Choosing Your Emt Tube Bender: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for emt tube bender

In an increasingly interconnected global marketplace, sourcing the right EMT tube bender can be a pivotal challenge for international B2B buyers. Whether you’re operating in the bustling construction sectors of Brazil or the expanding electrical infrastructure in Saudi Arabia, selecting the appropriate conduit bender is crucial for efficiency and project success. This guide serves as a comprehensive resource, addressing the diverse types of EMT tube benders available, their various applications, and essential criteria for vetting suppliers effectively.

Buyers will gain insights into the nuances of different bender models, including manual versus electric options, along with their respective advantages in specific contexts. Additionally, the guide delves into cost considerations, helping you navigate pricing structures and identify value for your investment. As you explore this resource, you’ll be equipped to make informed purchasing decisions that align with your operational needs and budget constraints.

Understanding the global market dynamics is essential for optimizing your procurement strategy. This guide is tailored for B2B buyers across Africa, South America, the Middle East, and Europe, ensuring you have the knowledge to confidently select the right EMT tube bender for your projects. By leveraging this expertise, you can enhance productivity, streamline operations, and ultimately achieve greater success in your ventures.

Understanding emt tube bender Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual EMT Tube Bender | Operated by hand, typically made of aluminum or steel. | Electrical installations, HVAC systems | Pros: Cost-effective, portable. Cons: Labor-intensive, requires skill. |

| Electric EMT Tube Bender | Powered by electricity, allowing for quicker bends. | Large-scale manufacturing, construction | Pros: Faster operation, less physical effort. Cons: Higher initial investment, requires power source. |

| Hydraulic EMT Tube Bender | Utilizes hydraulic pressure for bending, suitable for heavy-duty applications. | Industrial fabrication, heavy machinery | Pros: Effortless bending of thick materials, precise control. Cons: Bulkier, more expensive. |

| 2-in-1 EMT Tube Bender | Capable of bending multiple sizes (e.g., 1/2″ and 3/4″). | Versatile applications in electrical work | Pros: Space-saving, cost-effective for varying needs. Cons: Limited to specific sizes, may not handle larger diameters. |

| Digital EMT Tube Bender | Features digital readouts for precise angle measurements. | High-precision projects, custom fabrications | Pros: Enhanced accuracy, easier to use for complex bends. Cons: More expensive, requires calibration. |

What Are the Key Characteristics of Manual EMT Tube Benders?

Manual EMT tube benders are the most traditional and widely used type, favored for their simplicity and cost-effectiveness. Made from materials like aluminum or steel, these tools require physical effort to bend the conduit. They are ideal for small-scale electrical installations and HVAC systems, where precision can be achieved with practice. B2B buyers should consider the skill level of their workforce, as manual benders require hands-on experience for optimal results.

How Do Electric EMT Tube Benders Enhance Efficiency?

Electric EMT tube benders offer a significant advantage in terms of speed and ease of use. These powered devices can bend conduit quickly, making them suitable for large-scale manufacturing and construction projects where time is of the essence. Buyers should assess their operational needs, as the initial investment is higher compared to manual options. However, the reduction in labor costs and increased productivity often justify the expense.

What Advantages Do Hydraulic EMT Tube Benders Provide?

Hydraulic EMT tube benders are designed for heavy-duty applications, utilizing hydraulic pressure to bend thick materials with ease. This makes them ideal for industrial fabrication and heavy machinery projects. While they offer precise control and require less physical effort, buyers should be aware of their bulkiness and higher price point. These factors may influence purchasing decisions, especially for businesses with limited space or budget.

Why Consider 2-in-1 EMT Tube Benders for Versatility?

2-in-1 EMT tube benders are particularly advantageous for businesses that frequently work with different conduit sizes, such as 1/2″ and 3/4″. These tools save space and reduce costs by eliminating the need for multiple benders. However, they may be limited in their ability to handle larger diameters, so buyers should evaluate their specific needs before purchasing. This type is especially beneficial for electrical contractors who require adaptability in their work.

How Do Digital EMT Tube Benders Improve Precision?

Digital EMT tube benders incorporate technology to provide precise angle measurements, making them suitable for high-precision projects and custom fabrications. They simplify the bending process, allowing users to achieve complex angles with confidence. Despite their higher cost and the need for calibration, the accuracy and ease of use make them an attractive option for businesses focused on quality and efficiency. B2B buyers should weigh the benefits against their budget constraints when considering this advanced tool.

Key Industrial Applications of emt tube bender

| Industry/Sector | Specific Application of emt tube bender | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Contracting | Bending conduits for electrical installations | Ensures precise bends for efficient wiring layouts | Quality of the bender, ease of use, and durability |

| Construction | Fabricating structural supports and framework | Enhances structural integrity and safety | Material compatibility and bending capacity |

| HVAC Systems | Creating ductwork for heating and cooling systems | Improves energy efficiency and airflow management | Size versatility and precision of bends |

| Telecommunications | Installing conduits for cabling systems | Reduces installation time and labor costs | Availability of various sizes and types |

| Automotive Manufacturing | Bending tubes for exhaust systems and frames | Optimizes performance and compliance with standards | Precision engineering and supplier reliability |

How is EMT Tube Bender Used in Electrical Contracting?

