Choosing Your Clamp Bungee Cord: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for clamp bungee cord

In the ever-evolving landscape of global trade, sourcing the right clamp bungee cord can be a daunting task for international B2B buyers. With increasing demand for versatile and durable fastening solutions across various industries, understanding the nuances of clamp bungee cord sourcing is crucial. This guide serves as a comprehensive resource, addressing the diverse types of clamp bungee cords available, their wide-ranging applications—from industrial uses to creative DIY projects—and the importance of effective supplier vetting.

We delve into critical factors such as cost considerations, material quality, and shipping logistics, which are especially pertinent for businesses operating in regions like Africa, South America, the Middle East, and Europe, including Brazil and Vietnam. By equipping buyers with the knowledge to make informed purchasing decisions, this guide empowers businesses to navigate the complexities of the global market confidently.

Whether you are looking for high-quality brass clips for DIY projects or robust stainless steel clamps for industrial applications, understanding the specifications, compliance standards, and supplier reliability is essential. This guide aims to simplify your sourcing journey, ensuring you find the right products to meet your business needs efficiently and effectively.

Understanding clamp bungee cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brass Bungee Cord Crimp Clips | Durable brass material, designed for 3/16” cords | DIY projects, custom assembly | Pros: Affordable, easy to use. Cons: Limited to specific cord size. |

| Stainless Steel Shock Cord Clamps | Blunt ends for safety, corrosion-resistant | Fisheries, outdoor equipment | Pros: High durability, suitable for wet environments. Cons: May require additional tools for application. |

| Adjustable Bungee Cord Clamps | Versatile sizing options, adjustable tension | Shipping, securing loads | Pros: Customizable fit, reusable. Cons: Potentially higher initial cost. |

| Hog Rings for Bungee Cords | Secure grip, designed for various cord sizes | Industrial applications, manufacturing | Pros: Strong hold, suitable for heavy-duty use. Cons: Requires specific tools for installation. |

| Side Clamps with Bungee Cord | Integrated bungee for tension, compatible with specific frames | Quilting, crafting | Pros: Easy setup, designed for specific applications. Cons: Limited versatility outside intended use. |

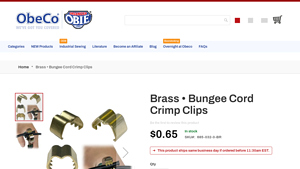

What Are the Key Characteristics of Brass Bungee Cord Crimp Clips?

Brass bungee cord crimp clips are notable for their robust construction, specifically made for 3/16” bungee cords. They are often utilized in DIY projects and custom assembly tasks. Buyers should consider their affordability and ease of use; however, they are limited to a specific cord size, which may restrict versatility in larger applications.

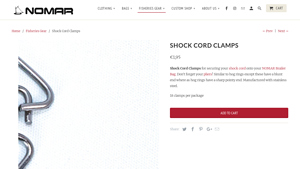

How Do Stainless Steel Shock Cord Clamps Stand Out in B2B Applications?

Manufactured from stainless steel, shock cord clamps are designed with blunt ends for enhanced safety. They are particularly popular in fisheries and outdoor equipment settings due to their corrosion resistance. While they provide exceptional durability in wet environments, buyers need to be aware that installation may require additional tools, which could add to the overall cost.

Why Choose Adjustable Bungee Cord Clamps for Your Business Needs?

Adjustable bungee cord clamps offer versatility with sizing and tension options, making them ideal for securing loads during shipping. Their reusable nature allows for cost-effective solutions in logistics and warehousing. Although they may come with a higher initial investment, their customizable fit can lead to long-term savings and efficiency.

What Advantages Do Hog Rings for Bungee Cords Offer?

Hog rings are designed to provide a secure grip for various bungee cord sizes, making them suitable for industrial applications and manufacturing processes. Their strong hold makes them ideal for heavy-duty use. However, buyers should note that specific tools are required for installation, which could be a consideration in terms of additional costs and training.

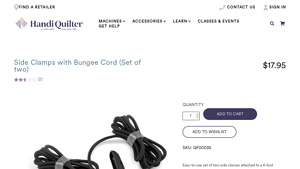

In What Scenarios Are Side Clamps with Bungee Cord Most Effective?

Side clamps with bungee cords are specifically designed for quilting and crafting, featuring an integrated bungee for tension. They are compatible with various quilting frames, making them easy to set up. While they excel in their intended applications, their versatility may be limited, which buyers should consider when assessing their overall utility.

Key Industrial Applications of clamp bungee cord

| Industry/Sector | Specific Application of clamp bungee cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Maritime | Securing fishing nets and gear | Enhances operational efficiency and safety in fishing operations | Durability in saltwater environments; corrosion resistance required |

| Construction | Temporary securing of materials and tools | Reduces risk of accidents and loss of materials on-site | Strength ratings; compliance with safety regulations |

| Automotive | Fastening parts during assembly | Streamlines production processes and improves assembly efficiency | Compatibility with various automotive components; load ratings |

| Agriculture | Holding tarps over crops or equipment | Protects crops from weather and enhances yield quality | UV resistance; adaptability to various agricultural setups |

| Textile and Quilting | Clamping fabric layers during sewing | Improves precision and quality of finished products | Compatibility with different fabric types; ease of use |

How is clamp bungee cord utilized in the maritime industry?

