Choosing Your Deburring Machine: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for deburring machine

In the competitive landscape of metal fabrication, sourcing a reliable deburring machine is a critical challenge for international B2B buyers. Deburring machines are essential for eliminating sharp edges and imperfections that can compromise product quality and worker safety. As manufacturers aim to enhance efficiency and maintain high standards, understanding the various types of deburring machines and their applications becomes paramount. This guide delves into the comprehensive world of deburring machines, exploring the diverse models available, their specific use cases, and the latest technological advancements in the industry.

For buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Vietnam, navigating the global market requires a strategic approach. This guide will empower you with actionable insights on how to vet suppliers, assess cost implications, and determine the best fit for your operational needs. By focusing on key considerations such as machine performance, maintenance, and supplier reliability, you will be better equipped to make informed purchasing decisions that align with your business objectives. Whether you’re looking for automated solutions to streamline production or specialized machines for specific metal types, this guide is your roadmap to success in the deburring machine market.

Understanding deburring machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wet Deburring Machines | Utilize liquid coolant for effective burr removal; integrated drying systems. | Ideal for high-volume production of complex parts. | Pros: Excellent for cooling and cleaning; reduces dust. Cons: Higher maintenance due to fluid management. |

| Dry Deburring Machines | Operate without liquid; often use brushes or abrasives for finishing. | Suitable for smaller parts and less complex operations. | Pros: Lower maintenance and operational costs; compact design. Cons: May produce more dust; less effective on heavy burrs. |

| Rotary Brush Machines | Employ rotating brushes for multi-dimensional deburring and edge rounding. | Effective for various material types, including delicate parts. | Pros: Versatile for different applications; consistent finish. Cons: May require frequent brush replacements. |

| Slag Grinders | Designed specifically for heavy dross removal from plasma cut parts. | Common in industries dealing with heavy materials and high burr formations. | Pros: Robust design for heavy-duty tasks; efficient for thick burrs. Cons: Larger footprint; higher initial investment. |

| Manual Deburring Machines | Simple, cost-effective machines for manual deburring tasks. | Best for small-scale operations and custom parts. | Pros: Low cost; flexibility in operation. Cons: Labor-intensive; inconsistent results compared to automated machines. |

What Are the Key Characteristics of Wet Deburring Machines?

Wet deburring machines are characterized by their use of liquid coolant, which not only aids in the removal of burrs but also helps in cooling the workpiece and reducing dust. They are particularly suited for high-volume production environments where complex geometries are common. When considering a wet deburring machine, buyers should evaluate the machine’s fluid management system, as efficient drainage and filtration are crucial for maintaining performance and minimizing operational costs.

How Do Dry Deburring Machines Differ in Functionality?

Dry deburring machines operate without coolant, utilizing brushes or abrasive belts to achieve a smooth finish. They are ideal for smaller parts and less intricate applications, making them a cost-effective choice for many manufacturers. Buyers should consider the machine’s dust collection capabilities, as dust can be a significant drawback in dry operations. Additionally, the simplicity of these machines often translates to lower maintenance costs.

Why Choose Rotary Brush Machines for Your Operations?

Rotary brush machines stand out for their versatility, employing rotating brushes that can handle various materials and shapes, including delicate components. They are particularly effective for edge rounding and achieving a consistent finish. When purchasing rotary brush machines, businesses should assess the availability of replacement brushes and the machine’s adaptability to different materials, as this will influence long-term operational efficiency.

What Makes Slag Grinders Essential for Heavy-Duty Applications?

Slag grinders are specifically designed to handle the heavy dross generated by plasma cutting processes. Their robust construction allows them to tackle thick burrs effectively, making them a staple in industries that work with heavy materials. Buyers should consider the machine’s duty cycle and the expected volume of slag to ensure that the grinder can meet production demands without excessive downtime.

Are Manual Deburring Machines Still Relevant in Modern Manufacturing?

Manual deburring machines offer a low-cost solution for small-scale operations and custom part production. They provide flexibility in handling various tasks but require more labor and can lead to inconsistent results compared to automated systems. When considering manual options, companies should weigh the trade-off between initial investment and the potential for increased labor costs over time, especially in high-volume environments.

Key Industrial Applications of deburring machine

| Industry/Sector | Specific Application of Deburring Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Deburring of machined engine components | Enhances safety and performance of vehicle parts | Need for precision, reliability, and compliance with automotive standards |

| Aerospace | Edge finishing of aircraft components | Reduces weight and increases fuel efficiency | Requirement for high-quality finishes and lightweight materials |

| Metal Fabrication | Deburring laser-cut and plasma-cut sheet metals | Improves surface quality and prepares for coating processes | Versatility in handling various materials and thicknesses |

| Construction Machinery | Finishing of heavy machinery parts | Increases durability and longevity of construction equipment | Ability to handle large, heavy components with robust design |

| Electronics Manufacturing | Deburring of circuit boards and metal housings | Ensures proper assembly and functionality of electronic devices | Precision in handling small parts and minimizing damage during processing |

How Are Deburring Machines Utilized in the Automotive Industry?

In the automotive sector, deburring machines are essential for processing machined engine components, such as crankshafts and cylinder heads. These machines eliminate sharp edges and burrs that can compromise the safety and performance of vehicle parts. Buyers from this industry should consider machines that offer precise and consistent results, ensuring compliance with stringent automotive standards. Additionally, the ability to operate efficiently in high-volume production environments is crucial for maintaining competitive pricing.

What Role Do Deburring Machines Play in Aerospace Applications?

In aerospace manufacturing, deburring machines are employed to finish aircraft components, including wings and fuselage sections. The deburring process is vital for reducing weight and enhancing fuel efficiency, as any imperfections can lead to increased drag. Buyers must prioritize machines that deliver high-quality finishes and are capable of working with lightweight materials such as aluminum and titanium. Furthermore, adherence to aerospace safety regulations and standards is a critical consideration for international buyers.

