Choosing Your Escaleras De Aluminio: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for escaleras de aluminio

In today’s competitive landscape, sourcing high-quality escaleras de aluminio presents a unique challenge for international B2B buyers. With a diverse range of products available, including professional and industrial-grade options, making the right choice can significantly impact safety, efficiency, and overall project success. This comprehensive guide aims to address these complexities by providing a detailed exploration of the various types of aluminum ladders, their applications, and essential factors to consider during the procurement process.

Throughout this guide, we will delve into the different categories of aluminum ladders, such as telescopic, multi-use, and scaffold models, ensuring that buyers understand which products align best with their specific needs. Additionally, we will cover vital aspects such as supplier vetting procedures, cost considerations, and market trends, enabling buyers from regions like Africa, South America, the Middle East, and Europe—specifically Brazil and Nigeria—to make informed purchasing decisions.

By equipping B2B buyers with actionable insights and expert recommendations, this guide serves as a valuable resource for navigating the global market for aluminum ladders. As you explore the contents, you will gain the knowledge necessary to select the right ladder solutions that enhance productivity while adhering to safety standards, ultimately supporting your business objectives.

Understanding escaleras de aluminio Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Escalera de Tijera | Compact design, self-supporting, typically 2-3 steps high | Warehousing, maintenance, construction | Pros: Space-efficient, easy to store. Cons: Limited height. |

| Escalera Telescópica | Adjustable height, collapsible, lightweight | Industrial, maintenance, outdoor tasks | Pros: Versatile, portable. Cons: May lack stability at full height. |

| Escalera de Extensión | Multi-section design for greater reach, typically wall-mounted | Construction, exterior maintenance | Pros: Extended reach, sturdy. Cons: Requires wall support, heavier. |

| Escalera Convertible | Adaptable design for multiple configurations (e.g., A-frame) | Diverse applications in construction | Pros: Highly versatile, space-saving. Cons: More complex to operate. |

| Escalera de Aluminio Aislante | Non-conductive materials, designed for electrical work | Electrical maintenance, utilities | Pros: Enhanced safety, lightweight. Cons: Higher cost due to material. |

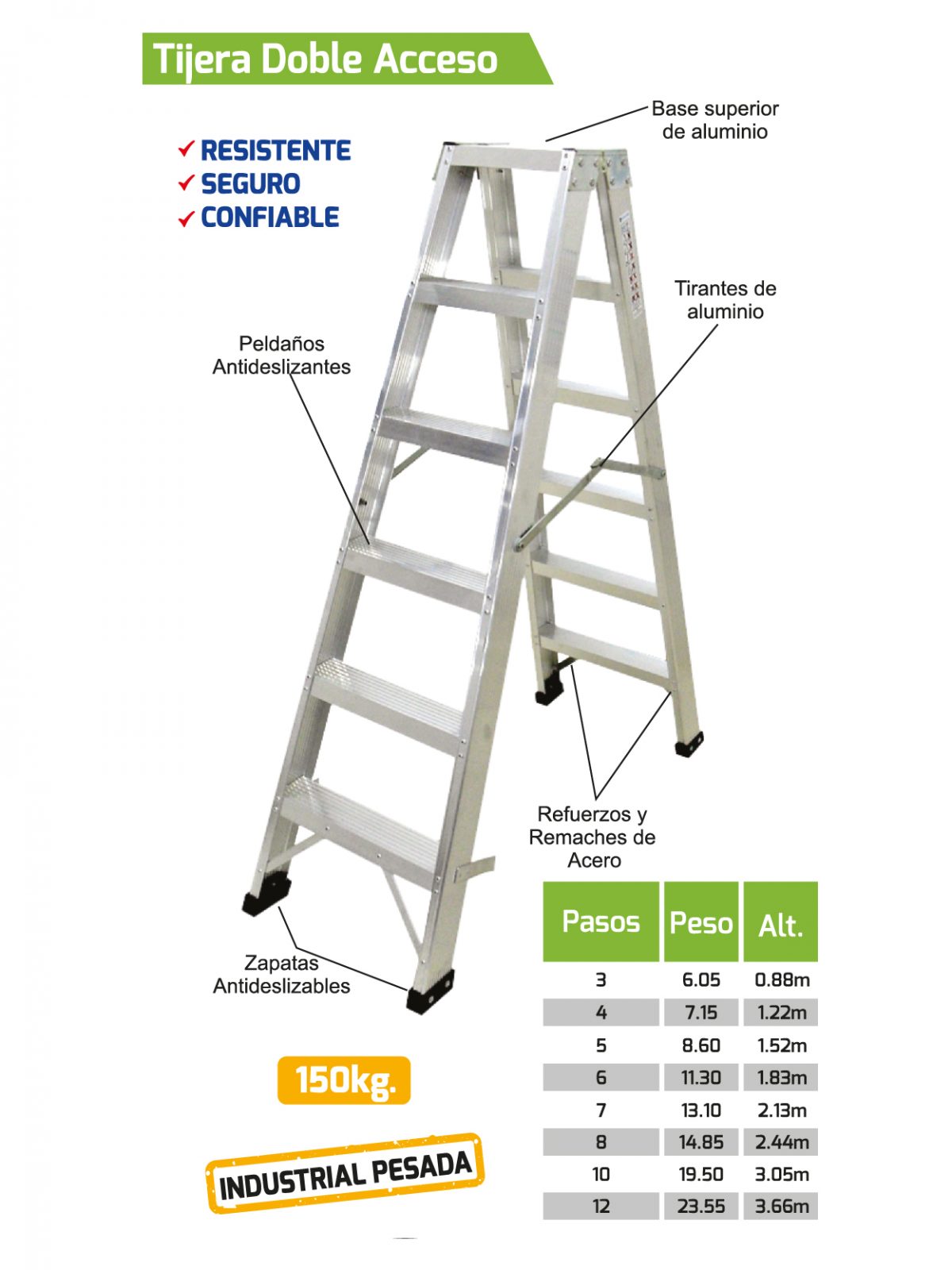

What are the Characteristics and Uses of Escalera de Tijera?