In the maritime sector, clamp bungee cords are essential for securing fishing nets and gear during transport and storage. Their elasticity allows for a snug fit that can adapt to varying loads, minimizing the risk of gear loss overboard. For international buyers, especially those in coastal regions of Africa and South America, sourcing bungee cords with high corrosion resistance is crucial to withstand harsh saltwater environments, ensuring longevity and reliability in demanding conditions.

What role does clamp bungee cord play in construction applications?

In construction, clamp bungee cords serve as a temporary fastening solution for materials and tools, enhancing safety by preventing accidental falls. Their versatility allows for quick adjustments, making them ideal for securing tarps or scaffolding. Buyers from Europe and the Middle East must consider strength ratings and compliance with local safety regulations to ensure that the bungee cords meet industry standards and can handle the specific loads expected on construction sites.

How do automotive manufacturers benefit from clamp bungee cord?

Automotive manufacturers use clamp bungee cords to fasten parts during assembly, which helps streamline the production process. These cords can hold components in place without the need for permanent fixtures, allowing for flexibility in assembly lines. When sourcing for automotive applications, international buyers should look for cords that meet stringent load ratings and compatibility requirements to ensure they can withstand the rigors of production environments.

In what ways do clamp bungee cords assist in agriculture?

In the agricultural sector, clamp bungee cords are utilized to hold tarps over crops or equipment, providing protection from adverse weather conditions. This application not only safeguards crops but can also enhance yield quality by controlling environmental exposure. Buyers, particularly from regions prone to intense weather fluctuations, should prioritize UV-resistant materials to ensure durability and effectiveness throughout the growing season.

How are clamp bungee cords beneficial in textile and quilting?

In the textile and quilting industries, clamp bungee cords are used to hold fabric layers together during sewing, ensuring precision and consistency in the final product. This application is particularly advantageous for manufacturers looking to improve the quality of their finished goods. Buyers should consider the compatibility of the bungee cords with various fabric types and the ease of use to ensure a seamless integration into their production processes.

3 Common User Pain Points for ‘clamp bungee cord’ & Their Solutions

Scenario 1: Misalignment of Product Specifications

The Problem: B2B buyers often face challenges when the specifications of clamp bungee cords do not align with their project requirements. This misalignment can occur due to a lack of clarity in the product descriptions or inadequate understanding of the intended use. For instance, a construction company might order clamp bungee cords designed for lightweight applications, only to find that they cannot withstand the tension required for heavy-duty equipment. Such discrepancies can lead to project delays and increased costs as the buyer scrambles to source the correct materials.

The Solution: To avoid such misalignment, buyers should invest time in thoroughly understanding the specifications of the clamp bungee cords they intend to purchase. This includes not only the load capacity and material type but also the dimensions and compatibility with other components in their systems. Engaging in direct communication with suppliers can provide clarity on product features. Additionally, creating a checklist of requirements tailored to specific projects can streamline the selection process. By ensuring that the specifications match the intended application, buyers can minimize the risk of costly errors and enhance project efficiency.

Scenario 2: Durability and Performance Concerns

The Problem: Another common pain point for B2B buyers is the durability and long-term performance of clamp bungee cords. In industries such as logistics and transportation, where bungee cords are frequently used for securing cargo, subpar quality can result in failures that compromise safety and increase liability. Buyers may discover that the cords they sourced degrade quickly under environmental stressors such as UV exposure or extreme temperatures, leading to unexpected replacements and operational disruptions.

The Solution: To ensure the durability of clamp bungee cords, buyers should prioritize sourcing from reputable manufacturers known for their quality standards. Investigating the material composition, such as whether the bungee cord is made from high-quality rubber or synthetic materials, can provide insights into longevity. Additionally, requesting samples or conducting performance tests can help assess their resistance to environmental factors. Establishing long-term relationships with suppliers that offer warranties or guarantees on their products can also be advantageous. By focusing on quality, buyers can protect their investments and maintain smooth operations.

Scenario 3: Sourcing and Supply Chain Challenges

The Problem: In today’s global market, B2B buyers often encounter sourcing and supply chain challenges that can delay project timelines. For instance, international buyers may face shipping delays or customs issues when importing clamp bungee cords, especially if they are reliant on suppliers from different regions. Such challenges can lead to stock shortages and the inability to fulfill orders on time, which can negatively impact client relationships and overall business performance.