How Are Deburring Machines Applied in Metal Fabrication?

Metal fabrication companies utilize deburring machines to process laser-cut and plasma-cut sheet metals, ensuring a smooth surface finish that prepares parts for subsequent coating processes. This application enhances the overall quality of the final product, as it prevents issues like paint peeling or corrosion. B2B buyers in this sector should look for versatile machines that can accommodate various materials and thicknesses while maintaining high process reliability. Efficient operation and low unit costs are also key factors for sourcing decisions.

What Benefits Do Deburring Machines Offer in Construction Machinery?

In the construction machinery industry, deburring machines are used to finish heavy machinery parts, such as excavator arms and bulldozer blades. The removal of burrs and sharp edges improves the durability and longevity of these components, which are subjected to harsh operating conditions. Buyers should focus on machines that can handle large, heavy parts and provide robust performance under continuous operation. Additionally, sourcing machines that offer ease of maintenance can minimize downtime and enhance productivity.

Illustrative image related to deburring machine

Why Are Deburring Machines Important in Electronics Manufacturing?

Deburring machines are critical in electronics manufacturing for processing circuit boards and metal housings, where precision is paramount. The removal of burrs ensures proper assembly and functionality of electronic devices, reducing the risk of malfunctions. Buyers in this sector must seek machines capable of handling small parts delicately while delivering consistent results. Furthermore, the ability to adapt to various materials and configurations can significantly impact sourcing decisions for international buyers.

3 Common User Pain Points for ‘deburring machine’ & Their Solutions

Scenario 1: Inconsistent Surface Quality Affects Product Standards

The Problem: B2B manufacturers often struggle with maintaining consistent surface quality across batches of machined parts. Variability in manual deburring processes can lead to uneven finishes, which not only jeopardizes product quality but can also result in costly rework and delays. This inconsistency can become especially problematic when dealing with high-precision industries, such as aerospace or automotive, where strict quality standards are paramount.

The Solution: To tackle this issue, investing in an automated deburring machine can significantly enhance surface quality consistency. When selecting a deburring machine, B2B buyers should consider models that offer programmable settings for different part sizes and shapes, allowing for tailored deburring processes. Moreover, machines equipped with advanced technologies such as abrasive belts and brushes can ensure uniform treatment of all workpieces. It’s advisable to conduct a thorough evaluation of the machine’s capabilities, including its ability to manage various materials and burr sizes. Engaging with manufacturers that provide training on machine operation can further minimize variability, ensuring that operators are well-versed in utilizing the equipment effectively.

Scenario 2: Labor Costs and Worker Safety Concerns

The Problem: Labor-intensive deburring processes can lead to high operational costs and safety risks for workers. Manual deburring often requires significant time and effort, which can strain labor resources and result in increased operational costs. Additionally, the manual handling of sharp-edged components poses a safety hazard, raising concerns about workplace injuries and compliance with safety regulations.

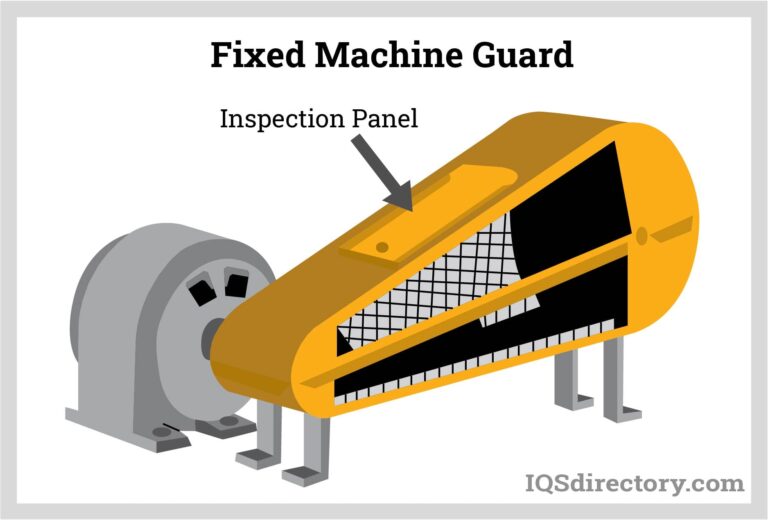

The Solution: Transitioning to an automated deburring solution can greatly alleviate both labor costs and safety risks. When sourcing a deburring machine, buyers should look for models that are designed with safety features, such as enclosed work areas and automatic shutoff mechanisms. These features help protect workers from sharp edges and minimize the risk of injury. To maximize labor efficiency, consider machines that allow for minimal operator intervention, such as those with automated loading and unloading systems. Additionally, manufacturers that provide ongoing parts support and maintenance services can help ensure that the machines operate smoothly, reducing the need for extensive manual oversight and further enhancing workplace safety.

Scenario 3: Inadequate Adaptability to Diverse Materials

The Problem: Many B2B buyers face challenges when their existing deburring machines are not adaptable enough to handle a range of materials and thicknesses. This inadequacy can lead to inefficient processing, as businesses may need to invest in multiple machines or spend extra time adjusting settings for different materials. As industries evolve and diversify, the need for versatile deburring solutions becomes increasingly critical.

The Solution: To address material adaptability concerns, buyers should prioritize deburring machines that offer customizable configurations and settings. Machines that can handle a variety of materials, such as thin sheet metal, heavy plates, or laser-cut parts, provide greater flexibility in production processes. When evaluating potential machines, consider those equipped with interchangeable tools or attachments that can easily switch between different deburring methods—whether wet or dry. Additionally, it’s beneficial to collaborate with manufacturers who understand the specific requirements of your industry, as they can offer tailored solutions that enhance operational versatility and efficiency. Regular maintenance checks and operator training can further ensure that the machine performs optimally across various applications, making it a more valuable investment.

