Choosing Your Elevator Bucket: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for elevator bucket

In an increasingly competitive global landscape, sourcing the right elevator buckets can pose significant challenges for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With varying material requirements, performance specifications, and compliance standards, selecting the ideal elevator bucket for your specific application can be daunting. This comprehensive guide is designed to streamline your decision-making process, providing insights into the various types of elevator buckets available, including agricultural and industrial options, as well as their distinct applications.

Throughout this guide, we will explore critical aspects of the elevator bucket market, including supplier vetting processes, cost considerations, and technical specifications. By understanding the nuances of elevator bucket design and performance, you will be better equipped to make informed purchasing decisions that align with your operational needs.

Whether you are in Vietnam, Brazil, or any other location, this guide empowers international B2B buyers to navigate the complexities of sourcing elevator buckets efficiently and effectively. By leveraging the insights provided, you can optimize your supply chain, enhance productivity, and ultimately drive your business success in a global marketplace.

Understanding elevator bucket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Agricultural Buckets | Made from durable materials like plastic or steel; designed for bulk handling of grains and seeds | Grain elevators, feed mills | Pros: High capacity, resistant to wear. Cons: May require specific compatibility with existing systems. |

| Industrial Buckets | Typically made from heavy-duty plastic or steel; designed for high throughput and handling abrasive materials | Manufacturing, recycling, mining | Pros: Long lifespan, customizable sizes. Cons: Higher initial cost compared to standard options. |

| Low Profile Buckets | Compact design for space-constrained environments; often made from lightweight materials | Food processing, packaging | Pros: Space-efficient, easy to install. Cons: Limited capacity for very heavy materials. |

| High-Efficiency Buckets | Engineered for optimal material flow; often feature unique designs for minimal spillage | Bulk material handling, logistics | Pros: Increased efficiency, reduced operational costs. Cons: May require specific installation techniques. |

| Fabricated Steel Buckets | Constructed from multiple steel components; ideal for handling sharp or heavy materials | Heavy-duty industrial applications | Pros: Extremely durable, customizable. Cons: Heavier, which may affect energy consumption in operation. |

What Are Agricultural Buckets and Their B2B Benefits?

Agricultural buckets are primarily designed for handling bulk materials such as grains, seeds, and feed. Constructed from robust materials like plastic or steel, these buckets are built to withstand the rigors of agricultural environments. For B2B buyers, the key consideration is ensuring compatibility with existing grain handling systems. Their high capacity and durability make them a preferred choice in grain elevators and feed mills, although they may require specific fittings.

How Do Industrial Buckets Serve Diverse Industries?

Industrial buckets are engineered for high-performance applications, often crafted from heavy-duty plastic or steel to manage abrasive materials in manufacturing and recycling sectors. Their customizable sizes and long lifespan cater to a variety of industrial needs. When purchasing, B2B buyers should consider the initial investment versus the potential cost savings from reduced maintenance and replacement needs. These buckets excel in environments requiring efficiency and durability, making them indispensable in mining and heavy manufacturing.

What Are the Advantages of Low Profile Buckets?

Low profile buckets are designed for environments where space is limited, featuring a compact design that allows for easier installation in tight spots. Commonly used in food processing and packaging applications, these buckets are often made from lightweight materials. B2B buyers benefit from their space-saving design, although they should be aware that their capacity may be limited compared to standard buckets. This makes them ideal for operations where weight and height restrictions are critical.

Why Choose High-Efficiency Buckets for Material Handling?

High-efficiency buckets are specifically designed to optimize material flow and minimize spillage, making them ideal for bulk material handling and logistics. These buckets often feature innovative designs that enhance operational efficiency. B2B buyers should consider the potential for reduced operational costs through improved efficiency and lower waste. However, installation may require specialized techniques, so ensuring access to technical support is crucial for a smooth implementation.

What Makes Fabricated Steel Buckets a Heavy-Duty Option?

Fabricated steel buckets are constructed from multiple components, offering exceptional durability for handling sharp or heavy materials in demanding industrial applications. They are particularly suited for heavy-duty environments like construction and mining. B2B buyers should weigh the benefits of their robustness against the potential increase in energy consumption due to their weight. Customization options allow for specific needs, making them a versatile choice for various industrial applications.

Key Industrial Applications of elevator bucket

| Industry/Sector | Specific Application of elevator bucket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Grain handling and storage | Efficient transport of bulk grains with minimal damage | Material durability, resistance to corrosion, and capacity |

| Mining | Transporting minerals and aggregates | Enhanced efficiency in material handling processes | Load capacity, resistance to wear, and compatibility with existing systems |

| Food Processing | Handling bulk ingredients like flour and sugar | Ensures hygiene and reduces contamination risk | Compliance with food safety standards and material safety |

| Waste Management | Moving waste materials to processing facilities | Streamlined waste handling, reducing operational costs | Strength, durability, and adaptability to various waste types |

| Construction | Elevating construction materials | Increases productivity and reduces labor costs | Custom sizing, load ratings, and material specifications |

How Are Elevator Buckets Utilized in Agriculture for Grain Handling?

In the agricultural sector, elevator buckets are pivotal for the efficient handling and storage of bulk grains. They transport grains from silos to processing areas or loading docks, ensuring minimal spillage and damage. For international buyers, particularly in regions like Africa and South America, sourcing durable buckets that can withstand harsh environmental conditions is crucial. Buyers must consider materials that resist corrosion and wear while also accommodating the specific capacities required for their operations.

What Role Do Elevator Buckets Play in Mining Operations?

In mining, elevator buckets are essential for transporting minerals and aggregates from extraction sites to processing plants. Their robust design allows for handling heavy materials without compromising structural integrity. Buyers in the Middle East and Europe should focus on buckets with high load capacities and wear-resistant materials to ensure longevity and efficiency. Additionally, compatibility with existing conveyor systems is a key consideration for seamless integration.

How Are Elevator Buckets Important in Food Processing?

In food processing, elevator buckets are used to transport bulk ingredients such as flour and sugar. Their design minimizes contamination risks, adhering to stringent hygiene standards essential in food safety. Buyers must prioritize materials that meet food-grade certifications, especially in markets like Europe where regulations are stringent. The ability to customize bucket sizes for specific production lines can also enhance operational efficiency.

How Do Elevator Buckets Benefit Waste Management?

Elevator buckets are instrumental in waste management, facilitating the movement of waste materials to processing facilities. They streamline operations, significantly reducing labor costs and improving efficiency. For buyers in developing regions, sourcing durable and versatile buckets that can handle various waste types is essential. It’s important to consider the strength and adaptability of the buckets to different waste handling environments to ensure smooth operations.

