Choosing Your Fiberglass Sheets 4X8 Price: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for fiberglass sheets 4×8 price

Navigating the global market for fiberglass sheets, particularly the 4×8 size, presents unique challenges for international B2B buyers. Sourcing these materials at competitive prices while ensuring quality and compliance with local regulations can be daunting, especially in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide aims to demystify the intricacies of the fiberglass sheets market by providing valuable insights into various types, applications, supplier vetting processes, and pricing strategies.

Throughout this guide, you will discover detailed analyses of different fiberglass sheet variants, including their mechanical properties and suitability for specific applications. Understanding the nuances of fiberglass sheets—ranging from clear flat sheets to reinforced wall panels—will empower you to make informed purchasing decisions tailored to your business needs. Additionally, we will discuss the importance of selecting reliable suppliers, offering tips on how to assess quality and negotiate favorable terms.

As the global demand for fiberglass products continues to rise, this guide serves as an essential resource for B2B buyers looking to navigate the complexities of sourcing fiberglass sheets. By equipping yourself with the right knowledge and tools, you can streamline your procurement process, optimize costs, and ultimately enhance your operational efficiency in your respective markets.

Understanding fiberglass sheets 4×8 price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Fiberglass Sheets | Transparent, lightweight, high clarity | Windows, skylights, protective barriers | Pros: Excellent visibility; Cons: Prone to scratching. |

| Fiberglass Reinforced Wall Panels | Durable, water-resistant, available in various colors | Commercial kitchens, bathrooms, clean rooms | Pros: Easy to clean; Cons: Limited aesthetic options. |

| Gel-Coated Fiberglass Sheets | Smooth finish, UV resistant, customizable colors | Automotive, marine applications, roofing | Pros: Aesthetic appeal; Cons: Higher price point. |

| Anti-Corrosion Fiberglass Panels | Resistant to chemicals and environmental damage | Industrial settings, chemical storage | Pros: Long-lasting; Cons: Heavier than standard options. |

| Embossed Fiberglass Panels | Textured surface, slip-resistant, decorative designs | Flooring, wall coverings | Pros: Enhanced grip; Cons: May require more maintenance. |

What are the Characteristics of Clear Fiberglass Sheets?

Clear fiberglass sheets are known for their high transparency and lightweight nature, making them ideal for applications requiring visibility, such as windows and skylights. They provide excellent durability against weather conditions but can be susceptible to scratching. B2B buyers should consider the balance between aesthetics and functional durability, especially in high-traffic areas where scratches may detract from appearance.

How Do Fiberglass Reinforced Wall Panels Serve B2B Needs?

These panels are designed for high durability and are resistant to water, making them suitable for environments like commercial kitchens and clean rooms. Available in various colors, they can meet specific design requirements while providing ease of maintenance. Buyers should evaluate the cost-effectiveness of these panels, especially in terms of long-term maintenance and cleaning needs.

What Makes Gel-Coated Fiberglass Sheets a Preferred Choice?

Gel-coated fiberglass sheets offer a smooth finish that is aesthetically pleasing and UV resistant, making them popular in automotive and marine applications. Customizable colors enhance their appeal for branding and design. However, their higher price point may be a consideration for budget-conscious buyers, who should weigh the benefits of aesthetics against the initial investment.

Why Choose Anti-Corrosion Fiberglass Panels for Industrial Applications?

Anti-corrosion fiberglass panels are engineered to withstand harsh chemicals and environmental factors, making them ideal for industrial settings. Their long-lasting nature can significantly reduce replacement costs over time. Buyers must consider the weight of these panels, as they may require additional structural support, impacting overall project costs.

What Are the Benefits of Embossed Fiberglass Panels?

Embossed fiberglass panels feature a textured surface that enhances slip resistance, making them suitable for flooring and wall coverings in various commercial settings. Their decorative designs add an aesthetic element while providing practical benefits. Buyers should be aware of the potential for increased maintenance needs due to the textured surface, which may trap dirt and grime more than smooth options.

Key Industrial Applications of fiberglass sheets 4×8 price

| Industry/Sector | Specific Application of fiberglass sheets 4×8 price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Wall and Ceiling Panels | Durable, lightweight, and moisture-resistant building materials | Ensure compliance with local building codes and regulations; focus on fire resistance and insulation properties. |

| Transportation | Truck and Vehicle Body Panels | Enhanced strength-to-weight ratio and corrosion resistance | Verify compatibility with existing vehicle designs; consider local climate effects on material performance. |

| Agriculture and Aquaculture | Greenhouse Glazing and Aquaculture Tanks | UV stability and excellent light transmission for plant growth | Assess local UV exposure levels; ensure material can withstand chemical exposure from fertilizers and fish feed. |

| Food Processing | Hygienic Wall and Ceiling Linings | Easy to clean and maintain, meeting health and safety standards | Confirm FDA compliance for food contact; prioritize antimicrobial properties. |

| Electrical and Electronics | Insulating Panels for Electrical Enclosures | High dielectric strength and thermal stability | Evaluate electrical insulation ratings; ensure materials can withstand local environmental conditions. |

How Are Fiberglass Sheets 4×8 Used in Construction?

