Choosing Your Electrical Outlets In Jamaica: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for electrical outlets in jamaica

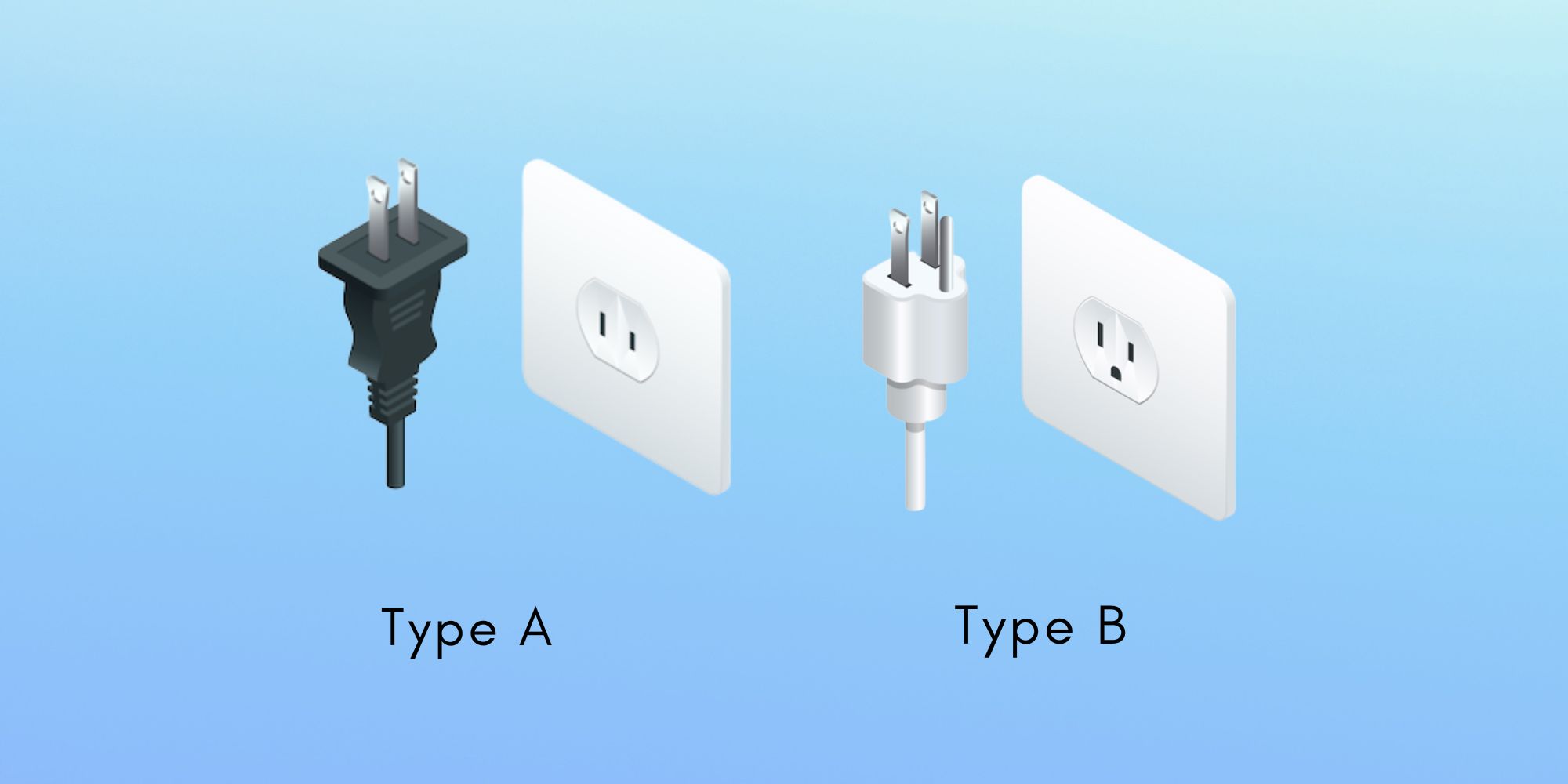

Navigating the complexities of sourcing electrical outlets in Jamaica can pose a significant challenge for international B2B buyers. With Jamaica’s unique electrical standards featuring Type A and B sockets, along with a supply voltage of 110V at 50Hz, understanding these specifications is crucial to ensuring compatibility and safety for your electrical devices. This comprehensive guide delves into the intricacies of the Jamaican electrical outlet market, covering various types of outlets, their applications, and the essential considerations for sourcing the right products.

As a buyer from regions such as Africa, South America, the Middle East, or Europe, it is imperative to understand the local market nuances, including potential supplier vetting processes and cost implications. This guide equips you with actionable insights to make informed purchasing decisions, enabling you to confidently navigate the logistics of importing electrical outlets into Jamaica. From evaluating supplier reliability to understanding the necessary adapters and converters for your devices, we aim to streamline your sourcing process.

In addition, we address common pitfalls and provide expert recommendations tailored to your specific needs. By leveraging this guide, you will not only enhance your purchasing strategy but also ensure compliance with Jamaica’s electrical standards, thereby facilitating smoother operations in your business ventures on this vibrant Caribbean island.

Understanding electrical outlets in jamaica Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel pins | General consumer electronics, portable devices | Pros: Widely available, compatible with US devices. Cons: Lacks grounding, may not support higher power appliances. |

| Type B | Two flat parallel pins and a grounding pin | Commercial equipment, appliances requiring grounding | Pros: Grounding offers safety, suitable for higher wattage devices. Cons: Less common than Type A, may require adapters for some devices. |

| Universal Travel Adapter | Adapts multiple plug types | International business travel, tourism | Pros: Versatile, useful for multiple destinations. Cons: May not support high-wattage devices, can be bulky. |

| Voltage Converter | Converts voltage levels | Heavy machinery, sensitive electronics | Pros: Essential for non-dual voltage devices. Cons: Can be expensive, bulky, and may not be needed for dual voltage devices. |

| Power Strip with Surge Protection | Multiple outlets and surge protection | Offices, trade shows, equipment rentals | Pros: Allows multiple devices to connect, provides surge protection. Cons: May require a specific plug type, can be cumbersome to transport. |

