Choosing Your Expansion Joints For Pipes: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for expansion joints for pipes

In the ever-evolving landscape of industrial piping systems, sourcing high-quality expansion joints for pipes poses a significant challenge for international B2B buyers. These critical components are essential for managing thermal expansion, vibration, and ground movement, ensuring the integrity and longevity of piping systems across various industries. This comprehensive guide delves into the multifaceted world of expansion joints, exploring different types—such as rubber, metal, and PTFE joints—and their specific applications in sectors ranging from HVAC to chemical processing.

As you navigate this guide, you will gain valuable insights into effective supplier vetting processes, cost considerations, and best practices for maintenance and installation. Understanding these elements is crucial for making informed purchasing decisions that can enhance system performance and reduce downtime. The guide is tailored to meet the needs of B2B buyers in regions like Africa, South America, the Middle East, and Europe, including key markets such as Brazil and Germany.

By equipping you with knowledge on the latest trends, technologies, and supplier capabilities, this resource empowers you to make strategic choices that align with your operational goals. Whether you are looking to enhance efficiency, ensure compliance, or mitigate risks, this guide serves as your roadmap to successfully navigating the global market for expansion joints for pipes.

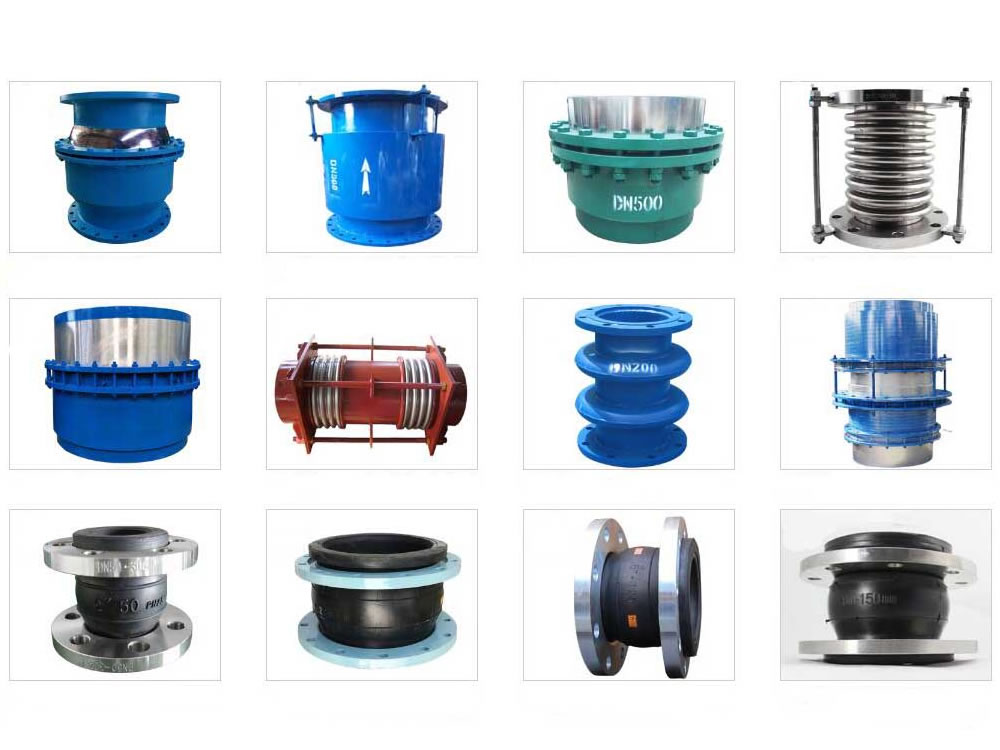

Understanding expansion joints for pipes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rubber Expansion Joints | Flexible elastomeric material; good for vibration isolation | HVAC systems, wastewater treatment | Pros: Cost-effective, versatile; Cons: Limited temperature range, shorter lifespan. |

| Metal Expansion Joints | Durable metal construction; high-temperature resistance | Power plants, chemical processing | Pros: High durability, suitable for extreme conditions; Cons: Higher initial cost, heavier. |

| PTFE Expansion Joints | Non-reactive synthetic material; excellent for corrosive environments | Chemical processing, food and beverage | Pros: Chemical resistance, longevity; Cons: Higher price point, limited flexibility. |

| Ducting Expansion Joints | Combination of rubber and fabric; designed for ducting systems | Industrial ventilation, HVAC | Pros: Reduces noise and vibration; Cons: Potential for wear in harsh environments. |

| Braided Pipe Connectors | Flexible stainless steel; accommodates misalignment | Pumping systems, high-temperature applications | Pros: High flexibility, mitigates stress; Cons: More complex installation, potential for corrosion. |

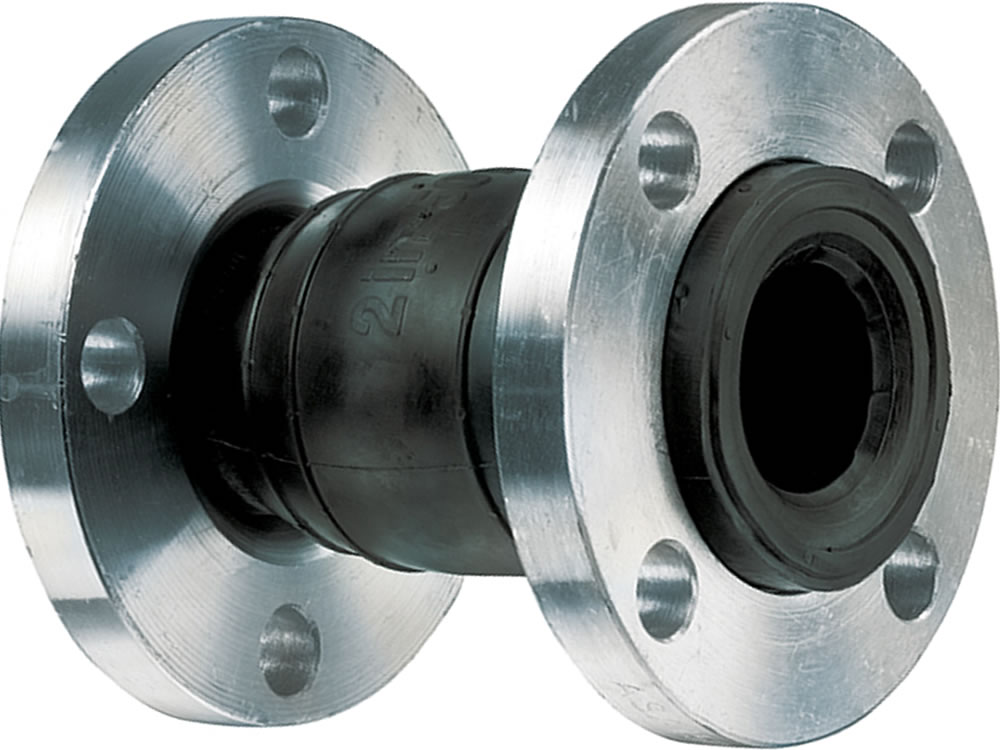

What Are Rubber Expansion Joints and When Should They Be Used?

