Choosing Your Cargo Aircraft For Sale: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for cargo aircraft for sale

In today’s rapidly evolving global marketplace, sourcing cargo aircraft for sale poses a significant challenge for international B2B buyers. With fluctuating demand, diverse regulatory environments, and the need for efficient logistics solutions, stakeholders from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—must navigate a complex landscape. This guide serves as a comprehensive resource, offering insights into the various types of cargo aircraft, their applications, and the critical factors that influence purchasing decisions.

Buyers will gain a thorough understanding of the different aircraft configurations available, from freighters to converted passenger planes, as well as their respective payload capacities and operational efficiencies. The guide also delves into essential topics such as supplier vetting processes, cost considerations, and maintenance requirements, equipping decision-makers with the knowledge to make informed investments. By addressing the unique challenges faced by international buyers, this guide empowers organizations to streamline their procurement processes, ensuring they secure the right aircraft to meet their logistics needs effectively.

In a market characterized by rapid changes and increasing competition, having access to reliable information is paramount. This guide not only demystifies the purchasing process but also positions buyers for success in leveraging cargo aircraft to enhance their operational capabilities.

Understanding cargo aircraft for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Narrow-Body Freighters | Typically converted from passenger aircraft, smaller cargo capacity | Regional shipping, express freight | Pros: Lower operating costs; flexible routes. Cons: Limited cargo volume. |

| Wide-Body Freighters | Larger cargo capacity, often designed for heavy loads | Intercontinental shipping, bulk freight | Pros: High payload; efficient for long distances. Cons: Higher acquisition and operating costs. |

| Dedicated Cargo Aircraft | Built specifically for cargo with optimized loading systems | Specialized freight services, heavy machinery | Pros: Tailored design for cargo; maximized efficiency. Cons: Limited versatility for passenger use. |

| Combi Aircraft | Dual configuration for both cargo and passengers | Mixed-use operations in niche markets | Pros: Flexibility in operations; diversified revenue. Cons: Complexity in management and maintenance. |

| Regional Cargo Aircraft | Smaller aircraft designed for short-haul routes | Local delivery services, small parcel shipping | Pros: Cost-effective for short distances; quick turnaround. Cons: Limited range and payload capacity. |

What are the Characteristics of Narrow-Body Freighters?

Narrow-body freighters are often converted from existing passenger aircraft models, such as the Boeing 737 or Airbus A320. They are characterized by their smaller cargo holds and typically accommodate around 10 to 20 tons of payload. These aircraft are ideal for regional shipping and express freight services, allowing businesses to efficiently transport goods over shorter distances. When considering a purchase, buyers should evaluate the aircraft’s conversion history and maintenance records to ensure reliability and cost-effectiveness.

How Do Wide-Body Freighters Stand Out in the Cargo Market?

Wide-body freighters, like the Boeing 747 or Airbus A330, are designed to handle larger cargo volumes, often exceeding 100 tons. Their spacious interiors and advanced loading systems make them suitable for intercontinental shipping and bulk freight operations. Buyers should consider factors such as fuel efficiency, range, and payload capacity when assessing these aircraft. While they offer high performance for long-distance transportation, their higher acquisition and operating costs necessitate a thorough financial analysis.

What Advantages Do Dedicated Cargo Aircraft Offer?

Dedicated cargo aircraft are specifically engineered for freight operations, featuring optimized cargo loading systems and configurations. Models such as the Boeing 767 Freighter provide significant advantages in terms of efficiency and capacity. These aircraft excel in specialized freight services, including the transport of heavy machinery or perishable goods. Buyers should prioritize the aircraft’s operational history and compliance with regulatory standards to ensure it meets their logistics needs.

Why Choose Combi Aircraft for Mixed Operations?

Combi aircraft are unique in that they can transport both cargo and passengers simultaneously, making them ideal for mixed-use operations in niche markets. They typically feature a flexible cabin layout that can be adjusted based on demand. This versatility allows businesses to diversify revenue streams, but it also introduces complexity in management and maintenance. Buyers must assess the operational requirements and market demand in their regions to determine the viability of such an investment.

What Makes Regional Cargo Aircraft Suitable for Local Deliveries?

Regional cargo aircraft are designed for short-haul routes and typically have a smaller payload capacity, making them cost-effective for local delivery services. They are well-suited for transporting small parcels and time-sensitive shipments. Buyers should evaluate the aircraft’s range and turnaround capabilities, as these factors significantly impact operational efficiency. While they may not handle large volumes, their quick delivery times can be a competitive advantage in local markets.

Key Industrial Applications of cargo aircraft for sale

| Industry/Sector | Specific Application of cargo aircraft for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Logistics | Rapid delivery of goods across regions | Enhanced supply chain efficiency and customer satisfaction | Aircraft capacity, range, and operational costs |

| Humanitarian Aid | Transport of emergency supplies to disaster zones | Quick response to crises, saving lives and resources | Aircraft reliability, payload capacity, and turnaround time |

| Mining & Resource Extraction | Transporting heavy machinery and supplies | Reduced downtime and efficient logistics in remote areas | Cargo hold dimensions and loading systems |

| Agriculture & Food Supply | Air freight for perishable goods | Maintaining product freshness and reducing spoilage | Temperature control capabilities and cargo handling systems |

| Pharmaceuticals | Distribution of medical supplies and vaccines | Timely delivery of critical health products | Compliance with international regulations and storage conditions |

How Are Cargo Aircraft Used in E-commerce & Logistics?