The Solution: To mitigate these supply chain risks, buyers should diversify their supplier base and consider local or regional manufacturers that can provide faster turnaround times. Establishing relationships with multiple suppliers allows for greater flexibility and reduces reliance on a single source. Additionally, implementing inventory management systems can help track stock levels and forecast demand more accurately, enabling proactive ordering. Keeping open lines of communication with suppliers regarding lead times and potential disruptions can also prepare buyers to adjust their strategies accordingly. By being proactive in their sourcing approach, businesses can enhance their resilience against supply chain challenges and maintain consistent operations.

Strategic Material Selection Guide for clamp bungee cord

When selecting materials for clamp bungee cords, it is essential to consider the properties, advantages, disadvantages, and specific applications of each material. This analysis will focus on four common materials: rubber, nylon, polyester, and stainless steel. Each material offers unique benefits and limitations that can impact the overall performance and suitability for various applications.

What Are the Key Properties of Rubber for Clamp Bungee Cords?

Rubber is a widely used material in the production of clamp bungee cords due to its excellent elasticity and flexibility. It can withstand a wide range of temperatures, typically from -40°F to 200°F (-40°C to 93°C), making it suitable for various environments. Rubber is also resistant to abrasion and provides good grip, which enhances the performance of the bungee cord in securing loads.

Pros: The primary advantage of rubber is its high elasticity, allowing for significant stretch without permanent deformation. It is also relatively inexpensive and easy to manufacture into various shapes and sizes.

Illustrative image related to clamp bungee cord

Cons: However, rubber can degrade over time when exposed to UV light and certain chemicals, which may limit its lifespan in outdoor applications. Additionally, its temperature resistance, while decent, is not as high as some synthetic alternatives.

Impact on Application: Rubber bungee cords are ideal for applications requiring flexibility and stretch, such as securing lightweight items in transportation. However, they may not be suitable for heavy-duty applications where chemical exposure is likely.

How Does Nylon Perform in Clamp Bungee Cord Applications?

Nylon is a synthetic polymer known for its strength and durability. It offers excellent resistance to abrasion and wear, making it suitable for high-stress applications. Nylon can operate effectively in temperatures ranging from -40°F to 200°F (-40°C to 93°C) and has good UV resistance compared to rubber.

Pros: The key advantage of nylon is its high tensile strength, which allows it to handle heavy loads without breaking. It is also resistant to mildew and mold, making it suitable for outdoor use.

Illustrative image related to clamp bungee cord

Cons: On the downside, nylon can be more expensive than rubber and may require more complex manufacturing processes. Additionally, it can absorb moisture, which may weaken its structural integrity over time.

Impact on Application: Nylon bungee cords are particularly useful in applications requiring high strength and durability, such as in the marine industry or heavy-duty transportation. However, buyers must ensure that moisture exposure is managed to maintain performance.

What Are the Benefits of Polyester in Clamp Bungee Cords?

Polyester is another synthetic material that offers a balance between strength and flexibility. It is known for its excellent UV resistance and dimensional stability, making it suitable for outdoor applications. Polyester can typically withstand temperatures from -40°F to 180°F (-40°C to 82°C).

Pros: One of the main benefits of polyester is its resistance to fading and degradation from UV exposure, which extends the lifespan of the bungee cord in outdoor settings. It also has low moisture absorption, which helps maintain its strength.

Cons: However, polyester may not have the same level of elasticity as rubber or nylon, which can limit its stretch capabilities. It can also be more expensive than rubber.

Impact on Application: Polyester bungee cords are ideal for applications where UV exposure is a concern, such as in outdoor sports or camping gear. They offer a good compromise between durability and flexibility.

Why Choose Stainless Steel for Clamp Hardware?

Stainless steel is commonly used for the hardware components of clamp bungee cords, such as clips and hooks, due to its exceptional strength and corrosion resistance. It typically withstands temperatures ranging from -100°F to 800°F (-73°C to 427°C), making it suitable for various environments.

Pros: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which is essential for outdoor and marine applications. It also provides a secure connection, enhancing the overall performance of the bungee cord system.

Cons: The downside is that stainless steel can be heavier and more expensive than other materials, which may impact the overall weight and cost of the final product.

Impact on Application: Stainless steel is ideal for applications where strength and corrosion resistance are critical, such as in marine or industrial settings. Buyers should ensure compliance with relevant standards to ensure safety and performance.

Summary Table of Material Selection for Clamp Bungee Cords

| Material | Typical Use Case for clamp bungee cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General-purpose securing lightweight items | High elasticity and low cost | UV degradation and limited temperature range | Low |

| Nylon | Heavy-duty applications in marine and transport | High tensile strength and durability | Higher cost and moisture absorption | Med |

| Polyester | Outdoor sports and camping gear | Excellent UV resistance | Limited elasticity compared to rubber | Med |

| Stainless Steel | Hardware components in marine and industrial use | Exceptional strength and corrosion resistance | Heavier and more expensive | High |

This strategic material selection guide should assist international B2B buyers in making informed decisions regarding the most suitable materials for clamp bungee cords based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for clamp bungee cord

What Are the Key Stages in the Manufacturing Process of Clamp Bungee Cords?

