Choosing Your Continuos Hinge: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for continuos hinge

In today’s global marketplace, sourcing continuous hinges can be a daunting challenge for international B2B buyers. With applications ranging from high-traffic commercial doors in airports and schools to specialized uses in medical facilities and hotels, selecting the right continuous hinge is crucial for operational efficiency and longevity. This guide is designed to illuminate the complexities of the continuous hinge market, offering insights into various types, their specific applications, and key considerations for supplier vetting and cost analysis.

Navigating this diverse landscape requires an understanding of the different materials, such as aluminum and stainless steel, and hinge designs available in the market. Buyers from regions including Africa, South America, the Middle East, and Europe will find valuable information tailored to their unique sourcing needs, empowering them to make informed purchasing decisions. By addressing critical questions regarding durability, load capacity, and finish options, this guide equips international buyers with the knowledge needed to choose the best continuous hinge solutions for their specific requirements.

Furthermore, we will explore effective strategies for evaluating suppliers, ensuring quality assurance, and understanding the implications of shipping and logistics in the global supply chain. Whether you are looking to enhance the functionality of commercial doors or optimize your manufacturing processes, this comprehensive resource will serve as your roadmap to success in sourcing continuous hinges.

Understanding continuos hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Continuous Geared Hinge | Features geared teeth along the entire length, suitable for high-traffic doors. | Airports, schools, hospitals, commercial buildings | Pros: Durable, suitable for heavy use; Cons: Higher initial cost compared to standard hinges. |

| Continuous Piano Hinge | Long, narrow design with a consistent width, often made of aluminum or stainless steel. | Cabinets, furniture, and lightweight doors | Pros: Smooth operation, versatile; Cons: May require specific installation techniques. |

| Full Mortise Continuous Hinge | Installed flush with the door and frame, providing a clean aesthetic. | High-end residential and commercial applications | Pros: Enhanced aesthetics, minimal protrusion; Cons: Complex installation process. |

| Full Surface Continuous Hinge | Mounted on the surface of the door and frame, easy to install and replace. | Industrial doors, gates, and heavy equipment | Pros: Simple installation, strong support; Cons: Less visually appealing than mortised options. |

| Concealed Continuous Hinge | Hidden from view when the door is closed, offering a sleek look. | High-end cabinetry, custom doors | Pros: Aesthetically pleasing, space-saving; Cons: Can be more expensive and requires precise fitting. |

What Are the Key Characteristics of Continuous Geared Hinges?

Continuous geared hinges are designed with interlocking gears that facilitate smooth and consistent door movement, making them ideal for high-traffic environments. Their robust construction allows them to bear substantial weight, making them suitable for large doors found in airports, stadiums, and hospitals. When considering a purchase, buyers should assess the hinge’s load capacity and the specific demands of their application, as the initial investment may be higher than traditional hinges.

How Do Continuous Piano Hinges Differ from Other Types?

Continuous piano hinges are characterized by their long, narrow design, which provides stability across the entire length of the door or panel. Made from materials like aluminum or stainless steel, they are lightweight yet durable, making them suitable for cabinets and lightweight doors. Buyers should consider the hinge’s material and thickness based on their specific application, as this will affect both longevity and performance.

What Advantages Do Full Mortise Continuous Hinges Offer?

Full mortise continuous hinges are installed flush with the door and frame, providing a seamless look that enhances the aesthetic appeal of high-end residential and commercial spaces. Their design allows for smooth operation and minimizes wear on both the hinge and the door. However, buyers should be prepared for a more complex installation process, which may require specialized tools and skills.

Why Choose Full Surface Continuous Hinges for Industrial Applications?

Full surface continuous hinges are mounted directly onto the surface of the door and frame, making them straightforward to install and replace. They are particularly effective in industrial settings where heavy equipment and doors are common. While they provide strong support and are easy to maintain, buyers should be aware that they may not offer the same aesthetic appeal as mortised options.

What Makes Concealed Continuous Hinges Ideal for High-End Applications?

Concealed continuous hinges are designed to be hidden from view when the door is closed, making them an excellent choice for high-end cabinetry and custom doors. Their sleek appearance contributes to a modern aesthetic, while their design allows for efficient space use. However, buyers should consider the precision required for installation and the potentially higher costs associated with these hinges.

Key Industrial Applications of continuos hinge

| Industry/Sector | Specific Application of Continuous Hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Construction | High-traffic doors in airports and stadiums | Enhanced durability and security for frequent use | Material specifications, weight capacity, and corrosion resistance |

| Healthcare | Hospital room doors and medical cabinets | Improved hygiene and ease of access for medical staff | Compliance with health regulations and ease of cleaning |

| Transportation | Train and bus doors | Reliable operation under varying weather conditions | Weatherproofing, maintenance requirements, and safety standards |

| Manufacturing | Factory equipment access panels | Streamlined access for maintenance and operational efficiency | Load capacity, material compatibility, and customization options |

| Retail | Storefront entry doors and display cases | Aesthetically pleasing design while ensuring security | Design options, finish quality, and installation ease |

How is Continuous Hinge Used in Commercial Construction?

In the commercial construction sector, continuous hinges are critical for high-traffic applications such as airport and stadium doors. These hinges provide enhanced durability and security, essential for environments that experience frequent use. Buyers in this sector should prioritize material specifications, such as stainless steel or aluminum, to ensure longevity and corrosion resistance, especially in humid or coastal regions. Additionally, weight capacity is crucial to accommodate heavy doors without compromising performance.

Illustrative image related to continuos hinge

What Role Does Continuous Hinge Play in Healthcare Settings?