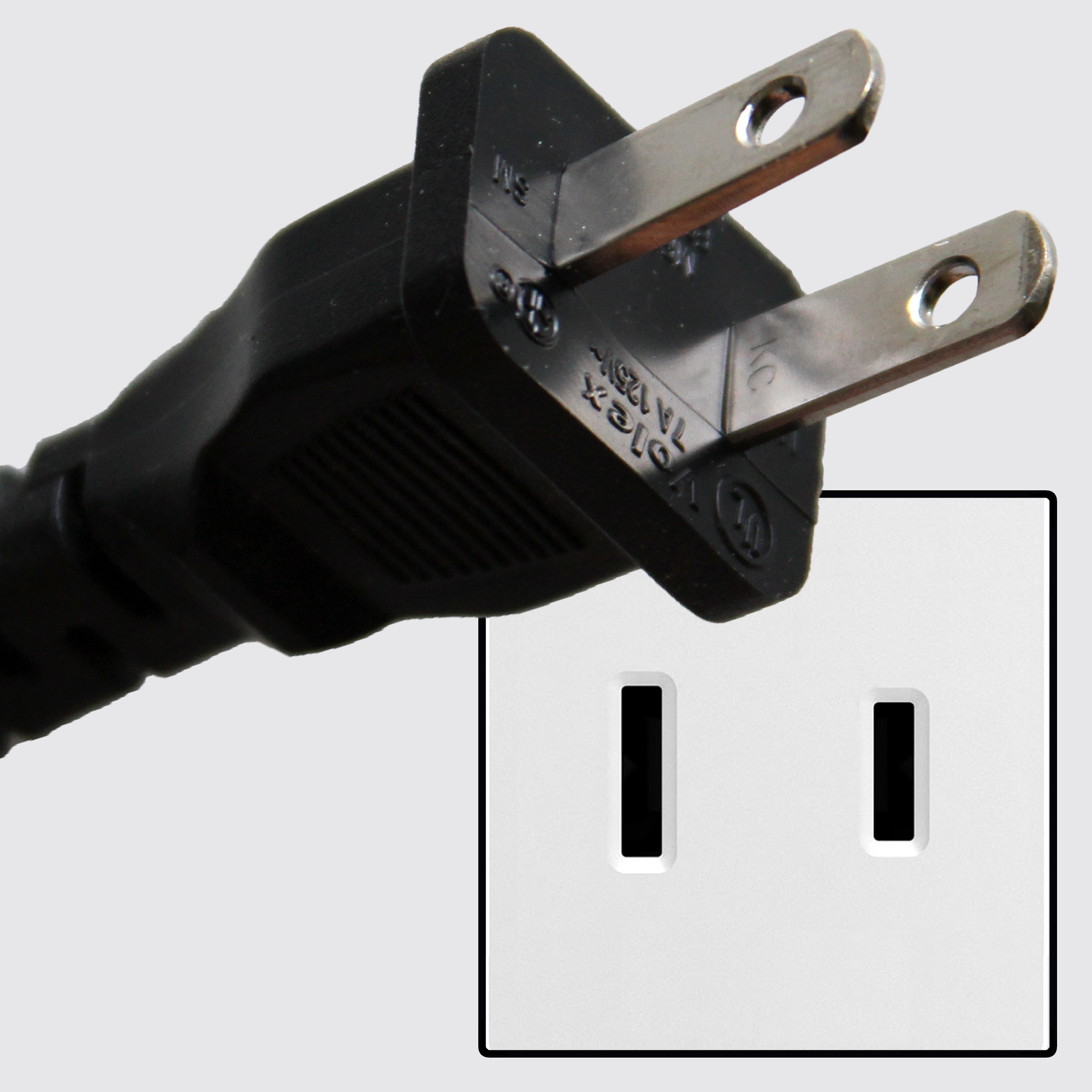

What Are the Key Characteristics of Type A Outlets in Jamaica?

Type A outlets feature two flat parallel pins and are primarily used for low-power devices such as chargers and small electronics. These outlets are similar to those found in the United States, making them familiar to many international travelers. For B2B buyers, it is crucial to consider that while Type A is widely available, it lacks grounding, which may pose safety risks for devices that require a stable power source.

How Do Type B Outlets Differ in Functionality?

Type B outlets include an additional grounding pin, making them safer for high-wattage appliances and commercial equipment. This grounding feature is vital for devices that may produce excess heat or require a stable power supply. B2B buyers should prioritize Type B outlets for any equipment that necessitates grounding to prevent electrical hazards.

Why Consider Universal Travel Adapters for Business Needs?

Universal travel adapters are designed to accommodate various plug types, making them ideal for international business travelers. They facilitate the use of devices across multiple countries without needing to purchase specific adapters for each location. However, buyers should be cautious about the wattage limitations of these adapters, as they may not support high-power devices.

When Is a Voltage Converter Necessary for B2B Operations?

Voltage converters are essential for appliances that do not support dual voltage. They convert the electrical supply to match the requirements of the device, ensuring safe operation. B2B buyers should assess their equipment’s voltage ratings before purchasing a converter, as using the wrong voltage can lead to equipment failure or safety issues.

How Can Power Strips with Surge Protection Enhance Business Operations?

Power strips with surge protection are invaluable in settings where multiple devices need to be connected simultaneously. They provide a safeguard against voltage spikes, which can damage sensitive electronics. For businesses, investing in quality power strips can enhance operational reliability and protect against costly equipment repairs. However, ensure compatibility with the specific outlet types in Jamaica to avoid connection issues.

Key Industrial Applications of electrical outlets in jamaica

| Industry/Sector | Specific Application of electrical outlets in Jamaica | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Power outlets in hotel rooms for guest electronics | Enhances guest experience, encourages longer stays | Availability of type A and B outlets, safety certifications |

| Telecommunications | Outlets for telecommunications equipment in local offices | Supports reliable communication infrastructure | Compatibility with local voltage and frequency standards |

| Manufacturing | Power supply for machinery and tools in factories | Increases operational efficiency and productivity | Need for heavy-duty outlets and circuit breakers |

| Retail | Outlets for point-of-sale systems and customer charging stations | Improves customer service and sales opportunities | Accessibility and placement of outlets for customer use |

| Healthcare | Electrical outlets for medical devices in clinics and hospitals | Ensures patient safety and operational reliability | Compliance with health regulations and safety standards |

How Are Electrical Outlets Used in the Hospitality Industry in Jamaica?

