Choosing Your Cylinder Block Gasket: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for cylinder block gasket

In the intricate world of automotive components, sourcing high-quality cylinder block gaskets can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These vital components serve as a critical seal between engine surfaces, ensuring optimal performance and preventing leaks that can lead to costly repairs. As engines evolve with advanced technology, understanding the diverse types of gaskets—ranging from traditional fiber options to modern multi-layer steel variants—becomes essential for maintaining engine integrity and efficiency.

This comprehensive guide delves into the multifaceted landscape of cylinder block gaskets, offering insights into various types and their applications across different engine models. It also equips buyers with essential knowledge on supplier vetting processes, cost considerations, and the importance of material selection to meet specific engine requirements. By exploring these key areas, international B2B buyers can navigate the complexities of sourcing and make informed purchasing decisions that align with their operational needs.

Whether you are a procurement manager in Nigeria seeking reliable suppliers or a distributor in Vietnam aiming to expand your product offerings, this guide is tailored to empower you with the expertise necessary to choose the right cylinder block gaskets. With the right information, you can enhance your supply chain efficiency, reduce downtime, and ultimately, drive greater profitability in your business operations.

Understanding cylinder block gasket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Gasket | Fiber material, often reinforced with metal inserts | Older engine models | Pros: Good for sealing irregular surfaces; Cons: Limited to older engines, less heat resistance. |

| Multi-Layer Steel (MLS) | Composed of multiple steel layers, high temperature resistance | Modern vehicles, performance | Pros: Excellent sealing, handles high pressures; Cons: Requires precise surface finishing. |

| Performance Gasket | Designed for high-performance applications, often cut ring types | Racing, high-torque engines | Pros: Enhanced durability and performance; Cons: Higher cost, may require specialized installation. |

| Elastomeric Gasket | Made from rubber or silicone, flexible and compressible | General automotive applications | Pros: Good for a variety of sealing applications; Cons: Limited temperature range compared to metal gaskets. |

| Composite Gasket | Combination of materials, often including fiber and metal | Heavy-duty applications | Pros: Versatile, can handle various conditions; Cons: May not provide the same durability as pure metal options. |

What Are the Characteristics of Classic Gaskets?

Classic gaskets are primarily made from fiber materials reinforced with metal inserts, making them suitable for older engine models. Their soft material allows them to conform to irregular surfaces, providing effective sealing. However, they are less effective in high-temperature and high-pressure environments compared to modern alternatives. When considering classic gaskets, B2B buyers should assess the age and specifications of the engine, ensuring compatibility with their existing systems.

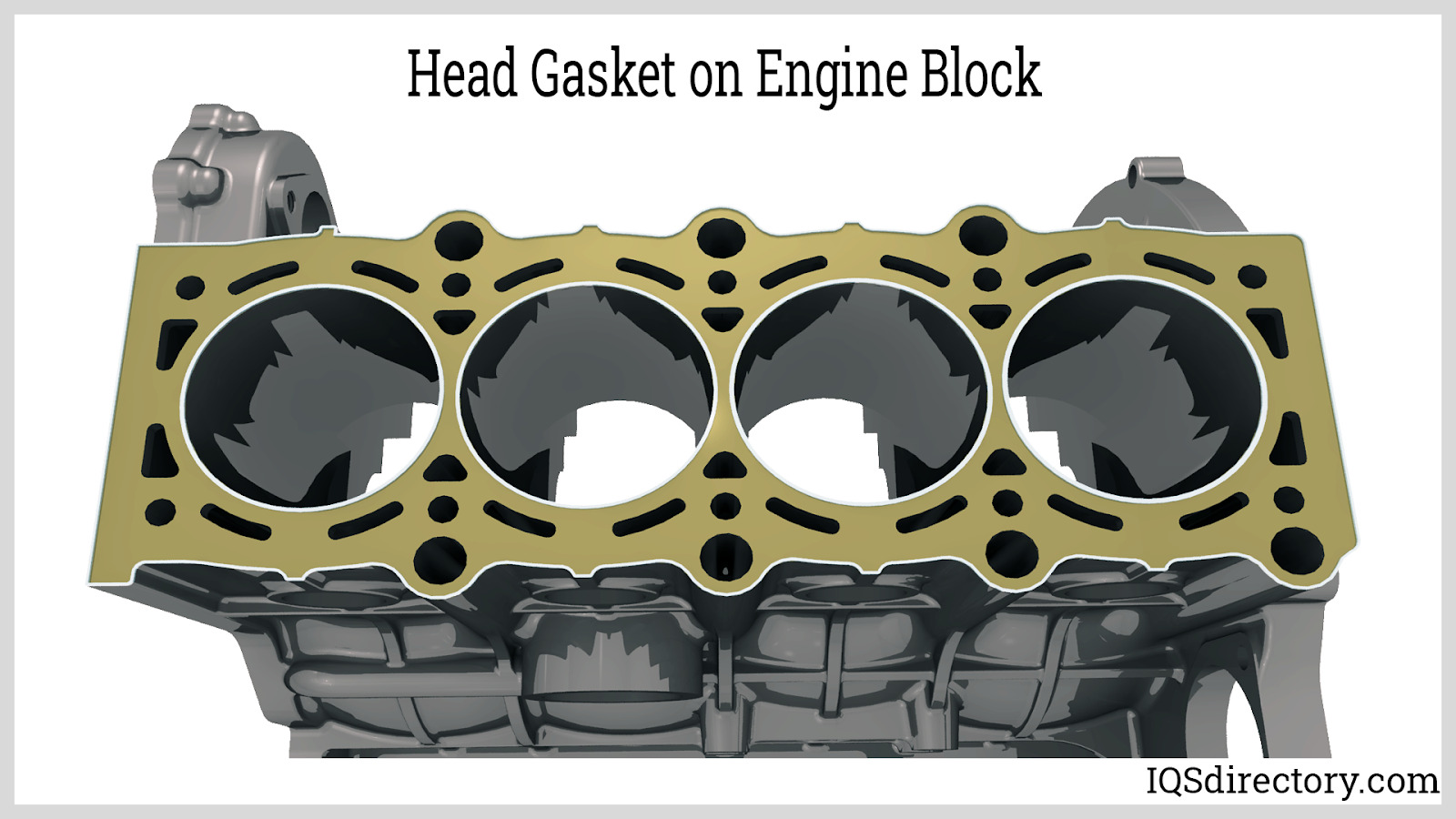

How Do Multi-Layer Steel (MLS) Gaskets Stand Out?

MLS gaskets are engineered with multiple layers of steel, providing exceptional sealing capabilities and resistance to high temperatures and pressures. They are commonly used in modern vehicles and high-performance applications due to their durability and reliability. For B2B buyers, the precision of the engine’s surface finish is crucial, as MLS gaskets require meticulous installation. This type is ideal for businesses looking to enhance engine performance while ensuring longevity.

What Makes Performance Gaskets Suitable for High-Torque Engines?

Performance gaskets are specifically designed for high-performance and racing applications, often utilizing cut ring designs to withstand extreme conditions. These gaskets offer enhanced durability and sealing capabilities, making them essential for high-torque engines. B2B buyers should consider the specific demands of their applications, including temperature and pressure requirements, as well as installation complexity, which may necessitate specialized skills or tools.