Why Are Elevator Buckets Critical in Construction?

In the construction industry, elevator buckets are utilized to elevate materials such as concrete and aggregates to various heights on job sites. This use increases productivity and minimizes manual labor, leading to cost savings. Buyers should focus on custom sizing and load ratings that meet their specific project requirements. Additionally, the choice of material is vital, as it must withstand the rigors of a construction environment while ensuring safety and reliability.

3 Common User Pain Points for ‘elevator bucket’ & Their Solutions

Scenario 1: High Wear and Tear on Elevator Buckets

The Problem: B2B buyers often face the issue of premature wear and tear on elevator buckets, particularly when handling abrasive materials like sand or gravel. This not only leads to increased downtime for maintenance and replacements but also results in lost productivity and higher operational costs. Buyers may feel frustrated as they grapple with selecting the right bucket materials that can withstand harsh conditions while also fitting within budget constraints.

The Solution: To mitigate wear and tear, it’s crucial to select elevator buckets made from high-durability materials. For example, opting for steel or high-density polyethylene (HDPE) buckets can significantly enhance longevity when dealing with abrasive products. Buyers should consider investing in engineered buckets designed specifically for heavy-duty applications, such as those with reinforced edges or made from specialized alloys. Additionally, regularly assessing the operating environment and adjusting the bucket design or material based on the type of materials being transported can extend the life of the buckets. It’s advisable to consult with manufacturers who provide insights on material performance and offer custom solutions tailored to specific operational needs.

Scenario 2: Inadequate Bucket Capacity Leading to Inefficiency

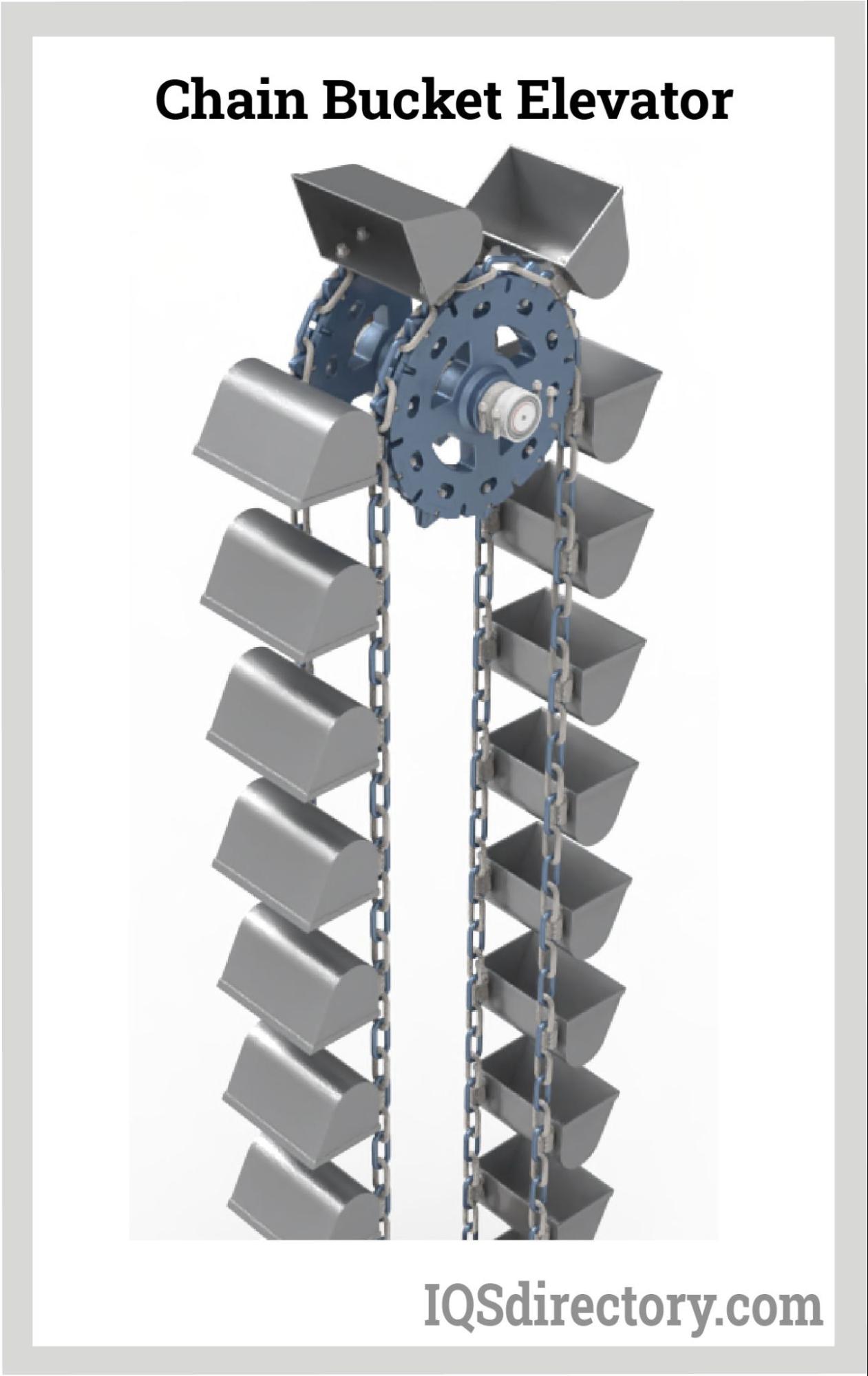

The Problem: Many businesses struggle with inadequate bucket capacity, which can lead to inefficient material handling and increased cycle times. This issue often arises when companies underestimate the volume of material their operations require or fail to account for the specific density of the materials being transported. As a result, they may find themselves in a situation where they have to operate multiple elevators or run longer cycles, ultimately wasting time and resources.