In the e-commerce sector, cargo aircraft are vital for ensuring rapid delivery of goods across vast distances, particularly in regions with limited infrastructure. International B2B buyers from areas like Africa and South America can leverage cargo aircraft to enhance their supply chain efficiency. The ability to transport large volumes of products quickly can significantly improve customer satisfaction and competitiveness in the market. Buyers should consider aircraft capacity, range, and operational costs when sourcing to optimize their logistics operations.

What Role Do Cargo Aircraft Play in Humanitarian Aid?

Cargo aircraft are essential in humanitarian aid scenarios, allowing for the swift transport of emergency supplies to disaster-stricken areas. This capability is crucial for timely responses that can save lives and resources. For international buyers, especially in regions prone to natural disasters, sourcing reliable aircraft with substantial payload capacity and efficient turnaround times becomes a priority. The ability to respond quickly can make a significant difference in crisis situations.

How Do Cargo Aircraft Support Mining & Resource Extraction?

In the mining and resource extraction industries, cargo aircraft facilitate the transport of heavy machinery and supplies to remote locations, significantly reducing downtime. This is particularly important in regions with challenging access, such as parts of Africa and South America. Buyers in this sector should focus on the aircraft’s cargo hold dimensions and loading systems to ensure compatibility with their specific operational needs. Efficient logistics can lead to increased productivity and cost savings.

Why Are Cargo Aircraft Important for Agriculture & Food Supply?

Cargo aircraft are increasingly used to air freight perishable goods, such as fruits and vegetables, to maintain product freshness and reduce spoilage during transport. This is particularly valuable for international B2B buyers in agricultural sectors across Europe and the Middle East, where timely delivery can directly impact market prices and consumer satisfaction. Buyers should evaluate the aircraft’s temperature control capabilities and cargo handling systems to ensure compliance with food safety standards.

Illustrative image related to cargo aircraft for sale

How Do Cargo Aircraft Facilitate Pharmaceutical Distribution?

In the pharmaceutical industry, cargo aircraft are crucial for the distribution of medical supplies and vaccines, especially in times of urgent need. Timely delivery can be life-saving, making it essential for international buyers to source aircraft that comply with stringent regulations regarding medical transport. Factors such as storage conditions and reliability are critical considerations when selecting cargo aircraft for this high-stakes sector.

3 Common User Pain Points for ‘cargo aircraft for sale’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance in Different Regions

The Problem: When considering the purchase of cargo aircraft, B2B buyers often face the challenge of navigating complex regulatory requirements that vary significantly by region. For instance, regulations in Europe may differ from those in Africa or South America, complicating the acquisition process. Buyers may struggle with understanding airworthiness standards, maintenance requirements, and operational regulations, which can delay purchases and lead to compliance issues post-acquisition.

The Solution: To effectively manage these regulatory challenges, buyers should engage with local aviation authorities or industry consultants who specialize in aircraft acquisition and compliance. Researching the specific regulations in the target purchase region is critical. Establishing a relationship with a knowledgeable broker who understands the nuances of these regulations can help streamline the process. Additionally, buyers should prioritize aircraft that come with documentation verifying compliance with the necessary regulations, which can ease the transition into their operational environment. Regularly attending industry forums and workshops can also provide insights into changing regulations, ensuring that buyers stay informed.

Illustrative image related to cargo aircraft for sale

Scenario 2: Assessing Aircraft Condition and Maintenance History

The Problem: A significant pain point for B2B buyers is assessing the condition and maintenance history of cargo aircraft for sale. Buyers often encounter difficulty verifying the aircraft’s maintenance records, which are crucial for ensuring safety and reliability. Insufficient or unclear documentation can lead to unexpected maintenance costs or operational downtimes, causing financial strain and potential loss of business.

The Solution: To mitigate this risk, buyers should adopt a rigorous due diligence process before finalizing any purchase. This includes requesting comprehensive maintenance logs, airworthiness certificates, and any documentation related to previous inspections or repairs. Engaging a third-party maintenance inspector or aviation consultant to conduct a pre-purchase inspection can provide an unbiased assessment of the aircraft’s condition. Buyers should also look for aircraft with a well-documented history of compliance with maintenance schedules and inspections. Establishing a checklist of critical components to inspect, such as engine health, airframe condition, and avionics functionality, can further aid in making informed decisions.

Scenario 3: Understanding Total Cost of Ownership

The Problem: Many B2B buyers overlook the total cost of ownership when purchasing cargo aircraft, focusing primarily on the initial purchase price. This can lead to unexpected financial burdens, as ongoing costs such as maintenance, insurance, fuel, and regulatory compliance can significantly impact the overall expenditure associated with aircraft operation. Buyers might find themselves unprepared for these costs, affecting their operational budgets and profit margins.

The Solution: To navigate this challenge, prospective buyers should conduct a comprehensive cost analysis that goes beyond the purchase price. This analysis should include estimates for maintenance costs, insurance premiums, fuel consumption, and potential upgrades needed to meet regulatory standards. Engaging with financial advisors or aircraft management firms can provide valuable insights into these ongoing costs. Buyers should also consider the aircraft’s operational efficiency and fuel economy, as these factors can lead to substantial savings over time. Utilizing financial modeling tools to project long-term costs can help buyers make more informed purchasing decisions and secure a more sustainable investment.

