Choosing Your Cold Heading: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for cold heading

In today’s fast-paced manufacturing landscape, sourcing high-quality cold heading fasteners presents a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly rely on these efficient, cost-effective solutions for their production needs, understanding the intricacies of cold heading becomes paramount. This guide serves as a comprehensive resource, addressing key factors such as various types of cold heading processes, their applications in diverse sectors, and the critical aspects of supplier vetting.

Buyers will find valuable insights into the cold heading market, including the advantages of different manufacturing techniques, which can lead to improved product quality and reduced costs. We also delve into the importance of selecting the right suppliers, ensuring compliance with international standards, and evaluating cost structures to maximize value. By equipping B2B buyers with the knowledge and tools necessary for informed decision-making, this guide empowers businesses to navigate the complexities of sourcing cold heading fasteners effectively.

Whether you are based in Germany, Vietnam, or any other region, understanding the nuances of cold heading will enable you to enhance your production capabilities and maintain a competitive edge in the global market. Dive into this guide to unlock the potential of cold heading and make purchasing decisions that drive your business forward.

Understanding cold heading Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Upset Heading | Increases diameter while reducing height; creates heads | Automotive fasteners, construction bolts | Pros: Efficient, strong parts; Cons: Limited to specific shapes. |

| Extrusion | Material is forced through a die to change shape | Pipe fittings, structural components | Pros: Versatile shapes; Cons: May require complex tooling. |

| Multi-part Assembly | Combines several components into a single part | Aerospace, machinery manufacturing | Pros: Reduces assembly time; Cons: Higher initial costs. |

| Cold Forming | General term encompassing various cold heading methods | Fasteners, brackets, custom components | Pros: Cost-effective for large volumes; Cons: Initial setup can be expensive. |

| Secondary Operations | Additional processes post-cold heading (e.g., threading) | Complex fasteners, automotive parts | Pros: Enhances functionality; Cons: Adds to lead time. |

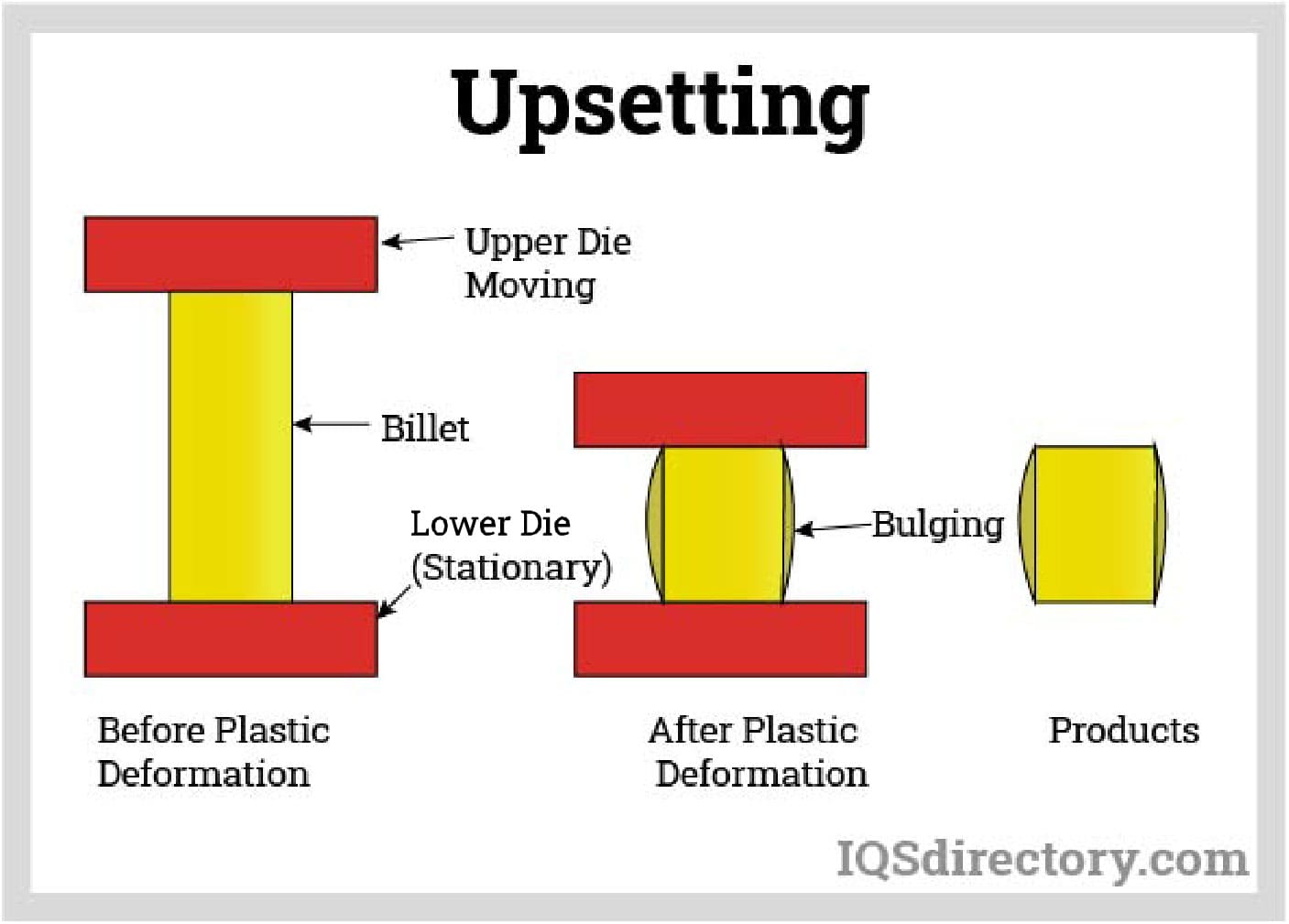

What Are the Characteristics of Upset Heading in Cold Heading?

Upset heading is characterized by the simultaneous increase in diameter and decrease in height of the metal slug. This method is commonly used to create heads on fasteners, making it ideal for applications in automotive and construction industries. B2B buyers should consider the specific shapes required, as upset heading is limited to certain configurations. The efficiency of this process results in strong, durable parts, making it a preferred choice for high-stress applications.

