Choosing Your Conveyor Gate: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for conveyor gate

The global market for conveyor gates is rapidly evolving, presenting a unique challenge for B2B buyers seeking efficient solutions for material handling. As industries strive for seamless operations, sourcing the right conveyor gate becomes critical to enhancing workflow and optimizing space. This guide offers a comprehensive exploration of various conveyor gate types, their applications across different sectors, and strategic insights into supplier vetting.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—will find valuable information tailored to their specific needs. The guide delves into the cost implications of conveyor gates, enabling businesses to make informed purchasing decisions that align with their budget constraints and operational demands.

Additionally, we will address how to evaluate suppliers effectively, ensuring that buyers can identify reliable partners who offer quality products and support. By equipping buyers with the necessary knowledge about features, benefits, and best practices, this guide empowers businesses to navigate the complexities of the conveyor gate market confidently. Whether you are looking to enhance safety, improve accessibility, or streamline processes, understanding the nuances of conveyor gates will be instrumental in driving your operational success.

Understanding conveyor gate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas Spring Gate | Utilizes a gas strut mechanism for easier operation | Warehousing, Assembly Lines | Pros: Low effort to operate, reliable. Cons: May require maintenance over time. |

| Roller Gate | Features rollers for smooth product movement | Packaging, Distribution Centers | Pros: Efficient material handling, durable. Cons: Can be more expensive to install. |

| Skatewheel Gate | Employs skatewheels to facilitate lightweight items | Retail, Food Processing | Pros: Cost-effective, easy to install. Cons: Limited load capacity compared to roller gates. |

| Walk-Thru Gate | Functions like a drawbridge for easy access | Manufacturing, Modular Work Cells | Pros: Enhances accessibility, flexible design. Cons: Requires careful space planning. |

| Retractable Gate | Can be extended or retracted for variable access | Automated Systems, Maintenance Areas | Pros: Space-saving, versatile. Cons: Mechanism complexity may lead to higher maintenance needs. |

What are the characteristics and suitability of Gas Spring Gates for B2B buyers?

Gas spring gates are designed to facilitate easy access through conveyor systems, utilizing a gas strut mechanism that minimizes the physical effort required to operate the gate. This makes them particularly suitable for high-traffic areas in warehousing and assembly lines where frequent access is necessary. B2B buyers should consider the reliability and low operational effort of gas spring gates, though they may require periodic maintenance to ensure optimal performance.

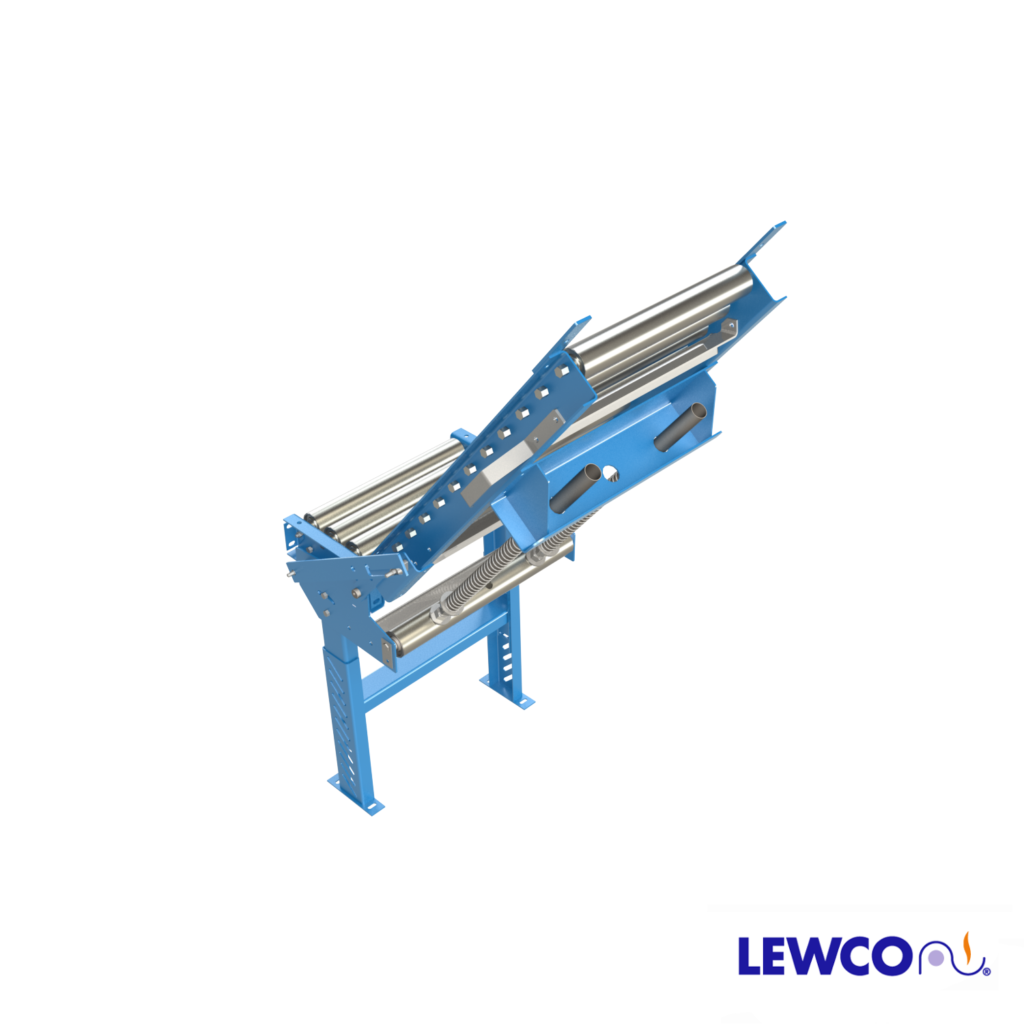

How do Roller Gates enhance material handling in B2B applications?