In the construction industry, fiberglass sheets measuring 4×8 are commonly utilized as wall and ceiling panels. Their lightweight nature and moisture resistance make them ideal for various environments, including commercial and residential buildings. By providing insulation and durability, these panels help mitigate issues related to mold and structural degradation. International buyers, particularly from regions with humid climates, should prioritize sourcing materials that comply with local building regulations and standards, ensuring they provide adequate fire resistance and thermal insulation.

What Role Do Fiberglass Sheets 4×8 Play in Transportation?

In the transportation sector, fiberglass sheets are essential for manufacturing truck and vehicle body panels. Their superior strength-to-weight ratio allows for fuel efficiency without compromising durability. Additionally, the corrosion resistance of fiberglass is critical in prolonging the lifespan of vehicles exposed to harsh weather conditions. For B2B buyers in Africa and South America, sourcing fiberglass sheets that can withstand local environmental factors is crucial, as is ensuring compatibility with existing vehicle designs for seamless integration.

How Are Fiberglass Sheets 4×8 Beneficial for Agriculture and Aquaculture?

Fiberglass sheets are increasingly used in agriculture, particularly in greenhouse glazing and aquaculture tanks. Their UV stability and excellent light transmission properties promote optimal plant growth while providing a robust solution for fish farming. Buyers in regions with high UV exposure, such as parts of the Middle East and Africa, should evaluate the sheets’ ability to withstand environmental stressors and chemical exposure from fertilizers or fish feed, ensuring long-term functionality and sustainability.

Why Are Fiberglass Sheets 4×8 Important in Food Processing?

In the food processing industry, fiberglass sheets serve as hygienic wall and ceiling linings, providing a smooth, easy-to-clean surface that meets strict health and safety standards. The materials are designed to resist moisture and bacteria, making them ideal for environments where cleanliness is paramount. B2B buyers must verify that the fiberglass sheets comply with FDA regulations for food contact and consider antimicrobial properties to enhance hygiene and safety in food production facilities.

How Do Fiberglass Sheets 4×8 Enhance Electrical and Electronics Applications?

Fiberglass sheets are critical in the electrical and electronics industries, used primarily as insulating panels for electrical enclosures. Their high dielectric strength and thermal stability make them suitable for protecting sensitive electronic components. Buyers should assess the electrical insulation ratings and ensure that the materials can withstand local environmental conditions, particularly in regions with extreme temperatures or humidity, to guarantee reliable performance over time.

3 Common User Pain Points for ‘fiberglass sheets 4×8 price’ & Their Solutions

Scenario 1: Navigating Price Variability Across Suppliers

The Problem: B2B buyers often encounter significant price fluctuations for fiberglass sheets 4×8, which can lead to budgeting challenges and project delays. This variability can stem from differences in supplier pricing, local market conditions, and even shipping costs. For international buyers, understanding the total landed cost—including tariffs and taxes—adds an additional layer of complexity. This uncertainty can result in over-budget projects or difficulty in securing necessary materials at competitive rates.

The Solution: To effectively navigate these price variabilities, buyers should adopt a multi-supplier strategy. Begin by identifying at least three reputable suppliers of fiberglass sheets in different regions, ensuring a mix of local and international options. Request quotes that include all potential costs—material, shipping, and duties. Utilize online platforms and trade directories to compare prices and gather insights on market trends. Additionally, consider negotiating bulk purchase discounts or long-term contracts to lock in favorable rates. Regularly review supplier performance and price competitiveness to make informed procurement decisions.

Scenario 2: Understanding Quality vs. Cost in Fiberglass Sheets

The Problem: Another common pain point for B2B buyers is the challenge of balancing quality with cost when purchasing fiberglass sheets. Lower-priced options may appear attractive but can lead to issues with durability and performance, ultimately increasing long-term costs due to replacements or repairs. Buyers must discern the quality of materials, which can vary significantly, especially when sourcing from international suppliers with different manufacturing standards.

The Solution: To ensure quality while managing costs, buyers should establish clear specifications for the fiberglass sheets required for their projects. Research and understand the key quality indicators such as thickness, tensile strength, and corrosion resistance. When evaluating suppliers, request samples to assess the material firsthand and ask for certifications that validate their compliance with international standards. Establishing a robust quality assurance process can also help; this might include periodic audits of suppliers and reviews of product performance in real-world applications. By prioritizing quality upfront, buyers can prevent costly issues down the line.

Scenario 3: Shipping and Delivery Delays Impacting Projects

The Problem: International B2B buyers often face logistical challenges that can lead to shipping delays, affecting project timelines. Factors such as customs clearance, shipping routes, and local infrastructure can complicate the timely delivery of fiberglass sheets. These delays not only disrupt project schedules but can also escalate costs due to penalties or expedited shipping fees needed to meet deadlines.

