Choosing Your Dana Plastics Roselle Il: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for dana plastics roselle il

In an increasingly competitive global market, sourcing high-quality blow-molded plastic products from Dana Plastics in Roselle, IL, presents a unique challenge for B2B buyers. With diverse applications ranging from food and beverage packaging to personal care items, the need for reliable suppliers who can deliver innovative solutions is paramount. This guide serves as a comprehensive resource for international buyers, specifically those from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany.

Within these pages, you will explore the extensive product offerings available from Dana Plastics, including containers, bottles, and customized solutions tailored to meet specific industry requirements. We delve into crucial aspects of the supplier vetting process, enabling you to assess quality assurance measures and production capabilities effectively. Additionally, we provide insights on cost considerations and trends that influence pricing in the global market.

By equipping you with actionable insights and a thorough understanding of Dana Plastics’ capabilities, this guide empowers you to make informed purchasing decisions. Whether you are looking to enhance your product line or optimize supply chain efficiencies, navigating the offerings from Dana Plastics in Roselle, IL, will be a strategic advantage in your business operations.

Understanding dana plastics roselle il Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Blow-Molded Containers | Hollow plastic products, high durability, custom shapes available | Food & beverage, personal care, industrial storage | Pros: Lightweight, customizable, cost-effective. Cons: Limited to specific shapes; may require minimum order quantities. |

| Plastic Bottles | Variety of materials (PET, HDPE), available in multiple sizes | Beverages, cleaning products, pharmaceuticals | Pros: Versatile, recyclable, strong. Cons: May not be suitable for all liquids (e.g., solvents). |

| Custom Injection Molded Parts | Tailored designs, high precision, rapid prototyping | Automotive, electronics, consumer goods | Pros: Exact specifications, high quality. Cons: Higher initial costs due to tooling. |

| Sprayer Containers | Ergonomic designs, various sizes, and shapes | Cleaning agents, personal care products | Pros: User-friendly, efficient dispensing. Cons: May require additional investments in design for unique applications. |

| Plastic Tanks | Large capacity, available in various configurations | Water storage, chemical processing | Pros: Durable, resistant to corrosion. Cons: Bulkiness can be a challenge for shipping and installation. |

What Are the Characteristics of Blow-Molded Containers from Dana Plastics in Roselle, IL?

Blow-molded containers are a core offering from Dana Plastics, known for their hollow structure and robust durability. These containers can be customized in various shapes and sizes, making them suitable for a wide range of industries, including food and beverage, personal care, and industrial storage. When considering these products, B2B buyers should evaluate their specific application needs, as well as the potential for minimum order quantities that may apply.

Illustrative image related to dana plastics roselle il

How Do Plastic Bottles Stand Out Among Dana Plastics Products?

Plastic bottles manufactured by Dana Plastics are made from materials like PET and HDPE, providing versatility across various applications, including beverages and cleaning products. They come in multiple sizes, catering to different market needs. Buyers should consider the specific material requirements for their products, as certain chemicals may not be compatible with all types of plastics. Additionally, the recyclability of these bottles adds an eco-friendly advantage that can enhance brand appeal.

What Are the Advantages of Custom Injection Molded Parts from Dana Plastics?

Custom injection molded parts are tailored to meet precise specifications, allowing for high-quality production and rapid prototyping. This service is particularly beneficial for industries such as automotive, electronics, and consumer goods where precision is critical. However, B2B buyers should be aware of the higher initial costs associated with tooling and the potential for longer lead times during the design phase.

Why Choose Sprayer Containers from Dana Plastics?

Dana Plastics’ sprayer containers are designed for ergonomics and efficiency, making them ideal for dispensing cleaning agents and personal care products. These containers come in various sizes and shapes, allowing businesses to select the most appropriate design for their needs. Buyers should evaluate the user experience and design features to ensure they meet their target market’s preferences, which can influence purchasing decisions.

What Should Buyers Know About Plastic Tanks Offered by Dana Plastics?

Plastic tanks from Dana Plastics are designed for large capacity storage and are available in various configurations, making them suitable for water storage and chemical processing applications. Their durability and resistance to corrosion make them a reliable choice for many industries. However, buyers should consider the challenges of bulkiness for shipping and installation, as this can impact overall logistics and costs.

Illustrative image related to dana plastics roselle il

Key Industrial Applications of dana plastics roselle il

| Industry/Sector | Specific Application of dana plastics roselle il | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Custom blow-molded containers for packaging | Enhanced product preservation and visual appeal | Compliance with food safety regulations and certifications |

| Personal Care and Cosmetics | Bottles and jars for lotions and creams | Attractive design and functionality for consumer appeal | Material safety and customization options |

| Industrial Chemicals | Specialty containers for hazardous materials | Reliable containment and safety during transportation | Durability, chemical resistance, and compliance standards |

| Pharmaceuticals and Healthcare | Medical-grade bottles and containers | Ensured product integrity and patient safety | ISO certifications and quality assurance processes |

| Household Goods | Versatile storage containers and jugs | Space-efficient solutions for various household needs | Custom sizes and designs to meet specific customer needs |

How Does Dana Plastics Serve the Food and Beverage Industry?

Dana Plastics provides custom blow-molded containers that are essential for the food and beverage sector. These containers are designed to enhance product preservation, ensuring that items like juices and sauces maintain their freshness and flavor. For international buyers, particularly from regions like Africa and South America, it is crucial that these products comply with local food safety regulations. Dana Plastics excels in offering solutions that not only meet regulatory standards but also provide attractive packaging options that enhance shelf appeal.

What Are the Benefits for Personal Care and Cosmetics Businesses?

The personal care and cosmetics industry relies heavily on aesthetically pleasing and functional packaging. Dana Plastics manufactures bottles and jars specifically tailored for lotions, creams, and other beauty products. By focusing on design and usability, Dana Plastics helps brands stand out in a competitive market. Buyers from Europe, especially Germany, should prioritize sourcing products that are not only visually appealing but also safe, ensuring that the materials used are compliant with cosmetic regulations.

