Choosing Your Door Latch Brass: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for door latch brass

In an increasingly interconnected world, sourcing high-quality door latch brass can pose significant challenges for international B2B buyers. Whether you’re a distributor in Nigeria, a manufacturer in Vietnam, or a contractor in Europe, the demand for durable and aesthetically pleasing door latches remains a constant. This guide serves as your comprehensive resource for navigating the complexities of the global door latch brass market, addressing key aspects such as types, applications, supplier vetting, and pricing strategies.

Understanding the various types of door latches available, from cabin hooks to security chains, allows businesses to tailor their offerings to meet specific customer needs. This guide also emphasizes the importance of thoroughly vetting suppliers to ensure quality and reliability, thereby minimizing risks associated with procurement. Additionally, we delve into cost considerations, helping you make informed decisions that align with your budget while maintaining high standards of quality.

By providing actionable insights and expert recommendations, this guide empowers B2B buyers across Africa, South America, the Middle East, and Europe to make confident purchasing decisions. Whether you’re looking to enhance your product line or secure reliable partnerships, our insights will equip you with the knowledge necessary to thrive in the competitive door latch brass market.

Understanding door latch brass Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cabin Hooks | Swivel design for easy operation; available in various sizes and finishes | Residential, marine, and RV applications | Pros: Versatile and easy to install. Cons: May not offer maximum security. |

| Door Guards | Fixed latch design providing enhanced security; often features a robust build | Commercial and high-security environments | Pros: High durability and security. Cons: Installation may require additional hardware. |

| Shutter Door Latches | Designed specifically for shutters; typically compact and robust | Agricultural, residential, and decorative uses | Pros: Aesthetic appeal and functionality. Cons: Limited to specific applications. |

| Security Chains | Chain-based mechanism allowing for partial door opening; offers added security | Residential and commercial settings | Pros: Increases security while allowing ventilation. Cons: Can be cumbersome to use frequently. |

| Dutch Door Quadrants | Unique design for split doors; allows independent operation of top and bottom halves | Residential and specialty door applications | Pros: Functional and stylish for unique door designs. Cons: Limited compatibility with standard doors. |

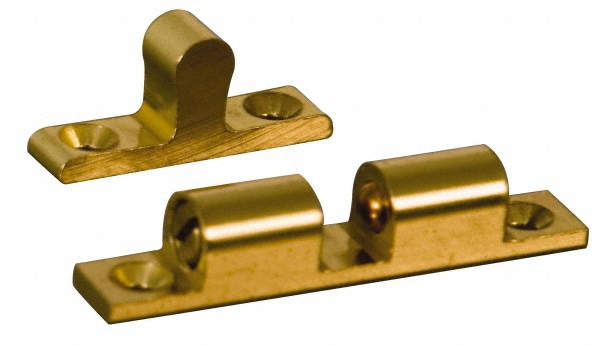

What Are the Key Characteristics of Cabin Hooks?

Cabin hooks are versatile latching mechanisms characterized by their swivel design, allowing for easy and secure door closure. Typically available in various sizes and finishes, they are suitable for a range of applications, including residential, marine, and recreational vehicles (RVs). B2B buyers should consider the ease of installation and the aesthetic compatibility with existing fixtures. While cabin hooks are user-friendly and cost-effective, they may not provide the maximum security required for high-risk environments.

How Do Door Guards Enhance Security?

Door guards feature a fixed latch design that offers enhanced security and durability, making them ideal for commercial and high-security environments. Their robust construction ensures they withstand significant force, providing peace of mind for businesses. When purchasing, B2B buyers should evaluate the material quality and installation requirements, as some models may need additional hardware. While door guards excel in security, their installation can be more complex compared to simpler latch types.