The manufacturing process of clamp bungee cords involves several critical stages, ensuring that the final product meets the high standards expected by B2B buyers. Here’s a breakdown of the main stages:

-

Material Preparation: The first step involves sourcing high-quality raw materials, primarily elastic materials such as rubber, nylon, or polyester for the bungee cord itself, and metals like brass or stainless steel for clamps. Suppliers should provide material certifications to ensure compliance with international standards.

-

Forming: In this stage, the raw materials are cut and shaped into their respective forms. For bungee cords, this might involve extruding the elastic material into the desired diameter and length. Clamps are typically stamped or forged from metal sheets, ensuring they meet the required specifications for strength and durability.

-

Assembly: This stage involves the integration of bungee cords with clamps. Techniques like crimping or welding may be used to attach the clamps securely to the bungee cords. Automated assembly lines are often employed to enhance efficiency and consistency, but skilled labor is also crucial for quality control.

-

Finishing: The final stage includes any necessary finishing processes, such as applying protective coatings to metal parts to prevent corrosion or adding aesthetic elements. Quality checks are conducted throughout this stage to ensure that the products are free from defects and meet the specified tolerances.

How Do Quality Assurance Measures Ensure the Reliability of Clamp Bungee Cords?

Quality assurance (QA) is a vital aspect of the manufacturing process, particularly for products like clamp bungee cords, where safety and reliability are paramount. Here are some key QA measures:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with these standards ensures that manufacturers maintain consistent quality throughout their processes. Additionally, industry-specific standards such as CE marking for European markets or API for oil and gas applications may apply.

-

Quality Control Checkpoints: Effective QA processes incorporate several checkpoints, including:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): This entails ongoing inspections during manufacturing to identify and rectify issues in real time.

– Final Quality Control (FQC): A comprehensive inspection of finished products ensures they meet all design specifications and safety standards before shipping. -

Common Testing Methods: Various testing methods are employed to assess the performance and durability of clamp bungee cords. These may include tensile strength tests, fatigue tests, and environmental tests (e.g., UV exposure, temperature resistance). Manufacturers often conduct these tests in-house or through accredited third-party laboratories to ensure impartiality.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks. Here are actionable steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards and determine if the supplier has robust QA systems in place.

-

Requesting Quality Reports: Buyers should ask suppliers for documentation regarding their quality control processes, including inspection reports, testing results, and certifications. This transparency can help buyers make informed decisions.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control systems and product quality. These services can include pre-shipment inspections to ensure that products meet the agreed specifications.

-

Understanding Certification Nuances: Different regions may have varying certification requirements. For instance, while CE marking is crucial for products sold in Europe, other regions may require different certifications. Buyers should familiarize themselves with these requirements to ensure compliance and avoid potential issues.

How Do Regional Considerations Impact Quality Control for Clamp Bungee Cords?

Quality control practices may vary significantly across different regions, influenced by local regulations, market demands, and manufacturing capabilities. Here’s how regional considerations can impact quality control for clamp bungee cords:

Illustrative image related to clamp bungee cord

-

Regulatory Environment: Each region may have distinct regulations regarding materials and safety standards. For instance, European buyers might prioritize compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, while buyers in the Middle East may focus on local standards that govern materials used in construction or marine applications.

-

Market Expectations: B2B buyers in emerging markets may have different expectations regarding quality and pricing compared to those in established markets. Understanding these expectations can help manufacturers tailor their quality assurance processes to meet diverse customer needs.

-

Supply Chain Logistics: The complexities of international logistics can impact quality control. Delays or mishandling during transportation can affect product integrity. Buyers should work closely with suppliers to ensure that quality is maintained throughout the supply chain, from production to delivery.

In conclusion, the manufacturing processes and quality assurance measures for clamp bungee cords are intricate and vital for ensuring product reliability. By understanding these processes and implementing effective verification strategies, B2B buyers can secure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘clamp bungee cord’

This guide provides a structured approach for B2B buyers to effectively source clamp bungee cords, ensuring that they procure high-quality products suited for their specific applications. By following these steps, buyers can minimize risks and enhance their supply chain efficiency.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the clamp bungee cords. Consider factors such as size, material, load capacity, and intended use.

– Material Types: Look for durable options like nylon or elastomer blends for longevity.

– Dimensions: Specify the diameter and length that align with your application needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of reputable suppliers who specialize in clamp bungee cords. Utilize industry directories, trade shows, and online platforms to identify potential vendors.

– Supplier Background: Assess their experience in the industry and product offerings.

– Geographical Presence: Consider suppliers with a local or regional presence to facilitate quicker shipping and communication.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Quality Assurance: Inquire about their quality control processes to ensure consistency in product standards.

– Certifications: Verify any relevant industry certifications that demonstrate compliance with safety and quality regulations.