In healthcare environments, continuous hinges are commonly used for hospital room doors and medical cabinets. Their design allows for smooth operation, which is vital for medical staff who require quick access to treatment areas. The hinges also contribute to improved hygiene, as they can be easier to clean than traditional hinges. Buyers should consider compliance with health regulations and the need for materials that withstand frequent cleaning and disinfection processes, ensuring that they meet the stringent requirements of healthcare facilities.

How is Continuous Hinge Beneficial in Transportation?

The transportation sector utilizes continuous hinges for train and bus doors, where reliability is paramount. These hinges must operate smoothly under various weather conditions, ensuring passenger safety and comfort. Buyers should focus on sourcing hinges that offer weatherproofing features and comply with relevant safety standards. Additionally, maintenance requirements should be minimal to prevent operational downtime, making it essential to evaluate the durability and ease of upkeep of the selected hinges.

Why are Continuous Hinges Important in Manufacturing?

In manufacturing, continuous hinges are often used on access panels for machinery and equipment. These hinges facilitate easy access for maintenance, which is crucial for operational efficiency. Businesses should consider load capacity and material compatibility when sourcing continuous hinges to ensure they can withstand the demands of heavy industrial use. Customization options may also be important to fit specific machinery designs and operational needs, allowing for a tailored solution that enhances productivity.

What Advantages Do Continuous Hinges Offer in Retail?

In the retail industry, continuous hinges are applied in storefront entry doors and display cases, where both aesthetics and security are vital. These hinges provide a clean, streamlined look while ensuring robust security against unauthorized access. Buyers should evaluate design options and finish quality to match their brand image, as well as the ease of installation. Additionally, considering the long-term performance and maintenance of the hinges can help retailers maintain a welcoming environment for customers while safeguarding their assets.

3 Common User Pain Points for ‘continuos hinge’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Continuous Hinge for High-Traffic Areas

The Problem: B2B buyers often struggle with identifying the appropriate continuous hinge for high-traffic environments, such as airports, hospitals, or schools. These locations demand hinges that can withstand frequent usage without compromising durability or functionality. Buyers might face challenges in finding hinges that not only meet the required load specifications but also align with aesthetic considerations and regulatory standards. Moreover, the risk of selecting subpar products can lead to costly repairs and replacements, resulting in operational downtime and increased maintenance expenses.

The Solution: To overcome this sourcing challenge, buyers should conduct a thorough needs assessment that includes understanding the traffic patterns and load requirements of their specific application. Engaging with reputable suppliers who specialize in continuous hinges is crucial. They can provide detailed specifications, including load ratings, material types (such as aluminum or stainless steel), and finish options that align with the overall design of the facility. Additionally, buyers should consider investing in samples or prototypes to test the hinges under real-world conditions before making a bulk purchase. This proactive approach ensures that the selected hinges will perform reliably in high-traffic situations.

Scenario 2: Installation Complexity Leading to Project Delays

The Problem: Many B2B buyers encounter installation complexities when working with continuous hinges, especially in commercial settings where precision is critical. The intricacies of aligning the hinge correctly, ensuring proper load distribution, and achieving smooth operation can be daunting. Poor installation can result in misaligned doors, increased wear and tear on the hinges, and potential safety hazards. As a result, project timelines may be extended, leading to dissatisfaction among stakeholders and potential financial repercussions.

The Solution: To mitigate installation issues, buyers should invest in comprehensive training for their installation teams. This can include workshops or online tutorials provided by hinge manufacturers that cover best practices for installation. Additionally, utilizing installation guides and templates specific to the continuous hinge model can streamline the process. Buyers should also consider collaborating with experienced contractors or hinge specialists during the initial phases of installation to ensure that the process adheres to best practices. By prioritizing proper installation techniques, organizations can enhance the longevity and functionality of their continuous hinges while keeping projects on schedule.

Scenario 3: Ensuring Compliance with Safety Standards and Regulations

The Problem: Compliance with safety standards and building regulations can pose significant challenges for B2B buyers sourcing continuous hinges. In many regions, specific codes dictate the types of hardware that can be used in commercial applications, particularly in public buildings like schools and hospitals. Failing to meet these regulations can lead to legal liabilities, increased scrutiny from regulatory bodies, and the need for costly retrofitting. Buyers may feel overwhelmed by the constantly evolving landscape of building codes and the implications for their hinge choices.

The Solution: To navigate compliance challenges effectively, buyers should stay informed about local and international building codes relevant to their projects. This can be achieved by consulting with industry associations or regulatory bodies that provide updates on safety standards. Additionally, partnering with suppliers who offer hinges specifically designed to meet these codes can simplify the process. Many manufacturers provide certifications and documentation that demonstrate compliance, which can be invaluable during inspections. Buyers should also consider conducting regular audits of their hardware choices to ensure ongoing compliance, helping to mitigate risks associated with non-compliance and reinforcing a commitment to safety.

Strategic Material Selection Guide for continuos hinge

What Are the Key Properties of Common Materials Used in Continuous Hinges?

When selecting materials for continuous hinges, several options stand out due to their unique properties and applications. The most common materials include stainless steel, aluminum, brass, and plastic. Each material offers distinct advantages and disadvantages that can significantly impact performance, durability, and suitability for specific applications.