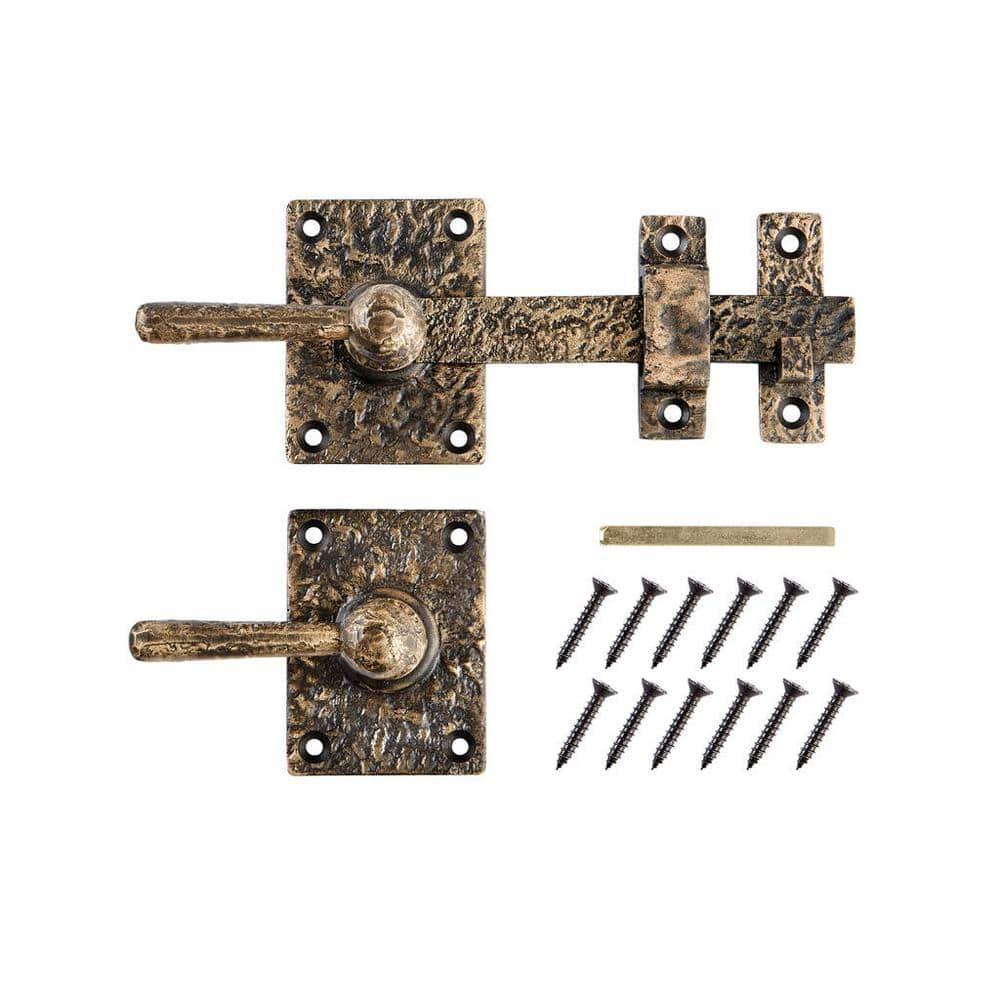

Illustrative image related to door latch brass

What Makes Shutter Door Latches Unique?

Shutter door latches are specifically designed for shutters, combining compactness with robustness. Their unique design makes them ideal for agricultural, residential, and decorative uses, where both functionality and aesthetics are important. Buyers should consider the latch’s compatibility with different shutter styles and its ease of use. While they provide an attractive solution, their specialized nature means they may not be suitable for general door applications.

Why Choose Security Chains for Doors?

Security chains offer a chain-based mechanism that allows for partial opening of doors, enhancing security while permitting ventilation. This feature makes them particularly suitable for both residential and commercial settings where safety and airflow are priorities. B2B buyers should assess the chain’s material and length to ensure it meets their security needs. However, while security chains are effective, they can be cumbersome for frequent use, which may deter some buyers.

What Are the Benefits of Dutch Door Quadrants?

Dutch door quadrants provide a unique solution for split doors, allowing independent operation of the top and bottom halves. This design is particularly useful in residential and specialty applications where ventilation and accessibility are desired. B2B buyers should evaluate the quadrant’s compatibility with existing door frames and its ease of installation. Although they add functional charm to unique door designs, their limited compatibility with standard doors may restrict some buyers’ options.

Illustrative image related to door latch brass

Key Industrial Applications of door latch brass

| Industry/Sector | Specific Application of door latch brass | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Door hardware for residential and commercial buildings | Enhances security and durability in building projects | Compliance with local regulations and standards; availability of various styles and finishes |

| Hospitality | Latches for hotel room doors and facilities | Improves guest safety and experience with reliable locks | Bulk purchasing options; customization for branding needs; lead times for delivery |

| Automotive | Latches for vehicle doors and compartments | Ensures safety and functionality in vehicle design | Material specifications for automotive standards; resistance to corrosion and wear |

| Furniture Manufacturing | Cabinet and drawer latches | Adds functionality and aesthetic appeal to furniture | Variety in sizes and styles; compatibility with different materials used in furniture |

| Security Services | High-security door latches | Provides enhanced protection for sensitive areas | Certification for security standards; ability to provide bulk orders for large facilities |

How is Door Latch Brass Used in Construction?

In the construction sector, door latch brass is utilized extensively in both residential and commercial buildings. These latches are integral to doors, ensuring security and ease of access. For international buyers, particularly from Africa and South America, it’s essential to source latches that comply with local building codes and standards. Durability and resistance to environmental factors such as humidity and temperature variations are critical considerations, making brass an ideal choice due to its corrosion resistance.

What Role Does Door Latch Brass Play in Hospitality?

In the hospitality industry, brass door latches are crucial for hotel room doors and other facilities. They enhance guest safety while providing a touch of elegance that aligns with the overall design aesthetics of the property. B2B buyers in this sector should focus on suppliers that offer customization options, allowing for branding and unique designs. Additionally, bulk purchasing arrangements can lead to cost savings, and timely delivery is vital to meet construction or renovation timelines.

How is Door Latch Brass Applied in Automotive Manufacturing?

The automotive industry employs door latch brass in vehicle doors and compartments, ensuring safety and functionality. These latches must meet stringent automotive standards for durability and performance under various conditions. Buyers from regions like the Middle East and Europe should prioritize suppliers that can guarantee compliance with these standards, as well as provide latches that resist corrosion and wear, critical for long-lasting vehicle components.

Why is Door Latch Brass Important in Furniture Manufacturing?

In furniture manufacturing, door latch brass is used in cabinets and drawers to enhance both functionality and aesthetic appeal. The choice of material can significantly influence the overall design and usability of furniture pieces. International buyers should consider the variety of sizes and styles available to ensure compatibility with different furniture designs. Additionally, sourcing latches that are easy to install and maintain can improve the efficiency of the manufacturing process.