Strategic Material Selection Guide for deburring machine

What Are the Key Materials for Deburring Machines?

When selecting a deburring machine, the choice of materials used in its construction plays a critical role in performance, longevity, and suitability for specific applications. Below, we analyze four common materials used in deburring machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Impact Deburring Machine Performance?

Key Properties: Steel is known for its high tensile strength and durability, making it an excellent choice for components that undergo significant wear and tear. It typically has a good temperature resistance, allowing it to function effectively in various operational environments.

Pros & Cons: Steel is relatively cost-effective and widely available. However, it may be prone to corrosion if not properly treated, which can affect its longevity. Manufacturing complexity can also be a consideration, as high-precision components may require advanced machining processes.

Impact on Application: Steel’s compatibility with various deburring media, including abrasives and brushes, makes it versatile for different applications. It can handle a range of materials, from thin sheets to heavy plates.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN. Corrosion resistance is particularly important in humid climates, which may necessitate additional coatings or treatments.

What Benefits Does Aluminum Offer for Deburring Machines?

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it ideal for components that require frequent handling or mobility. It also has good thermal conductivity, which can be beneficial in heat-sensitive applications.

Pros & Cons: The lightweight nature of aluminum can enhance the efficiency of deburring machines, but it may lack the strength of steel in high-stress situations. While aluminum is generally more expensive than steel, its longevity in corrosive environments can offset initial costs.

Impact on Application: Aluminum is particularly suitable for applications involving softer materials, as it minimizes the risk of damaging the workpieces during deburring. Its compatibility with various finishing processes adds to its appeal.

Illustrative image related to deburring machine

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that meet their operational needs and comply with international standards. Additionally, sourcing aluminum from local suppliers can reduce costs and lead times.

Why Is Stainless Steel a Preferred Material for Deburring Machines?

Key Properties: Stainless steel is renowned for its exceptional corrosion resistance and mechanical strength. It can withstand high temperatures and is less likely to deform under stress, making it suitable for rigorous applications.

Pros & Cons: While stainless steel is more expensive than carbon steel, its durability and resistance to rust make it a long-term investment. However, the manufacturing process can be more complex, requiring specialized techniques.

Impact on Application: Stainless steel’s ability to maintain integrity under extreme conditions makes it ideal for deburring machines used in industries like aerospace and food processing, where hygiene and safety are paramount.

Considerations for International Buyers: For buyers in the Middle East and Europe, ensuring compliance with food safety and hygiene standards is crucial when selecting stainless steel components. Familiarity with local regulations can facilitate smoother procurement processes.

Illustrative image related to deburring machine

How Do Composite Materials Enhance Deburring Machines?

Key Properties: Composite materials, often made from a combination of plastics and fibers, offer lightweight yet robust solutions. They exhibit excellent resistance to corrosion and can be designed to meet specific performance criteria.

Pros & Cons: Composites can reduce the overall weight of deburring machines, enhancing maneuverability. However, they may not be suitable for high-temperature applications and can be more expensive than traditional materials.

Impact on Application: The flexibility of composite materials allows for innovative designs that can improve the efficiency of deburring processes. They are often used in applications where weight reduction is critical.

Considerations for International Buyers: Buyers should evaluate the specific properties of composite materials to ensure they meet the demands of their applications. Understanding the lifecycle and disposal regulations for composites in their region is also essential.

Summary Table of Material Selection for Deburring Machines

| Material | Typical Use Case for deburring machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General-purpose deburring applications | High strength and durability | Prone to corrosion without treatment | Low |

| Aluminum | Lightweight applications | Excellent corrosion resistance | Less strength under stress | Medium |

| Stainless Steel | Food processing, aerospace | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

| Composite | Specialized lightweight applications | Reduces overall weight | Not suitable for high temperatures | Medium to High |

This guide provides a comprehensive overview of material selection for deburring machines, enabling international B2B buyers to make informed decisions tailored to their specific operational needs and regional requirements.

Illustrative image related to deburring machine

In-depth Look: Manufacturing Processes and Quality Assurance for deburring machine

What Are the Key Stages in the Manufacturing Process of Deburring Machines?

The manufacturing process of deburring machines involves several critical stages, each designed to ensure high-quality output and optimal performance. Understanding these stages can help B2B buyers make informed decisions when evaluating suppliers.

Material Preparation: Selecting the Right Components

The first stage in manufacturing deburring machines is the careful selection and preparation of materials. High-quality steel and aluminum alloys are commonly used due to their durability and resistance to wear. Suppliers often source materials from certified vendors to meet international quality standards. After procurement, materials undergo a rigorous inspection process to check for defects, ensuring that only the best components are used in production.

Forming: Precision Engineering Techniques

Once the materials are prepared, they are subjected to various forming techniques. Common methods include:

- CNC Machining: This allows for precise cuts and shapes, essential for components that require exact dimensions.

- Laser Cutting: Often used for sheet metal components, laser cutting ensures clean edges, reducing the need for excessive deburring later in the process.

- Bending and Stamping: These techniques shape metal into the desired forms and are particularly useful for parts that require specific angles or profiles.

Each technique is selected based on the design requirements of the deburring machine, ensuring efficiency and accuracy.

Illustrative image related to deburring machine

Assembly: Integrating Components for Optimal Functionality

The assembly stage is where all the manufactured components come together. This process can vary significantly based on the complexity of the machine. Key practices include:

- Modular Assembly: Many manufacturers adopt a modular approach, allowing for easier upgrades and repairs. This is particularly beneficial for B2B buyers looking for machines that can adapt to future needs.