How Are Industrial Chemicals Packaged Safely?

In the industrial chemicals sector, Dana Plastics specializes in creating specialty containers designed for hazardous materials. These containers provide reliable containment, which is critical during transportation and storage to prevent leaks and spills. Buyers in the Middle East and Africa should consider the durability and chemical resistance of these products, ensuring they meet stringent safety and compliance standards. Dana Plastics’ commitment to quality assurance further assures businesses of the reliability of their packaging solutions.

What Role Does Dana Plastics Play in Pharmaceuticals and Healthcare?

Dana Plastics caters to the pharmaceutical and healthcare industries by offering medical-grade bottles and containers. These products are designed to ensure product integrity and patient safety, which are paramount in this sector. International buyers must focus on sourcing from companies with ISO certifications and robust quality assurance processes to guarantee that the packaging meets strict health and safety standards. Dana Plastics’ expertise in this area makes them a trusted partner for healthcare businesses.

How Does Dana Plastics Address Household Goods Needs?

For the household goods sector, Dana Plastics provides versatile storage containers and jugs that meet a wide range of consumer needs. These products are designed to be space-efficient and functional, making them ideal for everything from kitchen storage to outdoor use. Buyers from South America should seek customizable options that cater to specific household requirements, ensuring that the products not only fit their needs but also resonate with local consumer preferences.

Illustrative image related to dana plastics roselle il

3 Common User Pain Points for ‘dana plastics roselle il’ & Their Solutions

Scenario 1: Navigating Diverse Product Requirements for Different Industries

The Problem: B2B buyers often face the challenge of sourcing plastic containers that meet specific industry standards and regulations. For example, a beverage company looking to package juice must ensure that the containers are food-safe and compliant with health regulations. Similarly, a pharmaceutical company requires containers that are not only safe but also capable of maintaining product integrity over time. This complexity can lead to confusion and delays in the procurement process, especially when dealing with multiple suppliers who may not fully understand the unique requirements of each sector.

The Solution: To effectively navigate these diverse product requirements, buyers should engage directly with Dana Plastics Container Corporation’s experienced customer support team. Initiating a dialogue can clarify specific needs, allowing Dana to recommend suitable product options from their extensive portfolio, which includes containers designed for various applications, such as food and beverage, pharmaceuticals, and personal care. Additionally, buyers should prepare a comprehensive list of specifications, including material types, size requirements, and regulatory compliance standards, to facilitate a more efficient conversation. Leveraging Dana’s expertise in custom solutions can also help in developing tailored products that meet precise industry needs, thereby reducing time-to-market and ensuring compliance with all necessary regulations.

Scenario 2: Ensuring Consistent Quality Across Large Orders

The Problem: One of the most pressing pain points for international B2B buyers is ensuring that they receive consistent quality across large volume orders. Variability in product quality can lead to significant financial losses, especially for companies that rely on the integrity of packaging to maintain their brand reputation. This is particularly critical in markets where product recalls due to packaging failures can damage consumer trust and lead to substantial financial repercussions.

The Solution: Buyers should take advantage of Dana Plastics’ robust quality control processes, which are integral to their manufacturing operations. Before placing a large order, it is advisable to request a quality assurance plan that outlines the measures Dana takes to maintain product consistency. Buyers should also consider starting with a smaller pilot order to evaluate the quality and performance of the products before scaling up. This approach not only allows for testing but also provides an opportunity to establish a strong working relationship with Dana, fostering ongoing communication and adjustments as needed. Buyers can further enhance quality assurance by incorporating regular audits and feedback mechanisms into their procurement process, ensuring that any quality issues are addressed promptly.

Scenario 3: Addressing Sustainability Concerns in Packaging

The Problem: As global awareness of environmental issues rises, B2B buyers are increasingly pressured to adopt sustainable practices in their supply chains. Companies face the challenge of sourcing packaging solutions that not only meet their operational needs but also align with their sustainability goals. This is especially relevant in regions where consumers are becoming more eco-conscious, and regulatory frameworks are tightening around plastic usage and waste management.

The Solution: To address sustainability concerns, buyers should engage with Dana Plastics to explore their eco-friendly product offerings and practices. Dana emphasizes the use of recycled materials and sustainable manufacturing processes, which can help buyers meet their own sustainability targets. When sourcing products, buyers should inquire about the lifecycle of the packaging solutions they are considering, including materials used, recyclability, and the company’s commitment to reducing environmental impact. Moreover, incorporating sustainability criteria into the procurement process can help ensure that all packaging solutions align with corporate social responsibility goals. By choosing Dana Plastics, buyers can not only enhance their product offerings but also position themselves as responsible market players, catering to a growing demographic that values sustainability.

Strategic Material Selection Guide for dana plastics roselle il

When selecting materials for blow-molded products at Dana Plastics in Roselle, IL, it is essential to consider the specific properties, advantages, and limitations of commonly used plastics. This understanding helps international B2B buyers make informed decisions that align with their operational needs and regulatory requirements.

What Are the Key Properties of Polyethylene (PE) in Blow-Molded Products?

Polyethylene (PE) is a widely utilized plastic in the manufacturing of containers and bottles. Its key properties include excellent chemical resistance, low-density, and a temperature tolerance ranging from -100°F to 180°F (-73°C to 82°C). PE is versatile, making it suitable for various applications, including food and beverage packaging.

Pros and Cons: The advantages of PE include its lightweight nature, cost-effectiveness, and recyclability. However, it may not withstand high temperatures or aggressive chemicals, limiting its use in certain applications.

Impact on Application: PE is particularly effective for packaging non-corrosive liquids, making it a popular choice in the food and beverage industry.

Illustrative image related to dana plastics roselle il

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local food safety regulations, which may align with international standards such as ASTM and DIN.

How Does Polypropylene (PP) Compare for Blow-Molded Applications?