In electrical contracting, EMT tube benders are essential for bending conduits that house electrical wiring. The ability to create precise bends ensures that installations are both efficient and compliant with safety regulations. This minimizes the risk of damage to wires during installation and enhances the overall safety of electrical systems. International buyers, especially from regions like the Middle East and South America, should consider the bender’s ease of use and durability, ensuring it can withstand frequent use in diverse working conditions.

What Role Does EMT Tube Bender Play in Construction?

In the construction industry, EMT tube benders are utilized to fabricate structural supports and framework. The accurate bending of EMT conduits helps in constructing scaffolding and other structural elements that require precise angles for stability. This not only improves the structural integrity of buildings but also ensures compliance with local construction codes. Buyers should focus on the bender’s material compatibility and bending capacity, especially in regions with varying material standards such as Africa and Europe.

How is EMT Tube Bender Used in HVAC Systems?

For HVAC systems, EMT tube benders are crucial in creating ductwork that facilitates heating and cooling. The precision of bends directly impacts the efficiency of airflow, which is vital for energy conservation and maintaining comfortable environments. A well-designed duct system can significantly reduce energy costs. Buyers in regions like Brazil and Saudi Arabia should prioritize the size versatility and precision of bends offered by the bender, ensuring it meets the specific requirements of their HVAC installations.

What is the Application of EMT Tube Bender in Telecommunications?

In telecommunications, EMT tube benders are used to install conduits that protect cabling systems. The efficiency of bending conduits reduces installation time and labor costs, making projects more profitable. Precise bends also prevent potential damage to cables during installation, ensuring long-term reliability of communication systems. When sourcing benders, international buyers should consider the availability of various sizes and types to match their specific project needs, particularly in rapidly developing markets.

How Does EMT Tube Bender Benefit Automotive Manufacturing?

In automotive manufacturing, EMT tube benders are utilized for bending tubes used in exhaust systems and vehicle frames. The precision in bending is critical for optimizing vehicle performance and ensuring compliance with safety and environmental regulations. Effective bending reduces the need for additional fittings, streamlining the manufacturing process. Buyers should focus on precision engineering and the reliability of suppliers to ensure that the benders can handle the specific requirements of automotive applications, especially in competitive markets.

3 Common User Pain Points for ’emt tube bender’ & Their Solutions

Scenario 1: Difficulty Achieving Accurate Bends in EMT Conduit

The Problem: Many B2B buyers, especially those in electrical contracting, face challenges in achieving precise bends when working with EMT (Electrical Metallic Tubing) conduit. Inaccurate bends can lead to wasted materials, increased labor costs, and ultimately, project delays. This is particularly troublesome in regions with strict electrical codes, such as Europe and the Middle East, where compliance is critical. Buyers often find that their existing benders do not have clear measurement markings or that they struggle with the physical mechanics of bending, resulting in frustration and inefficiencies on the job site.

The Solution: To overcome this challenge, it is essential to invest in high-quality EMT tube benders that feature clear and accurate measurement markings. For instance, consider benders with built-in offset multiplier charts directly on the handle, which provide quick reference points for various bend angles. When sourcing these tools, prioritize manufacturers known for their precision engineering, such as IDEAL or Klein Tools. Additionally, training your team on proper bending techniques can enhance accuracy. Conduct workshops that focus on the mechanics of bending, emphasizing the importance of grip and angle settings. This training will not only improve the quality of the bends but also boost overall productivity and reduce material wastage.

Scenario 2: Struggles with Tool Durability in Harsh Environments

The Problem: Buyers operating in regions like South America and Africa often contend with harsh working conditions, such as high humidity or dust-laden environments. These factors can significantly impact the durability and longevity of EMT tube benders. Many B2B buyers report that their tools corrode or wear out quickly, leading to frequent replacements and increased operational costs. This is particularly concerning for businesses looking to maintain their bottom line while ensuring their teams have reliable tools.

Illustrative image related to emt tube bender

The Solution: To mitigate durability issues, select EMT tube benders made from corrosion-resistant materials such as aluminum or high-grade steel. Look for products that come with warranties indicating their resilience in challenging conditions. Companies should also implement a routine maintenance schedule that includes cleaning tools after use and applying protective coatings to prevent rust and wear. Additionally, consider investing in tools designed for multi-use, such as a 2-in-1 conduit bender that can handle different sizes of EMT tubing, maximizing both utility and longevity. By focusing on quality and proper maintenance, businesses can reduce replacement frequency and save costs in the long run.

Scenario 3: Complexity in Selecting the Right Tool for Different Applications

The Problem: B2B buyers often struggle with selecting the right EMT tube bender for various applications. This challenge is exacerbated when projects require bending different sizes of conduit or when buyers are unsure about the specifications needed for specific jobs. This confusion can lead to purchasing multiple tools, increasing upfront costs and complicating inventory management. Buyers in regions with diverse project requirements, such as the Middle East, frequently report feeling overwhelmed by the choices available in the market.