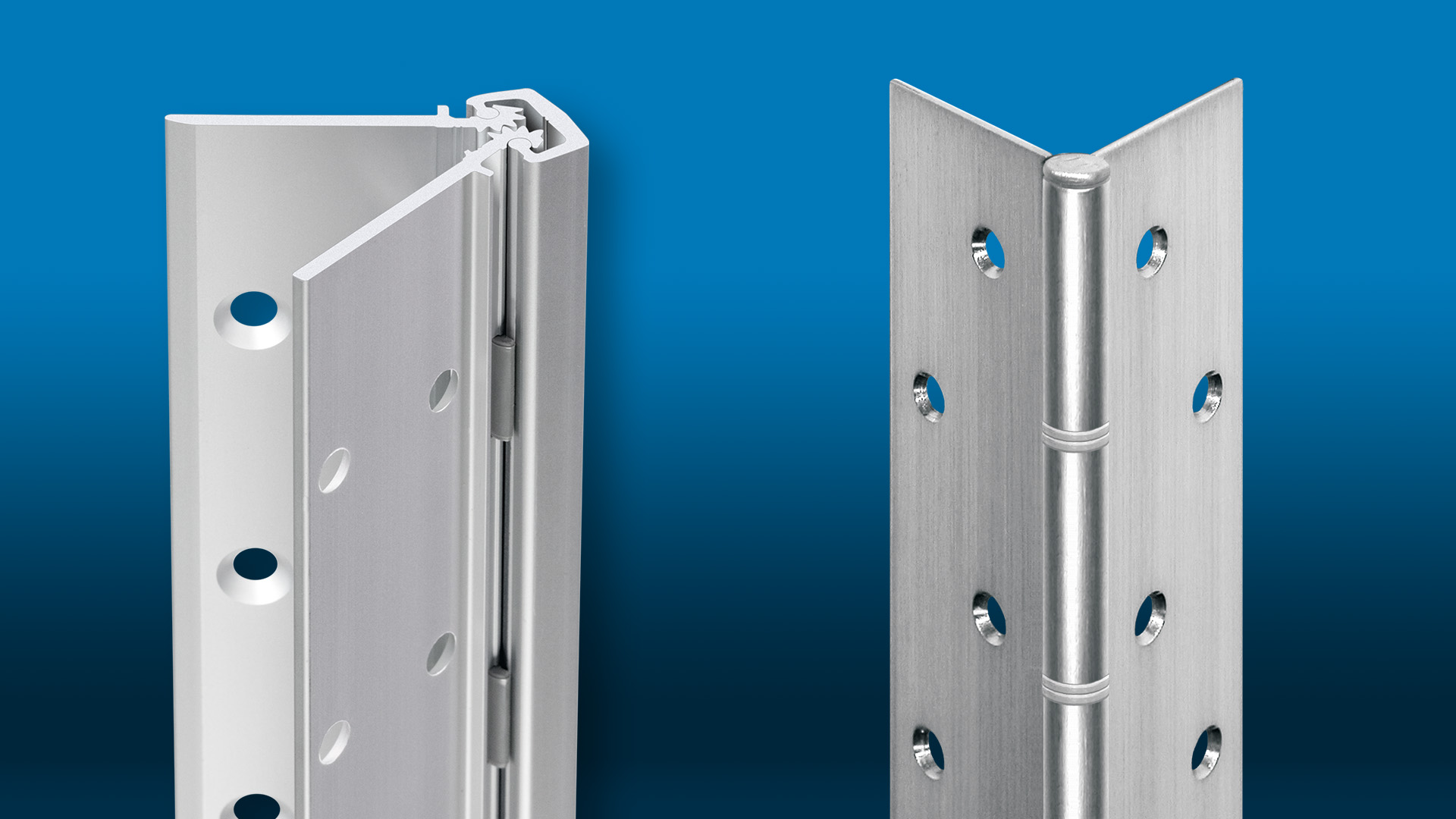

How Does Stainless Steel Perform in Continuous Hinge Applications?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it ideal for high-traffic environments and outdoor applications. It can withstand extreme temperatures and pressures, which is essential in industries such as construction and transportation. The primary advantage of stainless steel is its durability, ensuring longevity even in harsh conditions. However, the cost can be relatively high compared to other materials, which may deter budget-conscious buyers. Furthermore, manufacturing stainless steel hinges can be complex, requiring specialized equipment and processes.

For international buyers, particularly in regions with stringent environmental regulations like Europe, compliance with standards such as ASTM and DIN is crucial. Stainless steel hinges often meet these standards, making them a reliable choice for various applications.

Illustrative image related to continuos hinge

What Are the Benefits of Using Aluminum for Continuous Hinges?

Aluminum is a lightweight and cost-effective alternative to stainless steel. It exhibits good corrosion resistance and is suitable for applications where weight is a concern, such as in aviation or portable structures. The manufacturing process for aluminum hinges is generally simpler, allowing for quicker production times and lower costs. However, aluminum may not be as durable as stainless steel, particularly in high-impact situations.

International buyers should consider the specific applications of aluminum hinges in their regions. For instance, in humid climates like parts of South America and Southeast Asia, the corrosion resistance of aluminum may be beneficial, but buyers should ensure that the material meets local compliance standards.

How Does Brass Compare in Terms of Aesthetic Appeal and Performance?

Brass is often chosen for its aesthetic appeal, as it provides a classic look that can enhance the design of doors and cabinets. It possesses good corrosion resistance and is particularly well-suited for indoor applications. However, brass is softer than stainless steel and aluminum, which may limit its use in high-traffic areas. Additionally, the cost of brass can be higher than aluminum, making it less attractive for large-scale projects.

For international buyers, especially in Europe and the Middle East, brass hinges may need to comply with specific design and quality standards. The visual appeal of brass can be a selling point in markets where aesthetics are prioritized.

Illustrative image related to continuos hinge

What Role Does Plastic Play in Continuous Hinge Applications?

Plastic hinges are lightweight, inexpensive, and resistant to corrosion, making them suitable for various applications, including residential and light commercial use. They are particularly advantageous in environments where moisture is prevalent, as they do not rust or corrode. However, plastic hinges may lack the strength and durability of metal options, limiting their use in high-stress applications.

International buyers should consider the environmental impact of plastic materials, as regulations regarding plastic use are becoming stricter in many regions. Compliance with local standards is essential, particularly in Europe, where sustainability is a significant concern.