In the hospitality sector, electrical outlets are essential for enhancing the guest experience. Hotels and resorts typically equip rooms with multiple type A and B outlets to accommodate various electronic devices, such as laptops, smartphones, and chargers. This convenience not only meets the needs of international travelers but also encourages longer stays. For B2B buyers from regions like Africa and South America, sourcing outlets that comply with local safety standards and ensuring they are easily accessible within the room layout are crucial considerations.

What Role Do Electrical Outlets Play in Telecommunications?

Telecommunications companies in Jamaica rely on electrical outlets to power essential equipment, including routers, switches, and servers. The availability of reliable power sources is vital for maintaining uninterrupted communication services. B2B buyers, particularly from Europe and the Middle East, must ensure that the outlets they source are compatible with the local voltage (110V) and frequency (50Hz) to avoid operational disruptions. Additionally, investing in surge protectors can safeguard equipment from power fluctuations.

How Are Electrical Outlets Integral to Manufacturing Operations?

In manufacturing, electrical outlets are critical for powering machinery and tools necessary for production processes. Factories in Jamaica require outlets that can handle high voltage and heavy loads, necessitating the use of type B outlets equipped with grounding pins for safety. International buyers must consider the specific power requirements of their machinery and ensure compliance with local electrical codes to minimize risks. Efficient sourcing of heavy-duty outlets can significantly enhance operational productivity.

Why Are Electrical Outlets Important for Retail Businesses?

Retail environments use electrical outlets for point-of-sale systems and customer charging stations, which are increasingly popular. Providing accessible outlets improves customer service, allowing shoppers to charge their devices while they browse, thereby increasing sales opportunities. B2B buyers in this sector should focus on the strategic placement of outlets to maximize accessibility and ensure they meet safety standards. Additionally, sourcing aesthetically pleasing outlet covers can enhance the overall retail environment.

How Do Electrical Outlets Support Healthcare Facilities?

In healthcare settings, electrical outlets are crucial for powering medical devices, such as monitors, infusion pumps, and sterilizers. The reliability of these outlets directly impacts patient safety and the quality of care provided. For B2B buyers from various regions, ensuring that sourced outlets comply with strict health regulations and safety standards is paramount. Additionally, outlets must be strategically placed to facilitate easy access for medical staff while minimizing trip hazards in patient areas.

3 Common User Pain Points for ‘electrical outlets in jamaica’ & Their Solutions

Scenario 1: Incompatibility with Local Electrical Standards

The Problem:

International B2B buyers often face significant challenges when dealing with electrical outlets in Jamaica, particularly regarding compatibility issues. For example, a company may import equipment designed for different electrical standards (like European or African standards) that do not fit Jamaican sockets. This incompatibility can lead to delays in operations, increased costs for additional adapters, and potential safety hazards if the equipment is improperly connected. The unfamiliarity with local electrical standards can create confusion and frustration for businesses looking to establish operations or partnerships in Jamaica.

The Solution:

To mitigate compatibility issues, B2B buyers should conduct thorough research on Jamaica’s electrical standards before importing equipment. Ensure that all devices meet the local specifications—Jamaica uses Type A and Type B sockets, with a voltage of 110V and a frequency of 50Hz. When sourcing equipment, opt for dual-voltage appliances that support a range of voltages (e.g., 110-240V) to avoid the need for voltage converters. Additionally, consider purchasing a bulk supply of travel adapters or socket converters from reliable local suppliers or international wholesalers who specialize in electrical components. This proactive approach ensures that all equipment can be safely and efficiently used upon arrival, reducing downtime and enhancing operational efficiency.

Scenario 2: Frequent Power Surges and Voltage Fluctuations

The Problem:

Another common pain point for businesses operating in Jamaica is the prevalence of power surges and voltage fluctuations. These irregularities can damage sensitive electronic equipment, leading to costly repairs and extended downtime. For example, a manufacturing facility may experience interruptions in production due to unexpected power surges that affect their machinery, causing financial losses and jeopardizing contracts.

The Solution:

To safeguard against power surges, B2B buyers should invest in high-quality surge protectors and voltage stabilizers for all electrical equipment. Partnering with local electrical supply companies that understand the nuances of Jamaican infrastructure can provide access to reliable surge protection solutions. Furthermore, incorporating power backup systems, such as uninterruptible power supplies (UPS), can help maintain operations during outages and fluctuations. Regular maintenance checks and consulting with local electricians can also ensure that the electrical systems are up to code and adequately protected against surges, thus enhancing overall equipment longevity and reliability.

Scenario 3: Limited Availability of Specialized Electrical Components

The Problem:

Many international buyers encounter difficulties in sourcing specialized electrical components that meet their specific needs in Jamaica. For instance, a company may require specific types of outlets or connectors that are not readily available in local markets, which can delay project timelines and increase operational costs. This scarcity can pose significant challenges, especially for companies looking to implement complex electrical installations or upgrades.

The Solution:

To overcome this challenge, B2B buyers should establish relationships with both local suppliers and international manufacturers who can provide specialized electrical components. It is advisable to conduct a comprehensive market analysis to identify key suppliers in Jamaica that can meet specific requirements. Additionally, creating a contingency plan that includes pre-ordering critical components and maintaining an inventory can prevent project delays. Engaging in direct communication with manufacturers about the unique needs of the Jamaican market can also lead to customized solutions that enhance operational efficiency. By strategically planning and sourcing, businesses can ensure they have the necessary components on hand when needed, minimizing downtime and maximizing productivity.

Strategic Material Selection Guide for electrical outlets in jamaica

When selecting materials for electrical outlets in Jamaica, international B2B buyers must consider several factors including local standards, environmental conditions, and the specific requirements of their target markets. Below is an analysis of common materials used in the manufacturing of electrical outlets, focusing on their properties, pros and cons, and implications for application.