Roller gates are equipped with rollers that allow for smooth movement of products across the conveyor system. This design is particularly advantageous in packaging and distribution centers, where efficiency in material handling is critical. Buyers should evaluate the durability and efficiency of roller gates, as they can handle heavier loads compared to other gate types. However, the installation costs may be higher, which is an important consideration for budget-conscious organizations.

Why are Skatewheel Gates a cost-effective option for lightweight items?

Skatewheel gates are ideal for handling lightweight items and are often used in retail and food processing environments. Their design allows for easy installation and lower upfront costs, making them a budget-friendly option for businesses looking to optimize their conveyor systems. However, buyers should be mindful of their load limitations, as skatewheel gates may not be suitable for heavier materials.

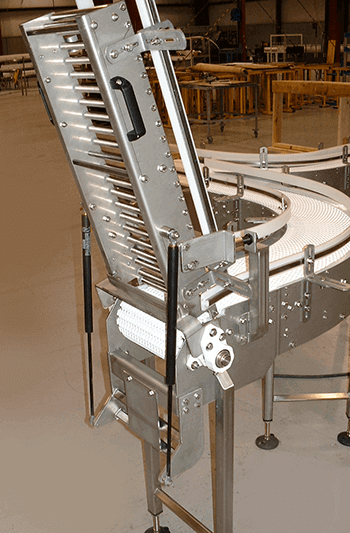

What advantages do Walk-Thru Gates offer for accessibility in manufacturing?

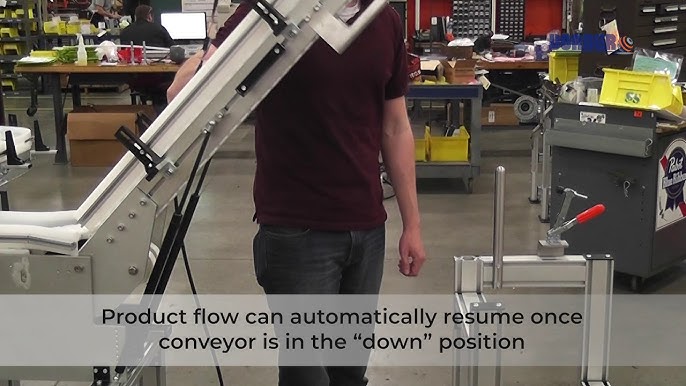

Walk-thru gates operate like a drawbridge, allowing for quick access to equipment and workspaces within manufacturing and modular work cells. They enhance accessibility and are designed to create a more efficient workflow by eliminating obstacles. B2B buyers should consider the flexibility and ease of access provided by walk-thru gates, although careful planning is necessary to accommodate their design within existing layouts.

How can Retractable Gates improve space utilization in B2B environments?

Retractable gates are designed to extend or retract as needed, making them an excellent choice for environments where space is at a premium. They are commonly used in automated systems and maintenance areas, where variable access is required. Buyers should weigh the versatility and space-saving benefits of retractable gates against their potential complexity, which may lead to increased maintenance requirements.

Key Industrial Applications of conveyor gate

| Industry/Sector | Specific Application of Conveyor Gate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Walk-thru gates in modular work cells | Enhances accessibility and workflow efficiency for operators | Durability of materials, ease of installation, and customization options |

| Food and Beverage | Conveyor gates for packaging lines | Streamlines production and improves hygiene standards | Compliance with food safety regulations and material certifications |

| Logistics and Warehousing | Gate conveyors for sorting and distribution | Increases throughput and optimizes space utilization | Load capacity, adaptability to existing systems, and maintenance requirements |

| Pharmaceuticals | Lift gates in fulfillment centers | Facilitates quick access for inventory management and safety | Compliance with health regulations, ease of cleaning, and operational reliability |

| Automotive | Gates for assembly line integration | Improves efficiency in material handling and reduces downtime | Compatibility with existing conveyor systems and load handling capabilities |

How are Conveyor Gates Used in the Manufacturing Sector?

In manufacturing, conveyor gates serve as crucial access points in modular work cells, allowing operators to navigate easily between different sections of the production line. This design minimizes disruptions and enhances workflow efficiency, as workers can quickly move in and out of areas without halting the conveyor system. Buyers in this sector should consider the durability of materials used for the gates, ease of installation, and the availability of customization options to fit their specific needs.

What Role Do Conveyor Gates Play in the Food and Beverage Industry?

In the food and beverage sector, conveyor gates are often integrated into packaging lines to ensure smooth transitions and maintain hygiene standards. They act as barriers that can be opened or closed to control the flow of products, reducing contamination risks. For international buyers, compliance with food safety regulations is paramount, so sourcing gates made from certified materials that can withstand cleaning processes is essential.

How Do Conveyor Gates Enhance Logistics and Warehousing Operations?

In logistics and warehousing, conveyor gates are vital for sorting and distribution processes. They enable efficient product flow while maximizing space utilization, allowing for a smoother transition between different conveyor systems. Businesses benefit from increased throughput and improved operational efficiency. Buyers should focus on load capacity, adaptability to existing systems, and the ease of maintenance when selecting conveyor gates for these applications.

Why Are Conveyor Gates Critical in the Pharmaceutical Industry?

In the pharmaceutical industry, lift gates are essential for fulfillment centers, providing quick access to inventory while ensuring safety protocols are met. These gates facilitate the movement of products without compromising quality, as they can be designed to meet stringent health regulations. Buyers should prioritize ease of cleaning, operational reliability, and compliance with health standards when sourcing conveyor gates for this sector.

How Do Conveyor Gates Contribute to the Automotive Industry?

In the automotive sector, conveyor gates are used to integrate assembly lines effectively. They allow for seamless material handling, reducing downtime and enhancing production efficiency. The right gates can help streamline operations, making it easier to manage the flow of parts. Buyers should consider compatibility with existing conveyor systems and the specific load handling capabilities required for automotive applications.