Illustrative image related to cargo aircraft for sale

Strategic Material Selection Guide for cargo aircraft for sale

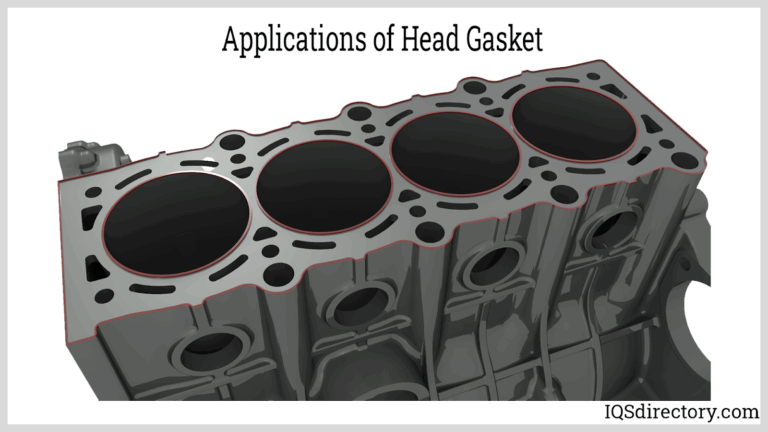

What Are the Key Materials Used in Cargo Aircraft Construction?

When considering the purchase of cargo aircraft, understanding the materials used in their construction is crucial for making informed decisions. The materials not only affect the performance and durability of the aircraft but also influence maintenance costs and compliance with international standards. Here, we analyze four common materials used in cargo aircraft construction: aluminum alloys, composite materials, titanium, and steel.

How Do Aluminum Alloys Contribute to Aircraft Performance?

Aluminum alloys are widely used in the aerospace industry due to their excellent strength-to-weight ratio and corrosion resistance. Key properties include a temperature rating of up to 150°C and a pressure rating that can withstand significant loads, making them suitable for various structural components.

Pros: Aluminum alloys are lightweight, which enhances fuel efficiency and payload capacity. They are also relatively cost-effective and easy to manufacture, allowing for complex shapes and designs.

Cons: While durable, aluminum alloys can be susceptible to fatigue over time, particularly in high-stress areas. They may also require protective coatings to enhance corrosion resistance, adding to maintenance costs.

Impact on Application: Aluminum’s compatibility with various media, including fuel and hydraulic fluids, makes it a preferred choice for aircraft construction.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential, especially in regions like Europe and the Middle East, where stringent regulations govern aircraft materials.

What Role Do Composite Materials Play in Cargo Aircraft?

Composite materials, particularly carbon fiber reinforced polymers (CFRP), are increasingly used in cargo aircraft for their high strength and low weight. They can withstand temperatures up to 200°C and are highly resistant to corrosion.

Pros: Composites offer superior durability and reduced weight, leading to significant fuel savings and lower operational costs. They also provide design flexibility, allowing for aerodynamic shapes that enhance performance.

Cons: The manufacturing process for composites is complex and can be more expensive than traditional materials. Repairing composite structures can also be challenging, requiring specialized skills and equipment.

Impact on Application: Composites are particularly effective in areas subject to high stress and corrosion, such as cargo doors and fuselage sections.

Considerations for International Buyers: In markets like Africa and South America, where maintenance capabilities may vary, the complexity of composite repairs could be a limiting factor.

How Does Titanium Enhance Aircraft Durability?

Titanium is known for its exceptional strength and corrosion resistance, making it ideal for critical components such as landing gear and engine mounts. It can handle extreme temperatures and pressures, withstanding conditions that would compromise other materials.

Pros: Titanium’s durability reduces the frequency of replacements and repairs, leading to lower long-term costs. Its lightweight nature also contributes to overall fuel efficiency.

Cons: The high cost of titanium and the complexity of its machining can increase initial manufacturing expenses. Additionally, its availability may be limited in certain regions.

Impact on Application: Titanium is particularly beneficial in environments where corrosion is a significant concern, such as coastal or humid regions.

Illustrative image related to cargo aircraft for sale

Considerations for International Buyers: Buyers from the Middle East and Europe should ensure compliance with international material standards, as titanium’s use is often regulated due to its strategic importance.

What Advantages Does Steel Offer in Cargo Aircraft?

Steel is traditionally used in cargo aircraft for structural components due to its high strength and durability. It can withstand high temperatures and pressures, making it suitable for various applications.

Pros: Steel is relatively inexpensive compared to other aerospace materials and is widely available. Its strength makes it an excellent choice for high-stress areas, ensuring structural integrity.

Cons: The weight of steel can negatively impact fuel efficiency and payload capacity. Additionally, it is prone to corrosion, necessitating protective coatings and regular maintenance.

Impact on Application: Steel is commonly used in landing gear and other load-bearing structures, where strength is paramount.

Considerations for International Buyers: Compliance with standards like JIS and ASTM is crucial, especially in regions with strict aviation regulations.

Summary Table of Material Selection for Cargo Aircraft

| Material | Typical Use Case for cargo aircraft for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Fuselage and wing structures | Lightweight, cost-effective | Susceptible to fatigue | Medium |

| Composite Materials | Cargo doors and fuselage sections | High strength, low weight | Complex manufacturing and repair | High |

| Titanium | Landing gear and engine mounts | Exceptional strength and durability | High cost and limited availability | High |

| Steel | Structural components like landing gear | Inexpensive and widely available | Heavy and prone to corrosion | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, aiding in the decision-making process when purchasing cargo aircraft. Understanding the properties, advantages, and limitations of these materials will enable buyers to choose the most suitable options for their operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for cargo aircraft for sale

What Are the Main Stages in the Manufacturing Process of Cargo Aircraft?