Rubber expansion joints are designed to absorb thermal movement and isolate vibrations in piping systems. Their flexible elastomeric material makes them ideal for applications in HVAC systems and wastewater treatment facilities. Buyers should consider the operating temperature and pressure, as these joints typically have a lifespan of 5 to 20 years, depending on environmental conditions and installation quality. Regular maintenance is essential to maximize their durability and effectiveness.

How Do Metal Expansion Joints Differ from Other Types?

Metal expansion joints are constructed from durable materials like stainless steel, making them suitable for high-temperature and high-pressure applications in power plants and chemical processing facilities. They offer excellent resistance to wear and corrosion but come at a higher initial investment. Buyers should evaluate the specific operating conditions and the potential need for custom designs, especially for larger diameters or extreme environments.

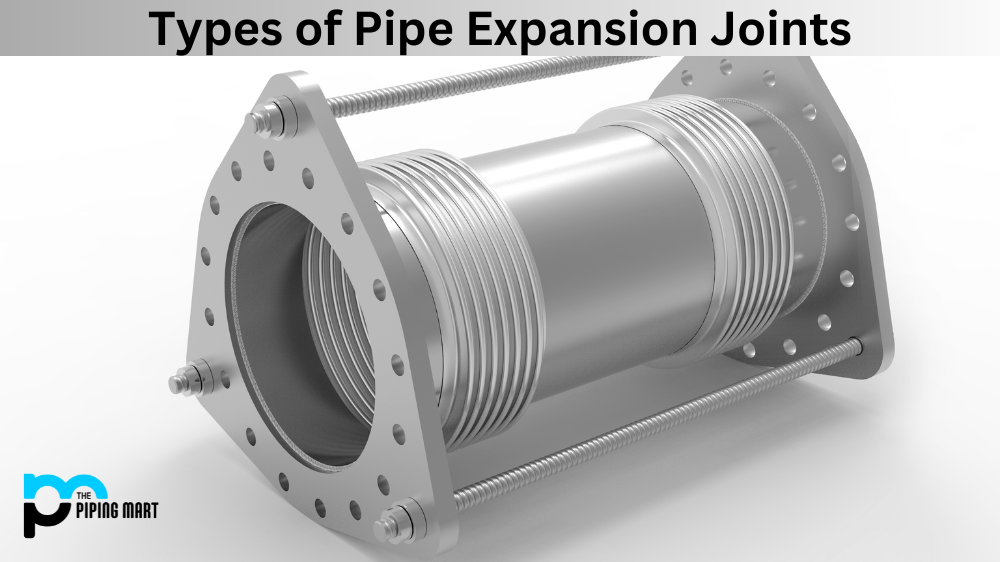

Illustrative image related to expansion joints for pipes

Why Choose PTFE Expansion Joints for Chemical Processing?

PTFE (Polytetrafluoroethylene) expansion joints are non-reactive, making them a perfect choice for the chemical processing industry. They can withstand extreme temperatures and are highly resistant to corrosive substances, ensuring system integrity in demanding environments. While they tend to be more expensive than rubber or metal options, their longevity and reliability in harsh conditions can justify the investment for B2B buyers focused on performance.

What Are the Benefits of Ducting Expansion Joints?

Ducting expansion joints combine rubber and fabric reinforcement to provide flexibility in industrial ducting systems. They are effective at reducing noise and vibration, making them suitable for HVAC and industrial ventilation applications. However, buyers should be aware of their potential wear in harsh environments, which may necessitate more frequent inspections and replacements.

How Do Braided Pipe Connectors Enhance System Performance?

Braided pipe connectors are made of flexible stainless steel and designed to accommodate misalignment and control pump vibrations. They are particularly useful in high-temperature applications, providing a reliable solution for maintaining system integrity. Buyers should consider the complexity of installation and the potential for corrosion when selecting braided connectors, as these factors can impact long-term performance and maintenance requirements.

Key Industrial Applications of expansion joints for pipes

| Industry/Sector | Specific Application of Expansion Joints for Pipes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water and Wastewater | Used in pumping stations and treatment facilities | Reduces maintenance costs and downtime due to vibration and thermal expansion | Material compatibility with water and chemicals, pressure ratings, and environmental factors |

| Chemical Processing | Integration in pipelines transporting corrosive materials | Enhances safety by preventing leaks and protecting equipment from damage | Chemical resistance, temperature limits, and compliance with industry standards |

| HVAC Systems | Installed in ducting systems for thermal expansion | Improves energy efficiency and system longevity by reducing stress on components | Flexibility in design, temperature range, and noise isolation capabilities |

| Power Generation | Employed in steam and cooling water systems | Increases operational efficiency and reliability while minimizing thermal stress | High-temperature tolerance, pressure ratings, and durability against thermal cycling |

| Mining and Metals | Utilized in slurry pipelines and dust collection systems | Enhances equipment lifespan and operational safety by absorbing vibrations and thermal movements | Resistance to abrasive materials, environmental conditions, and ease of installation |

How Are Expansion Joints for Pipes Used in the Water and Wastewater Industry?