Escalera de Tijera, or step ladders, are designed for stability and ease of use, making them ideal for tasks requiring frequent access to moderate heights. Their compact form allows for easy storage, making them an excellent choice for businesses with limited space. Commonly used in warehousing and maintenance sectors, these ladders provide a safe platform for tasks like inventory management and light repairs. When purchasing, consider the maximum height and weight capacity to ensure they meet your operational needs.

How Do Escaleras Telescópicas Offer Versatility for B2B Buyers?

Telescopic ladders are highly adaptable, featuring adjustable height settings that cater to various tasks, from indoor maintenance to outdoor projects. Their collapsible nature makes them easy to transport, a significant advantage for businesses that require mobility across different job sites. However, while they are lightweight and versatile, it’s crucial to assess their stability at extended heights to prevent accidents. Buyers should prioritize models with robust locking mechanisms for enhanced safety during operation.

What Makes Escaleras de Extensión Essential for Construction Applications?

Escaleras de Extensión are designed for larger projects, allowing users to reach significant heights safely. These ladders typically consist of multiple sections that can be extended and locked into place, making them suitable for construction and maintenance tasks on tall buildings or structures. Their sturdy design provides reliable support, though they often require wall anchoring for optimal safety. Buyers should evaluate the ladder’s load capacity and ease of extension when considering these for professional use.

Why Choose Escaleras Convertibles for Diverse Applications?

Convertible ladders are incredibly versatile, allowing users to switch configurations between A-frame, extension, and straight ladder forms. This adaptability makes them suitable for a wide range of applications, from construction to home improvement projects. While they save space and offer multiple uses, they can be more complex to set up and use effectively. Businesses should assess the ladder’s weight capacity and ease of transition between configurations to ensure they can meet various operational demands.

What are the Benefits of Using Escaleras de Aluminio Aislante in Electrical Work?

Escaleras de Aluminio Aislante are specifically designed for electrical work, constructed from non-conductive materials to enhance safety. These ladders are lightweight yet robust, making them ideal for utility and maintenance tasks where electrical hazards are present. While they typically come at a higher price point due to their specialized materials, the added safety features can significantly reduce the risk of accidents. Buyers should ensure that these ladders meet industry safety standards before purchase.

Key Industrial Applications of escaleras de aluminio

| Industry/Sector | Specific Application of escaleras de aluminio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Accessing rooftops and high structures | Increases safety and efficiency in construction tasks | Weight capacity, stability, and corrosion resistance |

| Maintenance and Repair | Facilitating repairs in industrial facilities | Reduces downtime and enhances worker safety | Durability, ease of transport, and height versatility |

| Warehousing and Logistics | Stock management and inventory checks | Improves operational efficiency and reduces risks | Load capacity, portability, and storage options |

| Electrical and HVAC Services | Installation and maintenance of systems | Ensures compliance with safety standards | Insulation properties and adaptability to various heights |

| Event Management | Setting up stages and lighting | Enhances event setup speed and safety | Lightweight design and ease of assembly |

How Are Escaleras de Aluminio Used in the Construction Industry?

In the construction sector, escaleras de aluminio are essential for accessing rooftops, scaffolding, and high structures. They offer a lightweight yet sturdy option for workers who need to perform tasks at elevated heights. The primary problems solved include enhancing safety during construction activities and improving efficiency by providing reliable access. Buyers in this sector should prioritize weight capacity, stability, and corrosion resistance, especially in regions with varying weather conditions, such as Africa and South America.

What Role Do Escaleras de Aluminio Play in Maintenance and Repair?

In maintenance and repair applications, escaleras de aluminio facilitate access to hard-to-reach areas within industrial facilities. They enable technicians to conduct repairs on machinery, electrical systems, and HVAC units without excessive downtime. The benefits include increased worker safety and reduced operational interruptions. When sourcing these products, businesses should consider the durability of the materials, ease of transport, and the ladder’s height versatility to meet specific maintenance needs.

How Do Escaleras de Aluminio Improve Efficiency in Warehousing and Logistics?

In warehousing and logistics, escaleras de aluminio are used for stock management and inventory checks, allowing employees to access high shelves safely. This application significantly improves operational efficiency by minimizing the time required for inventory management and reducing the risk of accidents. Key considerations for sourcing include load capacity to handle various types of inventory, portability for ease of movement, and storage options for compact environments.

How Are Escaleras de Aluminio Utilized in Electrical and HVAC Services?

Electrical and HVAC service providers use escaleras de aluminio for the installation and maintenance of systems, ensuring technicians can safely reach ceilings and rooftops. This application is crucial for compliance with safety standards, as it reduces the risk of falls during service tasks. Buyers should focus on the insulation properties of the ladders, which are particularly important in electrical applications, along with their adaptability to various heights to accommodate different job requirements.

What Benefits Do Escaleras de Aluminio Offer in Event Management?

