Choosing Your Cajas De Herramientas Para Trocas: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for cajas de herramientas para trocas

In today’s competitive landscape, sourcing high-quality cajas de herramientas para trocas can be a daunting task for international B2B buyers. With a myriad of options available, businesses must navigate through varying quality standards, pricing models, and supplier reliability. This guide serves as an essential resource for those looking to make informed purchasing decisions in the global market.

Covering a wide array of topics, this comprehensive guide delves into the different types of toolboxes available, their specific applications across various industries, and crucial supplier vetting processes. It also provides insights into cost considerations and value assessments, helping buyers understand what to expect in terms of investment and return. Whether you are an established distributor in Europe, a contractor in the Middle East, or a startup in South America or Africa, this guide is tailored to empower you with the knowledge needed to effectively source the right toolboxes for your needs.

By leveraging this resource, B2B buyers will gain a clearer understanding of product features, market trends, and supplier landscapes, ensuring that every decision is backed by reliable information. Equip yourself with the tools for success as you explore the global market for cajas de herramientas para trocas.

Understanding cajas de herramientas para trocas Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cross Box | Dual lid access, weather-resistant sealing, fits full-size trucks | Construction, logistics, maintenance | Pros: Easy access from both sides; robust design. Cons: May require precise fit for specific truck models. |

| Underbed Box | Low-profile design, maximizes bed space, heavy-duty materials | Heavy-duty transport, tool storage | Pros: Efficient space utilization; secure storage for heavy tools. Cons: Installation may be complex. |

| Lo-Side Box | Mounted on bed rails, quick access, compact design | Landscaping, plumbing, electrical work | Pros: Convenient access; does not obstruct bed space. Cons: Limited storage capacity compared to larger boxes. |

| Hi-Side Box | Elevated design, weatherproof, enhanced security features | Utility services, emergency response | Pros: Great for storing larger items; superior protection against elements. Cons: Higher cost due to advanced features. |

| Saddle Box | Sits above truck bed, large storage capacity, easy installation | General trades, mobile workshops | Pros: Ample storage; easy to install and access. Cons: Can obstruct rear visibility when loaded. |

What are the Key Characteristics of Cross Boxes?

Cross boxes are designed with dual lid access, allowing for easy retrieval of tools from either side of the truck. They feature robust weather-resistant sealing to protect tools from the elements, making them ideal for construction and logistics applications. When purchasing a cross box, buyers should consider the compatibility with their truck’s dimensions and the potential need for additional security features to prevent theft.

How Do Underbed Boxes Enhance Storage Efficiency?

Underbed boxes provide a low-profile storage solution that maximizes the available bed space of a truck. Constructed from heavy-duty materials, these boxes are designed to hold substantial weight while keeping tools secure and protected. They are particularly suitable for heavy-duty transport and tool storage in industries like construction. Buyers should evaluate the ease of installation and ensure that the box fits their specific truck model to avoid complications.

Why Choose Lo-Side Boxes for Quick Access?

Lo-side boxes are mounted on the bed rails of the truck, allowing for quick and easy access to tools without taking up valuable bed space. Their compact design is particularly beneficial for landscaping, plumbing, and electrical work where frequent tool access is necessary. When selecting a lo-side box, buyers should assess the storage capacity and the ease of installation to ensure it meets their operational needs.

What Advantages Do Hi-Side Boxes Offer for Utility Services?

Hi-side boxes are elevated to provide superior protection against weather and vandalism, making them a preferred choice for utility services and emergency response teams. These boxes often include enhanced security features, such as three-point locking mechanisms, to deter theft. Buyers should consider the box’s dimensions and how it fits into their overall vehicle configuration, as well as the additional cost associated with these advanced features.

Why are Saddle Boxes Popular Among General Trades?

Saddle boxes are one of the most popular storage solutions for trucks, thanks to their large storage capacity and ease of installation. They sit above the truck bed, providing ample space for tools and equipment while ensuring quick access. However, buyers should be mindful of potential visibility issues when the box is loaded and ensure that it complies with any local regulations regarding vehicle modifications.

Key Industrial Applications of cajas de herramientas para trocas

| Industry/Sector | Specific Application of cajas de herramientas para trocas | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | On-site tool storage and organization | Enhances efficiency by keeping tools secure and accessible, reducing downtime. | Durability, weather resistance, and security features are critical. |

| Automotive Repair | Mobile tool storage for mechanics | Facilitates quick access to tools, improving service speed and customer satisfaction. | Compatibility with various vehicle models and robust locking mechanisms are essential. |

| Agriculture | Storage for farming tools and equipment | Protects tools from the elements and theft, maximizing asset longevity. | Need for weatherproof materials and ease of installation on various vehicle types. |

| Landscaping & Gardening | Transport and storage of landscaping tools | Streamlines operations by providing organized access to tools, enhancing productivity. | Consideration of size, weight capacity, and accessibility features is important. |

| Oil & Gas | Secure storage for specialized tools in remote locations | Ensures safety and organization in hazardous environments, reducing risk of loss. | Must meet industry safety standards and provide high levels of security. |

How Are ‘Cajas de Herramientas para Trocas’ Used in the Construction Industry?

In the construction sector, ‘cajas de herramientas para trocas’ serve as essential on-site tool storage solutions. They keep tools organized and secure, preventing loss and damage from environmental factors. The need for durability and weather resistance is paramount, as these toolboxes are often exposed to harsh conditions. International buyers should prioritize options with robust locking mechanisms and materials that withstand the rigors of construction work.

Illustrative image related to cajas de herramientas para trocas

What Are the Applications in Automotive Repair?

Automotive repair businesses rely heavily on mobile tool storage for mechanics. ‘Cajas de herramientas para trocas’ allow for quick access to necessary tools, significantly improving service speed and customer satisfaction. Buyers in this sector should focus on toolboxes that offer compatibility with various vehicle models and robust security features to deter theft, ensuring their investment is protected while on the go.

How Do These Toolboxes Benefit Agriculture?

