Choosing Your Elastic Cord For Tent Pole Repair: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for elastic cord for tent pole repair

Navigating the complexities of sourcing elastic cord for tent pole repair can be a daunting challenge for international B2B buyers. With the outdoor and recreational sectors experiencing significant growth, the demand for reliable, durable, and cost-effective shock cords is on the rise. This guide aims to equip you with essential insights into the diverse types of elastic cord available, their various applications, and practical advice on supplier vetting. Understanding these elements is crucial for making informed purchasing decisions, especially for buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam.

Within this comprehensive guide, we delve into the specifications of different shock cords, including materials, sizes, and performance attributes that are vital for tent pole repair. We will also explore how to assess supplier credibility, ensuring you partner with manufacturers who meet international quality standards. Additionally, we will provide a breakdown of cost considerations, helping you to identify budget-friendly options without compromising on quality.

By the end of this guide, you will have the knowledge and tools necessary to navigate the global market effectively. This empowers you to make strategic purchasing decisions that enhance your product offerings and meet the growing demands of your customers in the outdoor recreation space.

Understanding elastic cord for tent pole repair Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shock Cord | Elastic, typically made from nylon; available in various diameters (1/8″ to 1/4″) | Tent pole repair, bungee straps, and canopies | Pros: Durable, versatile; Cons: Can wear out over time. |

| Heavy-Duty Shock Cord | Thicker and more robust; designed for heavy-duty applications | Commercial tents, large canopies, outdoor events | Pros: High tensile strength; Cons: Heavier, potentially less flexible. |

| UV-Resistant Cord | Treated to resist UV degradation; often made from polyester | Long-term outdoor use, tents in sunny climates | Pros: Longer lifespan in sunlight; Cons: May be more expensive. |

| Reflective Shock Cord | Incorporates reflective materials for visibility at night | Camping gear, safety applications | Pros: Enhances visibility; Cons: Limited applications. |

| Multi-Purpose Elastic Cord | Flexible use in various settings; can be used for tent poles, crafts, or bungee applications | DIY repairs, outdoor gear modifications | Pros: Highly versatile; Cons: May lack the specific strength needed for heavy-duty use. |

What are the Characteristics of Shock Cord for Tent Pole Repair?

Shock cord is the most common type of elastic cord used for tent pole repair. Made primarily from nylon, it is available in various diameters, typically ranging from 1/8″ to 1/4″. This type of cord is elastic and resilient, making it ideal for restoring the tension in tent poles. When purchasing, B2B buyers should consider the specific diameter and length required for their tent models, as well as the tensile strength to ensure durability.

How Does Heavy-Duty Shock Cord Differ from Standard Options?

Heavy-duty shock cord is designed for more demanding applications, featuring a thicker diameter and enhanced tensile strength. This type is particularly suitable for commercial tents or large canopies used in outdoor events. Buyers should evaluate the specific weight and stress loads expected in their applications to determine if this robust option is necessary. While it offers superior strength, it may be heavier and less flexible than standard shock cords.

Why Choose UV-Resistant Cord for Tent Applications?

UV-resistant cords are treated to withstand the damaging effects of sunlight, making them ideal for tents that will be exposed to prolonged sunlight. This type of cord is typically made from polyester, which enhances its durability against UV rays. B2B buyers in regions with high sun exposure should consider this option for a longer lifespan of their tent poles. Although these cords may come at a premium price, the investment can lead to significant long-term savings.

What Advantages Does Reflective Shock Cord Offer?

Reflective shock cord incorporates materials that enhance visibility, making it an excellent choice for nighttime camping or safety applications. While primarily used for tent poles, its reflective properties can also be beneficial for guy lines or securing other outdoor gear. B2B buyers should consider the specific environments in which their products will be used, as this type of cord may be limited to niche applications, despite its unique advantages.

How Can Multi-Purpose Elastic Cord Benefit Buyers?

Multi-purpose elastic cord is versatile and can be used for various applications, including tent pole repairs, crafting, and creating bungee straps. This flexibility makes it appealing for businesses looking to stock a single type of cord for multiple uses. However, buyers should be aware that while it is suitable for light to moderate applications, it may not provide the same level of strength as specialized cords designed for heavy-duty use.

Key Industrial Applications of elastic cord for tent pole repair

| Industry/Sector | Specific Application of elastic cord for tent pole repair | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Repairing tent poles for camping and hiking | Cost-effective maintenance solution, prolongs equipment life | Durability against weather conditions, ease of installation |

| Event Management | Supporting temporary structures like tents and canopies | Enhances safety and functionality of outdoor events | UV resistance, availability in bulk |

| Military and Defense | Maintaining mobile shelters and tents | Ensures operational readiness and reliability | Compliance with military standards, high tensile strength |

| Disaster Relief Organizations | Quick repairs for emergency shelters | Rapid deployment and enhanced shelter durability | Lightweight, portable options, ease of sourcing |

| Manufacturing and Retail | Retailing repair kits for consumer tents | Generates additional revenue stream through value-added services | Packaging options, branding opportunities |

How is Elastic Cord Used in the Outdoor Recreation Industry?

In the outdoor recreation sector, elastic cord is primarily utilized for repairing tent poles that may have frayed or lost elasticity over time. This application is crucial for maintaining the structural integrity of tents used during camping or hiking trips. For B2B buyers in this industry, sourcing high-quality elastic cord that is durable and resistant to environmental wear is essential. Buyers should consider the cord’s thickness and elasticity to ensure compatibility with various tent models, which can significantly reduce costs compared to purchasing new poles.