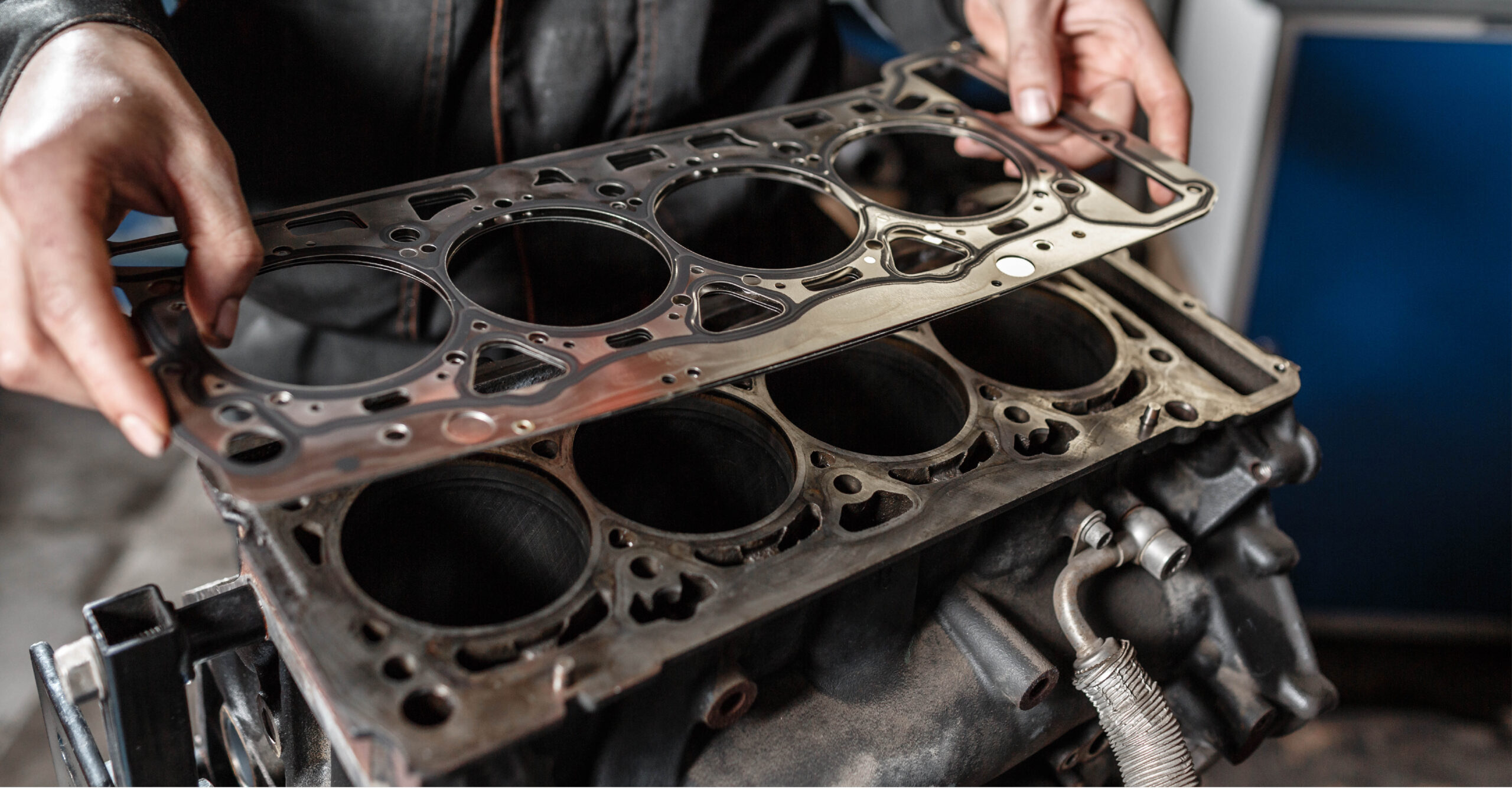

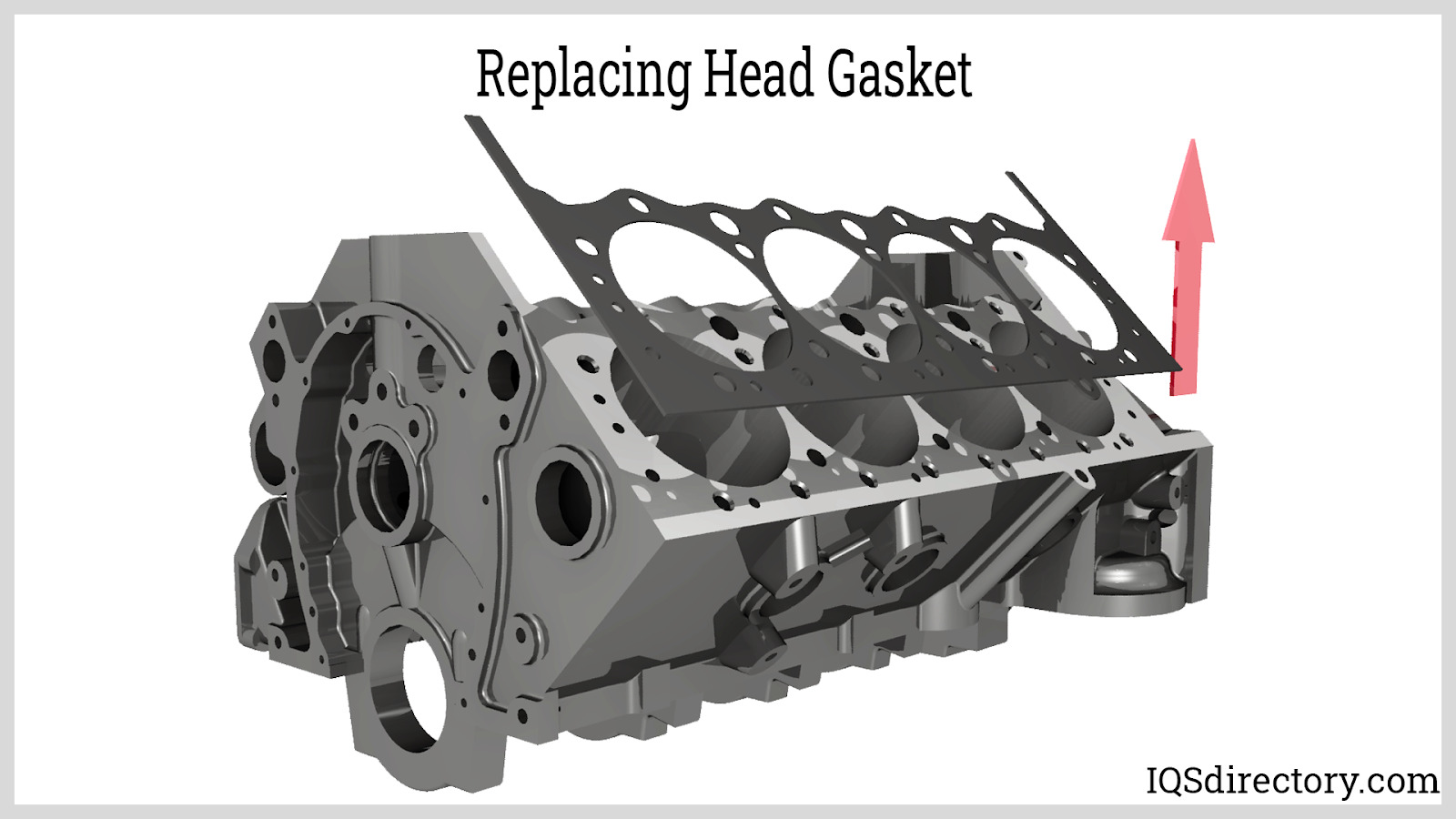

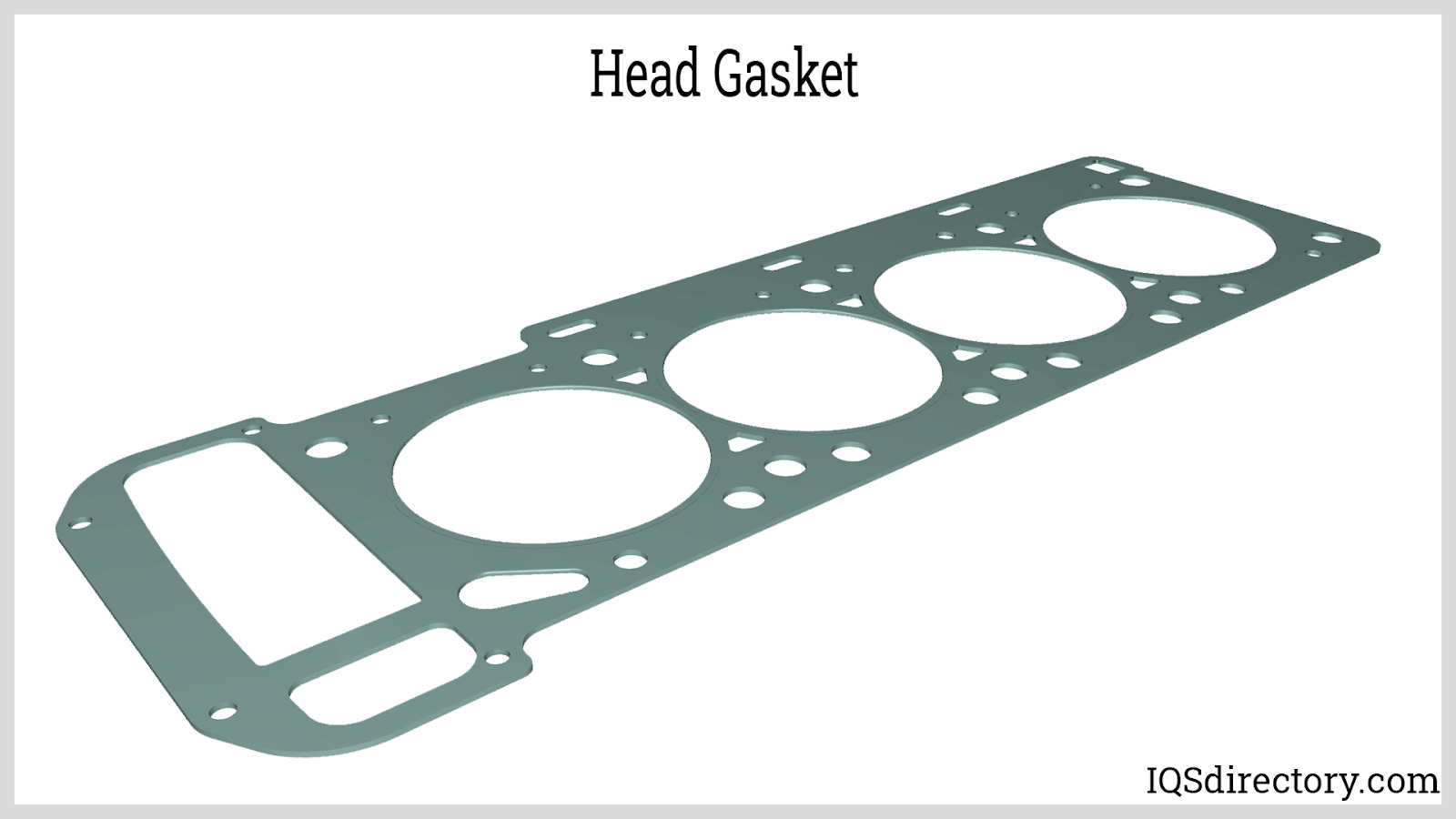

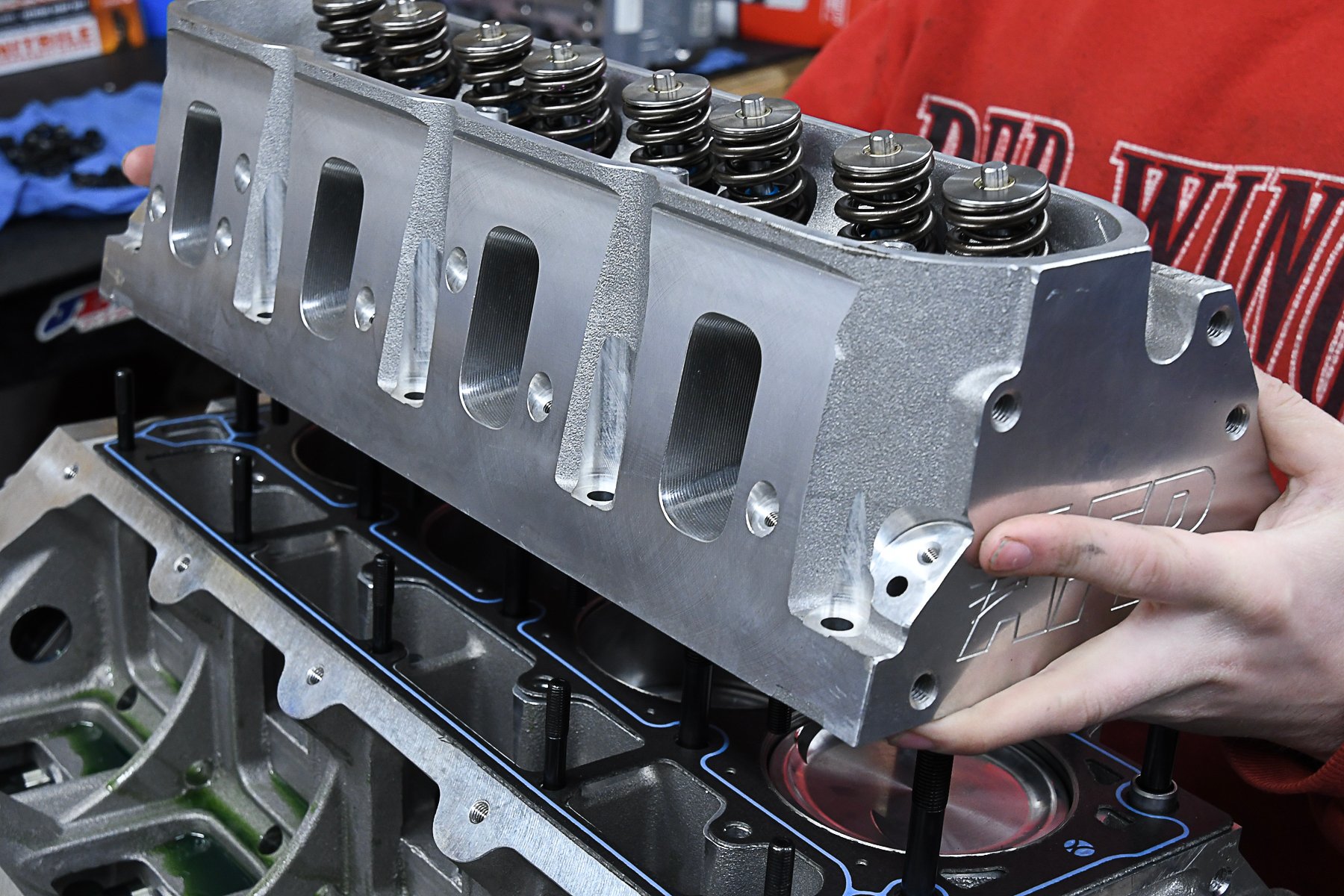

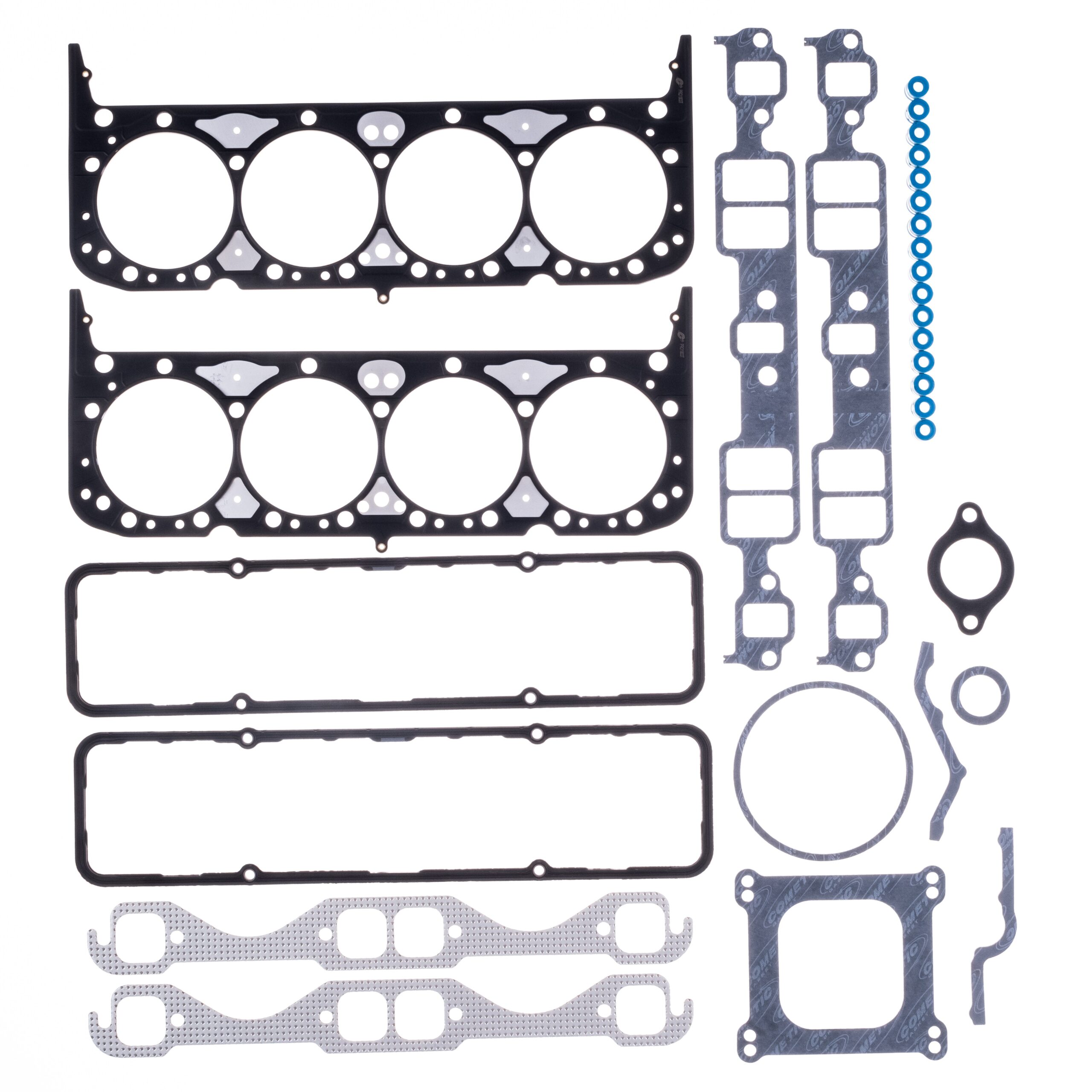

Illustrative image related to cylinder block gasket

Why Choose Elastomeric Gaskets for Versatile Applications?

Elastomeric gaskets, made from rubber or silicone, are flexible and compressible, making them suitable for a variety of automotive sealing applications. They are often used in general automotive contexts due to their adaptability and ease of installation. However, their temperature range is limited compared to metal gaskets. For B2B buyers, evaluating the specific sealing needs and operating conditions is essential to ensure the right choice.

What Are the Advantages of Composite Gaskets in Heavy-Duty Applications?

Composite gaskets combine various materials, including fibers and metals, to offer versatility in sealing capabilities. They are particularly effective in heavy-duty applications where conditions can be harsh. While they provide a balance of performance and cost, B2B buyers should weigh their specific durability requirements against the potential limitations of composite materials, especially in extreme environments.