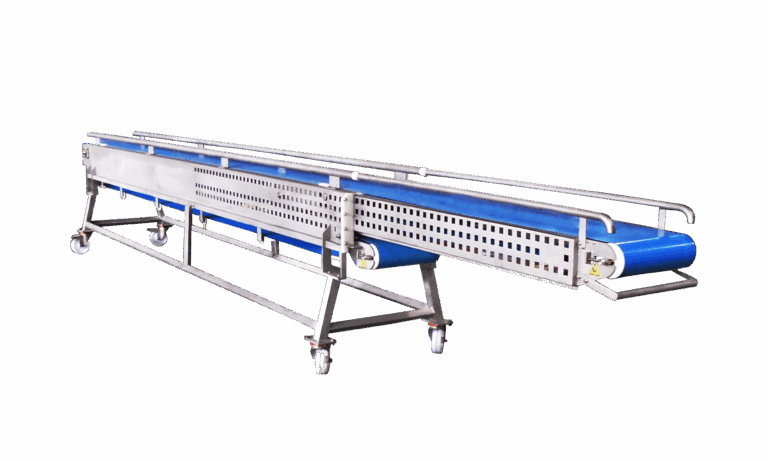

Illustrative image related to conveyor gate

3 Common User Pain Points for ‘conveyor gate’ & Their Solutions

Scenario 1: Limited Access and Workflow Disruption in Production Lines

The Problem: In many manufacturing environments, conveyor gates are crucial for maintaining efficient workflow and access. However, buyers often face the challenge of limited access to certain areas of their production lines due to traditional conveyor setups. This can lead to workflow disruptions, safety hazards, and increased downtime when operators need to reach equipment or perform maintenance tasks. Manual lifting of heavy gates can cause physical strain and may result in accidents, compounding the frustration of workers and managers alike.

The Solution: To address this issue, consider investing in conveyor gates that feature gas strut assist mechanisms. These systems significantly reduce the lifting force required, making it easier for operators to open and close gates without physical strain. When sourcing these gates, look for products with modular designs that can be easily integrated into existing systems. Ensure that the gates are placed strategically to allow for quick access to machinery and work areas. Additionally, implementing a regular maintenance schedule for these gates will help ensure they function smoothly and safely, minimizing disruptions in workflow.

Scenario 2: Frequent Equipment Jams and Safety Risks

The Problem: Conveyor systems are often plagued by equipment jams that can halt production. Buyers frequently report that poorly designed gates or inadequate gate controls contribute to these jams, leading to potential safety risks for operators. When gates do not function as intended, they can cause materials to pile up, resulting in both operational delays and hazardous working conditions. This is especially critical in industries where heavy materials or hazardous goods are transported, as jams can lead to accidents or damage to the conveyor system itself.

The Solution: To mitigate this issue, opt for conveyor gates with advanced features like automatic sensors or safety relays that can detect jams and halt operations before they escalate. When specifying conveyor gates, ensure they are equipped with features like low-friction belting and quick-release mechanisms to enhance reliability and reduce the likelihood of jams. Additionally, consider implementing training programs for employees on how to properly operate and troubleshoot conveyor systems, empowering them to address minor issues before they become significant problems. Investing in high-quality gates and proper training can drastically improve both safety and operational efficiency.

Scenario 3: High Maintenance Costs Due to Inefficient Gate Systems

The Problem: Many companies encounter unexpectedly high maintenance costs related to their conveyor gate systems. Buyers often find that outdated or poorly specified gates require frequent repairs and replacements, leading to increased operational costs. This issue is compounded in regions with limited access to quality spare parts or service providers, making it difficult to maintain efficient operations. As a result, businesses may struggle with budget overruns and unplanned downtime, which can adversely affect profitability.

The Solution: To reduce maintenance costs, prioritize sourcing conveyor gates made from durable materials such as cut-resistant polypropylene or modular snap-link belting. These materials not only enhance longevity but also simplify repairs, as damaged sections can be replaced without needing to overhaul the entire system. When evaluating suppliers, consider those that offer comprehensive warranties and support services, as this can mitigate long-term maintenance costs. Additionally, investing in training for your maintenance team on the proper care and operation of these gates can prevent premature wear and tear, ensuring your investment yields long-term benefits.

Strategic Material Selection Guide for conveyor gate

What are the Key Materials for Conveyor Gates and Their Properties?

When selecting materials for conveyor gates, it is crucial to consider their physical properties, durability, and suitability for specific applications. The right material can significantly enhance the performance and longevity of the conveyor system, especially in varying environmental conditions. Below, we analyze four common materials used in conveyor gates: steel, aluminum, plastic, and stainless steel.

How Does Steel Perform in Conveyor Gate Applications?

Steel is a widely used material for conveyor gates due to its strength and durability. It offers excellent load-bearing capabilities, making it suitable for heavy-duty applications. Steel gates can withstand high temperatures and pressures, which is beneficial in manufacturing environments where heavy materials are transported.

Pros: Steel is highly durable and offers a long service life, making it a cost-effective choice in the long run. It is also readily available and can be easily fabricated into various designs.

Cons: On the downside, steel is prone to corrosion if not properly treated or coated, which can lead to increased maintenance costs. Additionally, its weight can complicate installation and operation, especially in manual gate designs.

Impact on Application: Steel gates are ideal for industries that require robust solutions, such as automotive or heavy machinery manufacturing. However, in humid or corrosive environments, protective coatings or alternative materials may be necessary.

What Advantages Does Aluminum Offer for Conveyor Gates?

Aluminum is another popular choice for conveyor gates due to its lightweight nature and resistance to corrosion. This metal is particularly advantageous in applications where weight reduction is critical, such as in portable conveyor systems.

Pros: Aluminum is easy to fabricate and can be anodized for enhanced corrosion resistance, making it suitable for outdoor applications. Its lightweight nature simplifies installation and reduces the overall energy consumption of the conveyor system.