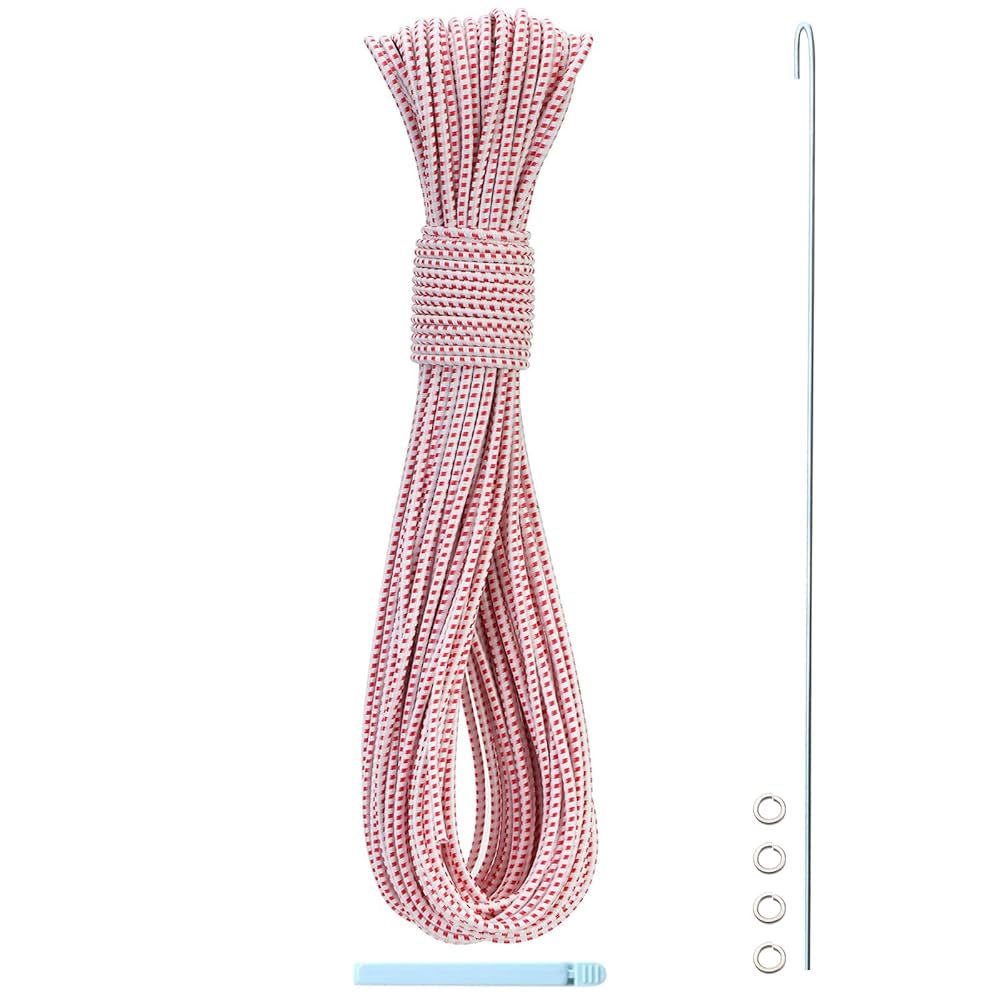

Illustrative image related to elastic cord for tent pole repair

What Role Does Elastic Cord Play in Event Management?

Event management companies often rely on elastic cord for the quick repair of tents and canopies used in outdoor events. This application not only ensures the safety of the structures but also enhances their functionality, allowing for seamless event execution. For international buyers in regions like Africa and South America, sourcing elastic cords that are UV resistant and capable of withstanding diverse weather conditions is vital. Additionally, bulk purchasing options can help manage costs effectively while ensuring a reliable supply for various events.

How is Elastic Cord Essential for Military and Defense Applications?

In military and defense contexts, elastic cord is used to maintain mobile shelters and tents, which are crucial for operational readiness in various environments. The reliability of these structures can significantly impact mission success. B2B buyers in this sector need to focus on sourcing elastic cords that comply with military standards, ensuring high tensile strength and durability. Additionally, the ability to procure these materials quickly and in large quantities is essential to meet the demands of military operations.

Why is Elastic Cord Important for Disaster Relief Organizations?

Disaster relief organizations utilize elastic cord for the quick repair of emergency shelters, allowing for rapid deployment in crisis situations. This application is critical in enhancing the durability and effectiveness of temporary housing solutions during natural disasters. Buyers in this sector should prioritize lightweight and portable elastic cords that can be easily transported and stored. Furthermore, sourcing from reliable suppliers who can guarantee availability during peak disaster response times is crucial for operational efficiency.

How Can Manufacturing and Retail Benefit from Elastic Cord Repair Kits?

Manufacturers and retailers can capitalize on the demand for tent repair solutions by offering elastic cord repair kits to consumers. This value-added service not only enhances customer satisfaction but also generates additional revenue streams. For B2B buyers in this industry, considerations should include packaging options that appeal to consumers and branding opportunities that can differentiate their products in a competitive market. Ensuring the kits contain high-quality elastic cords and clear instructions for use will further enhance their appeal.

3 Common User Pain Points for ‘elastic cord for tent pole repair’ & Their Solutions

Scenario 1: Sourcing Quality Elastic Cord for Diverse Applications

The Problem: Many B2B buyers struggle to find high-quality elastic cord that can withstand varied environmental conditions. For companies involved in outdoor equipment, manufacturing tents, or even providing rental services, the durability and elasticity of the cord are critical. Low-quality cords can lead to frequent replacements, which not only increases operational costs but can also compromise customer satisfaction. Buyers often face uncertainty in selecting the right specifications, such as diameter and elasticity, for different tent models, which can further complicate the sourcing process.

The Solution: To mitigate these issues, it’s essential to establish relationships with reliable suppliers who specialize in outdoor materials. Conduct thorough research to identify manufacturers that provide high-quality nylon shock cord, as it is known for its durability and UV resistance. When requesting samples, specify the intended use—such as for tent poles or canopies—to ensure the elasticity meets your performance requirements. Additionally, consider bulk purchasing to negotiate better pricing and ensure a consistent supply of materials. It’s also helpful to keep a variety of cord diameters on hand to accommodate different tent designs and repair needs.