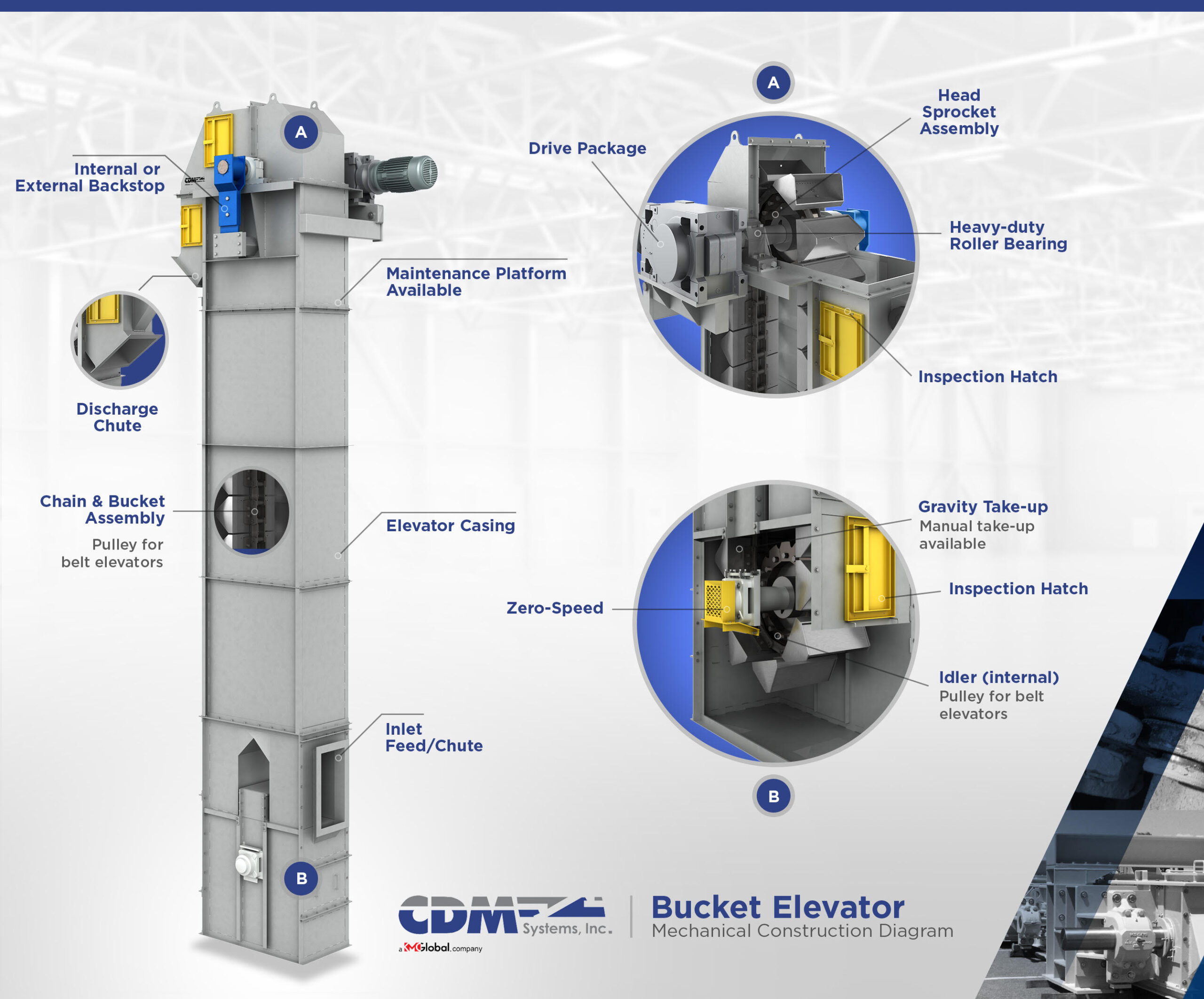

Illustrative image related to elevator bucket

The Solution: To address capacity-related challenges, buyers should start by conducting a thorough analysis of their material handling needs, including the type, density, and throughput requirements. This allows for precise bucket sizing. For optimal efficiency, consider utilizing bucket elevators designed with high-capacity options, like Jumbo or High-Efficiency styles, which can significantly increase throughput without requiring additional equipment. It is also beneficial to collaborate with manufacturers who can provide expert guidance on selecting the right bucket style and size based on detailed calculations of material volume and elevator speed. Buyers should also remain open to customizing bucket dimensions to fit specific operational parameters.

Scenario 3: Installation and Maintenance Challenges

The Problem: Many buyers encounter difficulties during the installation and maintenance of elevator buckets, particularly if they lack the technical expertise or resources. This can lead to incorrect installations that compromise safety and efficiency, resulting in costly repairs and potential operational disruptions. Buyers may feel overwhelmed by the complexity of installation instructions or the unavailability of skilled technicians.

The Solution: To streamline the installation process, it’s essential for buyers to prioritize sourcing buckets from suppliers that offer comprehensive support services, including installation guides and technical assistance. Suppliers should provide clear and detailed instructions, as well as access to training resources or on-site support. Additionally, implementing a preventive maintenance schedule can significantly reduce the frequency and severity of issues. Buyers are encouraged to invest in training programs for their staff, ensuring they are well-equipped to handle routine maintenance and minor repairs. This not only enhances operational efficiency but also contributes to a safer workplace. Establishing a relationship with a trusted supplier who can provide ongoing technical support and resources can prove invaluable in overcoming these installation challenges.

Strategic Material Selection Guide for elevator bucket

What Are the Key Properties of Common Materials Used in Elevator Buckets?

When selecting materials for elevator buckets, it is essential to consider properties that influence performance, such as temperature resistance, pressure ratings, and corrosion resistance. Different materials offer unique advantages and limitations, making them suitable for various applications.

How Do Steel Elevator Buckets Perform in Industrial Applications?

Steel is a traditional choice for elevator buckets, particularly in industrial settings where durability is paramount. Steel buckets can withstand high temperatures and are resistant to wear from abrasive materials. They are often used in applications involving sharp or heavy products, such as minerals or grains. However, steel buckets can be prone to corrosion unless treated or coated, which may increase maintenance costs over time. Additionally, their weight can lead to higher energy consumption in elevator systems.

Illustrative image related to elevator bucket

What Advantages Do Plastic Elevator Buckets Offer?

Plastic materials, such as polyethylene and nylon, are increasingly popular due to their lightweight nature and resistance to corrosion. These buckets are ideal for handling agricultural products, as they do not rust and are less likely to damage delicate grains. The manufacturing process for plastic buckets is generally less complex, leading to lower production costs. However, they may not withstand extreme temperatures or heavy loads as effectively as steel, making them less suitable for high-stress environments.

How Do Stainless Steel Buckets Compare to Other Materials?

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it a versatile option for elevator buckets. This material is particularly beneficial in environments where hygiene is crucial, such as food processing. Stainless steel buckets can handle a range of temperatures and are less likely to degrade over time. The downside is that they are typically more expensive than both carbon steel and plastic options, which could be a consideration for budget-conscious buyers.

What Role Do Specialty Materials Play in Elevator Bucket Applications?