The manufacturing process for cargo aircraft is a sophisticated endeavor, involving several critical stages that ensure the final product meets stringent performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to cargo aircraft for sale

Material Preparation: This initial stage involves sourcing high-quality materials that meet the rigorous specifications for aerospace applications. Common materials include lightweight aluminum alloys, composite materials, and titanium, all of which contribute to the aircraft’s durability and efficiency. Suppliers must adhere to international standards like ISO 9001, which ensures quality management systems are in place.

Forming: In the forming stage, raw materials are shaped into components using various techniques such as machining, stamping, and forging. Advanced technologies like computer numerical control (CNC) machining are commonly employed to achieve precise tolerances and complex geometries. This stage is crucial for parts like fuselage sections, wings, and cargo doors, which must withstand significant stress during operation.

Assembly: The assembly process involves bringing together the various components into a cohesive unit. This stage often employs modular assembly techniques, allowing for efficiency and flexibility in production. Skilled technicians meticulously assemble parts, ensuring that each component fits perfectly and functions as intended. This stage is also where systems like avionics, hydraulic systems, and cargo loading mechanisms are integrated.

Illustrative image related to cargo aircraft for sale

Finishing: The final stage of manufacturing involves surface treatments, painting, and final inspections. Coatings are applied to protect against corrosion and enhance aerodynamics. Quality assurance checks are performed at this stage to confirm that all specifications have been met before the aircraft is delivered to the buyer.

How Is Quality Assurance Implemented in Cargo Aircraft Manufacturing?

Quality assurance (QA) in the manufacturing of cargo aircraft is paramount, given the critical safety and operational standards required in aviation. Manufacturers typically adhere to a combination of international standards and industry-specific regulations.

International Standards: ISO 9001 is one of the primary international standards for quality management systems. Compliance with ISO 9001 ensures that manufacturers maintain consistent quality throughout their processes. Other relevant certifications may include AS9100, which is specifically tailored for the aerospace industry.

Industry-Specific Standards: In addition to ISO certifications, manufacturers must comply with aviation authority regulations, such as the European Union Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) in the United States. These organizations set stringent safety and performance criteria that manufacturers must meet.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that cargo aircraft meet all necessary specifications before they reach the market. Common QC checkpoints include:

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials and components upon arrival to verify that they meet specified quality standards. This includes checking certifications and conducting material tests.

In-Process Quality Control (IPQC): During the manufacturing process, IPQC ensures that each stage of production adheres to quality standards. This involves regular inspections and tests to catch any deviations early in the process.

Final Quality Control (FQC): Once assembly is complete, the FQC stage includes comprehensive testing and inspections of the finished aircraft. This may involve functional testing of systems, structural integrity tests, and verification of compliance with all regulatory requirements.

What Common Testing Methods Are Used in Cargo Aircraft Quality Assurance?

Various testing methods are employed to ensure the safety and reliability of cargo aircraft. Some of the most common methods include:

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle testing, and radiographic testing are used to detect internal flaws without damaging the components. These methods are critical for ensuring the integrity of structural components.

Functional Testing: This involves testing all aircraft systems, including avionics, hydraulics, and cargo handling systems, to ensure they operate correctly under simulated conditions.

Load Testing: Structural components undergo load testing to confirm they can withstand operational stresses. This is especially important for cargo aircraft, which must handle heavy loads efficiently.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are some actionable steps:

Conduct Audits: Regular audits of suppliers can provide insight into their quality management systems and compliance with international standards. Buyers should request access to audit reports and corrective action plans.

Request Documentation: Buyers should ask for quality assurance documentation, including certificates of compliance, inspection reports, and test results. This documentation provides evidence that the supplier adheres to established quality standards.

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspectors can conduct thorough evaluations and provide detailed reports on the supplier’s adherence to quality standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating quality control and certification nuances can be complex for international B2B buyers. Here are several considerations:

Understanding Local Regulations: Buyers must familiarize themselves with the regulatory requirements in their respective countries. For instance, cargo aircraft sold in Europe must comply with EASA regulations, while those in the U.S. must meet FAA standards.

Illustrative image related to cargo aircraft for sale

Language and Documentation Barriers: When dealing with international suppliers, language differences can create challenges. Buyers should ensure that all documentation is available in a language they understand, and they should seek clarification on any ambiguous terms.

Cultural Differences in Quality Standards: Different regions may have varying perceptions of quality and safety standards. It is crucial for buyers to establish clear expectations and communicate these effectively to suppliers to ensure alignment.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when purchasing cargo aircraft, ensuring they invest in reliable and compliant products tailored to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cargo aircraft for sale’

In the competitive market for cargo aircraft, making an informed purchase is crucial. This practical sourcing guide serves as a step-by-step checklist for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By following these steps, you can ensure a successful procurement process that meets your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the type of cargo you will transport, the weight capacity required, and the range needed for your operations. This will help narrow down options and ensure that the aircraft you select meets your logistical demands.

- Payload Capacity: Determine the maximum weight your aircraft needs to carry.

- Cargo Volume: Assess the cubic meter (CBM) requirements based on your typical shipments.

Step 2: Research Available Aircraft Models

Conduct thorough research on the models available in the market. This includes understanding the specifications, maintenance history, and performance of different aircraft types, such as the Boeing 747F, 767F, or smaller freighters like the 737F.

Illustrative image related to cargo aircraft for sale

- Market Trends: Analyze current market trends to identify which aircraft types are in demand.

- Manufacturer Reputation: Look for models from reputable manufacturers known for reliability and performance.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This helps ensure that you are dealing with a credible and experienced supplier.

- Supplier Certifications: Check for necessary certifications like FAA or EASA approvals.

- Client Testimonials: Look for reviews or testimonials from previous clients to gauge their satisfaction.