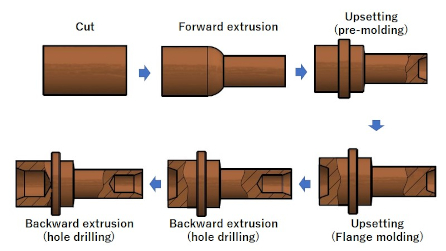

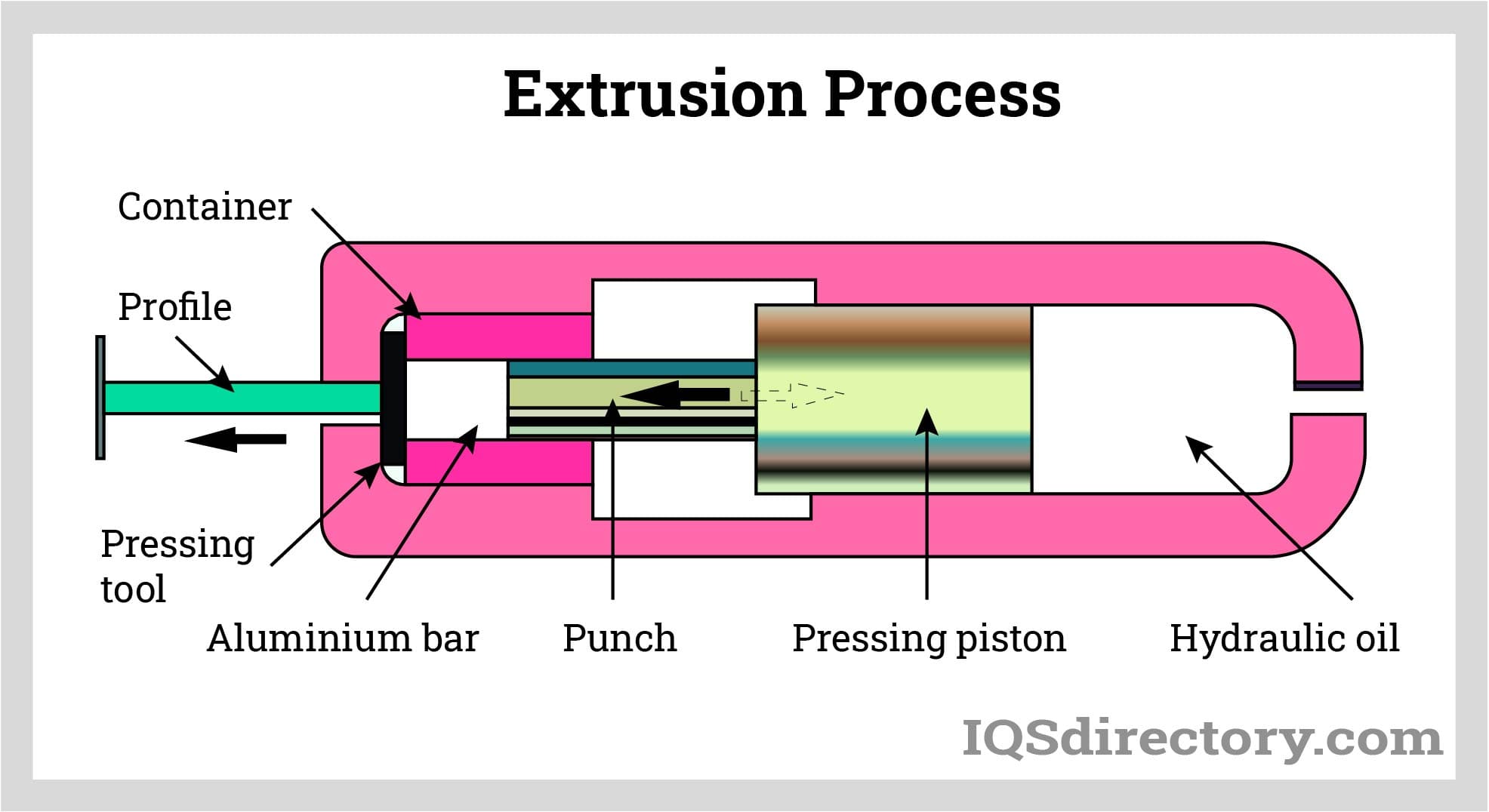

How Does Extrusion Differ from Other Cold Heading Techniques?

Extrusion involves forcing the material through a die, resulting in varying shapes and sizes. This technique can produce both forward and backward extrusions, allowing for complex designs such as pipe fittings and structural components. Buyers should evaluate the material requirements and the potential need for specialized tooling. While extrusion offers versatility, it may entail higher costs and longer lead times due to the complexity of the dies involved.

Illustrative image related to cold heading

Why Consider Multi-part Assembly in Cold Heading?

Multi-part assembly cold heading combines multiple components into a single part, enhancing efficiency in manufacturing. This technique is particularly beneficial in the aerospace and machinery sectors, where reducing assembly time is crucial. Buyers should weigh the initial investment against long-term savings in labor and assembly. Although the upfront costs may be higher, the reduction in assembly complexity can lead to significant operational efficiencies.

What Does Cold Forming Entail?

Cold forming is an umbrella term that encompasses various cold heading methods, including upset heading and extrusion. This technique is widely used to manufacture fasteners, brackets, and custom components for diverse industries. For B2B buyers, the cost-effectiveness of cold forming in high-volume production is a significant advantage. However, the initial setup can be costly, making it essential to assess the production scale and design requirements before committing to this method.

What Are the Benefits of Secondary Operations in Cold Heading?

Secondary operations refer to additional processes that enhance the functionality of cold-headed parts, such as threading, knurling, and plating. These operations are crucial for producing complex fasteners and automotive components that require specific features. Buyers should consider the added lead time and costs associated with these operations. While secondary processes can significantly improve part functionality and performance, they require careful planning to align with production timelines.

Key Industrial Applications of cold heading

| Industry/Sector | Specific Application of cold heading | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of fasteners for assembly systems | High-volume production with reduced waste | Quality certifications, material specifications, lead times |

| Aerospace | Production of high-strength components | Enhanced strength-to-weight ratio | Compliance with aerospace standards, traceability, testing |

| Construction | Fabrication of structural bolts and anchors | Cost-effective solutions with tight tolerances | Sourcing from reliable suppliers, custom designs, delivery timelines |

| Electronics | Creation of connectors and terminals | Improved reliability and conductivity | RoHS compliance, material compatibility, precision requirements |

| Medical Devices | Production of specialized fasteners for devices | Ensured safety and performance in critical applications | Biocompatibility, regulatory compliance, custom tooling |

How is Cold Heading Used in the Automotive Industry?

In the automotive sector, cold heading is primarily employed to manufacture fasteners used in assembly systems, such as bolts, screws, and nuts. This method allows for high-volume production while minimizing raw material waste. The fasteners produced are characterized by tight tolerances and enhanced physical properties, which are crucial for ensuring the durability and safety of vehicles. For international buyers, especially those in Africa and South America, sourcing must include quality certifications and adherence to local automotive standards to ensure compatibility and reliability.

What Role Does Cold Heading Play in Aerospace Manufacturing?

Cold heading is critical in the aerospace industry for producing high-strength components, such as rivets and fasteners, that require exceptional durability and resistance to extreme conditions. The process enables manufacturers to achieve an enhanced strength-to-weight ratio, which is vital for aircraft performance. Buyers in Europe, particularly Germany, should prioritize suppliers who comply with stringent aerospace standards and can provide traceability for materials used, ensuring safety and reliability in flight operations.

How is Cold Heading Beneficial for Construction Applications?

In construction, cold heading is utilized to fabricate structural bolts and anchors that are essential for building integrity. The method’s efficiency leads to cost-effective solutions, enabling the production of components with tight tolerances that can withstand significant loads. For buyers in the Middle East, where construction projects are rapidly expanding, it’s essential to source from reliable suppliers that can offer custom designs and ensure timely delivery to meet project deadlines.

What Advantages Does Cold Heading Offer in Electronics?

The electronics industry leverages cold heading to create connectors and terminals that require high reliability and excellent conductivity. The cold heading process allows for the production of intricate shapes and precise dimensions, which are crucial for electronic performance. International buyers, particularly from regions like South America and Europe, should focus on sourcing components that meet RoHS compliance and material compatibility to ensure the safety and effectiveness of their electronic devices.

How is Cold Heading Applied in Medical Device Manufacturing?

Cold heading is increasingly used in the medical device sector for producing specialized fasteners that are integral to device assembly. These components must meet rigorous safety and performance standards due to their critical applications in healthcare. Buyers must prioritize sourcing from manufacturers who ensure biocompatibility and regulatory compliance, especially in regions like Africa, where the medical device market is growing rapidly and demands high-quality, reliable components.

3 Common User Pain Points for ‘cold heading’ & Their Solutions

Scenario 1: Navigating Tight Tolerances in Cold Heading

The Problem: As a B2B buyer, you may often encounter challenges related to achieving tight tolerances in cold heading processes. Industries such as automotive and aerospace demand precision components that meet specific engineering standards. Failing to meet these tolerances can lead to product failures, safety issues, and costly rework. The pressure to maintain competitive pricing while ensuring high-quality output only complicates matters further.

The Solution: To effectively address tolerance challenges, start by collaborating closely with your cold heading supplier during the design phase. Ensure that you provide detailed specifications, including dimensional tolerances, material properties, and any secondary operations required. Select suppliers with a robust quality assurance process, including in-house capabilities for testing and validation. Additionally, leverage advanced CAD software to simulate the cold heading process, allowing for adjustments before production. This proactive approach minimizes the risk of errors and ensures that the final products adhere to required specifications.