What are the Key Properties of Thermoplastic Materials for Electrical Outlets?

Thermoplastics, such as polycarbonate and nylon, are widely used in electrical outlet manufacturing due to their excellent insulating properties and resistance to impact and heat. They typically have a temperature rating of up to 85°C and can withstand moderate pressure. Their corrosion resistance is also notable, making them suitable for various environments, including those with humidity, which is common in Jamaica.

Pros: Thermoplastics are lightweight, cost-effective, and easy to mold, allowing for complex designs. They also provide good electrical insulation, which is crucial for safety in electrical applications.

Cons: However, thermoplastics can be less durable than other materials under extreme conditions, such as high temperatures or exposure to UV light, which may lead to degradation over time.

Impact on Application: These materials are suitable for standard residential and commercial applications but may not be ideal for heavy-duty industrial settings where higher durability is required.

How Do Metal Components Enhance Electrical Outlet Performance?

Metal components, typically made from brass or copper, are often used for the conductive parts of electrical outlets. These materials offer excellent conductivity and thermal properties, with high corrosion resistance when properly coated.

Pros: Metals provide a robust connection and are capable of handling higher electrical loads, making them suitable for heavy-duty applications. Their durability ensures a longer lifespan for the electrical outlet.

Cons: The primary disadvantage is the higher cost of metal components compared to thermoplastics. Additionally, metals can corrode if not adequately protected, particularly in humid environments like Jamaica.

Impact on Application: Metal components are essential for outlets used in industrial applications or where high current is expected, ensuring reliable performance under demanding conditions.

What Role Do Composite Materials Play in Electrical Outlet Manufacturing?

Composite materials, which combine thermoplastics with reinforcing fibers, offer a balance between strength and weight. They can withstand higher temperatures and pressures than standard thermoplastics, making them suitable for more demanding applications.

Pros: Composites are highly durable and can be engineered to meet specific performance criteria, including enhanced thermal stability and impact resistance.

Cons: The manufacturing complexity of composites can lead to higher production costs. Additionally, they may not be as widely accepted in all markets due to varying standards.

Impact on Application: These materials are particularly useful in specialized applications where both strength and electrical insulation are required, such as in outdoor or industrial environments.

How Do Environmental Considerations Affect Material Selection for Electrical Outlets?

Environmental factors such as humidity, temperature fluctuations, and exposure to chemicals can significantly impact material selection. For instance, materials must be resistant to corrosion and able to maintain performance in Jamaica’s tropical climate.

Pros: Selecting materials that are specifically designed for high humidity and temperature resistance can enhance safety and reliability.

Cons: However, these materials can be more expensive and may require compliance with specific international standards, which can complicate sourcing for international buyers.

Impact on Application: Buyers must ensure that the materials used comply with local and international standards, such as ASTM or IEC, to guarantee safety and performance.

Summary Table of Material Selection for Electrical Outlets in Jamaica

| Material | Typical Use Case for electrical outlets in jamaica | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Residential and light commercial outlets | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Metal | Heavy-duty and industrial outlets | Excellent conductivity and durability | Higher cost and potential corrosion | High |

| Composite | Specialized industrial applications | Enhanced strength and thermal stability | Higher manufacturing complexity | Medium |

| Environmentally Resistant Material | Outdoor and high-humidity environments | Superior corrosion resistance | Potentially higher costs and compliance needs | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers looking to source electrical outlets suitable for the Jamaican market. Understanding the properties, advantages, and limitations of each material will aid in making informed purchasing decisions that align with both performance requirements and budget considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical outlets in jamaica

What Are the Key Stages in the Manufacturing Process of Electrical Outlets in Jamaica?

The manufacturing of electrical outlets in Jamaica involves several critical stages that ensure both functionality and safety for end-users. This process typically encompasses material preparation, forming, assembly, and finishing, with each stage incorporating specific techniques aimed at maintaining quality and compliance with international standards.

How Is Material Prepared for Electrical Outlet Manufacturing?

The first step in manufacturing electrical outlets involves selecting high-quality materials, primarily plastics and metals. The plastics used are often thermoplastics that provide insulation and durability, while metals, such as copper and brass, are utilized for conductive components.

Material preparation includes the following steps:

– Material Selection: Manufacturers choose materials based on electrical and thermal conductivity, resistance to environmental factors, and compliance with safety regulations.

– Material Testing: Before production, raw materials undergo rigorous testing to ensure they meet specific standards, including tensile strength and thermal stability.

– Preprocessing: This may involve cutting, molding, or shaping materials to ensure they fit the design specifications required for the outlets.

What Techniques Are Used in the Forming Stage of Electrical Outlets?

Once the materials are prepared, the forming stage begins. This is where the actual shape and structure of the electrical outlets are created.

- Injection Molding: A primary technique used for creating the plastic housing of electrical outlets. This method involves injecting molten plastic into a mold where it cools and solidifies into the desired shape.

- Die-Casting: For metal components, die-casting is commonly employed. This involves forcing molten metal into a mold, allowing for precision and a smooth finish.

- Stamping: This technique is often used for creating contacts and other metal parts within the outlet. Stamping ensures uniformity and high production rates.

How Are Electrical Outlets Assembled and Finished?

The assembly stage is where various components come together to create the final product.

- Assembly Techniques: Components such as the plastic housing, metal contacts, and screws are assembled using automated machinery. This reduces human error and increases efficiency.

- Soldering and Connections: Electrical connections are soldered to ensure conductivity. This process must be carefully controlled to avoid overheating and damaging components.

- Finishing Touches: The final stage includes applying surface treatments, such as coatings to enhance durability and aesthetics. Additionally, components are inspected for alignment and proper function.

What Quality Control Measures Are Implemented During Manufacturing?

Quality assurance is crucial in the manufacturing of electrical outlets to ensure safety and reliability. Various international standards, such as ISO 9001, and industry-specific certifications, such as CE and UL, guide these processes.

Illustrative image related to electrical outlets in jamaica

What Are the Key Quality Control Checkpoints?

- Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards before being used in production.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and identify defects early. This includes checking dimensions, mechanical properties, and electrical safety.

- Final Quality Control (FQC): After assembly, the final products undergo rigorous testing to ensure they function correctly and meet all safety standards. This may involve electrical testing, durability testing, and compliance checks.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to mitigate risks associated with defective products.

- Supplier Audits: Conducting audits at the manufacturing facility can provide insights into the quality control processes and adherence to international standards.

- Quality Assurance Reports: Requesting detailed QA reports from suppliers can help assess their compliance with relevant standards and their internal quality measures.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and the final products. These inspections should be conducted at various stages of production, from raw material acquisition to final assembly.

What Are the Common Testing Methods for Electrical Outlets?

Testing is a critical component of quality assurance, particularly in ensuring the safety and functionality of electrical outlets. Common testing methods include:

- Electrical Safety Testing: This involves verifying that the outlet can handle the specified voltage and current without risk of failure.

- Insulation Resistance Testing: This test checks for proper insulation between conductive parts to prevent short circuits.

- Thermal Testing: Outlets are subjected to conditions that simulate prolonged use to ensure they can withstand heat without degrading.

- Durability Testing: This assesses the physical robustness of the outlet through repeated insertions and removals of plugs.

What Nuances Should International B2B Buyers Be Aware of Regarding QC and Certifications?

International B2B buyers must navigate various certifications and quality control nuances specific to their regions. Understanding the following can aid in smoother transactions:

- Regional Standards Compliance: Different regions may have unique regulations and standards. For example, CE marking is essential for products sold in Europe, while UL certification is critical for the North American market.

- Documentation and Traceability: Ensure that suppliers provide all necessary documentation for compliance and traceability of materials used in the manufacturing process.

- Communication of Standards: Establish clear communication with suppliers about the standards that must be met for your specific market, including any certifications required for importation.

In conclusion, the manufacturing processes and quality assurance measures for electrical outlets in Jamaica are intricate and designed to ensure compliance with international standards. For B2B buyers, understanding these processes is essential for making informed decisions and ensuring the safety and reliability of electrical outlets sourced from Jamaica.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical outlets in jamaica’

In the context of international business, sourcing electrical outlets for use in Jamaica requires a systematic approach to ensure compliance with local standards and compatibility with devices. This guide provides a practical checklist for B2B buyers looking to procure electrical outlets that meet the specific needs of the Jamaican market.

Step 1: Understand Local Electrical Standards

Before sourcing, familiarize yourself with Jamaica’s electrical specifications. The country utilizes Type A and Type B outlets, with a standard voltage of 110V and a frequency of 50Hz. Understanding these specifications is crucial as they directly affect the compatibility of your electrical devices and the safety of their usage.

Step 2: Identify Your Device Requirements

Assess the electrical appliances you plan to use in Jamaica. Check whether they are single or dual voltage rated. Devices labeled as dual voltage (e.g., “INPUT: 110-240V”) can operate safely without a voltage converter, while single voltage appliances will require additional equipment to function properly.

- Single Voltage Devices: Ensure you have a voltage transformer or converter.

- Dual Voltage Devices: Only a plug adapter will be needed.

Step 3: Research Reliable Suppliers

Conduct thorough research on potential suppliers for electrical outlets. Look for suppliers with a proven track record in exporting to Jamaica or similar markets. Verify their certifications and compliance with international safety standards to ensure product reliability.

- Request Documentation: Ask for compliance certificates, safety testing results, and product specifications.

- Check References: Contact other businesses that have procured from the supplier to gauge their reliability.

Step 4: Evaluate Product Quality

Quality assurance is paramount when sourcing electrical outlets. Request samples or product specifications to assess materials used and manufacturing standards. Low-quality products can lead to safety hazards and operational failures.

Illustrative image related to electrical outlets in jamaica

- Material Standards: Ensure outlets are made from durable, heat-resistant materials.

- Testing: Confirm if the products have undergone rigorous testing for safety and efficiency.

Step 5: Consider Adaptability and Compatibility

Choose electrical outlets that are adaptable to various plug types, especially if you anticipate using devices from different regions. This adaptability can enhance the utility of your outlets, making them versatile for various applications.

- Multi-Function Outlets: Look for outlets that can accommodate both Type A and Type B plugs.

- Universal Adapters: Consider sourcing universal adapters that can fit multiple plug types.

Step 6: Plan for Distribution and Logistics

Once you have selected your supplier and products, develop a comprehensive distribution and logistics plan. This includes shipping methods, lead times, and customs regulations specific to Jamaica.

- Shipping Options: Evaluate different shipping methods for cost-effectiveness and reliability.

- Customs Clearance: Understand the documentation required for importing electrical goods into Jamaica to avoid delays.

Step 7: Establish a Communication Channel

Maintain open communication with your supplier throughout the procurement process. This ensures any issues can be addressed promptly, and you can receive updates on your order status.

- Regular Updates: Set expectations for regular updates on production and shipping timelines.

- Feedback Loop: Create a mechanism for providing feedback on product quality and service.

By following this checklist, B2B buyers can effectively source electrical outlets for use in Jamaica, ensuring compatibility, safety, and reliability in their operations.

Comprehensive Cost and Pricing Analysis for electrical outlets in jamaica Sourcing

What are the Key Cost Components for Sourcing Electrical Outlets in Jamaica?

When sourcing electrical outlets in Jamaica, several cost components must be considered to develop a comprehensive pricing analysis. The primary costs include:

-

Materials: The quality of materials used in manufacturing electrical outlets significantly influences the overall cost. High-grade plastics and metals that conform to international safety standards can raise costs but ensure durability and compliance.

-

Labor: Labor costs in Jamaica can vary based on the skill level of workers. Skilled labor may be required for quality control and assembly, impacting the overall production costs. It’s essential to consider local wage rates and the availability of skilled labor when calculating costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. In Jamaica, these costs can be influenced by local economic conditions and infrastructure efficiency.

-

Tooling: Initial costs for tooling, including molds and machinery required for manufacturing, can be substantial. These costs are typically amortized over the production volume, making them a critical factor in pricing, especially for custom or specialized outlets.