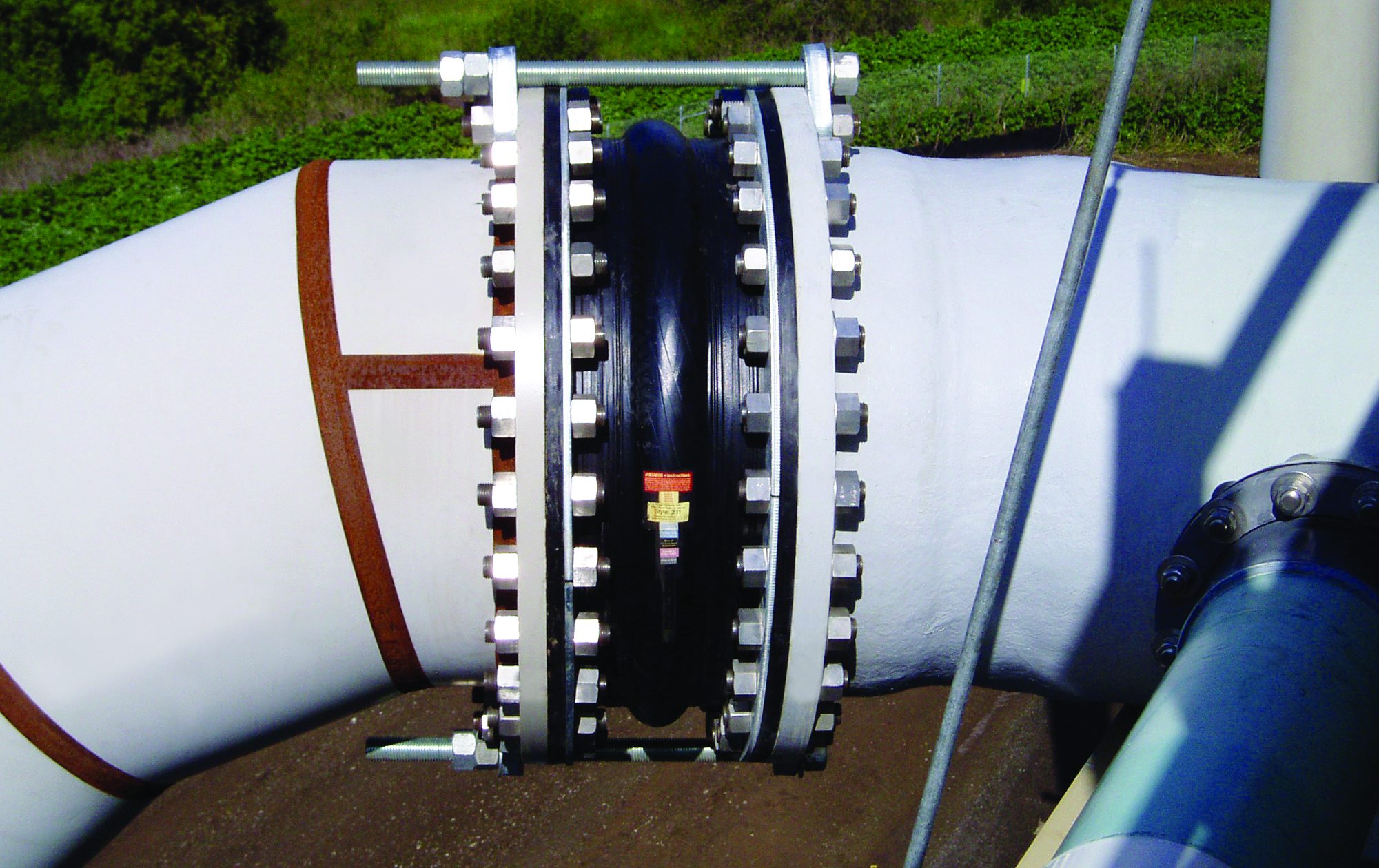

In water and wastewater applications, expansion joints are critical in pumping stations and treatment facilities. They absorb thermal expansion and vibrations caused by fluid flow, preventing damage to pipes and associated equipment. Buyers should consider material compatibility with various water conditions, pressure ratings, and environmental factors, as these joints must withstand harsh conditions while maintaining system integrity.

What Role Do Expansion Joints Play in Chemical Processing?

In the chemical processing sector, expansion joints are essential for pipelines that transport corrosive materials. They mitigate the risk of leaks and protect equipment from the damaging effects of thermal expansion and contraction. When sourcing, businesses must ensure that the materials used offer sufficient chemical resistance, can handle high temperatures, and comply with relevant safety standards to maintain operational safety.

Why Are Expansion Joints Important in HVAC Systems?

In HVAC systems, expansion joints are installed within ducting to accommodate thermal expansion and contraction. This flexibility helps to prevent stress on components, improving energy efficiency and extending the system’s lifespan. Buyers should prioritize flexibility in design, the temperature range of operation, and noise isolation capabilities to ensure optimal performance in various climates.

How Do Expansion Joints Enhance Power Generation Systems?

In power generation, expansion joints are integrated into steam and cooling water systems to manage thermal expansion and vibration. This application enhances operational efficiency and reliability, minimizing the risk of equipment failure due to thermal stress. Key considerations for sourcing include high-temperature tolerance, appropriate pressure ratings, and durability against thermal cycling to ensure longevity in demanding environments.

What Benefits Do Expansion Joints Provide in Mining and Metals Industries?

In the mining and metals industry, expansion joints are used in slurry pipelines and dust collection systems to absorb vibrations and thermal movements. This application enhances equipment lifespan and operational safety by reducing wear and tear. Buyers should focus on sourcing joints that resist abrasive materials, can withstand challenging environmental conditions, and are easy to install, ensuring seamless integration into existing systems.

3 Common User Pain Points for ‘expansion joints for pipes’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Material for Harsh Environments

The Problem: B2B buyers often encounter challenges in selecting expansion joints that can withstand harsh environmental conditions. For industries such as chemical processing, wastewater treatment, or mining, the expansion joints must resist extreme temperatures, corrosive substances, and mechanical stress. A miscalculation can lead to premature failure, causing significant operational disruptions and costly repairs. Buyers may feel overwhelmed by the variety of materials available, such as rubber, stainless steel, and PTFE, each with its own specifications and limitations.

The Solution: To effectively choose the right material for expansion joints, buyers should start by conducting a thorough analysis of their operational environment. Consider the chemical composition of the media being transported, as well as temperature and pressure conditions. For instance, PTFE expansion joints are excellent for corrosive environments due to their non-reactive nature, while rubber joints are suitable for applications involving less aggressive substances. Collaborating with reputable manufacturers who can provide technical data sheets and performance specifications is essential. Additionally, implementing regular inspection schedules will help in identifying any wear and tear early, ensuring that replacements are made before failures occur.

Scenario 2: Managing Installation Challenges for Piping Systems

The Problem: Installation of expansion joints can present a host of challenges, particularly in complex piping systems. B2B buyers may struggle with improper alignment, inadequate support, or the incorrect type of joint for their specific application. Such issues can lead to misalignment during operation, increased stress on the joints, and ultimately, a higher likelihood of leaks or joint failure. The intricacies of installation often lead to frustration, as even minor errors can result in significant operational downtime.

The Solution: To mitigate installation challenges, buyers should prioritize comprehensive training for their installation teams. This includes understanding the specific requirements for each type of expansion joint, such as the proper orientation and support needed. It is also advisable to engage with manufacturers who offer technical support during the installation phase. They may provide installation guides, video tutorials, or on-site assistance. Furthermore, utilizing state-of-the-art alignment tools can help ensure that joints are installed correctly. Regular post-installation inspections can also help to identify and rectify any potential issues before they escalate.

Illustrative image related to expansion joints for pipes

Scenario 3: Longevity and Maintenance Concerns for Expansion Joints

The Problem: One of the most pressing concerns for B2B buyers is the longevity of expansion joints in their systems. Given that these components are crucial for absorbing thermal expansion and mitigating vibrations, their failure can lead to catastrophic system failures. Buyers often worry about how to ensure that their expansion joints last as long as possible, especially in challenging environments where exposure to extreme temperatures and pressures is common.

The Solution: To enhance the lifespan of expansion joints, buyers should implement a proactive maintenance strategy. This involves regular inspections and condition monitoring, focusing on signs of wear such as cracking, discoloration, or deformation. Choosing high-quality joints from reputable manufacturers is crucial, as these products typically have better durability and longer warranties. Additionally, buyers should consider environmental factors that might affect the joints, such as exposure to UV rays or chemicals, and take preventive measures like protective coatings or shelters. Finally, establishing a replacement schedule based on the expected lifespan of the materials used can help avoid unexpected failures and ensure consistent operation.

Strategic Material Selection Guide for expansion joints for pipes

What Are the Key Properties of Rubber Expansion Joints for Pipes?