The Solution: To mitigate shipping-related issues, buyers should partner with logistics experts familiar with the shipping regulations and customs procedures of their specific regions. Opt for suppliers who provide reliable shipping options and can offer real-time tracking for better transparency. Additionally, consider using local suppliers when feasible to reduce shipping distances and times. Establishing a clear communication channel with suppliers regarding expected delivery dates and potential delays can also help in proactive planning. Incorporating buffer time in project schedules for potential delays can further enhance project management and reduce stress associated with tight timelines.

Strategic Material Selection Guide for fiberglass sheets 4×8 price

What Are the Key Properties of Fiberglass Sheets for B2B Buyers?

Fiberglass sheets, particularly the 4×8 size, are widely used in various industries due to their unique properties. The most common materials used in these sheets include standard fiberglass reinforced plastic (FRP), gel-coated fiberglass, and fire-resistant fiberglass. Each material offers distinct advantages and limitations that can significantly impact their application in B2B environments.

What Are the Key Properties of Standard Fiberglass Reinforced Plastic (FRP)?

Standard FRP sheets are known for their lightweight and high strength-to-weight ratio. They exhibit excellent corrosion resistance, making them ideal for environments exposed to chemicals or moisture. Additionally, they can withstand temperatures up to 120°C (248°F), which is suitable for many industrial applications.

Pros: Their durability and resistance to environmental factors make them suitable for long-term use. They are also relatively easy to fabricate, allowing for custom shapes and sizes.

Cons: The initial cost may be higher compared to traditional materials like plywood, and they can be less impact-resistant than metals.

Impact on Application: FRP sheets are commonly used in construction, marine, and automotive sectors, where moisture and chemical exposure are prevalent.

How Does Gel-Coated Fiberglass Compare for B2B Applications?

Gel-coated fiberglass sheets provide a smooth, glossy finish that enhances aesthetic appeal while maintaining the durability of standard fiberglass. They are often used in applications where appearance is critical, such as in interior wall panels and decorative surfaces.

Pros: The gel coating adds an extra layer of protection against UV rays and scratches, extending the lifespan of the product.

Cons: The manufacturing process can be more complex and costly due to the additional gel coating step, which may deter some buyers.

Impact on Application: These sheets are particularly suitable for environments where both functionality and aesthetics are important, such as in commercial buildings and high-end residential projects.

What Advantages Do Fire-Resistant Fiberglass Sheets Offer?

Fire-resistant fiberglass sheets are engineered to withstand high temperatures and resist ignition. These materials are essential in applications where fire safety is a priority, such as in industrial settings or public buildings.

Pros: They provide peace of mind by enhancing safety and compliance with fire regulations, making them a preferred choice for many industries.

Cons: The cost of fire-resistant fiberglass can be significantly higher than standard options, which may be a consideration for budget-conscious buyers.

Impact on Application: These sheets are crucial in industries where fire safety codes must be met, such as in construction and manufacturing.

What Should International B2B Buyers Consider?

When selecting fiberglass sheets, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM, DIN, or JIS. Understanding the specific requirements for their applications, including temperature ratings and chemical compatibility, is vital. Additionally, factors like shipping costs, import duties, and local availability can influence the overall pricing and procurement process.

Summary Table of Fiberglass Sheet Materials

| Material | Typical Use Case for fiberglass sheets 4×8 price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard FRP | Marine and construction applications | Excellent corrosion resistance | Less impact-resistant than metals | Medium |

| Gel-Coated Fiberglass | Decorative wall panels and interiors | Enhanced aesthetic appeal and durability | Higher manufacturing complexity | High |

| Fire-Resistant Fiberglass | Industrial settings and public buildings | Compliance with fire safety regulations | Significantly higher cost | High |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to invest in fiberglass sheets. By understanding the properties, pros and cons, and application impacts of each type, buyers can make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fiberglass sheets 4×8 price

What Are the Main Stages of Manufacturing Fiberglass Sheets?

The manufacturing process of fiberglass sheets, particularly the 4×8 size, is intricate and involves several key stages. Understanding these stages helps B2B buyers assess the quality and suitability of the product for their specific applications.

Material Preparation

The first stage involves selecting high-quality raw materials, primarily fiberglass strands and resins. Fiberglass is typically made from silica sand, limestone, and other materials that are melted and drawn into fibers. For fiberglass sheets, the type of resin used—such as unsaturated polyester or epoxy—significantly affects the final properties of the product, including its strength, durability, and resistance to environmental factors. Suppliers often conduct pre-manufacturing tests to ensure that the materials meet the necessary specifications.

Forming

Once the materials are prepared, they undergo the forming stage. This involves laying down the fiberglass strands in a mold and applying the resin. Key techniques in this stage include:

-

Hand Lay-Up: Suitable for smaller production runs, this technique involves manually placing layers of fiberglass and resin into a mold.

-

Spray-Up: For larger volumes, resin and chopped fiberglass are sprayed into the mold, allowing for quicker production.