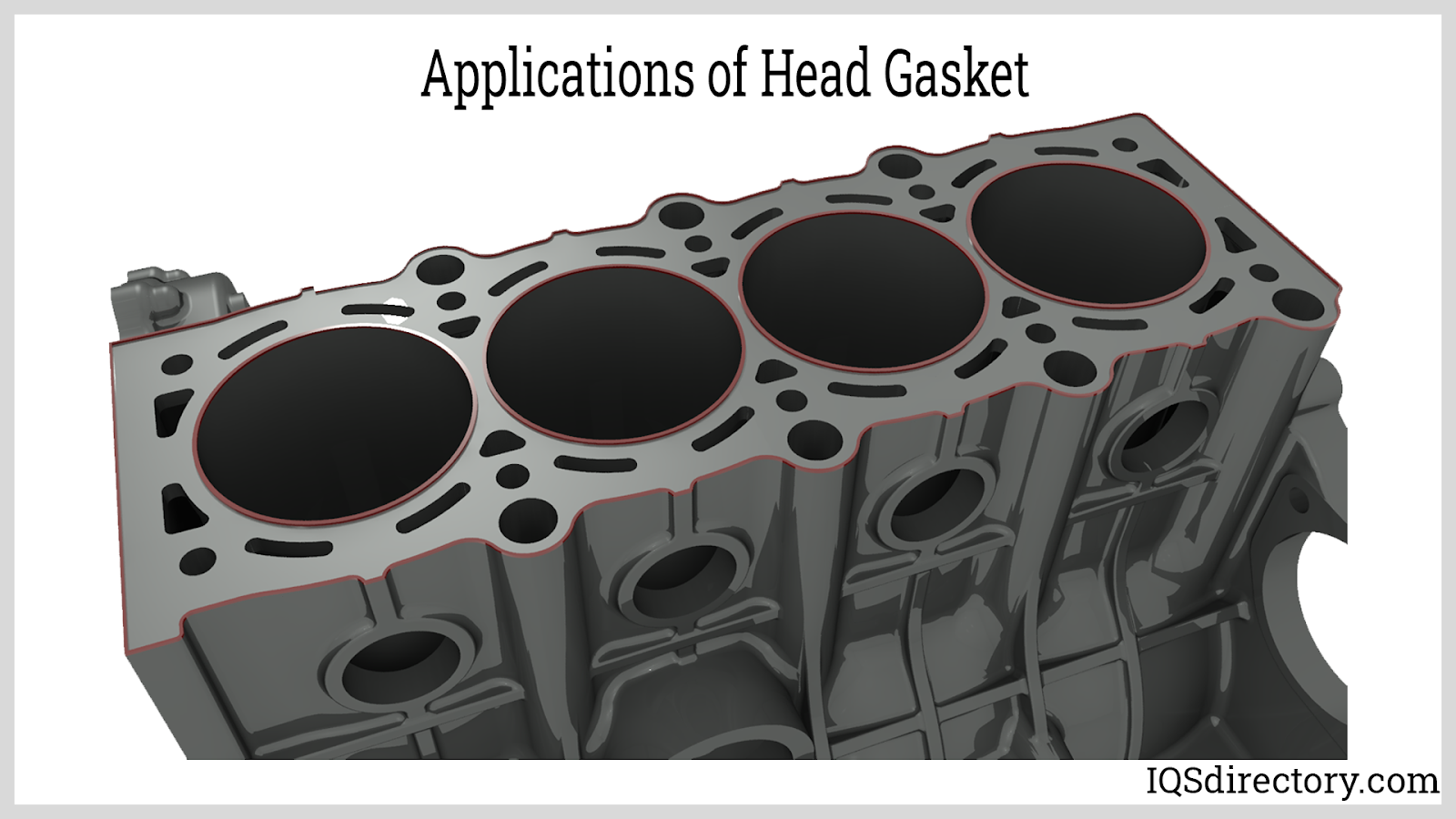

Key Industrial Applications of cylinder block gasket

| Industry/Sector | Specific Application of Cylinder Block Gasket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Sealing engine blocks in vehicles | Enhances engine performance and longevity | Material quality, compatibility with engine specifications |

| Heavy Machinery | Used in diesel engines for construction equipment | Ensures operational efficiency and minimizes downtime | Temperature resistance, durability under heavy loads |

| Marine Engineering | Sealing engine blocks in marine vessels | Prevents leaks and enhances safety in marine operations | Corrosion resistance, compliance with maritime standards |

| Agricultural Equipment | Used in tractors and farm machinery | Maximizes engine efficiency and reduces fuel consumption | Availability of specialized gaskets for various engine types |

| Renewable Energy | Sealing components in bioenergy equipment | Supports sustainable energy production and efficiency | Compatibility with high-performance materials and environments |

How is Cylinder Block Gasket Used in Automotive Manufacturing?

In the automotive sector, cylinder block gaskets are critical for sealing engine blocks in vehicles. They ensure that the high-pressure environment of the engine is maintained, preventing leaks of oil and coolant that can lead to engine failure. For international buyers, particularly in regions like Africa and South America, sourcing high-quality gaskets is essential to enhance engine performance and longevity. Buyers must consider material quality and compatibility with specific engine models to avoid costly repairs and downtime.

What Role Does Cylinder Block Gasket Play in Heavy Machinery?

In heavy machinery, particularly diesel engines used for construction, cylinder block gaskets are vital for ensuring operational efficiency. These gaskets withstand extreme conditions, including high temperatures and pressures, which are common in heavy-duty applications. For buyers in the Middle East, where machinery is often subjected to harsh environments, sourcing gaskets with superior temperature resistance and durability is crucial. This prevents leaks and minimizes downtime, ultimately supporting productivity on construction sites.

Why is Cylinder Block Gasket Important in Marine Engineering?

In marine engineering, cylinder block gaskets are used to seal engine blocks in vessels, preventing leaks that could compromise safety. Given the unique challenges of marine environments, these gaskets must be resistant to corrosion and capable of performing under varying pressures. Buyers from Europe and Africa should prioritize gaskets that comply with maritime standards to ensure reliability. This focus on quality not only enhances safety but also contributes to the overall efficiency of marine operations.

Illustrative image related to cylinder block gasket

How Does Cylinder Block Gasket Benefit Agricultural Equipment?

For agricultural equipment, such as tractors and harvesters, cylinder block gaskets play a crucial role in maximizing engine efficiency. By ensuring a tight seal, these gaskets help reduce fuel consumption and enhance overall performance, which is vital for farmers operating in competitive markets. Buyers in regions like Vietnam should look for specialized gaskets tailored to various engine types to ensure compatibility and performance. This consideration leads to improved productivity and cost-effectiveness in agricultural operations.

What is the Significance of Cylinder Block Gasket in Renewable Energy?

In renewable energy applications, cylinder block gaskets are essential for sealing components in bioenergy equipment. They help maintain optimal performance and support sustainable energy production by preventing leaks that could hinder efficiency. International buyers, especially in emerging markets, need to focus on sourcing gaskets made from high-performance materials that can withstand demanding environments. This strategic sourcing ensures that renewable energy systems operate effectively, contributing to global sustainability goals.

3 Common User Pain Points for ‘cylinder block gasket’ & Their Solutions

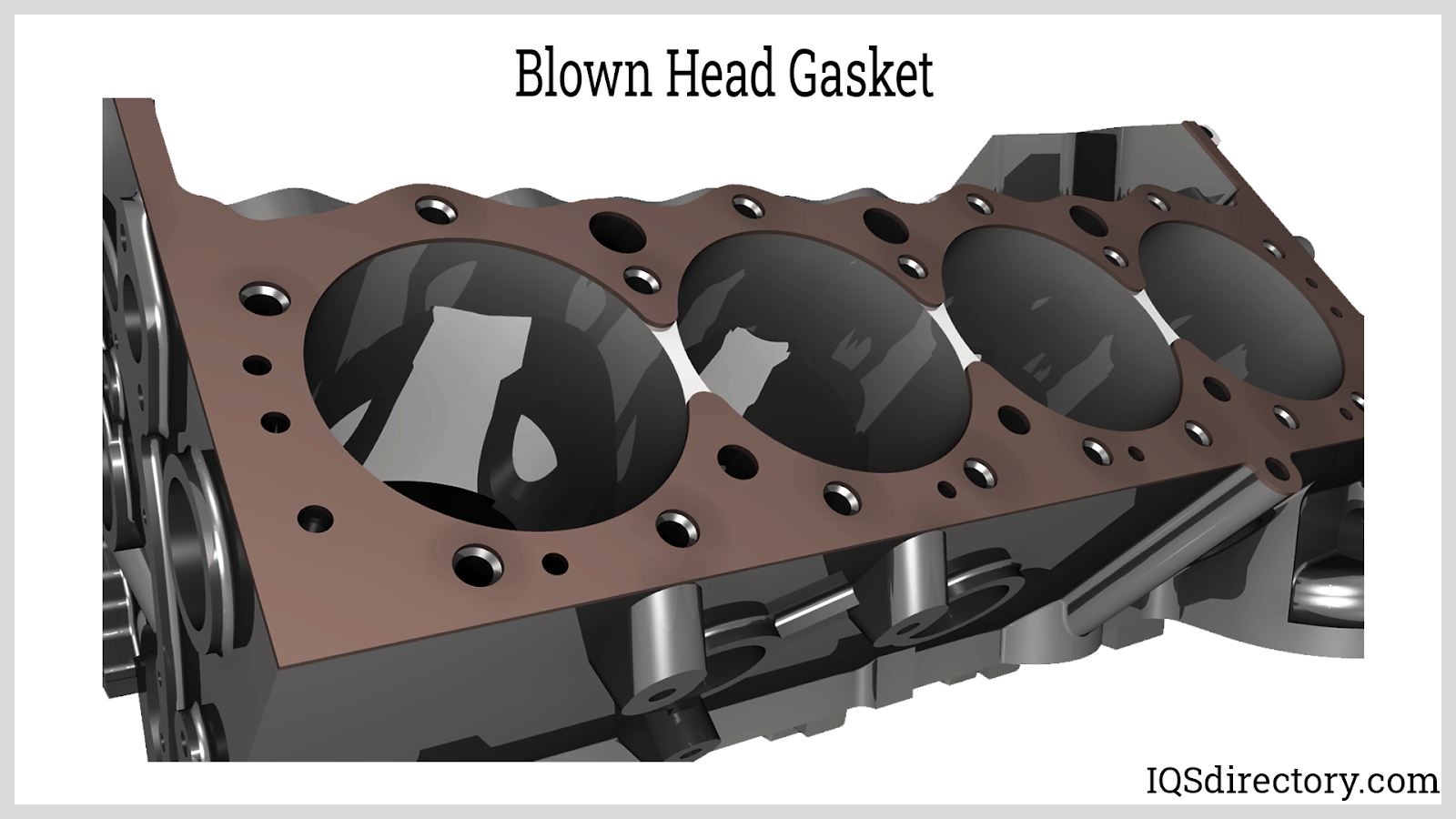

Scenario 1: Managing Frequent Cylinder Block Gasket Failures

The Problem: A common issue for B2B buyers, especially those dealing with heavy machinery or automotive engines, is the frequent failure of cylinder block gaskets. This can lead to oil leaks, coolant leaks, or even catastrophic engine failure if not addressed promptly. Buyers often struggle with understanding the root causes of these failures, which can stem from poor-quality gaskets, incorrect installation, or inadequate surface preparation. This not only affects the performance of the machinery but can also result in costly downtime and repairs.

The Solution: To mitigate frequent gasket failures, it is essential to invest in high-quality cylinder block gaskets that are specifically designed for the intended application. Buyers should thoroughly vet suppliers, looking for gaskets that utilize advanced materials like Multi-Layer Steel (MLS) or composites that can withstand high temperatures and pressures. Additionally, ensuring that installation procedures are meticulously followed can drastically reduce the likelihood of failure. This involves proper cleaning of the mating surfaces, using the correct torque specifications during assembly, and allowing adequate curing time for any sealants used. Regular maintenance checks should also be implemented to identify early signs of wear or leaks.