Scenario 2: Managing Material Waste and Cost Efficiency

The Problem: In the current economic climate, managing production costs while minimizing waste is a significant concern for B2B buyers in manufacturing. Traditional machining processes can result in substantial material waste—sometimes as much as 60%. This not only inflates production costs but also poses environmental sustainability challenges, particularly for companies focused on green manufacturing practices.

Illustrative image related to cold heading

The Solution: Transitioning to cold heading can drastically reduce material waste, as the process involves forming metal rather than cutting it away. To maximize this benefit, engage with suppliers who offer customized tooling and can accommodate specific material types and configurations. Request a detailed waste analysis from potential partners to understand their efficiency metrics. Moreover, consider bulk purchasing of raw materials to take advantage of cost savings and ensure a steady supply for high-volume production runs. By doing so, you can align your procurement strategy with your sustainability goals while achieving significant cost reductions.

Scenario 3: Overcoming Limitations in Customization and Design Complexity

The Problem: As a B2B buyer, you may face hurdles when sourcing cold-headed components that require intricate designs or customized features. Standardized parts may not meet your unique application needs, and sourcing custom solutions can often lead to extended lead times and increased costs. This can be particularly frustrating when working on time-sensitive projects or when trying to gain a competitive edge with innovative product designs.

The Solution: To effectively manage customization challenges, it is crucial to work with suppliers who specialize in bespoke solutions. Start by providing a comprehensive design brief that outlines your specific requirements, including dimensions, material characteristics, and any special features. Engage in a collaborative design process with your supplier, utilizing their expertise in tooling and production methods to refine your concepts. Look for manufacturers that offer prototyping services, allowing you to test designs before committing to full production. This iterative approach not only accelerates the development process but also enhances the likelihood of a successful final product that meets your specifications.

Illustrative image related to cold heading

Strategic Material Selection Guide for cold heading

What Are the Key Materials for Cold Heading?

When selecting materials for cold heading, it is crucial to consider their properties, advantages, limitations, and the specific requirements of international markets. Here, we analyze four common materials used in cold heading: carbon steel, stainless steel, aluminum, and brass.

How Does Carbon Steel Perform in Cold Heading Applications?

Key Properties: Carbon steel is known for its strength, hardness, and excellent wear resistance. It typically has a temperature rating up to 300°C and can withstand significant pressure, making it suitable for various applications.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and high durability, which makes it ideal for mass production. However, it has lower corrosion resistance compared to other materials, which can limit its use in harsh environments. Additionally, the manufacturing complexity can increase with higher carbon content, necessitating precise control during the cold heading process.

Impact on Application: Carbon steel is widely used in automotive fasteners, construction, and machinery. Its compatibility with various media is generally good, but it may not be suitable for environments with high moisture or corrosive chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM A307 or DIN 933 is essential. Buyers from regions like Europe and the Middle East should ensure that their suppliers adhere to these standards to guarantee product quality and performance.

Illustrative image related to cold heading

What Advantages Does Stainless Steel Offer for Cold Heading?

Key Properties: Stainless steel is renowned for its corrosion resistance, temperature stability (up to 800°C), and mechanical strength. It is particularly beneficial in environments exposed to moisture and chemicals.

Pros & Cons: The key advantage of stainless steel is its durability and aesthetic appeal, which is important for applications requiring high-quality finishes. However, it is more expensive than carbon steel and can be more challenging to work with due to its toughness, potentially increasing manufacturing costs.

Impact on Application: Stainless steel is commonly used in medical devices, food processing equipment, and automotive components where hygiene and corrosion resistance are critical. Its compatibility with various media, including aggressive chemicals, makes it a preferred choice in many industries.

Illustrative image related to cold heading

Considerations for International Buyers: Buyers should look for compliance with ASTM A276 or JIS G4303 standards. In regions like Africa and South America, where corrosion may be a concern, specifying high-grade stainless steel can enhance product longevity.

Why Choose Aluminum for Cold Heading?

Key Properties: Aluminum is lightweight, has excellent corrosion resistance, and can withstand temperatures up to 200°C. Its low density makes it a favorable option for applications where weight is a concern.

Pros & Cons: The primary advantage of aluminum is its ease of fabrication and low cost, making it ideal for high-volume production. However, its mechanical strength is lower than that of steel, which can limit its use in high-stress applications.

Impact on Application: Aluminum is often used in aerospace, automotive, and consumer goods where weight reduction is essential. Its compatibility with various media is generally good, although it may not perform well in high-temperature environments.

Illustrative image related to cold heading

Considerations for International Buyers: Compliance with standards like ASTM B211 or EN 573 is important for ensuring quality. Buyers in Europe and the Middle East should be aware of the specific grades of aluminum that meet their application requirements.

What Role Does Brass Play in Cold Heading?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and machinability. It performs well in temperatures up to 300°C and offers good electrical conductivity.

Pros & Cons: The key advantage of brass is its aesthetic appeal and resistance to tarnishing, making it suitable for decorative applications. However, it is more expensive than carbon steel and may not be as strong, which can limit its use in high-stress environments.

Impact on Application: Brass is commonly used in plumbing fittings, electrical connectors, and decorative fasteners. Its compatibility with various media is excellent, particularly in plumbing and electrical applications.

Considerations for International Buyers: Buyers should ensure compliance with ASTM B16 or JIS H3250 standards. In regions like Africa and South America, where availability may vary, sourcing from reputable suppliers is essential to ensure quality.

Summary Table of Material Selection for Cold Heading

| Material | Typical Use Case for cold heading | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive fasteners | Cost-effective and durable | Lower corrosion resistance | Low |

| Stainless Steel | Medical devices, food equipment | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, consumer goods | Lightweight and easy to fabricate | Lower mechanical strength | Med |

| Brass | Plumbing fittings, electrical connectors | Aesthetic appeal and corrosion resistance | Higher cost and lower strength | Med |

This guide provides a comprehensive overview of material selection for cold heading, equipping international B2B buyers with the insights necessary to make informed decisions based on their specific applications and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cold heading

The manufacturing process for cold heading encompasses several critical stages, each contributing to the efficiency and quality of the final product. Understanding these stages is essential for B2B buyers who aim to optimize their supply chain and ensure that they receive high-quality components.

Illustrative image related to cold heading

What Are the Main Stages of Cold Heading Manufacturing?

How is Material Prepared for Cold Heading?

The cold heading process begins with material preparation, which typically involves selecting the appropriate wire stock, usually made from steel or other metals. The wire is drawn to the required diameter, ensuring it meets the specific needs of the intended application. This wire is then cut into short lengths known as “slugs,” which serve as the starting point for the heading process. Material selection is crucial, as it affects the mechanical properties of the final product. Buyers should verify that suppliers provide detailed specifications of the wire material, including chemical composition and mechanical properties, to ensure compatibility with their applications.