In the event management sector, escaleras de aluminio are vital for setting up stages, lighting, and other equipment. Their lightweight design allows for quick assembly and disassembly, enhancing the speed of event setup while maintaining safety standards. When sourcing these ladders, event planners should look for options that are easy to transport and assemble, ensuring they can efficiently manage various event configurations.

3 Common User Pain Points for ‘escaleras de aluminio’ & Their Solutions

Scenario 1: Navigating Compliance and Safety Regulations

The Problem:

B2B buyers in industries such as construction or maintenance often face the challenge of ensuring that their aluminum ladders comply with local safety regulations and standards. For example, in many regions, ladders must meet specific load-bearing criteria, anti-slip features, and durability assessments. The complexity increases when dealing with multiple suppliers or when sourcing from different countries, where regulations may vary significantly. This not only poses a risk to worker safety but can also lead to costly delays if non-compliant products are purchased.

The Solution:

To effectively navigate these compliance challenges, buyers should start by thoroughly researching the safety standards that apply in their region. It’s advisable to consult local regulatory bodies or industry associations for the latest guidelines regarding ladder specifications. When sourcing aluminum ladders, ensure that the manufacturer provides certifications or compliance documentation, such as ISO standards or local safety certifications.

Additionally, working with reputable suppliers who specialize in industrial-grade products can provide peace of mind. These suppliers often have a deep understanding of regulatory requirements and can offer a range of compliant products. Buyers should also consider investing in ladders that come with a warranty or guarantee, as this often indicates adherence to safety standards. Regular training for staff on proper ladder usage can further mitigate safety risks.

Scenario 2: Ensuring Durability in Harsh Environments

The Problem:

Aluminum ladders are popular due to their lightweight and corrosion-resistant properties. However, B2B buyers in regions with extreme weather conditions—such as heavy rainfall, high humidity, or intense sunlight—may struggle with ladder durability. Frequent exposure to these elements can lead to structural weaknesses, making the ladders unsafe for use. This situation can lead to increased maintenance costs and the need for frequent replacements, impacting overall project budgets.

The Solution:

To combat durability issues, buyers should prioritize purchasing aluminum ladders specifically designed for harsh environments. Look for products that feature protective coatings or treatments that enhance corrosion resistance. Additionally, selecting ladders made from high-grade aluminum alloys can provide added strength and longevity.

Illustrative image related to escaleras de aluminio

Buyers should also consider the type of ladder that best fits their operational needs. For example, ladders with reinforced joints and additional bracing can withstand heavier use and environmental stress. Regular inspections and maintenance checks should be scheduled to identify any signs of wear or corrosion early. Establishing a relationship with the supplier can also be beneficial, as they may offer maintenance services or advice on ladder care specific to the materials used.

Scenario 3: Managing Inventory and Storage Challenges

The Problem:

For businesses that rely on multiple aluminum ladders, inventory management and storage can become significant pain points. Ladders can be cumbersome to store, and insufficient space can lead to damage or safety hazards. Additionally, managing the purchase and replacement cycles for these ladders can be challenging, especially if they are frequently used across various job sites. This can result in either over-purchasing, leading to unnecessary costs, or under-purchasing, which can delay projects.

The Solution:

To address inventory and storage challenges, B2B buyers should implement a systematic inventory management approach. Utilizing a digital inventory management system can help track ladder usage, monitor conditions, and predict when replacements are necessary.

When it comes to storage, consider investing in vertical storage solutions or wall-mounted racks to maximize space and minimize the risk of damage. Suppliers often offer space-efficient ladder designs, such as foldable or telescopic ladders, which are ideal for businesses with limited storage capacity.

Establishing a routine for regular audits of ladder conditions and usage can also help in making informed purchasing decisions. By analyzing usage patterns, businesses can better predict their needs and avoid the pitfalls of both excess and insufficient inventory. This proactive approach will not only optimize costs but also enhance safety and operational efficiency.

Strategic Material Selection Guide for escaleras de aluminio

When selecting materials for aluminum ladders (escaleras de aluminio), it’s essential to consider the specific properties, advantages, and challenges associated with each material. Here, we analyze four common materials used in the construction of aluminum ladders, focusing on their performance, suitability for various applications, and considerations for international B2B buyers.

What are the Key Properties of Aluminum Alloys for Ladders?

Aluminum alloys, particularly those in the 6000 series, are widely used for manufacturing aluminum ladders due to their excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication. These alloys typically exhibit good thermal conductivity and can withstand a range of temperatures, making them suitable for both indoor and outdoor applications. Their lightweight nature facilitates ease of transport and maneuverability, which is crucial for professional use.

What are the Pros and Cons of Using Aluminum for Ladder Construction?

Pros:

– Durability: Aluminum ladders resist corrosion and rust, ensuring longevity even in harsh environments.

– Lightweight: Their low weight allows for easy handling and transportation, making them ideal for various applications.

– Cost-Effective: While the initial investment may be higher than some alternatives, the long-term savings due to durability and low maintenance make aluminum a cost-effective choice.

Cons:

– Temperature Sensitivity: While aluminum is generally stable, extreme temperatures can affect its structural integrity.

– Cost Variability: Depending on the alloy and treatment, costs can vary significantly, which may impact budget considerations for large-scale purchases.

Illustrative image related to escaleras de aluminio

How Does Material Selection Impact Ladder Applications?