- Quality Control at Assembly: During assembly, quality control checkpoints are established to ensure that each component fits correctly and functions as intended. This can include visual inspections and functional tests.

Finishing: Enhancing Performance and Aesthetics

The final stage of manufacturing involves finishing processes such as:

- Surface Treatment: Techniques like powder coating or anodizing are used to enhance the machine’s durability and resistance to corrosion.

- Final Assembly Inspection: A thorough inspection is conducted to ensure that the machine meets all specifications. This includes testing for functionality and safety.

How Is Quality Assurance Implemented in Deburring Machine Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process for deburring machines, ensuring that they meet both operational and safety standards. B2B buyers should be familiar with various international and industry-specific standards that govern quality assurance.

What International Standards Are Relevant for Deburring Machines?

The most widely recognized quality standard is ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has a systematic approach to managing its processes, ensuring consistent quality in its products.

In addition to ISO, certain industry-specific certifications can be important, including:

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates that the product complies with EU safety, health, and environmental protection standards.

- API Certification: Relevant for manufacturers dealing with the oil and gas industry, API certification ensures that products meet stringent quality and safety requirements.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, random checks are performed to monitor ongoing quality and identify any issues early.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes comprehensive testing to ensure it meets all operational specifications.

What Testing Methods Are Commonly Used?

Common testing methods in the deburring machine manufacturing process include:

- Functional Testing: Machines are operated under load to verify performance against specifications.

- Safety Testing: Ensures compliance with safety standards, particularly in terms of electrical and mechanical safety.

- Durability Testing: Machines may undergo stress tests to evaluate their performance over extended periods.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure product reliability and compliance with local regulations. Here are several strategies to effectively assess supplier quality:

What Audits and Reports Should Buyers Request?

Buyers should consider requesting:

- Quality Management System Audits: These audits provide insight into a manufacturer’s adherence to quality standards like ISO 9001.

- Production Process Reports: Detailed reports on manufacturing processes can reveal the effectiveness of quality control measures at each stage.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These services typically include:

- Random Inspections: Conducting unscheduled checks during the production process to ensure compliance with specified standards.

- Final Product Inspections: Assessing finished products before shipment to confirm they meet quality expectations.

What Quality Control Nuances Should International Buyers Consider?

When sourcing deburring machines, international buyers must be aware of specific nuances that can affect quality control:

- Regulatory Compliance: Different regions may have varying compliance requirements. Buyers should understand the local regulations in their markets, such as safety and environmental standards.

- Cultural Differences: Communication barriers and differing business practices can affect the clarity of quality expectations. Establishing clear agreements and maintaining open lines of communication can mitigate these risks.

By understanding the manufacturing processes and quality assurance practices associated with deburring machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘deburring machine’

Introduction

When sourcing a deburring machine, it is essential to follow a structured approach to ensure you select a solution that meets your operational needs while optimizing efficiency and product quality. This checklist provides a step-by-step guide for B2B buyers, particularly in international markets, to navigate the procurement process effectively.

Illustrative image related to deburring machine

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the materials you will be working with, the size and thickness of the parts, and the type of deburring required (e.g., wet or dry). This step is critical as it directly impacts the machine’s performance and your overall production capabilities.

- Material Types: Identify whether you’ll be working with metals, plastics, or composites.

- Burr Characteristics: Determine the size and type of burrs generated in your processes.

Step 2: Assess Your Production Volume Requirements

Understanding your production volume is vital for selecting the right machine capacity. Evaluate both your current and projected production needs to ensure the deburring machine can handle the workload without bottlenecks.

- Operational Hours: Consider whether you need a machine for single-shift or multi-shift operations.

- Scalability: Look for machines that can be upgraded or expanded as your production demands grow.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is crucial to ensure reliability and quality. Request detailed company profiles, customer testimonials, and case studies from businesses in similar industries or regions to understand their experience and capabilities.

- Certifications: Check for industry certifications that validate the supplier’s quality standards.

- After-Sales Support: Inquire about the availability of maintenance, spare parts, and technical support.

Step 4: Compare Machine Features and Technologies

Different deburring machines come with varying features and technologies. Assess which features align with your operational needs, such as automation capabilities, ease of use, and adaptability to different materials.

Illustrative image related to deburring machine

- Automation Level: Determine if you require a fully automated solution or a semi-automated machine.

- Additional Features: Look for machines that offer integrated functionalities, such as edge rounding and surface finishing.

Step 5: Review Total Cost of Ownership

The total cost of ownership (TCO) extends beyond the initial purchase price. Evaluate operational costs, including maintenance, energy consumption, and potential downtime, to get a comprehensive view of the machine’s financial impact over its lifespan.

- Maintenance Costs: Inquire about routine maintenance requirements and associated costs.

- Energy Efficiency: Assess the energy consumption of the machine to gauge long-term operational costs.

Step 6: Request Demonstrations and Trials

Before making a final decision, request demonstrations or trials of shortlisted machines. This hands-on experience allows you to evaluate the machine’s performance, usability, and the quality of the finished product.

- Performance Metrics: Observe how effectively the machine handles your specific materials and burr types.

- Operator Feedback: Involve operators in the trial to gain insights on usability and ergonomics.

Step 7: Finalize Contracts and Terms

Once you have selected a supplier and machine, ensure that all contractual terms are clearly defined. Pay attention to warranty coverage, delivery timelines, and payment terms to avoid any future disputes.

- Warranty and Support: Confirm the warranty terms and what support is included post-purchase.

- Flexibility: Negotiate terms that allow for adjustments based on changing production needs.

By following this practical sourcing checklist, you can make informed decisions that enhance your production efficiency and product quality, ensuring a successful investment in deburring machinery.