Scenario 2: Difficulty in Sourcing the Right Cylinder Block Gasket

The Problem: B2B buyers often face challenges in sourcing the correct cylinder block gasket for specific engine models, particularly in regions with limited access to genuine parts. This issue can lead to the use of incompatible or substandard gaskets that do not perform adequately, resulting in engine inefficiencies and potential damage. Buyers may find themselves overwhelmed by the variety of gaskets available, each with different specifications and performance ratings.

Illustrative image related to cylinder block gasket

The Solution: To simplify the sourcing process, buyers should develop a robust relationship with reliable suppliers who can provide detailed product catalogs and specifications. Utilizing technology, such as online databases or parts identification software, can streamline the selection process. Buyers should also consider establishing partnerships with local distributors who can provide timely access to genuine parts, including gaskets that meet OEM standards. Additionally, maintaining a detailed inventory of commonly used gaskets can help in quickly fulfilling urgent requests, reducing lead times and ensuring operational efficiency.

Scenario 3: Understanding the Technical Specifications for Cylinder Block Gaskets

The Problem: Many B2B buyers lack the technical knowledge required to understand the specifications and performance characteristics of cylinder block gaskets. This gap can lead to misinformed purchasing decisions, where buyers may choose gaskets that do not align with the operational demands of their engines or machinery. Without a solid understanding of factors like material composition, thickness, and thermal expansion properties, buyers risk compromising engine performance and longevity.

The Solution: To bridge the knowledge gap, companies should invest in training for their procurement and maintenance teams. This could involve workshops led by gasket manufacturers or industry experts who can explain the critical factors that influence gasket performance. Additionally, creating a reference guide that outlines the specifications needed for different engine types can serve as a valuable resource for buyers. Leveraging online resources, such as technical datasheets and comparison charts, can also empower buyers to make informed decisions when selecting cylinder block gaskets. By enhancing their technical understanding, buyers can ensure they procure the most suitable gaskets, ultimately improving engine performance and reliability.

Strategic Material Selection Guide for cylinder block gasket

When selecting materials for cylinder block gaskets, it is crucial to consider the specific performance requirements and environmental conditions that the gaskets will face. Here, we analyze four common materials used in the production of cylinder block gaskets, focusing on their properties, advantages and disadvantages, and implications for international B2B buyers.

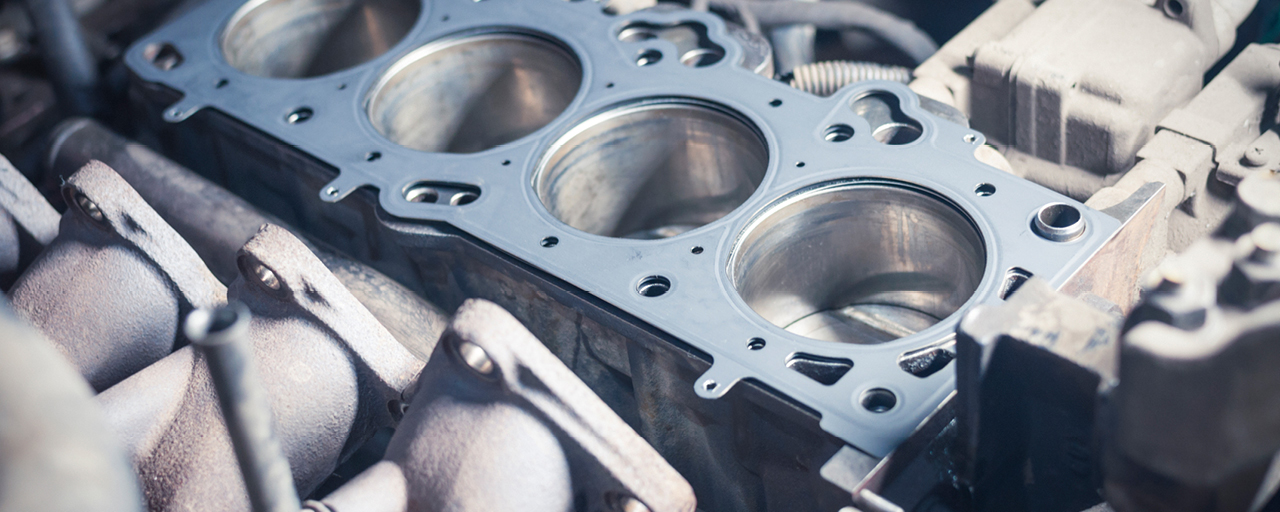

What Are the Key Properties of Multi-Layer Steel (MLS) Gaskets?

Multi-Layer Steel (MLS) gaskets are made from several layers of steel, often coated with a sealing material. They are designed to withstand high temperatures and pressures, making them suitable for modern engines. The key properties of MLS gaskets include excellent thermal stability, high pressure resistance, and good compatibility with various engine oils and coolants.

Pros: MLS gaskets offer superior sealing capabilities and durability, making them ideal for high-performance applications. They are also less prone to deformation under heat and pressure compared to traditional gaskets.

Cons: The manufacturing process for MLS gaskets can be complex and costly, requiring precise machining of engine surfaces to ensure proper fit. Additionally, they may not be suitable for older engines that require softer materials for effective sealing.

How Do Fiber Gaskets Compare in Terms of Performance?

Fiber gaskets are composed of a mixture of organic fibers and fillers, often reinforced with metal. They are typically used in older engines or less demanding applications. The key properties of fiber gaskets include good compressibility and the ability to conform to uneven surfaces.

Pros: Fiber gaskets are generally less expensive and easier to manufacture, making them a cost-effective option for many applications. Their flexibility allows for effective sealing even in less-than-perfect mating surfaces.

Illustrative image related to cylinder block gasket

Cons: They have lower temperature and pressure ratings compared to MLS gaskets and may degrade faster in high-stress environments. This can lead to leaks and reduced engine performance over time.

What Are the Benefits of Compressed Non-Asbestos Fiber (CNAF) Gaskets?

Compressed Non-Asbestos Fiber (CNAF) gaskets are an alternative to traditional fiber gaskets, utilizing synthetic fibers and fillers. They offer improved performance characteristics, including higher temperature and pressure resistance.

Pros: CNAF gaskets are more durable than standard fiber gaskets and are resistant to various automotive fluids, making them suitable for a wide range of applications. They also comply with modern environmental regulations, which is a significant advantage for international buyers.

Cons: While they offer better performance than traditional fiber gaskets, CNAF gaskets can be more expensive. Additionally, they may still require careful installation to avoid leaks.

How Do Silicone Gaskets Perform in Engine Applications?

Silicone gaskets are made from silicone rubber, providing flexibility and excellent resistance to heat, chemicals, and aging. They are often used in applications where a high degree of sealing is required, especially in areas exposed to extreme temperatures.

Illustrative image related to cylinder block gasket

Pros: Silicone gaskets are highly resistant to degradation from oils and coolants, making them ideal for long-term use. They also provide a reliable seal under varying temperature conditions.

Cons: The main limitation of silicone gaskets is their cost, which can be higher than other materials. They may also require specific installation techniques to ensure optimal performance.

Summary for International Buyers

When selecting gasket materials, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider compliance with local standards (e.g., ASTM, DIN, JIS) and the specific needs of their applications. Understanding the performance characteristics and limitations of each material will aid in making informed purchasing decisions.

Illustrative image related to cylinder block gasket

| Material | Typical Use Case for cylinder block gasket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Multi-Layer Steel (MLS) | High-performance engines | Excellent thermal and pressure resistance | Complex manufacturing process | High |

| Fiber | Older engines or low-demand applications | Cost-effective and easy to manufacture | Lower temperature/pressure ratings | Low |

| Compressed Non-Asbestos Fiber (CNAF) | Versatile engine applications | Durable and compliant with regulations | Higher cost than traditional fiber | Medium |

| Silicone | Extreme temperature applications | High resistance to degradation | Higher cost and installation complexity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for cylinder block gasket

What Are the Main Stages in the Manufacturing Process of Cylinder Block Gaskets?

The manufacturing of cylinder block gaskets involves several critical stages, ensuring that the final product meets the high performance and durability standards required in automotive applications.

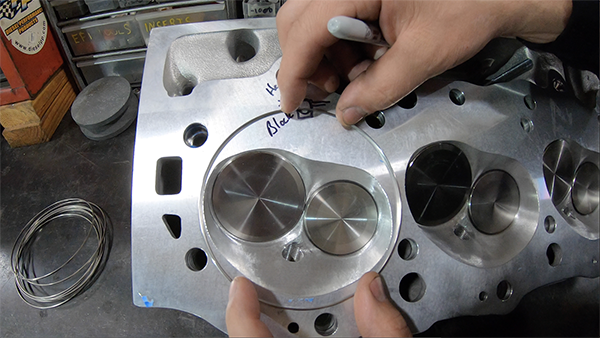

How Is Material Prepared for Cylinder Block Gaskets?

The process begins with the selection and preparation of materials. Gaskets are typically made from a variety of materials, including rubber, silicone, and metal composites, which are chosen based on their thermal and chemical resistance properties. Manufacturers often utilize advanced computer-aided design (CAD) software to create precise specifications for the gasket’s dimensions and features.

Once the materials are selected, they undergo a thorough inspection to ensure quality and compliance with industry standards. This inspection includes assessing the physical properties of the materials, such as tensile strength and elasticity, which are crucial for the gasket’s performance in high-pressure environments.

Illustrative image related to cylinder block gasket

What Techniques Are Used in Forming Cylinder Block Gaskets?

The forming stage employs several techniques to create the gasket shapes. Common methods include die cutting, extrusion, and molding.

-

Die Cutting: This method involves using a die to cut the gasket shape from a flat sheet of material. It is suitable for producing large quantities of gaskets with consistent dimensions.

-

Extrusion: For gaskets with complex profiles, extrusion is often utilized. The material is heated and forced through a die to create long sections of the desired shape, which are then cut to size.