The choice of aluminum alloy directly impacts the ladder’s suitability for specific applications. For instance, ladders used in construction or industrial settings may require higher strength alloys to support heavier loads. Additionally, the design and manufacturing processes can affect the ladder’s stability and safety features, such as anti-slip mechanisms and load ratings. Buyers must ensure that the selected material meets relevant safety standards, such as those set by ASTM or DIN.

What Should International Buyers Consider When Sourcing Aluminum Ladders?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, compliance with local and international standards is paramount. Buyers should verify that the ladders meet safety regulations and certifications applicable in their respective countries. Additionally, understanding the local market preferences regarding ladder features—such as height, weight capacity, and portability—can significantly influence purchasing decisions. It’s also essential to consider the availability of after-sales support and warranty options, which can vary by manufacturer.

Summary Table of Material Selection for Escaleras de Aluminio

| Material | Typical Use Case for escaleras de aluminio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy 6000 Series | Construction, industrial use | Excellent strength-to-weight ratio | Sensitive to extreme temperatures | Medium |

| Aluminum Alloy 7000 Series | Heavy-duty applications, aviation | Superior strength and durability | Higher cost and limited availability | High |

| Fiberglass Reinforced Aluminum | Electrical work, environments with risk of electric shock | Non-conductive, safe for electrical work | Heavier than pure aluminum | Medium |

| Anodized Aluminum | Decorative and aesthetic applications | Enhanced corrosion resistance | More expensive due to treatment process | High |

This material selection guide provides critical insights for B2B buyers looking to procure aluminum ladders. By understanding the properties, advantages, and limitations of various materials, buyers can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to escaleras de aluminio

In-depth Look: Manufacturing Processes and Quality Assurance for escaleras de aluminio

What Are the Key Stages in the Manufacturing Process of Aluminum Ladders?

The manufacturing process of aluminum ladders involves several crucial stages that ensure the final product meets the required safety and quality standards.

-

Material Preparation: The process begins with the selection of high-grade aluminum alloys, typically 6061 or 6063, known for their strength and corrosion resistance. The aluminum is then extruded into various shapes and sizes, depending on the ladder design. This stage may also involve cutting the aluminum to specific lengths and forming it into profiles that will be used for the ladder’s rungs and sides.

-

Forming Techniques: Once the material is prepared, various forming techniques are applied. These may include bending, rolling, and stamping to create the ladder’s frame and rungs. Advanced technologies such as CNC (Computer Numerical Control) machining can be utilized for precision cutting and shaping, ensuring uniformity across production batches.

-

Assembly: After forming, the individual components are assembled. This step can involve welding, riveting, or using screws and bolts to join the different parts. Manufacturers often use robotic systems for welding to enhance accuracy and efficiency. During assembly, features such as stabilizing bases and anti-slip foot pads are integrated to enhance safety.

-

Finishing: The final stage includes surface treatment processes such as anodizing or powder coating, which not only improve the aesthetic appeal of the ladders but also provide additional protection against environmental factors. Anodizing creates a durable oxide layer, while powder coating offers a colorful and resilient finish.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a critical aspect of aluminum ladder manufacturing, ensuring that products meet international safety and performance standards.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines quality management principles. This standard focuses on customer satisfaction and continuous improvement. Additionally, compliance with industry-specific standards such as CE marking in Europe and API (American Petroleum Institute) standards ensures that products are fit for purpose.

-

Quality Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Upon receiving raw materials, inspections are conducted to verify that the aluminum meets specified standards.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections help catch defects early. This may include checking for dimensional accuracy, weld integrity, and adherence to specifications.

– Final Quality Control (FQC): Before shipment, each ladder undergoes a thorough inspection, including load testing, to ensure it can handle specified weight limits and that safety features function correctly. -

Common Testing Methods: Testing methods can vary but typically include:

– Static Load Testing: Assessing the ladder’s ability to support weight without deformation.

– Dynamic Load Testing: Evaluating the ladder under simulated usage conditions to ensure it can withstand everyday stresses.

– Corrosion Resistance Testing: Ensuring that surface treatments effectively protect against rust and wear.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can include examining production lines, testing facilities, and reviewing documentation related to quality management systems.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their testing methods, frequency of inspections, and historical data on product performance. These reports should also outline compliance with relevant international standards.

-

Third-Party Inspections: Utilizing third-party inspection services can add an additional layer of assurance. These independent organizations can perform inspections and testing to validate the supplier’s claims and ensure compliance with standards.

What Are the Quality Control Nuances for International Buyers?

When sourcing aluminum ladders from international suppliers, buyers must be aware of specific nuances that can affect quality and compliance.

-

Regulatory Differences: Quality standards may differ significantly between regions. For example, European standards may be stricter than those in other regions. Understanding these differences is crucial for ensuring that products meet the buyer’s local regulations.

-

Documentation and Certification: It is vital for suppliers to provide documentation proving compliance with international standards. This may include certificates of conformity, test reports, and material safety data sheets (MSDS).

-

Cultural and Logistical Considerations: Cultural differences may impact communication regarding quality expectations. Moreover, logistical issues such as shipping delays can affect product availability and compliance with agreed-upon standards. Buyers should establish clear communication channels and timelines to manage these challenges effectively.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in the Ladder Industry

A deep understanding of manufacturing processes and quality assurance protocols is essential for B2B buyers in the aluminum ladder industry. By focusing on the key stages of production and implementing robust quality control measures, manufacturers can ensure that their products meet the highest safety and performance standards. For international buyers, verifying these practices is crucial to securing reliable, high-quality products that fulfill their business needs.