Specialty materials like ductile iron and urethane are designed for specific applications that require unique performance characteristics. Ductile iron buckets offer excellent strength and impact resistance, making them suitable for heavy-duty applications. Urethane buckets provide superior wear resistance and flexibility, ideal for handling abrasive materials. However, these materials often come with higher costs and may have more complex manufacturing processes, which can affect lead times.

Summary of Material Selection for Elevator Buckets

| Material | Typical Use Case for Elevator Bucket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High durability and strength | Prone to corrosion without treatment | Medium |

| Plastic | Agricultural applications, handling grains and seeds | Lightweight and corrosion-resistant | Limited temperature and load capacity | Low |

| Stainless Steel | Food processing and hygienic environments | Excellent corrosion resistance and hygiene | Higher cost compared to other materials | High |

| Ductile Iron | Heavy-duty applications requiring impact resistance | Exceptional strength and durability | Higher manufacturing complexity | Medium |

| Urethane | Handling abrasive materials with flexibility needs | Superior wear resistance | Higher cost and potential complexity in sourcing | High |

Selecting the right material for elevator buckets involves evaluating the specific application requirements, environmental conditions, and budget constraints. Understanding these factors can help international B2B buyers make informed decisions that enhance operational efficiency and reduce long-term costs.

Illustrative image related to elevator bucket

In-depth Look: Manufacturing Processes and Quality Assurance for elevator bucket

Elevator buckets are essential components in various industries, serving as critical elements in bulk material handling systems. Understanding the manufacturing processes and quality assurance (QA) measures is vital for B2B buyers seeking reliable and durable products. This section provides an in-depth examination of typical manufacturing processes and quality assurance practices for elevator buckets, along with actionable insights for international buyers.

What Are the Main Stages in the Manufacturing Process of Elevator Buckets?

The manufacturing process for elevator buckets generally involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the final product meets industry standards and customer specifications.

How Is Material Prepared for Elevator Bucket Manufacturing?

Material preparation begins with selecting the appropriate raw materials, which may include various types of steel, plastics, or specialized alloys depending on the application. For agricultural applications, materials like high-density polyethylene (HDPE) and nylon are common, while industrial applications may require steel or stainless steel for enhanced durability.

Illustrative image related to elevator bucket

Once the materials are selected, they undergo a series of treatments such as cutting, surface cleaning, and pre-coating to ensure they are free from impurities that could affect performance. This stage also includes sourcing materials from certified suppliers to ensure compliance with international standards.

What Techniques Are Used in Forming Elevator Buckets?

The forming stage involves shaping the prepared materials into bucket forms. Common techniques include:

- Injection Molding: Predominantly used for plastic buckets, this technique allows for the creation of complex shapes with high precision.

- Metal Fabrication: For steel buckets, processes such as cutting, bending, and welding are employed. Automated laser cutting and CNC machining are often utilized to enhance accuracy and reduce production time.

- Stamping: This is another method used for metal buckets, where sheets of metal are stamped into the desired shape using high-pressure machinery.

The choice of forming technique depends on the material used and the specific requirements of the elevator bucket, such as size, shape, and load capacity.

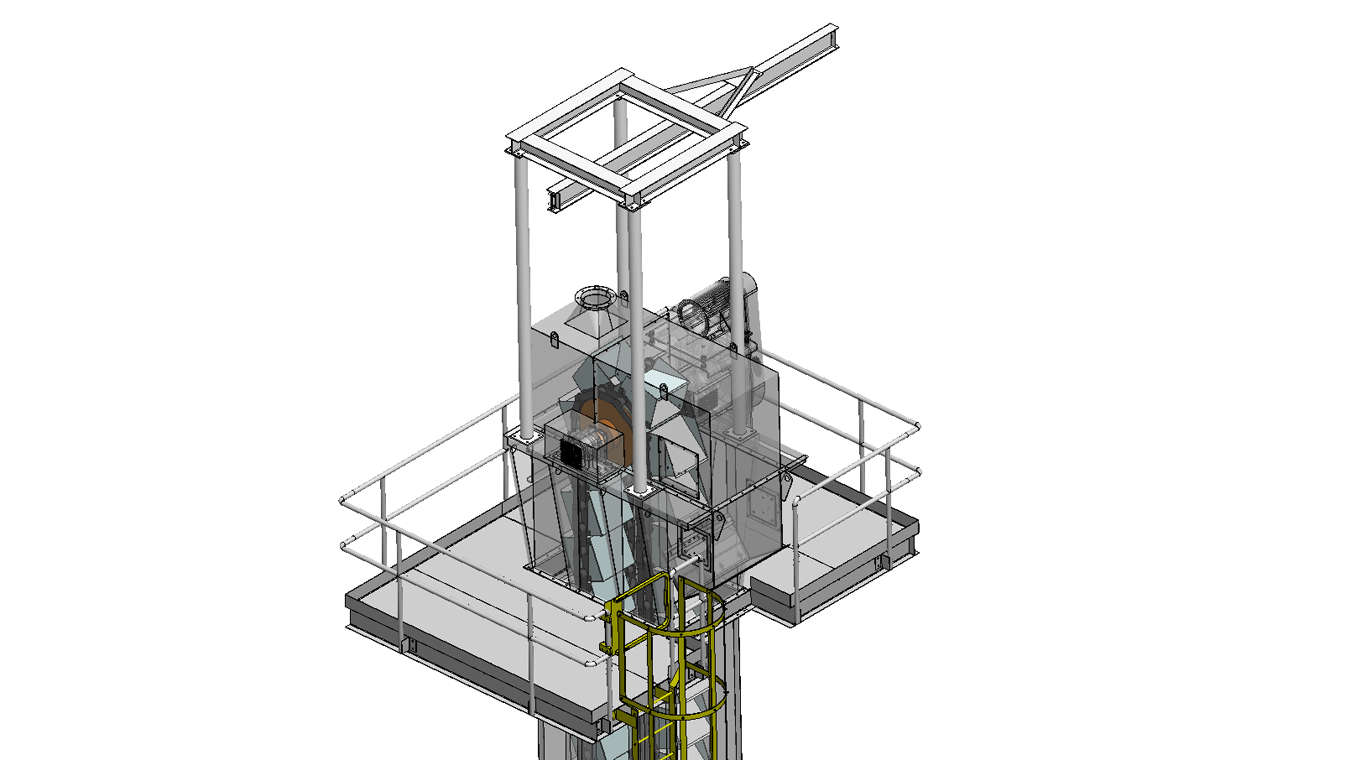

What Happens During the Assembly Process of Elevator Buckets?