Step 4: Request Samples

Once you have narrowed down your list of suppliers, request samples of the clamp bungee cords. This allows you to evaluate the product quality firsthand.

– Performance Testing: Assess the samples under actual working conditions to gauge durability and performance.

– Compatibility Checks: Ensure that the clamps are compatible with your existing equipment or applications.

Step 5: Analyze Pricing and Terms

Compare pricing structures from different suppliers while considering the total cost of ownership, including shipping and potential duties.

– Volume Discounts: Inquire about bulk purchasing options to reduce costs.

– Payment Terms: Understand the payment options and terms offered, which can impact cash flow.

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations to finalize terms and conditions.

– Lead Times: Clarify production and delivery timelines to ensure alignment with your project schedules.

– Return Policies: Understand the return and warranty policies in case the products do not meet your expectations.

Step 7: Establish a Long-Term Relationship

After successful procurement, focus on building a long-term relationship with your supplier. Regular communication can lead to better service and pricing in the future.

– Feedback Loop: Provide feedback on product performance and service quality to foster improvements.

– Continuous Improvement: Discuss opportunities for product enhancements or custom solutions that may benefit your operations.

By following this checklist, B2B buyers can navigate the complexities of sourcing clamp bungee cords effectively, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for clamp bungee cord Sourcing

What Are the Key Cost Components for Clamp Bungee Cord Sourcing?

When sourcing clamp bungee cords, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to clamp bungee cord

-

Materials: The cost of raw materials varies significantly based on the type of bungee cord and clamps used. Common materials include rubber, nylon, and brass. The choice of material impacts not only the price but also the durability and performance of the product.

-

Labor: Labor costs encompass the wages paid to workers involved in production, assembly, and quality assurance. Regions with lower labor costs, such as parts of South America and Asia, may offer more competitive pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize overhead, leading to lower prices for buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs are usually amortized over the production run, making it essential to consider order quantities.

-

Quality Control: Ensuring product quality often involves additional testing and inspection costs. Buyers should inquire about the QC processes of suppliers to ensure they meet required standards.

-

Logistics: Shipping costs, including freight and insurance, can vary based on the Incoterms used and the shipping distance. International buyers should factor in these logistics costs to understand the total landed cost.

-

Margin: Suppliers will add a profit margin to cover their operational costs and risks. Understanding typical margins in the industry can assist buyers in evaluating offers.

How Do Price Influencers Affect Clamp Bungee Cord Costs?

Several factors influence the pricing of clamp bungee cords, which buyers must consider when sourcing.

-

Volume/MOQ: Many manufacturers have minimum order quantities (MOQ) that can significantly affect the price per unit. Higher order volumes often lead to discounts, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom-designed bungee cords or specific technical specifications may incur higher costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Premium materials and relevant certifications (e.g., ISO, CE) can increase costs but are often necessary for specific applications. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Established suppliers may command higher prices due to their experience and quality assurance practices.

-

Incoterms: The choice of Incoterms (such as FOB, CIF, or EXW) will influence logistics costs and risk allocation. Buyers should be well-versed in these terms to negotiate favorable shipping arrangements.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in sourcing clamp bungee cords.

-

Negotiate Terms: Engage suppliers in negotiations to explore flexible payment terms or bulk purchase discounts. Establishing a good relationship can lead to better pricing and terms over time.

-

Total Cost of Ownership: Consider the total cost of ownership, which includes purchase price, shipping, customs duties, and potential costs related to quality issues. This holistic view helps in making informed purchasing decisions.

-

Leverage Local Suppliers: Whenever possible, consider sourcing from local or regional suppliers to reduce logistics costs and lead times. This can also simplify communication and support.

-

Stay Informed on Market Trends: Regularly monitor material costs, tariffs, and international shipping rates to make timely purchasing decisions. Awareness of market fluctuations can enable buyers to capitalize on favorable pricing.

-

Request Samples: Before committing to large orders, request samples to assess quality. This practice helps ensure that the products meet your specifications and reduces the risk of costly returns.

In summary, a comprehensive understanding of the cost structure, pricing influencers, and strategic sourcing practices can significantly enhance the procurement process for clamp bungee cords. By applying these insights, international buyers can optimize their purchasing decisions and achieve better value in their sourcing endeavors.

Alternatives Analysis: Comparing clamp bungee cord With Other Solutions

When evaluating solutions for securing or fastening items, it is essential for B2B buyers to consider various alternatives to the clamp bungee cord. Each solution offers unique advantages and drawbacks that may align differently with specific operational needs and environments. This analysis will compare clamp bungee cords with two viable alternatives: shock cord clamps and traditional tie-down straps.