-

Filament Winding: This method is employed for cylindrical products but can also be used to create flat sheets with specific mechanical properties.

These forming techniques not only influence the production speed but also the structural integrity of the fiberglass sheets.

Assembly and Finishing

After forming, the sheets go through assembly, where multiple layers may be bonded together for added strength. The finishing stage involves curing the resin, which hardens the sheets and gives them their final shape and dimensions. This may include trimming excess material, sanding surfaces for smoothness, and applying protective coatings or finishes that enhance durability and aesthetics.

What Are the Key Quality Control Standards for Fiberglass Sheets?

Quality assurance is critical in the manufacturing of fiberglass sheets, especially for B2B transactions. International standards such as ISO 9001 are widely recognized, ensuring that manufacturers follow consistent quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications are essential for ensuring compliance with safety and performance requirements.

Key QC Checkpoints

To maintain high standards, manufacturers implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): Once the sheets are produced, they undergo a comprehensive inspection to ensure they meet all specifications before shipment.

What Testing Methods Are Commonly Used for Fiberglass Sheets?

Various testing methods are employed to verify the quality and performance of fiberglass sheets:

-

Mechanical Testing: This includes tensile strength tests, flexural strength tests, and impact resistance tests to determine the physical properties of the sheets.

-

Chemical Resistance Testing: Given the applications of fiberglass sheets in various environments, testing for resistance to chemicals and corrosion is essential.

-

Dimensional Inspection: Ensures that the sheets meet the specified dimensions and tolerances.

By understanding these testing methods, B2B buyers can better evaluate the reliability of their suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is crucial for B2B buyers. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control systems, and compliance with international standards. This hands-on approach can reveal insights into a supplier’s operational capabilities.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC results. These reports should detail any deviations and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These organizations often have the expertise to conduct thorough evaluations based on international standards.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, additional factors come into play:

-

Regulatory Compliance: Understanding regional regulations and standards is vital. For example, products sold in Europe must meet CE marking requirements, while those in the U.S. may require ASTM compliance.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and service. Building relationships and understanding local business practices can enhance collaboration and trust.

-

Logistics and Supply Chain Management: Ensure that suppliers have robust logistics in place to manage shipping, handling, and customs clearance, which can impact product quality upon arrival.

Conclusion

In summary, the manufacturing and quality assurance processes for fiberglass sheets, particularly the 4×8 size, are complex but essential for ensuring product reliability. By understanding these processes, B2B buyers can make informed decisions when sourcing materials, ensuring they partner with suppliers who meet rigorous quality standards. Engaging in thorough due diligence, including audits and third-party inspections, will further mitigate risks and enhance the success of international transactions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiberglass sheets 4×8 price’

In the competitive landscape of B2B procurement, sourcing high-quality fiberglass sheets, particularly the 4×8 size, requires careful planning and execution. This guide provides a structured checklist to ensure you secure the best materials at the right price while minimizing risks.

Step 1: Define Your Technical Specifications

Understanding your requirements is crucial. Clearly outline the specifications you need, such as thickness, color, and type (e.g., clear, reinforced, or gel-coated). This will help you communicate effectively with suppliers and ensure that the products meet your application needs, whether for construction, automotive, or other industrial uses.

Step 2: Research Market Prices

Conduct thorough market research to gauge price ranges. Utilize online platforms and industry reports to gather data on the average costs of 4×8 fiberglass sheets. Be aware of regional price variations, as costs may differ significantly between suppliers in Africa, South America, the Middle East, and Europe. This knowledge will empower you to negotiate better deals.

Step 3: Evaluate Potential Suppliers

Assessing suppliers is vital for ensuring quality and reliability. Look for manufacturers with a solid reputation in the industry. Request company profiles, product samples, and references from previous clients. This step helps you verify their credibility and ensures they can meet your quality standards and delivery timelines.

- Check for certifications: Ensure suppliers comply with relevant industry standards and certifications, which can indicate product reliability and safety.

Step 4: Request Quotes and Compare Offers

Solicit detailed quotes from multiple suppliers. When reaching out, provide your specifications to ensure that the quotes are comparable. Pay attention to the total costs, including shipping and potential tariffs, as these can significantly impact your budget. A comprehensive comparison will help you identify the most competitive offer.

Step 5: Verify Supplier Capabilities

Confirm that suppliers can meet your volume and delivery requirements. Inquire about their production capacity, lead times, and ability to handle bulk orders. This is particularly important if you anticipate fluctuations in demand or require just-in-time delivery.

- Ask about their customer support: Reliable communication channels are essential for resolving issues quickly.

Step 6: Negotiate Terms and Conditions

Effective negotiation can lead to significant savings. Discuss payment terms, delivery schedules, and warranty conditions to ensure they align with your business needs. A clear agreement can prevent misunderstandings and protect your investment.