Scenario 2: Difficulty in Measuring and Installing Shock Cords

The Problem: B2B buyers often encounter challenges when it comes to measuring and installing shock cords correctly. Miscalculations in length can lead to underperforming tent poles, resulting in structural failures during use. This is particularly problematic for companies that provide tents for events or camping, where reliability is paramount. Additionally, improper installation techniques can lead to further damage or safety hazards, deterring repeat business from customers.

The Solution: To address measurement and installation issues, create a detailed guideline for your team that outlines the correct procedures for measuring and cutting shock cords. Encourage the use of measuring tapes and provide training on understanding the relationship between relaxed and stretched lengths of the cords. A recommended practice is to use a formula—taking 75% of the pole length to determine the relaxed cord length—to ensure accuracy. Providing instructional videos or hands-on training sessions can significantly enhance your team’s skills in this area. Additionally, consider investing in specialized tools for threading and securing the cords within the poles, which can streamline the repair process and minimize errors.

Scenario 3: Managing Inventory and Supply Chain Challenges

The Problem: For B2B buyers, managing inventory levels of elastic cords for tent pole repairs can be a significant pain point. Fluctuating demand, seasonal peaks, and supply chain disruptions can lead to either excess inventory or stockouts. This situation can hinder a company’s ability to respond promptly to customer needs, ultimately affecting service quality and profitability.

The Solution: Implement a robust inventory management system that tracks usage patterns and forecasts demand based on historical data and seasonal trends. Collaborate closely with suppliers to establish a reliable supply chain that includes contingency plans for delays or shortages. Consider utilizing just-in-time (JIT) inventory practices to minimize holding costs while ensuring that you have sufficient stock during peak seasons. Additionally, regular audits of your inventory can help identify slow-moving items that may need to be discounted or bundled with other products to reduce waste. By proactively managing your inventory and maintaining open communication with suppliers, you can ensure that your elastic cord supply aligns closely with market demands.

Illustrative image related to elastic cord for tent pole repair

Strategic Material Selection Guide for elastic cord for tent pole repair

What are the Key Materials for Elastic Cord Used in Tent Pole Repair?

When selecting elastic cord for tent pole repair, understanding the properties and characteristics of various materials is crucial for ensuring durability and performance. Below, we analyze four common materials used in elastic cords, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Nylon

Key Properties:

Nylon is known for its excellent elasticity, abrasion resistance, and UV stability. It can withstand a temperature range from -40°F to 200°F (-40°C to 93°C) and has a high tensile strength, making it suitable for outdoor applications.

Pros & Cons:

Nylon’s durability and elasticity make it a preferred choice for tent pole repair. However, it can be more expensive than other materials and may degrade over time when exposed to harsh UV rays without proper treatment. Manufacturing complexity is moderate, as it requires specific processes to ensure the right elasticity and strength.

Impact on Application:

Nylon is compatible with various environmental conditions, including humidity and temperature fluctuations. Its elasticity allows it to maintain tension in tent poles effectively.

Considerations for International Buyers:

Nylon products should comply with international standards such as ASTM and ISO. Buyers from regions like Africa and South America may need to consider local availability and import regulations regarding synthetic materials.

2. Polyester

Key Properties:

Polyester offers good UV resistance and is less prone to stretching than nylon. It can operate effectively in temperatures ranging from -50°F to 180°F (-45°C to 82°C) and has excellent water resistance.

Pros & Cons:

The primary advantage of polyester is its durability and lower cost compared to nylon. However, it may not provide the same level of elasticity, which can affect the performance of tent poles under tension. Manufacturing polyester cords is generally simpler and more cost-effective.

Impact on Application:

Polyester is suitable for various outdoor applications, especially in humid environments where moisture resistance is critical. Its lower elasticity may require careful consideration during installation.

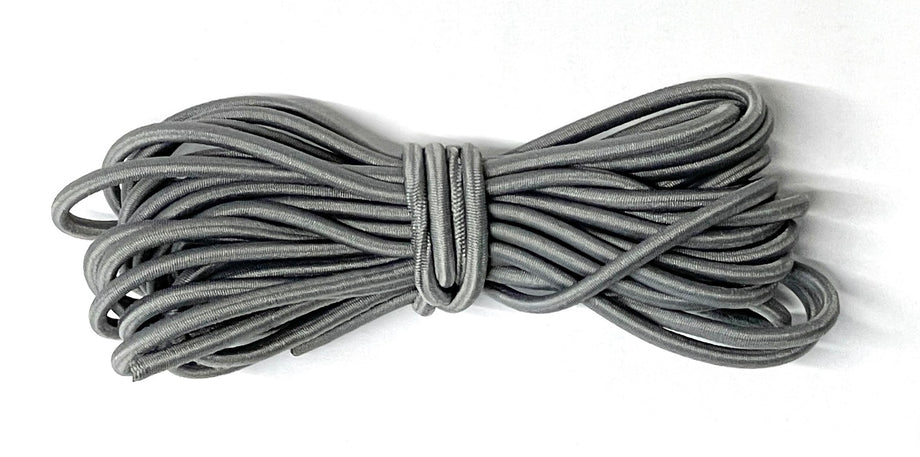

Illustrative image related to elastic cord for tent pole repair

Considerations for International Buyers:

Buyers should ensure that polyester cords meet local standards and regulations. In regions like the Middle East, where UV exposure is high, selecting treated polyester can enhance longevity.

3. Rubber

Key Properties:

Rubber is highly elastic and can withstand a wide range of temperatures, typically from -40°F to 160°F (-40°C to 71°C). It also has excellent resistance to wear and tear.