The Solution: A strategic approach to sourcing EMT tube benders is essential. Start by conducting a thorough analysis of the typical projects your business undertakes and the sizes of conduit most frequently used. Invest in versatile tools that can accommodate multiple sizes, such as 2-in-1 or 3-in-1 benders, which allow for flexibility across various jobs. Additionally, engage with suppliers who offer comprehensive product specifications and usage guides. Leverage digital tools and resources for product comparisons to make informed decisions. Establishing strong relationships with manufacturers can also provide insights into the latest innovations and best practices, ensuring your team is equipped with the right tools for every job. By focusing on versatility and informed purchasing, businesses can streamline their operations and reduce costs.

Illustrative image related to emt tube bender

Strategic Material Selection Guide for emt tube bender

What Are the Key Materials Used in EMT Tube Benders?

When selecting materials for EMT (Electrical Metallic Tubing) tube benders, several factors must be considered, including durability, cost, and performance characteristics. The most common materials used in the manufacturing of EMT tube benders are aluminum, ductile iron, steel, and plastic. Each material has its unique properties and advantages, making them suitable for different applications.

How Does Aluminum Perform in EMT Tube Benders?

Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for EMT tube benders. It has a good strength-to-weight ratio and can withstand moderate temperatures and pressures, which is beneficial for various bending applications. However, while aluminum benders are durable, they may not perform as well under extreme conditions compared to heavier materials.

Pros: Aluminum benders are easy to handle due to their lightweight nature, which reduces fatigue during use. They are also generally more affordable than other materials, making them a cost-effective option for many buyers.

Cons: The primary limitation of aluminum is its lower tensile strength compared to steel, which may affect its performance in high-stress applications. Additionally, aluminum can be more susceptible to deformation under excessive force.

What Advantages Does Ductile Iron Offer for EMT Tube Benders?

Ductile iron is known for its high strength and impact resistance, making it a robust option for EMT tube benders. It can handle higher temperatures and pressures, which is crucial for heavy-duty applications. Ductile iron also has excellent wear resistance, which prolongs the life of the bender.

Pros: The durability of ductile iron makes it suitable for industrial applications where benders are subjected to rigorous use. Its strength allows for precise bends without compromising the integrity of the tool.

Cons: The main drawback is the weight of ductile iron, which can make handling more cumbersome. Additionally, ductile iron benders are typically more expensive than their aluminum counterparts, which may deter some buyers.

How Does Steel Compare as a Material for EMT Tube Benders?

Steel is another common material used in EMT tube benders, known for its exceptional strength and durability. It can withstand high temperatures and pressures, making it suitable for various applications, including industrial settings.

Illustrative image related to emt tube bender

Pros: Steel benders are highly durable and can provide precise bends, making them ideal for professional use. They are also resistant to deformation and wear, ensuring a long lifespan.

Cons: The weight of steel can be a disadvantage for users who require portability. Moreover, steel is prone to corrosion if not properly coated or maintained, which can limit its suitability in humid or corrosive environments.

What Role Does Plastic Play in EMT Tube Benders?

Plastic is a less common material for EMT tube benders but is gaining traction due to its lightweight and corrosion-resistant properties. Plastic benders are often used for lighter applications where flexibility and ease of use are prioritized.

Pros: The lightweight nature of plastic benders makes them easy to handle, reducing user fatigue. They are also resistant to corrosion, making them suitable for use in various environments.

Cons: However, plastic lacks the strength and durability of metal options, making it unsuitable for heavy-duty applications. It can also be more prone to wear and tear over time, limiting its lifespan.

Summary Table of Material Selection for EMT Tube Benders

| Material | Typical Use Case for EMT Tube Bender | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Residential and light commercial use | Lightweight and cost-effective | Lower tensile strength | Low |

| Ductile Iron | Industrial applications | High strength and impact resistance | Heavier and more expensive | High |

| Steel | Heavy-duty industrial use | Exceptional durability | Heavy and prone to corrosion | Medium |

| Plastic | Light applications | Lightweight and corrosion-resistant | Lacks strength for heavy use | Low |

In summary, the choice of material for EMT tube benders should be guided by the specific application requirements, including the expected load, environmental conditions, and budget constraints. Buyers from regions like Africa, South America, the Middle East, and Europe should also consider local compliance standards and preferences when selecting the appropriate material for their needs.

In-depth Look: Manufacturing Processes and Quality Assurance for emt tube bender

What Are the Key Stages in the Manufacturing Process of EMT Tube Benders?

The manufacturing process of EMT (Electrical Metallic Tubing) tube benders involves several critical stages that ensure high-quality and reliable products. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-grade materials, typically aluminum or ductile iron, which are preferred for their strength-to-weight ratios and corrosion resistance. The raw materials are then cut into appropriate lengths and subjected to pre-processing, which may involve cleaning and inspection to ensure that no impurities affect the final product. This step is crucial for maintaining the integrity of the bender, especially in harsh environments encountered in regions like Africa and the Middle East.