Step 7: Finalize the Order and Monitor Delivery

Once you’ve selected a supplier, finalize the order with clear documentation. Ensure that all specifications, terms, and conditions are outlined in the purchase agreement. After placing the order, monitor the delivery process closely to address any potential issues proactively.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing 4×8 fiberglass sheets, ensuring they obtain the right materials at the best price while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for fiberglass sheets 4×8 price Sourcing

What Are the Key Cost Components Influencing Fiberglass Sheets Pricing?

When sourcing fiberglass sheets, particularly the widely used 4×8 size, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

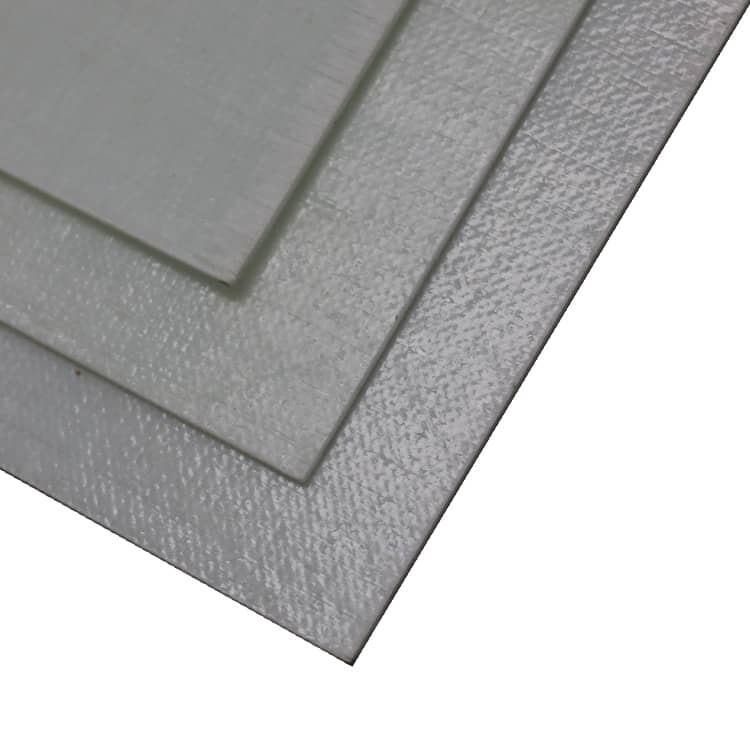

Illustrative image related to fiberglass sheets 4×8 price

-

Materials: The choice of resin and fiberglass significantly affects pricing. High-quality materials, such as unsaturated polyester or epoxy resins, tend to be more expensive but offer better durability and performance.

-

Labor: Labor costs vary by region and can influence the final price. In countries with higher wage standards, production costs will reflect this, impacting the overall pricing structure.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, which may be passed on to buyers.

-

Tooling: Initial setup costs for molds and machinery can be substantial, especially for customized orders. These costs are often amortized over the production volume, affecting unit pricing.

-

Quality Control: Rigorous QC processes ensure that the fiberglass sheets meet industry standards. While this adds to the cost, it is essential for maintaining product reliability and customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer to the buyer, mode of transport, and any tariffs or duties applicable in the buyer’s country.

-

Margin: Suppliers typically add a profit margin to cover their costs and earn revenue. This margin can fluctuate based on market demand and competition.

How Do Pricing Influencers Affect the Sourcing of Fiberglass Sheets?

Several factors can influence the pricing of fiberglass sheets, particularly for international buyers:

-

Volume/MOQ: Suppliers often offer better pricing for bulk purchases. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate more favorable terms.

-

Specifications and Customization: Custom orders, such as specific thicknesses or colors, can lead to increased costs. Standard products generally have lower prices due to established manufacturing processes.

-

Material Quality and Certifications: Higher-grade materials or those with specific certifications (e.g., ISO, ASTM) usually command premium pricing. Buyers should weigh the benefits of investing in certified products against their project requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may offer better service but at a higher price point.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

What Are the Best Practices for Negotiating Prices on Fiberglass Sheets?

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield better pricing outcomes:

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and suppliers’ offerings. This knowledge can empower buyers during negotiations.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but the TCO, which includes installation, maintenance, and eventual disposal. A slightly higher upfront cost for higher-quality sheets may lead to lower long-term expenses.

-

Building Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Trust can facilitate negotiations and encourage suppliers to offer discounts or favorable payment terms.

-

Flexibility in Order Size: If possible, combine orders with other purchases to meet MOQs without overcommitting to a single supplier. This can lead to lower shipping costs and better pricing.

-

Local Regulations and Subsidies: Be aware of any local regulations or subsidies that may affect pricing. Understanding these factors can help in negotiating better terms and understanding total costs.

Disclaimer on Indicative Prices

Prices for fiberglass sheets can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is advisable for buyers to obtain quotes from multiple suppliers to ensure they are getting competitive rates that reflect current market conditions. Always consider the total cost implications rather than just the purchase price when making sourcing decisions.