Polypropylene (PP) is another common material known for its high melting point (up to 320°F or 160°C) and resistance to fatigue and chemicals. This makes it suitable for applications requiring durability and resistance to stress.

Pros and Cons: The key advantage of PP is its robustness, making it ideal for containers that need to endure rough handling. However, it can be more expensive than PE and may require more complex manufacturing processes.

Impact on Application: PP is often used in medical and pharmaceutical packaging due to its ability to withstand sterilization processes.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure that PP products comply with the EU’s stringent regulations on safety and environmental impact.

What Role Does Polyethylene Terephthalate (PET) Play in Packaging?

Polyethylene Terephthalate (PET) is favored for its clarity, strength, and barrier properties, making it an excellent choice for beverage containers. It can withstand temperatures up to 190°F (88°C) and is resistant to impact and moisture.

Pros and Cons: PET’s transparency and strength make it ideal for consumer products, but its production can be more costly than that of PE and PP. Additionally, while PET is recyclable, its recycling infrastructure varies by region.

Impact on Application: PET is particularly suitable for carbonated beverage packaging, where pressure resistance is crucial.

Considerations for International Buyers: Buyers should be aware of recycling regulations in their respective countries, as compliance with local standards can affect product acceptance in the market.

How Does Polyvinyl Chloride (PVC) Fit into the Blow-Molding Landscape?

Polyvinyl Chloride (PVC) is known for its rigidity and chemical resistance, making it a good choice for containers that require a strong, durable option. It can withstand temperatures up to 140°F (60°C) and is often used in industrial applications.

Illustrative image related to dana plastics roselle il

Pros and Cons: The major advantage of PVC is its durability and resistance to environmental degradation. However, it may not be suitable for food applications without proper treatment due to potential leaching of harmful substances.

Impact on Application: PVC is commonly used in industrial packaging and construction applications, but its use in food-related products is limited.

Considerations for International Buyers: Buyers in the Middle East should ensure that PVC products meet local health and safety regulations, which may differ significantly from those in Europe or the Americas.

Summary Table of Material Selection

| Material | Typical Use Case for dana plastics roselle il | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Food and beverage containers | Lightweight and cost-effective | Limited high-temperature resistance | Low |

| Polypropylene (PP) | Medical and pharmaceutical packaging | High durability and chemical resistance | Higher cost and manufacturing complexity | Medium |

| Polyethylene Terephthalate (PET) | Carbonated beverage containers | Clarity and strength | Higher production costs | Medium |

| Polyvinyl Chloride (PVC) | Industrial packaging and construction | Durability and environmental resistance | Limited food application suitability | Medium |

This strategic material selection guide provides insights into the properties and considerations of various plastics used in Dana Plastics’ products, enabling international B2B buyers to make informed decisions that align with their specific needs and compliance requirements.

Illustrative image related to dana plastics roselle il

In-depth Look: Manufacturing Processes and Quality Assurance for dana plastics roselle il

What Are the Main Stages of the Manufacturing Process at Dana Plastics in Roselle, IL?

Dana Plastics employs a sophisticated manufacturing process that encompasses several key stages, ensuring the production of high-quality blow-molded plastic products. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the careful selection and preparation of raw materials, primarily thermoplastic resins such as polyethylene and polypropylene. These materials are sourced from reputable suppliers, ensuring they meet stringent quality standards. Before use, the materials undergo a thorough inspection to verify their properties and suitability for the intended application.