Step 4: Inspect Aircraft Condition

Conduct a thorough inspection of any aircraft you are considering. This includes reviewing maintenance records, checking the aircraft’s physical condition, and confirming compliance with safety regulations.

- Maintenance History: Request detailed maintenance logs to ensure the aircraft has been properly cared for.

- Physical Inspection: If possible, arrange for a physical inspection by a qualified aircraft engineer.

Step 5: Verify Legal and Regulatory Compliance

Ensure that the aircraft complies with all legal and regulatory requirements in your target operating regions. This is particularly important for international transactions, as regulations can vary significantly.

- Documentation: Verify that all necessary documents, including airworthiness certificates and registration, are in order.

- Import Regulations: Understand the import regulations in your country to avoid legal issues post-purchase.

Step 6: Negotiate Purchase Terms

Once you have selected an aircraft and verified its condition, negotiate the purchase terms. This includes price, payment methods, and delivery timelines. Clear terms can prevent misunderstandings and ensure a smooth transaction.

- Payment Terms: Discuss whether a full payment or a deposit is required upfront.

- Delivery Schedule: Confirm the expected delivery date to align with your operational plans.

Step 7: Conduct Post-Purchase Follow-Up

After the purchase, maintain communication with the supplier and ensure a smooth transition into operation. This includes setting up maintenance schedules and training for your crew if necessary.

- Maintenance Contracts: Consider establishing a maintenance contract with the supplier for ongoing support.

- Operational Training: Ensure that your team is trained on the specific aircraft systems for efficient operation.

By following this structured approach, B2B buyers can successfully navigate the complexities of sourcing cargo aircraft, ensuring that their investment aligns with their business objectives and operational needs.

Comprehensive Cost and Pricing Analysis for cargo aircraft for sale Sourcing

What Are the Key Cost Components for Sourcing Cargo Aircraft?

When sourcing cargo aircraft, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: This encompasses the raw materials used in aircraft construction, which can vary significantly based on aircraft type and specifications. Advanced materials for lightweight construction can lead to higher upfront costs but lower operating expenses due to fuel efficiency.

-

Labor: Skilled labor is required for manufacturing and assembling cargo aircraft. Labor costs vary by region and can be influenced by local wage standards and labor laws.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The equipment and tools required for the manufacturing process also contribute to costs. Custom tooling for specialized aircraft can add to the initial investment.

-

Quality Control (QC): Ensuring compliance with aviation standards requires rigorous quality checks, which can add to the overall cost. Aircraft with higher certifications may command a premium due to their proven reliability.

-

Logistics: Transportation of aircraft and components can be a significant cost factor, especially for international buyers. Understanding Incoterms is crucial for managing these logistics costs effectively.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the aircraft’s demand, market conditions, and supplier reputation.

How Do Price Influencers Affect Cargo Aircraft Costs?

Several factors influence the pricing of cargo aircraft, impacting the final purchase price.

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers should negotiate for better rates when acquiring multiple aircraft.

-

Specifications and Customization: Custom features or modifications can significantly increase costs. Buyers should carefully evaluate their needs against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications that ensure compliance with international standards can raise costs. However, investing in quality can lead to lower maintenance and operational costs.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers may charge a premium for their brand, but this can also provide assurance of quality and service.

What Buyer Tips Can Enhance Cost-Efficiency in Aircraft Procurement?

When navigating the procurement of cargo aircraft, especially for international transactions, several strategies can enhance cost-efficiency.

Illustrative image related to cargo aircraft for sale

-

Negotiation: Engaging in thorough negotiations can yield better pricing and terms. Understanding market rates and being prepared to walk away can empower buyers during discussions.

-

Total Cost of Ownership (TCO): Buyers should consider the TCO rather than just the purchase price. This includes maintenance, operational costs, fuel efficiency, and potential resale value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and taxes that may impact the final cost. Understanding local regulations and working with knowledgeable local partners can mitigate these risks.

-

Research and Due Diligence: Conducting comprehensive research on aircraft models, suppliers, and market trends can provide insights that lead to more informed purchasing decisions.

Conclusion and Disclaimer

Prices for cargo aircraft can vary widely based on numerous factors, including model, condition, specifications, and market dynamics. The indicative prices observed in the market should not be regarded as fixed; they can fluctuate based on supply and demand, economic conditions, and geopolitical factors. Always consult with industry experts and conduct thorough due diligence before making significant investments in cargo aircraft.

Alternatives Analysis: Comparing cargo aircraft for sale With Other Solutions

When considering the acquisition of cargo aircraft, it’s essential to explore alternative solutions that can meet similar logistical needs. This analysis will compare cargo aircraft for sale against two viable alternatives: leasing cargo aircraft and utilizing ground transportation solutions. Each method presents unique advantages and challenges that may influence a B2B buyer’s decision.

| Comparison Aspect | Cargo Aircraft For Sale | Leasing Cargo Aircraft | Ground Transportation Solutions |

|---|---|---|---|

| Performance | High payload capacity; long-range capabilities | Flexible options based on needs; quick availability | Limited by road infrastructure; slower transit times |

| Cost | High upfront investment; depreciation risk | Lower initial cost; monthly lease payments | Variable costs; fuel and maintenance can add up |

| Ease of Implementation | Requires significant planning and certification | Easier to implement; less commitment | Generally straightforward; dependent on local availability |

| Maintenance | Ongoing costs for upkeep and inspections | Typically covered by leasing company | Regular maintenance for vehicles required |

| Best Use Case | High-volume, long-distance cargo shipments | Short-term projects, seasonal demands | Local deliveries, smaller loads, less urgent shipments |

What are the Pros and Cons of Leasing Cargo Aircraft?