Alternatives Analysis: Comparing fiberglass sheets 4×8 price With Other Solutions

Understanding Alternatives for Fiberglass Sheets 4×8

When considering fiberglass sheets, particularly the 4×8 variety, it’s crucial to evaluate alternatives that fulfill similar requirements in terms of performance, cost, and application. This analysis will help international B2B buyers make informed decisions based on their specific needs, whether they are in construction, manufacturing, or other industries. The following alternatives will be compared: Polycarbonate Sheets and PVC Panels.

Comparison Table

| Comparison Aspect | Fiberglass Sheets 4X8 Price | Polycarbonate Sheets | PVC Panels |

|---|---|---|---|

| Performance | High durability, corrosion-resistant, good insulation | High impact resistance, lightweight, UV protection | Moderate durability, water-resistant, lightweight |

| Cost | Moderate ($20-$40 per sheet) | Moderate to high ($30-$60 per sheet) | Low to moderate ($10-$25 per panel) |

| Ease of Implementation | Requires cutting tools, moderate skill | Easy to cut and handle, minimal skill required | Very easy to install, often comes with adhesive backing |

| Maintenance | Low maintenance, clean with soap | Low maintenance, resistant to staining | Low maintenance, can be cleaned easily |

| Best Use Case | Industrial applications, construction, insulation | Greenhouses, skylights, safety glazing | Interior wall coverings, decorative applications |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Polycarbonate Sheets?

Polycarbonate sheets are known for their high impact resistance and lightweight nature, making them ideal for applications like greenhouses and safety glazing. They provide excellent UV protection, which is beneficial for outdoor applications. However, they can be more expensive than fiberglass sheets, especially for thicker options. Additionally, while they are easy to cut and install, they may not offer the same level of insulation as fiberglass sheets.

Why Consider PVC Panels as an Alternative?

PVC panels are a cost-effective option, particularly for interior applications like wall coverings. They are water-resistant and easy to install, often requiring minimal tools. Their lightweight nature also makes handling simple. However, PVC panels may not provide the same durability or structural integrity as fiberglass sheets, especially in heavy-duty applications. While they are easy to maintain, they may not hold up as well under extreme conditions compared to fiberglass.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right material for your project depends on various factors, including application, budget, and desired longevity. Fiberglass sheets 4×8 offer a strong balance of performance and durability, making them suitable for industrial and construction uses. However, alternatives like polycarbonate sheets and PVC panels can also meet specific needs, particularly in terms of cost and ease of installation. B2B buyers should assess their unique requirements and weigh the pros and cons of each option to ensure they choose the most effective solution for their projects.

Essential Technical Properties and Trade Terminology for fiberglass sheets 4×8 price

When considering fiberglass sheets, particularly the 4×8 variety, understanding the essential technical properties and industry terminology is crucial for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances negotiations and project planning.

What Are the Key Technical Properties of 4×8 Fiberglass Sheets?

-

Material Grade

– Fiberglass sheets are typically available in various grades, such as E-glass or S-glass. E-glass is the most commonly used for general applications due to its balance of strength and cost-effectiveness. S-glass offers higher tensile strength and is often used in demanding applications. Understanding the material grade is essential for determining the sheet’s suitability for specific projects. -

Thickness

– The thickness of fiberglass sheets can vary, with common options being 1/16″, 1/8″, or 1/4″. The thickness impacts the sheet’s strength, weight, and insulation properties. For instance, a thicker sheet may provide better durability and insulation, making it suitable for industrial applications, while thinner sheets might be more appropriate for decorative uses. -

Tensile Strength

– This property measures how much force the material can withstand while being stretched or pulled. Fiberglass sheets can exhibit tensile strengths comparable to metals, making them ideal for structural applications. Understanding tensile strength helps in assessing whether the sheets can endure the operational stresses of specific environments. -

Corrosion Resistance

– Fiberglass is inherently resistant to many chemicals and environmental factors, which is crucial for applications in harsh conditions. This property extends the lifespan of the product and reduces maintenance costs, making it a preferred choice for industries such as construction, automotive, and marine. -

Fire Resistance

– While fiberglass itself is not completely fireproof, many fiberglass sheets are treated with fire-retardant chemicals to enhance their fire resistance. This is particularly important for applications in sectors where fire safety is a regulatory requirement. -

Surface Finish

– The surface finish of fiberglass sheets can vary from smooth to textured. A smooth surface is typically easier to clean and maintain, while textured surfaces can enhance grip and aesthetic appeal. Understanding the finish is essential for applications where appearance and usability are critical.

What Are Common Trade Terms Related to Fiberglass Sheets?