Illustrative image related to door latch brass

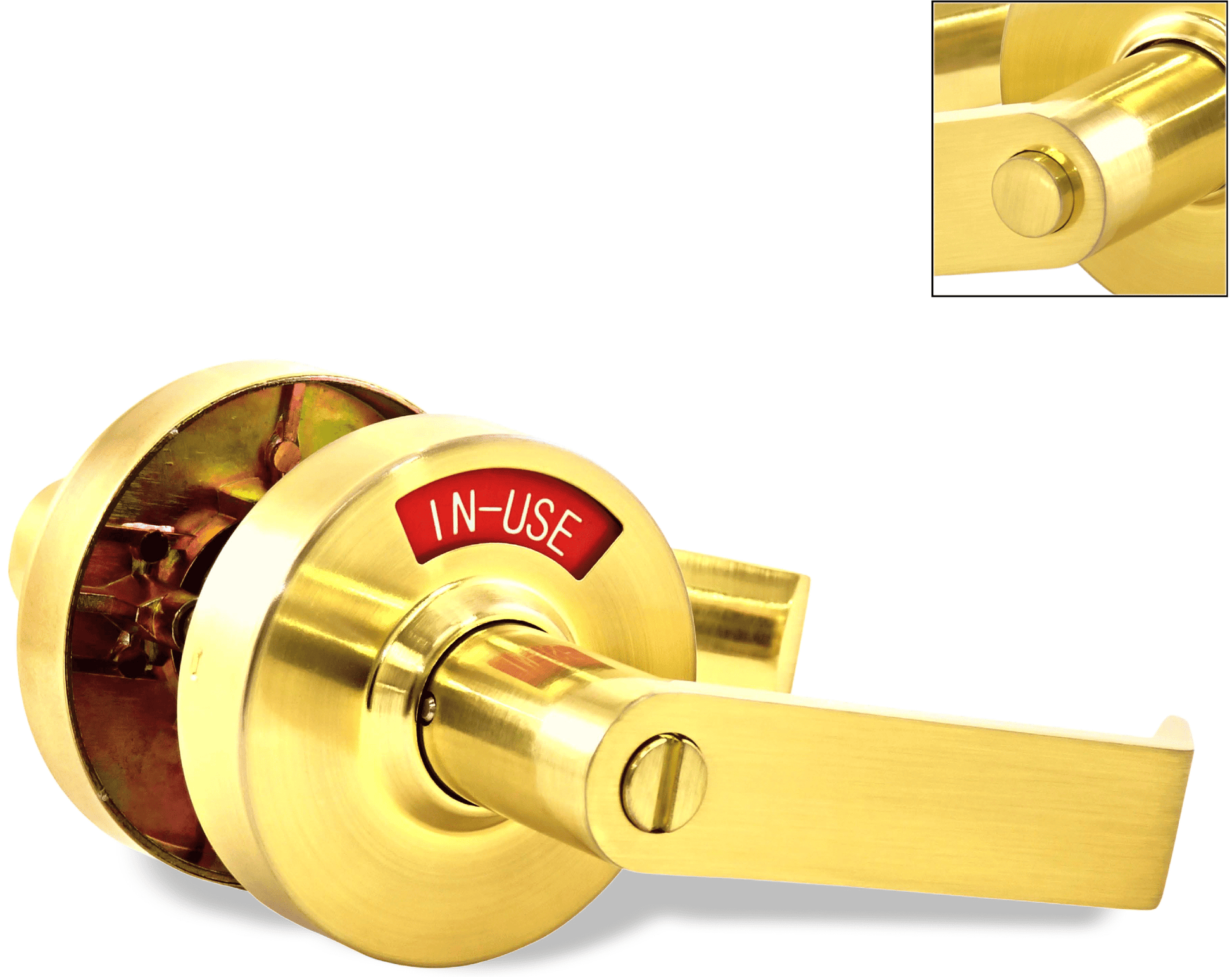

How Do Security Services Utilize Door Latch Brass?

Security services rely on high-security door latches made from brass to protect sensitive areas such as data centers and secure facilities. These latches provide an added layer of protection against unauthorized access. For B2B buyers in this sector, sourcing latches that meet specific security certifications is paramount. Additionally, suppliers should be able to accommodate bulk orders, ensuring that all security installations are uniform and compliant with safety regulations.

3 Common User Pain Points for ‘door latch brass’ & Their Solutions

Scenario 1: Sourcing Quality Brass Door Latches in Emerging Markets

The Problem: B2B buyers in regions such as Africa and South America often face challenges in sourcing high-quality brass door latches due to limited local suppliers and inconsistent product quality. In these markets, buyers may receive subpar materials that can lead to rapid wear and tear, affecting both functionality and aesthetic appeal. This not only impacts customer satisfaction but can also result in costly replacements and repairs.

The Solution: To ensure the procurement of high-quality brass door latches, buyers should establish relationships with reputable manufacturers and suppliers who specialize in brass hardware. Conduct thorough due diligence by requesting samples and certifications of material quality. Utilizing platforms that connect buyers with manufacturers from different parts of the world can also be beneficial. Look for suppliers that offer transparent sourcing processes and guarantees on product quality. Consider specifying particular grades of brass, such as C360 or C377, known for their durability and resistance to corrosion, ensuring that the products meet both local and international standards.

Scenario 2: Understanding the Technical Specifications for Brass Door Latches

The Problem: Many B2B buyers, particularly those new to the hardware industry, struggle to understand the technical specifications associated with brass door latches. Terms like “gauge,” “finish,” and “type of latch” can create confusion, leading to poor purchasing decisions that do not meet the intended application. This misalignment can result in increased installation costs and project delays.

The Solution: Buyers should invest time in educating themselves about the various technical specifications of brass door latches. Engaging with industry experts or attending workshops can provide valuable insights. It’s also advisable to create a checklist that outlines the specific requirements for each project, including the type of door, expected usage (residential vs. commercial), and environmental conditions (humidity, exposure to elements). When reaching out to suppliers, provide them with detailed project specifications so they can recommend the most suitable products. Additionally, consider using online resources and tools that offer comparison features to evaluate different latch types and their applications.

Scenario 3: Ensuring Timely Delivery and Availability of Brass Door Latches

The Problem: Timely delivery is critical in the B2B sector, especially for buyers managing large-scale projects. Delays in receiving brass door latches can hinder construction timelines, leading to financial penalties and strained relationships with clients. Factors such as global shipping issues, local customs regulations, and inventory shortages can exacerbate these challenges, particularly in regions with complex logistics.