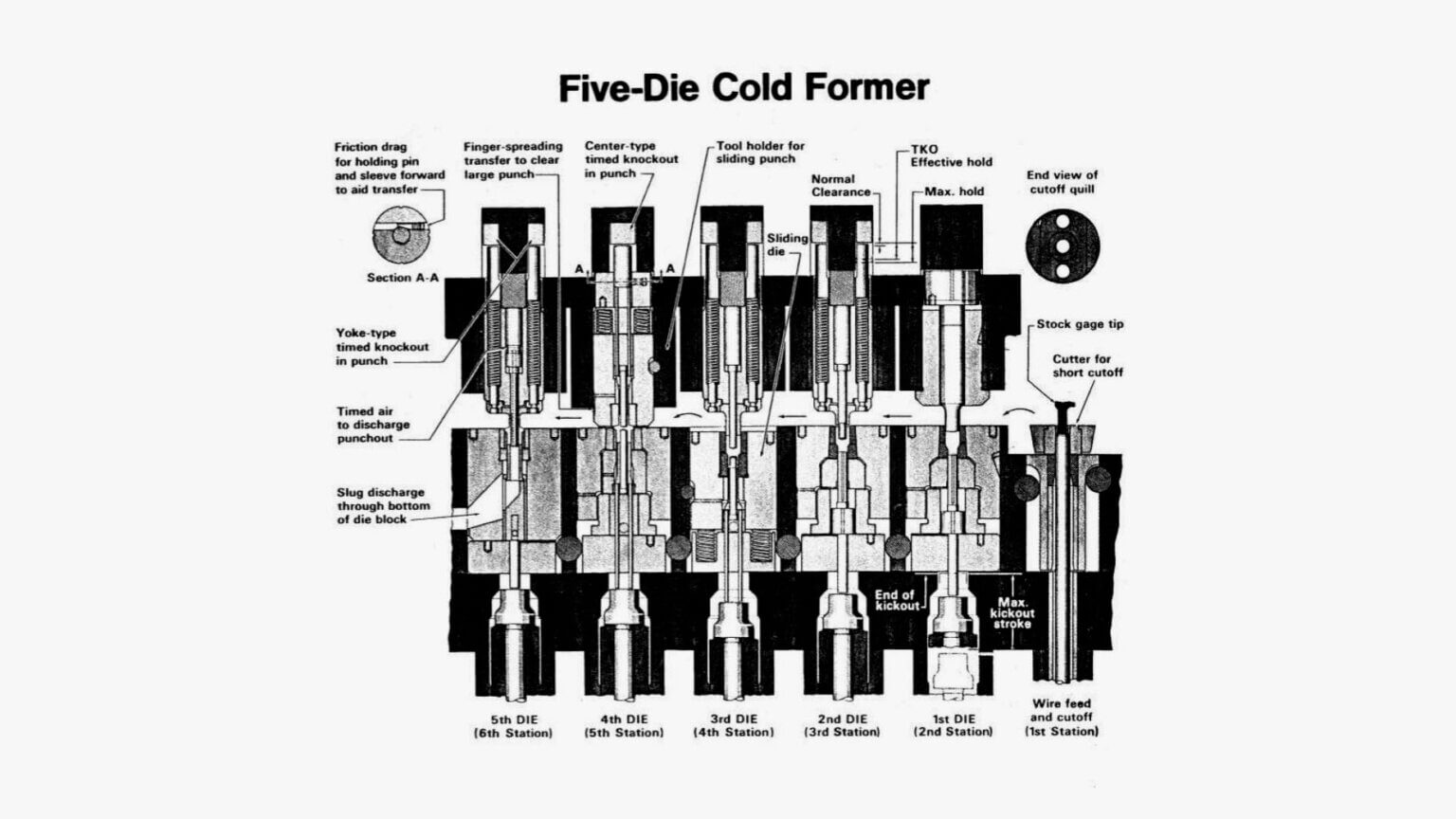

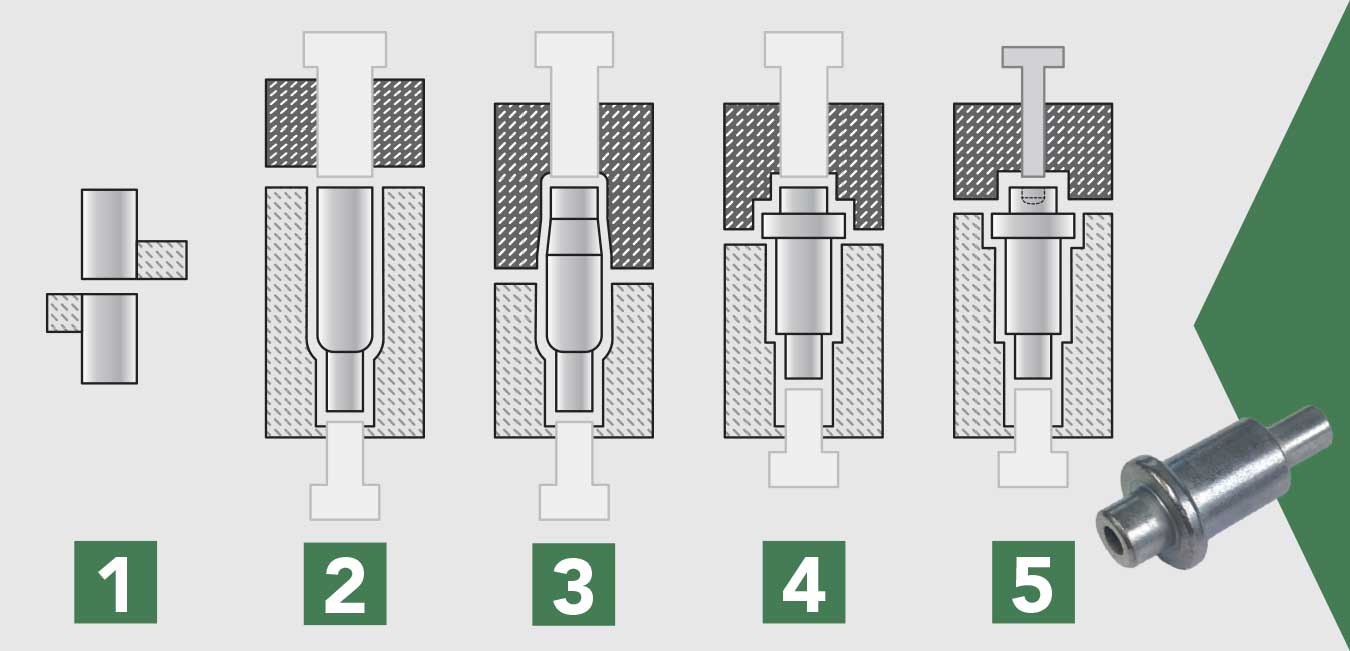

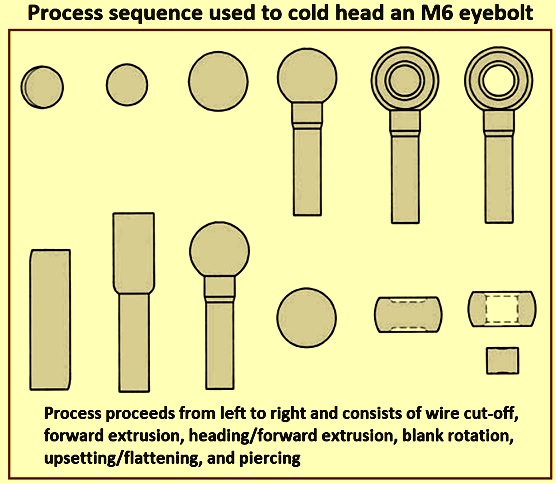

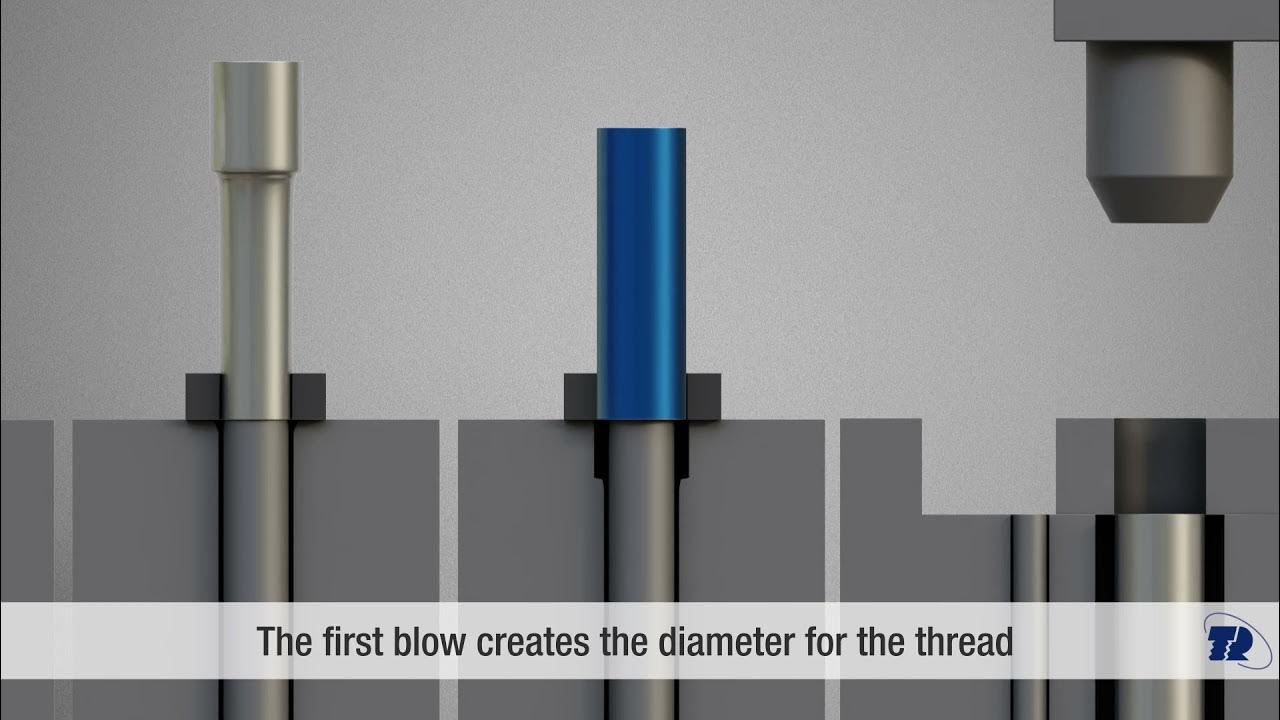

What Techniques Are Used During the Forming Stage?

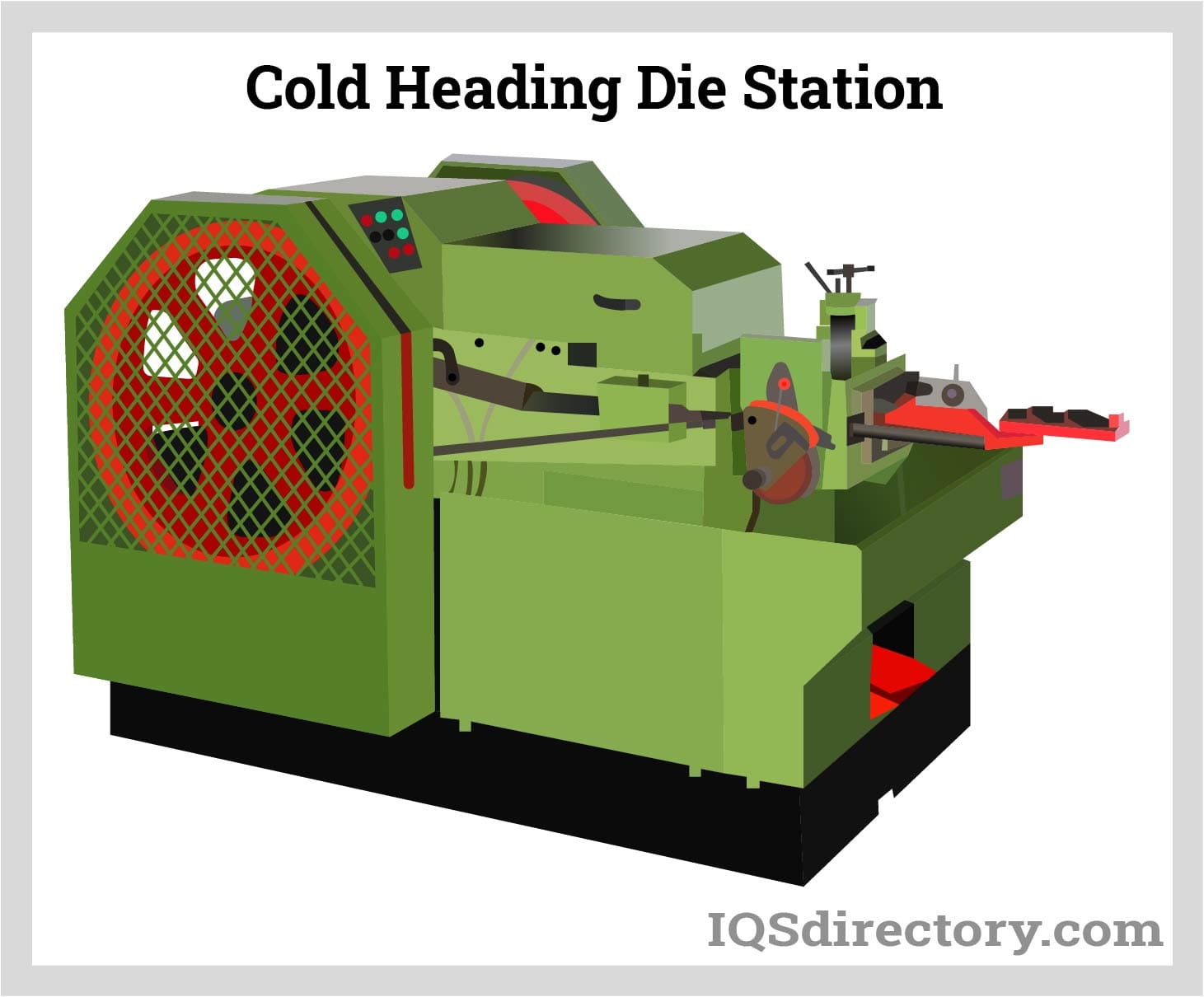

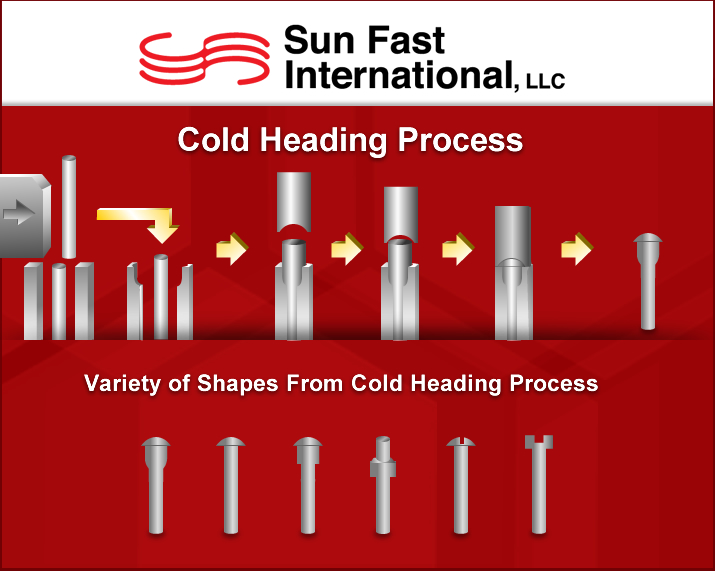

The forming stage is where the cold heading magic happens. Using specialized machinery, slugs are fed into a cold heading machine equipped with a series of dies, hammers, and punches. The process involves multiple steps, often referred to as “progressions,” where the slug is progressively shaped into the desired form without the application of heat. Key techniques in this stage include:

- Upsetting: This technique increases the diameter of the slug while reducing its height, typically used to form the head of a fastener.

- Extrusion: Material is forced through a die to create a desired shape, either by forward or backward extrusion, depending on the design requirements.

The efficiency of cold heading allows for the production of parts with tight tolerances, often within +/- 0.002 inches, and with minimal waste. Buyers should inquire about the machine capabilities and tooling used by their suppliers, as these factors influence production speed and precision.

How is the Assembly Process Managed?

While cold heading primarily focuses on forming metal parts, the assembly process may be necessary for complex components that require multiple parts to be joined. This could involve secondary operations such as threading, drilling, or other forms of machining that cannot be accomplished during the cold heading process. B2B buyers should consider suppliers who offer comprehensive services, including assembly, to streamline their supply chain and reduce the need for multiple vendors.