Summary Table of Material Selection for Continuous Hinges

| Material | Typical Use Case for continuous hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-traffic commercial doors | Exceptional durability and strength | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight and portable structures | Cost-effective and lightweight | Less durable than stainless steel | Medium |

| Brass | Decorative applications in residential settings | Aesthetic appeal and good corrosion resistance | Softer material, less suitable for high-traffic areas | Medium |

| Plastic | Residential and light commercial applications | Lightweight and corrosion-resistant | Limited strength and durability | Low |

This strategic material selection guide provides a comprehensive overview of the most common materials used in continuous hinges, offering valuable insights for international B2B buyers. Understanding the properties, advantages, and limitations of each material can significantly influence purchasing decisions and ensure that the selected hinges meet specific application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for continuos hinge

What Are the Key Manufacturing Processes for Continuous Hinges?

The manufacturing of continuous hinges is a multi-stage process that ensures both functionality and durability. It typically involves the following main stages:

-

Material Preparation: The first step involves selecting the right material, often aluminum or stainless steel, due to their strength and resistance to corrosion. Sheets of metal are inspected for defects before being cut into specific dimensions based on product requirements. This stage may also include the treatment of materials to enhance their properties, such as anodizing aluminum to improve corrosion resistance.

-

Forming: After preparation, the metal sheets undergo forming processes. Techniques like stamping or laser cutting are employed to create the hinge’s leaf and pin. Precision is critical here, as any inaccuracies can affect the hinge’s functionality. Advanced machinery, such as CNC (Computer Numerical Control) machines, is commonly used to ensure high precision in the shaping and cutting of metal.

-

Assembly: Once the individual components are formed, they are assembled. This may involve welding or riveting the leaves to the pin, depending on the design specifications. For geared continuous hinges, special care is taken to align the geared teeth accurately to ensure smooth operation. Automated assembly lines may be utilized to improve efficiency and reduce labor costs.

-

Finishing: The final stage involves applying finishes to the hinges. This can include powder coating, painting, or electroplating, which not only enhances aesthetic appeal but also adds an extra layer of protection against wear and corrosion. Quality checks are performed throughout the finishing process to ensure that the coatings are applied uniformly and meet industry standards.

How Is Quality Assurance Integrated into the Manufacturing of Continuous Hinges?

Quality assurance (QA) is a critical component of the manufacturing process for continuous hinges, ensuring that the final products meet both international and industry-specific standards. The following are key aspects of quality assurance in hinge manufacturing:

-

Adherence to International Standards: Many manufacturers comply with ISO 9001, which outlines the requirements for a quality management system. This certification ensures that the manufacturer has processes in place for continuous improvement and customer satisfaction. In addition, compliance with industry-specific standards such as CE marking for products sold in Europe or API standards for specific applications can be crucial for B2B buyers.

-

Quality Control Checkpoints: Quality control (QC) is implemented at various stages of the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt to ensure they meet specifications.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor compliance with design specifications and tolerances.

– Final Quality Control (FQC): Once the hinges are assembled and finished, they undergo comprehensive testing to ensure they function correctly and meet all quality standards. -

Common Testing Methods: Various testing methods are employed to verify the quality of continuous hinges, including:

– Load Testing: Ensures that hinges can withstand the required weight and force without deformation.

– Corrosion Resistance Testing: Evaluates the durability of finishes under environmental stress.

– Cycle Testing: Simulates repeated opening and closing to assess the hinge’s longevity.

What Can B2B Buyers Do to Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with standards. Here are actionable steps buyers can take:

-

Conduct Audits: Requesting a factory audit can provide insight into the manufacturing processes and quality control measures in place. This allows buyers to assess the capabilities and practices of potential suppliers firsthand.

-

Review Quality Assurance Reports: Suppliers should provide documentation of their quality assurance processes, including inspection reports and compliance certificates. Reviewing these documents can give buyers confidence in the supplier’s commitment to quality.

-

Engage Third-Party Inspection Services: Utilizing independent third-party inspection services can add an extra layer of verification. These services can assess product quality before shipment, ensuring that the products meet specified requirements and standards.

-

Understand Regional Certification Nuances: Buyers should familiarize themselves with the specific quality certification requirements in their regions. For instance, products sold in the European market must comply with CE marking requirements, while those in the Middle East may have different regulations. Understanding these nuances helps in selecting compliant suppliers.

What Are the Benefits of Rigorous Quality Assurance for Continuous Hinges?

Implementing rigorous quality assurance measures in the manufacturing of continuous hinges offers numerous benefits to both manufacturers and buyers. These include:

-

Enhanced Product Reliability: Consistent quality control leads to products that perform reliably over time, reducing the likelihood of failures in high-traffic applications such as commercial buildings and public spaces.

-

Improved Customer Satisfaction: High-quality products contribute to customer satisfaction, fostering loyalty and repeat business. For B2B buyers, this is crucial as they depend on reliable components for their own products or services.

-

Reduced Costs: Effective quality assurance processes can minimize defects and rework, ultimately reducing production costs. For buyers, this translates into better pricing and fewer disruptions in their supply chain.

-

Market Competitiveness: Manufacturers that prioritize quality assurance can differentiate themselves in the marketplace. This reputation for quality can lead to increased sales and market share, particularly in competitive industries.

By understanding the manufacturing processes and quality assurance measures associated with continuous hinges, B2B buyers can make informed decisions that align with their operational needs and standards. This knowledge not only aids in supplier selection but also enhances the overall efficiency and effectiveness of their procurement strategies.