The Solution: To mitigate delivery issues, buyers should establish a reliable supply chain with clear communication channels. One effective strategy is to maintain a safety stock of essential door latches based on historical demand patterns. This buffer stock can prevent project delays due to unexpected shortages. Furthermore, consider using local suppliers who can offer faster turnaround times and better logistics management. Building strong relationships with suppliers can also facilitate priority processing for orders. Leveraging technology, such as supply chain management software, can enhance visibility into inventory levels and order statuses, allowing buyers to proactively address potential delays before they impact project timelines.

By understanding and addressing these common pain points, B2B buyers can enhance their procurement processes, ensuring they source the right brass door latches for their needs while minimizing risks associated with quality, specifications, and delivery.

Illustrative image related to door latch brass

Strategic Material Selection Guide for door latch brass

What Are the Key Properties of Different Materials Used in Door Latch Brass?

When selecting materials for door latch brass, it’s essential to understand their properties and how they influence performance. The most common materials include solid brass, stainless steel, zinc alloy, and aluminum. Each material has unique characteristics that cater to various applications and market preferences.

How Does Solid Brass Perform in Door Latch Applications?

Solid brass is a popular choice for door latches due to its excellent corrosion resistance and durability. It can withstand a range of temperatures and pressures, making it suitable for both indoor and outdoor applications. Solid brass also has a high tensile strength, which ensures that the latch maintains its integrity over time.

Pros: Solid brass is aesthetically pleasing and offers a classic look, making it suitable for high-end applications. Its resistance to tarnishing and corrosion makes it ideal for humid environments.

Illustrative image related to door latch brass

Cons: The primary drawback is its cost, as solid brass is generally more expensive than other materials. Additionally, it can be heavier, which may not be suitable for all applications.

Impact on Application: Solid brass latches are compatible with various door types and finishes, enhancing both functionality and aesthetics.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America may prefer solid brass for its durability in harsh climates.

What Are the Benefits and Limitations of Stainless Steel for Door Latches?

Stainless steel is another viable option for door latches, known for its strength and corrosion resistance. It can handle high-pressure environments and is less prone to rust compared to other metals.

Pros: Stainless steel latches are durable and can withstand extreme weather conditions, making them ideal for outdoor use. They are also relatively low maintenance.

Cons: The primary limitation of stainless steel is its susceptibility to scratching and denting, which can affect aesthetics. Additionally, it may be more expensive than zinc alloys.

Impact on Application: Stainless steel is compatible with a wide range of door types and finishes, providing a modern look.

Considerations for International Buyers: Buyers should ensure compliance with international standards like JIS for stainless steel quality. Regions with high humidity may favor stainless steel for its resistance to corrosion.

How Do Zinc Alloys Compare for Door Latch Manufacturing?

Zinc alloys are commonly used in door latch manufacturing due to their cost-effectiveness and ease of production. These alloys can be molded into intricate designs, making them suitable for decorative applications.

Pros: Zinc alloys are lightweight and less expensive than brass or stainless steel, allowing for lower manufacturing costs. They also offer decent corrosion resistance.

Cons: However, zinc alloys are generally less durable than solid brass or stainless steel, making them less suitable for heavy-duty applications. They may also have a shorter lifespan.

Impact on Application: Zinc alloy latches are best suited for interior doors or light-duty applications where aesthetic appeal is more critical than durability.

Considerations for International Buyers: Buyers should verify compliance with local standards and consider the environmental conditions of their regions, as zinc alloys may not perform well in highly corrosive environments.

What Role Does Aluminum Play in Door Latch Design?

Aluminum is a lightweight alternative for door latches, often used in commercial applications where weight is a concern. It offers good corrosion resistance and can be anodized for additional protection.

Pros: The lightweight nature of aluminum makes it easy to install and handle. It is also cost-effective and resistant to rust.

Cons: Aluminum latches may not be as strong as brass or stainless steel and can be prone to bending under heavy loads.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as in commercial buildings.

Considerations for International Buyers: Compliance with standards like ASTM is essential, especially for buyers in Europe, where quality and durability are prioritized.

Illustrative image related to door latch brass

Summary Table of Material Selection for Door Latch Brass

| Material | Typical Use Case for door latch brass | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Solid Brass | High-end residential and commercial | Excellent corrosion resistance | Higher cost | High |

| Stainless Steel | Outdoor and heavy-duty applications | Strong and low maintenance | Susceptible to scratching | Med |

| Zinc Alloy | Interior doors and decorative latches | Cost-effective and lightweight | Less durable than other metals | Low |

| Aluminum | Commercial applications | Lightweight and rust-resistant | Weaker than brass or stainless steel | Med |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding door latch brass materials, considering their unique requirements and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for door latch brass

What Are the Key Stages in the Manufacturing Process of Door Latch Brass?

The manufacturing of door latch brass involves a series of intricate stages, each critical to ensuring the final product meets both aesthetic and functional standards. Understanding these processes can empower B2B buyers to make informed decisions when sourcing products.

Material Preparation: How Is Brass Sourced and Processed?

The first step in manufacturing door latch brass is sourcing high-quality brass alloy, typically composed of copper and zinc. The selection of the alloy is crucial, as it affects the durability and appearance of the final product. Once sourced, the brass undergoes melting and casting, where it is poured into molds to create the desired shapes. The cast brass is then cooled and subjected to a series of processes, including annealing, which improves malleability and reduces brittleness.

Illustrative image related to door latch brass

Forming Techniques: What Methods Are Used to Shape Door Latch Brass?

After material preparation, the brass undergoes various forming techniques. Common methods include stamping, forging, and extrusion. Stamping involves using a die to cut and shape the brass into specific components, while forging uses compressive forces to mold the brass under high pressure. Extrusion, on the other hand, pushes heated brass through a die to create elongated shapes. Each technique offers unique advantages, such as enhanced strength or intricate designs, which can cater to the diverse requirements of B2B buyers.