Illustrative image related to clamp bungee cord

| Comparison Aspect | Clamp Bungee Cord | Shock Cord Clamps | Tie-Down Straps |

|---|---|---|---|

| Performance | High elasticity and flexibility, ideal for dynamic loads | Secure and stable, excellent for fixed applications | Strong load capacity, reliable for heavy-duty use |

| Cost | Moderate ($0.65 – $1.50 each) | Moderate ($1.50 per pack) | Varies widely ($5 – $30) |

| Ease of Implementation | Simple to use, requires minimal tools | Requires pliers for installation | Requires more time to set up and adjust |

| Maintenance | Low; durable but may wear over time | Low; stainless steel is resistant to corrosion | Moderate; may need periodic checks for wear |

| Best Use Case | Ideal for applications requiring frequent adjustments | Best for securing items in a fixed position | Suitable for heavy loads in transport or storage |

What Are the Pros and Cons of Shock Cord Clamps as an Alternative?

Shock cord clamps are designed to securely attach shock cords to various applications, such as fishing gear or cargo bags. The primary advantage of these clamps is their ease of use; they provide a stable hold without the need for complex setups. Made from stainless steel, they resist corrosion, making them suitable for marine and outdoor applications. However, they are less flexible than bungee cords and may not accommodate dynamic loads as effectively. Their use is most beneficial in scenarios where items need to be secured in a fixed position, such as during transport.

How Do Traditional Tie-Down Straps Compare?

Traditional tie-down straps are another alternative that is widely used in logistics and transportation. These straps offer a high load capacity and are available in various lengths and strengths, making them versatile for securing heavy items. Their strength is a significant advantage, especially for heavy-duty applications. However, they require more time and effort to set up compared to clamp bungee cords, and users must ensure that they are tightened correctly to avoid slippage. Maintenance is also a consideration, as wear and tear can occur over time, necessitating routine inspections.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right solution depends largely on the specific requirements of the operation. If flexibility and frequent adjustments are critical, clamp bungee cords may be the best option. For applications requiring fixed positions and stability, shock cord clamps provide a robust solution. In contrast, for heavy-duty needs, traditional tie-down straps are ideal despite their longer setup time. B2B buyers should assess their operational needs, budget constraints, and maintenance capabilities when deciding on the most suitable securing method for their applications.

Essential Technical Properties and Trade Terminology for clamp bungee cord

What Are the Essential Technical Properties of Clamp Bungee Cord?

When sourcing clamp bungee cords, understanding their technical specifications is crucial for ensuring product suitability and performance in various applications. Below are key properties that international B2B buyers should consider:

-

Material Composition

Clamp bungee cords are typically made from rubber, nylon, or elastomeric materials. The choice of material affects elasticity, durability, and resistance to environmental factors such as UV light and moisture. For example, nylon offers high tensile strength, making it ideal for heavy-duty applications, while rubber provides excellent stretchability and resistance to wear. -

Diameter and Length Specifications

The diameter of bungee cords generally ranges from 1/8 inch to 1 inch, with lengths varying based on application needs. The diameter impacts the load capacity; thicker cords can handle heavier weights. Buyers should assess the specific requirements of their projects to select the appropriate size, ensuring safety and functionality. -

Tensile Strength

This property indicates the maximum load a bungee cord can support without breaking. It is essential for applications that require securing heavy items. Tensile strength is usually measured in pounds or kilograms, and understanding this measurement helps businesses determine the suitability of a product for their intended use. -

Elasticity and Recovery Rate

Elasticity refers to the ability of a bungee cord to stretch and return to its original shape. The recovery rate is the speed at which it returns to its original length after being stretched. High elasticity and a quick recovery rate are critical for applications involving repeated use, as they ensure reliability and efficiency. -

End Fittings and Compatibility

Clamp bungee cords come with various end fittings, such as hooks, clips, or crimped ends. Compatibility with existing equipment or systems is vital for seamless integration. Buyers should verify that the fittings match their specific use cases, whether for securing cargo, in manufacturing, or other applications. -

Environmental Resistance

Depending on the application, bungee cords may need to withstand specific environmental conditions such as extreme temperatures, moisture, or exposure to chemicals. Products designed for outdoor use often feature materials that resist UV degradation and water absorption, extending their lifespan and functionality.

What Trade Terminology Should B2B Buyers Understand for Clamp Bungee Cord?

Navigating the procurement process involves familiarizing oneself with industry-specific jargon. Here are essential terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products or components that are used in another company’s end product. Understanding this term helps buyers identify reputable suppliers who produce high-quality bungee cords that meet industry standards. -

MOQ (Minimum Order Quantity)

This term refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for businesses looking to maintain lean operations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. This process helps buyers compare costs and terms across multiple suppliers, ensuring competitive pricing and value for their purchases. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping responsibilities, risk management, and cost allocation. -

Lead Time

This term refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for effective project planning and inventory management, especially in industries where timing is critical. -

Custom Assemblies

Custom assemblies refer to products that are tailored to meet specific customer requirements. Buyers should inquire about options for custom bungee cord assemblies to ensure they receive solutions that fit their unique needs without compromising on quality.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their procurement processes and ensure the successful application of clamp bungee cords in their operations.