Pros & Cons:

The primary advantage of rubber is its superior elasticity and ability to absorb shocks. However, it can degrade when exposed to UV light and ozone, making it less suitable for prolonged outdoor use. Manufacturing rubber cords can be complex due to the need for specific formulations to enhance durability.

Illustrative image related to elastic cord for tent pole repair

Impact on Application:

Rubber is ideal for applications requiring high elasticity and shock absorption, making it suitable for tent pole repairs. However, its susceptibility to environmental factors may limit its use in certain regions.

Considerations for International Buyers:

Compliance with local standards is essential, especially concerning environmental regulations. Buyers in Europe and Africa should be aware of the potential need for UV-resistant formulations.

4. Elastic Bungee Cord

Key Properties:

Elastic bungee cords typically consist of a core made from natural or synthetic rubber covered with a durable fabric. They are designed to stretch significantly and return to their original shape.

Illustrative image related to elastic cord for tent pole repair

Pros & Cons:

Bungee cords offer exceptional elasticity and are often more affordable than other materials. However, they may not be as durable in harsh weather conditions and can wear out faster. Manufacturing is generally straightforward, but quality can vary widely.

Impact on Application:

These cords are particularly effective for tent pole repairs due to their high stretchability. However, they may not perform well in extreme conditions without additional protective coatings.

Considerations for International Buyers:

Buyers should look for bungee cords that comply with international safety standards. In regions with varying climates, selecting cords with weather-resistant properties is advisable.

Summary Table of Material Selection for Elastic Cord

| Material | Typical Use Case for elastic cord for tent pole repair | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General tent pole repair | High elasticity and durability | Higher cost and UV degradation | High |

| Polyester | Tent pole repair in humid environments | Good UV resistance and lower cost | Less elasticity compared to nylon | Medium |

| Rubber | Shock absorption in tent pole systems | Superior elasticity | Degrades under UV exposure | Medium |

| Elastic Bungee Cord | Quick repairs and temporary fixes | Exceptional stretchability | May wear out faster in harsh conditions | Low |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for elastic cords used in tent pole repair, enabling informed decisions tailored to their specific needs and regional considerations.

Illustrative image related to elastic cord for tent pole repair

In-depth Look: Manufacturing Processes and Quality Assurance for elastic cord for tent pole repair

What Are the Key Stages in the Manufacturing Process for Elastic Cord Used in Tent Pole Repairs?

The manufacturing process for elastic cord, particularly for tent pole repair, involves several critical stages that ensure the final product meets the necessary quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves selecting high-quality raw materials, typically nylon or polyester, which provide the necessary elasticity, durability, and resistance to environmental factors such as UV light and abrasion. Suppliers often conduct rigorous quality assessments of these materials to ensure they meet specifications before they are used in production. This step may also involve blending different materials to achieve specific properties, such as increased strength or flexibility.

Forming

In the forming stage, the prepared materials are extruded into the desired diameter—commonly 1/8” for tent pole repair cords. This process involves melting the raw material and forcing it through a die to create long strands of elastic cord. The extrusion process is closely monitored to maintain consistent diameter and elasticity throughout the production batch.

Assembly

After forming, the elastic cord may undergo additional processes such as braiding or weaving, which can enhance its strength and functionality. In some cases, manufacturers may integrate additional features such as reflective threads for visibility or coatings for added UV protection.

Finishing

The finishing stage includes cutting the cord to specified lengths, often determined by the intended use, and applying any necessary treatments, such as heat setting, to stabilize the material. Quality control checks at this stage ensure that the cords meet the required specifications for elasticity and tensile strength.

How is Quality Assurance Implemented in the Production of Elastic Cord?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that the elastic cord meets both industry standards and customer expectations. Several international and industry-specific standards guide these quality assurance practices.

International Standards

ISO 9001 is the primary international standard for quality management systems. Compliance with ISO 9001 ensures that manufacturers consistently produce high-quality products and maintain effective quality management processes. For elastic cord production, this means adhering to strict documentation, process control, and continual improvement practices.

Industry-Specific Standards

In addition to ISO standards, manufacturers may also comply with other industry-specific certifications such as CE marking for European markets, which indicates conformity with health, safety, and environmental protection standards. These certifications are particularly important for B2B buyers who need assurance that products meet regulatory requirements in their respective markets.

What Are the Quality Control Checkpoints Throughout the Manufacturing Process?

Quality control (QC) is integrated at multiple checkpoints during the manufacturing process to detect and address potential issues early on. Key checkpoints include:

Incoming Quality Control (IQC)

Before production begins, raw materials undergo IQC to verify their quality against specifications. This includes checking for defects, measuring physical properties, and assessing compliance with supplier certifications. Any subpar materials are rejected to prevent downstream quality issues.

Illustrative image related to elastic cord for tent pole repair

In-Process Quality Control (IPQC)

During production, IPQC involves monitoring critical processes such as extrusion and forming. This may include regular measurements of diameter, tensile strength tests, and visual inspections to ensure consistency. Operators are trained to identify and correct deviations from established standards immediately.

Final Quality Control (FQC)

Once production is complete, FQC involves a comprehensive assessment of the finished product. This includes testing for elasticity, durability, and resistance to environmental factors. Products that pass these tests are then labeled and prepared for shipment, while those that do not meet specifications are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensuring product reliability. Here are some methods to consider:

Supplier Audits

Conducting on-site audits allows buyers to assess the supplier’s quality management systems, production processes, and compliance with relevant standards. This firsthand observation can reveal the effectiveness of a supplier’s quality assurance practices.

Quality Control Reports

Requesting detailed QC reports can provide insights into the supplier’s testing procedures and results. These reports should detail the methodologies used, the frequency of tests, and any corrective actions taken in response to non-conformance.

Illustrative image related to elastic cord for tent pole repair

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices. These inspections can occur at various stages of production, providing additional assurance that the products meet quality standards.