Rubber is a widely used material for expansion joints due to its inherent flexibility and ability to absorb vibrations. Key properties include a temperature rating typically ranging from -40°C to 130°C and pressure ratings of 15-25 bar. Rubber expansion joints are particularly resistant to ozone, UV radiation, and weathering, making them suitable for outdoor applications. They are often utilized in HVAC systems, plumbing, and industrial processes.

Pros & Cons: Rubber expansion joints are generally cost-effective and easy to install, which can minimize manufacturing complexity. However, they may have a limited lifespan of 5-20 years depending on environmental conditions and chemical exposure. They are not suitable for high-temperature applications exceeding 130°C or for use with oils and hydrocarbons.

Impact on Application: Rubber joints are compatible with a variety of media, including water and mild chemicals, making them versatile for many industries. However, improper material selection can lead to premature failure, especially in harsh environments.

Illustrative image related to expansion joints for pipes

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or ISO. In Europe, DIN standards are commonly referenced. Understanding local environmental conditions is crucial for selecting the right rubber type.

How Do PTFE Expansion Joints Perform in Chemical Applications?

Polytetrafluoroethylene (PTFE) is renowned for its chemical resistance, making it ideal for applications involving corrosive substances. PTFE expansion joints can withstand temperatures up to 200°C and pressures of around 15 bar. They are particularly effective in the chemical processing industry and are often used in environments where traditional materials would degrade.

Pros & Cons: The primary advantage of PTFE is its non-reactive nature, which allows it to handle a wide range of chemicals without degradation. However, PTFE joints can be more expensive than rubber options and may require specialized manufacturing processes, increasing lead times.

Impact on Application: PTFE’s compatibility with aggressive chemicals makes it a preferred choice for sectors like pharmaceuticals and petrochemicals. Buyers must consider the specific chemical media when selecting PTFE, as certain formulations may be required for optimal performance.

Considerations for International Buyers: Compliance with industry standards is critical, especially in regulated markets like Europe and North America. Buyers should also be aware of the specific chemical compatibility charts to ensure that the selected PTFE joint meets their application requirements.

What Are the Advantages of Metal Expansion Joints for High-Pressure Systems?

Metal expansion joints are designed for high-pressure and high-temperature applications, with capabilities often exceeding 500°F and pressure ratings up to 300 psi. They are constructed from durable materials like stainless steel, providing excellent corrosion resistance and mechanical strength.

Illustrative image related to expansion joints for pipes

Pros & Cons: The durability and high-performance characteristics of metal joints make them suitable for demanding environments, such as power plants and heavy industrial applications. However, they tend to be more expensive than rubber or PTFE options and may require more complex installation processes.

Impact on Application: Metal expansion joints are ideal for systems that experience significant thermal expansion and contraction, such as steam lines and exhaust systems. Their robust nature allows them to handle extreme conditions, but they may not be suitable for all media types, particularly those that can cause corrosion.

Considerations for International Buyers: Buyers should ensure that metal expansion joints comply with relevant international standards, such as ASME or API in the Americas and EN standards in Europe. Understanding local material availability and manufacturing capabilities can also influence procurement decisions.

Summary Table of Material Selection for Expansion Joints

| Material | Typical Use Case for expansion joints for pipes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | HVAC systems, plumbing, industrial processes | Cost-effective and easy to install | Limited lifespan and temperature range | Low |

| PTFE | Chemical processing, pharmaceuticals | Excellent chemical resistance | Higher cost and specialized manufacturing | High |

| Metal | Power plants, heavy industrial applications | High durability and pressure resistance | More expensive and complex installation | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling informed decisions based on specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for expansion joints for pipes

What Are the Key Stages in the Manufacturing Process of Expansion Joints for Pipes?

The manufacturing of expansion joints involves several critical stages, each designed to ensure the product’s durability, flexibility, and overall performance. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Expansion Joints?

The initial step in the manufacturing process is material preparation. Depending on the type of expansion joint, various materials such as rubber, stainless steel, or PTFE are selected based on their specific properties and intended applications. For instance, rubber expansion joints often use elastomers like EPDM or Neoprene, while metal joints utilize stainless steel for its strength and corrosion resistance.

During material preparation, suppliers conduct thorough inspections to verify the quality and consistency of the raw materials. This may include checking for chemical compatibility, tensile strength, and elasticity. This stage sets the foundation for ensuring that the final product meets the rigorous demands of its intended environment.

What Techniques Are Used in the Forming Process?

The forming process varies depending on the material used. For rubber expansion joints, techniques such as molding or extrusion are common. Molding involves shaping the rubber into the desired form using heat and pressure, while extrusion allows for continuous production of specific shapes. Metal expansion joints, on the other hand, often involve processes like hydroforming or stamping to create bellows and other components.

Illustrative image related to expansion joints for pipes

Precision is crucial in this phase. Advanced machinery and computer numerical control (CNC) technology are often employed to ensure exact dimensions and tolerances. This accuracy is vital, as even minor discrepancies can lead to significant operational issues in the field.

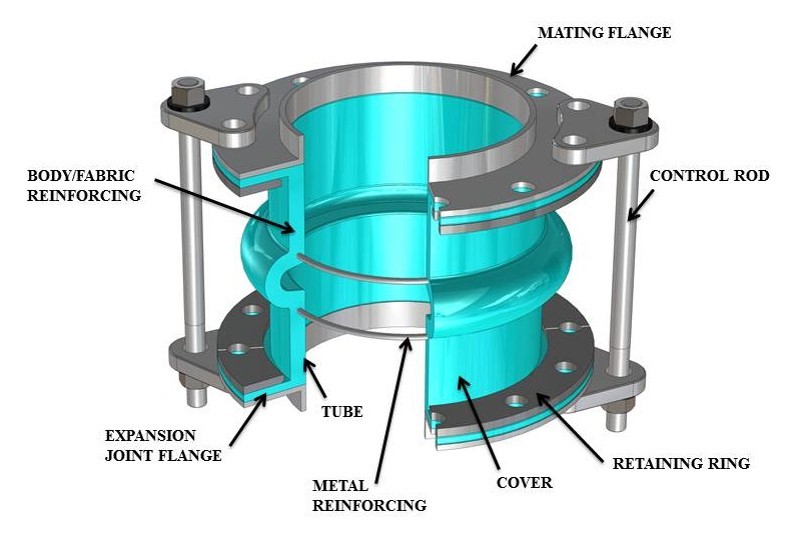

How Are Expansion Joints Assembled?

Assembly is the next critical stage, where various components are brought together to create the final product. For rubber joints, this may involve layering the elastomer with reinforcement materials such as fabric or metal rings. For metal joints, the assembly includes welding or bolting together the different parts, ensuring that all connections are robust and leak-proof.

Throughout the assembly process, manufacturers often implement checks to ensure that each component fits correctly and meets the specified design criteria. This might involve using jigs or fixtures to maintain alignment during assembly, which is particularly important for maintaining the integrity of the expansion joint under operational stress.

What Finishing Processes Are Commonly Used?