In the assembly stage, individual components are brought together. For fabricated steel buckets, this typically involves welding different parts, such as the body, end plates, and wear lips, to create a sturdy structure. Quality welds are essential for ensuring the bucket can withstand heavy loads and harsh operating conditions.

For plastic buckets, assembly may include bonding or fastening components together. In both cases, attention to detail during assembly is critical to avoid structural weaknesses that could lead to premature failure in operation.

Illustrative image related to elevator bucket

How Is the Finishing of Elevator Buckets Conducted?

Finishing processes may include painting, coating, or polishing the surface of the buckets. These treatments serve multiple purposes, such as enhancing corrosion resistance, improving aesthetics, and reducing friction during operation. For example, galvanized coatings are often applied to steel buckets to protect against rust, especially in humid environments prevalent in regions like Africa and South America.

What Are the Key Quality Assurance Practices for Elevator Buckets?

Quality assurance is paramount in the manufacturing of elevator buckets, ensuring that products meet both customer specifications and international standards. Here are the key practices involved in the QA process:

Which International Standards Are Relevant for Elevator Bucket Quality Assurance?

Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This certification indicates that a company consistently provides products that meet customer and regulatory requirements.

Additionally, industry-specific certifications like CE marking for European markets and API standards for oil and gas applications may be applicable depending on the end use of the elevator buckets. Compliance with these standards assures B2B buyers of the product’s quality and safety.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are established at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, random sampling and inspections are conducted to monitor the production process and identify any deviations from standards.

- Final Quality Control (FQC): Before shipment, finished products are subjected to rigorous testing, including dimensional checks, load testing, and visual inspections to ensure they meet the required specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should consider several strategies to verify the quality control practices of potential suppliers:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance measures. Buyers can request to review the supplier’s quality management system and production facilities.

- Request Quality Reports: Suppliers should be able to provide documentation of quality control tests performed, including results and certifications. This transparency is crucial for verifying compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s production quality, ensuring that the products meet the necessary specifications before shipment.

What Nuances Should International Buyers Consider Regarding Quality Assurance?

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, several nuances in quality assurance should be considered:

- Regulatory Compliance: Different regions may have varying regulations regarding material handling and safety. Understanding local compliance requirements is essential for avoiding potential legal issues.

- Cultural Differences in Quality Expectations: Cultural perceptions of quality can differ, which may affect how quality assurance practices are implemented and perceived. Buyers should communicate their quality expectations clearly to avoid misunderstandings.

- Supply Chain Logistics: Ensuring that quality is maintained throughout the supply chain is crucial, especially when sourcing materials from multiple countries. Establishing strong communication channels with suppliers can help mitigate risks associated with quality control.

In conclusion, understanding the manufacturing processes and quality assurance practices for elevator buckets is vital for B2B buyers seeking reliable products. By focusing on material preparation, forming techniques, assembly, and finishing, alongside robust quality control measures, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘elevator bucket’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure elevator buckets. Understanding the specific requirements and evaluating potential suppliers is crucial for making informed purchasing decisions. This checklist will help streamline the sourcing process, ensuring that you select the right products for your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline the technical specifications of the elevator buckets you require. Consider factors such as the material (plastic, steel, or stainless steel), size, and shape based on your operational needs.

- Material Considerations: Different materials offer varying durability and performance under specific conditions. For example, steel buckets are ideal for high-temperature applications, while plastic may be suitable for lighter loads.

- Capacity Requirements: Determine the volume and weight of the materials you intend to transport to ensure you select a bucket that meets your capacity needs.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to compile a list of potential suppliers that specialize in elevator buckets. Look for companies with a strong reputation and extensive product offerings to ensure they can meet your specific needs.

- Industry Experience: Suppliers with a long history in the industry are often more reliable and knowledgeable about product performance.

- Geographical Reach: Consider suppliers that have a presence in your region or offer international shipping, especially if you are located in Africa, South America, or the Middle East.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Quality Assurance: Inquire about quality control processes and certifications that the supplier holds, such as ISO certifications, which indicate adherence to international quality standards.

- Client Testimonials: Look for reviews or testimonials from past clients to gauge the supplier’s reliability and product performance.

Step 4: Request Samples and Technical Data

Once you have shortlisted potential suppliers, request samples of the elevator buckets along with technical data sheets. This will allow you to assess the quality and suitability of the products.

- Performance Testing: Evaluate the samples under conditions that replicate your operational environment to determine their effectiveness.

- Compatibility Checks: Ensure that the buckets can seamlessly integrate with your existing systems and equipment.

Step 5: Negotiate Terms and Pricing

After selecting a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules.

- Volume Discounts: If you plan to order in bulk, inquire about potential discounts that could reduce your overall costs.

- Delivery Timelines: Discuss lead times and ensure they align with your operational timelines to avoid disruptions in your supply chain.

Step 6: Finalize the Purchase Agreement

Before finalizing the order, ensure that all terms are clearly outlined in a purchase agreement. This should include specifications, pricing, delivery schedules, and warranty information.

- Legal Considerations: Review the terms for any legal implications, especially if dealing with international suppliers, to avoid misunderstandings.

- Post-Purchase Support: Confirm the availability of technical support and after-sales service, which can be crucial for maintenance and troubleshooting.

Step 7: Plan for Installation and Maintenance

Once the elevator buckets are procured, develop a plan for their installation and maintenance.

- Installation Guidance: Ensure that the supplier provides clear installation instructions or support to facilitate a smooth setup.

- Regular Maintenance: Implement a maintenance schedule to prolong the lifespan of the buckets and ensure optimal performance over time.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing elevator buckets, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for elevator bucket Sourcing

What Are the Key Cost Components in Sourcing Elevator Buckets?

Understanding the cost structure of elevator buckets is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of material—plastic, steel, or stainless steel—significantly impacts cost. For instance, while plastic buckets are generally less expensive, steel and stainless steel buckets provide greater durability and are essential for high-temperature or abrasive materials. Depending on the application, selecting the right material can influence both initial costs and long-term performance.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Automated processes can reduce labor costs but may require higher initial investment in machinery. In regions like Africa and South America, labor costs may be lower, which can affect overall pricing.

-

Manufacturing Overhead: This includes costs related to the operation of the production facility such as utilities, depreciation of equipment, and salaries of non-production staff. Efficient manufacturing practices can help minimize these costs, directly impacting the final pricing of elevator buckets.

-

Tooling: The initial investment in tooling is significant, especially for custom designs. Buyers should consider whether the supplier can accommodate specific design needs without excessive tooling costs, as this can affect the overall cost per unit.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and performance, which can add to costs but ultimately saves money by reducing failures and downtime. Certifications (e.g., ISO standards) may also influence pricing, as they indicate a commitment to quality.