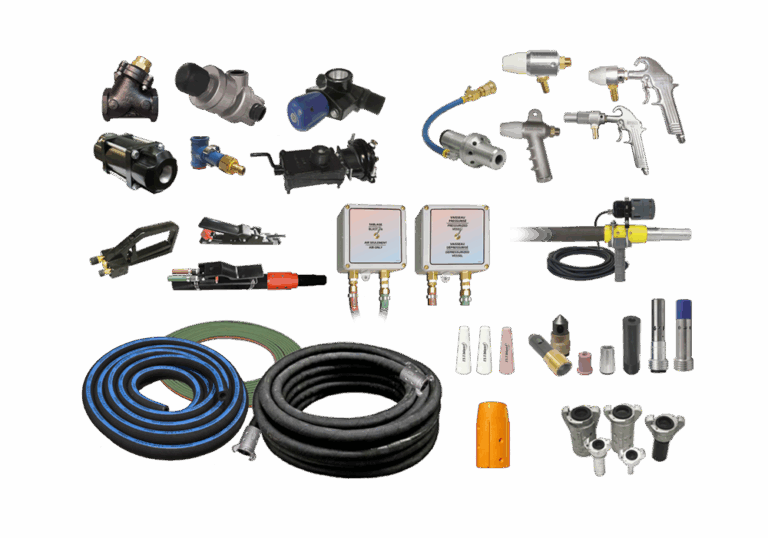

Illustrative image related to conveyor gate

Cons: However, aluminum is not as strong as steel, which can limit its use in high-load applications. It is also typically more expensive than steel, which can impact budget considerations.

Impact on Application: Aluminum gates are commonly used in food processing and pharmaceutical industries, where hygiene and corrosion resistance are paramount. Compliance with food safety standards is essential in these sectors.

Why Choose Plastic for Conveyor Gates?

Plastic materials, such as polypropylene, are increasingly utilized in conveyor gate applications due to their versatility and resistance to chemicals. These materials can be engineered to meet specific requirements, such as low friction or high impact resistance.

Illustrative image related to conveyor gate

Pros: Plastic gates are lightweight, corrosion-resistant, and can be manufactured in various colors for visibility. They are also less expensive than metal options, making them an attractive choice for budget-conscious projects.

Cons: The primary drawback is that plastic may not withstand high temperatures or heavy loads as effectively as metals. Additionally, certain plastics can degrade over time when exposed to UV light or harsh chemicals.

Impact on Application: Plastic gates are suitable for light-duty applications, such as packaging and assembly lines. They are particularly advantageous in environments where chemical exposure is a concern.

What Role Does Stainless Steel Play in Conveyor Gate Design?

Stainless steel is an excellent choice for conveyor gates in environments that require high levels of hygiene and corrosion resistance. This material combines the strength of steel with the corrosion resistance of chromium, making it ideal for demanding applications.

Illustrative image related to conveyor gate

Pros: Stainless steel is highly durable, easy to clean, and resistant to rust and corrosion. It is also capable of withstanding extreme temperatures, making it suitable for a variety of industrial applications.

Cons: The main disadvantage of stainless steel is its higher cost compared to other materials. Additionally, it can be heavier and more challenging to fabricate, which may require specialized equipment.

Impact on Application: Stainless steel gates are widely used in the food and beverage, pharmaceutical, and chemical industries, where compliance with strict hygiene standards is mandatory. Buyers should ensure that the selected grade meets relevant standards such as ASTM or DIN.

Summary Table of Material Selection for Conveyor Gates

| Material | Typical Use Case for conveyor gate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty manufacturing applications | High strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Food processing and portable systems | Lightweight and corrosion-resistant | Lower load capacity compared to steel | High |

| Plastic | Light-duty packaging and assembly lines | Cost-effective and versatile | Limited temperature and load resistance | Low |

| Stainless Steel | Food, beverage, and pharmaceutical industries | Excellent hygiene and corrosion resistance | Higher cost and fabrication complexity | High |

This strategic material selection guide provides international B2B buyers with valuable insights into the properties, advantages, and limitations of various materials used in conveyor gates. Understanding these factors can aid in making informed purchasing decisions that align with specific operational needs and compliance standards.

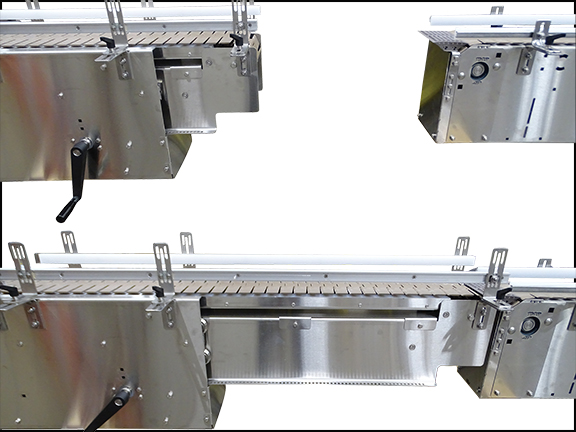

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor gate

What Are the Main Stages in the Manufacturing Process of Conveyor Gates?

The manufacturing process of conveyor gates is critical to ensure durability, functionality, and safety in various industrial applications. This process typically involves several key stages, including material preparation, forming, assembly, and finishing.

Material Preparation: The journey begins with the selection of high-quality materials, often including steel, aluminum, and high-density plastics. These materials are chosen for their strength, corrosion resistance, and weight efficiency. Prior to forming, materials undergo cutting and surface treatment processes to enhance their performance characteristics. For instance, steel components may be galvanized or powder-coated to prevent rust and wear.

Forming Techniques: The forming stage employs various techniques such as bending, stamping, and welding. Advanced machinery, including CNC (Computer Numerical Control) machines, ensures precision in shaping parts according to design specifications. For instance, the use of laser cutting provides clean edges and reduces the need for extensive finishing work later on.