Illustrative image related to escaleras de aluminio

Practical Sourcing Guide: A Step-by-Step Checklist for ‘escaleras de aluminio’

In the competitive landscape of B2B procurement, sourcing high-quality aluminum ladders (escaleras de aluminio) requires careful consideration and strategic planning. This guide provides a structured checklist to assist international buyers in making informed decisions when sourcing these essential tools for various applications, from construction to maintenance.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your aluminum ladders. Consider factors such as:

– Type of Ladder: Determine whether you need extension, folding, or multi-use ladders.

– Weight Capacity: Ensure the ladders can support the maximum load they will encounter.

– Height Requirements: Specify the necessary height range for your projects.

Establishing these parameters will help streamline the selection process and ensure that the ladders meet your operational needs.

Step 2: Conduct Market Research

Thorough market research is vital to understanding the various options available. Explore different suppliers and product offerings through:

– Online Marketplaces: Platforms like MercadoLibre and Walmart can provide insights into pricing and availability.

– Industry Reviews: Look for testimonials and reviews from other businesses to gauge product reliability.

This step allows you to identify potential suppliers and understand competitive pricing.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request the following:

– Company Profiles: Assess their experience and market presence.

– Case Studies: Review examples of previous projects similar to your needs.

– References: Contact other buyers to gather feedback on their experiences.

A well-vetted supplier reduces the risk of procurement issues and ensures you receive quality products.

Step 4: Verify Compliance and Certifications

It’s crucial to ensure that the ladders comply with international safety standards and regulations. Check for:

– Quality Certifications: Look for ISO or other relevant certifications that demonstrate adherence to quality control processes.

– Safety Standards: Confirm that the ladders meet safety guidelines applicable in your region, such as EN 131 in Europe or ANSI in the United States.

This step protects your company from liability and promotes workplace safety.

Step 5: Request Samples

Before making a bulk purchase, request samples from your shortlisted suppliers. This allows you to:

– Assess Quality: Evaluate the materials and construction firsthand.

– Test Usability: Ensure the ladders perform as expected in real-world conditions.

Testing samples can save you from costly mistakes and help you make a more informed decision.

Step 6: Negotiate Terms and Pricing

Once you’ve chosen a supplier, engage in negotiations to establish favorable terms. Focus on:

– Pricing Structures: Discuss bulk purchase discounts or payment terms.

– Delivery Schedules: Ensure that the delivery timelines align with your project requirements.

Effective negotiation can enhance your procurement strategy and improve your bottom line.

Step 7: Establish a Long-term Relationship

Consider building a long-term partnership with your supplier. This can provide benefits such as:

– Better Pricing: Loyalty may lead to more favorable pricing structures in the future.

– Priority Service: Long-term partners often receive expedited service and support.

Fostering a strong relationship can lead to more seamless transactions and collaborative problem-solving in the future.

Illustrative image related to escaleras de aluminio

By following this checklist, B2B buyers can navigate the complexities of sourcing aluminum ladders effectively, ensuring they select the right products for their specific needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for escaleras de aluminio Sourcing

What Are the Key Cost Components of Sourcing Escaleras de Aluminio?

When sourcing escaleras de aluminio, understanding the cost structure is crucial for effective budgeting and procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

- Materials: The most significant portion of the cost typically comes from the aluminum itself, along with additional materials like rubber for non-slip bases. Prices can fluctuate based on global aluminum markets and sourcing locations.

- Labor: Labor costs can vary significantly depending on the manufacturing country. Skilled labor in countries like Brazil and Nigeria may command higher wages than in other regions.

- Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these expenses.

- Tooling: Specialized tools for producing various designs and specifications can add to the initial costs. This is particularly relevant for custom or high-spec models.

- Quality Control: Ensuring compliance with international safety standards may require additional testing and certification, which can increase costs.

- Logistics: Transportation costs depend on the distance from the manufacturer to the buyer, as well as the chosen shipping methods. Factors like customs duties and tariffs should also be considered.

- Margin: Suppliers typically add a margin to cover overhead and profit. This margin can vary based on market conditions and competition.

How Do Price Influencers Affect the Sourcing of Escaleras de Aluminio?

Several factors influence the pricing of escaleras de aluminio, particularly for international B2B buyers.

- Volume/MOQ: Manufacturers often provide better pricing for larger orders. Understanding the minimum order quantities (MOQs) can lead to significant cost savings.

- Specifications and Customization: Tailored products may incur higher costs. Buyers should weigh the necessity of customization against potential savings from standardized products.

- Materials and Quality Certifications: Higher quality materials and certifications can elevate prices but also enhance the product’s durability and safety, ultimately impacting the total cost of ownership (TCO).

- Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium, but they often provide better assurance in terms of quality and delivery.

- Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is essential. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can influence overall costs.

What Negotiation Strategies Can Buyers Use to Optimize Costs?

Effective negotiation is vital for maximizing cost-efficiency in sourcing escaleras de aluminio. Here are some actionable tips:

Illustrative image related to escaleras de aluminio

- Research Market Prices: Having a solid understanding of market rates helps in negotiating better deals. This includes knowing competitor prices and alternative suppliers.

- Leverage Volume Discounts: If your business can commit to larger orders, use this as leverage to negotiate lower prices per unit.

- Explore Long-term Relationships: Establishing long-term partnerships with suppliers can lead to more favorable pricing and terms.

- Focus on Total Cost of Ownership: Emphasize the importance of durability and lower maintenance costs in your negotiations. A higher upfront cost may be justified by long-term savings.