Illustrative image related to continuos hinge

Practical Sourcing Guide: A Step-by-Step Checklist for ‘continuos hinge’

To assist B2B buyers in navigating the procurement of continuous hinges, this guide provides a structured checklist that outlines critical steps in the sourcing process. Continuous hinges, known for their durability and suitability for high-traffic applications, require careful consideration to ensure compatibility and performance. Use this checklist to streamline your sourcing efforts and make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for identifying the right continuous hinge for your needs. Consider factors such as material (e.g., aluminum or stainless steel), size, weight capacity, and finish. This step ensures that the hinges will meet the operational demands of your application, whether it’s for commercial doors, cabinets, or gates.

Step 2: Research Supplier Options

Conduct comprehensive research to identify potential suppliers of continuous hinges. Look for manufacturers with a strong market presence and positive reviews. Focus on suppliers who specialize in hinges and have experience serving your specific industry, as they are more likely to understand your unique requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality control processes, and delivery timelines. Ensure they can meet your order quantities and deadlines.

- Check Certifications: Verify that suppliers hold relevant industry certifications, which can indicate adherence to quality and safety standards.

Step 4: Request Samples

Obtaining samples of the continuous hinges is a vital step before making a bulk purchase. This allows you to assess the quality, functionality, and compatibility with your existing systems. Pay attention to the hinge’s movement, durability, and ease of installation.

Illustrative image related to continuos hinge

Step 5: Compare Pricing and Terms

Once you have narrowed down your options, compare pricing among suppliers. Look beyond just the unit price; consider shipping costs, bulk discounts, and payment terms. Understanding the total cost of ownership will help you evaluate the best value for your investment.

Step 6: Inquire About Warranty and Support

A robust warranty and support structure are indicators of a reliable supplier. Confirm the warranty terms for the continuous hinges and ensure you have access to customer support for installation or maintenance queries. This is crucial for minimizing downtime in your operations.

Step 7: Finalize Your Order

After thorough evaluation and comparison, proceed to finalize your order. Ensure that all specifications, quantities, and delivery timelines are clearly outlined in the purchase agreement. Maintain open communication with the supplier throughout the process to address any potential issues proactively.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing continuous hinges, ensuring they select the best products for their specific applications while optimizing cost and quality.

Comprehensive Cost and Pricing Analysis for continuos hinge Sourcing

What Are the Key Cost Components for Continuous Hinge Sourcing?

When evaluating the cost structure of continuous hinges, several key components come into play. The material cost is significant, with aluminum and stainless steel being the most common choices due to their durability and lightweight properties. Prices can vary based on the alloy composition and treatment processes, influencing the overall hinge performance and longevity.

Labor costs encompass the wages paid to workers involved in manufacturing, assembly, and quality control. In regions with higher labor costs, such as parts of Europe, this can significantly affect the final price. Manufacturing overhead includes expenses related to facility operations, utilities, and equipment depreciation, which also contribute to the total cost.

Another important aspect is tooling costs, which refer to the investment in molds and machinery needed for production. This is particularly relevant for custom hinges where specific shapes or designs are required. Quality control (QC) measures ensure that the hinges meet industry standards, adding another layer of cost.

Finally, logistics plays a crucial role in the pricing structure. The cost of transporting hinges from the manufacturer to the buyer, including warehousing and handling, must be factored in.

How Do Price Influencers Impact Continuous Hinge Costs?

Several factors can influence the pricing of continuous hinges. The volume of order or minimum order quantity (MOQ) can lead to bulk discounts, significantly lowering the per-unit price. Buyers who commit to larger orders are often in a better position to negotiate favorable terms.

Customization and specific specifications can also affect pricing. Custom designs or finishes may incur additional costs, so it’s essential to understand the trade-offs between standard products and tailored solutions. The quality of materials used, along with any certifications (such as ISO), can further influence the price, as higher-quality products typically command a premium.

Supplier factors, including their reputation, reliability, and location, can also affect costs. For instance, sourcing from local suppliers may reduce logistics costs but could lead to higher material expenses compared to overseas manufacturers.

Additionally, understanding Incoterms—the international commercial terms that define the responsibilities of buyers and sellers—can help buyers manage logistics and shipping costs effectively.

What Are Essential Buyer Tips for Cost-Efficient Continuous Hinge Procurement?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, adopting strategic purchasing practices can lead to significant savings. One effective approach is to focus on negotiation tactics. Engaging in open discussions with suppliers about pricing, payment terms, and lead times can yield better deals.

Considering the Total Cost of Ownership (TCO) is crucial. This concept goes beyond the initial purchase price and includes maintenance, potential downtime, and longevity of the product. A slightly higher upfront cost for a durable hinge may lead to lower replacement and maintenance costs over time.

Understanding pricing nuances specific to international procurement is also beneficial. Currency fluctuations can impact costs, and buyers should account for potential tariffs or taxes when importing hinges.

Lastly, keeping abreast of market trends and supplier capabilities can position buyers to make informed decisions. Regularly reviewing supplier performance and market conditions allows for proactive adjustments in sourcing strategies, ensuring optimal cost management and quality assurance.

Disclaimer on Pricing

It is important to note that the prices mentioned in this analysis are indicative and can vary widely based on specific requirements, supplier agreements, and market conditions. Buyers should conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing information tailored to their needs.

