the fast-paced demands of a restaurant environment. The initial cost can be low, but ongoing fuel expenses can vary significantly based on usage.

Conclusion: How Should B2B Buyers Choose the Right Grilling Solution?

When selecting the appropriate grilling solution for a business, B2B buyers should consider factors such as performance, cost, ease of use, maintenance, and the specific culinary goals of their operation. For establishments focused on seafood quality, a fish griller may provide unmatched results. Conversely, if versatility and convenience are paramount, electric grills can serve well. Finally, for those who prioritize flavor and an authentic grilling experience, traditional charcoal grills may be the preferred choice. Understanding these alternatives empowers buyers to select the most suitable solution tailored to their unique operational needs.

Essential Technical Properties and Trade Terminology for fish griller

What Are the Key Technical Properties of a Fish Griller?

When evaluating fish grillers for commercial use, several technical properties are essential for ensuring efficiency, durability, and quality of cooking. Here are some critical specifications to consider:

-

Material Grade

The material used in constructing a fish griller significantly impacts its performance and longevity. Stainless steel is the most common choice due to its resistance to corrosion and high temperatures. The grade of stainless steel (e.g., 304 or 316) determines its durability and suitability for different environments, particularly in humid conditions. A higher-grade material may come at a premium but will often lead to lower long-term maintenance costs. -

Heat Distribution

Uniform heat distribution is crucial for cooking fish evenly, preventing undercooked or overcooked sections. Grillers should feature advanced heating elements or design technologies that ensure consistent temperature across the cooking surface. This property is particularly important for businesses that prioritize quality and consistency in their offerings. -

Cooking Surface Area

The size of the cooking surface dictates how much fish can be grilled simultaneously. A larger surface area can accommodate higher volumes, making it essential for restaurants or catering services that handle large orders. B2B buyers should assess their operational needs to choose a griller that aligns with their expected throughput. -

Temperature Control

Precision in temperature control allows chefs to adjust cooking conditions based on the type of fish and desired doneness. Look for grillers equipped with digital temperature gauges and programmable settings. This feature enhances cooking efficiency and reduces the risk of human error, which can be particularly valuable during peak service times. -

Energy Efficiency

Energy consumption is an important consideration for businesses looking to minimize operating costs. Fish grillers with energy-efficient designs can reduce utility bills and environmental impact. B2B buyers should inquire about energy ratings and certifications to ensure they are making an eco-friendly choice without compromising on performance.

What Common Trade Terms Should B2B Buyers Know When Purchasing Fish Grillers?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some key terms relevant to purchasing fish grillers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fish grillers, sourcing from an OEM can ensure high-quality components that meet specific standards. Buyers should consider established OEMs for reliable products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is critical for buyers as it can impact inventory levels and cash flow. Understanding the MOQ helps businesses plan their purchases more effectively, ensuring they meet supplier requirements while managing costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For B2B buyers of fish grillers, submitting an RFQ can clarify pricing, delivery times, and terms of service. This practice helps in comparing different suppliers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to understand shipping costs and liabilities involved in the importation of fish grillers. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for businesses to align their inventory and operational schedules. Buyers should inquire about lead times to avoid disruptions in service, particularly in industries with high demand.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing fish grillers, ultimately improving operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the fish griller Sector

What are the Key Market Dynamics and Trends Influencing the Fish Griller Sector?

The fish griller sector is experiencing significant evolution driven by a combination of health consciousness, culinary trends, and technological advancements. A global shift towards healthier eating habits has resulted in an increased demand for grilled seafood options, particularly fish known for their omega-3 fatty acids. This trend is particularly pronounced in regions like Europe and North America, where consumers are looking for nutritious dining options, while emerging markets in Africa and South America are beginning to embrace these preferences.

Additionally, the rise of technology in sourcing and supply chain management is reshaping the landscape for international B2B buyers. Companies are increasingly leveraging data analytics and AI to optimize sourcing processes, ensuring they can meet consumer demand while maintaining cost efficiency. Online platforms for B2B transactions are also gaining traction, enabling buyers from diverse regions to connect with suppliers more effectively. Notably, the integration of e-commerce solutions allows for streamlined operations, reducing lead times and enhancing supplier relationships.