The finishing stage focuses on enhancing the performance and appearance of the expansion joints. This may involve surface treatments, coatings, or the application of protective layers to improve resistance to environmental factors like UV light, moisture, and chemicals.

For rubber joints, a curing process is often applied to ensure optimal elasticity and durability. Metal joints may undergo processes such as galvanization or painting to prevent corrosion. Each finishing technique is selected based on the intended application of the expansion joint, ensuring it can withstand the operational conditions it will face.

What Quality Control Measures Are Implemented During Manufacturing?

Quality assurance is a vital aspect of the manufacturing process for expansion joints, ensuring that products meet international standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are crucial benchmarks for quality management systems. Manufacturers often seek certification to demonstrate their commitment to maintaining high quality in their production processes. In addition, industry-specific certifications, such as CE marking for European markets or API standards for oil and gas applications, are essential for ensuring compliance with regulatory requirements.

B2B buyers should inquire about these certifications when evaluating suppliers, as they reflect a manufacturer’s adherence to recognized quality standards.

Illustrative image related to expansion joints for pipes

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process, typically categorized into Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified quality criteria before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted at various stages. This ensures that any deviations from specifications are identified and corrected promptly.

-

Final Quality Control (FQC): Once the expansion joints are assembled, a comprehensive inspection is performed. This may include dimensional checks, pressure testing, and performance evaluations to ensure the products meet all operational requirements.

What Common Testing Methods Are Used for Quality Assurance?

Common testing methods for expansion joints include:

- Hydrostatic Testing: This test assesses the joint’s ability to withstand internal pressure without leaking.

- Fatigue Testing: This evaluates how well the joint can handle repeated movement or thermal expansion over time.

- Material Testing: This involves analyzing the raw materials for tensile strength, elongation, and chemical resistance.

These tests help ensure that the expansion joints are reliable and will perform effectively in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability and performance. Here are several strategies:

Illustrative image related to expansion joints for pipes

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality control processes and adherence to industry standards.

-

Request Quality Reports: Suppliers should be willing to provide quality assurance reports that detail testing results, compliance with standards, and any corrective actions taken for past issues.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures and product reliability.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, may encounter specific challenges when assessing quality control in suppliers. Factors such as varying regulatory standards, logistical issues, and cultural differences in business practices can impact the evaluation process.

To navigate these nuances, buyers should:

- Understand Regional Standards: Familiarize themselves with local regulations and standards that may differ from international norms.

- Establish Clear Communication: Open lines of communication with suppliers to clarify quality expectations and ensure mutual understanding of quality requirements.

- Build Long-Term Relationships: Developing long-term partnerships with reliable suppliers can enhance trust and improve the likelihood of consistent quality over time.

By focusing on these aspects, B2B buyers can make informed decisions and ensure they partner with manufacturers that prioritize quality in the production of expansion joints for pipes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expansion joints for pipes’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring expansion joints for pipes. As critical components in piping systems, expansion joints help manage thermal expansion, vibrations, and other movements. Following this checklist will ensure you select the right products and suppliers to meet your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing the right expansion joints. Consider factors such as the type of media (liquid, gas, or steam), operating temperature, pressure ratings, and movement requirements. Define the material compatibility, especially if the joints will be exposed to chemicals or extreme temperatures.

- Media Type: Different joints are suitable for various media; for example, PTFE joints are ideal for corrosive substances.

- Temperature and Pressure: Identify the maximum and minimum operating conditions to ensure longevity and reliability.

Step 2: Research Available Materials

Understanding the materials used in expansion joints is vital for ensuring performance and durability. Common materials include rubber, metal, and PTFE, each offering unique advantages based on application.

- Rubber Expansion Joints: Best for vibration isolation and thermal movement in HVAC or wastewater systems.

- Metal Expansion Joints: Suitable for high-pressure and high-temperature applications, often used in power plants and industrial processes.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies to assess their expertise and reliability.

- Certifications: Verify that suppliers have relevant industry certifications, such as ISO standards, to ensure quality assurance.

- References: Ask for references from other clients in similar industries to gauge their satisfaction and reliability.

Step 4: Assess Product Performance and Longevity

Investigate the performance characteristics and expected lifespan of the expansion joints. A reliable supplier should provide data on factors influencing durability, including material composition and design features.

- Service Life: Inquire about the average lifespan and maintenance requirements to minimize downtime.

- Performance Data: Request performance tests and certifications that validate the joints’ capabilities under specified conditions.

Step 5: Consider Customization Options

Evaluate whether the supplier offers customization options to meet specific project requirements. Custom expansion joints can be tailored to accommodate unique specifications and operational conditions.

- Size and Configuration: Ensure the supplier can provide joints in the required dimensions and with the appropriate connections (flanged, grooved, or welded).

- Special Features: Look for options such as seismic or vibration control features that may be necessary for certain applications.

Step 6: Request Sample Products

Before finalizing your order, request sample products to evaluate their quality and compatibility with your systems. This step allows you to assess the materials and workmanship firsthand.

Illustrative image related to expansion joints for pipes

- Compatibility Testing: Conduct tests to ensure that the expansion joints meet your operational demands and integrate well with existing systems.

- Quality Assurance: Use samples to verify that the manufacturing quality aligns with your expectations.

Step 7: Review Terms and Conditions

Finally, review the supplier’s terms and conditions, including warranty, return policy, and delivery timelines. Understanding these factors will help you avoid potential disputes and ensure timely project completion.

- Warranty Coverage: Ensure that the warranty covers defects and provides adequate protection for your investment.

- Delivery Commitments: Confirm lead times to align with your project schedule and avoid delays.

By following this checklist, B2B buyers can make informed decisions when sourcing expansion joints for pipes, ultimately enhancing system performance and reliability.

Comprehensive Cost and Pricing Analysis for expansion joints for pipes Sourcing

What Are the Key Cost Components for Sourcing Expansion Joints for Pipes?

When sourcing expansion joints for pipes, several cost components contribute to the overall price. Key elements include:

-

Materials: The choice of materials significantly influences costs. Common materials include rubber, stainless steel, and polytetrafluoroethylene (PTFE). For instance, PTFE-based joints are often more expensive due to their chemical resistance properties.

-

Labor: Labor costs encompass the workforce required for manufacturing and assembly. This varies by region; for example, labor costs in Europe may be higher than in parts of Africa or South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Customization often necessitates specialized tooling, which can increase initial costs. Buyers should consider whether a standard product meets their needs to avoid these expenses.

-

Quality Control (QC): Ensuring that products meet regulatory and safety standards incurs additional costs. Quality assurance processes can add to the total expenditure, particularly for industries with stringent requirements.

-

Logistics: Transportation and handling costs are crucial, especially for international shipments. Factors such as shipping distances, freight methods, and customs duties can significantly affect the final price.

-

Margin: Suppliers will typically include a profit margin that varies based on market conditions, competition, and the supplier’s positioning. Buyers should be aware of standard markups in their region.

How Do Price Influencers Affect the Cost of Expansion Joints?

Several factors can influence the pricing of expansion joints, including:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide better pricing for larger orders. Buyers should assess their needs to leverage economies of scale effectively.