Forming Techniques

Once prepared, the materials undergo forming processes. Common techniques include bending, which is often accomplished using hydraulic or mechanical benders. CNC (Computer Numerical Control) technology is frequently employed for precision and repeatability, particularly for complex bends that meet industry specifications. The forming stage also includes the creation of specific angles and offsets, which are vital for EMT installations.

Assembly Processes

Following the forming stage, the components are assembled. This may involve attaching handles, ensuring that all parts fit together seamlessly to facilitate ease of use. Quality checks are often integrated into this stage, where initial inspections are performed to catch any discrepancies before moving forward.

Illustrative image related to emt tube bender

Finishing Touches

The final stage of the manufacturing process involves finishing treatments, such as anodizing or powder coating, to enhance durability and aesthetics. This not only protects against corrosion but also provides a professional look that is appealing to B2B buyers in various international markets. The finishing process may also include final inspections to ensure compliance with required standards.

How Is Quality Assurance Implemented in EMT Tube Bender Manufacturing?

Quality assurance (QA) is essential in the manufacturing of EMT tube benders, ensuring that products meet international and industry-specific standards. The QA process typically involves several checkpoints, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

International Standards and Certifications

Manufacturers often adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with CE marking indicates that products meet EU safety, health, and environmental protection standards. Additionally, industry-specific certifications like API (American Petroleum Institute) may be relevant, depending on the application of the EMT tube bender.

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of incoming materials. Suppliers are required to provide documentation, including certificates of compliance, to ensure that materials meet specified criteria.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process at various stages. Techniques such as statistical process control (SPC) may be employed to track performance metrics and ensure that production remains within acceptable limits.

-

Final Quality Control (FQC): At this stage, the finished products are thoroughly inspected. Common testing methods include dimensional checks, functional tests, and load-bearing assessments to ensure that the benders can withstand expected operational stresses.

What Testing Methods Are Commonly Used for EMT Tube Benders?

To guarantee the reliability and performance of EMT tube benders, manufacturers employ various testing methods throughout the production process. These include:

-

Dimensional Testing: Ensures that all specifications for size, angles, and tolerances are met. This often involves the use of calipers and gauges.

-

Functional Testing: Verifies that the bender operates correctly under simulated conditions. This may include bending tests to assess the ease of use and effectiveness of the tool.

-

Load Testing: Measures the structural integrity of the bender under stress. This is especially critical for benders designed for heavy-duty applications.

-

Corrosion Resistance Testing: Particularly important for products used in environments prone to moisture or chemical exposure. Salt spray tests are commonly used to assess how well the finishes hold up against corrosion.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source EMT tube benders should take proactive steps to verify the quality control measures of their suppliers. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control systems firsthand. This can provide insights into the supplier’s commitment to quality and adherence to international standards.

-

Requesting Quality Reports: Buyers should request detailed quality control reports, including IQC, IPQC, and FQC findings. These documents can provide a comprehensive overview of the supplier’s quality management practices.

-

Third-Party Inspections: Engaging independent third-party inspectors can add an additional layer of assurance. These inspectors can conduct quality assessments and provide unbiased reports on product compliance with specified standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing EMT tube benders from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances regarding quality control and certification:

-

Understanding Local Regulations: Each region may have its own set of regulations and standards for electrical and construction tools. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Navigating Import Certifications: Some countries may require additional certifications or documentation for imported goods. Understanding these requirements can prevent delays and ensure smooth customs processes.

-

Cultural Differences in Quality Perception: Quality standards and expectations may vary across cultures. B2B buyers should engage in clear communication with suppliers to align on quality expectations and standards.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing EMT tube benders, ensuring they invest in reliable and compliant products tailored to their specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’emt tube bender’

To assist B2B buyers in efficiently sourcing EMT tube benders, this practical checklist outlines essential steps to ensure a successful procurement process. Each step emphasizes critical considerations and best practices tailored for international buyers across various regions, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the EMT tube bender you need. This includes factors such as pipe size compatibility (e.g., 1/2″, 3/4″, or 1″), material type (aluminum or iron), and bending capacity. Specificity helps in narrowing down options and ensures that the product meets your operational needs.

- Consider the application: Will it be used for residential, commercial, or industrial purposes?

- Identify additional features: Look for features like built-in angle guides or multi-size capabilities that can enhance usability.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Utilize online directories, trade shows, and industry networks to find reputable manufacturers or distributors.

- Check for experience and specialization: Look for suppliers with a proven track record in providing EMT tube benders.

- Review customer testimonials: Feedback from other B2B buyers can provide insights into reliability and product performance.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with international standards. This is crucial for ensuring product quality and safety.

- Look for certifications: Common certifications include ISO 9001 for quality management and CE marking for compliance with European standards.

- Request documentation: Ask for copies of certifications to ensure they are current and relevant.