Alternatives Analysis: Comparing continuos hinge With Other Solutions

Exploring Alternatives to Continuous Hinges for B2B Applications

In the realm of industrial and commercial hardware, continuous hinges serve a unique purpose by providing robust support for doors and gates. However, buyers often explore alternatives that may better suit their specific needs, whether those needs are driven by cost, performance, or maintenance considerations. This analysis compares continuous hinges against two viable alternatives: butt hinges and pivot hinges. Each option has distinct advantages and disadvantages, making it essential for B2B buyers to assess which solution aligns best with their operational requirements.

| Comparison Aspect | Continuous Hinge | Butt Hinges | Pivot Hinges |

|---|---|---|---|

| Performance | High durability; supports heavy doors; smooth operation | Suitable for lighter doors; limited range of motion | Allows for 180-degree opening; ideal for space-saving |

| Cost | Higher upfront cost; long lifespan | Lower initial cost; may require more frequent replacement | Moderate cost; installation can be complex |

| Ease of Implementation | Requires precise installation; typically more labor-intensive | Easy to install; widely available | Installation may require specialized tools |

| Maintenance | Low maintenance; durable construction | Moderate maintenance; can wear out over time | Low maintenance; minimal wear |

| Best Use Case | High-traffic environments (e.g., airports, schools) | Residential doors, cabinets | Commercial settings requiring space efficiency |

In-Depth Analysis of Alternatives

Butt Hinges

Butt hinges are one of the most common types of hinges used in various applications, particularly in residential settings. They consist of two plates, or leaves, that are joined by a pin. One of the main advantages of butt hinges is their ease of installation, making them accessible for smaller projects or DIY applications. They are also cost-effective, which is appealing for budget-conscious buyers. However, their performance is limited to lighter doors, and they may require more frequent replacement in high-traffic areas, leading to higher long-term costs.

Pivot Hinges

Pivot hinges offer a unique solution for doors that need to swing open fully without the constraints of traditional hinges. They are designed to support the weight of the door at its top and bottom, allowing for a full 180-degree opening. This makes them particularly useful in tight spaces where standard hinges may not provide adequate clearance. While pivot hinges can be moderately priced, their installation may require specialized tools and expertise, which could be a barrier for some buyers. However, once installed, they require minimal maintenance and can last a long time in commercial settings.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the best hinge solution for your business, it’s crucial to evaluate your specific requirements and operational environment. Continuous hinges excel in high-traffic situations where durability and longevity are paramount, making them ideal for commercial buildings. Conversely, if your project involves lighter doors or requires a more budget-friendly option, butt hinges may be suitable. For applications where space is a concern, pivot hinges can provide an innovative solution. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for continuos hinge

What Are the Key Technical Properties of Continuous Hinges?

Understanding the technical properties of continuous hinges is crucial for international B2B buyers to ensure they select the right product for their specific applications. Here are some essential specifications:

Illustrative image related to continuos hinge

-

Material Grade

Continuous hinges are commonly made from materials such as stainless steel, aluminum, or brass. Stainless steel offers excellent corrosion resistance and strength, making it ideal for outdoor or high-moisture environments. Aluminum, being lightweight, is often used in applications where weight savings are critical, while brass is chosen for aesthetic appeal and moderate strength. -

Length and Width Dimensions

The dimensions of continuous hinges are vital for compatibility with doors and frames. Standard lengths vary, typically ranging from 48 inches to 120 inches, while widths can affect the hinge’s load-bearing capacity and ease of installation. Buyers should measure their door specifications accurately to avoid mismatches. -

Load Capacity

This specification indicates the maximum weight the hinge can support. It is essential for ensuring durability and functionality in high-traffic environments like airports or hospitals. A hinge with inadequate load capacity can lead to failure, resulting in costly repairs and safety hazards. -

Material Thickness

The thickness of the material affects the hinge’s strength and durability. For example, a hinge with a thickness of 0.120 inches is more robust and suited for heavy-duty applications compared to thinner alternatives. Buyers should consider the expected wear and tear of their specific use cases when evaluating material thickness. -

Finish

The finish of a continuous hinge (e.g., anodized, powder-coated, or polished) not only impacts aesthetics but also enhances resistance to rust and corrosion. Selecting the right finish can prolong the hinge’s lifespan, especially in harsh environments. -

Tolerance

Tolerance refers to the allowable variation in dimensions and is crucial for ensuring that hinges fit correctly during installation. High tolerance levels are especially important in precision applications where misalignment can cause operational issues.

What Are Common Trade Terms Related to Continuous Hinges?

Familiarity with industry jargon can help B2B buyers navigate the procurement process more effectively. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding the OEM can help buyers identify trusted sources for continuous hinges that meet specific quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is critical for buyers to consider, as it can affect inventory management and cash flow. Knowing the MOQ helps buyers negotiate better terms and plan their purchases accordingly. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes details about the product specifications, quantities, and delivery requirements. Crafting a clear RFQ can streamline the purchasing process and ensure that buyers receive competitive pricing. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and tariffs. Understanding Incoterms is essential for avoiding misunderstandings regarding costs and responsibilities in the global supply chain. -

Lead Time

Lead time is the period between placing an order and receiving the goods. This metric is crucial for project planning, as longer lead times can impact timelines, especially in industries requiring quick turnarounds. -

Certification Standards

These are industry benchmarks that ensure products meet specific quality and safety requirements. Familiarity with relevant certification standards (such as ISO or ASTM) can help buyers assess the reliability of their suppliers and the products they offer.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding continuous hinges, ensuring they choose the right products for their projects while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the continuos hinge Sector

What Are the Key Market Drivers and Trends in the Continuous Hinge Sector?

The continuous hinge sector is witnessing a dynamic evolution, driven by several global factors. The increasing demand for durable and efficient hardware solutions in high-traffic environments—such as airports, hospitals, and commercial buildings—is a significant market driver. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on sourcing high-quality continuous hinges that can withstand rigorous usage. The trend towards lightweight yet robust materials, such as aluminum, is gaining traction, offering an attractive balance between performance and cost-effectiveness.

Emerging technologies are reshaping the sourcing landscape as well. The integration of e-commerce platforms and digital supply chain management tools is streamlining procurement processes, enabling buyers to access a broader range of products and manufacturers globally. Additionally, the rise of automation in manufacturing is enhancing the precision and quality of continuous hinges, which is crucial for meeting the strict standards demanded by modern construction and architectural projects. Buyers are increasingly looking for suppliers who can provide not just the product, but also detailed specifications and customization options to suit their specific needs.