Leasing cargo aircraft offers a flexible approach that can be particularly beneficial for companies with fluctuating shipping needs. The primary advantage is the lower upfront cost compared to purchasing, allowing businesses to allocate resources elsewhere. Leasing also provides access to the latest aircraft technology without the burden of depreciation. However, the downside includes ongoing monthly payments and potential limitations on customization. Additionally, lease agreements may come with stipulations that could restrict operational flexibility.

How Do Ground Transportation Solutions Compare?

Ground transportation solutions, such as trucks and freight trains, present a cost-effective alternative for local and regional logistics. They are often easier to implement, with established networks in many areas. However, this method is limited by road conditions and can be significantly slower than air transport, especially for long-distance deliveries. While the initial investment in vehicles may be lower, ongoing fuel and maintenance costs can accumulate over time. Ground solutions are best suited for smaller shipments or less time-sensitive deliveries.

Illustrative image related to cargo aircraft for sale

Conclusion: How to Choose the Right Solution for Your Business Needs

Selecting the right logistics solution requires a thorough assessment of your specific operational requirements. B2B buyers should consider factors such as the volume and urgency of shipments, budget constraints, and the geographical areas served. For high-volume, long-distance transport, purchasing or leasing cargo aircraft may be the best fit. Conversely, for smaller, regional deliveries, ground transportation might provide a more practical and economical option. By analyzing these alternatives carefully, businesses can make informed decisions that align with their strategic objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for cargo aircraft for sale

What Are the Key Technical Properties of Cargo Aircraft?

When considering the purchase of cargo aircraft, understanding the technical specifications is crucial for making informed decisions. Here are several critical specifications to evaluate:

-

Payload Capacity

– Definition: The maximum weight a cargo aircraft can safely carry.

– B2B Importance: This directly affects the operational efficiency and profitability of cargo transport. Buyers need to ensure that the aircraft can accommodate their specific cargo needs, whether it’s heavy machinery or bulk goods. -

Maximum Takeoff Weight (MTOW)

– Definition: The total weight at which the aircraft is certified to take off, including cargo, fuel, and passengers (if applicable).

– B2B Importance: Understanding MTOW helps buyers assess whether the aircraft can handle their logistical requirements while adhering to safety regulations. It also impacts fuel efficiency and operational costs. -

Cargo Volume and Configuration

– Definition: The total internal volume available for cargo, often measured in cubic meters or cubic feet, and how the cargo area is configured (e.g., pallet positions, side doors).

– B2B Importance: This determines how efficiently the aircraft can be loaded and unloaded, which is critical for time-sensitive shipments. Different configurations may be better suited for specific types of cargo. -

Range

– Definition: The maximum distance a cargo aircraft can fly without refueling.

– B2B Importance: Buyers must evaluate range in relation to their operational routes. A longer range may reduce the need for stopovers, enhancing efficiency and reducing overall transit time. -

Engine Type and Maintenance History

– Definition: The specific engines used, including their performance specifications and maintenance records.

– B2B Importance: The engine type affects fuel efficiency, operational costs, and maintenance schedules. A thorough maintenance history can indicate the reliability and longevity of the aircraft. -

Aircraft Age and Condition

– Definition: The age of the aircraft and its overall physical condition, including hours flown and maintenance checks completed.

– B2B Importance: Older aircraft may require more frequent maintenance and repairs, impacting the total cost of ownership. Buyers should weigh the cost savings of purchasing older models against potential future expenditures.

What Common Trade Terms Should Buyers Know?

Familiarity with industry terminology is essential for effective communication and negotiation in the cargo aircraft market. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

– Definition: The company that originally manufactured the aircraft or its components.

– Importance: Understanding the OEM helps buyers assess the quality, reliability, and support available for parts and service. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of aircraft or parts that a supplier is willing to sell.

– Importance: Knowing the MOQ can impact procurement strategies and budget considerations, especially for buyers looking to make bulk purchases. -

RFQ (Request for Quotation)

– Definition: A formal request sent to suppliers to obtain price quotations for specific aircraft or services.

– Importance: An RFQ allows buyers to compare prices and terms from multiple suppliers, aiding in cost-effective decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Importance: Familiarity with Incoterms helps buyers understand their obligations and risks in the shipping process, ensuring smoother transactions. -

ACMI (Aircraft, Crew, Maintenance, Insurance)

– Definition: A leasing arrangement where the lessor provides the aircraft along with crew, maintenance, and insurance.

– Importance: This term is significant for buyers looking for operational flexibility without the long-term commitment of purchasing an aircraft outright. -

C Check

– Definition: A comprehensive maintenance check that occurs after a specified number of flight hours or cycles, involving detailed inspections and repairs.

– Importance: Understanding the timing and requirements of C Checks can help buyers assess the maintenance status of a prospective aircraft, impacting long-term operational plans.

By grasping these technical properties and trade terms, B2B buyers can navigate the cargo aircraft market with greater confidence and precision, leading to more strategic purchasing decisions.

Illustrative image related to cargo aircraft for sale

Navigating Market Dynamics and Sourcing Trends in the cargo aircraft for sale Sector

What Are the Current Market Dynamics and Key Trends in the Cargo Aircraft Sector?

The cargo aircraft market is witnessing significant transformations driven by globalization and e-commerce growth. International trade demands have led to increased logistics and freight capacity needs, particularly in emerging markets across Africa, South America, and the Middle East. For instance, countries like Brazil and Saudi Arabia are ramping up their air cargo capabilities to enhance their trade networks, leading to a surge in demand for both new and used cargo aircraft.