-

Molding: In situations where the gasket needs to be formed into a specific shape, molding techniques such as compression or injection molding are employed. These methods are particularly effective for rubber and silicone gaskets.

How Is the Assembly Process Conducted for Cylinder Block Gaskets?

After the gaskets are formed, they are assembled with any necessary components, such as metal reinforcements or sealing beads, depending on the design requirements. This step often involves manual labor, where skilled workers inspect each gasket for defects and ensure that all components are correctly positioned.

The assembly line is equipped with quality control checkpoints to monitor the integrity of each gasket, ensuring that they meet the specifications outlined during the design phase.

What Finishing Processes Are Essential for Cylinder Block Gaskets?

Finishing processes are critical to enhancing the performance and appearance of the gaskets. These processes may include:

Illustrative image related to cylinder block gasket

-

Surface Treatment: To improve adhesion and sealing capabilities, gaskets often undergo treatments such as surface roughening or applying a coating.

-

Trimming and Cutting: Final trimming ensures that all gaskets meet the precise dimensions required for installation. This is crucial, as even minor deviations can lead to failures in sealing and performance.

-

Packaging: Proper packaging protects the gaskets during transportation and storage. Manufacturers often use moisture-resistant and durable materials to prevent damage.

What Quality Assurance Practices Are Followed in Gasket Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process for cylinder block gaskets. Manufacturers adhere to international and industry-specific standards to ensure product reliability and safety.

Which International Standards Are Relevant for Cylinder Block Gasket Quality Assurance?

ISO 9001 is a key international standard that outlines requirements for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established a systematic approach to managing processes, ensuring consistent quality in products.

Other relevant standards may include CE marking, which ensures products meet European safety, health, and environmental protection standards, and API standards for gaskets used in oil and gas applications.

What Are the Key Quality Control Checkpoints in Gasket Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process:

-

Incoming Quality Control (IQC): This checkpoint assesses raw materials before they enter the production process. Ensuring high-quality materials is vital for the overall quality of the gaskets.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC monitors production to identify and rectify any deviations from quality standards in real-time.

-

Final Quality Control (FQC): After production, each gasket undergoes rigorous testing to verify its performance characteristics, such as sealing ability and durability under pressure.

What Common Testing Methods Are Used for Cylinder Block Gaskets?

Several testing methods are employed to verify the quality of cylinder block gaskets:

-

Compression Testing: This measures how well the gasket can withstand pressure without deforming or leaking.

-

Leak Testing: This involves applying pressure to the gasket in a controlled environment to check for leaks.

-

Thermal Cycling Tests: These tests simulate the temperature fluctuations that gaskets experience in real-world conditions, assessing their ability to maintain integrity under thermal stress.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some effective methods:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers should request to visit the manufacturing facility to observe processes, quality control checkpoints, and overall production practices. An audit can help identify potential issues before placing large orders.

Illustrative image related to cylinder block gasket

How Important Are Quality Control Reports and Certifications?

Buyers should request quality control reports and certifications from suppliers. These documents provide insights into the manufacturer’s compliance with international standards and their internal quality assurance processes. Certifications from recognized organizations can serve as an additional layer of assurance.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These services can conduct random checks during production and pre-shipment inspections to ensure that the gaskets meet the required specifications and standards.

What Are the Unique QC Considerations for International B2B Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several unique quality control considerations come into play:

-

Regulatory Compliance: Understanding the specific regulatory requirements in the buyer’s region is crucial. This includes compliance with local safety standards and environmental regulations.

-

Cultural and Logistical Differences: Buyers should be aware of cultural differences that may affect communication and negotiation with suppliers. Additionally, logistical challenges can impact the timely delivery of quality products.

-

Currency Fluctuations and Trade Policies: Changes in currency and trade policies can affect pricing and availability. Buyers should factor these elements into their sourcing strategy to ensure they are receiving value for their investment.

By understanding the manufacturing processes and quality assurance practices associated with cylinder block gaskets, B2B buyers can make informed decisions, ensuring they select reliable suppliers who provide high-quality products that meet their operational needs.

Illustrative image related to cylinder block gasket

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cylinder block gasket’

To assist B2B buyers in procuring cylinder block gaskets effectively, this guide outlines a step-by-step checklist. Following these actionable steps will ensure that you select the right gasket for your engine needs while minimizing risks associated with procurement.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the cylinder block gasket. Consider factors such as the engine model, material compatibility, and the expected operating conditions. This foundational step will help you communicate your needs accurately to suppliers and avoid costly mismatches.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in cylinder block gaskets. Look for companies with a solid reputation in the automotive parts industry, particularly those that cater to your specific geographical market. Utilize online directories, trade shows, and industry forums to gather a list of candidates.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial to ensuring quality and reliability. Check for ISO certifications or other industry-specific accreditations that demonstrate a commitment to quality standards. Additionally, look for suppliers with experience in your region, as they may better understand local compliance requirements.

Illustrative image related to cylinder block gasket

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the cylinder block gaskets you are considering. Testing samples will allow you to evaluate material quality, fit, and performance under simulated operating conditions. This step mitigates risks associated with poor-quality products that could lead to engine failure.

Step 5: Assess Pricing and Payment Terms

Once you have shortlisted suppliers, compare pricing structures and payment terms. While cost is a significant factor, consider the total value offered, including warranty terms, after-sales support, and delivery timelines. Negotiate terms that align with your budget while ensuring you don’t compromise on quality.

Step 6: Review Customer Feedback and Case Studies

Look for customer reviews and case studies related to the suppliers you are considering. Feedback from other B2B buyers can provide insights into the supplier’s reliability, customer service, and product performance. This real-world information can guide you in making an informed decision.

Illustrative image related to cylinder block gasket

Step 7: Establish a Long-Term Relationship

Once you have selected a supplier, work towards establishing a long-term relationship. A reliable partnership can lead to better pricing, priority service, and tailored solutions in the future. Regular communication and feedback will help both parties grow and adapt to changing market needs.

By following these steps, B2B buyers can navigate the complexities of sourcing cylinder block gaskets with confidence, ensuring they make informed decisions that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for cylinder block gasket Sourcing

What Are the Key Cost Components for Sourcing Cylinder Block Gaskets?

When sourcing cylinder block gaskets, understanding the cost structure is crucial for effective budget management and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Common materials for gaskets include rubber, fiber, and metal. High-performance gaskets made from multi-layer steel (MLS) are generally more expensive due to their superior properties, such as heat resistance and durability.

-

Labor: Labor costs can vary based on the complexity of the gasket manufacturing process. Skilled labor is often required for high-precision gaskets, which can increase overall costs.

-

Manufacturing Overhead: This encompasses utilities, maintenance, and indirect labor associated with production. Higher overheads in regions with increased energy costs can lead to elevated prices for gaskets.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom or specialized gaskets. This cost is often amortized over a larger production volume, making it essential to consider expected order quantities.

-

Quality Control: Ensuring the quality of gaskets is paramount, especially for automotive applications. Rigorous QC processes can add to the cost but are necessary to prevent failures that could lead to significant repair expenses.

-

Logistics: Shipping costs can vary based on distance, weight, and shipping methods. International buyers should consider the implications of Incoterms, as they dictate the responsibilities of buyers and sellers regarding shipping costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition, brand reputation, and customer relationships.

How Do Price Influencers Affect Cylinder Block Gasket Costs?

Several factors influence the pricing of cylinder block gaskets, making it vital for buyers to be aware of these elements:

-

Volume/MOQ: Bulk purchases can lead to discounted pricing. Suppliers are often willing to negotiate better rates for larger orders, which can significantly reduce per-unit costs.

-

Specifications/Customization: Custom gaskets tailored to specific applications typically cost more due to the additional design and manufacturing processes involved. Standardized gaskets are usually more affordable.

-

Quality and Certifications: Gaskets that meet higher industry standards or come with certifications (like ISO or OEM) may command higher prices. Buyers should weigh the benefits of these certifications against their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products, which can be justified by their track record of quality and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They determine who is responsible for shipping, insurance, and tariffs, which can significantly impact the total landed cost of the gaskets.

What Are the Best Practices for Negotiating Cylinder Block Gasket Prices?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, effective negotiation and cost-efficiency strategies can lead to substantial savings:

Illustrative image related to cylinder block gasket

-

Research Market Prices: Before engaging suppliers, conduct thorough research on market rates for the specific types of gaskets you need. This knowledge will empower you during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Focus on TCO rather than just the upfront price. Consider factors like durability, warranty, and potential failure costs. A slightly higher initial investment in a high-quality gasket may result in lower long-term costs.

-

Be Open to Alternative Materials: If specifications allow, consider gaskets made from alternative materials that may offer similar performance at a lower cost.

-

Establish Long-term Relationships: Building a strong relationship with suppliers can lead to better pricing and service. Suppliers may be more inclined to offer discounts or favorable terms to repeat customers.

-

Utilize Payment Terms to Your Advantage: Negotiate payment terms that align with your cash flow. Some suppliers may offer discounts for upfront payments, while others may provide extended terms.

Conclusion: Why Understanding Pricing Nuances is Essential for International Buyers

Navigating the complexities of sourcing cylinder block gaskets requires a nuanced understanding of cost components and price influencers. By recognizing these elements and employing strategic negotiation tactics, international buyers can optimize their purchasing decisions, ensuring they receive high-quality gaskets at competitive prices. Keep in mind that prices can vary widely based on specifications, supplier relationships, and market conditions, making it essential to conduct thorough due diligence before making a commitment.

Alternatives Analysis: Comparing cylinder block gasket With Other Solutions

When evaluating solutions for sealing engine components, it’s essential to consider alternatives to the traditional cylinder block gasket. These alternatives can provide different benefits and drawbacks, making them more suitable for certain applications or operating conditions. This analysis compares the cylinder block gasket with two viable alternatives: Metal O-Rings and Liquid Gasket Sealants.