In agriculture, ‘cajas de herramientas para trocas’ provide a secure storage solution for farming tools and equipment. These toolboxes protect valuable assets from theft and the elements, thereby extending their lifespan. Buyers from regions with varying climates, such as Africa and South America, should look for weatherproof materials and easy installation options that can accommodate different vehicle types, ensuring maximum utility on farms.

Why Are They Important for Landscaping and Gardening?

For landscaping and gardening professionals, ‘cajas de herramientas para trocas’ streamline operations by organizing tools for easy access during jobs. This organization enhances productivity and reduces time spent searching for equipment. Key considerations for buyers include the size and weight capacity of the toolboxes, as well as accessibility features that allow for quick retrieval of tools, ensuring efficiency in landscaping tasks.

What Role Do They Play in the Oil & Gas Industry?

In the oil and gas sector, ‘cajas de herramientas para trocas’ are vital for securely storing specialized tools in remote and often hazardous locations. These toolboxes help maintain organization and safety, significantly reducing the risk of tool loss. Buyers in this industry must ensure that their chosen toolboxes meet stringent safety standards and provide high levels of security, given the high-value tools involved and the potential risks associated with their use.

3 Common User Pain Points for ‘cajas de herramientas para trocas’ & Their Solutions

Scenario 1: Struggling with Security and Theft Protection

The Problem: One of the primary concerns for B2B buyers of ‘cajas de herramientas para trocas’ is the risk of theft. Businesses relying on trucks for daily operations often have valuable tools and equipment stored in toolboxes, making them prime targets for theft. The challenge lies in finding toolboxes that offer not only convenience but also robust security features to protect against unauthorized access. A toolbox that is easily accessible can also be easily stolen, leading to significant financial losses and operational delays.

Illustrative image related to cajas de herramientas para trocas

The Solution: To address this issue, buyers should prioritize toolboxes with advanced security features such as three-point locking systems and durable materials that resist tampering. When sourcing ‘cajas de herramientas para trocas’, look for products that highlight their theft protection capabilities, such as reinforced locking mechanisms and heavy-duty construction materials like aluminum or high-grade steel. Additionally, consider investing in toolboxes with integrated security features, such as alarm systems or GPS tracking, to further enhance protection. To ensure that these toolboxes meet your security needs, request detailed specifications and user reviews focused on security performance.

Scenario 2: Inadequate Space and Organization

The Problem: Another common pain point for B2B buyers is inadequate storage space and poor organization within toolboxes. Many buyers find that standard-sized toolboxes do not accommodate all their tools efficiently, leading to clutter and inefficiencies during work. This disorganization can result in wasted time searching for tools, which is particularly detrimental in fast-paced industries where every minute counts.

The Solution: To overcome space and organization challenges, opt for customizable toolboxes that offer modular storage solutions. Look for ‘cajas de herramientas para trocas’ that include features such as adjustable dividers, removable bins, and dedicated compartments for specific tools. This allows users to tailor the storage to their unique needs. Additionally, consider toolboxes with integrated mounting systems like L-Track rails or Molle panels that enable the attachment of additional storage accessories. When purchasing, inquire about the toolbox’s interior layout and organization options, and seek recommendations from other professionals in similar industries to find the most effective solutions.

Scenario 3: Weather Resistance and Durability Concerns

The Problem: For businesses operating in diverse climates, ensuring that tools are protected from environmental elements is a critical concern. Many toolboxes fail to provide adequate protection against rain, snow, and extreme temperatures, leading to rust, corrosion, and ultimately, damage to the tools inside. Buyers are often frustrated by the lack of durable options that can withstand harsh weather conditions while still being functional.

The Solution: To tackle weather resistance issues, it is essential to choose toolboxes specifically designed for durability in various environmental conditions. Seek out ‘cajas de herramientas para trocas’ made from weather-resistant materials such as powder-coated aluminum or heavy-duty steel with rust-proof finishes. Look for features like weather seals and drain holes that prevent water accumulation and protect contents from moisture. When sourcing these toolboxes, request product specifications that detail their weatherproofing capabilities, and ask for performance reviews from users who have tested them in extreme conditions. This will ensure that your investment not only protects your tools but also lasts for years, reducing the need for frequent replacements.

Strategic Material Selection Guide for cajas de herramientas para trocas

What Are the Key Properties of Common Materials Used in Cajas de Herramientas para Trocas?

When selecting materials for cajas de herramientas para trocas, it’s essential to consider their properties, advantages, and limitations. Here, we examine four common materials: aluminum, steel, plastic, and composite materials.

Illustrative image related to cajas de herramientas para trocas

Aluminum: A Lightweight and Corrosion-Resistant Option

Aluminum is a popular choice for toolboxes due to its lightweight nature and excellent corrosion resistance. It can withstand a wide range of temperatures and is less likely to rust compared to steel. The typical manufacturing process involves extrusion or sheet fabrication, which can be complex but allows for intricate designs.

Pros: Aluminum toolboxes are durable and lightweight, making them easy to handle. They also provide good resistance against weather elements, which is crucial for outdoor applications.

Cons: The primary downside is cost; aluminum is generally more expensive than steel. Additionally, while it is strong, it may not withstand heavy impacts as well as steel.

Impact on Application: Aluminum toolboxes are ideal for environments with high humidity or exposure to saltwater, such as coastal regions in Africa and South America.

International Considerations: Buyers should ensure compliance with relevant standards like ASTM for aluminum alloys and consider the availability of aluminum products in their region.

Steel: Strength and Durability

Steel is known for its strength and durability, making it a favored material for heavy-duty toolboxes. It has a high-temperature resistance and can endure significant pressure, making it suitable for demanding applications.

Pros: Steel toolboxes are robust and provide excellent security against theft. They are also generally less expensive than aluminum.

Cons: The main drawback is susceptibility to rust and corrosion, especially in humid environments. Protective coatings are necessary to mitigate this issue, adding to manufacturing complexity.

Illustrative image related to cajas de herramientas para trocas

Impact on Application: Steel is suitable for harsh environments, but buyers in humid regions, such as parts of the Middle East, should prioritize galvanized or powder-coated options.