-

Logistics: Shipping costs, including freight charges, insurance, and tariffs, can vary greatly depending on the destination and Incoterms. Buyers should evaluate logistics as part of the total cost of ownership (TCO) to understand the complete financial picture.

-

Margin: Suppliers will typically add a margin to their costs to ensure profitability. Understanding the competitive landscape can help buyers negotiate better prices.

What Factors Influence Pricing for Elevator Buckets?

Several factors can influence the pricing of elevator buckets, including order volume, specifications, material quality, and supplier considerations.

-

Volume/MOQ: Bulk orders often lead to lower per-unit prices due to economies of scale. Establishing a minimum order quantity (MOQ) with suppliers can yield significant savings, making it essential for buyers to plan their purchasing strategies accordingly.

-

Specifications and Customization: Custom features, such as specific sizes, materials, or additional functionalities (like venting options), can increase costs. Buyers should balance the need for customization with budget constraints to ensure they are not overpaying for unnecessary features.

-

Quality and Certifications: Higher-quality products typically command higher prices. Certification requirements, particularly in markets with stringent safety regulations, can also add to costs. Buyers should assess whether the additional quality justifies the increased price.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms can significantly impact the overall cost. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears the shipping costs and risks, which can affect the final price paid by the buyer.

What Tips Can Help Buyers Negotiate Better Prices?

To achieve cost efficiency in sourcing elevator buckets, international buyers should consider the following strategies:

Illustrative image related to elevator bucket

-

Negotiate Terms: Engage in discussions about pricing, MOQ, and payment terms. Suppliers may be willing to offer discounts for larger orders or longer payment terms.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider factors like maintenance, durability, and potential downtime costs. This approach can lead to better long-term financial decisions.

-

Research Market Prices: Understanding the market price range for elevator buckets can empower buyers during negotiations. Having data on competitors’ pricing can provide leverage.

-

Seek Local Suppliers: For buyers in Africa and South America, sourcing from local manufacturers may reduce logistics costs and lead times, making it a more cost-effective option.

-

Consider Long-Term Relationships: Building a relationship with suppliers can lead to better pricing over time, as trust and reliability develop. Suppliers may offer better terms to long-term partners.

Disclaimer

Prices for elevator buckets can vary significantly based on the factors discussed. Always seek multiple quotes and consider all cost components before making a purchasing decision.

Alternatives Analysis: Comparing elevator bucket With Other Solutions

Understanding Alternatives to Elevator Buckets

In the realm of material handling, the choice of technology is crucial for optimizing efficiency and productivity. While elevator buckets are a proven solution for vertical transport of bulk materials, various alternatives exist that may better suit specific operational needs. This analysis compares elevator buckets with two alternative solutions: conveyor belts and pneumatic conveying systems.

Comparison Table

| Comparison Aspect | Elevator Bucket | Conveyor Belt | Pneumatic Conveying System |

|---|---|---|---|

| Performance | High capacity; suitable for bulk materials | Versatile; can transport various materials | Effective for fine materials; can handle long distances |

| Cost | Moderate initial investment; durable | Lower initial cost; may require more maintenance | Higher upfront cost; operationally efficient |

| Ease of Implementation | Requires specific installation; may need structural modifications | Easier to install; flexible layout options | Complex installation; needs specialized design |

| Maintenance | Low maintenance; periodic checks needed | Moderate; requires regular inspections | High; regular maintenance of air supply systems needed |

| Best Use Case | Ideal for agricultural and industrial applications with bulk materials | Suitable for diverse materials in various industries | Best for sensitive materials or when space is limited |

In-Depth Look at Alternatives

Conveyor Belts

Conveyor belts are a widely used alternative for transporting bulk materials horizontally or at a slight incline. Their versatility allows them to handle a variety of materials, including granular and packaged goods. The initial investment is typically lower than that of elevator buckets, making them attractive for businesses on a budget. However, conveyor belts can require more maintenance due to wear and tear, especially in harsh environments. They are best suited for operations that need flexibility in layout and material handling.

Pneumatic Conveying Systems

Pneumatic conveying systems utilize air pressure to move materials through pipes, making them an excellent option for transporting fine powders and fragile materials. They can handle longer distances and are particularly useful in applications where space is limited. However, the complexity of their installation and the need for specialized equipment can drive up initial costs significantly. Regular maintenance is essential to ensure the air supply systems function efficiently, making them a high-maintenance option. Pneumatic systems are ideal for industries where material integrity is paramount, such as food or pharmaceuticals.

Making the Right Choice for Your Business

Choosing the right material handling solution depends on several factors, including the type of materials being transported, available space, budget, and maintenance capabilities. Elevator buckets excel in high-capacity environments where bulk materials are involved, while conveyor belts offer flexibility and lower initial costs. Pneumatic systems, though more costly, are unrivaled in their ability to protect sensitive materials over longer distances.

B2B buyers should assess their specific operational needs and constraints to determine which solution aligns best with their goals. Conducting a thorough analysis of each option’s pros and cons will ensure informed decision-making, ultimately leading to improved efficiency and productivity in their operations.

Essential Technical Properties and Trade Terminology for elevator bucket

What Are the Key Technical Properties of Elevator Buckets?

Understanding the essential technical properties of elevator buckets is crucial for B2B buyers looking to optimize material handling processes. Here are some critical specifications to consider:

1. Material Grade

Elevator buckets are typically made from various materials, including plastic, steel, and stainless steel. The choice of material affects durability, weight, and resistance to corrosion. For example, steel buckets are preferred for handling sharp or hot materials, while plastic buckets may be more suitable for lighter, non-abrasive materials. Selecting the right material ensures that the bucket meets the specific operational demands and reduces the risk of premature wear.

Illustrative image related to elevator bucket

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions, crucial for ensuring proper fit and function in the elevator system. For instance, a tolerance of ±0.25 inches for length and ±0.03125 inches for depth can significantly impact how buckets align within the system. Proper tolerances help maintain efficiency and reduce operational downtime, making it vital for buyers to understand these specifications when sourcing buckets.

3. Capacity

The capacity of an elevator bucket indicates how much material it can hold, typically measured in cubic inches or liters. This specification is essential for determining how many buckets are needed for a specific application and how efficiently the elevator will perform. Buyers should consider both gross and usable capacity, as the latter accounts for the practical load-bearing capability during operation.

4. Bolt Pattern

The bolt pattern indicates how the bucket attaches to the elevator system. Understanding the standard drilling size and configuration is critical for ensuring compatibility with existing equipment. Custom drilling options may also be available, allowing buyers to specify their needs. Proper bolt patterns reduce installation time and improve system reliability.