Assembly: How Are Door Latch Brass Components Brought Together?

Once the individual components are shaped, the assembly phase begins. This stage may involve manual or automated processes, depending on the scale of production. Components such as springs, bolts, and latches are carefully assembled to ensure proper function and alignment. Quality control checks are integrated into the assembly line, minimizing the risk of defects. This attention to detail is essential for B2B buyers, as it directly impacts the reliability and performance of the door latch.

Finishing: What Techniques Are Used to Enhance Aesthetics and Durability?

The finishing stage is where the door latch brass truly comes to life. Various techniques, including polishing, plating, and coating, are employed to enhance the visual appeal and durability of the product. Polishing creates a smooth, reflective surface, while plating (e.g., chrome or nickel) provides additional protection against corrosion. Coatings such as lacquer can also be applied to maintain the brass’s appearance over time. For B2B buyers, understanding these finishing options is vital, as it allows them to select products that align with their branding and performance expectations.

How Is Quality Assurance Implemented in Door Latch Brass Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that door latch brass products meet international standards and customer expectations. B2B buyers should be aware of the various QA measures in place, as these can significantly impact the quality of the products they source.

What International Standards Are Relevant for Door Latch Brass?

Manufacturers of door latch brass typically adhere to international quality standards such as ISO 9001, which focuses on effective quality management systems. In addition, industry-specific certifications like CE marking for products sold in Europe and API standards for oil and gas applications may also apply. These standards ensure that products meet rigorous safety and performance criteria, providing assurance to buyers that they are investing in quality.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. Key stages include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested to ensure that production processes are consistently meeting quality standards.

- Final Quality Control (FQC): Once the products are assembled, a final inspection is conducted to assess the overall quality, functionality, and aesthetic finish of the door latches.

These checkpoints not only help maintain high-quality standards but also provide transparency for B2B buyers regarding the manufacturing processes.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers employ various testing methods to verify the quality of door latch brass products. Common tests include:

Illustrative image related to door latch brass

- Mechanical Testing: Assessing the strength, ductility, and hardness of the brass to ensure it can withstand operational stresses.

- Corrosion Resistance Testing: Exposing samples to harsh environments to evaluate how well the brass resists corrosion over time.

- Functional Testing: Ensuring that the latch operates smoothly and meets design specifications.

These tests are essential for B2B buyers, as they indicate the product’s reliability and longevity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial to ensuring they receive high-quality products. Here are several strategies to consider:

What Audits and Reports Should Buyers Request from Suppliers?

Buyers should conduct supplier audits to assess their manufacturing processes, quality control measures, and compliance with international standards. Requesting quality reports, including ISO certifications and test results, can provide insight into a supplier’s commitment to quality.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further validate a supplier’s quality claims. These independent organizations can conduct thorough evaluations of the manufacturing process and final products, providing an unbiased assessment of quality. This step is particularly important for B2B buyers operating in regions where local quality standards may vary.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control that may affect their sourcing decisions. Variations in local regulations, material availability, and manufacturing capabilities can impact product quality. Buyers should also consider cultural differences in business practices and communication styles, as these can influence supplier relationships and quality assurance processes.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for door latch brass is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and quality control measures, buyers can make informed decisions that align with their business needs and ensure the procurement of high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door latch brass’

In the competitive landscape of B2B procurement, sourcing high-quality brass door latches requires a structured approach. This guide provides a checklist to ensure that your sourcing process is efficient, cost-effective, and aligned with your project requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for your sourcing process. Consider factors such as the type of door latch (e.g., cabin hooks, door guards), dimensions, and finish (polished, antique, or un-lacquered brass). This will help you communicate your needs effectively to potential suppliers and ensure that the products meet your project’s requirements.

Step 2: Research Market Trends and Pricing

Understanding market trends and pricing for brass door latches can significantly influence your purchasing decisions. Conduct market research to identify the average prices, popular designs, and emerging trends in different regions, such as Africa, South America, and Europe. This knowledge will enable you to negotiate better terms and select products that resonate with your target audience.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record of delivering high-quality products and reliable service. This step helps mitigate risks associated with product quality and delivery timelines.

- Check Certifications: Ensure that suppliers comply with relevant industry standards and certifications. This could include ISO certifications or compliance with local regulations.

Step 4: Request Samples

Obtaining product samples is a crucial step in the sourcing process. Samples allow you to assess the quality, design, and functionality of the brass door latches firsthand. Evaluate the finish, durability, and overall craftsmanship to ensure they align with your specifications before placing a larger order.

Step 5: Negotiate Terms and Conditions

Once you have identified potential suppliers and evaluated their products, it’s time to negotiate terms. Discuss pricing, payment terms, shipping costs, and lead times. Ensure that you have a clear understanding of the return policy and warranty options. Effective negotiation can result in better pricing and favorable terms, ultimately impacting your bottom line.

Step 6: Establish a Quality Assurance Process

Implementing a quality assurance process is vital to ensure that the brass door latches you receive meet your specifications. Consider setting up inspection protocols for incoming shipments and determining quality benchmarks that align with industry standards. This proactive approach helps prevent quality issues and enhances customer satisfaction.

Step 7: Build Long-Term Relationships with Suppliers

Developing long-term relationships with suppliers can provide significant advantages, including preferential pricing, priority service, and exclusive access to new products. Regular communication and feedback can foster a collaborative partnership that benefits both parties in the long run.

By following this checklist, B2B buyers can streamline their sourcing process for brass door latches, ensuring they acquire high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for door latch brass Sourcing

When sourcing brass door latches, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The following analysis breaks down the various cost components, price influencers, and provides actionable tips for negotiating the best deals.