Emerging trends in food service, such as the popularity of food trucks and casual dining concepts, are further driving innovation in the fish griller market. As restaurateurs seek unique offerings to attract customers, there is a growing emphasis on diverse and customizable menu options, which can incorporate local flavors and ingredients. This adaptability is crucial for international buyers looking to tailor their offerings to specific regional tastes.

Illustrative image related to fish griller

How are Sustainability and Ethical Sourcing Shaping the Fish Griller Industry?

Sustainability has become a cornerstone of the fish griller sector, with increasing consumer awareness around the environmental impact of seafood sourcing. International B2B buyers are now prioritizing suppliers that adhere to sustainable fishing practices and possess relevant certifications, such as the Marine Stewardship Council (MSC) and the Aquaculture Stewardship Council (ASC). These certifications not only assure buyers of the product’s sustainability but also enhance brand reputation among eco-conscious consumers.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the practices of their suppliers, focusing on issues such as labor conditions and fair trade. Establishing transparent supply chains is essential for fostering trust and loyalty among consumers, particularly in markets where ethical considerations are paramount. Suppliers that can demonstrate their commitment to sustainability and ethical practices are better positioned to capture market share in competitive landscapes.

In addition to sourcing sustainably caught fish, the use of eco-friendly materials in the production of grilling equipment and packaging is gaining traction. Buyers are encouraged to explore options that utilize recyclable or biodegradable materials, aligning with broader environmental goals and appealing to a growing segment of environmentally aware consumers.

Illustrative image related to fish griller

What is the Historical Context of the Fish Griller Sector?

The fish griller sector has its roots in traditional cooking methods, where grilling was utilized to enhance the flavors of fresh fish, a staple in many coastal communities worldwide. As culinary techniques evolved, grilling became synonymous with health-conscious eating, paving the way for its integration into modern dining experiences. In the late 20th century, the rise of casual dining restaurants and food trucks further popularized grilled fish dishes, making them accessible to a broader audience.

Today, the fish griller market is characterized by innovation and adaptation, as suppliers and restaurateurs continuously seek to meet the demands of a diverse and health-conscious consumer base. Understanding this historical context is vital for B2B buyers looking to navigate the current market dynamics, as it informs sourcing decisions and product development strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of fish griller

-

How do I choose the right fish griller for my business needs?

Selecting the appropriate fish griller involves assessing your specific requirements, such as the volume of fish you intend to grill and the type of fish you will be serving. Consider factors like size, fuel type (electric, gas, or charcoal), and the griller’s cooking capabilities. Additionally, look for features such as adjustable temperature controls and ease of cleaning. Engaging with suppliers for product demonstrations or samples can also help you make an informed decision. -

What features should I look for in a commercial fish griller?

When evaluating commercial fish grillers, prioritize features that enhance efficiency and safety. Look for options with non-stick surfaces for easy cleaning, adjustable grates for various fish sizes, and built-in temperature gauges for precise cooking. Safety features such as automatic shut-off systems and cool-touch handles are also essential. Ensure the griller is constructed from durable, rust-resistant materials suitable for commercial use. -

What are the minimum order quantities (MOQ) for fish grillers?

MOQs for fish grillers can vary significantly based on the manufacturer and model. Generally, larger suppliers may have MOQs ranging from 10 to 50 units, while smaller manufacturers might accommodate smaller orders. When sourcing, inquire about flexibility in MOQs, especially if you are testing the market or starting a new business line. Some suppliers may also offer tiered pricing based on order volume, providing better rates for larger purchases. -

What payment terms are commonly offered by suppliers of fish grillers?

Payment terms can differ by supplier and region but typically include options such as net 30, net 60, or cash in advance. Some suppliers may offer financing options or payment plans for larger orders. It’s crucial to discuss and negotiate terms upfront to ensure they align with your cash flow management. Additionally, consider using secure payment methods to protect your transactions, especially in international trade. -

How can I ensure the quality of the fish grillers I am purchasing?

To ensure quality, conduct thorough research on potential suppliers. Request certifications, such as ISO or CE marks, that indicate compliance with international safety and quality standards. Ask for product samples to evaluate construction and performance. Establishing a quality assurance protocol, including inspections during production and pre-shipment, can further safeguard your purchase. Building a long-term relationship with reliable suppliers will also help maintain consistent quality. -

What logistics considerations should I keep in mind when importing fish grillers?