Comprehensive Cost and Pricing Analysis for deburring machine Sourcing

What Are the Key Cost Components in Deburring Machine Sourcing?

When sourcing deburring machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in manufacturing deburring machines directly impacts the final price. Higher-grade materials enhance durability and performance, but they come at a premium. Buyers should evaluate the trade-off between cost and longevity.

-

Labor: Labor costs encompass wages for skilled workers involved in the assembly and quality control of machines. In regions with higher labor costs, such as parts of Europe, this may significantly influence the overall pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, ultimately benefiting the buyer through more competitive pricing.

-

Tooling: The machinery required for production, including specialized tools and dies, contributes to the initial setup costs. Custom tooling for specialized deburring applications can further increase costs.

-

Quality Control (QC): Rigorous quality assurance processes ensure that machines meet specified standards. This involves inspection and testing, which can add to the overall manufacturing costs but is crucial for ensuring product reliability.

-

Logistics: Shipping costs can vary widely based on destination and mode of transport. B2B buyers must consider these costs, especially when sourcing from international suppliers, as they can significantly affect the total purchase price.

-

Margin: Suppliers include a margin in their pricing to cover risks, investments, and profit. Understanding the supplier’s pricing strategy can provide insights into potential negotiation points.

How Do Price Influencers Impact Deburring Machine Costs?

Several factors can influence the pricing of deburring machines:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often results in lower per-unit costs. B2B buyers should assess their production needs to maximize savings through volume purchases.

-

Specifications and Customization: Customized machines tailored to specific applications typically cost more than standard models. Buyers should clearly define their requirements to ensure they receive the best value for their investment.

-

Materials and Quality Certifications: Machines built with high-quality materials and certified for industry standards tend to command higher prices. However, the investment pays off in terms of reliability and performance.

-

Supplier Factors: The reputation and experience of the supplier can affect pricing. Established manufacturers with a track record of quality and service may charge a premium, while emerging suppliers might offer more competitive rates.

-

Incoterms: International shipping terms can significantly affect overall costs. Understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers anticipate additional expenses related to shipping and insurance.

What Buyer Tips Can Help Negotiate Better Pricing?

B2B buyers can leverage various strategies to negotiate more favorable terms:

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing for similar machines. This information can serve as leverage during negotiations.

-

Total Cost of Ownership (TCO): Assessing the long-term costs associated with a deburring machine, including maintenance, energy consumption, and potential downtime, can provide a more comprehensive view of value versus initial price.

-

Negotiation Strategies: Engaging in open discussions about pricing and exploring flexible payment options, such as leasing or financing, can lead to cost savings. Buyers should not hesitate to negotiate on volume discounts or service agreements.

-

Consider Local Suppliers: For buyers in regions like Africa and South America, sourcing from local manufacturers may reduce logistics costs and lead times, offering a competitive advantage.

What Should International B2B Buyers Keep in Mind?

International buyers must navigate additional complexities:

-

Currency Fluctuations: Changes in currency exchange rates can impact pricing. Buyers should consider locking in rates or negotiating payment terms that mitigate risks.

-

Regulatory Compliance: Different regions may have specific regulations regarding machinery safety and emissions. Ensuring compliance can prevent costly penalties and modifications later.

-

Cultural Differences: Understanding cultural nuances in business practices can improve negotiations and foster better supplier relationships.

Disclaimer on Indicative Prices

Prices for deburring machines can vary widely based on the aforementioned factors. It is advisable for buyers to request detailed quotes from multiple suppliers to ensure competitive pricing and alignment with specific operational needs.

Alternatives Analysis: Comparing deburring machine With Other Solutions

Exploring Alternative Solutions to Deburring Machines

In the realm of metalworking, deburring is essential for achieving high-quality finishes and ensuring the safety of manufactured parts. While deburring machines are a popular choice, there are alternative solutions available that can also meet the needs of various production environments. This analysis will compare deburring machines with two viable alternatives: manual deburring and chemical deburring processes.

Comparison Table

| Comparison Aspect | Deburring Machine | Manual Deburring | Chemical Deburring |

|---|---|---|---|

| Performance | High efficiency and consistency | Variable, dependent on operator skill | Effective on complex geometries |

| Cost | Higher initial investment | Lower initial cost, but higher labor costs | Moderate, but requires proper safety measures |

| Ease of Implementation | Requires training and setup | Simple to implement | Complex setup and safety training needed |

| Maintenance | Regular maintenance required | Minimal maintenance | Requires careful handling of chemicals |

| Best Use Case | High-volume production | Low-volume, custom parts | Delicate parts with intricate details |

Pros and Cons of Alternative Solutions

Manual Deburring

Manual deburring involves using hand tools such as files, grinders, or sanders to remove burrs from metal parts. This method is typically less expensive to implement initially, as it does not require the capital outlay associated with purchasing machinery. However, its effectiveness heavily relies on the skill and experience of the operator, leading to variability in finish quality. Manual processes can be suitable for low-volume production or custom parts, where precision is paramount. The downside is that manual deburring can be time-consuming and labor-intensive, potentially leading to higher overall labor costs in the long run.

Chemical Deburring

Chemical deburring utilizes corrosive solutions to dissolve burrs from metal surfaces. This method is particularly effective for complex geometries or delicate parts that may be difficult to deburr mechanically. Chemical deburring can achieve a high-quality finish without the risk of altering the part’s dimensions. However, this process requires careful handling and disposal of chemicals, necessitating comprehensive safety training for personnel. The initial setup can be complex, and ongoing costs may arise from chemical procurement and disposal. This method may be most suitable for specialized applications where traditional mechanical deburring falls short.