International Considerations: Compliance with standards like DIN for steel quality is crucial, especially for buyers in Europe.

Plastic: Cost-Effective and Lightweight

Plastic toolboxes are often made from high-density polyethylene (HDPE) or polypropylene, known for their lightweight and cost-effective properties. They are resistant to many chemicals and can handle a range of temperatures.

Pros: Plastic toolboxes are affordable and resistant to corrosion and chemicals. They are also lightweight, making them easy to transport.

Cons: While they are resistant to rust, plastic can become brittle over time and may not provide the same level of security as metal options.

Illustrative image related to cajas de herramientas para trocas

Impact on Application: Plastic toolboxes are ideal for storing tools in non-harsh environments, such as urban settings in Europe or South America.

International Considerations: Buyers should check for compliance with local regulations regarding plastic materials, especially in regions with stringent environmental laws.

Composite Materials: The Best of Both Worlds

Composite materials, which often combine plastic with fiberglass or other reinforcements, offer a balance between weight, strength, and resistance to environmental factors.

Pros: These materials are often lighter than steel and provide excellent resistance to corrosion and impacts. They can also be molded into various shapes, allowing for innovative designs.

Cons: The manufacturing process can be complex and more expensive compared to traditional materials. Additionally, the long-term durability may vary based on the specific composite used.

Illustrative image related to cajas de herramientas para trocas

Impact on Application: Composite toolboxes are suitable for diverse environments, including those with high humidity or exposure to chemicals, making them versatile for international buyers.

International Considerations: Buyers should ensure that the composites meet international standards for safety and environmental impact.

Summary Table of Material Selection for Cajas de Herramientas para Trocas

| Material | Typical Use Case for cajas de herramientas para trocas | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight tool storage for outdoor use | Excellent corrosion resistance | Higher cost than steel | High |

| Steel | Heavy-duty applications in construction settings | Superior strength and security | Susceptible to rust | Medium |

| Plastic | General-purpose tool storage in urban settings | Cost-effective and lightweight | Less durable under impact | Low |

| Composite | Versatile storage for various environments | Good balance of weight and strength | Complex manufacturing process | Medium |

This material selection guide provides B2B buyers with actionable insights to make informed decisions when sourcing cajas de herramientas para trocas, ensuring they choose the right materials for their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cajas de herramientas para trocas

What Are the Key Stages in Manufacturing Cajas de Herramientas para Trocas?

The manufacturing process for cajas de herramientas para trocas, or truck toolboxes, involves several critical stages that ensure the final product meets both functional and aesthetic requirements. Each stage is designed to optimize efficiency while adhering to high-quality standards.

How Is Material Prepared for Truck Toolboxes?

The first stage in the manufacturing process is material preparation. Typically, high-grade aluminum or steel is selected due to its durability and lightweight properties. The materials undergo a thorough inspection to ensure they meet specifications. This stage may include cutting sheets to size, removing any impurities, and pre-treating surfaces to enhance adhesion for coatings. It is crucial that the materials used are resistant to corrosion and environmental damage, which is essential for outdoor applications.

Illustrative image related to cajas de herramientas para trocas

What Techniques Are Used in Forming Cajas de Herramientas?

Once the materials are prepared, the forming process begins. Techniques such as stamping, bending, and welding are commonly employed. Stamping is used to create the basic shape of the toolbox, while bending shapes the edges and contours. For more complex designs, advanced CNC (Computer Numerical Control) machines are often utilized to ensure precision. Welding is essential for assembling different parts, providing a strong and durable bond. The choice of forming technique can significantly impact the toolbox’s structural integrity and overall quality.

How Are Cajas de Herramientas Assembled?

After forming, the assembly process takes place. This phase includes fitting components such as locks, hinges, and gas struts. Quality checks are performed at various points during assembly to ensure that each part fits correctly and operates smoothly. This is vital for the end-user experience, as a toolbox that is difficult to open or close can lead to frustration and decreased productivity. Utilizing modular designs can enhance flexibility, allowing for customization based on the specific needs of the buyer.

What Finishing Techniques Are Applied to Enhance Durability?

The final stage of manufacturing is finishing, which involves applying protective coatings and surface treatments. The most common method is powder coating, which provides a robust layer of protection against rust, scratches, and UV damage. Some manufacturers may also use anodizing for aluminum toolboxes, which not only enhances corrosion resistance but also improves aesthetic appeal. A thorough finishing process is critical for ensuring the longevity of the product, especially in harsh environments.

What Are the Quality Assurance Standards for Cajas de Herramientas?

Quality assurance is an essential aspect of the manufacturing process for cajas de herramientas, ensuring that products meet both international and industry-specific standards. This is particularly important for international B2B transactions, where compliance with regulations can vary significantly.

Illustrative image related to cajas de herramientas para trocas

Which International Standards Are Relevant for Toolboxes?

ISO 9001 is a globally recognized standard for quality management systems. Manufacturers that adhere to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may be relevant depending on the intended use of the toolboxes. These certifications ensure that products comply with safety, health, and environmental protection standards.

What Are Common Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) is conducted on raw materials to ensure they meet specified standards. In-Process Quality Control (IPQC) checks are performed during various stages of production to catch defects early. Finally, Final Quality Control (FQC) is executed before products are shipped, verifying that each toolbox meets design specifications and quality standards. This systematic approach minimizes the risk of defects reaching the customer.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is vital to ensuring product reliability. Here are some actionable strategies:

What Are Effective Methods for Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control practices. This includes on-site inspections to evaluate manufacturing processes, quality management systems, and adherence to international standards. Buyers should request documentation of previous audits, corrective actions taken, and continuous improvement initiatives.

Illustrative image related to cajas de herramientas para trocas

How Can Buyers Obtain Quality Assurance Reports?