What Are Common Testing Methods for Elastic Cord in Tent Pole Repair?

Several testing methods are commonly employed to assess the quality and performance of elastic cord used in tent pole repairs:

Tensile Strength Testing

This test measures the maximum amount of tensile (pulling) force the cord can withstand before breaking. It is crucial for ensuring that the cord can support the weight and tension of a tent structure.

Elasticity Testing

Elasticity tests determine how well the cord returns to its original shape after being stretched. This characteristic is vital for the functionality of tent poles, as it ensures they maintain their structural integrity during use.

Illustrative image related to elastic cord for tent pole repair

UV Resistance Testing

Given that tent poles are often exposed to sunlight, testing for UV resistance is essential to ensure that the cord does not degrade over time. This involves exposing samples to UV light for specified durations and assessing any changes in material properties.

What Are the Challenges and Considerations for International Buyers in Quality Assurance?

International buyers face unique challenges when it comes to ensuring quality assurance in the procurement of elastic cords. Variations in manufacturing practices, regulatory requirements, and cultural differences can complicate the purchasing process.

Regulatory Nuances

Different regions may have specific regulations regarding materials and safety standards. Buyers must stay informed about these requirements to ensure compliance and avoid costly penalties.

Cultural Differences

Understanding cultural norms in business practices can enhance communication and foster better relationships with suppliers. This is particularly important in regions with distinct business customs, such as Africa and the Middle East.

Logistical Considerations

Shipping and handling practices can affect product quality. Buyers should consider how products are packaged and transported to ensure they arrive in optimal condition.

By understanding the manufacturing processes and quality assurance practices for elastic cord used in tent pole repairs, B2B buyers can make informed decisions and secure reliable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘elastic cord for tent pole repair’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure elastic cords specifically designed for tent pole repair. With a focus on quality, supplier reliability, and cost-effectiveness, this guide will help ensure you select the right materials for your business needs, minimizing downtime and maximizing customer satisfaction.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clarify the technical requirements for the elastic cord. Consider factors such as diameter, material composition, and elasticity.

– Key Considerations:

– Diameter typically ranges from 1/8″ to 3/32″, which affects compatibility with various tent models.

– Material should be durable, often nylon or polyester, to withstand abrasion and UV exposure.

Step 2: Research and Identify Suppliers

Begin your search by compiling a list of potential suppliers specializing in outdoor or camping gear. Use industry directories, trade shows, and online platforms to discover reputable vendors.

– Where to Look:

– B2B marketplaces such as Alibaba or Global Sources.

– Industry-specific trade shows for networking and direct supplier interactions.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers meet international quality standards, such as ISO certifications. This step is crucial for ensuring the products will perform reliably under various conditions.

– What to Check:

– Request documentation of certifications and quality control processes.

– Look for suppliers who can provide test results for their products.

Step 4: Assess Product Samples

Request samples of the elastic cord from shortlisted suppliers. This hands-on evaluation allows you to assess the quality, elasticity, and durability of the materials before making a bulk purchase.

– Testing Criteria:

– Test for stretchability and recovery after stretching.

– Evaluate resistance to UV light and abrasion.

Step 5: Compare Pricing and Terms

Once you have evaluated samples, compare pricing across suppliers. Ensure you understand the total cost of ownership, including shipping, tariffs, and potential bulk discounts.

– Important Factors:

– Look for suppliers offering competitive pricing without compromising quality.

– Inquire about payment terms and return policies, which can impact cash flow and risk management.

Step 6: Confirm Lead Times and Availability

Discuss production lead times and stock availability with your chosen supplier. Understanding these timelines is essential for planning inventory and meeting customer demand.

– What to Confirm:

– Ask for guaranteed delivery dates.

– Discuss the supplier’s capacity to handle rush orders or increased demand.

Step 7: Establish a Communication Plan

Effective communication is vital for a successful partnership. Establish clear lines of communication with your supplier to address any issues that may arise during production or delivery.

– Communication Strategies:

– Schedule regular check-ins during the production phase.

– Utilize project management tools to track progress and timelines.

Illustrative image related to elastic cord for tent pole repair

By following this detailed checklist, B2B buyers can streamline the sourcing process for elastic cords for tent pole repair, ensuring high-quality products that meet their specific business needs.

Comprehensive Cost and Pricing Analysis for elastic cord for tent pole repair Sourcing

What Are the Key Cost Components in Sourcing Elastic Cord for Tent Pole Repair?

When evaluating the cost structure of elastic cord for tent pole repair, several components come into play. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. High-quality nylon or polyester shock cords, known for their durability and resistance to UV rays, typically cost more but provide better performance and longevity.

-

Labor: Labor costs are associated with the manufacturing processes, including cutting, stitching, and assembling the cords into repair kits. Regions with lower labor costs may offer more competitive pricing, making it essential to consider sourcing locations.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility operations. Efficient manufacturing processes can reduce overhead, thereby lowering costs.

-

Tooling: Initial tooling costs for production can be significant, especially if specialized machinery is required. These costs can be amortized over larger production runs, which is an important factor when negotiating prices.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection processes incurs additional costs. However, investing in quality control can reduce returns and enhance customer satisfaction.

-

Logistics: Transportation and shipping costs vary based on distance, mode of transport, and shipping terms. International buyers should consider these costs as they can significantly affect the total landed cost.

-

Margin: Suppliers will incorporate their profit margin into the final pricing, which can vary based on market competition and demand.

How Do Volume and Customization Affect Pricing for Elastic Cord?

Volume and minimum order quantities (MOQ) play a crucial role in determining the price per unit. Suppliers often offer tiered pricing models where larger orders lead to lower costs per unit. This is particularly beneficial for businesses that can forecast demand and manage inventory effectively.

Customization options, such as specific lengths, colors, or elastic properties, can influence pricing. While custom orders may incur additional costs due to setup and production adjustments, they can also provide a competitive edge in the market by offering unique products tailored to customer needs.