Illustrative image related to deburring machine

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate deburring solution, B2B buyers should carefully assess their specific production requirements, including volume, part complexity, and available budget. Deburring machines offer high efficiency and consistent quality for high-volume applications, making them ideal for larger manufacturing environments. In contrast, manual deburring can serve smaller operations or custom projects where operator skill can shine. Chemical deburring stands out for intricate designs but comes with its own set of challenges. By evaluating these factors, buyers can make informed decisions that align with their operational goals and ensure optimal results in their metalworking processes.

Essential Technical Properties and Trade Terminology for deburring machine

What Are the Key Technical Properties of Deburring Machines?

When considering the purchase of a deburring machine, it’s essential to understand several key technical properties that directly impact operational efficiency and product quality. Below are critical specifications to keep in mind:

-

Material Grade

The material grade of the machine components (e.g., stainless steel, aluminum, or specialized alloys) is crucial as it influences durability and resistance to wear. Higher-grade materials can withstand harsher operating conditions, extending the machine’s lifespan and reducing maintenance costs. For B2B buyers, investing in machines made from superior materials can lead to long-term savings and consistent performance. -

Deburring Method

Different machines utilize various deburring methods such as wet, dry, or brush-based systems. Wet deburring typically provides a smoother finish and helps manage dust, while dry systems are more efficient for certain metal types. Understanding the method best suited for your production requirements can lead to improved efficiency and quality in the final product. -

Tolerances

Tolerance levels refer to the acceptable limits of deviation in the dimensions of the parts being processed. High-precision deburring machines can achieve tighter tolerances, which is vital in industries such as aerospace and automotive. B2B buyers should consider their specific tolerance needs to ensure the selected machine can consistently meet these standards. -

Production Speed

The machine’s production speed, often measured in parts per hour, is a significant factor that affects overall productivity. Faster machines can help meet high demand and reduce labor costs, making them an attractive option for companies looking to enhance their throughput. Evaluating production speed against operational needs is critical for optimizing workflow. -

Versatility

Machines that can handle a range of materials and part sizes offer greater flexibility in production. Some deburring machines are designed for both thin and thick materials, making them suitable for diverse applications. This adaptability is particularly beneficial for companies that manage varying project demands. -

Automation Features

Advanced automation features, such as robotic loading and unloading systems, can greatly enhance efficiency and reduce manual labor. Automated systems minimize human error and improve safety in the workplace. For B2B buyers, investing in machines with robust automation capabilities can lead to significant operational improvements.

What Are Common Trade Terms Related to Deburring Machines?

Understanding industry jargon can facilitate better communication and decision-making during the procurement process. Here are essential trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing deburring machines, identifying OEMs can help ensure quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects inventory costs and purchasing decisions, especially for smaller operations that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on providing specific products or services. For deburring machines, submitting an RFQ allows buyers to compare pricing and features from multiple manufacturers. -

Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping costs, risks, and delivery timelines effectively. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For buyers, knowing the lead time is crucial for planning production schedules and ensuring timely project completion. -

Service Level Agreement (SLA)

An SLA is a contract that defines the expected service levels between a supplier and a customer. For deburring machines, this can include maintenance schedules, response times for repairs, and uptime guarantees, ensuring that operational expectations are met.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that align with your operational goals and enhance your production capabilities.

Navigating Market Dynamics and Sourcing Trends in the deburring machine Sector

What Are the Global Drivers Influencing the Deburring Machine Market?

The deburring machine market is witnessing significant growth driven by various global factors. The rising demand for high-quality metal products across industries such as automotive, aerospace, and electronics is a primary catalyst. As manufacturers strive for improved safety and product quality, deburring machines have become essential to eliminate sharp edges and enhance the surface finish of components. Furthermore, the increasing automation in manufacturing processes is reshaping sourcing trends. International buyers are increasingly looking for automated solutions that offer higher efficiency, reduced labor costs, and consistent quality output.