Buyers should also request quality assurance reports, which detail the results of various tests performed on the toolboxes. These reports should include information on material properties, structural integrity tests, and environmental resistance assessments. A reputable supplier will readily provide this documentation, which can serve as a basis for trust in their manufacturing capabilities.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further validate a supplier’s claims regarding quality assurance. These independent organizations conduct thorough inspections and testing, providing an unbiased perspective on the product’s quality. For buyers in regions like Africa, South America, the Middle East, and Europe, third-party inspections can be particularly valuable in ensuring compliance with local regulations and standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must be aware of various nuances that could affect quality control in different regions. For instance, suppliers in certain countries may have different approaches to quality assurance based on local regulations and market expectations. Understanding these cultural and operational differences can help buyers make informed decisions when selecting suppliers.

In conclusion, the manufacturing processes and quality assurance for cajas de herramientas para trocas are critical components that directly influence product quality and reliability. By understanding these processes and the associated standards, international B2B buyers can make informed decisions, ensuring they source high-quality toolboxes that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cajas de herramientas para trocas’

To assist B2B buyers in the procurement of ‘cajas de herramientas para trocas’, this guide provides a structured approach to ensure you make informed decisions. The following checklist outlines essential steps to follow when sourcing toolboxes for trucks, helping you evaluate options effectively and align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right toolboxes. Consider the size, material (e.g., aluminum or steel), and design features that will best suit your operations. For instance, if your team frequently transports heavy tools, opt for models with reinforced construction and secure locking mechanisms.

Step 2: Research Market Trends and Needs

Understanding current market trends will provide insights into what products are in demand. Analyze the preferences of your target audience in regions like Africa, South America, and Europe. Investigate features such as weather resistance, ease of access, and modular designs that are gaining popularity in these markets.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from other businesses in similar sectors. Look for suppliers that have established credibility and positive reviews, particularly those that emphasize customer service and warranty support.

Step 4: Verify Quality Assurance and Certifications

Ensure that the toolboxes you consider meet relevant quality assurance standards and certifications. This includes looking for compliance with industry standards for durability and safety. Suppliers should provide documentation proving their products have undergone rigorous testing to withstand environmental challenges.

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or product demonstrations to assess quality firsthand. This allows you to evaluate the construction, functionality, and ease of use of the toolboxes. Pay attention to details such as the locking mechanisms, weatherproofing features, and overall design to ensure they meet your operational needs.

Step 6: Compare Pricing and Payment Terms

Conduct a thorough comparison of pricing structures from different suppliers. While it may be tempting to go for the lowest price, consider the overall value, including warranty terms and after-sales support. Negotiate payment terms that align with your budget and cash flow requirements, ensuring flexibility where possible.

Step 7: Establish a Long-Term Relationship

Once you have selected a supplier, focus on building a long-term relationship. Regular communication and feedback will help you stay informed about new products and developments in the market. A reliable supplier can become a vital partner in your business, providing ongoing support and solutions tailored to your evolving needs.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for ‘cajas de herramientas para trocas’, ensuring they select high-quality products that meet their operational demands.

Comprehensive Cost and Pricing Analysis for cajas de herramientas para trocas Sourcing

What Are the Key Cost Components Influencing Cajas de Herramientas para Trocas Pricing?

When sourcing cajas de herramientas para trocas (toolboxes for trucks), understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used—such as aluminum or steel—significantly impacts costs. High-grade materials may increase initial expenses but offer better durability and longevity, which can lead to lower Total Cost of Ownership (TCO).

-

Labor: Labor costs vary by region and can be influenced by local wage standards and workforce availability. Skilled labor may command higher wages, impacting overall pricing.

-

Manufacturing Overhead: This encompasses costs associated with factory operations, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tool designs for specific toolbox specifications can add to the initial costs. Investing in quality tooling is essential for consistent production quality.

-

Quality Control (QC): Rigorous QC processes ensure that products meet safety and performance standards. While this may add to costs, it can prevent costly recalls or customer dissatisfaction.

-

Logistics: Transportation and warehousing costs must be factored in, especially for international shipping. Shipping distances, modes of transport, and regional tariffs can all influence total logistics costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the margin expectations of suppliers in different regions can provide leverage during negotiations.

How Do Price Influencers Affect the Sourcing of Toolboxes for Trucks?

Several factors can influence pricing when sourcing cajas de herramientas para trocas:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for volume discounts, allowing buyers to reduce their per-unit costs. Understanding the supplier’s MOQ can help buyers strategize their purchasing.

-

Specifications and Customization: Customized toolboxes with specific dimensions or features (like weather resistance or additional security) may incur higher costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or safety compliance) often come at a premium. However, they can enhance product reliability and appeal to quality-conscious markets.

-

Supplier Factors: Established suppliers with a strong reputation may command higher prices due to perceived value. New or lesser-known suppliers may offer lower prices but could present risks in terms of quality and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for managing costs associated with shipping and delivery. Different terms can shift responsibilities and costs between buyers and sellers, impacting overall pricing.

What Are the Best Buyer Tips for Negotiating Prices on Toolboxes?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation and sourcing strategies can significantly influence costs:

-

Leverage Negotiation: Engage suppliers in discussions about pricing, especially regarding bulk orders. Highlighting long-term partnership potential can also encourage suppliers to offer better terms.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership, which includes initial purchase price, maintenance, and potential replacement costs. Opting for higher-quality toolboxes may lead to lower long-term expenses despite higher upfront costs.

-

Understand Pricing Nuances: Be aware of regional market dynamics, including local competition and currency fluctuations, which can affect pricing. Tailoring negotiations based on these factors can yield better results.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, terms, and service. Frequent communication and transparency about your needs can foster trust.

In conclusion, understanding the cost components, price influencers, and effective negotiation strategies are essential for B2B buyers sourcing cajas de herramientas para trocas. By employing these insights, buyers can make informed decisions that align with their operational needs and budget constraints.