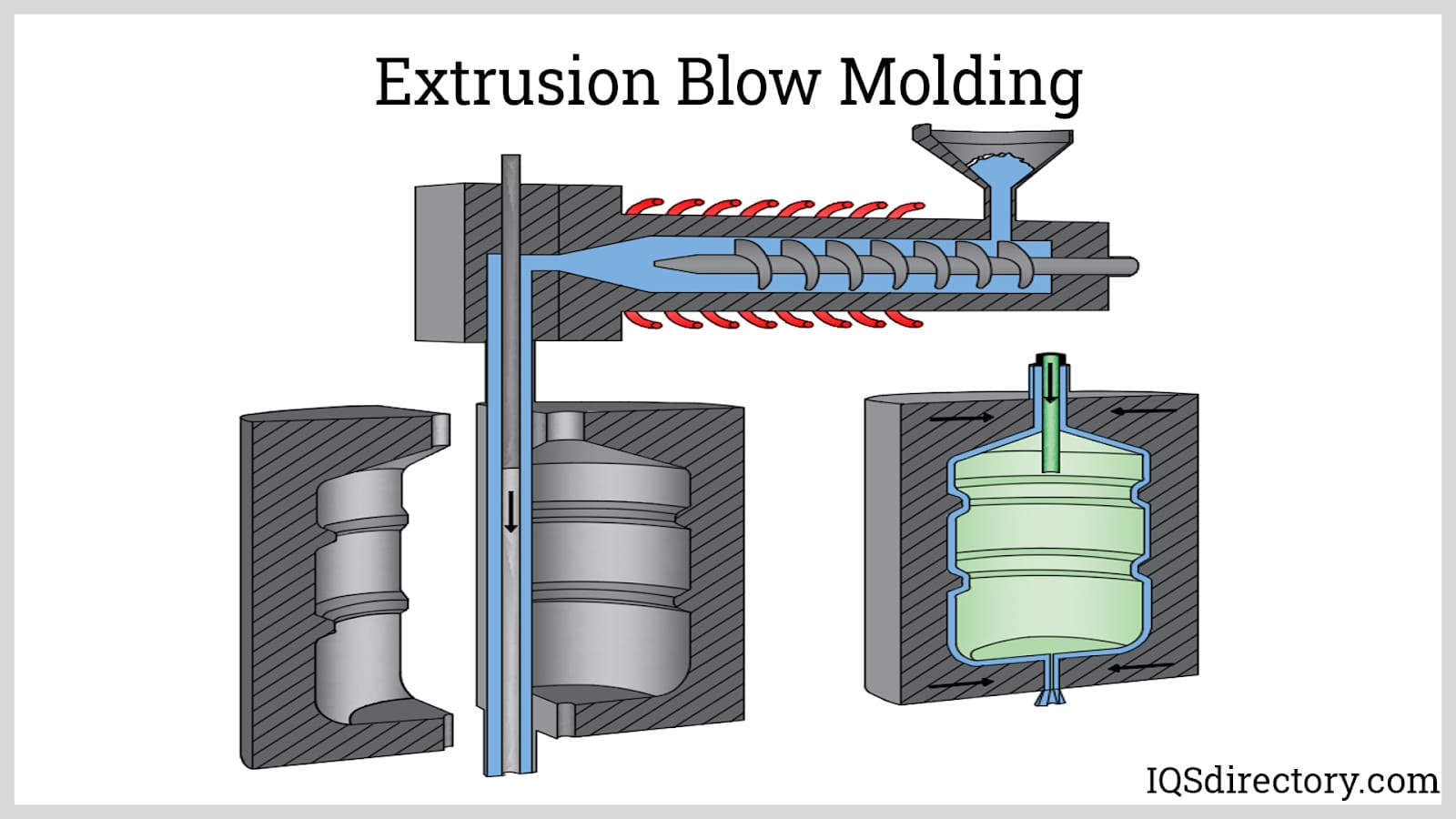

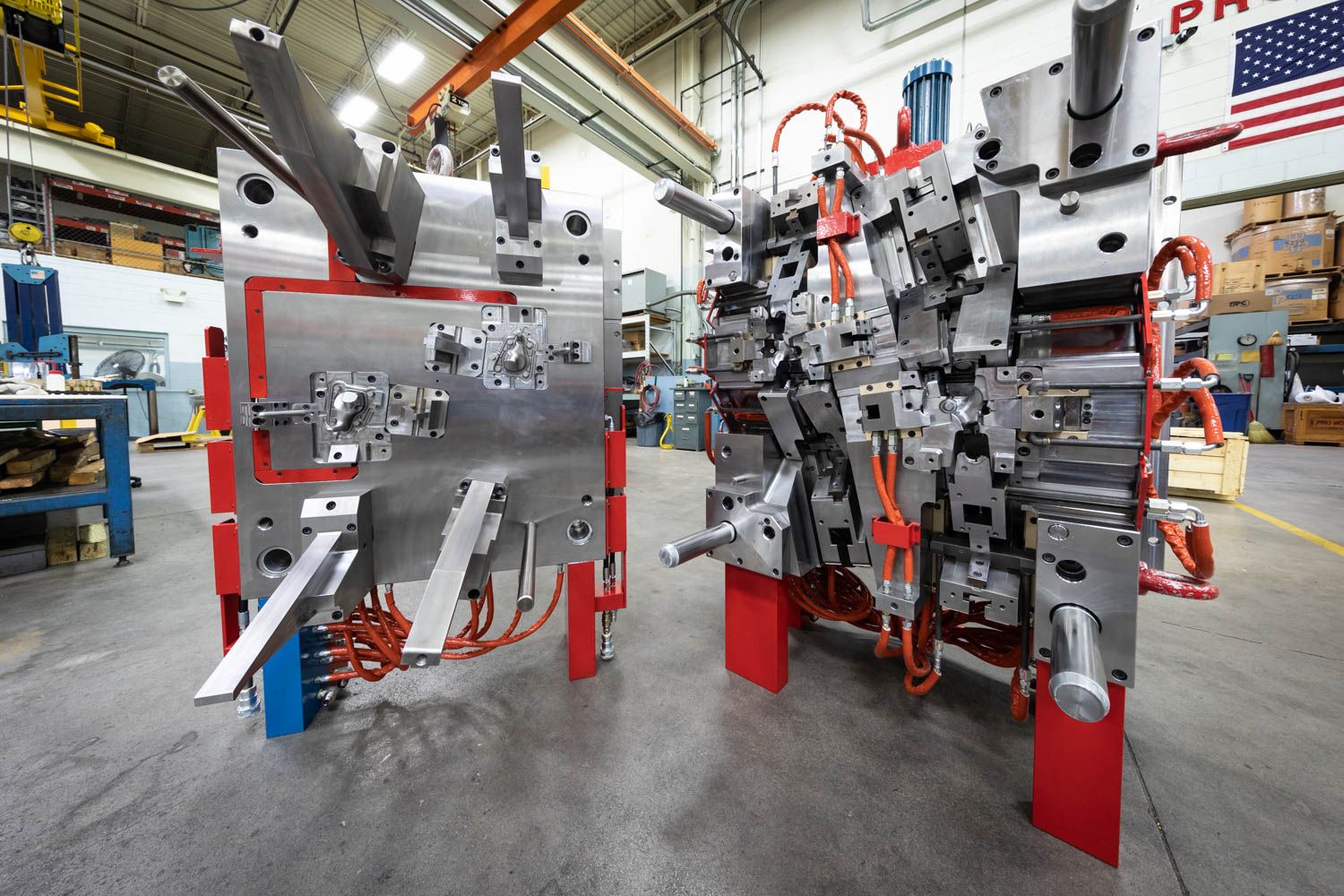

Forming Techniques

Dana Plastics specializes in blow molding, a technique that allows for the creation of hollow plastic products. This process involves heating a parison—a preformed plastic tube—until it becomes pliable. The parison is then inflated within a mold to form the desired shape, such as containers, bottles, or jars. The use of advanced blow molding machinery ensures precision and efficiency, enabling the production of complex shapes while minimizing material waste.

Assembly and Secondary Operations

Once the forming stage is complete, the products may undergo various assembly processes. This can include the integration of components like closures or handles, and additional operations such as hot stamping, pad printing, and labeling. These secondary processes enhance the product’s functionality and branding, catering to specific customer needs.