Illustrative image related to elevator bucket

5. Design Style

Different design styles, such as centrifugal or continuous bucket styles, affect how material is handled during the lifting process. For instance, centrifugal buckets are ideal for high-speed applications, while continuous buckets are more suited for slower, steady operations. Buyers should match the bucket design with their operational requirements to enhance efficiency.

What Are the Common Trade Terminology and Jargon for Elevator Buckets?

Familiarity with industry terminology is essential for effective communication and decision-making in the B2B marketplace. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. When sourcing elevator buckets, understanding whether a product is OEM can assure buyers of its quality and compatibility with existing systems.

Illustrative image related to elevator bucket

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is critical for budgeting and planning inventory, especially for smaller businesses that may not need large quantities.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It often includes specifications, quantities, and delivery timelines. Submitting an RFQ allows buyers to compare offers and negotiate better terms.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is vital for managing logistics and ensuring that all parties are clear on shipping responsibilities, costs, and risks.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This term is crucial for project planning and inventory management, as longer lead times can impact operational efficiency.

Illustrative image related to elevator bucket

6. Customization

Customization in elevator buckets refers to the ability to modify design, size, or material according to specific operational needs. Understanding customization options allows buyers to tailor solutions that best fit their applications, enhancing productivity.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that optimize their material handling processes and ensure seamless operations.

Navigating Market Dynamics and Sourcing Trends in the elevator bucket Sector

What Are the Current Market Dynamics and Key Trends in the Elevator Bucket Sector?

The global elevator bucket market is experiencing significant growth, driven by increasing demand for efficient material handling solutions across various industries, including agriculture, construction, and manufacturing. Key market drivers include urbanization, industrialization, and the rising need for automation in material handling processes. In regions like Africa and South America, rapid infrastructure development is propelling demand for elevator buckets, particularly in agricultural applications where bulk material transport is essential.

Emerging technologies, such as IoT-enabled monitoring systems and advanced materials, are reshaping sourcing trends. B2B buyers are increasingly looking for suppliers that offer smart solutions, such as predictive maintenance systems that reduce downtime. The integration of automation in elevator systems is also influencing design preferences, prompting manufacturers to innovate with more durable and efficient bucket designs that cater to high-capacity needs.

Furthermore, international buyers are exploring partnerships with manufacturers that can provide customized solutions tailored to local market requirements. This trend highlights the importance of flexibility in production capabilities and the ability to meet diverse specifications across different regions, including Europe and the Middle East.

How Does Sustainability and Ethical Sourcing Impact the Elevator Bucket Sector?

Sustainability is becoming a crucial factor in the sourcing of elevator buckets, as businesses strive to minimize their environmental impact. The elevator bucket industry is increasingly focusing on materials that are not only durable but also environmentally friendly. This shift is evident in the growing demand for recyclable materials and the adoption of ‘green’ certifications, which assure buyers of a product’s sustainable sourcing.

Ethical supply chains are also gaining prominence, with buyers seeking transparency regarding the origins of materials and the labor practices of suppliers. Companies that prioritize ethical sourcing can enhance their brand reputation and appeal to environmentally conscious customers. The use of biodegradable plastics and sustainably sourced metals in manufacturing elevator buckets is becoming a competitive advantage for suppliers looking to attract international clients.

Additionally, implementing efficient manufacturing processes that reduce waste and energy consumption is becoming a standard practice. For B2B buyers, partnering with suppliers who are committed to sustainability not only aligns with corporate social responsibility goals but also mitigates risks associated with regulatory compliance and market acceptance.

What Is the Evolution of the Elevator Bucket Industry and Its Relevance Today?

The elevator bucket industry has evolved significantly since its inception, transitioning from simple wooden designs to highly engineered products made from advanced materials such as high-density polyethylene (HDPE), stainless steel, and specialized alloys. Early models were primarily used in agriculture for grain handling, but as industrial applications grew, so did the diversity of bucket designs to accommodate various materials, including aggregates and chemicals.

Today, the evolution continues with an emphasis on technology integration, such as automation and IoT capabilities, which enhance operational efficiency and performance monitoring. This evolution is particularly relevant for B2B buyers as they seek solutions that not only meet their current operational needs but also anticipate future demands in a rapidly changing market landscape. By understanding the historical context and the trajectory of technological advancements in elevator buckets, buyers can make informed decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of elevator bucket

-

How do I choose the right elevator bucket for my application?

Choosing the right elevator bucket involves considering several factors, including the material being handled, the required capacity, and the environmental conditions. For agricultural applications, plastic or steel buckets are often preferred due to their durability and resistance to corrosion. In industrial settings, buckets made from stainless steel or heavy-duty materials are recommended for handling sharp or hot materials. It’s essential to consult with suppliers who can provide guidance based on your specific needs and offer a range of bucket styles and sizes. -

What are the key features to look for in an elevator bucket?

When selecting an elevator bucket, prioritize features such as material strength, size, and design. Look for buckets with a high wear resistance, especially if they will handle abrasive materials. Additionally, consider buckets with optimized shapes for better material flow and reduced spillage. Customization options, such as different mounting hole configurations or venting capabilities, can also enhance performance. Ensure the supplier provides detailed specifications and can accommodate any unique requirements your application may have. -

What is the minimum order quantity (MOQ) for elevator buckets?

Minimum order quantities for elevator buckets can vary significantly between manufacturers. Typically, MOQs range from a few dozen to several hundred units, depending on the type of bucket and customization required. For international buyers, it is advisable to discuss MOQs upfront to avoid unexpected costs. Some suppliers may offer flexibility with MOQs for first-time orders or when combining different products, so it’s beneficial to negotiate terms that suit your purchasing strategy. -

How can I ensure the quality of the elevator buckets I purchase?

To ensure quality, work with reputable suppliers who provide certifications and compliance with international standards. Request samples to assess material quality and workmanship before placing a larger order. Additionally, inquire about the supplier’s quality assurance processes, including testing and inspections conducted throughout production. It may also be helpful to read reviews or testimonials from other customers to gauge their experiences regarding product quality and reliability. -

What payment terms are typically offered by suppliers for elevator buckets?

Payment terms can vary widely among suppliers, but common options include upfront payments, net 30, or net 60 days after delivery. For larger orders, some suppliers may offer financing options or payment plans. It is advisable to clarify payment terms before finalizing any agreements to ensure they align with your cash flow needs. Additionally, consider using secure payment methods and possibly escrow services for high-value transactions to protect your investment. -

What are the logistics considerations when sourcing elevator buckets internationally?