Step 4: Request Product Samples

Once you have shortlisted potential suppliers, request samples of the EMT tube benders. This allows you to assess the quality and functionality of the products firsthand.

- Test for performance: Evaluate how the bender handles different materials and sizes during your testing.

- Inspect build quality: Look for durability and ergonomic design, which can impact user experience and efficiency.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms. This step is essential for optimizing your budget while ensuring you receive a quality product.

- Discuss bulk pricing: If you plan to purchase in large quantities, inquire about volume discounts.

- Clarify payment terms: Ensure that payment schedules are clear, and check if there are options for financing.

Step 6: Verify Shipping and Delivery Options

Understanding the logistics involved in shipping is vital for timely project execution. Confirm the shipping methods and delivery timelines provided by the supplier.

- Assess international shipping capabilities: Ensure the supplier can handle customs and import regulations for your region.

- Inquire about tracking: A reliable tracking system can help you monitor shipment progress.

Step 7: Establish After-Sales Support

Finally, ensure that the supplier offers adequate after-sales support, including warranty information and customer service availability.

- Inquire about warranty terms: A robust warranty can protect your investment against manufacturing defects.

- Check for technical support: Reliable customer service can assist with any issues that arise post-purchase.

By following this checklist, international B2B buyers can streamline their sourcing process for EMT tube benders, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for emt tube bender Sourcing

What Are the Key Cost Components in Sourcing EMT Tube Benders?

When sourcing EMT tube benders, understanding the various cost components is crucial for making informed purchasing decisions. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts the price. For EMT tube benders, aluminum and ductile iron are common materials, each with different cost implications. Aluminum tends to be lighter and more corrosion-resistant, but may come at a higher price point compared to iron.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor in countries with higher wage standards will naturally increase production costs. Conversely, sourcing from regions with lower labor costs could offer savings, though this may come with trade-offs in quality.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be a negotiating point when discussing pricing with suppliers.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. If a buyer requires specific modifications or unique features, this may necessitate additional tooling investment, impacting the overall price.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and compliance with industry standards. Buyers should consider the costs associated with quality assurance as these can affect both the final price and the product’s lifespan.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as shipping distance, mode of transport, and customs duties can add to the total cost. Using Incoterms effectively can help clarify these responsibilities.

-

Margin: Supplier margins can vary widely based on market demand, competition, and brand reputation. Understanding the typical margin in the industry can help buyers negotiate more effectively.

How Do Price Influencers Affect the Cost of EMT Tube Benders?

Several factors can influence the pricing of EMT tube benders beyond the basic cost components:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Suppliers may offer better pricing tiers for minimum order quantities (MOQ), making bulk purchasing an attractive option for businesses looking to reduce costs.

-

Specifications and Customization: Customized products generally come at a premium. Buyers should assess whether standard products meet their needs or if customization is necessary, as this can significantly impact pricing.

-

Materials and Quality Certifications: Products that meet certain quality certifications, such as ISO or ASTM standards, may command higher prices due to the assurance of quality and reliability. Buyers should evaluate the necessity of these certifications based on their operational requirements.

-

Supplier Factors: Supplier reputation and reliability can also affect pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers may offer lower prices to gain market entry.

-

Incoterms: The choice of Incoterms can affect logistics costs and responsibilities. For international buyers, understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for managing total costs effectively.

What Are the Best Buyer Tips for Negotiating EMT Tube Bender Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Negotiate Wisely: Always approach negotiations with a clear understanding of your budget and the market rates for EMT tube benders. Be prepared to discuss volumes, payment terms, and delivery schedules to reach a favorable agreement.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the upfront price. This includes maintenance, operational costs, and potential downtime associated with lower-quality products.

-

Understand Pricing Nuances: Be aware that international transactions can introduce complexities such as tariffs, currency fluctuations, and additional shipping costs. Factor these into your budgeting and negotiation strategies to avoid unexpected expenses.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing and terms. Regular communication and a history of reliable transactions can enhance trust and facilitate smoother negotiations.

By considering these cost components, price influencers, and buyer tips, B2B buyers can make more informed decisions when sourcing EMT tube benders, ensuring they secure the best value for their investment.

Alternatives Analysis: Comparing emt tube bender With Other Solutions

Exploring Alternatives to EMT Tube Benders: A Comparative Analysis

When considering the use of EMT tube benders, it’s crucial for B2B buyers to explore alternative solutions that may offer similar benefits or address specific operational needs. This analysis compares the EMT tube bender with other bending technologies, including hydraulic benders and manual hand benders, to provide insight into their respective advantages and disadvantages.