Technological advancements are also reshaping the industry landscape. The integration of digital platforms facilitates easier sourcing and procurement processes, enabling buyers to access a broader inventory of aircraft. Moreover, data analytics tools are becoming increasingly popular, allowing businesses to make informed decisions based on market trends and aircraft performance metrics. As a result, international buyers are now more equipped to identify the best-value options that suit their operational needs.

Furthermore, the market is seeing a shift towards more versatile aircraft models that can handle diverse cargo types, including perishables and oversized freight. This adaptability is vital as supply chains become more complex and customer expectations for rapid delivery grow.

How Does Sustainability Impact Sourcing in the Cargo Aircraft Market?

Sustainability is emerging as a crucial consideration in the cargo aircraft sector. As the aviation industry grapples with its environmental footprint, buyers are increasingly prioritizing aircraft that comply with stricter emission regulations. This shift is leading manufacturers to innovate in areas such as fuel efficiency and alternative energy sources, such as electric and hybrid aircraft.

Ethical sourcing practices are also gaining traction. Buyers are encouraged to partner with manufacturers and suppliers who adhere to sustainable practices, ensuring that their procurement processes do not harm the environment. Certifications like ISO 14001 for environmental management and compliance with the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) are becoming benchmarks for responsible sourcing.

Moreover, the use of ‘green’ materials and technologies in aircraft manufacturing is on the rise. Buyers looking to invest in new cargo aircraft are advised to consider models that incorporate sustainable materials and advanced technologies, which not only enhance operational efficiency but also align with global sustainability goals.

How Has the Cargo Aircraft Market Evolved Over Time?

The evolution of the cargo aircraft market reflects broader changes in global trade and transportation. Initially dominated by military and large commercial aircraft, the sector has diversified significantly over the past few decades. The introduction of specialized freighters, such as the Boeing 747 Freighter and the Airbus A330-200F, has expanded capacity and efficiency in air cargo transport.

Illustrative image related to cargo aircraft for sale

The rise of e-commerce and the need for rapid logistics solutions have further accelerated this evolution. Today, the market is characterized by a mix of converted passenger aircraft and dedicated freighters, offering flexibility and scalability to meet varying cargo demands. This historical shift underscores the importance of adaptability in sourcing strategies, as buyers must navigate an increasingly competitive landscape marked by technological advancements and changing consumer expectations.

In summary, understanding the current market dynamics, prioritizing sustainability, and recognizing the historical context of cargo aircraft sourcing are essential for international B2B buyers looking to make informed investment decisions in this evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cargo aircraft for sale

-

How do I evaluate the condition of a used cargo aircraft?

To evaluate the condition of a used cargo aircraft, request detailed maintenance records and inspection reports. Key factors include total flight hours, cycles, and the status of major components such as engines and landing gears. Ensure that the aircraft has passed necessary checks (C-checks, D-checks) and is compliant with aviation regulations in your country. Additionally, consider hiring an independent aviation expert for a thorough pre-purchase inspection to identify any potential issues that could affect operational efficiency and safety. -

What are the most common types of cargo aircraft available for sale?

The most common types of cargo aircraft include the Boeing 747, 767, and 737 series, as well as the Airbus A300 and DC-8 models. Each type has its own specifications regarding payload capacity, range, and operational costs. For instance, the Boeing 747-400F is known for its large payload capacity and long range, making it suitable for international freight. When selecting an aircraft, consider your specific cargo needs, such as volume, weight, and destination requirements. -

What factors should I consider when customizing a cargo aircraft?

When customizing a cargo aircraft, consider factors such as payload capacity, cargo configuration, and operational routes. Customization options may include installing specialized loading systems, adjusting the cabin layout for different cargo types, and enhancing navigation and safety equipment. Collaborate with the manufacturer or a specialist company to ensure that modifications meet regulatory standards and enhance operational efficiency. Additionally, budget for potential delays in delivery due to customization needs. -

What are the typical payment terms for purchasing cargo aircraft?

Payment terms for purchasing cargo aircraft can vary significantly based on the seller, aircraft type, and buyer’s creditworthiness. Generally, expect to negotiate a deposit (often 10-30% of the purchase price) with the remainder due upon delivery or acceptance of the aircraft. Some sellers may offer financing options or installment plans, particularly for high-value aircraft. Ensure all payment terms are documented in a formal purchase agreement to protect both parties. -

How can I verify the credibility of a cargo aircraft supplier?

To verify the credibility of a cargo aircraft supplier, research their industry reputation, including reviews and testimonials from previous clients. Check for certifications from aviation authorities, such as the FAA or EASA, and ensure they have a history of compliance with safety standards. Additionally, consider contacting industry associations or using third-party verification services to assess the supplier’s reliability. A credible supplier should also provide transparent information about their aircraft inventory and be willing to share maintenance records. -

What logistics considerations should I keep in mind when buying cargo aircraft internationally?

When buying cargo aircraft internationally, consider logistical factors such as import/export regulations, customs duties, and transportation costs. Understand the legal requirements for registering the aircraft in your home country and ensure compliance with international aviation laws. Additionally, plan for the aircraft’s delivery logistics, including ground transportation and any necessary modifications or inspections upon arrival. Engage with a logistics expert who specializes in aviation to streamline the process and avoid potential delays. -

What are the key quality assurance (QA) measures for cargo aircraft?