Assembly Process: Following forming, the components are assembled. This stage typically involves the integration of mechanical systems such as gas struts or springs that facilitate the opening and closing of the gates. Automated assembly lines may be used to enhance efficiency, allowing for rapid production while maintaining high standards of quality.

Finishing Touches: The final stage includes surface finishing, where treatments like powder coating or painting are applied. These not only improve the aesthetic appeal but also enhance corrosion resistance and overall durability. Quality checks are performed at this stage to ensure that all components meet the required specifications before moving on to packaging and shipping.

Illustrative image related to conveyor gate

How Is Quality Assurance Implemented in Conveyor Gate Manufacturing?

Quality assurance (QA) is paramount in conveyor gate manufacturing to guarantee that products meet stringent international standards and customer expectations. Various frameworks and checkpoints are employed throughout the manufacturing process to ensure quality.

International Standards: Many manufacturers adhere to ISO 9001, a quality management system standard that emphasizes process consistency and customer satisfaction. Additionally, depending on the market, compliance with industry-specific standards such as CE marking for the European market or API (American Petroleum Institute) standards may be required. These certifications indicate that products have been tested and meet safety and performance criteria.

Quality Control Checkpoints: Quality control is integrated at multiple stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards. Non-conforming materials are rejected, and suppliers may be assessed based on their quality performance.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, operators conduct regular inspections to monitor the production process. This may include checking tolerances during forming and ensuring proper assembly techniques are followed.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted. This includes functional testing of the gates to ensure they operate smoothly and safely under expected loads.

What Testing Methods Are Commonly Used for Conveyor Gates?

Testing is an essential part of the quality assurance process for conveyor gates, ensuring that they function correctly and safely in operational environments. Common testing methods include:

-

Load Testing: This involves applying the maximum intended load to the gate to assess its structural integrity and operational performance. This test simulates real-world usage and identifies potential failure points.

-

Functional Testing: Each gate is tested for its ease of operation, ensuring that mechanisms such as gas struts or springs function correctly. This is crucial for user safety and operational efficiency.

-

Corrosion Resistance Testing: For gates that will be used in environments prone to moisture or corrosive substances, manufacturers often perform salt spray tests to evaluate the effectiveness of protective coatings.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, ensuring supplier quality control is vital. Here are several strategies to verify the quality practices of potential suppliers:

Illustrative image related to conveyor gate

-

Supplier Audits: Conducting audits of manufacturing facilities provides insights into the processes and controls in place. These audits can assess compliance with international standards and identify any potential risks.

-

Requesting Quality Reports: Suppliers should provide documentation outlining their quality control processes, including test results, inspection reports, and certifications. This transparency helps buyers evaluate the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of product quality. These services can verify that products meet specified requirements before they are shipped.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific quality control nuances that may affect their procurement processes. For example, varying standards and regulations across different regions can complicate compliance efforts. Buyers should familiarize themselves with:

-

Regional Standards: Understanding the specific quality standards required in their target markets is crucial. For instance, CE marking is mandatory for products sold within the European Union, while other regions may have different requirements.

-

Logistical Considerations: Shipping and logistics can impact product quality. Buyers should consider how products are packaged and transported, ensuring that they are protected from damage during transit.

-

Cultural Factors: Different cultures may have varying approaches to quality and business practices. Building strong relationships with suppliers and understanding their operational philosophies can lead to better alignment on quality expectations.

In conclusion, the manufacturing processes and quality assurance practices for conveyor gates are integral to ensuring that these products meet the high standards expected in various industrial applications. By understanding these processes, B2B buyers can make informed decisions and select suppliers that align with their quality requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor gate’

To assist B2B buyers in procuring conveyor gates, this guide provides a structured checklist to ensure a thorough and effective sourcing process. Conveyor gates are essential components in material handling systems, facilitating safe and efficient access while maintaining workflow.

Step 1: Define Your Technical Specifications

Start by identifying the specific requirements for your conveyor gate. Consider factors such as the gate type (manual, gas-assisted, or powered), dimensions, weight capacity, and material compatibility. Understanding these technical specifications will help you narrow down your options and ensure that the gate meets your operational needs.

- Key Considerations:

- Load capacity: Ensure the gate can support the weight of the items being transported.

- Size: Match the dimensions with your existing conveyor system to avoid compatibility issues.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in conveyor gates. Utilize industry directories, trade shows, and online platforms to find reputable manufacturers and distributors. This step is vital for ensuring a diverse range of options and competitive pricing.

- Sources to Explore:

- Online B2B marketplaces (e.g., Alibaba, ThomasNet)

- Industry-specific trade shows or exhibitions

- Local distributors in your region

Step 3: Evaluate Supplier Certifications and Compliance

Before engaging with suppliers, verify their certifications and compliance with international standards. This is crucial for ensuring that the products meet safety and quality benchmarks, particularly if you are operating in regulated industries.

- What to Look For:

- ISO certifications relevant to manufacturing and safety standards.

- Compliance with local regulations in your operational regions.

Step 4: Request and Compare Quotes

After identifying potential suppliers, request detailed quotes that include pricing, lead times, and shipping costs. Comparing these quotes will help you identify the best value for your investment without compromising on quality.

- Important Aspects to Compare:

- Total cost of ownership, including installation and maintenance.

- Warranty and service agreements offered by the supplier.

Step 5: Assess After-Sales Support and Warranty Terms

Consider the level of after-sales support provided by the supplier. Reliable customer service can significantly impact your operational efficiency, especially if issues arise post-purchase. Additionally, review warranty terms to understand the coverage for repairs or replacements.

- Key Questions to Ask:

- What is the duration of the warranty, and what does it cover?

- How does the supplier handle service requests or repairs?

Step 6: Conduct Site Visits or Request Product Samples

If possible, arrange site visits to the supplier’s facility or request product samples. This allows you to assess the quality of the conveyor gates firsthand and ask technical questions directly to the manufacturer.