What Finishing Techniques Are Commonly Used?

Once the cold headed parts are formed, finishing techniques are applied to enhance surface quality and meet specific functional requirements. Common finishing processes include:

- Heat Treatment: Improves the mechanical properties of the metal, increasing strength and durability.

- Plating and Coating: Provides corrosion resistance or aesthetic qualities, which can be crucial for applications in harsh environments.

- Grinding and Polishing: Ensures smooth surfaces and precise dimensions, enhancing the overall quality of the fastener or component.

Buyers should evaluate the finishing capabilities of suppliers, as this can significantly impact the performance and longevity of the components in their applications.

How is Quality Assurance Implemented in Cold Heading?

What International Standards Should B2B Buyers Consider?

Quality assurance in cold heading manufacturing is paramount, particularly for B2B buyers operating in regulated industries. Suppliers should adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector can further assure quality. Buyers should request documentation that confirms compliance with these standards to mitigate risks associated with supplier quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that products meet the required specifications. Common QC checkpoints include:

Illustrative image related to cold heading

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to verify they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive inspection of finished products before shipment to ensure they meet customer specifications.

Establishing clear QC checkpoints allows B2B buyers to identify potential issues early, reducing the risk of receiving non-conforming products.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. This can include:

- Conducting Audits: Regularly scheduled audits of suppliers can provide insight into their quality management systems and adherence to standards.

- Requesting Quality Reports: Suppliers should provide documentation, including inspection reports and test results, to demonstrate compliance with quality standards.

- Utilizing Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased assessment of product quality and supplier capabilities.

For international buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality certifications and compliance standards is essential. Buyers should be aware that different regions may have varying requirements, and ensuring alignment with local regulations is crucial for successful operations.

Conclusion: Why Is Understanding Cold Heading Processes and Quality Assurance Vital for B2B Buyers?

By comprehensively understanding the manufacturing processes and quality assurance protocols associated with cold heading, B2B buyers can make informed decisions about their suppliers. This knowledge enables buyers to ensure they receive high-quality products that meet their specifications, ultimately driving efficiency and reducing costs in their supply chain. As the global marketplace evolves, maintaining a focus on quality and manufacturing excellence will be key to sustaining competitive advantage.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cold heading’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring cold heading services and products. Cold heading, a process for shaping metal without heating, is essential for high-quality fasteners and components. This checklist outlines key steps to ensure you select the right supplier and achieve optimal outcomes for your manufacturing needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for successful sourcing. Outline the dimensions, materials, and tolerances required for your cold-headed products. This clarity will help suppliers understand your needs and provide accurate quotes.

- Material Requirements: Specify the types of metals you need (e.g., stainless steel, aluminum) and any particular grades.

- Tolerances: Indicate acceptable tolerances, which can significantly impact performance.

Step 2: Identify Potential Suppliers

Begin your search by identifying suppliers with expertise in cold heading. Look for companies that have a robust portfolio and a proven track record in your industry.

- Industry Experience: Prioritize suppliers with experience in your specific sector, such as automotive or aerospace.

- Global Reach: Consider suppliers with international capabilities, especially if you are sourcing from regions like Africa or South America.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the technical capabilities of potential suppliers. This ensures they can meet your production needs efficiently and effectively.

- Machinery and Technology: Verify that suppliers use advanced cold heading machinery for high-speed production and precision.

- Design and Engineering Services: Look for suppliers that offer custom tooling and engineering support to help optimize your designs.

Step 4: Check Quality Assurance Processes

A strong quality assurance process is crucial for ensuring that the products meet your specifications and standards.

Illustrative image related to cold heading

- Certifications: Confirm that suppliers hold relevant certifications (e.g., ISO 9001) to guarantee compliance with international quality standards.

- Testing Procedures: Inquire about their testing methods for material integrity, tolerances, and surface finish.

Step 5: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes to assess the quality of the cold-headed parts. This step is essential to ensure the product meets your expectations.

- Evaluation Criteria: Check for dimensional accuracy, surface finish, and overall functionality during the sample evaluation.

- Adjustments: Use the feedback from the samples to discuss any necessary adjustments with the supplier.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a potential supplier, engage in negotiations to finalize terms and pricing.

- Volume Discounts: Discuss pricing structures that accommodate your order volumes, as larger orders often qualify for discounts.

- Lead Times: Ensure that you understand the lead times for production and delivery to align with your project schedules.

Step 7: Establish a Communication Plan

Effective communication is key to a successful supplier relationship. Set up a communication plan that outlines how you will interact throughout the procurement process.

- Regular Updates: Schedule regular check-ins to discuss progress and address any concerns.

- Point of Contact: Designate a primary point of contact on both sides to facilitate smooth communication.

By following this checklist, B2B buyers can streamline their sourcing process for cold heading products, ensuring they partner with suppliers that meet their technical and quality requirements.

Comprehensive Cost and Pricing Analysis for cold heading Sourcing

What Are the Key Cost Components in Cold Heading Sourcing?

When assessing the costs associated with cold heading sourcing, several components contribute to the total expenditure. Understanding these elements is crucial for B2B buyers looking to optimize their procurement strategies.

-

Materials: The primary cost driver in cold heading is raw materials, typically metal wire. Prices fluctuate based on market conditions, material type (e.g., stainless steel vs. carbon steel), and availability. Buyers should consider sourcing materials from suppliers who can offer competitive rates without compromising quality.

-

Labor: Labor costs can vary significantly depending on the region and the skill level required for operating cold heading machinery. In regions like Europe and parts of the Middle East, skilled labor may be more expensive compared to South America or Africa. Efficient labor management can help mitigate these costs.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Buyers should evaluate suppliers’ overhead structures as these can impact pricing. A fully integrated supplier might offer better pricing due to economies of scale.

-

Tooling: Custom tooling can be a significant upfront cost, especially for unique specifications. While investing in custom tooling may increase initial costs, it can lead to lower per-unit costs in high-volume production runs. Buyers should discuss tooling amortization with suppliers to understand long-term cost implications.

-

Quality Control (QC): Ensuring high-quality standards in cold heading is essential. Quality control measures can add to costs but are necessary to avoid defects and ensure compliance with industry standards. Buyers should inquire about suppliers’ QC processes and certifications to gauge reliability.

-

Logistics: Transportation and warehousing costs can vary based on geographical location and chosen Incoterms. Buyers should analyze logistics options, considering both cost and delivery timelines. International buyers must also account for customs duties and potential tariffs.

-

Margin: Suppliers will typically include a profit margin that reflects their operational costs and market position. Understanding the industry standard margins can help buyers negotiate better pricing.

How Do Price Influencers Impact Cold Heading Costs?

Several factors can influence pricing in cold heading, which B2B buyers should consider when negotiating contracts.

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower per-unit costs. Buyers should assess their needs and negotiate MOQs that align with their production schedules to achieve better pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the need for specialized tooling or processes. Buyers should evaluate whether the benefits of customization outweigh the additional costs.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) may come at a premium. However, investing in quality can lead to reduced failure rates and improved performance, justifying the initial expense.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Conducting thorough supplier assessments can help identify partners who offer the best value.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will influence the overall cost structure. Buyers should be clear about responsibilities for shipping, insurance, and customs to avoid unexpected expenses.

What Negotiation Strategies Can Help Optimize Costs?

Effective negotiation is key to achieving favorable pricing in cold heading sourcing. Here are actionable tips for buyers:

-

Understand Total Cost of Ownership (TCO): Beyond the upfront costs, consider the long-term costs associated with quality, maintenance, and potential downtime. This holistic view can strengthen your negotiation position.

-

Leverage Volume Discounts: If possible, consolidate orders to increase volume and negotiate discounts. Establishing a long-term relationship with a supplier can also lead to better pricing.

-

Explore Alternative Suppliers: Don’t hesitate to seek multiple quotes. A competitive bidding process can reveal pricing discrepancies and provide leverage in negotiations.