Key quality assurance measures for cargo aircraft include adherence to maintenance schedules, inspections, and compliance with regulatory standards. Implement a robust QA program that involves regular audits of maintenance practices, documentation reviews, and performance evaluations. Additionally, consider utilizing third-party QA services to provide an objective assessment of the aircraft’s condition and operational readiness. This approach not only ensures safety but also enhances the longevity and reliability of your fleet. -

What is the minimum order quantity (MOQ) for cargo aircraft purchases?

The minimum order quantity (MOQ) for cargo aircraft purchases typically varies based on the manufacturer and the type of aircraft. For new aircraft, manufacturers may have a MOQ of one unit, but bulk orders can sometimes secure better pricing and terms. For used aircraft, the MOQ may not apply, as you can often purchase single units. When negotiating, it’s essential to clarify the MOQ and any associated benefits, such as warranties or maintenance packages, to ensure you receive optimal value for your investment.

Top 6 Cargo Aircraft For Sale Manufacturers & Suppliers List

1. AeroAcq – Aircraft Inventory

Domain: aeroacq.com

Registered: 2011 (14 years)

Introduction: B727-200: Total Time: 41,468; Total Cycles: 22,578; Stage III Hush Kits; Engine Type: JT8D-17; Number Available: 1. B737-300F: Engine Type: CFM-56-3C1; Number Available: 1. B747-269F: Excellent condition; only 17,000 cycles; Engine Type: JT9D-7J; Number Available: 1. B767-300ER-SF: Total Time: 84,200; Engine Type: CF6-80C2B6F; Number Available: 1. Boeing 747-200F: A/C #1: 13,900 Cycles; A/C #2: 14…

2. Air Charter Service USA – Comprehensive Cargo Aircraft Solutions

Domain: aircharterserviceusa.com

Registered: 2004 (21 years)

Introduction: Complete Cargo Aircraft Guide includes various cargo charter services such as: Urgent ‘Go Now’ time critical charters, Dangerous Goods charters for sensitive cargo, Heavy & Outsize Cargo charters for large freight, Humanitarian and Relief charters for urgent aid, Remote Destinations charters to hard-to-reach areas, Onboard Courier for personalized hand-carry service, AOG Solutions for grounded air…

3. Trade-A-Plane – Aviation Products

Domain: trade-a-plane.com

Registered: 1996 (29 years)

Introduction: Trade-A-Plane offers a wide range of aviation products including aircraft, engines, parts, and real estate. Categories include Single Engine Piston, Multi Engine Piston, Helicopters, Jets, Turboprop, Warbirds, Special Use, and Light Sport aircraft. Featured aircraft brands include Beechcraft, Cessna, Cirrus, Piper, and Robinson. The platform provides tools for financing, loan calculation, insuranc…

4. Accio – Kids Musical Transport Plane Model Aircraft Toy

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Small Cargo Aircraft for Sale: Results from 55000+ products and 8500+ suppliers. Key products include:

1. Kids Musical Transport Plane Model Aircraft Toy – $7.69-7.98, Min. order: 45 sets, Supplier: Shantou Capable Toys Co., Ltd.

2. Cessna 510 1/50 Model Cargo Aircraft – $14.12-15.38, Min. order: 100 pieces, Supplier: Shantou Tongde Craft Products Co., Ltd.

3. Full Carbon Fiber RC Drone – $180-200…

5. AirMart – Aircraft for Sale

Domain: airmart.com

Registered: 1998 (27 years)

Introduction: AirMart offers a variety of airplanes for sale, including featured models such as Beechcraft G36 Bonanza (N301BZ), Diamond DA40 XLS (N712PA), Cessna T182T Skylane (N147AJ), Columbia 350 (N46HD), Beechcraft A36 Bonanza (N8201E), and Piper Saratoga II TC (N9697S). They have over 200 aircraft listed for sale with prices ranging from $1 million to $5 million. The company has been in aircraft brokerage…

6. Aerocorner – Key Aircraft Models

Domain: aerocorner.com

Registered: 2020 (5 years)

Introduction: [{‘model’: ‘Airbus A380 Cargo’, ‘current_price’: ‘$432 million U.S.’}, {‘model’: ‘Antonov An-70’, ‘current_price’: ‘$60 million – $70 million U.S. For Export’}, {‘model’: ‘Antonov An-124 Ruslan’, ‘current_price’: ‘$50 million – $80 million estimated’}, {‘model’: ‘Antonov An-74’, ‘current_price’: ‘$18 to $22 million’}, {‘model’: ‘Airbus A300-600F’, ‘current_price’: ‘$105 million in 2006’}, {‘model’…

Strategic Sourcing Conclusion and Outlook for cargo aircraft for sale

In the evolving landscape of cargo aircraft procurement, strategic sourcing emerges as a critical component for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. The current market offers a diverse range of options, from well-maintained older models to newer, more efficient aircraft. Buyers must prioritize evaluating not only the purchase price but also the total cost of ownership, including maintenance, operational efficiency, and compliance with regulatory standards.

Understanding the specific needs of your logistics operations is essential. For instance, selecting aircraft with favorable payload capacities and range can significantly enhance your supply chain capabilities. Additionally, leveraging relationships with reputable brokers and manufacturers can provide insights into market trends and potential financing options.

As we look to the future, the demand for cargo aircraft is expected to grow, driven by increasing global trade and e-commerce. This is a prime opportunity for buyers to invest strategically. We encourage you to engage with industry experts, conduct thorough market analyses, and seize the moment to enhance your fleet’s capabilities. Start exploring your options today to ensure your logistics operations are well-equipped for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.