What Are the Key Cost Components in Brass Door Latch Manufacturing?

-

Materials: The primary cost driver in brass door latch production is the raw material itself—brass. Prices for brass fluctuate based on global metal markets, and buyers should monitor these trends to anticipate price changes. Additionally, the quality of brass used can vary, influencing both cost and durability.

-

Labor: Labor costs encompass wages for skilled workers involved in manufacturing and assembly. Regions with lower labor costs, such as certain areas in Africa and South America, may offer competitive pricing but could also affect quality and lead times.

-

Manufacturing Overhead: This includes utilities, maintenance, and factory expenses. Efficient production processes can help minimize overhead, leading to more competitive pricing for buyers.

-

Tooling: The initial investment in molds and machinery for producing custom designs can be substantial. If a buyer requires unique specifications, understanding these costs upfront is essential.

-

Quality Control (QC): Stringent quality checks ensure that the products meet international standards, which can add to the overall cost. Certifications such as ISO can further influence pricing but are often necessary for ensuring product reliability.

-

Logistics: Shipping and handling costs can vary significantly based on distance, volume, and chosen transportation methods. Buyers must consider the implications of logistics on the final pricing, particularly for international shipments.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can be influenced by competition and market demand.

How Do Price Influencers Impact Brass Door Latch Costs?

Several factors can significantly affect the pricing of brass door latches:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually lead to lower per-unit costs. Buyers should evaluate their needs to leverage bulk pricing effectively.

-

Specifications and Customization: Custom designs or specific features can increase costs. Understanding the balance between standard products and custom requests is crucial for managing budgets.

-

Quality and Certifications: Higher quality products often come with premium prices. Certifications may also add costs but can enhance marketability and compliance in specific regions.

-

Supplier Factors: The reputation and reliability of the supplier can influence costs. Established suppliers might charge more but offer better quality assurance and support.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the responsibility for shipping costs and risks. Buyers must clearly understand which terms apply to their purchase agreements.

What Are the Best Tips for Negotiating Brass Door Latch Prices?

-

Conduct Thorough Market Research: Understanding market prices and competitor offerings can provide leverage in negotiations.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider long-term costs associated with maintenance, durability, and replacement. A higher upfront cost may be justified by lower long-term expenses.

-

Build Relationships with Suppliers: Strong relationships can lead to better pricing and terms. Frequent communication can foster trust and potentially result in discounts or favorable payment terms.

-

Be Aware of Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and import duties can significantly affect final costs. Buyers should factor these elements into their budget and pricing negotiations.

-

Negotiate with Flexibility: Be open to alternative solutions, such as adjusting order quantities or payment terms, which may lead to more favorable pricing.

Conclusion

Sourcing brass door latches involves navigating a complex cost structure influenced by multiple factors. By understanding these dynamics and employing strategic negotiation techniques, international B2B buyers can secure competitive pricing while ensuring quality and compliance with their specific needs. Prices can vary widely based on the aforementioned components and influencers, so potential buyers should approach sourcing with comprehensive knowledge and a clear strategy.

Alternatives Analysis: Comparing door latch brass With Other Solutions

Understanding Alternatives to Door Latch Brass

When considering door security and functionality, door latch brass is a popular choice due to its durability and aesthetic appeal. However, there are several alternative solutions that may suit specific needs or preferences. This section analyzes these alternatives to help B2B buyers make informed decisions based on performance, cost, ease of implementation, and maintenance.

Comparison Table

| Comparison Aspect | Door Latch Brass | Stainless Steel Latch | Electronic Smart Lock |

|---|---|---|---|

| Performance | High durability, corrosion-resistant | Excellent strength, rust-resistant | High security, customizable access |

| Cost | Moderate ($10 – $80) | Moderate to high ($15 – $100) | High ($100 – $500+) |

| Ease of Implementation | Simple installation, requires basic tools | Similar installation, may require special tools for some designs | Requires wiring and setup, may need professional installation |

| Maintenance | Low maintenance, occasional polishing | Low maintenance, resistant to tarnishing | Regular software updates, battery replacement needed |

| Best Use Case | Residential and commercial doors | High-traffic areas, industrial applications | Smart homes, offices needing controlled access |

Detailed Breakdown of Alternatives

What Are the Benefits of Using a Stainless Steel Latch?

Stainless steel latches are known for their exceptional strength and resistance to rust and corrosion, making them suitable for both indoor and outdoor applications. They perform well in high-traffic areas, such as commercial spaces, where durability is crucial. While the cost is comparable to brass latches, stainless steel may require specific tools for installation, which could add to labor costs. Maintenance is minimal, as they do not tarnish, making them an attractive option for long-term use.

How Do Electronic Smart Locks Improve Security and Access Control?

Electronic smart locks offer advanced security features, including remote access, customizable entry codes, and integration with home automation systems. This technology allows businesses to manage access more effectively, particularly in environments where security is paramount. However, smart locks come with a higher price point and can involve complex installation processes, potentially requiring professional assistance. Regular maintenance is also necessary to keep software updated and batteries charged, which could be a downside for some users.

Conclusion: How to Choose the Right Door Latch Solution for Your Needs?

When selecting a door latch solution, B2B buyers should consider the specific requirements of their application. Door latch brass is an excellent choice for its classic appeal and durability, making it suitable for various settings. However, if strength and corrosion resistance are priorities, stainless steel may be the better option. For those seeking enhanced security features and convenience, electronic smart locks provide modern solutions but require a higher investment and ongoing maintenance. Ultimately, the decision should align with the operational needs, budget constraints, and long-term goals of the business.

Essential Technical Properties and Trade Terminology for door latch brass

What Are the Key Technical Properties of Door Latch Brass?