Illustrative image related to cajas de herramientas para trocas

Alternatives Analysis: Comparing cajas de herramientas para trocas With Other Solutions

When evaluating the best storage solutions for tools in commercial vehicles, it’s essential to consider alternatives to ‘cajas de herramientas para trocas’ (toolboxes for trucks). These alternatives can provide different benefits depending on the specific needs of businesses and their operational environments. The following analysis compares traditional toolboxes with two viable alternatives: mobile tool carts and truck bed storage systems.

| Comparison Aspect | Cajas De Herramientas Para Trocas | Mobile Tool Carts | Truck Bed Storage Systems |

|---|---|---|---|

| Performance | High durability and security | Moderate portability | Excellent space utilization |

| Cost | Mid to high price range | Generally lower cost | Varies widely, often mid-range |

| Ease of Implementation | Easy to install and secure | Requires minimal assembly | Installation can be complex |

| Maintenance | Low maintenance required | Moderate, requires regular checks | Low maintenance, durable materials |

| Best Use Case | Ideal for secure, organized storage | Best for frequent mobility | Perfect for maximizing truck bed space |

What Are the Benefits and Drawbacks of Mobile Tool Carts?

Mobile tool carts are designed for portability and flexibility, allowing workers to transport tools easily between job sites. This can be a significant advantage in fast-paced environments where tools need to be readily accessible. However, while they are typically more affordable than toolboxes, they often compromise on security. Tools stored in carts are more vulnerable to theft, making them less suitable for long-term storage.

How Do Truck Bed Storage Systems Compare?

Truck bed storage systems provide innovative solutions that maximize the available space in the truck bed. These systems can include drawers or compartments that utilize every inch of the truck bed, enabling the organization of tools and equipment efficiently. The main advantages are their high utility and minimal maintenance needs. However, installation can be complex and may require professional assistance, which could increase initial costs. Additionally, while they optimize space, they may not offer the same level of security as traditional toolboxes.

Which Solution Should B2B Buyers Choose?

Selecting the right storage solution for tools depends on various factors, including operational requirements, budget constraints, and security needs. For businesses focused on security and organization, ‘cajas de herramientas para trocas’ may be the best option, especially in environments where theft is a concern. Conversely, if mobility and flexibility are priorities, mobile tool carts offer a practical alternative. For companies looking to maximize storage space without sacrificing accessibility, truck bed storage systems could provide the optimal balance of utility and performance. Ultimately, B2B buyers should assess their specific needs and choose a solution that aligns with their operational goals and budgetary limitations.

Illustrative image related to cajas de herramientas para trocas

Essential Technical Properties and Trade Terminology for cajas de herramientas para trocas

What Are the Key Technical Properties of Toolboxes for Trucks?

When sourcing toolboxes for trucks, it is essential for B2B buyers to understand the technical specifications that influence performance, durability, and security. Here are several critical specifications to consider:

-

Material Grade

The material grade of toolboxes, such as aluminum or steel, determines their strength and resistance to corrosion. High-grade aluminum is lightweight and rust-resistant, making it ideal for frequent transport. Conversely, steel offers superior durability but may require additional protective coatings to prevent rust. Selecting the right material impacts the longevity and maintenance costs of the toolbox. -

Weight Capacity

Weight capacity refers to the maximum load a toolbox can safely carry. It is crucial for buyers to match the weight capacity with the intended use, ensuring that the toolbox can handle the tools and equipment without risk of failure. Overloading can lead to structural damage, which not only compromises safety but can also incur additional costs for replacements. -

Weather Resistance

A toolbox’s ability to withstand various environmental conditions is vital for protecting stored tools from moisture, dust, and temperature fluctuations. Features such as weather seals, powder-coated finishes, and rustproof materials enhance weather resistance. This property is particularly important in regions with harsh climates, as it directly affects the toolbox’s lifespan and performance. -