- Benefits of Site Visits:

- Verify the manufacturing process and quality control measures.

- Evaluate the supplier’s capability to meet your specific requirements.

Step 7: Finalize the Contract and Payment Terms

Once you have chosen a supplier, finalize the contract with clear terms regarding delivery, payment, and service commitments. Ensure that both parties understand their responsibilities to avoid misunderstandings in the future.

Illustrative image related to conveyor gate

- Key Elements to Include:

- Clear payment schedules and methods.

- Delivery timelines and penalties for delays.

By following this checklist, B2B buyers can make informed decisions when sourcing conveyor gates, ensuring that they select the right products for their operations while minimizing risks.

Comprehensive Cost and Pricing Analysis for conveyor gate Sourcing

What Are the Key Cost Components for Sourcing Conveyor Gates?

When analyzing the costs associated with sourcing conveyor gates, several key components come into play. First, the materials used in manufacturing the gates significantly influence pricing. Common materials include steel, aluminum, and specialized plastics, each with distinct costs and properties.

Next, labor costs encompass the expenses related to workforce wages during production. Skilled labor may be required for complex gate designs, impacting overall costs. Additionally, manufacturing overhead—which includes utilities, facility costs, and equipment depreciation—must be factored in, as it contributes to the unit cost of production.

Tooling costs for creating molds and dies also affect pricing, particularly for custom designs. Quality control (QC) measures are crucial for ensuring safety and functionality, and these processes can add to the expense. Finally, logistics costs, including shipping and handling, play a significant role, especially for international transactions where tariffs and duties may apply.

How Do Pricing Influencers Affect Conveyor Gate Costs?

Several factors can influence the pricing of conveyor gates. Volume and Minimum Order Quantity (MOQ) are critical; larger orders often lead to lower per-unit costs due to economies of scale. Customization and specific specifications can also drive up prices, as tailored solutions typically require additional resources and time to produce.

The quality of materials and any necessary certifications (such as ISO or CE) can affect pricing, as higher-quality components generally command a premium. Supplier factors, including their reputation, reliability, and location, can also lead to variations in cost. For international buyers, Incoterms play a vital role in determining who bears the risk and costs associated with shipping, impacting the total landed cost.

What Buyer Tips Can Help Optimize Costs in Conveyor Gate Sourcing?

For B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency. Negotiation is a key component; understanding the supplier’s cost structure and market conditions can provide leverage during discussions.

Consider evaluating the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, operational costs, and potential downtime. This comprehensive view can highlight the long-term value of investing in higher-quality gates versus cheaper alternatives.

When dealing with international suppliers, be mindful of pricing nuances such as currency fluctuations, import duties, and varying shipping costs. It’s advisable to request detailed quotations that include all potential fees to avoid unexpected expenses.

Lastly, buyers should remain informed about market trends and competitor pricing. This knowledge can empower them to make strategic purchasing decisions and foster long-term relationships with reliable suppliers.

Disclaimer on Indicative Prices

It is important to note that prices for conveyor gates can vary widely based on the aforementioned factors. As such, any price references should be viewed as indicative rather than definitive. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing in their sourcing endeavors.

Alternatives Analysis: Comparing conveyor gate With Other Solutions

When evaluating material handling solutions, it’s essential to consider various alternatives to conveyor gates, which are widely used for creating walk-through access in conveyor systems. By comparing different technologies, buyers can make informed decisions that suit their operational needs and budget constraints.

| Comparison Aspect | Conveyor Gate | SmartMove Gate Conveyor | Manual Lift Gates |

|---|---|---|---|

| Performance | Effective for gravity systems; allows manual access. | High efficiency with low power consumption; modular design. | Simple operation; suitable for low-volume applications. |

| Cost | Moderate initial cost; low maintenance. | Higher upfront cost; savings on energy and repairs over time. | Low initial cost; may incur higher long-term labor costs. |

| Ease of Implementation | Requires some customization; installation can be straightforward. | Plug-and-play design simplifies setup; adaptable to various layouts. | Typically easy to install; manual operation may require training. |

| Maintenance | Low maintenance needs; durable materials. | Minimal maintenance with modular belts; quick repairs. | Higher maintenance due to wear and tear; manual adjustments needed. |

| Best Use Case | Ideal for existing gravity systems needing periodic access. | Best for high-efficiency environments with frequent access needs. | Suitable for small-scale operations with infrequent use. |

What Are the Advantages and Disadvantages of SmartMove Gate Conveyors?

SmartMove Gate Conveyors offer a modern alternative, featuring a modular design that promotes quick access and flexibility in workflow. The low power consumption (only 25 watts for 200 lbs) makes them energy-efficient, which can lead to significant savings over time. Their snap-link belting system allows for easy repairs, reducing downtime. However, the initial investment is higher compared to traditional conveyor gates, which could be a concern for budget-conscious buyers.

How Do Manual Lift Gates Compare to Conveyor Gates?

Manual lift gates are a cost-effective solution for facilities with lower throughput requirements. They are straightforward to install and operate, making them an attractive option for smaller operations or those with limited budgets. However, they require more manual effort to operate and can lead to higher labor costs over time. Additionally, they may not be as durable as automated solutions, resulting in more frequent maintenance and replacements.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right solution depends largely on the specific operational needs and constraints of the business. For high-volume environments that require frequent access, SmartMove Gate Conveyors may be the best choice despite their higher initial cost. Conversely, for operations with lower throughput or budget constraints, manual lift gates or traditional conveyor gates could be more appropriate. Evaluating the performance, cost, ease of implementation, and maintenance requirements of each option will help B2B buyers make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for conveyor gate

What Are the Essential Technical Properties of Conveyor Gates?