Finishing Touches

The final stage involves finishing processes that enhance product quality and appearance. This can include quality checks, surface treatments, and packaging. The products are carefully prepared for shipment, ensuring they meet all specifications and are ready for their intended markets.

Illustrative image related to dana plastics roselle il

How Does Dana Plastics Ensure Quality Control Throughout the Manufacturing Process?

Quality assurance is a cornerstone of Dana Plastics’ operations. The company adheres to internationally recognized standards, particularly ISO 9001, which governs quality management systems. This certification emphasizes a commitment to continuous improvement and customer satisfaction.

Quality Control Checkpoints

Dana Plastics implements rigorous quality control checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications. This initial step is crucial for preventing defects in the final products.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular checks to monitor parameters such as temperature, pressure, and material flow. This real-time monitoring allows for immediate adjustments to maintain product quality.

-

Final Quality Control (FQC): Once production is complete, each batch of products undergoes a final inspection to verify compliance with quality standards. This includes dimensional checks, visual inspections, and functional testing.

What International Standards and Testing Methods Are Relevant for B2B Buyers?

For international B2B buyers, understanding the relevant quality standards and testing methods is essential for verifying supplier capabilities. In addition to ISO 9001, Dana Plastics may also comply with industry-specific standards such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for products used in the oil and gas industry.

Illustrative image related to dana plastics roselle il

Common Testing Methods

Dana Plastics employs various testing methods to ensure product reliability and performance, including:

-

Material Testing: Assessing the mechanical properties of the plastic materials used, such as tensile strength and impact resistance.

-

Dimensional Testing: Using precision instruments to ensure products meet specified dimensions and tolerances.

-

Performance Testing: Evaluating the functionality of products under different conditions to ensure they perform as intended.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for establishing a reliable partnership. Here are several ways to ensure supplier credibility:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and quality control processes firsthand. This is an effective way to gauge the supplier’s commitment to quality.

-

Quality Control Reports: Requesting detailed quality control reports can provide insight into the supplier’s testing methodologies, results, and corrective actions taken in response to any issues.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures and product compliance.

What Are the Nuances of Quality Control and Certification for International Buyers?

International buyers should be aware of specific nuances regarding quality control and certification that may vary by region. For example, in Europe, products often need to bear the CE mark, indicating compliance with EU safety and health regulations. In contrast, buyers from the Middle East may require adherence to local standards such as the Gulf Cooperation Council (GCC) regulations.

Additionally, understanding the nuances of logistics and customs can affect the delivery and acceptance of products. Buyers should ensure that all documentation, including certificates of conformity and test reports, accompanies shipments to facilitate smooth customs clearance.

Conclusion

Dana Plastics in Roselle, IL, exemplifies a commitment to excellence in manufacturing processes and quality assurance. By understanding the intricacies of these processes and the relevant quality control measures, B2B buyers can make informed decisions when sourcing blow-molded plastic products. This comprehensive approach not only enhances product reliability but also fosters long-lasting partnerships built on trust and quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dana plastics roselle il’

To assist international B2B buyers in procuring high-quality blow-molded plastic products from Dana Plastics in Roselle, Illinois, this step-by-step sourcing checklist is designed to streamline the procurement process. By following these steps, you can ensure that you make informed decisions while aligning with your specific business needs.

Step 1: Define Your Technical Specifications

Before initiating contact with Dana Plastics, clearly outline your technical requirements. Identify the type of blow-molded products you need, including dimensions, materials, and intended use (e.g., food packaging, industrial applications). This step is crucial as it sets the foundation for effective communication with the supplier and helps ensure that the products meet your operational needs.

Step 2: Research Supplier Capabilities

Investigate Dana Plastics’ manufacturing capabilities and product offerings. Evaluate their range of products such as containers, bottles, and custom solutions. Understanding their technological proficiency, including the machinery and materials used, will help you assess if they can meet your production requirements while maintaining quality standards.

- Considerations:

- Look for information on certifications (e.g., ISO 9001) that demonstrate their commitment to quality.

- Review their past projects or case studies to gauge their experience in your industry.

Step 3: Evaluate Supplier Certifications

It is essential to verify that Dana Plastics holds relevant certifications that reflect their adherence to industry standards. Certifications not only indicate quality assurance but also compliance with safety and environmental regulations.

- Key Certifications to Look For:

- ISO certifications related to manufacturing processes.

- Environmental certifications that demonstrate sustainable practices.

Step 4: Request Samples

Once you have established a line of communication, request product samples to evaluate quality firsthand. This step allows you to assess the physical attributes of the products, such as durability, finish, and functionality.

- Why This Matters:

- Samples provide insight into the supplier’s manufacturing consistency.

- They allow for testing within your specific application before placing a large order.

Step 5: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. Transparency during negotiations is vital to establish a mutually beneficial relationship.

- Important Considerations:

- Inquire about bulk order discounts or long-term partnership agreements.

- Clarify shipping terms and timelines to avoid any potential delays in your supply chain.

Step 6: Assess Customer Support and Communication

Evaluate the level of customer service provided by Dana Plastics. A responsive and knowledgeable support team can make a significant difference in your procurement experience.

Illustrative image related to dana plastics roselle il

- What to Look For:

- Availability for technical support and problem resolution.

- Responsiveness to inquiries and proactive communication regarding order status.

Step 7: Finalize Your Order and Monitor Delivery

After confirming all details and agreements, proceed with placing your order. Keep track of the delivery schedule and maintain communication with the supplier to address any issues that may arise during shipment.

- Why This Step Is Critical:

- Monitoring your order ensures that you receive the products on time and in the expected condition.

- Establishing a feedback loop with the supplier can enhance future transactions.

By following this practical sourcing guide, B2B buyers can ensure a successful procurement process with Dana Plastics, aligning their needs with a reliable supplier committed to quality and customer satisfaction.

Comprehensive Cost and Pricing Analysis for dana plastics roselle il Sourcing

What Are the Key Cost Components for Sourcing from Dana Plastics in Roselle, IL?