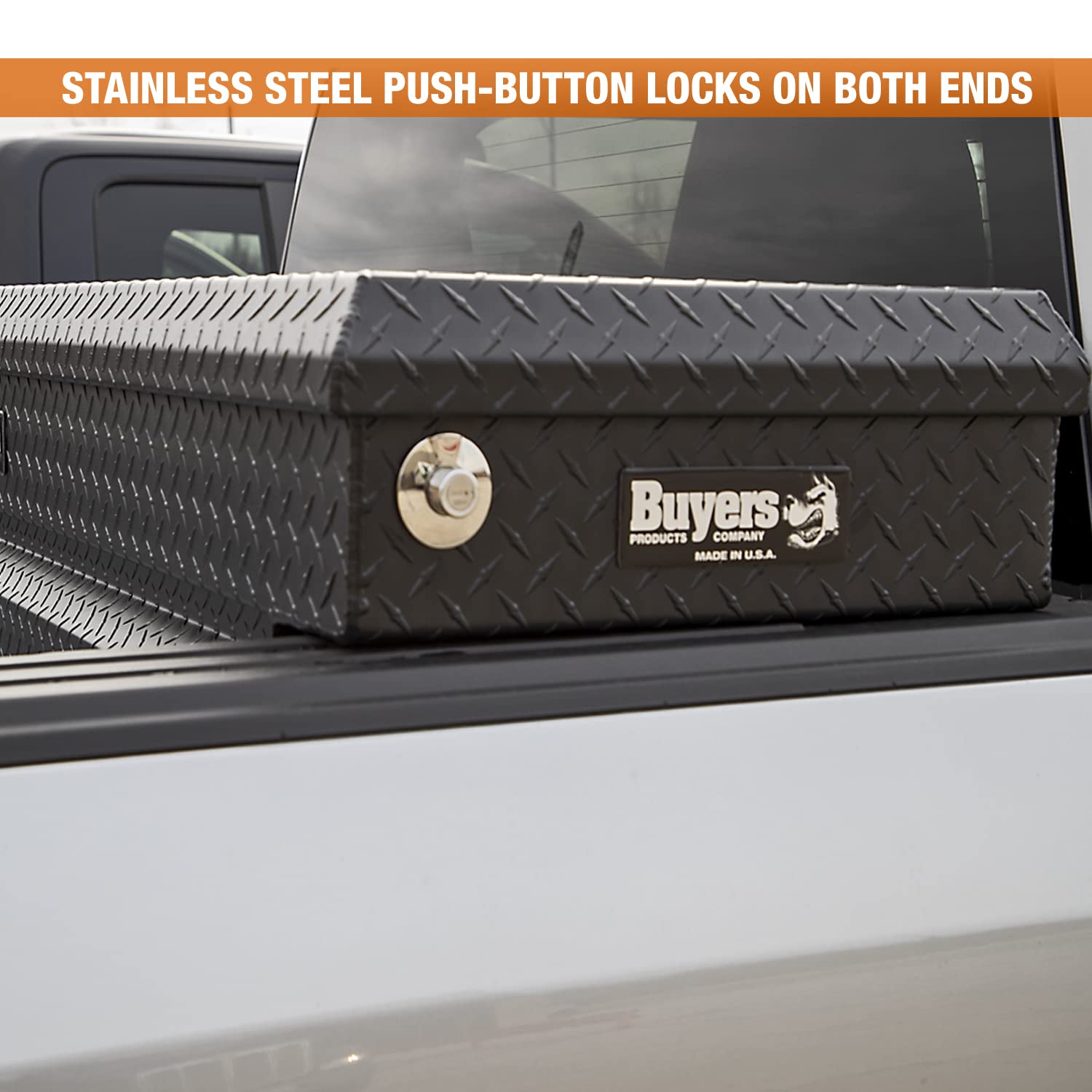

Locking Mechanism

The locking mechanism is a critical feature for security. Options include rotary-style locks, three-point locking systems, and electronic locks. A robust locking system protects tools from theft and vandalism, offering peace of mind to users. Buyers should consider the security level required based on the operating environment and local crime rates. -

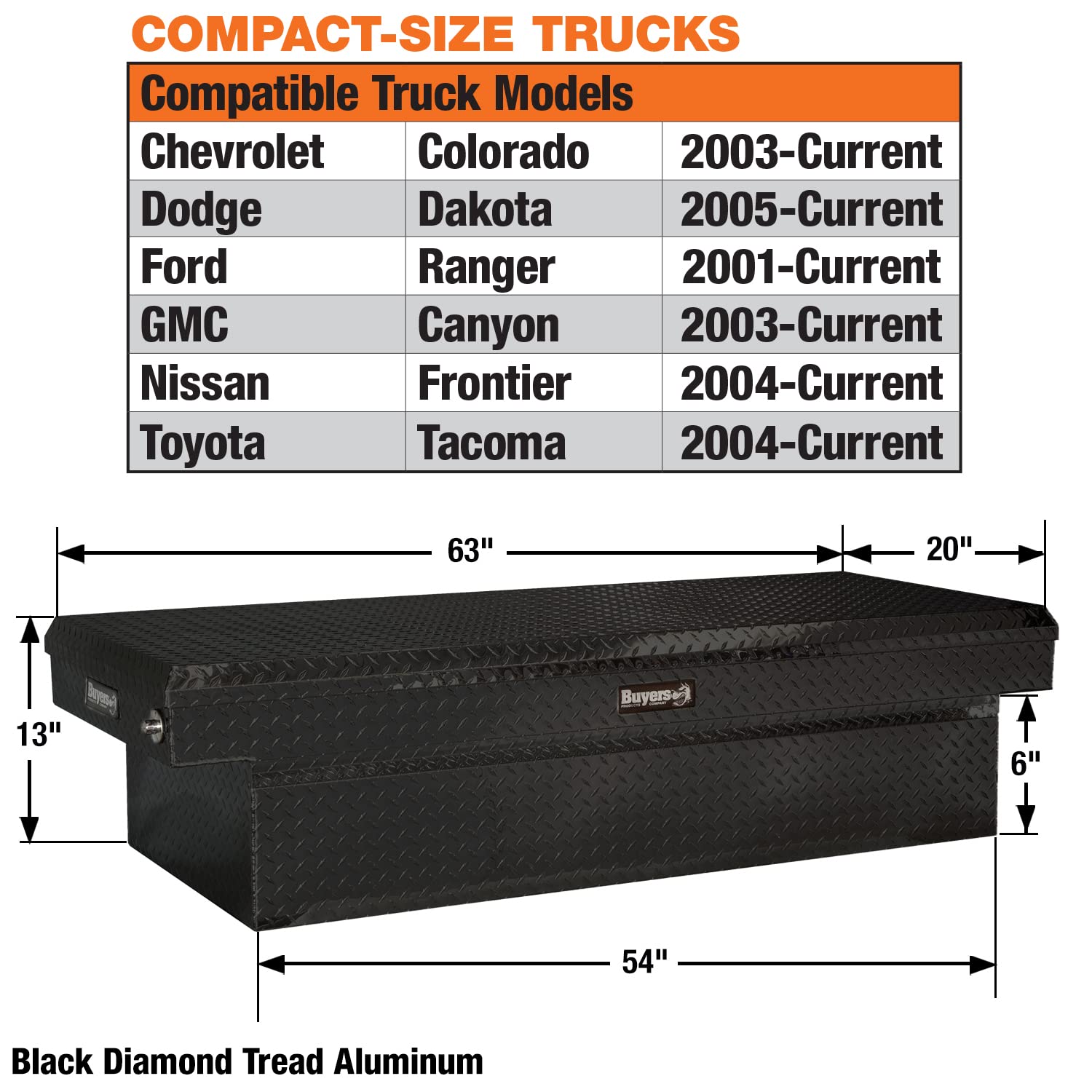

Dimensions and Fit

The dimensions of the toolbox must align with the truck’s bed specifications. Common sizes include full-size, mid-size, and compact options. Proper fit ensures optimal space utilization and easy access to tools. Buyers should verify compatibility with their truck models to avoid issues during installation. -

Installation Type

Toolboxes can be installed in various configurations, including under-bed, side-mount, and crossover styles. Understanding the installation type helps in selecting the right toolbox that meets specific needs. Some models require professional installation, while others offer DIY options, affecting overall costs and convenience.

What Are Common Trade Terms in the Toolbox Industry?