Illustrative image related to elastic cord for tent pole repair

What Are the Influencing Factors for Pricing Elastic Cord in International Markets?

Several factors influence pricing for international buyers, especially those from Africa, South America, the Middle East, and Europe:

-

Material Specifications and Certifications: Buyers may require specific certifications for quality and safety standards, which can affect pricing. Suppliers should be able to provide necessary documentation to justify premium pricing.

-

Supplier Reputation and Reliability: Established suppliers with a proven track record may charge higher prices due to their reliability and service quality. Buyers should weigh the potential risks and benefits of working with lesser-known suppliers against the savings.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they define the responsibilities of buyers and sellers regarding shipping and delivery. This affects the overall cost structure and should be clearly negotiated to avoid unexpected charges.

What Negotiation Strategies Can Buyers Use to Optimize Costs?

To achieve cost efficiency, buyers should consider the following negotiation strategies:

-

Volume Commitments: Committing to larger volumes can leverage better pricing and terms. Engage suppliers in discussions about long-term contracts to lock in favorable rates.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the unit price. Consider factors such as durability, replacement frequency, and potential warranty claims to determine the true cost of the product over its lifecycle.

-

Market Research: Conduct thorough market research to understand prevailing prices and competitor offerings. This knowledge can empower buyers during negotiations and help them identify the best value propositions.

-

Cultural Sensitivity: When negotiating with suppliers from different regions, be mindful of cultural differences and practices. Building relationships can foster better terms and long-term partnerships.

Conclusion: Why Understanding Pricing Nuances is Crucial for International B2B Buyers

For international B2B buyers, particularly those in diverse markets like Africa and South America, navigating the complexities of sourcing elastic cord for tent pole repair requires a comprehensive understanding of the cost structure, pricing influences, and effective negotiation strategies. By leveraging these insights, buyers can secure optimal pricing, ensure product quality, and enhance their operational efficiency. It is crucial to remember that indicative prices can vary based on numerous factors, and conducting thorough due diligence is essential before finalizing any sourcing decisions.

Alternatives Analysis: Comparing elastic cord for tent pole repair With Other Solutions

Exploring Alternatives for Tent Pole Repair Solutions

When it comes to tent pole repair, elastic cord is a popular choice among outdoor enthusiasts and manufacturers alike. However, various alternatives can also effectively restore tent functionality. In this analysis, we will compare elastic cord for tent pole repair with two viable alternatives: fiberglass tent pole replacement and bungee cord systems. Each option has unique strengths and weaknesses that can impact the decision-making process for B2B buyers.

| Comparison Aspect | Elastic Cord For Tent Pole Repair | Fiberglass Tent Pole Replacement | Bungee Cord Systems |

|---|---|---|---|

| Performance | Restores elasticity; easy to install | Durable; similar performance to original | Provides adjustable tension; versatile |

| Cost | Low-cost (typically $6-$12) | Moderate cost ($30-$100) | Variable cost ($10-$50) |

| Ease of Implementation | Requires basic skills; straightforward | More complex; may need professional help | Simple to use; quick installation |

| Maintenance | Minimal; replace when worn | Low; durable but can break | Moderate; may require adjustments |

| Best Use Case | Ideal for quick repairs on-the-go | Best for complete pole replacement | Suitable for adjustable setups |

Detailed Breakdown of Alternatives

1. Fiberglass Tent Pole Replacement

Fiberglass tent pole replacement involves sourcing and installing new fiberglass poles when the original poles are damaged beyond repair. This method offers high durability and can provide performance that closely matches the original setup. However, the cost can be significantly higher, ranging from $30 to $100 depending on the tent model. The installation process can be complex and may require professional assistance to ensure proper fit and functionality. This solution is best for users who prioritize long-term durability and are willing to invest more upfront.

2. Bungee Cord Systems

Bungee cord systems are another alternative that offers adjustable tension and versatility for various applications, including tent setups and other outdoor gear. These systems typically allow for quick installation and can be used in multiple contexts, making them a flexible choice. However, they may not provide the same level of structural integrity as traditional shock cords or fiberglass poles, particularly in high-wind situations. Additionally, bungee cords may require periodic adjustments and replacements, which can increase maintenance time. This option is ideal for those looking for a multi-functional solution that can adapt to different environments.

Illustrative image related to elastic cord for tent pole repair

Conclusion: How to Choose the Right Solution for Tent Pole Repair

When selecting a tent pole repair solution, B2B buyers should consider factors such as performance, cost, ease of implementation, and specific use cases. Elastic cord for tent pole repair is a cost-effective and straightforward option, making it suitable for those who need quick fixes. On the other hand, fiberglass replacements provide durability for long-term use, albeit at a higher cost. Bungee cord systems offer versatility for various applications but may require more maintenance. Ultimately, the decision should align with the buyer’s specific needs, budget constraints, and the intended use of the tent.

Essential Technical Properties and Trade Terminology for elastic cord for tent pole repair

What are the Key Technical Properties of Elastic Cord for Tent Pole Repair?

When sourcing elastic cord for tent pole repairs, understanding the following technical properties is crucial for making informed purchasing decisions:

1. Material Composition

The most common materials used for elastic cord are nylon and polyester. Nylon is favored for its elasticity and strength, while polyester is known for its UV resistance and durability. Selecting the right material ensures the cord can withstand outdoor conditions, reducing the risk of failure during use, which is particularly important for B2B buyers in regions with varying climates.

2. Diameter Specification

Elastic cords typically come in various diameters, commonly ranging from 1/8” to 1/4”. The diameter affects both the strength and the stretchability of the cord. A thicker cord generally offers higher tensile strength, making it suitable for larger tents or structures. Buyers should assess the specific requirements of their tent models to choose the appropriate diameter, as this can impact overall performance and longevity.