When evaluating conveyor gates for industrial applications, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several key properties to consider:

-

Material Grade

Conveyor gates are typically constructed from materials like steel, aluminum, or polypropylene. The choice of material affects durability, load capacity, and corrosion resistance. For example, stainless steel is often preferred in food processing environments due to its resistance to contamination and ease of cleaning. Selecting the right material ensures that the gate can withstand the operational demands of your facility. -

Load Capacity

This specification indicates the maximum weight the conveyor gate can safely support. It is essential to consider both the gate’s own weight and the loads it will transport. Understanding load capacity helps prevent operational failures that could lead to downtime or costly repairs. Different designs, such as gravity or powered gates, may have varying load capacities, so it’s vital to match the gate with your specific application requirements. -

Gate Dimensions

The size of the conveyor gate, including its width and height, plays a significant role in its functionality. Proper dimensions allow for seamless integration into existing conveyor systems and ensure efficient material handling. Buyers should assess the layout of their facility and the types of products being transported to determine the appropriate gate dimensions. -

Operating Temperature Range

Conveyor gates often operate in various environments, and the ability to withstand specific temperature ranges is crucial. For instance, gates used in high-temperature environments, such as food processing or manufacturing, must be constructed from materials that maintain integrity under heat. Understanding this property helps in selecting a gate that will perform reliably in your operational conditions. -

Actuation Mechanism

The method by which the gate opens and closes—manual, pneumatic, or electric—affects both efficiency and safety. Gas spring-assisted gates require less force to operate, making them user-friendly and reducing the risk of injury. The choice of actuation mechanism should align with the operational workflow and safety standards of the facility. -

Safety Features

Integrated safety features, such as emergency stop buttons or safety interlocks, are essential for protecting workers and minimizing liability. Gates that can be locked in the open or closed position prevent accidental movements, ensuring a safer working environment. Evaluating these features is critical for compliance with industry safety regulations.

What Are the Common Trade Terms Related to Conveyor Gates?

Understanding industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

Illustrative image related to conveyor gate

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of conveyor gates, working with an OEM can ensure you receive high-quality, compatible components for your systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers budget their purchases and manage inventory effectively, especially when integrating new conveyor gates into existing systems. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes detailed specifications of the desired products. Submitting an RFQ can streamline the procurement process and help buyers compare prices and terms from multiple vendors. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms published by the International Chamber of Commerce. Incoterms clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, making them essential for international procurement of conveyor gates. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for planning and ensuring that your operational timelines are met, particularly in industries with tight schedules. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the terms of service. Knowing the warranty details for conveyor gates can protect your investment and inform you of your rights should defects or failures occur.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding conveyor gate purchases, ensuring alignment with their operational needs and compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the conveyor gate Sector

What Are the Key Trends Shaping the Global Conveyor Gate Market?

The global conveyor gate market is currently experiencing significant growth, driven by factors such as automation in manufacturing, the rise of e-commerce, and the need for efficient material handling solutions across various sectors. Automation technologies, including robotics and IoT (Internet of Things), are increasingly being integrated into conveyor systems, making them smarter and more efficient. This trend is particularly relevant for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where industries are rapidly modernizing to enhance productivity.

Emerging technologies like AI-driven analytics are also influencing sourcing decisions, allowing companies to optimize inventory management and predict maintenance needs, thus reducing downtime. Additionally, modular conveyor systems that can be easily customized and expanded are gaining traction, providing flexibility that is especially beneficial for businesses operating in dynamic markets. B2B buyers are increasingly looking for suppliers who can provide tailored solutions that meet specific operational needs while ensuring quick delivery and installation.

Illustrative image related to conveyor gate

Furthermore, the demand for conveyor gates that prioritize user safety and ease of operation is on the rise. Features such as gas spring assists for manual gates and modular designs that facilitate quick access are becoming standard expectations. As businesses strive for more seamless operations, these innovations are positioning conveyor gates as essential components in modern logistics and manufacturing processes.

How Is Sustainability Influencing Conveyor Gate Sourcing Decisions?

Sustainability has become a pivotal concern in the B2B landscape, impacting sourcing strategies for conveyor gates. International buyers are increasingly prioritizing suppliers that adopt environmentally friendly practices and materials. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny, prompting companies to seek out “green” certifications and sustainable materials.

Incorporating recyclable materials and energy-efficient components into conveyor gate systems not only reduces environmental footprints but also aligns with global sustainability goals. Buyers are now more inclined to partner with manufacturers that demonstrate a commitment to ethical sourcing, such as fair labor practices and transparency in their supply chains. This focus on sustainability extends to the operational lifecycle of conveyor gates, where durability and maintenance-free features are sought after to minimize waste and resource consumption.

Moreover, emerging certifications, such as ISO 14001 for environmental management, are influencing supplier selection. B2B buyers are more likely to engage with companies that can prove their commitment to sustainable practices, as this aligns with their corporate social responsibility (CSR) objectives and enhances their brand reputation.

What Is the Historical Context of Conveyor Gate Development in B2B?

The evolution of conveyor gates can be traced back to the early 20th century, coinciding with the industrial revolution’s drive for efficiency. Initially designed for basic material handling, these systems have undergone significant transformations, incorporating advanced technologies and materials. The introduction of powered conveyor systems allowed for more complex operations, paving the way for innovations like automated gates and safety mechanisms.

In the 1970s and 1980s, as manufacturing processes became more sophisticated, the need for flexible and modular conveyor systems emerged. This led to the development of conveyor gates that not only facilitated the movement of goods but also enhanced accessibility for workers. The late 20th century saw a focus on ergonomic design and safety features, responding to increased awareness of workplace safety and employee well-being.

Today, the evolution continues with the integration of smart technologies and a heightened emphasis on sustainability. The modern conveyor gate is not merely a passageway but a critical component of complex logistics and manufacturing systems, embodying the latest advancements in efficiency, safety, and environmental responsibility. This historical context is essential for B2B buyers to appreciate the importance of investing in high-quality, innovative conveyor gate solutions that meet the demands of contemporary industry.

Illustrative image related to conveyor gate

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor gate

-

How do I choose the right conveyor gate for my application?