Familiarizing oneself with industry terminology can greatly enhance communication and negotiations in the toolbox market. Here are several key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the toolbox industry, understanding OEM specifications is vital for ensuring compatibility with specific truck models. Buyers often seek OEM parts for guaranteed quality and fit. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it impacts purchasing decisions, especially for small businesses. Understanding MOQ helps in budget planning and inventory management. -

RFQ (Request for Quotation)

An RFQ is a formal document soliciting price quotes from suppliers. By issuing an RFQ, buyers can compare costs, terms, and specifications from multiple vendors. This process is crucial for ensuring competitive pricing and quality assurance. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery responsibilities, ensuring a smoother transaction process. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. It is essential for inventory planning and meeting project deadlines. Buyers should inquire about lead times to manage expectations and avoid disruptions in their operations. -

Customization

Customization in the toolbox industry refers to the ability to tailor products to specific requirements, such as size, color, or features. Understanding customization options allows buyers to procure toolboxes that meet unique operational needs, enhancing functionality and efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs, ultimately leading to successful procurement outcomes.

Navigating Market Dynamics and Sourcing Trends in the cajas de herramientas para trocas Sector

What Are the Current Market Dynamics Influencing the Cajas de Herramientas para Trocas Sector?

The cajas de herramientas para trocas market is currently influenced by several global drivers, primarily the increasing demand for efficient and organized tool storage solutions among various industries. International buyers, particularly from Africa, South America, the Middle East, and Europe, are seeking high-quality, durable toolboxes that can withstand diverse climatic conditions and heavy usage. The rise in construction, logistics, and automotive industries in these regions is driving the need for reliable tool storage options that enhance productivity and safety.

Emerging trends in B2B sourcing include a shift towards customizable and modular toolbox designs, which allow users to tailor storage solutions to their specific needs. Additionally, the integration of technology in toolboxes, such as smart locking mechanisms and tracking systems, is becoming increasingly popular. These innovations not only improve security but also provide users with the ability to monitor their tools and equipment remotely. Furthermore, the emphasis on quick delivery and efficient supply chain management is becoming critical as companies aim to minimize downtime and maximize operational efficiency.

Illustrative image related to cajas de herramientas para trocas

How Are Sustainability and Ethical Sourcing Shaping the Cajas de Herramientas para Trocas Market?

Sustainability is becoming a central focus for B2B buyers in the cajas de herramientas para trocas sector. Companies are increasingly aware of their environmental impact and are seeking suppliers who prioritize sustainable practices. This includes the use of eco-friendly materials and manufacturing processes that minimize waste and carbon footprints. For instance, toolboxes made from recycled aluminum or sustainably sourced steel are gaining traction among buyers looking to enhance their corporate social responsibility (CSR) profiles.

Ethical sourcing is also paramount, as businesses strive to ensure that their suppliers adhere to fair labor practices and maintain transparent supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade certification for labor practices are becoming crucial in the decision-making process for many buyers. By choosing suppliers who prioritize these standards, companies not only mitigate risks associated with unethical practices but also appeal to an increasingly environmentally and socially conscious customer base.

What Is the Historical Context of Cajas de Herramientas para Trocas?

The evolution of cajas de herramientas para trocas can be traced back to the early days of the automotive industry when the need for organized tool storage solutions became apparent. Initially, these toolboxes were simple metal containers designed to hold basic tools. Over the decades, advancements in materials and design have transformed these products into highly functional and durable solutions that cater to a wide range of industries.

The introduction of lightweight yet sturdy materials like aluminum has revolutionized the industry, allowing for greater portability and ease of use. Today’s toolboxes not only prioritize durability and security but also incorporate innovative features such as weather resistance and customizable compartments, reflecting the diverse needs of modern users. As the market continues to evolve, international buyers can expect ongoing innovations that further enhance the functionality and sustainability of tool storage solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of cajas de herramientas para trocas

-

How can I ensure the quality of cajas de herramientas para trocas?

To ensure the quality of toolboxes, it’s crucial to vet suppliers thoroughly. Look for manufacturers with certifications such as ISO 9001, which indicates a commitment to quality management systems. Request product samples to assess materials, craftsmanship, and durability firsthand. Additionally, seek customer reviews and testimonials from other B2B buyers to gauge satisfaction and reliability. Establishing clear quality assurance (QA) protocols with your supplier can also help maintain standards throughout the production process. -

What features should I consider when choosing cajas de herramientas para trocas?

When selecting toolboxes, consider features such as material (aluminum vs. steel), weather resistance, locking mechanisms, and ease of access. Look for customizable options that fit your specific needs, such as compartments for organization or Molle panels for mounting accessories. Ensure the toolbox design accommodates the types of tools you need to store while maximizing space within the vehicle. Durability and resistance to theft are also essential factors to prioritize. -

What is the typical minimum order quantity (MOQ) for cajas de herramientas?

Minimum order quantities can vary significantly by supplier and product type. Generally, MOQs for toolboxes may range from 50 to several hundred units. It’s essential to discuss these quantities upfront with potential suppliers to understand their production capabilities and pricing structures. Some manufacturers may offer lower MOQs for custom designs, while others may require higher quantities to justify production costs. Be sure to negotiate terms that align with your business needs. -

What payment terms are commonly offered by suppliers of cajas de herramientas?

Payment terms can differ widely among suppliers. Common arrangements include full payment upfront, a deposit followed by the balance upon shipment, or payment on delivery. Some suppliers may offer credit terms for established businesses, allowing for payment within 30, 60, or 90 days after delivery. It’s advisable to discuss and negotiate payment terms during the initial stages of your relationship to ensure they align with your cash flow requirements. -

How can I customize my cajas de herramientas for specific needs?

Customization options often include size, color, and internal configuration. When working with suppliers, clearly outline your requirements, such as additional compartments, branding, or specialized locking mechanisms. Many manufacturers offer modular designs that allow for tailored setups to accommodate different tools or equipment. Requesting a prototype or sample of the customized product can help ensure it meets your expectations before full-scale production. -

What logistics considerations should I keep in mind when sourcing cajas de herramientas internationally?

When sourcing internationally, consider shipping methods, costs, and timelines. It’s essential to understand the import regulations and duties in your country to avoid unexpected fees. Working with a freight forwarder can help streamline the logistics process, ensuring compliance with international shipping laws. Additionally, consider the reliability of the supplier’s shipping methods and their ability to provide tracking information, so you can monitor your shipment’s progress. -

How do I vet suppliers for cajas de herramientas to ensure reliability?