3. Stretch Ratio

The stretch ratio defines how much the cord can elongate under tension. For instance, a typical shock cord may stretch up to 150% of its original length. Understanding the stretch ratio is vital for ensuring that the cord maintains its elasticity over time, which is crucial for tent pole functionality. B2B buyers should consider the expected load and usage frequency when evaluating this property.

Illustrative image related to elastic cord for tent pole repair

4. Abrasion and UV Resistance

Since tent poles are often exposed to harsh outdoor environments, the elastic cord must exhibit resistance to abrasion and UV degradation. A high-quality cord will maintain its integrity and performance even after prolonged exposure to sunlight and rough conditions. This property is particularly significant for international buyers operating in regions with intense sun exposure and rough terrains.

5. Break Strength

Break strength refers to the maximum load the cord can withstand before failing. This specification is crucial when choosing elastic cord for heavy-duty applications. It is essential for B2B buyers to ensure that the break strength meets or exceeds the requirements of the tent’s design to avoid potential failures during use.

What are Common Trade Terms Related to Elastic Cord for Tent Pole Repair?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are then marketed under another company’s brand. For buyers, understanding OEM capabilities can help in sourcing high-quality elastic cords that meet specific tent specifications without the need for extensive customization.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. This is a critical consideration for B2B buyers, as it affects inventory management and cash flow. Knowing the MOQ helps in planning purchases and ensuring that stock levels align with business needs.

Illustrative image related to elastic cord for tent pole repair

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for a specific quantity of goods. For B2B buyers, issuing an RFQ can lead to competitive pricing and better terms, ensuring that they secure the best deal for elastic cords.

4. Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping responsibilities, insurance, and risks associated with the delivery of elastic cords.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the context of elastic cord for tent pole repair, understanding lead times can help buyers manage inventory and project timelines effectively, ensuring that they have the necessary materials on hand when needed.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing elastic cord for tent pole repairs, ultimately leading to better operational outcomes and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the elastic cord for tent pole repair Sector

What Are the Key Drivers and Trends Shaping the Elastic Cord for Tent Pole Repair Market?

The global elastic cord market for tent pole repair is witnessing significant growth, driven by an increasing demand for outdoor recreational activities and camping gear. Factors such as the rise in eco-tourism, adventure sports, and an overall shift towards outdoor lifestyles contribute to this trend. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking reliable suppliers who can provide high-quality, durable shock cords at competitive prices.

Emerging technologies, such as advanced materials and manufacturing processes, are enhancing the performance and longevity of elastic cords. For example, nylon and polyester composites are gaining traction due to their superior elasticity and resistance to UV light and abrasion. Additionally, the integration of digital platforms for sourcing and purchasing is revolutionizing the way buyers interact with suppliers, making it easier to compare products and negotiate prices.

Illustrative image related to elastic cord for tent pole repair

Market dynamics are also influenced by regional variations in demand. For instance, in Africa and South America, where outdoor activities are gaining popularity, suppliers may need to focus on affordability without compromising quality. In contrast, buyers in Europe and the Middle East may prioritize premium products with higher durability and performance specifications. Understanding these nuances is crucial for international buyers looking to navigate the elastic cord market effectively.

How Can Sustainability and Ethical Sourcing Impact the Elastic Cord for Tent Pole Repair Sector?

As environmental concerns gain prominence globally, sustainability is becoming a pivotal factor in the sourcing of materials for elastic cords used in tent pole repairs. B2B buyers are increasingly looking for suppliers who prioritize ethical sourcing practices and offer eco-friendly products. This shift is not just a trend but a necessity, as consumers demand transparency regarding the environmental impact of their purchases.

The production of elastic cords often involves materials that can be harmful to the environment if not sourced responsibly. Suppliers that utilize recycled materials or renewable resources can appeal to a growing segment of eco-conscious buyers. Certifications such as Global Recycled Standard (GRS) or OEKO-TEX can serve as benchmarks for assessing the sustainability of products.

Moreover, incorporating sustainable practices can enhance a company’s brand reputation, attract environmentally aware consumers, and even lead to cost savings in the long run. For international buyers, understanding the sustainability credentials of their suppliers is essential, not only to comply with regulations but also to align with consumer preferences and market trends.

What Is the Historical Context of the Elastic Cord Market?

The elastic cord, particularly in the context of tent pole repairs, has evolved significantly over the decades. Initially, simple rubber cords were the norm, offering limited durability and elasticity. As outdoor activities gained popularity in the mid-20th century, manufacturers began to innovate with materials like nylon and polyester, which provided enhanced performance and longevity.

The introduction of advanced manufacturing techniques further revolutionized the market, allowing for the production of shock cords that could withstand extreme conditions. This evolution has been particularly relevant in regions experiencing a surge in outdoor recreational activities, where the demand for reliable and durable tent accessories has skyrocketed. Today, the market continues to adapt, with a growing emphasis on sustainability and ethical sourcing, reflecting broader societal shifts towards environmental responsibility.

In summary, understanding the market dynamics, sustainability trends, and historical context is crucial for B2B buyers in the elastic cord sector. By aligning with these trends, buyers can make informed sourcing decisions that not only meet their immediate needs but also contribute to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of elastic cord for tent pole repair

-

How do I replace the elastic cord in my tent poles?

To replace the elastic cord in your tent poles, first measure the total length of all pole sections combined. Purchase shock cord that is typically 1/8″ in diameter, ensuring you have enough length to account for the elasticity. Cut the old cord and remove the grommet pegs from the poles. Thread the new cord through the pole sections, knotting at the ends to secure the pegs. This DIY method can save significant costs compared to buying new poles. -

What is the best elastic cord for tent pole repair?