- Be Open to Alternative Suppliers: Diversifying your supplier base can create competitive pressure, enabling better pricing and terms.

What Should International Buyers Consider When Sourcing Escaleras de Aluminio?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, several pricing nuances are essential to consider:

- Local Market Conditions: Be aware of local economic conditions, currency fluctuations, and regional demand, which can influence pricing.

- Cultural Differences: Understanding negotiation styles and business practices in different cultures can enhance communication and foster successful negotiations.

- Logistics and Customs: Factor in the complexities of shipping and customs clearance, which can affect delivery timelines and costs.

Conclusion: Why Is It Important to Have a Comprehensive Understanding of Costs?

While indicative prices for escaleras de aluminio can vary widely, a thorough understanding of cost components, price influencers, and negotiation strategies enables B2B buyers to make informed decisions. By focusing on total cost of ownership and leveraging competitive dynamics, international buyers can optimize their sourcing strategies and achieve greater value in their purchases.

Alternatives Analysis: Comparing escaleras de aluminio With Other Solutions

Introduction: Exploring Alternatives to Escaleras de Aluminio

When considering the best solutions for access and height work, it’s essential to evaluate a range of options. While escaleras de aluminio (aluminum ladders) are known for their lightweight and durability, alternative solutions may also cater to specific operational needs, safety standards, and budget constraints. This analysis will compare aluminum ladders with other viable alternatives, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Escaleras De Aluminio | Escaleras de Fibra de Vidrio | Andamios (Scaffolding) |

|---|---|---|---|

| Performance | Lightweight and portable; strong | Non-conductive; good for electrical work | High load capacity; stable for large projects |

| Cost | Moderate initial investment | Higher cost due to material | Variable cost; depends on project scale |

| Ease of Implementation | Easy to set up and use | Slightly heavier; requires care in handling | Requires assembly; more complex to set up |

| Maintenance | Low maintenance; corrosion-resistant | Requires careful handling to avoid damage | Moderate; needs regular inspection and maintenance |

| Best Use Case | Residential and light commercial use | Electrical and outdoor work | Large construction projects needing extensive reach |

Detailed Breakdown of Alternatives

Escaleras de Fibra de Vidrio

Fiberglass ladders are particularly advantageous in environments where electrical hazards are a concern. Their non-conductive properties make them ideal for electricians and maintenance professionals working near live wires. However, they tend to be heavier than aluminum ladders, which can affect portability. Furthermore, the initial investment is usually higher, and they require careful handling to prevent cracks or damage.

Andamios (Scaffolding)

Scaffolding provides a versatile solution for extensive work at height, particularly on construction sites. With the capability to support multiple workers and tools simultaneously, scaffolding is ideal for large-scale projects requiring stability and access to various heights. However, it is more complex to set up and may involve additional costs for assembly and disassembly. Regular inspections are also necessary to ensure safety standards are maintained, adding to overall maintenance needs.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate solution for height access and work is crucial for safety and efficiency. B2B buyers should carefully consider the specific requirements of their projects, including the working environment, potential hazards, and budget constraints. While escaleras de aluminio offer a reliable, lightweight option for many applications, alternatives like fiberglass ladders and scaffolding may be better suited for specific tasks. Ultimately, understanding the performance, cost, and maintenance aspects of each solution will empower buyers to make the most suitable choice for their operational needs.

Essential Technical Properties and Trade Terminology for escaleras de aluminio

What Are the Key Technical Properties of Aluminum Ladders?

When considering aluminum ladders for B2B applications, several critical technical properties must be taken into account to ensure safety, durability, and efficiency. Understanding these specifications can help buyers make informed decisions that align with their operational needs.

1. Material Grade

Aluminum ladders are typically made from different grades of aluminum, with 6061 and 6063 being the most common. Grade 6061 is known for its strength and corrosion resistance, making it ideal for industrial applications. The material grade impacts the ladder’s weight capacity, durability, and resistance to wear. For B2B buyers, selecting the appropriate grade ensures that the ladder can withstand the specific demands of their work environment.

2. Load Capacity

Load capacity refers to the maximum weight the ladder can safely support, which is crucial for maintaining safety standards. Most aluminum ladders are rated for load capacities ranging from 150 kg to 225 kg. This specification is vital for businesses that require ladders for heavy-duty tasks, as exceeding the load capacity can lead to serious accidents and liability issues.

3. Height and Reach

The height of the ladder determines its suitability for various tasks. Common configurations include single, double, and multi-section ladders that can extend to various heights. Understanding the required reach for specific applications allows businesses to choose a ladder that optimizes efficiency while ensuring worker safety.

4. Stabilizing Features

Features such as rubber feet, stabilizing bases, and anti-slip rungs enhance the safety of aluminum ladders. These elements are crucial for preventing accidents, especially in environments where ladders are frequently moved or used on uneven surfaces. B2B buyers should prioritize ladders with robust stabilizing features to mitigate workplace hazards.

5. Corrosion Resistance

Aluminum’s inherent corrosion resistance is a significant advantage, especially in outdoor or high-humidity environments. Some ladders may also have additional coatings to enhance this property. For businesses operating in challenging conditions, investing in corrosion-resistant ladders can lead to lower maintenance costs and longer service life.

What Are Common Trade Terms Used in the Aluminum Ladder Industry?

Familiarity with industry jargon can significantly streamline communication between B2B buyers and suppliers. Here are some essential trade terms relevant to aluminum ladders:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aluminum ladders, understanding OEM relationships helps buyers identify quality manufacturers and ensure they are sourcing reliable products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers looking to manage inventory costs and negotiate bulk purchasing agreements. Knowing the MOQ can help businesses make strategic purchasing decisions.