To vet suppliers, begin by researching their reputation online, including customer reviews and industry ratings. Request references from other B2B clients to gain insights into their experiences. Conduct due diligence by verifying business licenses and certifications. Additionally, consider visiting the supplier’s manufacturing facility if possible, or request virtual tours. Establishing clear communication and transparency during initial interactions can also indicate the supplier’s reliability. -

What are the common warranty terms for cajas de herramientas?

Warranty terms for toolboxes typically range from one year to a lifetime, depending on the manufacturer and product type. A robust warranty often indicates a supplier’s confidence in their product quality. Be sure to clarify what is covered under the warranty, including defects in materials and workmanship, as well as any exclusions. Understanding the warranty process, including how to file a claim, is also crucial to ensure you are protected in case of issues with your purchase.

Top 7 Cajas De Herramientas Para Trocas Manufacturers & Suppliers List

1. Chandler Truck Accessories – Tool Boxes and Truck Accessories

Domain: chandlertruckaccessories.com

Registered: 2015 (10 years)

Introduction: Accesorios y cajas de herramientas para camionetas, incluyendo: 1. Cajas de herramientas ADAPT: Single Lid, Gullwing, Lo-Side, Topside, Wedge. 2. Accesorios para cajas de herramientas. 3. Ofertas de paquetes. 4. Parachoques para modelos Ford F250/F350, Chevy 2500/3500, GMC 2500/3500, RAM 2500/3500. 5. Cajas comerciales, cajas bajo la carrocería, cajas de puertas traseras, cajas de escalera, cajas …

2. Pinterest – Truck Tool Boxes

Domain: mx.pinterest.com

Registered: 2009 (16 years)

Introduction: Cajas de herramientas para camionetas, Pickup Tool Boxes, Truck Bed Tool Boxes, Tool Box Swing Mount, Swing Out Tool Box For Truck Bed, A Frame Trailer Tongue Tool Box, Underbody Tool Box For Pickup, Montezuma Triangle™ Toolboxes, Utility Truck Organization, Top Mount Truck Tool Box, Full Size Truck Tool Box, Truck Toolbox Organization, Headache Racks, Black Truck Accessories, Custom Truck Lightin…

3. Weather Guard – Cajas de Herramientas para Camionetas

Domain: vanproducts.com

Registered: 1998 (27 years)

Introduction: Cajas de herramientas Weather Guard para camionetas son de alta calidad, diseñadas para mantener herramientas organizadas y seguras. Características de los diferentes modelos incluyen: 1. Baúl para Todo Propósito: Instalación bajo el barandal, apertura de tapa de 90 grados, pestillo giratorio estilo automotriz, protección climática, entrada de 12 voltios, revestimiento ARMOR-TUF® Powder Coat, gara…

4. Buyers Products – 1701568

Domain: pr.ebay.com

Registered: 1995 (30 years)

Introduction: Las mejores ofertas en Cajas de herramientas de camiones en eBay. Productos destacados incluyen: 1. King 1705130 – USD 400.99 (Nuevo) 2. Buyers Products 1701568 – USD 959.95 (Nuevo) 3. Buyers Products 1702650 – USD 429.95 (Nuevo) 4. Buyers Products 1701285 – USD 348.00 (Nuevo) 5. Buyers Products 1702325 – USD 785.95 (Nuevo) 6. Buyers Products 1702840 – USD 669.95 (Nuevo) 7. RKI US48CB – USD 651.51…

5. Facebook – Cajón de Herramientas para Camionetas

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Cajón de Herramientas para Camionetas, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. eBay – Caja de Herramientas de Acero Inoxidable

Domain: bo.ebay.com

Registered: 1995 (30 years)

Introduction: Material: Acero inoxidable; Ancho: 20″ a 72″; Tipo: Caja de herramientas para acople de remolque, Caja de herramientas para placa del chasis, Caja de herramientas de montaje a nivel, Caja de herramientas de 5º rueda, Caja de herramientas de montaje superior; Color: Plateado, Negro, Blanco, Gris, Azul, Anaranjado, Rojo; Marca: Abex, Buyers Products, Dee Zee, Delta, GPI, Torin, Unbranded, UWS; Estad…

7. Obselectromecan – Custom Flatbed Truck Ideas

Domain: ar.pinterest.com

Registered: 2009 (16 years)

Introduction: caja herramientas, 8 Pins, 6y obselectromecan, ideas de caja herramientas, herramientas, camionetas, Flat Bed Truck Ideas, Flatbed Truck Beds, Custom Flatbed Work Bed, Welding Trucks, Welding Rig, Custom Truck Beds, Camper Awnings, Truck Bed Drawer Storage Systems, Toolbox, Behind Truck Seat Storage, Heavy-duty Truck Storage Solution, Organizing Tools For Mechanics, Green Tool Chest, Truck Tool Bo…

Strategic Sourcing Conclusion and Outlook for cajas de herramientas para trocas

The strategic sourcing of toolboxes for trucks presents a compelling opportunity for businesses across Africa, South America, the Middle East, and Europe. Understanding the diverse product offerings—from heavy-duty aluminum constructions to customizable organizational systems—enables B2B buyers to select solutions that enhance operational efficiency and security. The emphasis on quality features, such as weather resistance and anti-theft mechanisms, underscores the importance of investing in reliable equipment that minimizes long-term costs and maximizes productivity.

By establishing strong relationships with manufacturers and suppliers, businesses can secure favorable pricing, ensure timely delivery, and gain access to innovative products tailored to their specific needs. As the demand for robust storage solutions continues to rise, it is crucial for international buyers to stay informed about market trends and emerging technologies in toolbox design.

Looking ahead, the evolving landscape of the toolbox market presents an exciting opportunity for B2B buyers to enhance their fleets with cutting-edge storage solutions. Engage with reputable suppliers and explore the latest innovations to ensure your operations are equipped for success. Now is the time to invest in quality that drives efficiency and safeguards your assets.

Illustrative image related to cajas de herramientas para trocas

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.