The best elastic cord for tent pole repair is typically made from durable materials such as nylon, which is known for its elasticity and resistance to UV light and abrasion. Look for cords with a diameter of 1/8″ or smaller, as they fit most tent pole designs. Ensure the cord is heavy-duty and can withstand the tension applied during use to guarantee longevity and reliability in outdoor conditions. -

What are the minimum order quantities (MOQ) for elastic cords?

Minimum order quantities (MOQ) for elastic cords can vary significantly based on the supplier and region. Typically, MOQs can range from 100 to 500 meters, depending on the manufacturer’s production capabilities. When sourcing from international suppliers, it is advisable to discuss MOQs upfront to ensure your order aligns with your business needs and budget constraints. -

How can I vet suppliers for elastic cord products?

To vet suppliers effectively, begin by researching their reputation through online reviews and testimonials from previous clients. Look for suppliers who provide detailed product specifications and are willing to share certifications regarding quality and safety standards. Additionally, consider requesting samples before making a bulk purchase to evaluate the product quality firsthand. Engaging in direct communication can also provide insights into their reliability and customer service approach. -

What payment terms are commonly offered by suppliers?

Payment terms can vary widely among suppliers, but common options include upfront payment, partial payment upon order confirmation, or payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. It’s essential to negotiate terms that provide you with flexibility while ensuring the supplier has the incentive to fulfill the order promptly. -

What quality assurance measures should I look for?

When sourcing elastic cords, inquire about the supplier’s quality assurance (QA) processes. Look for certifications such as ISO or similar industry standards that indicate a commitment to quality. Suppliers should conduct regular testing of their products for elasticity, durability, and resistance to environmental factors. Request documentation of their QA procedures to ensure compliance with international standards, especially if you are importing to regions with strict regulations. -

How can logistics affect my order of elastic cords?

Logistics play a crucial role in the timely delivery of your elastic cord order. Factors such as shipping method, customs clearance, and the supplier’s location can impact lead times. It’s advisable to work with suppliers who have experience in international shipping and can provide reliable tracking information. Additionally, consider the potential for delays due to customs regulations in your region, and plan your orders accordingly to avoid disruptions in your supply chain. -

What are the best practices for storing elastic cords?

Proper storage of elastic cords is essential to maintain their elasticity and durability. Store them in a cool, dry place away from direct sunlight and moisture, as UV exposure can degrade the material over time. Avoid folding or crimping the cords, as this can lead to permanent deformation. Regularly inspect stored cords for signs of wear or deterioration, especially if they are kept for extended periods, to ensure they remain in good condition for future use.

Top 6 Elastic Cord For Tent Pole Repair Manufacturers & Suppliers List

1. Big Agnes – Shock Cord Repair Kit

Domain: bigagnes.com

Registered: 2000 (25 years)

Introduction: {‘name’: ‘Shock Cord Repair Kit’, ‘sku’: ‘ASCK21’, ‘price’: ‘$9.95’, ‘description’: ‘Refurbish your pole set by replacing fraying, severed, or slack shock cord. Note: one shock cord kit will not always be enough to restring your entire poleset. Typically 1-2 person tents will only need one shock cord repair kit; 3+ person tents will need 2 or more. If you would like to know the specific length of …

2. Instructables – Shock Cord 30′ Feet

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Shock Cord (1/8″ or smaller), 30′ feet of new shock cord for $6, scissors or knife, measuring tape, sharpie or marker, matches or lighter.

3. AceCamp – Shock Cord Pole Repair

Domain: acecamp.com

Registered: 2009 (16 years)

Introduction: AceCamp Shock Cord Pole Repair, Price: $9.99 – $11.99, Ideal for replacing worn tent pole elastic cords, also suitable for creating bungee straps and guy lines for canopies or tarps. Material: 100% nylon, elastic, abrasion and UV resistant. Size: 1/8″ in diameter, available in two options: package with two 16 foot lengths or a single 65 foot length.

4. Canoe Tripping – Essential Shock Cord for Tent Poles

Domain: canoetripping.net

Registered: 2011 (14 years)

Introduction: Shock cord for tent poles is essential for maintaining the structural integrity of tents. Key considerations include matching the diameter of the shock cord to the original, ensuring the length is slightly longer than the assembled poles (about 70-75% of the pole length when not under tension), and the possibility of reusing stoppers. Brands like Big Agnes and Eureka are noted for good customer se…

5. Backpacking Light – Shock Cord for Tent Poles

Domain: backpackinglight.com

Registered: 2000 (25 years)

Introduction: Shock cord for tent poles, available at outdoor retailers or online. Tools needed: table vice, 2 hammers or a hammer and mallet, forceps or needle nose pliers. Instructions include determining the type of pole tip (press fit or screw on), removing the tips, replacing the shock cord, and ensuring proper tension.

6. Nemo Equipment – Replacement Shock Cord

Domain: nemoequipment.com

Registered: 2002 (23 years)

Introduction: Replacement shock cord, 1/8″ in thickness, tools needed: scissors, clamp (optional).

Strategic Sourcing Conclusion and Outlook for elastic cord for tent pole repair

In navigating the competitive landscape of elastic cord sourcing for tent pole repair, businesses must prioritize strategic partnerships and quality assurance. Recognizing the diverse applications of shock cords—from tent repairs to creating bungee straps—can enhance product offerings and meet varied customer needs. Establishing relationships with reliable suppliers who provide durable, UV-resistant, and abrasion-resistant materials is crucial. This not only ensures customer satisfaction but also positions your business as a trusted provider in the outdoor and camping markets.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate their sourcing strategies, it is essential to consider local market demands and logistics. The growing outdoor recreation trend signals an increasing need for high-quality repair solutions, making it an opportune time to invest in elastic cord products.

Embrace this opportunity to enhance your supply chain and product offerings. By prioritizing strategic sourcing, you can strengthen your market position and drive growth. Take the next step today—evaluate your suppliers, assess your inventory needs, and ensure you are well-equipped to meet the demands of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.