-

Timing and Market Conditions: Be aware of market trends and seasonal fluctuations in material costs. Timing your orders strategically can help secure better pricing.

-

Build Relationships: Cultivating strong relationships with suppliers can lead to better communication and more favorable terms over time. Consider establishing partnerships based on mutual benefit rather than transactional relationships.

Conclusion and Pricing Disclaimer

While the costs associated with cold heading sourcing can vary widely, understanding the key components and influencers can empower B2B buyers to make informed decisions. It is important to note that the figures discussed are indicative and may change based on specific circumstances, market conditions, and supplier capabilities. Always seek tailored quotes that reflect your unique requirements and context.

Alternatives Analysis: Comparing cold heading With Other Solutions

Understanding Alternatives to Cold Heading

In the realm of manufacturing, particularly for fasteners and metal components, cold heading is a well-established process. However, various alternative methods can achieve similar objectives, each with its unique advantages and drawbacks. This analysis aims to provide B2B buyers with a comprehensive comparison of cold heading against other viable methods, enabling informed decisions based on their specific manufacturing needs.

Comparison Table

| Comparison Aspect | Cold Heading | CNC Machining | Casting |

|---|---|---|---|

| Performance | High-speed production, tight tolerances | High precision, versatile shapes | Good for complex shapes but slower |

| Cost | Lower material waste, cost-effective for large volumes | Higher setup costs, economical for low volumes | Lower material costs but longer lead times |

| Ease of Implementation | Requires specific tooling and setup | Easier for low to mid-volume runs | Requires molds, can be complex |

| Maintenance | Moderate; requires specialized knowledge | Low, but needs regular calibration | Low, but molds can wear out |

| Best Use Case | High-volume fasteners, automotive parts | Custom parts with intricate details | Large parts, complex geometries |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining involves the removal of material from a solid block to create the desired shape. This method is highly precise and allows for complex designs that cold heading may not accommodate.

Pros:

– Exceptional precision with tolerances as tight as +/- 0.001 inches.

– Versatile, suitable for both small and large production runs.

– Capable of working with a wide range of materials, including metals and plastics.

Cons:

– Higher initial setup costs, making it less economical for large volumes.

– Slower production rates compared to cold heading, especially for bulk items.

Casting

Casting is the process of pouring molten metal into a mold to achieve the desired shape. This method is particularly effective for creating complex geometries that would be challenging to form through cold heading.

Pros:

– Ideal for producing large parts and components with intricate shapes.

– Generally lower material costs since scrap is minimized.

– Suitable for high-volume production once molds are created.

Cons:

– Longer lead times due to the need for mold fabrication.

– Potential for defects such as air bubbles or uneven surfaces if not executed properly.

Conclusion: Choosing the Right Solution for Your Needs

When determining the best manufacturing method for your specific needs, consider factors such as production volume, cost constraints, and the complexity of the components required. Cold heading is optimal for high-volume fastener production, particularly in automotive applications where strength and precision are paramount. Conversely, CNC machining may suit projects requiring intricate designs with lower production runs, while casting can be ideal for larger components with complex geometries. By carefully evaluating these aspects, B2B buyers can select the most appropriate manufacturing solution that aligns with their operational objectives and budgetary considerations.

Essential Technical Properties and Trade Terminology for cold heading

What Are the Key Technical Properties of Cold Heading?

Cold heading is a highly efficient manufacturing process that shapes metal without heating, making it crucial for producing fasteners and components in various industries. Understanding the essential technical properties can help B2B buyers make informed decisions.

Illustrative image related to cold heading

1. Material Grade

The material grade refers to the specific classification of the metal being used, which can include steel, aluminum, brass, and others. Each grade has distinct mechanical properties, such as tensile strength and ductility, influencing the part’s performance and longevity. B2B buyers should ensure that the material grade aligns with their application requirements to guarantee the durability and functionality of the final product.

2. Tolerance

Tolerance is the allowable deviation from a specified dimension, usually expressed in thousandths of an inch (e.g., ±0.002″). Achieving tight tolerances is critical in applications where precision is paramount, such as in automotive or aerospace components. For buyers, understanding tolerance requirements helps in selecting suppliers capable of delivering parts that meet their specific quality standards.

3. Production Rate

This specification refers to the number of parts produced per hour. Cold heading allows for high-speed production rates due to its efficiency in forming metal. For businesses that require large volumes, understanding production rates can influence sourcing decisions, as it directly impacts lead times and inventory management.

4. Grain Flow

Grain flow describes the directional alignment of the metal’s internal structure after forming. Cold heading improves grain flow, resulting in enhanced strength and fatigue resistance in the final product. Buyers should consider grain flow when evaluating the mechanical properties of parts, especially for high-stress applications.

Illustrative image related to cold heading

5. Surface Finish

Surface finish refers to the texture and quality of the surface of the finished part. A smooth finish is often required for components that interact with other parts or where aesthetic considerations are important. Buyers should specify surface finish requirements to ensure compatibility with their assembly processes and end-use applications.

What Are Common Trade Terms in Cold Heading?

Understanding industry terminology is essential for effective communication and negotiation in the cold heading sector. Here are some key terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end product. For buyers, collaborating with OEMs can ensure that they receive parts that meet industry standards and specifications, crucial for maintaining quality in their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for buyers when budgeting and planning inventory, as understanding the MOQ can help avoid excess costs or understocking.

Illustrative image related to cold heading

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. It is a critical step in the procurement process, allowing buyers to compare offerings and ensure they are getting the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother transactions.

5. Secondary Operations

Secondary operations refer to additional processes, such as threading or plating, performed after the cold heading process. For buyers, knowing about secondary operations is essential for understanding the complete manufacturing capabilities of their suppliers and ensuring that all required specifications are met.

Illustrative image related to cold heading

By grasping these essential technical properties and trade terms, B2B buyers can navigate the cold heading landscape with confidence, leading to more effective partnerships and successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the cold heading Sector

What Are the Key Market Dynamics and Trends Influencing Cold Heading?

The cold heading sector is experiencing significant growth, driven by the rising demand for high-quality fasteners across various industries, particularly automotive, aerospace, and construction. Global economic recovery post-pandemic is boosting manufacturing activities, especially in emerging markets like Africa and South America. These regions are witnessing increased investments in infrastructure, leading to a surge in demand for cold-formed components. Additionally, advancements in technology, such as automation and Industry 4.0, are reshaping production processes. Manufacturers are increasingly adopting smart technologies for better efficiency and quality control, which is essential for meeting the stringent specifications required by international buyers.

In Europe, particularly in countries like Germany, the focus is on precision engineering and sustainability, aligning with the EU’s stringent regulations on manufacturing practices. International B2B buyers are looking for suppliers that not only meet quality standards but also offer innovative solutions. Vietnam is emerging as a manufacturing hub, leveraging its competitive labor costs and improving infrastructure, making it an attractive sourcing destination for cold heading products. The trend towards digitalization in supply chain management is also notable, as companies increasingly rely on data analytics and digital platforms for sourcing and procurement, enhancing transparency and reducing lead times.

How Is Sustainability and Ethical Sourcing Shaping the Cold Heading Industry?

Sustainability has become a cornerstone of business practices in the cold heading sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. This includes minimizing waste during production—a key advantage of cold heading, which inherently generates less scrap compared to traditional machining processes. International buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainability, often requiring certifications that validate eco-friendly practices.

Moreover, the importance of ethical sourcing is gaining traction. Buyers are looking for suppliers who ensure fair labor practices and transparency throughout their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming critical for suppliers aiming to attract international clients. The use of recycled materials and the implementation of energy-efficient technologies are additional areas where suppliers can differentiate themselves. By adopting these sustainable practices, cold heading manufacturers can not only meet regulatory requirements but also appeal to the growing segment of environmentally-conscious consumers.

What Is the Historical Context of Cold Heading and Its Relevance Today?