-

Specifications/Customization: Custom designs or specific material requirements can lead to higher costs. Buyers should evaluate whether standard products can fulfill their applications.

-

Material Selection: The choice of material not only impacts the cost but also the joint’s performance and lifespan. Investing in higher-quality materials may yield long-term savings through reduced maintenance.

-

Quality and Certifications: Products that meet international standards (such as ISO or API) typically cost more but offer assurance of reliability and performance, which can be critical for safety and compliance.

-

Supplier Factors: Supplier reputation, reliability, and service levels can also impact pricing. Established suppliers may charge more but often provide better support and product quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. These terms define responsibilities for shipping, insurance, and tariffs, which can significantly affect total costs.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

To maximize cost-efficiency when sourcing expansion joints, buyers should consider the following tips:

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better pricing and terms. Regular communication fosters trust and can lead to discounts on bulk orders or long-term contracts.

-

Analyze Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, buyers should evaluate the TCO, which includes maintenance, replacement, and operational costs over the product’s lifecycle. This approach can justify higher initial investments for products with longer lifespans or lower maintenance needs.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide insights into market pricing and help identify competitive offers. This practice also strengthens negotiation positions.

-

Understand Regional Pricing Nuances: Pricing for expansion joints can vary significantly across regions such as Africa, South America, the Middle East, and Europe. Buyers should be informed about local market conditions, import tariffs, and currency fluctuations that may impact costs.

-

Be Mindful of Payment Terms: Flexible payment terms can improve cash flow and reduce financial strain. Buyers should negotiate terms that align with their operational cycles.

Disclaimer on Indicative Prices

Prices for expansion joints can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and consult with suppliers to obtain the most accurate and current pricing information tailored to their specific needs and requirements.

Alternatives Analysis: Comparing expansion joints for pipes With Other Solutions

Understanding Alternative Solutions to Expansion Joints for Pipes

When considering the integrity and efficiency of piping systems, it is essential to explore alternative solutions to traditional expansion joints. While expansion joints are designed to absorb thermal expansion, vibration, and ground movement, other technologies can also provide similar functionalities. This analysis compares expansion joints for pipes with two viable alternatives: flexible couplings and rigid pipe supports.

Comparison Table

| Comparison Aspect | Expansion Joints For Pipes | Flexible Couplings | Rigid Pipe Supports |

|---|---|---|---|

| Performance | Excellent at absorbing movement; versatile for various applications. | Good at accommodating minor misalignments and vibrations. | Provides stability but does not absorb thermal expansion. |

| Cost | Moderate to high initial investment depending on materials and design. | Generally lower cost; varies by size and material. | Low initial cost; however, may incur higher costs in maintenance and adjustments. |

| Ease of Implementation | Requires careful installation; may need specialized knowledge. | Easier to install; often requires minimal adjustments. | Straightforward installation but can be complex in retrofitting. |

| Maintenance | Low maintenance; regular inspections recommended. | Low maintenance; may require periodic checks for wear. | Higher maintenance due to potential misalignment issues. |

| Best Use Case | Ideal for dynamic environments with significant movement. | Suitable for systems with minor misalignments or vibrations. | Best for static applications where movement is minimal. |

Detailed Breakdown of Alternatives

Flexible Couplings

Flexible couplings serve as a practical alternative to expansion joints, particularly in applications where minor misalignments and vibrations are common. They are typically made from rubber or other elastomeric materials that allow for some movement without compromising the integrity of the piping system. The advantages of flexible couplings include their lower cost and easier installation compared to expansion joints. However, they may not perform well under significant thermal expansion or heavy loads, making them less suitable for high-stress applications.

Rigid Pipe Supports

Rigid pipe supports are designed to provide stability and support to piping systems, ensuring that pipes remain in place during operation. These supports can prevent sagging and misalignment but do not absorb thermal expansion or vibration. While the initial cost of rigid supports is generally lower than that of expansion joints, they may lead to higher long-term costs due to maintenance needs and potential system adjustments over time. Rigid supports are best suited for static applications where movement is minimal, making them less versatile than expansion joints.

Conclusion: Choosing the Right Solution for Your Piping Needs

When selecting the appropriate solution for piping systems, B2B buyers must assess their specific operational requirements. Expansion joints offer superior performance in dynamic environments, making them ideal for applications with significant movement and thermal expansion. Conversely, flexible couplings provide a cost-effective alternative for systems with minor alignment issues, while rigid pipe supports can be suitable for static applications. By evaluating performance, cost, ease of implementation, maintenance needs, and the best use case for each option, buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for expansion joints for pipes

What Are the Key Technical Properties of Expansion Joints for Pipes?

When selecting expansion joints for pipes, understanding their technical properties is crucial for ensuring optimal performance and longevity. Here are several critical specifications to consider:

-

Material Grade

The material used in the construction of expansion joints significantly impacts their durability and compatibility with various media. Common materials include rubber (like EPDM and Neoprene), stainless steel, and Polytetrafluoroethylene (PTFE). Each material has unique properties suited for specific applications, such as resistance to chemicals, temperature extremes, and environmental factors. For example, EPDM is excellent for outdoor applications due to its ozone resistance, while PTFE is ideal for corrosive environments. -

Pressure Rating

This specification indicates the maximum pressure the expansion joint can withstand without failure. Typically measured in bar or psi, understanding the pressure rating is essential for ensuring safety and reliability in high-pressure systems. B2B buyers must match the pressure rating with the operational conditions of their piping systems to prevent leaks or catastrophic failures. -

Temperature Tolerance

Expansion joints must operate effectively within a specified temperature range. Materials like rubber can handle temperatures from -40°C to 200°C, while metal joints can withstand much higher temperatures. Knowledge of temperature tolerance is vital for applications in industries such as power generation and chemical processing, where extreme conditions are common. -

Movement Capability

This property defines the extent to which an expansion joint can accommodate movement caused by thermal expansion, vibration, or ground shifts. It is usually expressed in axial, lateral, and angular movements. Understanding movement capability is crucial for selecting the right type of joint to prevent stress on the piping system, which can lead to premature failure. -

Flange Configuration

Flanges are critical for connecting expansion joints to other piping components. They come in various configurations (e.g., welded, flanged, grooved) and must align with the existing piping system. Proper flange selection ensures leak-proof connections and simplifies installation, which is particularly important in large-scale industrial projects. -

Lifespan and Maintenance Needs

The expected lifespan of an expansion joint varies by material and application, generally ranging from 5 to 20 years. Regular maintenance can extend this lifespan. Buyers should consider the maintenance requirements and frequency of inspection to minimize downtime and repair costs, which can significantly impact operational efficiency.