Comparison Table

| Comparison Aspect | Cylinder Block Gasket | Metal O-Rings | Liquid Gasket Sealants |

|---|---|---|---|

| Performance | High, reliable sealing under temperature variations | Excellent, withstands high pressure and temperature | Variable, dependent on application and curing time |

| Cost | Moderate, varies by material and type | Higher initial cost, but reusable | Generally low-cost, but requires skill for application |

| Ease of Implementation | Requires precise fitting and installation | Easy to install with proper tooling | Simple application, but curing time can delay assembly |

| Maintenance | Moderate, replacement needed over time | Minimal, durable and long-lasting | May need reapplication after some time, especially under high stress |

| Best Use Case | Standard engines, regular maintenance | High-performance and racing applications | Applications where traditional gaskets are impractical |

Detailed Breakdown of Alternatives

What are Metal O-Rings and How Do They Compare?

Metal O-Rings are circular sealing devices made from materials such as aluminum or steel. They provide a robust sealing solution, particularly in high-pressure environments. The advantages of metal O-Rings include their durability and ability to withstand extreme temperatures, making them suitable for performance engines. However, they can be more expensive upfront and require precise machining to ensure a proper fit. Their reusability can offset the initial costs, making them an appealing option for long-term applications in competitive settings.

How Do Liquid Gasket Sealants Function as an Alternative?

Liquid gasket sealants offer a versatile sealing solution by forming a gasket-like barrier when applied between engine components. They are typically low-cost and easy to use, making them ideal for quick repairs or less accessible areas where traditional gaskets might fail. However, their performance can vary significantly based on the specific product and application conditions. The curing time can be a drawback, as it may delay reassembly and use. Additionally, the reliability of the seal can depend heavily on the skill of the user during application.

Conclusion: Choosing the Right Solution for Your Needs

In determining the best sealing solution for your engine, B2B buyers should carefully evaluate their specific requirements, including performance expectations, budget constraints, and the nature of the application. The cylinder block gasket remains a strong choice for standard applications due to its reliability and proven performance. However, for high-performance engines or unique situations where traditional gaskets may not suffice, alternatives like metal O-rings or liquid gasket sealants could provide significant advantages. Ultimately, understanding the pros and cons of each option will enable buyers to make informed decisions that align with their operational needs and budgetary considerations.

Illustrative image related to cylinder block gasket

Essential Technical Properties and Trade Terminology for cylinder block gasket

What Are the Key Technical Properties of Cylinder Block Gaskets?

When selecting a cylinder block gasket for engine applications, understanding its technical properties is crucial for ensuring optimal performance and longevity. Here are several essential specifications that B2B buyers should consider:

-

Material Grade

– Cylinder block gaskets are typically made from materials such as Multi-Layer Steel (MLS), composite, or rubber. Each material has specific thermal and mechanical properties that impact performance. For instance, MLS gaskets offer superior resistance to high temperatures and pressures, making them ideal for modern engines. Selecting the right material can prevent leaks and enhance engine efficiency. -

Compression Thickness

– The compression thickness of a gasket affects how well it seals the engine components under varying pressure and temperature conditions. A thicker gasket can compensate for surface irregularities but may reduce compression efficiency. Understanding the appropriate thickness for your application is vital to maintaining engine performance and preventing potential failures. -

Operating Temperature Range

– Each gasket material has a defined temperature range within which it can perform effectively. For example, gaskets made from rubber compounds may have lower temperature tolerances compared to MLS gaskets. It is essential to choose a gasket that can withstand the specific thermal environment of your engine to avoid premature wear or failure. -

Tensile Strength

– Tensile strength refers to the maximum stress that a material can withstand while being stretched or pulled before breaking. High tensile strength is critical for gaskets, as they must endure the dynamic forces generated within the engine. Gaskets with inadequate tensile strength may deform or fail under pressure, leading to leaks. -

Chemical Resistance

– Cylinder block gaskets are exposed to various fluids, including oil, coolant, and fuel. Therefore, the material must exhibit resistance to chemical degradation to ensure longevity. Buyers should verify that the gasket’s material is compatible with the fluids used in their specific engine applications to prevent premature gasket failure. -

Surface Finish Requirements

– The surface finish of the mating surfaces plays a significant role in the effectiveness of the gasket seal. Rough or uneven surfaces can lead to leaks, even with high-quality gaskets. It is recommended that buyers assess the surface finish of both the cylinder block and the gasket to ensure they meet the necessary specifications for optimal sealing.

What Are Common Trade Terms Related to Cylinder Block Gaskets?

Navigating the B2B landscape requires familiarity with specific terminology. Here are some essential terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– OEM refers to parts made by the same manufacturer that produced the original equipment. In the context of cylinder block gaskets, OEM parts are typically seen as higher quality and reliability, making them a preferred choice for many buyers. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and costs effectively, especially when sourcing gaskets for large-scale operations. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Submitting an RFQ for cylinder block gaskets allows buyers to compare offers and negotiate better terms, ensuring they receive the best value. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and responsibilities involved in purchasing cylinder block gaskets from overseas suppliers. -

Aftermarket Parts

– Aftermarket parts are components made by companies other than the original manufacturer. While they can often be more cost-effective, buyers must assess the quality and compatibility of aftermarket cylinder block gaskets to avoid potential issues with performance. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead time is critical for buyers to plan their production schedules and manage inventory effectively, especially in industries where downtime can be costly.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make informed decisions when sourcing cylinder block gaskets, ensuring they choose the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the cylinder block gasket Sector

What Are the Key Market Dynamics and Trends Affecting Cylinder Block Gasket Sourcing?

The cylinder block gasket market is experiencing significant growth, driven by increasing demand in automotive and industrial applications. Key global drivers include the surge in vehicle production, especially in emerging markets such as Africa and South America, where automotive industries are expanding rapidly. Additionally, the rise of electric vehicles (EVs) and hybrid technology is influencing gasket design and material selection, as these vehicles require gaskets that can withstand varying thermal and pressure conditions.

Illustrative image related to cylinder block gasket

Emerging B2B technology trends are reshaping sourcing strategies in this sector. Digital platforms and e-commerce solutions are becoming pivotal, allowing international buyers to access a broader range of suppliers and products efficiently. Additionally, advancements in materials science are leading to the development of high-performance gaskets, such as multi-layer steel (MLS) gaskets, which provide better sealing capabilities under high stress and temperature conditions. For buyers in regions like Nigeria and Vietnam, leveraging these technologies can enhance procurement processes and lead to cost savings.

Furthermore, market dynamics are influenced by fluctuating raw material prices and geopolitical factors. International buyers must remain vigilant regarding supply chain disruptions and consider diversifying their supplier base to mitigate risks. Establishing partnerships with manufacturers that offer transparency in their production processes can be beneficial in navigating these complexities.

How Is Sustainability Impacting the Cylinder Block Gasket Supply Chain?

Sustainability is becoming a critical consideration for B2B buyers in the cylinder block gasket sector. The environmental impact of manufacturing processes, particularly in terms of emissions and waste, has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and employing eco-friendly manufacturing methods.

Ethical sourcing is also gaining traction, with an emphasis on ensuring that materials used in gaskets are obtained responsibly. This includes verifying that suppliers adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and similar ‘green’ certifications can serve as indicators of a supplier’s commitment to sustainability.

Illustrative image related to cylinder block gasket

Moreover, the use of alternative materials, such as biodegradable composites and recycled metals, is on the rise. These innovations not only reduce environmental impact but can also enhance product performance. For B2B buyers, aligning with suppliers who invest in sustainable practices not only meets regulatory requirements but also appeals to increasingly eco-conscious consumers.