Illustrative image related to continuos hinge

How Is Sustainability Shaping Sourcing Decisions in the Continuous Hinge Market?

Sustainability is becoming a core consideration for B2B buyers in the continuous hinge sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who adopt sustainable practices and materials. The use of recycled metals, such as aluminum, and adherence to eco-friendly manufacturing processes can significantly reduce the carbon footprint associated with product sourcing.

Ethical sourcing is also gaining importance, as businesses strive to establish transparent supply chains that prioritize fair labor practices and responsible sourcing. Certifications like LEED (Leadership in Energy and Environmental Design) and the use of green materials are becoming essential criteria for many buyers. This trend not only aligns with corporate social responsibility goals but also appeals to environmentally conscious consumers and stakeholders, enhancing brand reputation and market competitiveness.

What Is the Historical Context of Continuous Hinges in the B2B Landscape?

The continuous hinge, also known as a piano hinge, has a rich history dating back to the early 19th century when it was first used in the construction of pianos. Its design, characterized by a long, continuous leaf that runs the entire length of the door, provided enhanced stability and support compared to traditional hinges. Over time, its application expanded beyond musical instruments to a wide array of architectural and industrial uses, particularly in settings requiring durability and reliability.

The evolution of materials has also played a significant role in the continuous hinge market. Originally crafted from heavy metals, advancements in manufacturing have introduced lightweight and corrosion-resistant materials, such as aluminum and stainless steel, which offer improved performance and longevity. This historical context underlines the continuous hinge’s adaptability and relevance in modern B2B applications, reflecting an enduring demand for high-quality hardware solutions across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of continuos hinge

-

1. How do I solve issues with continuous hinge installation?

To resolve installation issues with continuous hinges, first ensure that the door and frame are properly aligned. Use a level to check that the door swings evenly. If misalignment persists, consider adjusting the hinge placement or using shims to level the door. Additionally, verify that the screws are securely tightened and that the hinge is free from obstructions. For complex installations, consulting a professional or referring to specific manufacturer installation guides can also be beneficial. -

2. What is the best continuous hinge for high-traffic environments?

For high-traffic environments, such as airports or hospitals, heavy-duty continuous geared hinges are recommended. These hinges feature reinforced construction and geared teeth that provide smooth operation and durability under frequent use. Look for hinges made from corrosion-resistant materials, like stainless steel or aluminum, to ensure longevity. Additionally, consider the hinge’s load rating and size to match the specific door requirements, ensuring optimal performance in demanding conditions. -

3. How can I customize continuous hinges to fit my specific application?

Customization options for continuous hinges typically include size, material, and finish. Many manufacturers offer bespoke solutions where you can specify dimensions, pin diameter, and material thickness. It’s advisable to reach out directly to suppliers with your requirements and request product samples or drawings. Be clear about your application, whether it’s for a commercial or industrial setting, as this will help suppliers recommend the best options tailored to your needs. -

4. What are the minimum order quantities (MOQs) for continuous hinges?

Minimum order quantities for continuous hinges can vary significantly among suppliers. Some may require a MOQ of 50 units, while others might be flexible with smaller orders, especially for customized products. Always inquire about MOQs when sourcing to ensure they align with your project needs. Additionally, consider the potential for bulk discounts on larger orders, which can provide cost savings for your business. -

5. What payment terms should I expect when sourcing continuous hinges internationally?

Payment terms for international orders of continuous hinges often depend on the supplier’s policies and your relationship with them. Common terms include upfront payment, a deposit followed by balance payment before shipping, or net terms like 30 or 60 days post-invoice. It’s crucial to clarify these terms in advance and consider using secure payment methods such as letters of credit to mitigate risks in international transactions. -

6. How do I vet suppliers for continuous hinges?

To vet suppliers effectively, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients, particularly in your region. Verify their certifications and compliance with international standards, such as ISO, to ensure quality assurance. Additionally, consider requesting samples and assessing their customer service responsiveness to gauge their reliability and support capabilities. -

7. What quality assurance measures should I consider for continuous hinges?

Quality assurance measures for continuous hinges should include adherence to recognized industry standards, such as ASTM or EN specifications. Request documentation from suppliers that demonstrates their quality control processes, including material testing and performance evaluations. Additionally, consider conducting third-party inspections or audits, especially for large orders, to ensure that the products meet your specifications and standards before they are shipped. -

8. What logistics considerations are important when importing continuous hinges?

When importing continuous hinges, logistics considerations include shipping methods, customs clearance, and lead times. Determine the most cost-effective and timely shipping options based on your location and urgency. Familiarize yourself with import regulations and tariffs in your country to avoid unexpected costs. Additionally, communicate with your supplier about packaging and labeling requirements to ensure compliance and facilitate a smooth delivery process.

Top 9 Continuos Hinge Manufacturers & Suppliers List

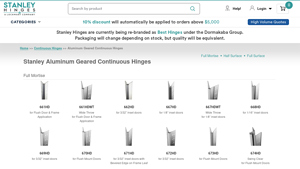

1. Stanley – Aluminum Geared Continuous Hinges

Domain: stanleyhinges.com

Registered: 2006 (19 years)

Introduction: Stanley Aluminum Geared Continuous Hinges include various models such as: 661HD (Full Mortise for Flush Door & Frame), 661HDWT (Wide Throw for Flush Door & Frame), 662HD (for 3/32″ inset doors), 667HD (for 1/8″ inset doors), 667HDWT (Wide Throw for 1/8″ inset doors), 668HD (for 1/16″ inset doors), 669HD (for 3/32″ inset doors), 670HD (for Flush Mount Doors), 671HD (for 3/32″ inset doors with Bevel…

2. Hinge Outlet – Continuous Geared Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Continuous Geared Hinges available at HingeOutlet. Free shipping on orders over $160. Trusted source for hinges and hardware for both commercial and residential applications. Includes a variety of door, cabinet, and gate hinges, along with specialty hinges and hardware. Expert support available at 888-250-8133.