-

Quality Control (QC): Ensuring that products meet safety and regulatory standards necessitates a robust QC process. This can include testing for voltage tolerance, durability, and compliance with local and international standards, which may add to production costs.

-

Logistics: Shipping and transportation costs are crucial, particularly for international buyers. Factors such as shipping method, distance, and import duties can significantly influence the total cost of acquisition.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin can vary based on competition, product demand, and the supplier’s positioning in the market.

How Do Price Influencers Affect the Sourcing of Electrical Outlets?

Several factors can influence the pricing of electrical outlets in Jamaica:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQ terms to ensure cost-effectiveness, especially when planning for multiple projects.

-

Specifications and Customization: Custom designs or specifications can increase costs due to the need for specialized tooling or materials. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Outlets that meet international safety and quality certifications (e.g., UL, CE) may command higher prices. However, investing in certified products can reduce the risk of liability and enhance customer trust.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can impact pricing. Established suppliers with a track record of quality and timely delivery may charge a premium, but they often provide greater assurance of product reliability.

-

Incoterms: Understanding the terms of sale is vital. Incoterms dictate responsibilities for shipping, insurance, and tariffs, which can affect the total cost. Buyers should clarify these terms to avoid unexpected fees.

What Are the Best Tips for Negotiating Electrical Outlet Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic purchasing are crucial for cost efficiency. Here are some actionable tips:

-

Understand Total Cost of Ownership: Look beyond the initial purchase price. Consider logistics, import duties, and potential maintenance costs associated with the electrical outlets. A lower upfront cost may lead to higher long-term expenses.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and favorable terms. Regular communication and transparency about your needs can foster trust and collaboration.

-

Request Samples: Before making bulk purchases, request samples to evaluate quality. This can prevent costly mistakes and ensure that the products meet your specifications.

-

Be Informed About Market Trends: Stay updated on market trends, material costs, and competitor pricing. This knowledge can empower buyers during negotiations and help secure better deals.

-

Consider Alternative Suppliers: Don’t hesitate to explore multiple suppliers to find the best combination of price and quality. Comparing offers can reveal opportunities for savings.

Disclaimer

The prices and cost structures discussed are indicative and subject to change based on market conditions, supplier negotiations, and other economic factors. Always conduct thorough research and engage in direct discussions with suppliers for the most accurate pricing.

Alternatives Analysis: Comparing electrical outlets in jamaica With Other Solutions

In the realm of electrical connectivity, particularly for international B2B buyers operating in Jamaica, understanding the local electrical outlets and comparing them with alternative solutions is essential. This section explores the electrical outlets in Jamaica, specifically the Type A and Type B configurations, and compares them with alternative solutions such as universal travel adapters and voltage converters.

| Comparison Aspect | Electrical Outlets In Jamaica | Universal Travel Adapters | Voltage Converters |

|---|---|---|---|

| Performance | Reliable for devices rated at 110V, 50Hz | Allows compatibility with various plug types | Converts voltage for devices not rated for local supply |

| Cost | Low (usually included in local infrastructure) | Moderate ($10-$30) | Higher ($20-$100 depending on wattage) |

| Ease of Implementation | Directly compatible with Type A and B plugs | Simple plug-in design | Requires understanding of wattage and device compatibility |

| Maintenance | Minimal (infrastructure stability) | Low (replace if damaged) | Moderate (ensure proper usage to avoid damage) |

| Best Use Case | For devices designed for North American markets | For travelers with multiple device types | For appliances rated for different voltages (e.g., European devices) |

What Are the Advantages and Disadvantages of Using Universal Travel Adapters?

Universal travel adapters are designed to accommodate various plug types, making them a versatile option for international travelers. They allow users to connect devices from different regions without the need for multiple adapters. The main advantage is convenience, as these adapters can be used in multiple countries. However, they do not convert voltage, meaning they are only effective for devices that are compatible with the local voltage. If a device requires a different voltage, using a universal adapter could damage the appliance.

How Do Voltage Converters Work and What Are Their Pros and Cons?

Voltage converters adjust the electrical voltage to match the requirements of specific devices. They are particularly useful for appliances that are not dual voltage rated and require a different voltage than what is supplied in Jamaica. The pros of using a voltage converter include the ability to safely operate a wide range of appliances from different regions. However, they can be more expensive and may require careful handling to ensure that the appliance’s wattage does not exceed the converter’s limits, which could lead to overheating or damage.

Conclusion: How Should B2B Buyers Choose the Right Electrical Solution?

For B2B buyers operating in Jamaica, the choice between using local electrical outlets, universal travel adapters, or voltage converters depends on the specific needs of their devices and operational context. Companies with a fleet of dual voltage appliances may find that simply using local outlets with the appropriate adapters is sufficient. In contrast, those relying on non-dual voltage equipment should consider investing in voltage converters to protect their investments. Ultimately, understanding the voltage and frequency compatibility of devices, along with the expected usage patterns, will guide buyers in selecting the most effective electrical solution for their business operations in Jamaica.

Essential Technical Properties and Trade Terminology for electrical outlets in jamaica

What Are the Key Technical Properties of Electrical Outlets in Jamaica?

When considering electrical outlets in Jamaica, several technical specifications are critical for B2B buyers to understand. These specifications not only ensure compatibility with devices but also affect the safety and efficiency of electrical systems.

1. Voltage Rating (110V)

Jamaica operates on a standard voltage of 110V, which is crucial for any electrical device or appliance. This specification is important because using devices rated for different voltages can lead to malfunctions or damage. B2B buyers must ensure that their products are compatible with this voltage to avoid costly returns and safety hazards.

2. Frequency (50Hz)

The frequency of electricity supplied in Jamaica is 50Hz. This differs from the 60Hz frequency commonly found in North America. Many electrical devices, particularly those with motors or timers, can be sensitive to frequency changes. Understanding this specification is essential for manufacturers and distributors to ensure optimal performance of their products in Jamaica.