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are sold under another company’s brand. In the context of fiberglass sheets, buyers may engage with OEMs to procure customized products tailored to specific requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units that a supplier is willing to sell. For fiberglass sheets, understanding MOQ is crucial for budgeting and inventory management, especially for smaller businesses or projects. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. B2B buyers use RFQs to gather competitive offers from multiple suppliers, ensuring they make cost-effective decisions. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers navigate shipping responsibilities, costs, and risks associated with the importation of fiberglass sheets. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. Understanding lead times is essential for project planning, ensuring that materials arrive on schedule to avoid delays. -

FRP (Fiberglass Reinforced Plastic)

– This term describes composite materials made from a polymer matrix reinforced with fiberglass. FRP is widely used in construction and manufacturing due to its strength, lightweight nature, and resistance to corrosion. Knowing this term aids in differentiating between various fiberglass products.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions regarding fiberglass sheets, optimizing both procurement processes and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the fiberglass sheets 4×8 price Sector

What Are the Global Drivers Influencing the Fiberglass Sheets 4×8 Price Market?

The fiberglass sheets market, particularly the 4×8 size, is experiencing significant growth driven by various global factors. Key drivers include the increasing demand for lightweight, durable materials across industries such as construction, automotive, and aerospace. As urbanization accelerates in regions like Africa and South America, the need for robust building materials has surged. Additionally, advancements in manufacturing technologies, such as automated production and improved resin formulations, have lowered production costs, enabling competitive pricing.

Emerging technologies are reshaping how businesses source fiberglass sheets. Digital platforms and e-commerce solutions facilitate direct connections between suppliers and buyers, streamlining procurement processes. Moreover, international trade agreements and logistics enhancements are expanding market access for B2B buyers, particularly in developing regions like Nigeria and Vietnam. As manufacturers adopt just-in-time inventory practices, buyers can expect greater flexibility in sourcing, which can lead to more favorable pricing.

Illustrative image related to fiberglass sheets 4×8 price

How Are Sustainability and Ethical Sourcing Shaping the Fiberglass Sheets Market?

Sustainability has become a pivotal factor in sourcing fiberglass sheets, with businesses increasingly prioritizing environmentally friendly practices. The production of fiberglass can have a significant environmental impact, including energy consumption and waste generation. As a result, buyers are now seeking suppliers who adhere to sustainable manufacturing processes and utilize recycled materials. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) ratings for green building materials are becoming essential for suppliers aiming to attract conscientious buyers.

Ethical sourcing is also a growing concern, especially for international buyers who are increasingly aware of labor practices within their supply chains. Ensuring that suppliers comply with ethical labor standards not only enhances brand reputation but also builds trust among customers. By prioritizing suppliers who demonstrate a commitment to ethical practices, B2B buyers can mitigate risks associated with supply chain disruptions and enhance their overall sustainability profiles.

What is the Historical Context of the Fiberglass Sheets Industry?

The fiberglass sheets industry has evolved significantly since its inception in the mid-20th century. Originally developed for its lightweight and durable properties, fiberglass quickly found applications in various sectors, including construction and automotive. Over the years, innovations in resin formulations and production techniques have improved the mechanical properties and versatility of fiberglass sheets, leading to wider adoption.

Illustrative image related to fiberglass sheets 4×8 price

In recent years, the market has shifted towards more specialized applications, such as corrosion-resistant panels and decorative wall coverings, driven by advancements in technology and changing consumer preferences. This evolution is particularly relevant for international B2B buyers, as the diverse applications of fiberglass sheets can cater to specific regional needs and market demands. Understanding this historical context can help buyers make informed decisions when sourcing fiberglass sheets, ensuring they choose materials that align with both current trends and future market directions.

Frequently Asked Questions (FAQs) for B2B Buyers of fiberglass sheets 4×8 price

1. How do I determine the right supplier for fiberglass sheets?

Choosing the right supplier for fiberglass sheets involves assessing several key factors. First, verify their manufacturing capabilities and product quality through certifications and quality assurance processes. Second, check their reputation by seeking reviews or testimonials from previous clients, particularly in your region. Third, consider their responsiveness and customer service, as effective communication can significantly impact your sourcing experience. Lastly, request samples before committing to larger orders to ensure that the product meets your specific requirements.

2. What factors influence the price of 4×8 fiberglass sheets?

The price of 4×8 fiberglass sheets can vary based on several factors, including material quality, thickness, and type of fiberglass (e.g., reinforced or transparent). Additional influences include the supplier’s location, shipping costs, and any import duties applicable in your country. Bulk purchasing often leads to discounts, so consider your order volume when negotiating prices. Lastly, fluctuations in raw material costs can also impact pricing, so it’s beneficial to stay informed about market trends.

3. What is the minimum order quantity (MOQ) for fiberglass sheets?

The minimum order quantity (MOQ) for fiberglass sheets typically varies by supplier. Many manufacturers set an MOQ of around 200 square meters, but this can differ based on their production capacity and your specific requirements. It’s important to communicate your needs upfront to negotiate favorable terms, especially if you’re a smaller buyer. Some suppliers may offer flexibility in MOQs for first-time customers or during promotional periods.

4. How can I customize fiberglass sheets for my project?

Customization options for fiberglass sheets can include varying thicknesses, colors, and surface finishes, depending on the supplier’s capabilities. To initiate the customization process, clearly outline your specifications, including dimensions and any desired features. Discuss your project’s application to ensure the materials meet performance standards. Be prepared to collaborate with the supplier’s design team, and request samples or prototypes to evaluate before finalizing your order.