Navigating Market Dynamics and Sourcing Trends in the clamp bungee cord Sector

What Are the Current Market Trends Impacting the Clamp Bungee Cord Sector?

The clamp bungee cord market is currently influenced by several global drivers, including the increasing demand for versatile fastening solutions across various industries such as construction, shipping, and outdoor recreation. The rise of e-commerce and the DIY culture has also contributed to the growing popularity of bungee cords, making them essential for both commercial and personal use. In regions like Africa, South America, and the Middle East, infrastructure development and urbanization are spurring demand for reliable, durable fastening products. Furthermore, technological advancements in materials and manufacturing processes are leading to innovative clamp designs that enhance usability and strength, appealing to a broader audience of international B2B buyers.

Emerging sourcing trends are centered around digital platforms that facilitate quicker decision-making and procurement processes. Many suppliers are adopting e-commerce solutions, allowing buyers from diverse regions to access a wider range of products, compare prices, and place orders more efficiently. Additionally, the shift towards customized solutions is significant, as businesses increasingly seek tailored products that meet specific operational requirements. This trend is particularly prevalent in Europe, where businesses value quality and are willing to invest in products that offer superior performance and longevity.

How Is Sustainability Influencing Sourcing in the Clamp Bungee Cord Sector?

Sustainability has become a pivotal consideration for B2B buyers in the clamp bungee cord sector. The environmental impact of production processes and materials used in manufacturing bungee cords is under scrutiny, prompting suppliers to adopt greener practices. Ethical sourcing is now a priority, with businesses seeking suppliers that demonstrate a commitment to sustainable practices, from the sourcing of raw materials to manufacturing processes that minimize waste and energy consumption.

Buyers are increasingly looking for products that come with green certifications, such as those that indicate the use of recycled or eco-friendly materials. For example, bungee cords made from natural rubber or biodegradable materials are gaining traction, appealing to companies aiming to reduce their carbon footprint. The importance of transparency in supply chains cannot be overstated; buyers are demanding visibility into sourcing practices to ensure compliance with environmental and ethical standards. This trend not only enhances brand reputation but also aligns with the growing consumer preference for sustainability.

How Has the Clamp Bungee Cord Market Evolved Over Time?

The clamp bungee cord market has undergone significant evolution, transitioning from basic elastic materials to sophisticated, high-performance products designed for a multitude of applications. Historically, bungee cords were primarily used in recreational settings, such as outdoor activities and sports. However, as industries recognized their utility, applications expanded to include logistics, automotive, and construction sectors.

Over the years, advancements in material science have led to the development of more durable and versatile bungee cords, with enhanced elasticity and weather resistance. The introduction of clamps and other hardware has further broadened their functionality, allowing for secure fastening and load management in various conditions. As a result, the market has seen an influx of innovative designs tailored to meet the evolving needs of B2B buyers, emphasizing the importance of adaptability in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of clamp bungee cord

-

How do I choose the right clamp bungee cord for my application?

Choosing the right clamp bungee cord involves considering the specific requirements of your application, including load capacity, material, and environmental conditions. For heavier loads, opt for heavy-duty bungee cords made from durable materials like nylon or EPDM. Additionally, evaluate the clamp type; some are designed for specific applications, such as fishing gear or industrial use. Always refer to the manufacturer’s specifications to ensure compatibility with your equipment. -

What are the advantages of using clamp bungee cords in industrial settings?

Clamp bungee cords offer versatility and reliability in industrial settings. They provide secure fastening for various equipment, reducing the risk of slippage or damage during transport. Their elasticity allows for easy adjustments and tension control, making them ideal for applications ranging from securing loads on trucks to supporting equipment in manufacturing processes. Moreover, their reusable nature promotes sustainability, making them a cost-effective choice for businesses. -

What are the common materials used in clamp bungee cords, and how do they differ?

Clamp bungee cords are typically made from materials such as latex, nylon, and EPDM rubber. Latex bungee cords offer high elasticity and are lightweight, suitable for lighter applications. Nylon cords provide enhanced durability and resistance to wear, making them ideal for heavy-duty use. EPDM rubber is known for its weather resistance, making it suitable for outdoor applications. Choose the material based on your specific needs, considering factors like load requirements and environmental exposure. -

How can I ensure the quality of clamp bungee cords from suppliers?

To ensure quality, select suppliers who provide clear product specifications, certifications, and testing results. Request samples to evaluate the materials and construction firsthand. It’s also beneficial to check for reviews or testimonials from other businesses that have sourced from the supplier. Lastly, establish a quality assurance process that includes regular inspections and compliance checks to maintain standards throughout the procurement process. -

What are typical minimum order quantities (MOQ) for clamp bungee cords?

Minimum order quantities for clamp bungee cords can vary significantly between suppliers. Generally, MOQs range from 100 to 1,000 units, depending on the product type and supplier policies. For custom orders, the MOQ might be higher due to production setup costs. It’s advisable to communicate your needs directly with the supplier to negotiate favorable terms, especially if you anticipate regular orders or larger volumes in the future. -

What payment terms should I expect when sourcing clamp bungee cords internationally?