When sourcing door latch brass, understanding the technical specifications is crucial for ensuring quality and performance. Here are several key properties to consider:

1. Material Composition

Door latches are typically made from solid brass, an alloy primarily composed of copper and zinc. The specific ratio can affect the corrosion resistance, strength, and color of the latch. For instance, a higher copper content results in better corrosion resistance, which is vital for products used in humid or coastal environments. Buyers should prioritize latches with a known composition to ensure durability and longevity.

2. Finish

The finish of brass latches can vary widely, including polished, antique, or unlacquered options. The finish not only affects the aesthetic appeal but also the latch’s resistance to tarnishing and wear. For B2B buyers, selecting the right finish is essential to match the design requirements of their projects while ensuring the longevity of the product under different environmental conditions.

3. Size and Dimensions

The size of door latches—typically expressed in inches for length and width—is critical for compatibility with door frames and styles. Common dimensions include the width of the latch and the length of the arm or hook. Accurate measurements are necessary to avoid installation issues, making it essential for buyers to understand the specific dimensions required for their applications.

4. Load-Bearing Capacity

The load-bearing capacity indicates how much weight a latch can securely hold. This specification is particularly important for heavy doors or those in high-traffic areas. Buyers should inquire about the load ratings to ensure that the chosen latch will meet the demands of their application, thereby reducing the risk of failure and enhancing safety.

5. Tolerance Levels

Tolerance refers to the allowable deviation in the dimensions of the latch. High precision in manufacturing ensures that latches fit correctly and operate smoothly. For B2B buyers, understanding tolerance levels can help in assessing the quality of the latch and its compatibility with other hardware, which is especially important for OEM projects.

What Are Common Trade Terms Related to Door Latch Brass?

Navigating the procurement landscape requires familiarity with specific trade terminology. Here are some common terms relevant to door latch brass:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. For buyers, understanding OEM relationships can help in sourcing high-quality components that meet specific brand standards while allowing for customization in design and functionality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is significant for buyers, as it can affect inventory costs and the ability to meet project demands. Knowing the MOQ can help businesses plan their orders effectively, ensuring they have sufficient stock without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific products. For B2B buyers, issuing an RFQ is essential for comparing costs and determining the best supplier for their needs. A well-prepared RFQ can lead to more favorable pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for buyers engaged in cross-border procurement to ensure clarity and minimize disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order to its delivery. Understanding lead times is vital for planning and inventory management, as it impacts project timelines. Buyers should account for lead time when making purchasing decisions to align with their operational schedules.

By grasping these properties and terms, B2B buyers can make informed decisions that enhance their procurement processes and product offerings in the door latch brass market.

Illustrative image related to door latch brass

Navigating Market Dynamics and Sourcing Trends in the door latch brass Sector

What Are the Key Trends Driving the Door Latch Brass Market?

The door latch brass sector is currently experiencing significant transformations influenced by various global drivers. One key factor is the growing demand for high-quality, durable materials in construction and renovation projects across regions such as Africa, South America, the Middle East, and Europe. This demand is further propelled by a rise in urbanization and infrastructural developments, particularly in emerging markets where new housing projects are on the rise.

Another trend is the integration of advanced technologies in sourcing and supply chain management. B2B buyers are increasingly utilizing digital platforms for procurement, allowing them to streamline operations and enhance transparency. Technologies like blockchain are becoming instrumental in tracking product origins and ensuring authenticity, which is critical for international buyers concerned about quality and compliance.

Moreover, customization is gaining traction, as buyers seek unique designs that cater to specific architectural styles and consumer preferences. Manufacturers are responding to this trend by offering a wider range of finishes and styles, from traditional to contemporary, thereby appealing to a broader market segment.

How Is Sustainability Shaping Sourcing Practices in the Door Latch Brass Sector?

Sustainability is increasingly becoming a focal point in the sourcing of door latch brass products. B2B buyers are now prioritizing suppliers who demonstrate a commitment to environmental stewardship. This includes sourcing materials from certified ethical mines, which not only reduces environmental impact but also supports local communities.

The importance of ethical supply chains cannot be overstated. International buyers are more likely to engage with manufacturers who can provide certifications such as ISO 14001 for environmental management or Fair Trade certifications, which indicate adherence to social and ethical standards. By opting for sustainably sourced materials, companies not only enhance their brand image but also meet the growing consumer demand for responsible products.

Additionally, the shift towards ‘green’ materials is evident, with manufacturers exploring alternatives such as recycled brass. This not only minimizes waste but also reduces the carbon footprint associated with new metal production. As global awareness around sustainability continues to rise, the door latch brass sector will likely see a greater emphasis on environmentally friendly practices and products.

How Has the Door Latch Brass Industry Evolved Over Time?

The evolution of the door latch brass industry reflects broader trends in construction and design. Historically, brass latches were favored for their durability and aesthetic appeal, often used in residential and commercial buildings alike. As technology progressed, manufacturers began to innovate, introducing new finishes and designs that cater to various architectural styles.

The industrial revolution marked a significant turning point, leading to mass production techniques that made brass door latches more accessible to a wider audience. With the advent of modern design movements, the focus has shifted toward not only functionality but also the visual appeal of hardware. Today, the market offers a diverse range of products that blend traditional craftsmanship with contemporary design sensibilities, catering to an increasingly discerning global customer base.

As the market continues to evolve, B2B buyers must remain attuned to these historical shifts and current trends to make informed sourcing decisions that align with both their operational needs and the expectations of their end customers.

Frequently Asked Questions (FAQs) for B2B Buyers of door latch brass

-

How do I choose the right type of brass door latch for my project?