3. Plug Types (A and B)

Jamaica uses two plug types: Type A (two flat parallel pins) and Type B (two flat parallel pins with a grounding pin). For B2B transactions, awareness of plug types is vital for ensuring that electrical products can be safely and effectively used in Jamaica. Companies exporting goods to Jamaica must consider these plug types in their product design or recommend appropriate adapters to their clients.

4. Current Rating (Amperage)

The current rating, typically expressed in amperes (A), indicates how much electrical current a device can handle safely. For electrical outlets in Jamaica, common ratings are 15A or 20A. B2B buyers should ensure that their equipment does not exceed these limits to prevent overheating and potential electrical fires. This is particularly important for commercial applications where multiple devices may be used simultaneously.

5. Material Standards

Electrical outlets must meet specific material standards to ensure durability and safety. This includes using fire-retardant plastics and corrosion-resistant metals. For B2B buyers, understanding these material properties is crucial for compliance with local regulations and ensuring long-term reliability of their electrical products.

What Are Common Trade Terms Used in the Electrical Outlet Industry?

Navigating the trade terminology associated with electrical outlets is essential for B2B buyers to make informed decisions. Here are some common terms that are frequently used in the industry.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electrical outlets, OEMs are critical for ensuring that components meet specific standards required for local markets, including those in Jamaica. Understanding OEM relationships helps buyers identify reliable suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers, as it impacts inventory management and cost-effectiveness. Understanding MOQ can help businesses negotiate better terms and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. In the electrical outlet industry, an RFQ helps buyers compare prices and specifications from different manufacturers, ensuring they make the most cost-effective purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, insurance, and liability, especially when importing electrical outlets into Jamaica.

5. Certification Standards

Certification standards are guidelines that products must meet to ensure safety and performance. For electrical outlets in Jamaica, compliance with local and international certification standards is essential for market acceptance. Buyers should verify that products meet these standards to avoid legal issues and ensure customer safety.

By grasping these technical properties and trade terminology, B2B buyers can better navigate the market for electrical outlets in Jamaica, ensuring successful transactions and product reliability.

Navigating Market Dynamics and Sourcing Trends in the electrical outlets in jamaica Sector

What Are the Key Trends Driving the Electrical Outlets Market in Jamaica?

The electrical outlets market in Jamaica is influenced by several global drivers, including the increasing demand for compatible electrical infrastructure for tourists and expatriates. As Jamaica attracts visitors from various regions, particularly Africa, South America, the Middle East, and Europe, the need for products that accommodate different plug types (A and B) becomes paramount. This demand is further fueled by the rise in e-commerce, enabling international buyers to easily source electrical products tailored for the Jamaican market.

Emerging trends in technology and sourcing strategies are also shaping the market. The integration of smart technology into electrical outlets, such as USB charging ports and energy-efficient designs, is becoming increasingly popular. Furthermore, the trend toward digitalization in supply chain management allows B2B buyers to track sourcing processes in real-time, enhancing transparency and efficiency. Buyers are also prioritizing local partnerships to mitigate import costs and improve supply chain resilience.

For international buyers, understanding the regulatory landscape is crucial. Compliance with local safety standards and certifications is non-negotiable when sourcing electrical outlets. As businesses seek to align with global best practices, they are increasingly looking for suppliers that can demonstrate adherence to quality and safety regulations, making these factors critical for successful market entry.

How Can Sustainability and Ethical Sourcing Impact Your Business in Jamaica?

Sustainability and ethical sourcing are becoming essential considerations for B2B buyers in the electrical outlets market in Jamaica. The environmental impact of electrical products, particularly those made from non-recyclable materials, is under scrutiny. Buyers are encouraged to seek suppliers who prioritize sustainable manufacturing practices, such as using eco-friendly materials and reducing waste in production processes.

Ethical supply chains not only enhance brand reputation but also align with the growing consumer demand for responsible business practices. Buyers should look for certifications that indicate compliance with environmental standards, such as ISO 14001 for environmental management systems or certifications for recyclable materials. These credentials can serve as a selling point in negotiations and marketing efforts, especially among environmentally conscious consumers and businesses.

Additionally, investing in sustainable products can yield long-term cost savings through energy efficiency. Electrical outlets that incorporate energy-saving technologies can significantly reduce electricity consumption, providing both economic and environmental benefits. By prioritizing sustainability in sourcing decisions, B2B buyers can position themselves as leaders in corporate social responsibility while also meeting the demands of a more environmentally aware market.

What Is the Historical Context of Electrical Outlets in Jamaica?

The evolution of electrical outlets in Jamaica is closely tied to the island’s historical relationship with colonial powers and subsequent development. Initially, the electrical infrastructure was heavily influenced by British and American standards, leading to the adoption of plug types A and B, which are similar to those used in the United States. This compatibility has facilitated trade and tourism, making it easier for visitors from North America to use their devices without the need for extensive adapters.

Illustrative image related to electrical outlets in jamaica

As Jamaica modernized, the demand for electrical outlets grew with the expansion of urban areas and the rise of tourism. The government and private sector have increasingly focused on improving the electrical grid and ensuring that it meets international standards, which has been critical for attracting foreign investment. The historical context of Jamaica’s electrical infrastructure reflects a blend of external influences and local adaptations, shaping the current market landscape for electrical outlets.

In summary, understanding the dynamics of the electrical outlets market in Jamaica, including key trends and the importance of sustainability, is essential for international B2B buyers looking to navigate this sector effectively. By aligning sourcing strategies with these insights, buyers can enhance their competitive edge and contribute to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical outlets in jamaica

-

How do I ensure compatibility with Jamaican electrical outlets?

To ensure compatibility with Jamaican electrical outlets, verify the type of plugs your devices utilize. Jamaica predominantly uses Type A and Type B sockets. Type A features two flat parallel pins, while Type B includes an additional grounding pin. If your devices use different plug types, you will need a travel adapter. It’s also crucial to check the voltage rating of your devices; Jamaica operates on 110V at 50Hz. Devices rated for dual voltage (100-240V) will work without a voltage converter, while single voltage devices will require one. -

What are the best practices for sourcing electrical outlets in Jamaica?