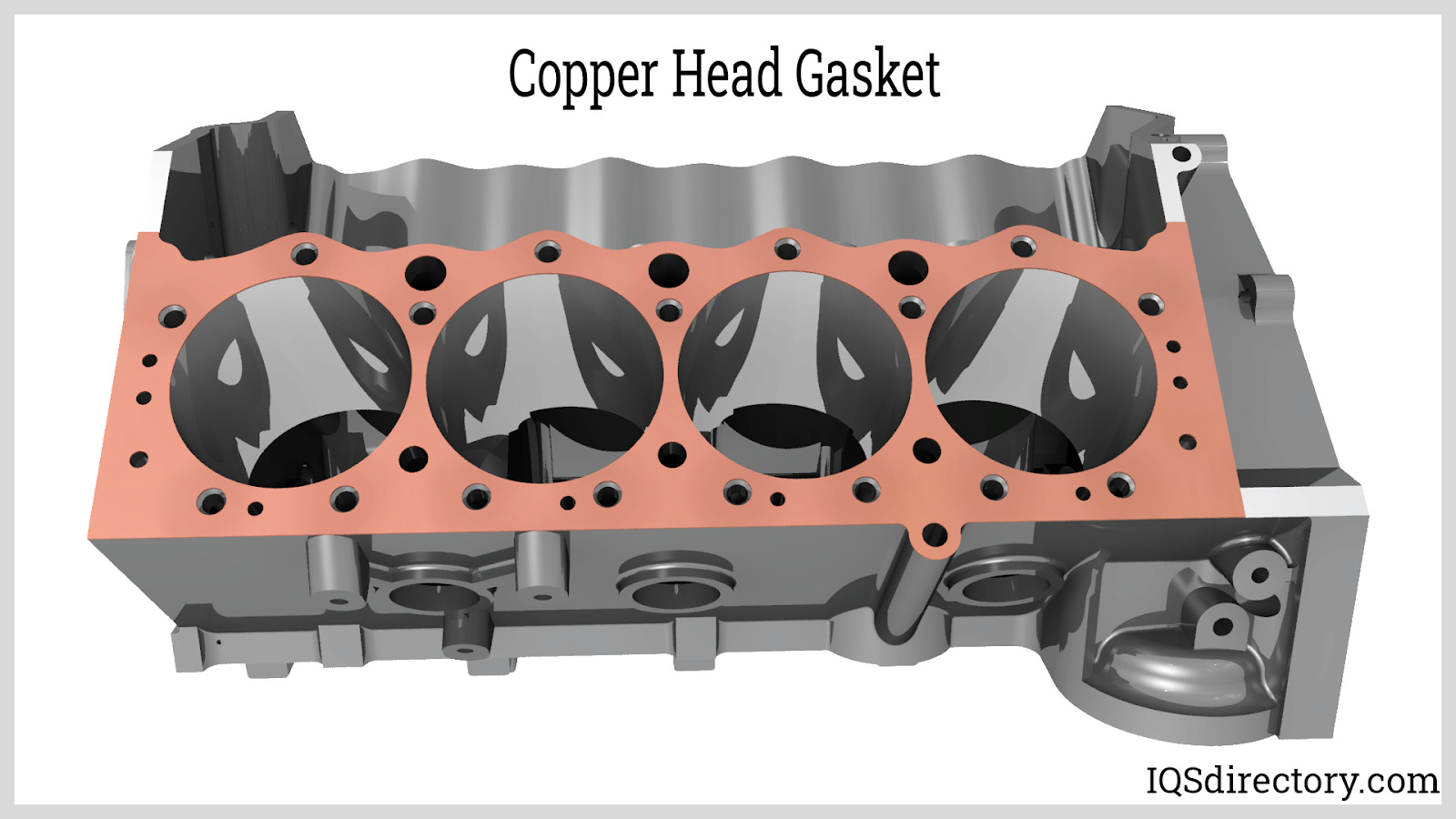

What Is the Evolution of Cylinder Block Gasket Technology and Its Relevance Today?

The evolution of cylinder block gasket technology has been significant over the decades. Historically, gaskets were primarily made from simple materials like paper or fiber, which were adequate for older engine designs. However, as engines have become more complex and performance-oriented, the need for more sophisticated sealing solutions has emerged.

Modern gaskets, particularly multi-layer steel (MLS) gaskets, have been developed to meet the demands of high-performance engines. These gaskets offer enhanced durability, better resistance to thermal expansion, and improved sealing capabilities. The transition from conventional to modern gaskets reflects broader trends in automotive engineering, where precision and efficiency are paramount.

For B2B buyers, understanding the evolution of gasket technology is crucial. It not only informs purchasing decisions but also highlights the importance of selecting the right gasket type for specific engine applications. As the industry continues to innovate, staying updated on the latest advancements will enable buyers to make informed choices that enhance engine performance and longevity.

Frequently Asked Questions (FAQs) for B2B Buyers of cylinder block gasket

-

How do I solve gasket leaks in my engine?

To address gasket leaks, first identify the source of the leak by inspecting engine surfaces for signs of oil or coolant leakage. Ensure that the surfaces are clean and free of debris before replacing the gasket. Selecting high-quality gaskets that are compatible with your engine’s specifications is crucial. Additionally, proper installation is essential; follow manufacturer guidelines and torque specifications to ensure an effective seal. Regular maintenance and inspections can help detect potential issues early, preventing costly repairs. -

What is the best material for a cylinder block gasket?

The best material for a cylinder block gasket depends on your engine’s requirements and operating conditions. Multi-layer steel (MLS) gaskets are commonly recommended for modern engines due to their superior heat resistance and sealing capabilities. For older engines, composite gaskets may be more suitable as they can accommodate surface irregularities. Always consider the operating temperature, pressure, and fluid exposure when selecting the appropriate gasket material for optimal performance. -

How can I verify the reliability of a gasket supplier?

To assess a gasket supplier’s reliability, start by researching their industry reputation through reviews and testimonials from previous clients. Verify their certifications and quality control processes, ensuring they comply with international standards. Request samples of their products to evaluate quality firsthand. Additionally, inquire about their supply chain stability, lead times, and customer service responsiveness, as these factors can significantly impact your procurement experience. -

What are the minimum order quantities (MOQ) for cylinder block gaskets?

Minimum order quantities for cylinder block gaskets can vary widely depending on the supplier and the type of gasket. Many manufacturers offer flexible MOQs to accommodate both small and large businesses. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Smaller orders may come with higher unit costs, so consider bulk purchasing if you anticipate ongoing demand to maximize cost efficiency. -

What payment terms should I expect when sourcing gaskets internationally?

International payment terms can differ based on supplier policies and your negotiation. Common terms include advance payments, letters of credit, or net 30/60/90 days after delivery. Be sure to clarify payment methods accepted, such as bank transfers, credit cards, or PayPal, and ensure that currency fluctuations are considered in pricing. Establishing clear terms upfront helps to avoid misunderstandings and ensures a smoother transaction process. -

How do I ensure quality assurance for gaskets purchased overseas?

To ensure quality assurance when sourcing gaskets from overseas, request detailed product specifications and certifications from suppliers. Consider implementing a third-party inspection service to verify product quality before shipment. Establishing a clear quality agreement that outlines acceptable tolerances and testing methods can also be beneficial. Additionally, maintaining open communication with the supplier throughout the production process will help address any concerns proactively. -

What logistics considerations should I be aware of for gasket shipments?

When planning logistics for gasket shipments, consider factors such as shipping methods, transit times, and customs regulations in your country. Choose a reliable freight forwarder experienced in handling automotive parts to ensure efficient delivery. Understand import duties and taxes that may apply, as these can impact overall costs. It’s also wise to discuss packaging requirements with suppliers to prevent damage during transit. -

Can I customize cylinder block gaskets for specific applications?

Yes, many suppliers offer customization options for cylinder block gaskets to meet specific application requirements. This may include adjustments in size, material, or design features to enhance performance in unique engine configurations. When requesting customization, provide detailed specifications and application data to ensure the supplier can meet your needs. Keep in mind that custom gaskets may involve longer lead times and potentially higher costs, so plan accordingly.

Top 6 Cylinder Block Gasket Manufacturers & Suppliers List

1. Fel-Pro – Engine Gaskets and Sealing Solutions

Domain: felpro.com

Registered: 1998 (27 years)

Introduction: Types of Engine Gaskets: Head Gaskets, Valve Stem Seals, Head Bolt Sets, Leak Repair, Intake Manifold Gasket Sets, Oil Pan Gaskets, Valve Cover Gaskets, Rear Main Seals, Timing Cover Gasket Sets, Timing Chain Tensioner Gasket Set, SpeedFit Gaskets, System Specific Sealing, Cooling System, Drivetrain, Exhaust System, Fuel System, Performance Head Gaskets, Intake Manifold Gaskets, Exhaust Manifold G…

2. Ohvale – Gasket, Cylinder Block

Domain: ohvaleusa.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “Gasket, Cylinder Block”, “price”: “$11.54 USD”, “availability”: “Sold out”, “unit_price”: “per”, “shipping_info”: “Shipping calculated at checkout.”}

3. Paccar Engine – Gasket Set, Cylinder Block, MX-13

Domain: bigrigworld.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Gasket Set, Cylinder Block, MX-13”, “Part Number”: “2005462PE”, “Type”: “OEM”, “Manufacturer”: “Paccar Engine”, “Shipping Info”: “Ships up to 72h”, “Shipping Cutoff Time”: “Monday – Friday 4:30pm Eastern Standard Time (EST)”, “Variations”: [“2005462”, “2005462 PE”], “Fits”: “Paccar Engine”}

4. Reddit – Head Gasket Preparation Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Use a plastic scraper, Scotchbrite pads, or sandpaper for cleaning the block before head gasket installation. Ensure a solid seal with the block; take time to clean every millimeter of the mating surfaces. Avoid metal scrapers unless experienced. Consider using drill attachments with Scotchbrite-like pads for efficiency, but maintain even pressure and movement to prevent uneven material removal.

5. John Deere – R131794 Cylinder Block Front Plate Gasket

Domain: rdoequipment.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “John Deere R131794 Cylinder Block Front Plate Gasket”, “sku”: “R131794”, “brand”: “John Deere”, “price”: “TBD”, “description”: “Cylinder Block Front Plate Gasket for John Deere equipment.”}

6. Wilmink – Cylinder Head Gaskets

Domain: wilminkengineparts.com

Registered: 2014 (11 years)

Introduction: Wilmink Engine Parts offers a wide range of cylinder head gaskets, categorized into three types: classic, modern, and performance gaskets. Classic gaskets are fiber-based with metal inserts, suitable for older engines. Modern gaskets (MLS) are designed for newer engines, providing better resistance to high temperatures and improved sealing. Performance gaskets include metal layer and cut ring type…

Strategic Sourcing Conclusion and Outlook for cylinder block gasket

In the rapidly evolving automotive landscape, the strategic sourcing of cylinder block gaskets is paramount for international B2B buyers. Understanding the diverse types of gaskets—ranging from classic to modern and performance variants—enables buyers to make informed decisions tailored to their specific engine needs. Prioritizing high-quality gaskets not only enhances engine performance but also mitigates the risk of costly repairs due to gasket failures.

Moreover, leveraging strategic sourcing practices can lead to cost efficiencies, improved supply chain resilience, and access to innovative gasket technologies that meet the demands of contemporary engines. For businesses operating in Africa, South America, the Middle East, and Europe, establishing strong relationships with reliable suppliers is essential. This approach ensures a steady supply of quality products while fostering collaboration and knowledge exchange.

Illustrative image related to cylinder block gasket

Looking ahead, as the market continues to adapt to advancements in engine technology and sustainability, it is crucial for B2B buyers to stay proactive. Engage with suppliers who demonstrate a commitment to quality and innovation, and be prepared to pivot as new materials and designs emerge. The future of your engine’s performance relies not only on the products you choose but also on the strategic partnerships you cultivate.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.