Illustrative image related to escaleras de aluminio

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers for specific goods or services. Submitting an RFQ for aluminum ladders allows businesses to compare offers from different manufacturers and make informed decisions based on price, quality, and delivery terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers importing aluminum ladders, as they clarify who is responsible for shipping, insurance, and tariffs. This knowledge helps businesses avoid unexpected costs and complications during the procurement process.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. For businesses that rely on timely delivery of aluminum ladders for projects, understanding lead times is essential for effective planning and scheduling.

By grasping these key technical properties and trade terms, B2B buyers can navigate the aluminum ladder market more effectively, ensuring they select the right products for their needs while also optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the escaleras de aluminio Sector

What Are the Key Market Trends Affecting the Escaleras de Aluminio Sector?

The global market for escaleras de aluminio is witnessing significant growth, driven by the increasing demand for lightweight, durable, and versatile products across various industries, including construction, maintenance, and home improvement. International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, are focusing on scalable solutions that can cater to both industrial and domestic needs. Emerging trends include the rise of telescopic and multi-position ladders that offer flexibility for diverse applications, as well as the integration of smart technologies such as load sensors and stability indicators that enhance safety and usability.

Moreover, the e-commerce boom is reshaping sourcing dynamics. Buyers are increasingly leveraging online platforms to compare products, assess suppliers, and make informed purchasing decisions, which can streamline procurement processes. The emphasis on supply chain transparency is also on the rise, compelling manufacturers to provide detailed information about their sourcing practices and product specifications. This trend is particularly relevant for B2B buyers in developing regions, where access to reliable information can significantly impact purchasing decisions.

How Is Sustainability Shaping the Sourcing of Escaleras de Aluminio?

Sustainability is becoming a critical factor in the sourcing of escaleras de aluminio. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. B2B buyers are increasingly favoring suppliers who adopt eco-friendly practices, such as using recycled aluminum and minimizing carbon footprints during production.

Ethical sourcing has emerged as a priority, with businesses seeking certifications that validate sustainable practices. Certifications such as ISO 14001 for environmental management and the Aluminium Stewardship Initiative (ASI) certification for responsible aluminum sourcing are gaining traction. These certifications not only enhance brand reputation but also foster trust among consumers who are increasingly conscious of the environmental implications of their purchases. For international buyers, aligning with manufacturers that emphasize sustainability can lead to improved market positioning and customer loyalty.

What Is the Historical Context of the Escaleras de Aluminio Market?

The evolution of the escaleras de aluminio market can be traced back to the early 20th century, when aluminum began to gain popularity as a lightweight and rust-resistant alternative to traditional materials like wood and steel. Initially used predominantly in industrial applications, the versatility and durability of aluminum ladders soon made them a staple in domestic settings as well.

Over the decades, innovations in design and manufacturing techniques have led to the development of specialized products, including telescopic and multi-position ladders, which cater to an expanding range of needs across various sectors. As global awareness around safety and efficiency has increased, the market has adapted by incorporating advanced technologies and sustainable practices, setting the stage for continued growth and innovation in the sector.

In summary, the escaleras de aluminio market is not only shaped by current trends in technology and sustainability but also by a rich history of innovation that continues to influence buyer preferences and sourcing strategies today.

Frequently Asked Questions (FAQs) for B2B Buyers of escaleras de aluminio

-

How do I choose the right aluminum ladder for my business needs?

Choosing the right aluminum ladder involves assessing your specific requirements such as height, weight capacity, and intended use. For example, if you’re in construction, consider a heavy-duty model with a higher load capacity and features like stabilizers or non-slip feet. Evaluate whether you need a single, double, or multi-section ladder based on the tasks at hand. Additionally, prioritize options that meet local safety standards and regulations to ensure compliance and worker safety. -

What are the key specifications to look for in aluminum ladders?

Key specifications include the ladder’s height, weight capacity, material thickness, and design type (e.g., extension, step, or multi-position). Ensure the ladder has a minimum load capacity of 150 kg for most industrial applications. Look for features such as slip-resistant rungs, stabilizing bases, and adjustable height settings. It’s also beneficial to check for certifications or compliance with international safety standards, which can enhance the ladder’s reliability and performance. -

What are the typical minimum order quantities (MOQs) for aluminum ladders from suppliers?

Minimum order quantities (MOQs) for aluminum ladders can vary significantly based on the manufacturer or supplier. Typically, MOQs range from 10 to 100 units, depending on the ladder type and customization options. For bulk purchases, negotiating lower MOQs is often possible, especially if you’re establishing a long-term relationship. Always clarify MOQs before placing an order to ensure they align with your business needs and budget. -

What should I consider when vetting suppliers for aluminum ladders?

When vetting suppliers, consider their experience, reputation, and product quality. Request samples to evaluate the ladder’s construction and durability. Investigate their compliance with safety standards and certifications, such as ISO or CE markings. Check reviews and references from other businesses to gauge their reliability and customer service. Additionally, assess their logistical capabilities and whether they can deliver to your region in a timely manner. -

What payment terms are common in international B2B transactions for aluminum ladders?

Common payment terms in international B2B transactions include net 30, net 60, or advance payment options. Some suppliers may accept letters of credit or escrow services for larger orders to mitigate risks. It’s essential to clarify payment methods upfront, as some suppliers may prefer bank transfers, while others might accept credit cards or payment platforms. Establishing clear payment terms helps build trust and ensures a smooth transaction process. -

How can I ensure quality assurance (QA) for aluminum ladders purchased internationally?