Payment terms can vary widely by supplier and region. Common terms include full payment upfront, partial payments (e.g., 30% deposit, 70% upon delivery), or net payment terms (e.g., net 30 or net 60 days). It’s essential to clarify these terms before placing an order and to consider using secure payment methods like letters of credit for international transactions. Be aware of currency fluctuations and potential transaction fees, especially when dealing with suppliers across different countries. -

How do I handle logistics and shipping for clamp bungee cords from international suppliers?

Logistics for international shipments can be complex. Start by understanding the supplier’s shipping options, including freight forwarders and carriers. Confirm shipping costs, delivery times, and customs requirements. It’s advisable to work with a logistics partner who specializes in international trade to navigate import/export regulations. Additionally, consider insurance for high-value shipments to mitigate risks during transit. -

What are the best practices for vetting suppliers of clamp bungee cords?

When vetting suppliers, conduct thorough research to evaluate their credibility and reliability. Check their business registration, certifications, and industry reputation. Request references from previous clients, and if possible, visit their manufacturing facilities. Assess their responsiveness and communication skills, as these factors can indicate their commitment to customer service. Additionally, verify their compliance with international quality standards to ensure they meet your expectations.

Top 6 Clamp Bungee Cord Manufacturers & Suppliers List

1. Organized Obie – Brass Bungee Cord Crimp Clips

Domain: organizedobie.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “Brass Bungee Cord Crimp Clips”, “price”: “$0.65”, “SKU”: “685-032-0-BR”, “availability”: “In stock”, “shipping_info”: “This product ships same business day if ordered before 11:30am EST.”, “description”: “Brass clips for mating bungee cords together and creating loops.”, “dimensions”: “3/8″ 9mm wide”, “compatible_bungee”: “For 3/16 bungee only. NOT for 1/4 bungee.”, “color”: “Bra…

2. NOMAR – Shock Cord Clamps

Domain: nomaralaska.com

Registered: 1999 (26 years)

Introduction: Shock Cord Clamps for securing shock cord onto NOMAR Brailer Bag. Price: $1.50. Quantity: 18 clamps per package. Material: Stainless steel. Features: Blunt end design, similar to hog rings but without the sharp point.

3. Handi Quilter – Side Clamps with Bungee Cord Set

Domain: handiquilter.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Side Clamps with Bungee Cord (Set of two)”, “sku”: “QF00035”, “price”: “$17.95”, “weight”: “0.4 lbs”, “dimensions”: “5 × 4 × 1.5 in”, “description”: “Easy-to-use set of two side clamps attached to a 6-foot bungee cord. Compatible with HQ Studio, HQ Studio2, or HQ Studio3 frames, HQ Gallery/Gallery2 Frame, or HQ Fusion Frame, which have an opening in the sidearms designed to hold …

4. The Bungee Store – Shock Cord Accessories

Domain: thebungeestore.com

Registered: 2014 (11 years)

Introduction: 1. Shock cord steel rings: Sizes 6mm to 10mm; used for crimping bungee cords, securing knots, preventing fraying, and attaching accessories. Requires ring pincers for secure attachment. 2. Shock cord clamps: Available in sizes 4-6mm and 8-10mm; used for securing bungee cords to hooks. Recommended to use alligator pliers for secure attachment. 3. Steel hog rings: Sizes small (4-5mm), medium (6-7mm)…

5. Bosun Supplies – Stainless Steel Shock Cord Hooks

Domain: bosunsupplies.com

Registered: 1997 (28 years)

Introduction: Stainless Steel Shock Cord Hooks and Hog Rings

6. Sailrite – Hog Rings & Shock Cord Clamps

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: This company, Sailrite – Hog Rings & Shock Cord Clamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for clamp bungee cord

The strategic sourcing of clamp bungee cords presents an essential opportunity for international B2B buyers to enhance operational efficiency and product reliability. By focusing on quality materials and reliable suppliers, organizations can ensure they meet the demands of diverse markets while managing costs effectively. The increasing trend towards customized solutions, as seen in various suppliers’ offerings, allows businesses to tailor products to specific applications, further adding value.

Illustrative image related to clamp bungee cord

Moreover, understanding the implications of global trade dynamics, such as tariffs and supply chain disruptions, is crucial for making informed purchasing decisions. Buyers should prioritize suppliers that demonstrate transparency and adaptability in their operations. This proactive approach not only mitigates risks but also fosters long-term partnerships that can lead to competitive advantages.

As we look ahead, the demand for high-quality clamp bungee cords is likely to grow, driven by their versatile applications across various industries. International buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to engage with reliable suppliers to capitalize on these market opportunities. Embrace strategic sourcing today to secure a robust supply chain that can support your business’s growth and innovation in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to clamp bungee cord

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.