Selecting the right brass door latch hinges on understanding your specific application. Consider factors such as door type, security needs, and aesthetic preferences. For example, cabin hooks are ideal for lightweight doors, while door guards offer enhanced security for heavier entry points. Assess the latch’s finish—polished versus antique brass—to ensure it complements your overall design. Finally, consult with suppliers for samples and technical specifications to ensure compatibility with your existing hardware. -

What are the key quality assurance standards for brass door latches?

Quality assurance for brass door latches typically includes adherence to international standards such as ISO 9001. Look for certifications that validate the durability, corrosion resistance, and safety of the product. Testing for tensile strength, resistance to wear, and functionality under various conditions is crucial. Reputable suppliers should provide detailed QA documentation, including material certifications and test reports, to ensure compliance with industry standards. -

What minimum order quantities (MOQs) should I expect when sourcing brass door latches?

Minimum order quantities can vary significantly between suppliers and regions. Many manufacturers may set MOQs ranging from 100 to 500 units to ensure cost-effectiveness in production and shipping. However, some suppliers may accommodate lower quantities for specific orders, particularly for custom designs. It’s essential to discuss your needs upfront and explore options for bulk purchasing, which can lead to better pricing and terms. -

What payment terms are typically offered by suppliers of brass door latches?

Payment terms can vary widely based on supplier policies and buyer relationships. Common terms include a 30% deposit upon order confirmation and the balance due prior to shipping. Some suppliers may offer net 30 or net 60 terms for established clients. Additionally, consider using secure payment methods such as letters of credit or escrow services for large transactions to mitigate risk. -

How can I effectively vet suppliers for brass door latches?

Vetting suppliers requires a multi-faceted approach. Start by researching potential suppliers online, checking their reputation through reviews and ratings. Request references from previous clients to gauge reliability and quality. Verify certifications and compliance with international standards. If possible, visit the supplier’s manufacturing facility or attend trade shows to assess their capabilities firsthand. Establish open communication to discuss your requirements and gauge their responsiveness. -

What are the logistics considerations for importing brass door latches?

When importing brass door latches, consider factors such as shipping methods, customs regulations, and lead times. Ensure that your supplier provides accurate shipping documentation, including invoices and packing lists. Familiarize yourself with local import duties and taxes to avoid unexpected costs. Collaborating with a freight forwarder can streamline the logistics process, ensuring timely delivery while managing compliance with international shipping laws. -

Can I customize brass door latches to meet specific design requirements?

Many manufacturers offer customization options for brass door latches, allowing you to tailor sizes, finishes, and designs to suit your project needs. Discuss your specifications with potential suppliers, as some may have design capabilities to create bespoke solutions. Be mindful of lead times and potential MOQs for customized products, as these can differ from standard offerings. -

What should I know about the durability and maintenance of brass door latches?

Brass door latches are known for their durability, but their longevity can be affected by environmental factors such as humidity and exposure to corrosive elements. Opt for solid brass latches for better resistance to wear and tarnishing. Regular maintenance, such as cleaning with a soft cloth and applying a protective lacquer, can enhance their lifespan. In harsh environments, consider using latches with a protective coating to prevent corrosion and maintain appearance.

Top 4 Door Latch Brass Manufacturers & Suppliers List

1. House of Antique Hardware – Narrow Mortise Latch

Domain: houseofantiquehardware.com

Registered: 1999 (26 years)

Introduction: This company, House of Antique Hardware – Narrow Mortise Latch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

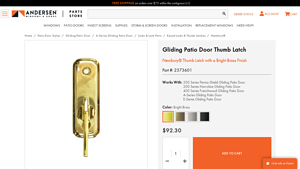

2. Andersen – Newbury Bright Brass Thumb Latch

Domain: parts.andersenwindows.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Newbury Bright Brass Thumb Latch”, “Part Number”: “2573601”, “Product Type”: “Gliding Patio Door Thumb Latch”, “Finish”: “Bright Brass”, “Compatible With”: [“200 Series Perma-Shield Gliding Patio Door”, “200 Series Narroline Gliding Patio Door”, “400 Series Frenchwood Gliding Patio Door”, “A-Series Gliding Patio Door”, “E-Series Gliding Patio Door”], “Price”: “$92.30”, “Descripti…

3. Deltana – Architectural Door Hardware

Domain: deltana.net

Registered: 2002 (23 years)

Introduction: Storm Door Latches: SDL980 (Round, Tubular Lock), SDLS480 (Rectangular, Tubular Lock), SDML334 (Square, Mortise Lock), SDL688 (Classic, Mortise Lock). Deltana offers a wide selection of architectural and door hardware made from solid brass, zinc, aluminum, steel, and stainless steel, available in over nine finishes.

4. Rejuvenation – Putman Screen Door Latch Set

Domain: rejuvenation.com

Registered: 1997 (28 years)

Introduction: Putman Screen Door Latch Set, Sale Price: $41.99 – $69, Ships in 1-2 Weeks, Free Shipping on Bedding, Decor & More.

Strategic Sourcing Conclusion and Outlook for door latch brass

In today’s competitive market, strategic sourcing for door latch brass is essential for international B2B buyers seeking quality and reliability. By understanding the diverse range of brass latch products available—from cabin hooks to door guards—buyers can tailor their selections to meet specific customer needs and preferences. Emphasizing the importance of quality sourcing not only enhances product durability but also strengthens brand reputation in various markets.

Leveraging partnerships with reputable suppliers ensures access to innovative designs and sustainable materials, catering to the growing demand for both aesthetics and functionality in door hardware. As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must remain agile and informed about emerging trends and technologies.

Moving forward, B2B buyers are encouraged to explore new sourcing strategies and foster relationships with manufacturers who prioritize quality and ethical practices. By doing so, they can position themselves as leaders in the door hardware industry, ready to meet the demands of an increasingly discerning customer base. Embrace the opportunity to innovate and elevate your product offerings in the dynamic world of door latch brass.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.