Illustrative image related to emt tube bender

| Comparison Aspect | EMT Tube Bender | Hydraulic Bender | Manual Hand Bender |

|---|---|---|---|

| Performance | High precision; suitable for various angles | Superior for large diameters; offers consistency | Basic functionality; limited to smaller sizes |

| Cost | Moderate initial investment | Higher upfront cost; requires additional hydraulic system | Low-cost option; minimal investment |

| Ease of Implementation | Easy to use; requires minimal training | More complex setup; requires training | Simple operation; intuitive for users |

| Maintenance | Low maintenance; occasional lubrication needed | Moderate maintenance; hydraulic fluid checks required | Minimal maintenance; no moving parts |

| Best Use Case | Ideal for electrical installations and tight spaces | Best for industrial applications and large projects | Suitable for DIY and small-scale tasks |

What Are the Advantages and Disadvantages of Hydraulic Benders?

Hydraulic benders are designed to handle larger pipe diameters and provide exceptional bending accuracy. Their primary advantage lies in their ability to produce consistent bends, making them ideal for high-volume industrial applications. However, the higher initial investment and the need for a hydraulic system can deter smaller businesses or those with limited budgets. Additionally, the complexity of hydraulic systems requires specialized training, which could lead to increased operational costs.

How Do Manual Hand Benders Compare to EMT Tube Benders?

Manual hand benders are an economical option for bending EMT conduit, particularly for smaller projects or DIY tasks. They are simple to operate, requiring little to no training, which can be advantageous for smaller businesses or one-off projects. However, their performance is limited to smaller sizes and less complex bends, making them less suitable for larger commercial applications. While the low cost is appealing, users may find that the quality of bends does not meet the standards required for professional electrical installations.

Conclusion: Which Bending Solution Should B2B Buyers Choose?

Selecting the right bending solution depends on the specific needs of your operations. For businesses focused on electrical installations requiring precision and versatility, the EMT tube bender remains a solid choice. Conversely, companies engaged in large-scale industrial projects may benefit from the capabilities of hydraulic benders, despite their higher costs. Manual hand benders can serve well for low-budget, small-scale tasks but may not meet the demands of more extensive projects. Ultimately, B2B buyers should assess their budget, project scope, and the complexity of their bending needs before making a decision.

Essential Technical Properties and Trade Terminology for emt tube bender

What Are the Key Technical Properties of an EMT Tube Bender?

When evaluating an EMT (Electrical Metallic Tubing) tube bender for industrial applications, several technical properties are crucial for ensuring optimal performance and longevity. Here are some of the essential specifications:

Illustrative image related to emt tube bender

-

Material Grade

EMT tube benders are typically made from materials like aluminum or ductile iron. Aluminum benders are lightweight and resistant to corrosion, making them suitable for portable applications. In contrast, ductile iron benders offer greater strength and durability, ideal for heavy-duty environments. Understanding material properties allows buyers to select a bender that meets specific operational requirements. -

Bend Radius

The bend radius indicates how sharply a tube can be bent without compromising its structural integrity. Common bend radii for EMT benders are 4.5 inches for ½ inch EMT and 5.125 inches for ¾ inch EMT. A proper bend radius is essential for maintaining the electrical integrity of the conduit, as sharp bends can lead to damage or increased resistance. -

Pipe Capacity

This specification refers to the maximum size of the EMT tubing that the bender can accommodate. EMT benders typically handle sizes ranging from ½ inch to 1 inch. Knowing the pipe capacity ensures that buyers select a bender compatible with their existing inventory and project requirements, preventing costly mistakes. -

Weight

The weight of the bender impacts its portability and ease of use. Lightweight models are preferable for on-site jobs where mobility is essential, while heavier models may offer enhanced durability. Buyers must consider how the weight aligns with their operational needs and transport capabilities. -

Accuracy and Tolerance

High precision in bending is vital to ensure that the bends meet industry standards. Tolerance levels should be within acceptable limits to ensure that conduit fits properly with connectors and other components. A bender with high accuracy minimizes rework and material waste, ultimately reducing project costs.

What Are Common Trade Terms Related to EMT Tube Benders?

Understanding industry terminology can facilitate smoother transactions and clearer communications with suppliers and manufacturers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of EMT tube benders, an OEM might provide proprietary designs or components that enhance the functionality of the bender. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they can meet purchasing requirements without overcommitting to excessive inventory. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to request price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Submitting a well-structured RFQ can lead to competitive pricing and better terms. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Key Incoterms relevant to EMT tube bender transactions include EXW (Ex Works), FOB (Free on Board), and CIF (Cost, Insurance, and Freight). Familiarity with these terms helps buyers understand their obligations regarding transportation and delivery. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times can help buyers plan their projects more effectively and avoid delays in production schedules. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the product. For EMT tube benders, warranties can cover defects in materials and workmanship, offering buyers peace of mind and protection against potential failures.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring they select the right EMT tube bender for their specific needs and operational contexts.

Navigating Market Dynamics and Sourcing Trends in the emt tube bender Sector

What Are the Key Market Dynamics and Trends Influencing the EMT Tube Bender Sector?

The EMT tube bender market is currently shaped by several global drivers, including the increasing demand for electrical infrastructure, the push towards renewable energy sources, and the expansion of construction and manufacturing sectors in emerging economies. In regions like Africa and South America, urbanization and industrialization are leading to a heightened need for reliable electrical conduit systems, which is driving the demand for effective bending solutions. In the Middle East and Europe, regulatory frameworks are increasingly emphasizing energy efficiency and safety standards, which influences the design and manufacturing of EMT tube benders.