Logistics is critical when importing fish grillers. Key factors include shipping methods (air freight vs. sea freight), customs clearance processes, and delivery timelines. Evaluate the total landed cost, including shipping, duties, and taxes, to ensure it fits your budget. Work with logistics partners who have experience in handling commercial kitchen equipment to streamline the shipping process. Additionally, consider the packaging to prevent damage during transit. -

How can I vet suppliers when sourcing fish grillers internationally?

Vetting suppliers is essential to ensure reliability and quality. Start by checking their business credentials, including registration, certifications, and industry reputation. Utilize platforms like Alibaba or Global Sources to read reviews and verify ratings. Request references from previous clients and check their production capabilities through factory visits or virtual tours. Engaging third-party inspection services can also provide an unbiased assessment of the supplier’s operations. -

What customization options are available for commercial fish grillers?

Many manufacturers offer customization options to meet specific business needs. Customization can include alterations in size, design, and features such as branding or additional cooking functionalities. Discuss your requirements with potential suppliers and inquire about their willingness to accommodate these changes. Keep in mind that custom orders may have longer lead times and potentially higher costs, so plan accordingly for your business needs.

Top 4 Fish Griller Manufacturers & Suppliers List

1. OXO – Obsidian Outdoor Carbon Steel Frypan

Domain: seriouseats.com

Introduction: The Best Grill Basket: OXO Obsidian Outdoor Carbon Steel 12-Inch Frypan with Silicone Sleeve – $70 (available for $50 at Amazon, $70 at Target). Features large holes for airflow, detachable handle for easy grilling. Another Good Grill Basket: Proud Grill UltraVersatile Stainless Steel Grill Basket – $42 (available at Amazon). Removable handle, wide design, includes dividers for cooking proteins an…

2. Fish City Grill – Fresh Seafood & Gulf Coast Cuisine

Domain: fishcitygrill.com

Registered: 2003 (22 years)

Introduction: Fresh seafood, Gulf Coast-inspired dishes, rotating chalkboard specials, signature oysters, casual dining atmosphere, locations in Texas, Oklahoma, Arkansas, and Florida.

3. Big Fish Grill – Seafood Dining

Domain: bigfishgrill.com

Registered: 1999 (26 years)

Introduction: Big Fish Grill, located at 20298 Coastal Highway, Rehoboth Beach, DE, offers a casual dining experience with a focus on seafood. Founded in 1997, it features original recipes and popular favorites, earning multiple ‘Best Seafood at the Beach’ awards. The restaurant serves dinner daily and includes a fresh raw bar, seasonal outdoor patio dining, and a family-friendly atmosphere. Special offerings i…

4. Reddit – Essential Grilling Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Two-sided fish basket – Easier and better than a spatula, convenient for sliced vegetables. 2. Fish spatula – Key for grilling fish, can be used for non-fish grilling as well. 3. Cedar plank – Avoids sticking and adds flavor. 4. Grill pan – Allows moisture to drip out and prevents sticking. 5. Grill mats (like Yoshi mats) – Nonstick pads that allow for grill marks without sticking, should not b…

Strategic Sourcing Conclusion and Outlook for fish griller

What Are the Key Insights for B2B Buyers in the Fish Griller Market?

In conclusion, strategic sourcing for fish grillers is not just about procurement; it’s about building long-term partnerships that enhance product quality and customer satisfaction. By leveraging local suppliers in Africa, South America, the Middle East, and Europe, businesses can ensure a steady supply of fresh and high-quality seafood, thus appealing to the growing consumer demand for authentic dining experiences. The emphasis on sustainability and responsible sourcing is becoming increasingly vital as global consumers prioritize eco-friendly practices.

Moreover, understanding regional preferences and culinary trends can guide product development and marketing strategies, allowing businesses to cater effectively to diverse markets. For instance, incorporating local flavors and techniques can differentiate offerings and attract a loyal customer base.

How Can B2B Buyers Prepare for Future Opportunities in the Fish Griller Industry?

As the fish grilling sector evolves, B2B buyers are encouraged to stay ahead by embracing innovative technologies and sustainable practices. This approach not only aligns with consumer expectations but also positions businesses as industry leaders. Engaging with suppliers who share these values can foster a collaborative environment that drives growth.

In this dynamic landscape, the call to action for international buyers is clear: invest in strategic sourcing now to capitalize on future market opportunities and meet the ever-growing demand for quality seafood experiences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to fish griller