What Are Common Trade Terms Related to Expansion Joints for Pipes?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that may be marketed by another manufacturer. In the context of expansion joints, knowing if a supplier is an OEM can provide insight into the quality and reliability of their products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for international buyers who may face higher shipping costs for smaller orders. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Issuing an RFQ helps businesses compare offers and negotiate better deals, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and potential risks when importing expansion joints from different regions. -

Lead Time

This term refers to the time required from placing an order to receiving the goods. In industries where downtime is costly, understanding lead times is essential for planning and ensuring that projects remain on schedule. -

Compliance Standards

These are regulations and guidelines that products must meet to ensure safety and performance. Familiarity with relevant compliance standards, such as ISO or ASME, can help buyers ensure that the expansion joints they procure meet necessary quality and safety benchmarks.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing expansion joints for pipes, ultimately enhancing operational efficiency and reducing risks in their projects.

Navigating Market Dynamics and Sourcing Trends in the expansion joints for pipes Sector

What Are the Key Market Dynamics and Trends Influencing the Expansion Joints for Pipes Sector?

The expansion joints for pipes sector is currently witnessing significant growth driven by several global factors. Rapid industrialization across regions such as Africa, South America, the Middle East, and Europe is leading to increased demand for robust piping systems capable of handling thermal expansion, vibration, and ground movement. The oil and gas, chemical processing, and water management sectors are particularly reliant on high-quality expansion joints to maintain operational integrity and efficiency. Emerging technologies, such as smart monitoring systems integrated into expansion joints, enable real-time performance tracking, helping companies optimize maintenance schedules and reduce downtime.

Another key trend is the shift towards customizable solutions. International buyers are increasingly seeking tailored expansion joints designed to meet specific operational requirements, such as extreme temperature and pressure conditions. This trend is particularly prevalent in markets like Brazil and Germany, where industries are demanding advanced materials such as PTFE and high-performance rubber that can withstand harsh environments. Moreover, the rise of e-commerce platforms is simplifying the sourcing process, enabling buyers to access a wider range of suppliers and products globally.

Illustrative image related to expansion joints for pipes

How Is Sustainability and Ethical Sourcing Impacting the Expansion Joints Market?

Sustainability has become a cornerstone of B2B purchasing decisions in the expansion joints for pipes sector. Environmental concerns are prompting buyers to seek products that minimize ecological impact, such as those manufactured from recyclable materials or those that exhibit lower emissions during production. The adoption of ‘green’ certifications is becoming increasingly important, as companies look to validate their commitment to sustainable practices.

Ethical sourcing is also gaining traction, with buyers placing higher importance on transparency throughout the supply chain. This includes understanding the origins of materials and ensuring that suppliers adhere to fair labor practices and environmental regulations. For example, sourcing expansion joints made from EPDM or other eco-friendly elastomers not only aligns with sustainability goals but also enhances brand reputation. By prioritizing ethical sourcing, companies can build stronger relationships with customers who value corporate responsibility, particularly in regions like Europe where consumers are increasingly conscious of environmental and social issues.

What Is the Historical Context of Expansion Joints in the Pipes Industry?

The evolution of expansion joints for pipes dates back to the early 20th century when the need for flexible piping systems became apparent in industrial applications. Initially, these joints were primarily made from rubber, designed to accommodate thermal expansion and contraction in piping systems. Over the decades, advancements in material science led to the development of a variety of options, including metal and composite expansion joints, capable of handling more extreme conditions.

The introduction of innovative materials such as PTFE in the late 20th century further enhanced the performance of expansion joints, particularly in corrosive environments like chemical processing. As industries have evolved, so too have the designs and applications of expansion joints, with modern solutions now integrating technology to offer enhanced durability and reliability. This historical context provides valuable insight into the current market dynamics, highlighting the ongoing need for innovation and adaptation in response to changing industrial requirements.

By understanding these market dynamics, sustainability considerations, and the historical evolution of expansion joints, international B2B buyers can make informed sourcing decisions that align with both operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of expansion joints for pipes

-

How do I select the right expansion joint for my piping system?

Choosing the right expansion joint involves assessing the specific application requirements, including the type of movement (axial, lateral, or angular), temperature, pressure, and the media being transported. Consider the environmental conditions, such as exposure to chemicals or UV light, as these factors can affect material selection. Consult with manufacturers to understand the available materials, such as rubber, PTFE, or metal, and their respective performance characteristics. A thorough analysis will ensure optimal functionality and longevity of the expansion joints in your system. -

What are the common applications for expansion joints in piping systems?

Expansion joints are critical in various applications, including HVAC systems, power generation, petrochemical plants, and water treatment facilities. They absorb thermal expansion, reduce vibration, and mitigate noise, ensuring system integrity and operational efficiency. Specialized sectors like marine and mining also utilize expansion joints to withstand harsh conditions. Understanding the specific needs of your application will help in selecting the most suitable expansion joint type. -

What is the expected lifespan of expansion joints, and how can I extend it?

The lifespan of expansion joints varies based on factors such as material type, operating conditions, and installation quality. Generally, rubber expansion joints last between 5 to 20 years, while metal joints may have a longer lifespan. To extend their longevity, ensure proper installation, conduct regular inspections, and perform maintenance checks. Monitoring operating conditions like temperature and pressure can also help in identifying potential issues early, thus enhancing the service life of the joints. -

What customization options are available for expansion joints?

Many manufacturers offer customization options for expansion joints to meet specific application requirements. Customizations can include size, material selection, pressure ratings, and design features tailored to unique operational conditions. Discuss your needs with suppliers to explore available options and ensure the expansion joints align with your system’s requirements. This tailored approach can enhance performance and reliability in demanding environments. -

What minimum order quantities (MOQs) should I expect when sourcing expansion joints?

Minimum order quantities can vary significantly between manufacturers and depend on factors such as product type and material. Some suppliers may have MOQs as low as one unit for standard products, while custom solutions might require higher volumes. It’s advisable to communicate directly with suppliers to understand their specific MOQs and explore options for smaller orders if necessary. Building a relationship with manufacturers may also provide flexibility in future orders. -

What payment terms are typically offered by suppliers for expansion joints?

Payment terms for expansion joints can vary based on the supplier and the buyer’s relationship. Common terms include net 30, net 60, or payment upon delivery. For international transactions, letters of credit or advance payments may be required. It’s essential to clarify payment terms upfront during negotiations to avoid misunderstandings. Establishing a good rapport with suppliers can also lead to more favorable terms as trust develops over time. -

How do I ensure quality assurance when sourcing expansion joints internationally?

To ensure quality assurance when sourcing expansion joints, conduct thorough due diligence on potential suppliers. Request certifications, quality control processes, and references from previous clients. Consider visiting the manufacturing facility or using third-party inspection services to assess product quality. Additionally, specifying clear quality standards in contracts can help maintain consistency and reliability in the products you receive. -

What logistics considerations should I keep in mind when importing expansion joints?

When importing expansion joints, consider shipping methods, lead times, and potential customs regulations in your country. Evaluate the supplier’s ability to handle logistics, including packaging and documentation for customs clearance. Factor in shipping costs and timelines to avoid delays in your projects. Engaging a logistics partner experienced in international trade can streamline the process and ensure timely delivery of your expansion joints.