Technological advancements are also revolutionizing sourcing trends within this sector. Automation and digitalization are becoming more prevalent, allowing manufacturers to streamline production processes and enhance product precision. Emerging B2B technologies such as cloud-based supply chain management systems and AI-driven analytics are enabling buyers to make data-driven decisions, optimize inventory, and reduce lead times. Additionally, there is a noticeable trend towards customization, as buyers increasingly prefer solutions tailored to specific applications and local market needs.

Illustrative image related to emt tube bender

How Is Sustainability Shaping the Sourcing of EMT Tube Benders?

Sustainability is increasingly influencing procurement strategies in the EMT tube bender sector, as stakeholders recognize the environmental impact of their sourcing decisions. The production of EMT tube benders often involves materials like aluminum and steel, which have significant carbon footprints. B2B buyers are now prioritizing suppliers who utilize sustainable practices, such as recycling scrap materials and minimizing energy consumption during manufacturing.

Ethical sourcing is gaining importance as well. Buyers are more inclined to collaborate with manufacturers who adhere to fair labor practices and demonstrate corporate social responsibility. Certifications such as ISO 14001 for environmental management and other ‘green’ labels are becoming essential criteria in supplier selection. These certifications not only assure buyers of the sustainability of the products but also enhance their marketability in increasingly eco-conscious markets.

What Is the Historical Context of EMT Tube Benders in the B2B Sector?

The evolution of EMT tube benders can be traced back to the early 20th century when electrical systems began to proliferate alongside urbanization and industrial expansion. Initially, manual bending tools were the norm, but as electrical installations grew in complexity, the need for more sophisticated solutions emerged. The introduction of materials like aluminum led to the development of lighter, more efficient benders, improving the installation process.

Over the decades, innovations in design and technology have continually shaped the sector. Today, modern EMT tube benders are not only designed for efficiency and precision but also increasingly integrate features that align with sustainability goals. This historical context is crucial for international B2B buyers, as it illustrates the ongoing evolution of products that cater to both performance and environmental standards, influencing purchasing decisions in a competitive marketplace.

This comprehensive understanding of market dynamics, sustainability practices, and historical context equips international B2B buyers with the insights needed to navigate the complexities of sourcing EMT tube benders effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of emt tube bender

-

How do I solve issues with bending accuracy when using an EMT tube bender?

To enhance bending accuracy, ensure you are using the correct bending method for the specific type of EMT conduit you are working with. Familiarize yourself with the manufacturer’s guidelines, as different models may have unique features. Additionally, mark your conduit appropriately before bending and practice on scrap pieces to refine your technique. Regularly inspect your bender for wear and tear, as a damaged tool can lead to inaccurate bends. -

What is the best EMT tube bender for small-scale electrical projects?

For small-scale electrical projects, a lightweight, manual EMT tube bender made from aluminum is often the best choice. Models like the Klein Tools 1/2 in. Aluminum Conduit Bender offer durability and ease of use, allowing for precise bends without excessive force. Additionally, consider benders with built-in measurement markings, which can save time and improve accuracy during the bending process. -

How can I ensure the quality of EMT tube benders from international suppliers?

To ensure quality when sourcing from international suppliers, request certifications that meet international standards, such as ISO 9001. Conduct thorough vetting by checking supplier reviews and requesting samples for testing. Establish clear quality assurance processes, including inspections at different production stages, to mitigate risks. Building a strong relationship with suppliers can also facilitate better quality control. -

What customization options are available for EMT tube benders?

Many manufacturers offer customization options, including specific sizes, materials, and branding. When discussing customization, be clear about your requirements, including the types of bends you need and any special features you desire, such as built-in measuring scales or ergonomic handles. Reach out to suppliers to discuss possibilities and lead times for custom orders, as these can vary significantly. -

What are typical minimum order quantities (MOQs) for EMT tube benders?

Minimum order quantities for EMT tube benders can vary widely depending on the supplier and the product specifications. Generally, MOQs can range from 50 to several hundred units. It’s essential to communicate your needs upfront and negotiate with suppliers to find a balance between your order size and their production capabilities. Some suppliers may offer flexibility, especially for repeat customers or bulk orders. -

What payment terms should I expect when sourcing EMT tube benders internationally?

Payment terms can vary based on the supplier’s policies and the nature of your agreement. Common terms include payment upfront, net 30, or 50% upfront with the balance due upon shipment. For larger orders, consider negotiating favorable terms, such as letters of credit or escrow services, to protect your investment. Always ensure that payment methods are secure and documented to avoid disputes. -

How can I manage logistics effectively when importing EMT tube benders?