Selecting the appropriate conveyor gate involves understanding your operational needs and the type of materials being handled. Consider factors such as the gate’s load capacity, dimensions, and the specific design features required for your workflow, like manual or automatic operation. Additionally, evaluate the environmental conditions, such as temperature and humidity, as well as safety standards relevant to your industry. Consulting with a supplier who offers customization options can ensure that the gate integrates seamlessly into your existing conveyor system. -

What is the best type of conveyor gate for a gravity conveyor system?

For gravity conveyor systems, roller or skatewheel gates are typically the best options. Roller gates provide smooth movement for items with varying weights, while skatewheel gates are ideal for lighter loads and offer reduced friction. Both types can be equipped with gas strut assist mechanisms to minimize manual lifting effort. When selecting a gate, consider the specific items being transported and the required access points along the conveyor to optimize efficiency. -

What should I consider when vetting suppliers of conveyor gates?

When vetting suppliers, assess their industry experience and reputation by reviewing customer testimonials and case studies. Ensure they provide robust after-sales support, including installation assistance and maintenance services. Check for certifications that comply with international safety and quality standards, which can be crucial for cross-border transactions. Additionally, inquire about their manufacturing processes and customization capabilities to ensure they can meet your specific requirements. -

What are the typical minimum order quantities (MOQs) for conveyor gates?

Minimum order quantities can vary significantly among suppliers and depend on factors such as customization and material type. Many manufacturers may set MOQs ranging from 5 to 20 units for standard models. However, for specialized or custom designs, the MOQ might be higher. Always discuss your needs with the supplier to negotiate terms that align with your purchasing strategy, especially if you are considering a larger project or ongoing supply needs. -

How can I ensure the quality of conveyor gates before purchasing?

To ensure quality, request samples or detailed specifications from suppliers, including material types, load capacities, and performance metrics. Inquire about their quality assurance processes, including testing methods and compliance with international standards. If possible, visit their manufacturing facility or request third-party inspection reports. Additionally, check if they offer warranties, as this can be an indicator of their confidence in product quality. -

What payment terms are typically offered by international suppliers?

Payment terms can vary widely, often influenced by the supplier’s location and your purchasing volume. Common terms include a deposit upfront (usually 30% to 50%) with the balance due before shipment. Some suppliers may also offer net terms, allowing you to pay within a set period after delivery. Discussing payment options early in negotiations can help establish a mutually beneficial agreement and facilitate smoother transactions. -

What logistics considerations should I keep in mind when importing conveyor gates?

When importing conveyor gates, consider shipping options, lead times, and customs regulations specific to your country. Work with logistics partners who have experience in handling industrial equipment to ensure compliance with import duties and taxes. Additionally, factor in the costs of freight insurance and storage if necessary. Clear communication with your supplier about delivery schedules will help prevent delays and streamline the installation process. -

Can conveyor gates be customized for specific operational needs?

Yes, many suppliers offer customization options for conveyor gates to meet specific operational requirements. Customizations can include modifications in size, load capacity, and design features such as automated mechanisms or safety enhancements. When discussing your needs with a supplier, provide detailed information about your workflow and any unique challenges to ensure they can deliver a solution that optimally fits your system.

Top 4 Conveyor Gate Manufacturers & Suppliers List

1. McMaster – Conveyor Gates

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Conveyor Gates, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Ashland Conveyor – Conveyor Gates

Domain: ashlandconveyor.com

Registered: 1999 (26 years)

Introduction: Conveyor Gates are used to create a manually opened walkway through a gravity conveyor system. A gas strut assist mechanism reduces the lifting force required to open the gate. The roller or skatewheel gate conveyor and gate hinge kits are sold separately. Types available include Gas spring, Gate hinge kit, Roller gate, and Skatewheel gate.

3. Dorner – Lift Gate Conveyors

Domain: dornerconveyors.com

Registered: 2007 (18 years)

Introduction: Lift Gate Conveyors by Dorner provide safe and quick access to essential equipment without disrupting operational flow. They are designed to maximize usable space in factories and warehouses by allowing workers to walk through the middle of the conveyor, reducing the need for long detours and minimizing injury risks. The lift gates operate like a drawbridge, using gas-spring assistance for easy ra…

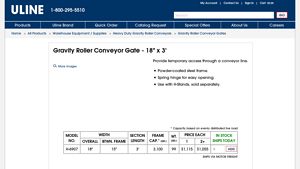

4. Uline – Gravity Roller Conveyor Gate

Domain: uline.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Gravity Roller Conveyor Gate”, “Model Number”: “H-6907”, “Dimensions”: {“Width”: “18 inches”, “Section Length”: “3 feet”, “Usable Length”: “35 1/4 inches”, “Overall Length”: “44 1/2 inches”, “Frame Height”: “3 1/2 inches”, “Flange Gap”: “1 1/2 inches”, “Gap Between Roller Centers”: “3 inches”, “Gap Between First Gate Roller and Conveyor Roller Center”: “5 1/8 inches”}, “Frame Cap…

Strategic Sourcing Conclusion and Outlook for conveyor gate

As businesses increasingly seek efficiency and flexibility in their operations, the strategic sourcing of conveyor gates emerges as a critical factor in optimizing material handling systems. By selecting the right conveyor gates, companies can enhance workflow, improve safety, and reduce operational costs. Key considerations include understanding the specific needs of your facility, such as the type of materials being handled, the required load capacities, and the integration with existing conveyor systems.

Investing in high-quality conveyor gates—whether gas spring, roller, or skatewheel types—can lead to significant long-term savings. With features like easy installation, low maintenance, and energy efficiency, these systems not only streamline operations but also create safer work environments.

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who offer customizable solutions, quick turnaround times, and strong support networks. By embracing innovative conveyor gate technologies, businesses can position themselves for growth and adaptability in an ever-evolving marketplace. Engage with suppliers today to ensure your material handling systems are equipped for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.