Top 6 Expansion Joints For Pipes Manufacturers & Suppliers List

1. Proco Products – Expansion Joints

Domain: procoproducts.com

Registered: 1998 (27 years)

Introduction: Proco Products is a leading manufacturer of expansion joints for piping and ducting systems, offering a variety of designs in rubber, stainless steel, and polytetrafluoroethylene (PTFE). Their expansion joints are designed to protect equipment from thermal expansion, vibration, and ground movement, ensuring safe and reliable operations. Key features include:

– **Materials**: Rubber (EPDM, Neopren…

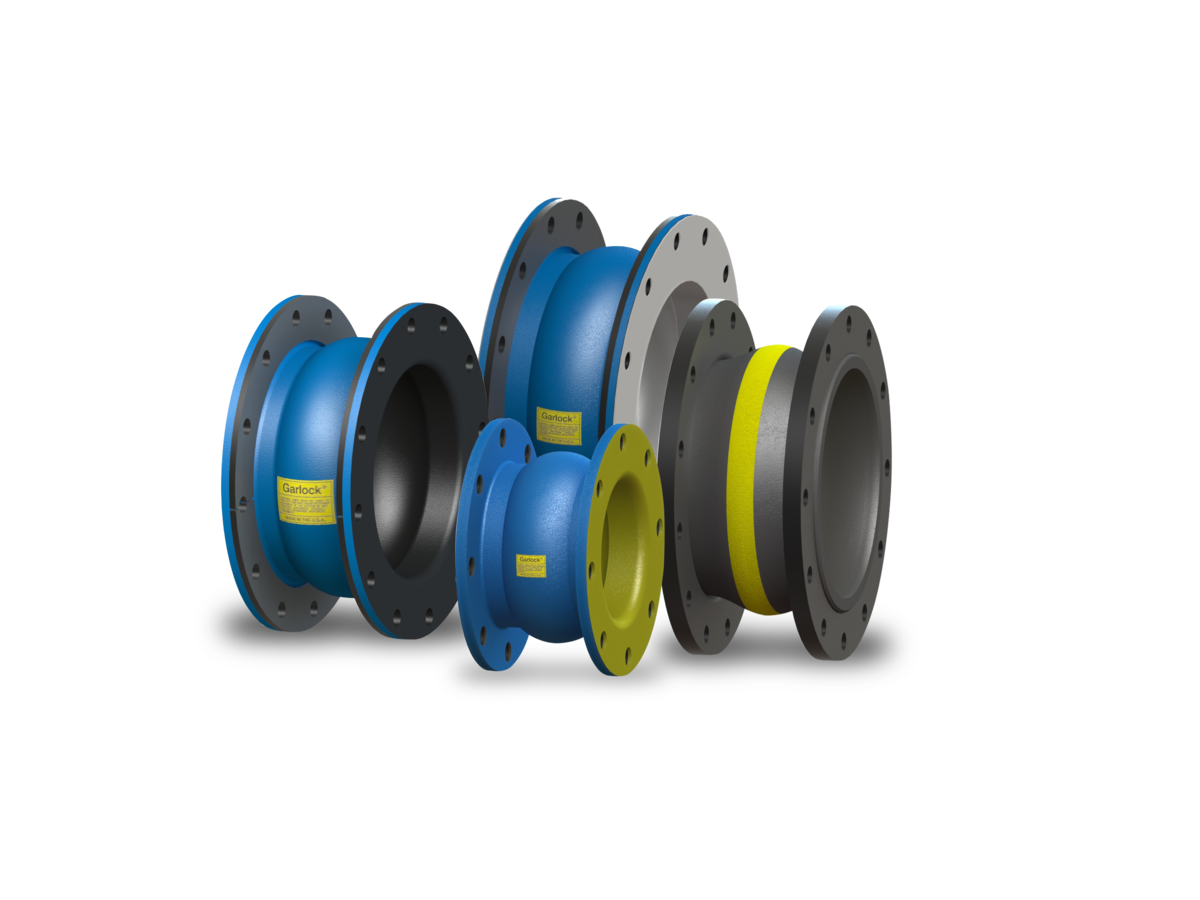

2. Garlock – Expansion Joints

Domain: garlock.com

Registered: 1995 (30 years)

Introduction: This company, Garlock – Expansion Joints, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. PD Blowers – Pipe Expansion Joints

Domain: pdblowers.com

Registered: 1998 (27 years)

Introduction: Pipe Expansion Joints isolate the blower or vacuum pump from other system components to allow for thermal expansion and misalignment of the piping. Common flanged rubber expansion joints feature single or double arched bellows constructed of molded elastomers. Standard single arch models from pdblowers are made of EPDM elastomer. Functions include reducing flange loading on the blower, allowing th…

4. Grainger – Pipe Expansion Joints

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Pipe Expansion Joints, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. EBAA Iron – Flexible Expansion Joints

Domain: ebaa.com

Registered: 1996 (29 years)

Introduction: EBAA Iron, Inc. offers a range of flexible and expansion joints for pipelines, including:

1. FLEX-TEND® Force Balanced Flexible Expansion Joints (3″ to 48″ sizes)

2. FLEX-TEND® Flexible Expansion Joints (2″ to 48″ sizes)

3. FLEX-TEND® DWV Flexible Expansion Joints for drain, waste, and vent (3″ to 8″ sizes)

4. EX-TEND® Force Balanced Expansion and Contraction Joint (4″ to 24″ sizes)

5. EX-TEN…

6. MISUMI – Expansion Joints

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Expansion joints are flexible connectors used in piping systems to absorb thermal expansion and contraction. They help reduce stress and movement in pipes created by temperature changes, protecting infrastructure from damage. Available in various materials and designs, these joints accommodate misalignment and vibrations, ensuring efficient fluid transfer. Expansion joints are essential in industr…

Strategic Sourcing Conclusion and Outlook for expansion joints for pipes

What Are the Key Takeaways for B2B Buyers in Sourcing Expansion Joints?

In today’s competitive landscape, effective sourcing of expansion joints is crucial for maintaining operational efficiency and ensuring the longevity of piping systems. Buyers should prioritize manufacturers that offer a diverse range of materials, such as rubber, stainless steel, and PTFE, to suit various applications and environmental conditions. Understanding the specific requirements of your projects—such as temperature, pressure, and chemical compatibility—will enable you to select the most suitable expansion joints, minimizing maintenance costs and downtime.

How Can Strategic Sourcing Enhance Your Operations?

Strategic sourcing not only optimizes procurement processes but also fosters strong supplier relationships that can lead to better pricing and improved product quality. By collaborating with reputable manufacturers, buyers can access the latest innovations in expansion joint technology, enhancing system reliability and performance. Regularly evaluating supplier performance and market trends will ensure that your sourcing strategies remain agile and effective.

What’s Next for International Buyers of Expansion Joints?

As the global market for expansion joints continues to evolve, buyers from Africa, South America, the Middle East, and Europe should remain proactive in their sourcing strategies. Emphasizing quality, sustainability, and technological advancements will position your operations for success. Engage with suppliers who understand your regional challenges and can provide tailored solutions. By doing so, you’ll not only enhance your supply chain resilience but also drive long-term growth in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.