To ensure quality assurance, request detailed specifications and certifications from your supplier. Consider conducting third-party inspections or audits before shipment to verify product quality. Establish a clear return policy for defective items and ensure the supplier commits to addressing any quality issues post-delivery. Regular communication with your supplier can also help maintain quality standards and facilitate improvements based on feedback. -

What logistics considerations should I keep in mind when importing aluminum ladders?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Determine whether to use air or sea freight based on your budget and urgency. Understand the import duties and taxes applicable to aluminum ladders in your country to avoid unexpected costs. Collaborating with a reliable freight forwarder can streamline the import process, ensuring compliance with local regulations and timely delivery. -

Can I customize aluminum ladders to fit my specific needs?

Yes, many suppliers offer customization options for aluminum ladders, including specific sizes, colors, and additional features such as safety rails or unique rungs. Discuss your requirements with potential suppliers during the vetting process to understand their capabilities. Custom orders may have different lead times and pricing, so it’s crucial to clarify these details upfront. Customization can enhance usability and branding for your business, making it a worthwhile investment.

Top 5 Escaleras De Aluminio Manufacturers & Suppliers List

1. Werner – Escalera Extensible

Domain: hn.ebay.com

Registered: 1995 (30 years)

Introduction: Escaleras de Aluminio, Tipos: Escalera extensible, Escalera de pie, Escalera de ático, Banco escalera, Escalera de plataforma, Escalera plegable, Escalera recta, Escalera de varias posiciones. Marcas: Werner, Louisville Ladder, Gorilla Ladders, Little Giant Ladder Systems, HBTower, entre otras. Capacidades de carga: 50 lb, 100 lb, 150 lbs, 200 lbs, 225 lb, 250 lb, 300 lbs, 375 lb, 400 lbs, 450 lb,…

2. La Casa de la Escalera – Escaleras Profesionales

Domain: lacasadelaescalera.com

Registered: 2003 (22 years)

Introduction: Escaleras Profesionales: 1 Tramo, 2 Tramos, Convertible Con Cuerda, 3 Tramos Convertible Con Cuerda, Escaleras Telescópicas Multiuso, Escaleras de Tijera Profesionales, Escaleras de 1 Subida, Doble Subida, Aislantes, Madera, Almacén, Andamios de Aluminio Modular, Plegable en Aluminio, Doméstica, Tijera 1 Subida, Doble Subida, Taburete, Escaleras de techo escamoteables, 3 Tramos, Madera, Aluminio, …

3. SomosRex – Escaleras y Soportes para Pintura

Domain: somosrex.com

Registered: 2019 (6 years)

Introduction: Escaleras, caballetes y banquetas como accesorios para pintar. Sección dentro de la categoría de pinturas y accesorios. Incluye una variedad de productos relacionados con escaleras y soportes para facilitar el trabajo de pintura.

4. Obramat – Escaleras Metálicas y de Aluminio

Domain: obramat.es

Introduction: Escaleras metálicas y de aluminio para construcción, diseñadas para ofrecer seguridad y durabilidad. Disponibles en diferentes modelos y alturas, adecuadas para diversas aplicaciones en obras y proyectos. Fabricadas con materiales de alta calidad, resistentes a la corrosión y al desgaste. Incluyen características como peldaños antideslizantes y sistemas de bloqueo para mayor estabilidad. Ideales p…

5. Escalum – Escalera de Tijera de Aluminio C-2312-06N

Domain: escalum.com.mx

Registered: 2005 (20 years)

Introduction: [{‘name’: ‘Escalera de Tijera de Aluminio C-2312-06N’, ‘price’: ‘$1,903.00’}, {‘name’: ‘Escalera de Tijera de Fibra de Vidrio C-3017-12’, ‘price’: ‘$8,090.00’}, {‘name’: ‘Escalera de Tijera de Fibra de Vidrio C-3017-10’, ‘price’: ‘$6,681.00’}, {‘name’: ‘Escalera con Plataforma de Fibra de Vidrio FXP1704’, ‘price’: ‘$4,809.00’}, {‘name’: ‘Escalera de Extensión de Aluminio 494-24N’, ‘price’: ‘$5,200…

Strategic Sourcing Conclusion and Outlook for escaleras de aluminio

In the rapidly evolving market for escaleras de aluminio, strategic sourcing emerges as a critical component for international B2B buyers seeking to optimize their procurement processes. By leveraging relationships with reputable manufacturers and distributors, businesses can ensure the availability of high-quality, durable aluminum ladders that meet safety standards while also offering competitive pricing. Understanding local market demands in regions such as Africa, South America, the Middle East, and Europe is essential for making informed purchasing decisions that align with specific operational needs.

Moreover, the diverse range of aluminum ladder types—ranging from telescopic and multi-use models to professional-grade options—provides buyers with flexibility and adaptability for various applications. As the industry trends towards sustainability and innovation, sourcing partners that prioritize eco-friendly manufacturing practices will be increasingly valuable.

Looking ahead, international buyers should actively seek out strategic partnerships that not only enhance their supply chain resilience but also provide insights into emerging market trends. By doing so, they can position themselves effectively in a competitive landscape, ensuring they are equipped to meet future demands. Engage with trusted suppliers today to secure your competitive edge in the aluminum ladder market.

Illustrative image related to escaleras de aluminio

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.