When evaluating the cost structure for sourcing from Dana Plastics Container Corporation, several critical components must be taken into account. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The choice of raw materials significantly impacts overall costs. Dana Plastics utilizes various plastics such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). The prices of these materials can fluctuate based on market demand and availability, which in turn influences the final pricing of products.

Labor: Labor costs encompass wages for skilled workers involved in manufacturing and quality assurance processes. Dana Plastics prides itself on a knowledgeable workforce, which may lead to slightly higher labor costs but also results in superior product quality.

Manufacturing Overhead: This includes costs related to the operation of machinery, facility maintenance, and utilities. Dana’s investment in state-of-the-art blow molding machinery contributes to efficient production but also adds to the overhead costs.

Tooling: Custom projects often require specific molds, which can be a significant upfront investment. Tooling costs vary depending on the complexity and specifications of the molds needed for unique product designs.

Quality Control (QC): Maintaining high-quality standards is crucial, especially for industries such as food and pharmaceuticals. The rigorous QC processes employed by Dana Plastics ensure compliance with industry standards, which may add additional costs but are essential for avoiding costly recalls and maintaining client trust.

Logistics: The cost of transporting products to international markets can vary based on shipping methods, distances, and Incoterms. Understanding logistics costs is vital for international buyers to assess the total cost of ownership.

Margin: Dana Plastics incorporates a profit margin into its pricing structure, reflecting its position as a trusted manufacturer of blow-molded products. This margin can be influenced by market competition and the perceived value of the product.

How Do Price Influencers Affect Sourcing Costs from Dana Plastics?

Several factors influence the pricing of Dana Plastics’ products, and understanding these can help international buyers negotiate better deals.

Illustrative image related to dana plastics roselle il

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders typically lead to lower per-unit costs, making it more cost-effective for buyers looking to stock inventory.

Specifications/Customization: Customization options are available for various products, which can alter costs significantly. While tailored solutions may incur higher costs due to unique tooling and materials, they can also lead to enhanced market differentiation.

Quality/Certifications: Products that meet stringent quality standards or hold specific certifications may come with a premium price tag. However, these certifications can be crucial for compliance in regulated industries.

Supplier Factors: The reliability of Dana Plastics as a supplier, including its track record for on-time delivery and product quality, can influence pricing. A reputable supplier may charge more but can save buyers from potential losses due to delays or defects.

Incoterms: Understanding the Incoterms used in the agreement is critical for determining liability and cost responsibilities during shipping. Different terms can affect the final price and the buyer’s total cost of ownership.

What Are the Best Negotiation Tips for International Buyers Sourcing from Dana Plastics?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, negotiating effectively with Dana Plastics can lead to better pricing and terms.

Illustrative image related to dana plastics roselle il

Cost-Efficiency: Always calculate the total cost of ownership, which includes purchase price, shipping, and handling costs, to ensure a comprehensive understanding of expenses.

Volume Leverage: If possible, commit to larger orders to leverage better pricing. Suppliers often provide discounts for bulk purchases, which can significantly reduce overall costs.

Customization Discussions: Clearly articulate any customization needs early in negotiations to avoid unexpected costs later. This helps in aligning expectations and pricing from the start.

Stay Informed: Research market trends and pricing benchmarks to strengthen your negotiation position. Being informed allows for more strategic discussions around pricing.

Illustrative image related to dana plastics roselle il

Flexibility in Terms: Be open to discussing different payment terms or logistics arrangements that may benefit both parties. Flexibility can lead to more favorable outcomes.

Disclaimer

All pricing and cost estimates are indicative and may vary based on market conditions, order specifics, and other factors. It is advisable for buyers to conduct thorough discussions with Dana Plastics to obtain precise quotes tailored to their unique requirements.

Alternatives Analysis: Comparing dana plastics roselle il With Other Solutions

Exploring Alternative Solutions to Dana Plastics Roselle IL

In the competitive landscape of blow-molded plastic manufacturing, businesses often seek alternatives that can meet their unique requirements. This section evaluates Dana Plastics Roselle IL against other viable solutions to help B2B buyers make informed decisions.

| Comparison Aspect | Dana Plastics Roselle IL | Alternative 1: Western Industries Plastic Products LLC | Alternative 2: Crown Packaging International |

|---|---|---|---|

| Performance | High-quality, innovative blow-molded products | Proven track record in custom plastic solutions | Extensive inventory of packaging products |

| Cost | Moderate pricing with a focus on customization | Competitive pricing; value for standard products | Variable pricing based on product type and volume |

| Ease of Implementation | Strong engineering support for custom designs | Streamlined processes for standard products | Simplified ordering system for bulk purchases |

| Maintenance | Regular quality checks and customer support | Established maintenance protocols | Comprehensive customer service and support |

| Best Use Case | Custom solutions for diverse industries | General-purpose plastic products for various sectors | Specialized packaging solutions for food and beverage |

In-Depth Analysis of Alternatives

Western Industries Plastic Products LLC

Western Industries is recognized for its extensive experience in custom plastic solutions. They offer a wide range of products, making them a suitable alternative for businesses requiring tailored solutions. Their competitive pricing and proven track record appeal to companies looking for reliability. However, they may not provide the same level of customization as Dana Plastics, which could be a limitation for specialized needs.

Crown Packaging International

Crown Packaging excels in providing a comprehensive inventory of packaging solutions, particularly for the food and beverage industry. Their simplified ordering process makes it easy for businesses to source products in bulk, which can save time and reduce costs. However, their focus on standard items may not cater to clients seeking highly customized solutions. Additionally, while they offer extensive product options, the variability in pricing can be a concern for budget-conscious buyers.