5. What payment terms should I expect when purchasing fiberglass sheets internationally?

Payment terms for international purchases of fiberglass sheets often include options such as upfront payment, partial payments, or letters of credit. Common practices involve a deposit (e.g., 30-50%) at the time of order, with the balance due prior to shipping. Ensure you clarify payment methods accepted by the supplier, such as bank transfers or credit terms. It’s advisable to negotiate terms that provide a balance of security and flexibility for both parties.

6. How do I ensure quality assurance for fiberglass sheets?

To ensure quality assurance when sourcing fiberglass sheets, request detailed specifications and certifications from the supplier, such as ISO or ASTM standards. Establish a quality control process that may include pre-shipment inspections or third-party testing to verify product compliance with your requirements. Additionally, maintain open communication with the supplier regarding any quality concerns and establish a clear return policy for defective products.

7. What are the logistics considerations when importing fiberglass sheets?

Logistics considerations for importing fiberglass sheets include selecting the right shipping method (air freight vs. sea freight) based on urgency and cost. Understand the customs regulations in your country, including tariffs and import duties that may apply. Collaborate with logistics partners experienced in handling fiberglass materials to ensure safe transport. Finally, track shipments closely to mitigate any delays and plan for delivery to your facility.

8. How do I handle potential customs issues when importing fiberglass sheets?

To handle potential customs issues when importing fiberglass sheets, ensure all documentation is complete and accurate, including invoices, packing lists, and certificates of origin. Familiarize yourself with your country’s import regulations specific to fiberglass products to avoid delays. It may also be beneficial to work with a customs broker who can navigate the complexities of international trade and assist with compliance. Keeping open lines of communication with your supplier can also expedite the resolution of any issues that arise during the customs clearance process.

Top 4 Fiberglass Sheets 4X8 Price Manufacturers & Suppliers List

1. ePlastics – 1/16 Flat Clear Fiberglass Sheet

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: 1/16″ x 48″ x 96″ Flat Clear Fiberglass Sheet

2. Dinuofrp – 4×8 Fiberglass Sheets

Domain: dinuofrp.com

Registered: 2019 (6 years)

Introduction: 4×8 Fiberglass Sheets; MOQ: 200 square meters; made of durable, shatter-resistant material; above 90% moisture resistant; thermal shock and chemical resistant; easy to clean; extensive color options; easy installation; high impact strength; low maintenance; applications include concrete form panels, temporary shelters, offshore living quarters, mobile stages, outdoor signs, safe rooms, and animal …

3. CRANE COMPOSITES – FRP FIBERGLASS REINFORCED PANEL 4X8 IVORY CLASS C

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “FRP FIBERGLASS REINFORCED PANEL 4X8 IVORY CLASS C (17 SHEETS) 615141”, “Condition”: “New”, “Brand”: “CRANE COMPOSITES”, “Model”: “4X8 IVORY CLASS C”, “MPN”: “84 IVORY”, “Country/Region of Manufacture”: “United States”, “Price”: “$499.99”, “Shipping”: “$599.00 Flat Rate Freight”, “Returns”: “Seller does not accept returns”, “California Prop 65 Warning”: “THIS PRODUCT CONTAINS STYR…

4. Runfeng – 4 By 8 Fiberglass Sheets

Domain: frpexpert.com

Registered: 2021 (4 years)

Introduction: Product Name: 4 By 8 Fiberglass Sheets

Supplier: Runfeng

Features:

– Lightweight

– Non-magnetic

– Corrosion resistant

– Mechanical properties similar to steel, aluminum, and concrete

– Versatile applications including warehouse walls, roofing, dry wall faces, hospital walls, floors, and prefabricated house panels

– Anti-aging film for improved performance

– UV absorbers to filter sunlight and red…

Strategic Sourcing Conclusion and Outlook for fiberglass sheets 4×8 price

In the rapidly evolving landscape of fiberglass sheet procurement, strategic sourcing has emerged as a critical component for international B2B buyers. The price of 4×8 fiberglass sheets can fluctuate based on market demand, supplier reliability, and material quality. Engaging with reputable suppliers ensures not only competitive pricing but also access to high-quality products that meet industry standards.

For buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging local market insights and supplier relationships can lead to significant cost savings and improved supply chain efficiency. It is essential to evaluate potential partners based on their product offerings, delivery capabilities, and customer service, as these factors can greatly impact project timelines and overall satisfaction.

As we look to the future, the demand for fiberglass sheets is expected to grow, driven by advancements in manufacturing technologies and increasing applications across various industries. Now is the time for B2B buyers to take proactive steps in establishing solid sourcing strategies that align with their business goals. By doing so, they can secure a competitive edge in the marketplace and ensure their operations are well-supported by high-quality materials. Engage with suppliers today to explore the best options tailored to your specific needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.