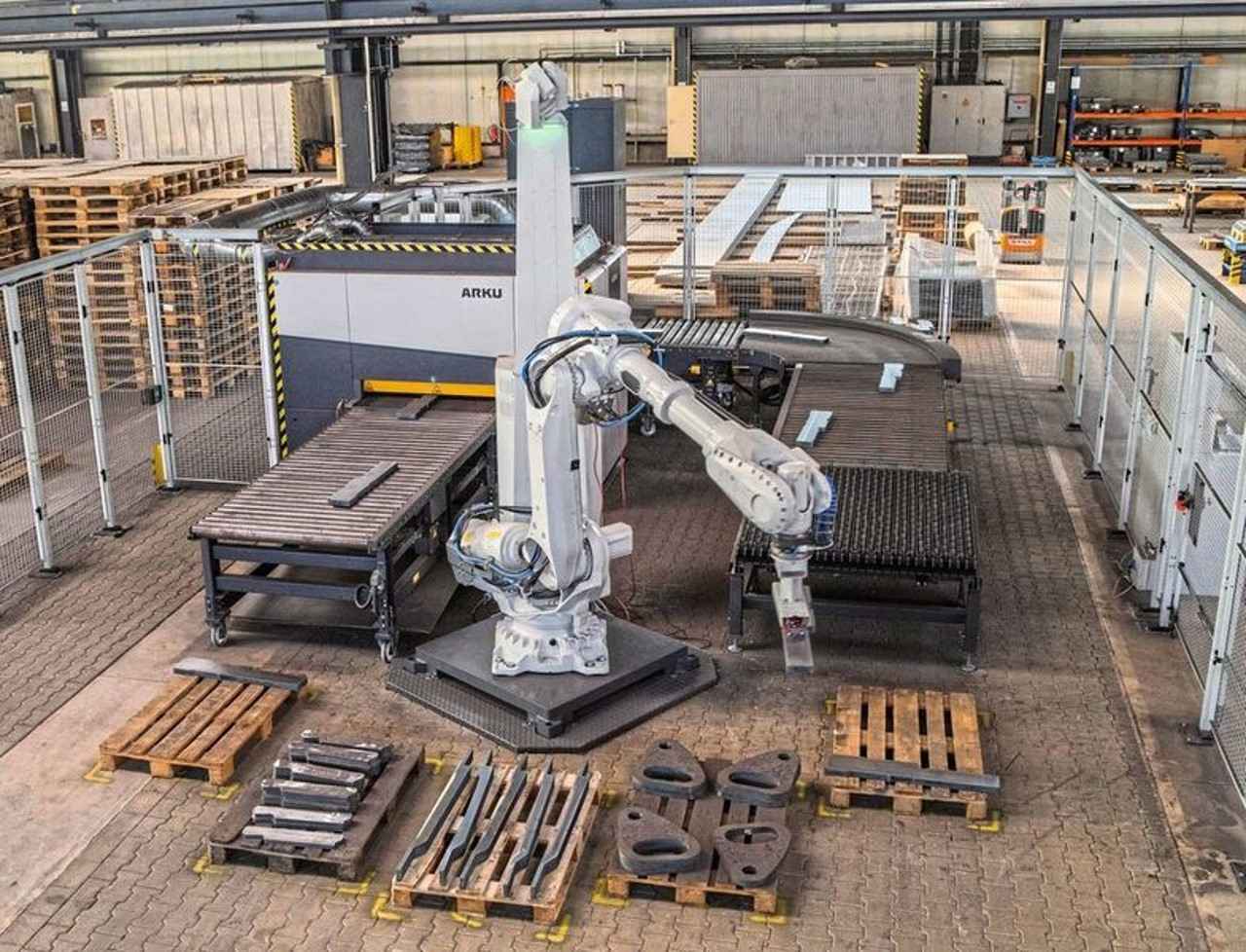

Emerging technologies such as robotics and artificial intelligence are also playing a crucial role in the evolution of deburring machines. These advancements enable real-time monitoring and adjustments during the deburring process, leading to enhanced operational efficiencies. Moreover, as industries in regions like Africa, South America, the Middle East, and Europe continue to modernize, there is a growing focus on machines that can handle diverse materials and varying production scales. Buyers are particularly interested in solutions that can accommodate laser-cut and punched parts, as these are prevalent in manufacturing.

How Are Sustainability and Ethical Sourcing Shaping the Deburring Machine Sector?

Sustainability has emerged as a pivotal concern for international B2B buyers, particularly in the deburring machine sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, has prompted companies to seek eco-friendly solutions. Deburring machines that utilize water-based systems rather than solvent-based ones, for example, are gaining popularity due to their lower environmental footprint.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly aware of the sourcing practices of their suppliers, seeking those who adhere to sustainable and ethical standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming prerequisites for suppliers in the deburring machine market. Companies are also exploring the use of recyclable materials in machine construction and packaging, aligning their operations with broader sustainability goals. As a result, choosing suppliers who prioritize sustainability not only enhances brand reputation but also meets regulatory requirements in various regions.

What Is the Evolution and History of Deburring Machines?

The evolution of deburring machines can be traced back to the industrial revolution when the need for precision in metalworking became paramount. Initially, manual deburring methods were employed, which were labor-intensive and inconsistent. As the metalworking industry advanced, the introduction of mechanical deburring tools marked a significant turning point, allowing for more efficient and uniform processing.

By the late 20th century, automation began to play a crucial role in the manufacturing process, leading to the development of sophisticated deburring machines that integrated advanced technologies. The introduction of programmable logic controllers (PLCs) and computer numerical control (CNC) systems revolutionized the industry, enabling precise control over the deburring process. Today, manufacturers are focusing on smart deburring solutions that incorporate IoT capabilities, further streamlining operations and enhancing productivity. This evolution reflects the industry’s commitment to meeting the growing demands of quality, efficiency, and sustainability in the modern manufacturing landscape.

Conclusion

In summary, international B2B buyers in the deburring machine sector are navigating a landscape shaped by technological advancements, sustainability considerations, and the need for operational efficiency. Understanding these dynamics and sourcing trends is crucial for making informed purchasing decisions, ensuring that investments align with both current market demands and future growth opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of deburring machine

-

How do I choose the right deburring machine for my production needs?

Selecting the right deburring machine involves assessing your specific production requirements, such as the type of materials you work with, the size and shape of the parts, and the volume of production. Consider whether you need a wet or dry deburring system based on your material and finish requirements. Additionally, evaluate the machine’s capabilities for handling various burr sizes and types. Consulting with manufacturers to understand their offerings and requesting demonstrations can also help in making an informed decision. -

What are the key benefits of investing in automated deburring machines?

Automated deburring machines offer numerous advantages, including improved product quality with consistent finishes, enhanced safety by reducing manual handling of sharp edges, and increased operational efficiency. They minimize labor costs by automating processes, allowing your workforce to focus on higher-value tasks. Moreover, these machines can significantly reduce production times, leading to faster turnaround and higher output, which is essential for maintaining competitiveness in the market. -

What is the typical lead time for purchasing a deburring machine?

Lead times for deburring machines can vary significantly based on the manufacturer, customization requirements, and order size. Standard machines might have a lead time of 4 to 8 weeks, while custom configurations could take longer, sometimes up to 12 weeks or more. It’s crucial to communicate your timelines and production schedules to suppliers early in the process to ensure that your machine arrives when you need it. -

What customization options are available for deburring machines?

Most manufacturers offer a range of customization options to meet specific production needs. Customization can include adjusting machine dimensions, incorporating additional tooling for various material types, and configuring the machine for specific deburring processes (like edge rounding or surface finishing). When discussing your requirements with suppliers, be clear about your production needs, and inquire about available options that can enhance the machine’s performance for your applications. -

How do I vet suppliers of deburring machines effectively?