Conclusion: How to Choose the Right Plastic Manufacturing Solution

Selecting the right solution for plastic manufacturing hinges on understanding your specific needs. Dana Plastics Roselle IL stands out for its commitment to quality and customization, making it ideal for businesses requiring tailored products. Conversely, companies looking for standard solutions may find better value with alternatives like Western Industries or Crown Packaging. Ultimately, B2B buyers should assess performance, cost, and ease of implementation in relation to their operational requirements and market demands to make the most informed choice.

Essential Technical Properties and Trade Terminology for dana plastics roselle il

What Are the Key Technical Properties of Dana Plastics Products?

When sourcing blow-molded plastic products from Dana Plastics in Roselle, IL, it’s essential for international B2B buyers to understand several critical technical specifications that can affect product quality and suitability for specific applications. Here are some of the key properties to consider:

-

Material Grade

The material grade refers to the specific type of plastic used in manufacturing products. Common grades include polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Each grade has unique properties such as chemical resistance, flexibility, and temperature tolerance, which can significantly impact product performance in various industries. Selecting the right material grade ensures that the product meets the end-use requirements and regulatory standards. -

Wall Thickness

Wall thickness is a crucial specification in blow-molded products as it affects both the strength and weight of the container. Thicker walls can enhance durability and resistance to impact but may increase material costs and weight. For B2B buyers, understanding the required wall thickness is vital for optimizing shipping costs and ensuring the product can withstand the rigors of its intended use. -

Tolerance

Tolerance refers to the allowable variation in dimensions during the manufacturing process. High precision in tolerance is essential for ensuring that parts fit together correctly, especially in applications where compatibility with other components is critical. For buyers, knowing the tolerance levels can aid in assessing product quality and ensuring that the final product meets their specifications. -

Volume Capacity

This specification indicates the maximum amount of liquid or solid that a container can hold. Understanding the volume capacity is essential for applications in industries such as food and beverage, where precise measurements are critical. Buyers should consider the volume requirements to ensure the product aligns with their operational needs. -

Recyclability

As sustainability becomes increasingly important, the recyclability of the materials used in Dana Plastics products is a key consideration. Many businesses are looking to reduce their environmental impact, and sourcing recyclable products can enhance a company’s sustainability profile. B2B buyers should inquire about the recyclability of specific products to align with their sustainability goals.

What Are Common Trade Terms in the Blow-Molding Industry?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to Dana Plastics:

Illustrative image related to dana plastics roselle il

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products or components that are used in another company’s end product. In the context of Dana Plastics, they may serve as an OEM for businesses needing custom blow-molded solutions tailored to specific applications. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of products a supplier is willing to sell. For B2B buyers, understanding the MOQ is critical for budgeting and inventory management. It can also influence purchasing decisions, especially for businesses with limited storage capacity or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms for specific products or services. This is an essential step in the procurement process, allowing buyers to compare offers from different suppliers, including Dana Plastics, and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and risks. Familiarity with Incoterms helps B2B buyers negotiate shipping arrangements effectively and understand their obligations in the supply chain. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the products. This can vary significantly based on manufacturing processes and product availability. For B2B buyers, understanding lead times is crucial for effective supply chain management and meeting customer demands.

By grasping these technical properties and trade terms, international buyers can make more informed decisions when sourcing products from Dana Plastics in Roselle, IL, ensuring that their needs are met with precision and efficiency.

Navigating Market Dynamics and Sourcing Trends in the dana plastics roselle il Sector

What Are the Key Market Dynamics Influencing the Dana Plastics Sector in Roselle, IL?

The Dana Plastics sector in Roselle, IL, is experiencing a transformative period driven by several global factors. Increased demand for sustainable packaging solutions is reshaping the landscape as businesses seek to minimize their environmental footprint. This trend is particularly prominent among international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where regulatory frameworks around packaging waste are tightening. Companies are looking for suppliers who can provide eco-friendly alternatives without compromising on quality or performance.

Emerging technologies in manufacturing, such as automation and advanced blow molding processes, are also playing a pivotal role. These technologies enable manufacturers like Dana Plastics to enhance efficiency and precision, thus reducing lead times and costs. Moreover, the rise of digital platforms for sourcing and procurement is allowing international buyers to streamline their purchasing processes, providing greater transparency and access to a wider range of products.

Another notable trend is the increasing customization of plastic products. B2B buyers are seeking tailored solutions that meet their specific needs, whether in terms of size, shape, or functionality. This shift is prompting manufacturers to invest in design and engineering capabilities, which can facilitate rapid prototyping and shorter product development cycles. As these dynamics unfold, international buyers are encouraged to engage with manufacturers who not only offer diverse product portfolios but also demonstrate agility in adapting to evolving market demands.

How Is Sustainability Shaping Sourcing Decisions in the Dana Plastics Sector?

Sustainability is no longer a niche consideration but a fundamental aspect of the sourcing strategy for international B2B buyers. In the context of Dana Plastics in Roselle, IL, the emphasis on environmentally responsible practices is evident. The company integrates eco-friendly materials and processes into its production line, which appeals to buyers keen on reducing their ecological impact.

Ethical sourcing is becoming increasingly important as businesses aim to establish transparent supply chains. Buyers are more inclined to partner with manufacturers that prioritize sustainable practices, such as using recycled materials and implementing energy-efficient processes. Certifications such as ISO 14001 for environmental management and the use of recycled content in products can significantly influence purchasing decisions.

Additionally, the demand for biodegradable and compostable materials is rising, particularly in regions with stringent environmental regulations. By adopting these materials, Dana Plastics can cater to a growing market segment that is not only looking for functionality but also for products that align with their sustainability goals. This focus on ethical sourcing and sustainability will likely continue to shape the competitive landscape, making it essential for B2B buyers to consider these factors when selecting suppliers.

What Is the Historical Context of Dana Plastics in Roselle, IL, and Its Relevance to Current B2B Trends?