When sourcing electrical outlets in Jamaica, begin by identifying reputable local suppliers or manufacturers who specialize in electrical components. Conduct thorough research, including checking online reviews and industry certifications. It’s advisable to request samples to evaluate the quality and compatibility of the products. Establish clear communication regarding your requirements, including specifications, quantities, and delivery timelines. Additionally, consider visiting trade shows or local markets to engage directly with suppliers. -

What customization options are available for electrical outlets?

Customization options for electrical outlets can vary by supplier, but many manufacturers in Jamaica offer tailored solutions to meet specific needs. This may include variations in color, material, or design to fit unique branding or functional requirements. Discuss your needs with potential suppliers, and inquire about their capacity to produce custom designs, including any minimum order quantities (MOQs) that may apply. Ensure to review prototypes before final production to confirm they meet your specifications. -

What are the minimum order quantities (MOQ) for electrical outlets in Jamaica?

Minimum order quantities (MOQs) for electrical outlets can differ significantly among suppliers. Generally, MOQs may range from as low as 100 units to several thousand, depending on the manufacturer and the type of outlet. When negotiating with suppliers, clarify MOQs early in the discussion to align your purchasing strategy with their production capabilities. Be prepared to adjust your order size or explore multiple suppliers if MOQs exceed your requirements. -

What payment terms are commonly offered by suppliers in Jamaica?

Payment terms can vary by supplier, but many offer flexible options to accommodate international buyers. Common terms include partial payment upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may also accept letters of credit or payment through secure platforms like PayPal or bank transfers. It’s essential to discuss payment terms upfront to avoid any misunderstandings and ensure that they align with your budget and cash flow. -

How can I verify the quality assurance (QA) of electrical outlets?

To verify the quality assurance (QA) of electrical outlets, request relevant certifications from suppliers, such as ISO 9001 or other industry-specific standards. Inquire about their manufacturing processes, including testing methods for durability and safety compliance. Conducting an audit of the supplier’s facilities can also provide insights into their quality control measures. If possible, consider third-party testing for additional assurance before placing large orders. -

What logistics considerations should I be aware of when importing electrical outlets?

When importing electrical outlets from Jamaica, logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with both Jamaican and your home country’s import regulations. Understand the documentation required for customs clearance, such as invoices, packing lists, and certificates of origin. Plan for potential delays and additional costs associated with customs duties to ensure smooth delivery. -

What are the common challenges faced when sourcing electrical outlets internationally?

Common challenges when sourcing electrical outlets internationally include language barriers, differing quality standards, and variations in electrical regulations. Additionally, navigating customs and import tariffs can lead to unexpected costs and delays. To mitigate these challenges, conduct thorough research on potential suppliers and establish clear communication channels. It’s also beneficial to work with a local partner or consultant who understands the market dynamics and can help facilitate transactions.

Top 5 Electrical Outlets In Jamaica Manufacturers & Suppliers List

1. Electrical Safety First – Travel Adaptor for Jamaica

Domain: electricalsafetyfirst.org.uk

Registered: 2013 (12 years)

Introduction: Travel Adaptor for Jamaica

– Plug Types: A (two flat parallel pins) and B (two flat parallel pins with a grounding pin)

– Voltage: 110V supply voltage

– Frequency: 50Hz

– Important Note: Travel adaptors do not convert voltage or frequency.

– Dual Voltage Appliances: If an appliance is rated 110-240V, only a travel adaptor is needed.

– Single Voltage Appliances: If not dual voltage rated, a voltage…

2. Wise – Power Plug Guide

Domain: wise.com

Registered: 1994 (31 years)

Introduction: Jamaica has 2 associated plug types: type A (two flat parallel pins) and type B (three pins – two flat parallel pins and one rounded pin). The standard voltage in Jamaica is 110V at a frequency of 50Hz. Travelers may need a power plug adaptor if their home country’s plug shape differs. A power converter may be necessary if the voltage of the appliance is different. Dual voltage appliances typicall…

3. Going In Style – Jamaica Travel Adapter Kit

Domain: goinginstyle.com

Registered: 1996 (29 years)

Introduction: Jamaica Travel Adapter Kit | Going In Style

– Regular price: $15.00 / Adapter Kit

– Available Kits:

– Deluxe Adapter Kit: $15.00 USD (includes two adapters, ships Priority Mail with tracking)

– Standard Adapter Kit: $9.00 USD (includes one grounded adapter)

– Basic Adapter Kit: $4.50 USD (includes one non-grounded adapter)

– Purpose: For charging smartphones, tablets, and other electronics …

4. Sandals Ochi – Electrical Outlet Compatibility

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The electrical outlets at Sandals Ochi are compatible with US plugs, so no adapters are needed.

5. World Standards – Jamaica Power Plugs

Domain: worldstandards.eu

Introduction: In Jamaica, the official standard power plugs and sockets are types A and B. Type A has 2 pins (not grounded), while Type B has 3 pins (grounded). Both types are rated at 15 A and operate on a mains voltage of 110 volts with a frequency of 50 Hz. Type A plugs have two flat parallel prongs, while Type B plugs include a round or U-shaped earth pin. The ungrounded Type A plug is polarized, meaning it…

Strategic Sourcing Conclusion and Outlook for electrical outlets in jamaica

In conclusion, understanding the electrical outlet landscape in Jamaica is essential for international B2B buyers seeking to source electrical equipment and appliances. With a standard voltage of 110V and frequency of 50Hz, Jamaica primarily utilizes plug types A and B, similar to the United States. This compatibility can facilitate smoother operations for businesses importing devices designed for these specifications, minimizing the need for additional converters or adapters.

Strategic sourcing in this context not only involves selecting the right products but also entails a thorough understanding of local requirements, ensuring that the equipment will function optimally without complications. Buyers should prioritize dual voltage appliances when possible to reduce logistical challenges and potential equipment failures.

As Jamaica continues to expand its market for electrical goods, especially in tourism and hospitality, there lies a significant opportunity for international buyers from Africa, South America, the Middle East, and Europe to engage in this growing sector. By aligning sourcing strategies with local standards, businesses can leverage this market’s potential, ensuring both compliance and customer satisfaction. Now is the time to explore partnerships and invest in high-quality electrical products that meet Jamaica’s unique requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.