To manage logistics effectively, work with experienced freight forwarders who understand international shipping regulations and can navigate customs clearance. Determine the most cost-effective shipping method based on your timeline and budget, whether air freight for speed or sea freight for cost savings. Ensure all documentation is in order, including commercial invoices and packing lists, to facilitate smooth customs processes. -

What quality assurance practices should I implement when sourcing EMT tube benders?

Implementing stringent quality assurance practices is crucial when sourcing EMT tube benders. Start with supplier audits to assess their production processes and quality management systems. Establish a clear inspection plan that includes evaluating raw materials, in-process inspections, and final product assessments. Additionally, consider third-party quality control services to provide an unbiased evaluation of the products before shipment.

Top 5 Emt Tube Bender Manufacturers & Suppliers List

1. Ideal Industries – Guardian™ Bender w/Handle

Domain: idealind.com

Registered: 2012 (13 years)

Introduction: {“category”:”Fishing, Bending & Lubricants”,”products”:[{“name”:”Guardian™ Bender w/Handle”,”sku”:”remote_image_1″,”reviews”:”5 Reviews”},{“name”:”Aluminum Bender w/Handle 3/4\” EMT”,”sku”:”74-047″},{“name”:”Ductile Iron Bender w/Handle 1-1/4\” EMT”,”sku”:”74-034″},{“name”:”Aluminum Bender Head 3/4\” EMT”,”sku”:”74-032″},{“name”:”Aluminum Bender Head 1/2\” EMT”,”sku”:”74-031″},{“name”:”Bender Hand…

2. TEMCo – 2 in 1 Conduit Bender

Domain: temcoindustrial.com

Registered: 2012 (13 years)

Introduction: TEMCo 2 in 1 Conduit Bender for 1/2″ & 3/4″ EMT; Standard Price: $48.50; Sale Price: $43.65 (savings of $4.85); SKU: TH1909; UPC: Not specified; Weight: 8.00 lbs; Dimensions: Width 14.00 in, Height 17.25 in, Depth 3.00 in; Availability: In stock, usually ships same day or next business day; Features: Bends both 1/2″ and 3/4″ EMT, uses industry standard stubs (5″ for 1/2″ and 6″ for 3/4″), bends to…

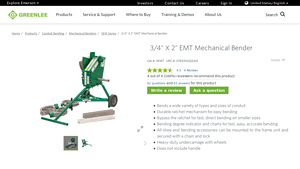

3. Greenlee – 3/4 X 2 EMT Mechanical Bender

Domain: greenlee.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “3/4″ X 2″ EMT Mechanical Bender”, “Catalog Number”: “1818T”, “UPC”: “0783310202325”, “Construction”: “Steel and Aluminum”, “Conduit Size”: “3/4″ Through 2″ EMT”, “Bending Degree Indicator”: “Yes”, “Durable Ratchet Mechanism”: “Yes”, “Bypass Ratchet”: “Yes, for fast direct bending on smaller sizes”, “Centerline Bend Radius”: “5-3/32” (129.400 MM) – 9-3/16” (233.400 MM) (EMT) for…

4. PRODUCTO ELECTRIC CORP. – 640 PECO 1 EMT CONDUIT BENDER

Domain: kellyhayes.com

Registered: 2000 (25 years)

Introduction: {“product_name”:”640 PECO 1″ EMT CONDUIT BENDER”,”manufacturer”:”PRODUCTO ELECTRIC CORP.”,”sku”:”640″,”price”:”$37.24 / EA”,”availability”:”1 EA”,”weight”:”6.2 lbs”,”bender_head_type”:”MALLEABLE IRON”,”handle_included”:”1″,”emt_conduit_size”:”1 INCH”,”handle_mounting_hole_size”:”STANDARD PACKAGE 5″}

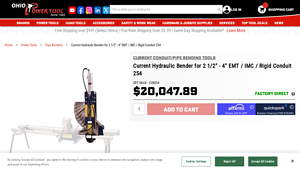

5. Ohio Power Tool – Current Hydraulic Bender

Domain: ohiopowertool.com

Registered: 2002 (23 years)

Introduction: Current Hydraulic Bender for 2 1/2″ – 4″ EMT / IMC / Rigid Conduit 254

Strategic Sourcing Conclusion and Outlook for emt tube bender

In conclusion, the strategic sourcing of EMT tube benders is pivotal for enhancing operational efficiency and achieving cost-effectiveness in various projects. By understanding the diverse range of products available, including different materials and capacities, buyers can make informed decisions that align with their specific needs. Key considerations such as supplier reliability, product quality, and after-sales support are essential in establishing long-term partnerships that foster business growth.

For international buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, the landscape of sourcing EMT tube benders presents unique opportunities. As demand for high-quality electrical tools continues to rise, leveraging strategic sourcing can lead to significant competitive advantages.

Looking ahead, it is crucial for businesses to stay attuned to market trends and advancements in technology that can enhance the functionality of EMT tube benders. By proactively engaging with suppliers and exploring innovative solutions, companies can position themselves for success in an increasingly dynamic marketplace. Take the next step in optimizing your sourcing strategy today—invest in quality tools that meet your operational needs and drive your projects forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.