To vet suppliers, start by researching their reputation in the industry, including customer reviews and testimonials. Request references from other businesses in your region or sector to gauge their experiences. Additionally, assess the supplier’s experience with international trade, their ability to support logistics, and the quality assurance processes they have in place. A reliable supplier should also provide comprehensive after-sales support, including maintenance and spare parts availability. -

What are the common payment terms for purchasing deburring machines?

Payment terms can vary widely between suppliers, but many manufacturers offer options such as upfront payments, deposits with balance upon delivery, or financing arrangements. It’s essential to clarify the terms before finalizing your order. Some suppliers may also provide leasing options, which can be beneficial for businesses looking to manage cash flow while investing in new equipment. Always ensure that the payment terms align with your financial capabilities and project timelines. -

What should I consider regarding logistics and shipping when sourcing deburring machines?

Logistics and shipping are critical considerations when sourcing deburring machines internationally. Factors to evaluate include shipping costs, customs duties, and potential delays in transit. Discuss with your supplier about their experience in handling international shipments and ask about their logistics partners. Ensure that they can provide tracking information and support for any customs clearance processes to avoid unexpected complications. -

How can I ensure quality assurance for the deburring machine I purchase?

To ensure quality assurance, choose suppliers who adhere to internationally recognized quality standards, such as ISO certifications. Request detailed specifications and performance metrics for the machine you intend to purchase. It’s also advisable to ask for a pre-shipment inspection or the option to visit the manufacturing facility to witness the quality control processes in action. Establishing a clear communication channel with your supplier regarding any quality concerns post-purchase is equally important for ongoing satisfaction.

Top 6 Deburring Machine Manufacturers & Suppliers List

1. ARKU – Deburring Machines

Domain: arku.com

Registered: 1999 (26 years)

Introduction: ARKU offers a range of deburring machines designed for efficient processing of metal parts, sheets, and plates. Key features include:

– Automated deburring machines tailored for various applications, including thin sheet metal and heavy plates.

– Solutions for deburring laser cut and punched parts with the Edgebreaker® model, suitable for a broad range of materials and dimensions.

– Specialized…

2. NS Maquinas – DM1100 DC EVO

Domain: nsmaquinas.com

Introduction: {“product_name”: “DM1100 DC EVO”, “category”: “Deburring and Edge Rounding”, “description”: “Single-Sided Slag Removal & Edge Rounding Heavy-Duty Automated 1100mm Width deburring machine for thick steel parts cut by plasma or oxyfuel.”, “key_features”: {“deburring”: “Powerful contact drum for heavy burrs deburring (D station)”, “edge_rounding”: “Set of 2 counter rotating edge rounding cross belts”…

3. Kent Corporation – Rotoburr & Burrmaster Tube Deburring Machines

Domain: kentcorporation.com

Registered: 1997 (28 years)

Introduction: Kent Corporation offers two tube deburring machines: the Rotoburr and the Burrmaster. The Rotoburr features dual action brush rotation for deburring both the I.D. and O.D. face of a profile in less than three seconds, eliminating the need to spin the part and ensuring quiet, efficient, and vibration-free operation. The Burrmaster is a double-end tube deburrer with automatic loading capabilities, c…

4. LISSMAC – SBM-XS G1E1

Domain: lissmac.com

Registered: 1997 (28 years)

Introduction: LISSMAC offers high-quality deburring machines designed for efficient burr removal, edge rounding up to a radius of 2 mm, oxide layer removal, effective slag removal, and precise surface grinding. Key products include:

1. SBM-XS G1E1 – Double sided deburring of small parts in a single pass.

2. SBM-M S2 – Deburring and edge rounding of steel and stainless steel on both sides in one single pass.

3….

5. Techniks USA – Spinner Deburring Machines

Domain: techniksusa.com

Registered: 2000 (25 years)

Introduction: Product: Spinner Deburring Machines

Key Features:

– Batch deburring for dozens to hundreds of small precision metal parts

– Eliminates hand-deburring, polishing, or finishing processes

– Effective for irregular parts and small precision parts with hard-to-reach internal cavities

– Free deburring test available

Models:

1. EHD-728:

– Dimensions: 19″ x 19″ x 37″

– Tank Size: 11″ x 11″

– C…

6. Deburring Machinery – Deburring Machines

Domain: deburringmachinery.com

Registered: 2000 (25 years)

Introduction: Deburring Machinery offers a range of products and equipment designed for the deburring process, which involves smoothing and neatening edges or ridges on machined parts. Key products include: 1. Deburring Machines: Specialized equipment for removing burrs from various materials. 2. Deburring Media: Materials used in the deburring process, such as ceramic or plastic pellets. 3. Deburring Tumblers:…

Strategic Sourcing Conclusion and Outlook for deburring machine

In the competitive landscape of metalworking, the importance of strategic sourcing for deburring machines cannot be overstated. By investing in high-quality, automated solutions, international B2B buyers can significantly enhance product quality, operational efficiency, and safety. The ability to choose from a diverse range of machines tailored to specific needs—whether for thin sheet metal or heavy plates—ensures that companies can meet the demands of various industries while maintaining consistent production standards.

Moreover, the integration of advanced technologies in deburring machines facilitates faster turnaround times and reduced labor costs, allowing businesses to focus on core competencies. As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for efficient and reliable deburring solutions will only increase.

To stay ahead, buyers should actively seek partnerships with reputable manufacturers known for innovation and customer support. Embrace the opportunity to upgrade your production capabilities—invest in state-of-the-art deburring machines today and secure a competitive edge in your market. Connect with leading suppliers for tailored solutions that will drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.