Cold heading, which dates back to the early 20th century, has evolved significantly since its inception. Originally developed to produce fasteners for the burgeoning automotive industry, this manufacturing process has continuously adapted to meet the demands of various sectors. The introduction of advanced machinery and materials has expanded the capabilities of cold heading, allowing manufacturers to produce complex geometries and tighter tolerances, which are now standard expectations in the industry.

Today, cold heading is pivotal in producing components that are essential for modern applications, from automotive assemblies to aerospace parts. As industries evolve, the ongoing development of cold heading techniques and technologies ensures that it remains a relevant and efficient manufacturing method. Understanding this historical context allows international buyers to appreciate the advancements in quality and efficiency that cold heading offers, making it a preferred choice for high-volume production needs.

Frequently Asked Questions (FAQs) for B2B Buyers of cold heading

-

How can I determine if cold heading is the right manufacturing process for my fasteners?

To determine if cold heading suits your needs, consider factors like the volume of parts required, design complexity, and material specifications. Cold heading excels in high-volume production, offering tight tolerances and minimal material waste. If your designs allow for near-net shapes and you need quick turnaround times, cold heading is likely a cost-effective solution. Collaborate with manufacturers to assess your specifications and get prototype samples before making a commitment. -

What are the key benefits of using cold heading for fastener production?

Cold heading provides numerous advantages, including reduced material waste, enhanced strength of the final product, and lower production costs compared to traditional machining methods. The process allows for high-speed production rates and the capability to achieve tight tolerances, typically around +/- 0.002 inches. Additionally, cold heading can accommodate a range of diameters and custom designs, making it suitable for diverse applications across various industries. -

What are the typical minimum order quantities (MOQs) for cold heading fasteners?

Minimum order quantities for cold heading fasteners can vary significantly based on the manufacturer and the complexity of the part. Generally, MOQs range from several thousand to tens of thousands of units, reflecting the efficiency of the cold heading process in high-volume runs. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that align with your purchasing capabilities and production schedules. -

How can I ensure quality assurance when sourcing cold heading products internationally?

To ensure quality assurance, start by selecting suppliers with established reputations and certifications, such as ISO 9001. Request samples and conduct on-site audits if possible. Additionally, establish clear quality specifications in your contracts, and consider third-party inspections at various production stages. Effective communication with your supplier regarding quality expectations and compliance can help mitigate risks in international sourcing. -

What should I consider regarding payment terms when sourcing cold heading products?

When negotiating payment terms, consider factors like the order size, supplier policies, and your own cash flow requirements. Common terms include advance payments, letters of credit, or payment upon delivery. It’s essential to establish a mutually agreeable arrangement that protects both parties. Discussing payment terms early in the negotiation process can prevent misunderstandings later and ensure a smooth transaction. -

How do I vet potential suppliers for cold heading components?

To vet suppliers, assess their experience in cold heading and their production capabilities. Review their portfolio, client testimonials, and industry certifications. It’s beneficial to ask for references from previous clients, particularly those in your industry. Conducting site visits or virtual audits can provide insights into their manufacturing processes and quality control measures, ensuring they meet your standards. -

What logistics considerations should I keep in mind when importing cold heading products?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Understand the incoterms (International Commercial Terms) that will govern your transaction, as they define responsibilities for shipping, insurance, and tariffs. Additionally, evaluate the reliability of your supplier’s logistics partners and consider lead times for production and shipping to avoid delays in your supply chain. -

Can cold heading be customized to meet specific design requirements?

Yes, cold heading can be highly customized to meet specific design requirements. Manufacturers can create custom tooling to produce unique shapes, sizes, and configurations, including multi-part assemblies. It’s essential to communicate your design specifications clearly and work closely with the manufacturer during the prototyping phase to ensure that the final products meet your expectations and functional requirements.

Top 8 Cold Heading Manufacturers & Suppliers List

1. Grandeur Fasteners – Cold Heading Solutions

Domain: grandeurfasteners.com

Registered: 1999 (26 years)

Introduction: Grandeur Fasteners specializes in cold heading, a process that forms metal wire into specified shapes without heat, using dies, hammers, and punches. Key features include:

– Custom tooling design and fabrication

– Manufacturing of various fastener forms, including multiple upset configurations and customized head shapes

– Capabilities for tight tolerances (up to +/- .002″)

– High-speed product…

2. TFG USA – Cold Heading Solutions

Domain: tfgusa.com

Registered: 2008 (17 years)

Introduction: Cold heading is a high-speed metal forming process that shapes parts at room temperature without the need for heat. It is primarily used for forming the heads on fasteners like bolts, screws, rivets, and nails. Key advantages include minimal waste, faster production, stronger parts, reduced costs, and the ability to simplify multi-piece assemblies. Cold heading supports sustainable manufacturing b…

3. BCEPI – Specialty Fasteners

Domain: bcepi.com

Registered: 2005 (20 years)

Introduction: Cold heading is a forging process used in manufacturing specialty fasteners, shaping metal at room temperature without removing material. Key techniques include cutting wire to length, heading to form the fastener’s head, extrusion for specific cross-sections, and threading for the fastener body. Advantages of cold heading include efficiency, cost-effectiveness, strength and durability through wor…

4. Hill Fastener – Cold Formed Fasteners

Domain: hillfastener.com

Registered: 1996 (29 years)

Introduction: Cold Formed Products including Hill Lock (R) Serrated Hex Flange Screws, Grade-8 Undercut Hex Flange Screws, Grade-5 Hex Flange Screws, Carriage Bolts, Metrics, WHIZ-Plus Pole Line Fasteners, Special Fasteners. Cold heading is a manufacturing process for fasteners that offers tighter tolerances compared to hot-rolled steel, making it ideal for precise manufacturing needs.

5. Cold Heading Company – Automotive Solutions

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Cold Heading Company – Automotive Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Components for Industry – Cold Forming Solutions

Domain: blog.componentsforindustry.com

Registered: 1999 (26 years)

Introduction: Cold forming and cold heading are interchangeable terms used for a manufacturing process that creates specified shapes from metal wire using dies and punches at room temperature. The process involves feeding wire into a machine, cutting it into slugs, and shaping it using high-speed hammers, dies, and punches. Cold forming is cost-effective, energy-efficient, and produces less scrap material compa…

7. Clark Engineering – Cold Heading Fasteners

Domain: clarkengineering.net

Registered: 2002 (23 years)

Introduction: Cold heading is a manufacturing process primarily used to create bolts, screws, and fasteners from metal. It minimizes raw material waste, producing net-shaped parts with little to no wastage. The process involves using specific machines tailored to the material and desired fastener type. Key techniques include ‘upsets’ and ‘extrusions,’ with forward and backward extrusion methods available. Cold …

8. ScienceDirect – Cold Heading Fasteners

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Cold heading is a specialized manufacturing method for producing fasteners and similar objects at room temperature using a coil of thick metal wire. The process involves shaping the wire through a series of blows in a machine called a ‘bolt maker.’ It relies on strain hardening and is primarily used for high-volume production of parts made from plain carbon and low alloy steels. Key features inclu…

Strategic Sourcing Conclusion and Outlook for cold heading

As the global manufacturing landscape continues to evolve, the significance of cold heading as a strategic sourcing method cannot be overstated. This efficient process not only minimizes waste but also enhances the physical properties of metal parts, making it an ideal choice for large-volume production. By leveraging tight tolerances and high-speed production rates, businesses can achieve significant cost reductions compared to traditional machining methods, thus optimizing their supply chains.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, embracing cold heading can lead to a competitive edge in both quality and pricing. The ability to customize fasteners and components tailored to specific applications allows for greater flexibility and innovation in product development.

Illustrative image related to cold heading

Looking ahead, as industries demand more sustainable and efficient manufacturing solutions, the cold heading process will undoubtedly play a pivotal role. We encourage you to explore partnerships with established cold heading suppliers to unlock the full potential of this technology. Engage with manufacturers who can deliver not just products, but comprehensive solutions that enhance your operational efficiencies and drive growth in your market. Your strategic sourcing decisions today will shape the success of your business tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.