When sourcing elevator buckets internationally, consider shipping costs, customs regulations, and lead times. Evaluate whether the supplier can handle logistics or if you need to arrange shipping independently. It’s essential to understand import duties and taxes that may apply to your shipment. Collaborate with logistics providers familiar with your destination’s regulations to ensure smooth customs clearance. Always factor in potential delays and plan your inventory levels accordingly to avoid operational disruptions. -

Can elevator buckets be customized to meet specific operational requirements?

Yes, many suppliers offer customization options for elevator buckets. This can include modifications to size, material, mounting styles, and design features to suit your operational needs. Customization is particularly beneficial for businesses with unique material handling requirements or those operating in specialized environments. When discussing custom options, provide detailed specifications and expectations to the supplier to ensure the final product meets your needs. -

What types of elevator buckets are best suited for high-temperature materials?

For high-temperature applications, steel or stainless steel elevator buckets are often the best choice due to their ability to withstand extreme heat without deforming. Additionally, buckets made from specialized materials like urethane or high-temperature plastics may be suitable for specific conditions. Always consult with suppliers about the temperature limits of their products and consider the nature of the materials being transported to select the most appropriate bucket type for your needs.

Top 8 Elevator Bucket Manufacturers & Suppliers List

1. MaxiLift – Agricultural and Industrial Buckets

Domain: maxilift.com

Registered: 1996 (29 years)

Introduction: {“Agricultural_Buckets”: [“Tiger-Tuff”, “Tiger-CC”, “HD-Max”, “CC-Max”, “HD-Stax”, “Dura-Buket”, “Peanut Bucket”, “CC Steel”], “Industrial_Buckets”: [“Tiger-Tuff (Industrial)”, “Tiger-CC (Industrial)”, “Maxi-Tuff AA”, “Maxi-Tuff MF”, “DI-Max AA”, “DI-Max AC”], “Welded_Steel_Belt_Splices”: [“Maxi-Splice”, “Super Maxi-Splice”, “Ultra Titan Splice”, “Maxi-Splice Template”], “Accessories”: [“Tape & Po…

2. Tapco Inc – Versatile Buckets

Domain: tapcoinc.com

Registered: 1996 (29 years)

Introduction: This company, Tapco Inc – Versatile Buckets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Muller Beltex – Elevator Buckets

Domain: mullerbeltex.com

Registered: 1999 (26 years)

Introduction: Elevator buckets from Muller Beltex include a variety of options suitable for different raw materials and conditions. Key products include: 1. **Columbus Elevator Bucket** – Seamless design for granules and floury products. 2. **Welded AC-Style Elevator Bucket** – Complies with DIN standards, customizable hole patterns, various steel types. 3. **Starco Steel Elevator Buckets** – Designed for highe…

4. Express FGP – Elevator Buckets

Domain: expressfgp.com

Registered: 2022 (3 years)

Introduction: Elevator buckets are designed for efficient material handling in various industries. They come in different sizes and materials to suit specific applications. The buckets are engineered for durability and performance, ensuring optimal flow and minimal spillage during operation. Key features include compatibility with various elevator systems, ease of installation, and resistance to wear and tear. …

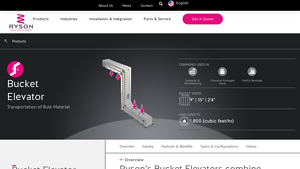

5. Ryson – Bucket Elevator

Domain: ryson.com

Registered: 1996 (29 years)

Introduction: Bucket Elevator – Ryson International

– Commonly used in: Industrial & Manufacturing, Consumer Packaged Goods, Food & Beverage

– Bucket Width Options: 9″, 15″, 2’4″

– Max Capacity: 1,800 cubic feet/hr

– Features:

– Combines vertical and horizontal transportation of bulk materials

– Durable and robust construction

– Gentle handling of products

– Completely enclosed and overlapping pivoting…

6. Tapco – BUCP0509B 9×5 Elevator Buckets

Domain: midwestagsystems.net

Registered: 2008 (17 years)

Introduction: {“product_name”: “BUCP0509B 9×5 Elevator Buckets”, “dimensions”: “9×5 inches”, “style”: “CC-HD”, “vendor”: “Tapco”, “price”: “$7.73”, “availability”: “In Stock”, “sku”: “BUCP0509B”, “category”: “Grain Elevator Parts & Accessories”, “tags”: [“Elevator Buckets”], “quantity_left”: 2}

7. Universal Industries – Bucket Elevators

Domain: universalindustries.com

Registered: 1997 (28 years)

Introduction: Universal Industries offers a range of bucket elevators designed for handling bulk products, including the following series:

1. **Twin Trunk Alpha Series**: Features EASY DUMP® capacity rating for gravity discharge, available in various capacities, speeds, and bucket types, ideal for gentle handling of bulk products.

2. **G Series**: Twin trunk casing, centrifugal discharge elevators designed t…

8. Grain Belt Supply Co. – Elevator Buckets

Domain: grainbeltsupply.com

Registered: 1998 (27 years)

Introduction: Elevator Buckets – Grain Belt Supply Co., Inc. offers custom manufacturing of elevator buckets in various materials including Carbon Steel, Stainless Steel, Ductile Iron, Aluminum, Polyethylene, Galvanized, and Special Alloys. Key product options include venting, special punching, lip braces, wear strips, and relief holes. The product line includes: 1. Superior Plastic Buckets (Style CC) – FDA app…

Strategic Sourcing Conclusion and Outlook for elevator bucket

How Can Strategic Sourcing Enhance Your Elevator Bucket Procurement?

In the evolving landscape of elevator bucket manufacturing, strategic sourcing emerges as a crucial component for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By prioritizing quality and durability, buyers can leverage advanced materials and innovative designs from industry leaders to optimize their operations. The variety of options—from agricultural to industrial buckets—ensures that businesses can find the right fit for their specific needs, enhancing operational efficiency and reducing downtime.

Moreover, forging strong partnerships with reputable suppliers can lead to cost savings through bulk purchasing and streamlined logistics. As sustainability becomes increasingly important, sourcing from manufacturers committed to eco-friendly practices can also align with corporate social responsibility goals.

Looking ahead, it is vital for businesses to stay informed about the latest advancements in elevator bucket technology and market trends. Engage with trusted suppliers, attend industry events, and utilize design and engineering services offered by manufacturers to ensure your operations remain competitive. Embrace strategic sourcing as a pathway to not just meet current demands, but to anticipate future challenges and opportunities in your sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.