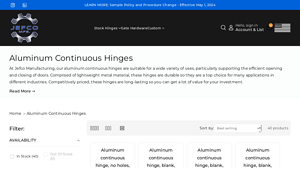

3. Jefco Manufacturing – Aluminum Continuous Hinges

Domain: jefcomfg.com

Registered: 1997 (28 years)

Introduction: Aluminum continuous hinges suitable for various applications, particularly for doors. Made from lightweight aluminum, these hinges are durable and competitively priced, offering long-lasting value. Available in standard 6-foot lengths with over 8 different widths measured in the open position. Material thickness ranges from 0.04 inches to 0.12 inches. Customizable options include knuckle length an…

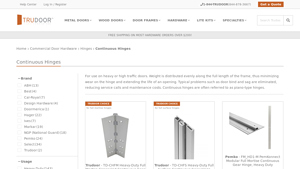

4. TruDoor – Continuous Hinges for Commercial Doors

Domain: trudoor.com

Registered: 2010 (15 years)

Introduction: Continuous Hinges for Commercial Doors, also known as piano-type hinges, are designed for heavy or high traffic doors. They distribute weight evenly along the full length of the frame, minimizing wear and extending the life of the opening. They eliminate common issues such as door bind and sag, reducing service calls and maintenance costs. Available in various types including Full Mortise, Full Su…

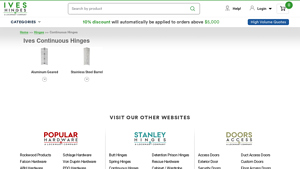

5. Ives – Continuous Hinges

Domain: iveshinges.com

Registered: 2007 (18 years)

Introduction: Ives Continuous Hinges include various models such as: 112HD Aluminum Geared Full Mortise Continuous Hinge, 112XY Aluminum Geared Full Mortise Continuous Hinge – Narrow Frame Leaf, 114XY Aluminum Geared Full Mortise Edge Protection, 224HD Aluminum Geared Full Mortise Edge Protection, 224XY Aluminum Geared Full Mortise Edge Protection, 157XY Aluminum Geared Full Surface Adjustable Continuous Hinge,…

6. SELECT – Premium Hinges

Domain: select-hinges.com

Registered: 1999 (26 years)

Introduction: SELECT offers a range of hinges including Geared Continuous, Concealed, Wide Throw, Swing Clear, Half Surface, Full Surface, Half Mortise, and Pin & Barrel hinges. The hinges are categorized into Standard Duty (now Heavy Duty 300) and Heavy Duty (now Heavy Duty 600). SELECT’s aluminum geared continuous hinges are designed for high-traffic commercial door openings, reducing maintenance costs and ou…

7. Pemko – Continuous Hinges

Domain: pemko.com

Registered: 1995 (30 years)

Introduction: Continuous hinges are designed for durability and strength, providing a seamless hinge solution for doors. They are available in various materials, including stainless steel and aluminum, and can be customized to fit specific door sizes and applications. Continuous hinges help to distribute weight evenly, reduce stress on the door and frame, and enhance security. They are suitable for high-traffic…

8. Beacon – Continuous Hinges

Domain: beaconcdl.com

Registered: 2017 (8 years)

Introduction: Continuous hinges are designed to match the full height of the door, carrying heavier doors and lasting longer than standard mortise or butt hinges. They distribute the weight of the door along the full height of the frame, reducing stress on the hinge and providing smooth operation for high traffic and high abuse areas. There are two main types of continuous hinges: 1. Aluminum Geared Continuous …

9. Roton – Roton 780-053HD Heavy Duty Half Surface Continuous Hinge

Domain: qualifiedhardware.com

Registered: 2006 (19 years)

Introduction: {“category”:”Continuous Hinges”,”brand”:”Roton”,”available_for”:”Continental U.S. only”,”shipping_info”:”Order in next 14 hours 8 minutes to ship tomorrow!”,”products”:[{“name”:”Roton 780-053HD Heavy Duty Half Surface Continuous Hinge”,”starting_price”:”$227.00″,”series”:”780″,”usage”:”Heavy Duty”},{“name”:”Roton 780-053 Standard Duty Half Surface Continuous Hinge”,”starting_price”:”$181.00″,”seri…

Strategic Sourcing Conclusion and Outlook for continuos hinge

In the evolving landscape of international trade, continuous hinges represent a critical element for businesses across various sectors, from commercial construction to specialized manufacturing. The strategic sourcing of these components not only enhances operational efficiency but also ensures durability and reliability in high-traffic applications. Buyers should prioritize suppliers who offer a range of options, including materials like aluminum and stainless steel, to meet diverse project requirements.

Illustrative image related to continuos hinge

Moreover, understanding the specific applications and benefits of continuous hinges can lead to better procurement decisions, ultimately impacting overall project success. As companies in Africa, South America, the Middle East, and Europe navigate their sourcing strategies, aligning with manufacturers that provide comprehensive technical support and customization options will be key to maximizing value.

Looking ahead, the demand for continuous hinges is expected to grow, driven by increasing infrastructure development and modernization projects. Now is the time for international B2B buyers to seize opportunities in this market. Engage with trusted suppliers, explore innovative hinge solutions, and ensure your sourcing strategies are robust to meet future challenges. Investing in quality hinges today will pave the way for operational excellence tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.