Dana Plastics Container Corporation has established itself as a prominent player in the blow-molded plastics industry since its inception in 1990. Located in Roselle, Illinois, the company has evolved from a traditional manufacturing operation to a forward-thinking entity that embraces innovation and sustainability. Initially focused on standard plastic containers, Dana has expanded its capabilities to include customized solutions that meet the diverse needs of various sectors, including food and beverage, personal care, and pharmaceuticals.

This evolution is significant for B2B buyers as it illustrates Dana’s commitment to adapting to market changes. The company’s ability to innovate and respond to the demands of international markets positions it as a reliable partner for businesses looking for high-quality, sustainable packaging solutions. As global trends continue to shift towards sustainability and customization, Dana Plastics’ historical adaptability underscores its relevance in the current B2B landscape, making it an attractive option for international buyers seeking to align with responsible manufacturing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of dana plastics roselle il

-

How do I solve my packaging needs for various industries using Dana Plastics?

Dana Plastics specializes in blow-molded plastic products, offering tailored solutions for industries such as food and beverage, personal care, and pharmaceuticals. To address your specific packaging requirements, start by reaching out to their customer support team. They can guide you through available product options, customization capabilities, and design assistance. Provide details about your product, intended use, and any regulatory considerations to ensure that the proposed solutions meet your industry standards. -

What is the best container type for my beverage product?

The best container type for your beverage product depends on several factors, including the product’s viscosity, shelf life, and packaging requirements. Dana Plastics offers a variety of containers, such as PET bottles, jugs, and jars, specifically designed to optimize product preservation and consumer appeal. Consult with their design team to explore options that enhance functionality while ensuring compliance with industry standards, particularly for international markets. -

Can I customize my order from Dana Plastics?

Yes, Dana Plastics offers extensive customization options for their blow-molded products. They collaborate closely with clients to develop solutions tailored to specific needs, including size, shape, and branding elements. Their experienced engineers utilize advanced design software to create prototypes, ensuring that the final product aligns with your vision and operational requirements. Be prepared to provide detailed specifications to facilitate the customization process. -

What is the minimum order quantity (MOQ) for products from Dana Plastics?

The minimum order quantity (MOQ) can vary based on the specific product and customization requirements. Typically, Dana Plastics has a flexible approach to MOQs, accommodating both small and large-scale orders. For precise information, it is advisable to contact their sales team directly to discuss your needs, as they can provide tailored solutions that fit your production volume and budget constraints. -

What payment terms are available for international buyers?

Dana Plastics offers various payment options tailored for international buyers, including wire transfers, letters of credit, and payment upon delivery. The specific terms may depend on the order size and the buyer’s creditworthiness. It is essential to discuss payment preferences with their sales team during the negotiation process to ensure a mutually beneficial agreement that aligns with your financial practices. -

How does Dana Plastics ensure product quality?

Quality assurance is a top priority at Dana Plastics. They implement rigorous quality control measures throughout the manufacturing process, from material selection to final inspection. The company is ISO 9001:2000 certified, ensuring adherence to international quality standards. Regular audits and testing are conducted to verify that products meet or exceed client specifications, providing confidence in the reliability and durability of their offerings. -

What logistics support does Dana Plastics provide for international shipping?

Dana Plastics is equipped to assist with logistics for international shipping, including coordination with freight forwarders and customs brokers. They can provide guidance on shipping options, lead times, and documentation required for cross-border transactions. Engaging with their logistics team early in the order process helps ensure a smooth delivery experience, particularly for buyers in Africa, South America, the Middle East, and Europe. -

How can I vet Dana Plastics as a reliable supplier?

To vet Dana Plastics as a reliable supplier, consider reviewing their industry certifications, client testimonials, and product quality standards. Additionally, assess their responsiveness and willingness to provide samples or prototypes before committing to a larger order. Conducting due diligence through industry references and understanding their manufacturing capabilities will help ensure they meet your specific needs and expectations for quality and service.

Top 3 Dana Plastics Roselle Il Manufacturers & Suppliers List

1. Dana Plastic Container Corporation – Blow-Molded Plastic Products

Domain: blowmoldedplastic.com

Registered: 2000 (25 years)

Introduction: Dana Plastic Container Corporation specializes in blow-molded plastic products, offering a diverse range including containers, bottles, jars, jugs, and customized solutions. Their products cater to various industries such as food and beverage, personal care, household goods, and industrial applications. The company utilizes state-of-the-art blow molding machinery and advanced technology to ensure …

2. Dana Plastics Container – Custom Packaging Solutions

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Dana Plastics Container – Custom Packaging Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Dana Plastic Container Corporation – Blow Molding Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Dana Plastic Container Corporation specializes in blow molding, serving industries such as food packaging, automotive, household chemical, medical diagnostic, and pharmaceuticals. They focus on providing high quality, service, delivery, and competitive pricing.

Strategic Sourcing Conclusion and Outlook for dana plastics roselle il

What Are the Key Takeaways for B2B Buyers Considering Dana Plastics in Roselle, IL?

Dana Plastic Container Corporation stands out as a premier manufacturer of blow-molded plastic products, offering a diverse array of containers tailored to various industries, including food and beverage, personal care, and industrial applications. The company’s commitment to quality is underscored by its ISO 9001:2000 certification and stringent quality control measures, ensuring that every product meets the highest standards. With state-of-the-art manufacturing capabilities and a focus on innovation, Dana Plastics not only meets but anticipates the needs of its clients.

How Can Strategic Sourcing Enhance Your Supply Chain?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic sourcing with Dana Plastics can optimize your supply chain. By leveraging their expertise in product design and engineering, buyers can collaborate closely with Dana to develop customized solutions that enhance functionality and appeal. Additionally, Dana’s commitment to sustainability aligns with the growing global demand for environmentally responsible practices.

Why Should You Partner with Dana Plastics for Future Growth?

As you explore sourcing options, consider the strategic advantages of partnering with Dana Plastics. Their dedication to customer satisfaction, innovative solutions, and sustainability positions them as a forward-thinking partner for your business. Engage with Dana today to discover how their tailored solutions can drive your success in the competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.