Choosing Your C Channle: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for c channle

In today’s competitive landscape, sourcing high-quality C channels for construction and manufacturing projects can be a daunting task for international B2B buyers. With varying standards, specifications, and supplier reliability across different regions, navigating the global market requires strategic insights and comprehensive knowledge. This guide aims to simplify the complexities of procuring C channels, offering an in-depth exploration of types, applications, and essential considerations for effective supplier vetting.

From structural steel channels to specialized aluminum options, understanding the nuances of each type is crucial for making informed purchasing decisions. Buyers will also gain insights into cost structures, allowing for more accurate budgeting and financial planning. Furthermore, this guide addresses the unique challenges faced by international buyers from Africa, South America, the Middle East, and Europe, such as regional availability and compliance with local regulations.

By equipping B2B buyers with actionable information and expert insights, this resource empowers organizations to confidently source C channels that meet their specific needs. Whether you are in Brazil, Vietnam, or elsewhere, this guide serves as a vital tool in ensuring that your procurement process is efficient, cost-effective, and aligned with industry standards. Embrace the opportunity to enhance your sourcing strategy and secure the best materials for your projects.

Understanding c channle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| A36 Structural Steel Channel | Standard carbon steel, good weldability, versatile | Construction, manufacturing, structural support | Pros: Cost-effective, widely available. Cons: Limited corrosion resistance. |

| Aluminum C-Channel | Lightweight, corrosion-resistant, non-magnetic | Marine applications, architectural projects | Pros: Lightweight, good strength-to-weight ratio. Cons: Higher cost than steel. |

| Galvanized C-Channel | Steel coated with zinc for corrosion resistance | Outdoor structures, industrial applications | Pros: Enhanced durability, weather-resistant. Cons: Can be more expensive than non-coated options. |

| Stainless Steel C-Channel | High corrosion resistance, aesthetic finish | Food processing, chemical handling, construction | Pros: Long-lasting, low maintenance. Cons: Higher initial investment. |

| Custom Fabricated C-Channel | Tailored dimensions and specifications | Specialized projects, unique structural needs | Pros: Perfect fit for specific applications. Cons: Longer lead times and potential higher costs. |

What Are the Characteristics of A36 Structural Steel Channel?

The A36 structural steel channel is a popular choice in construction and manufacturing due to its excellent weldability and versatility. Typically used for structural support, it is available in various sizes and can be easily cut or shaped to fit specific needs. Buyers should consider its cost-effectiveness and availability, but also be aware of its limitations in terms of corrosion resistance, making it less suitable for outdoor applications without protective coatings.

How Does Aluminum C-Channel Stand Out?

Aluminum C-channel is recognized for its lightweight properties and resistance to corrosion, making it ideal for marine applications and architectural projects. Its non-magnetic quality is advantageous in environments where magnetic interference is a concern. While it offers a superior strength-to-weight ratio, buyers should be prepared for higher costs compared to traditional steel options, which may impact budget considerations for large-scale projects.

What Are the Benefits of Galvanized C-Channel?

Galvanized C-channel is steel that has been coated with zinc to enhance its corrosion resistance, making it suitable for outdoor structures and industrial applications. This type of channel is particularly beneficial in environments exposed to moisture and harsh weather conditions. While the added durability and weather resistance are significant advantages, buyers should factor in the potentially higher costs associated with galvanized products when planning their procurement strategies.

Why Choose Stainless Steel C-Channel?

Stainless steel C-channel is prized for its exceptional corrosion resistance and aesthetic appeal, making it a preferred choice in industries such as food processing and chemical handling. Its longevity and low maintenance requirements can lead to cost savings over time. However, the initial investment is higher than other materials, which is an important consideration for B2B buyers who need to balance quality with budget constraints.

When Should You Consider Custom Fabricated C-Channel?

Custom fabricated C-channel provides tailored dimensions and specifications, making it ideal for specialized projects where standard sizes do not suffice. This flexibility allows businesses to achieve precise fit and functionality for unique structural needs. However, buyers should be aware of the longer lead times and potential for increased costs associated with custom orders, which can impact project timelines and budgets.

Key Industrial Applications of c channle

| Industry/Sector | Specific Application of c channel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support in buildings and frameworks | Provides durability and stability to structures | Consider material grade, length, and weight capacity |

| Manufacturing | Machinery frames and support structures | Enhances operational efficiency and equipment longevity | Assess load-bearing requirements and corrosion resistance |

| Transportation | Rail and vehicle chassis construction | Ensures safety and reliability in transportation systems | Evaluate specifications for weight and tensile strength |

| Energy & Utilities | Support for pipelines and electrical installations | Reduces maintenance costs and enhances system reliability | Look for compliance with international standards |

| Automotive | Production of vehicle components and assembly lines | Improves production speed and product quality | Focus on precision engineering and material specifications |

How is c channel utilized in construction projects?

In the construction industry, c channel is widely used as a structural support element in buildings and frameworks. Its shape provides excellent strength-to-weight ratios, allowing for the construction of stable and durable structures. International buyers, particularly from regions like Africa and South America, must consider local building codes and material grades to ensure compliance and safety. Sourcing c channel that meets specific load-bearing requirements is crucial for projects involving high-rise buildings or large industrial facilities.

What role does c channel play in manufacturing processes?

In manufacturing, c channel serves as a critical component in machinery frames and support structures. It offers the rigidity needed to withstand vibrations and operational stresses, thereby enhancing equipment longevity and operational efficiency. Buyers in this sector should prioritize sourcing high-quality materials with appropriate corrosion resistance, especially in humid or harsh environments. Understanding the specific load requirements of machinery is essential for selecting the right c channel dimensions and grades.

How is c channel important in transportation systems?

The transportation industry utilizes c channel in the construction of rail and vehicle chassis. Its robust design ensures safety and reliability in various transportation applications, from trucks to trains. For international buyers, particularly in the Middle East and Europe, it is vital to evaluate the specifications of c channel to ensure they meet stringent safety standards and performance requirements. Consideration of weight and tensile strength is essential to maintain the integrity of transportation systems.

In what ways does c channel support energy and utilities infrastructure?

In the energy and utilities sector, c channel is used to support pipelines and electrical installations. Its ability to withstand environmental stresses reduces maintenance costs and enhances the reliability of critical infrastructure. Buyers should focus on sourcing c channel that complies with international standards to ensure safety and performance. Additionally, assessing the corrosion resistance of materials is crucial, especially in regions with extreme weather conditions.

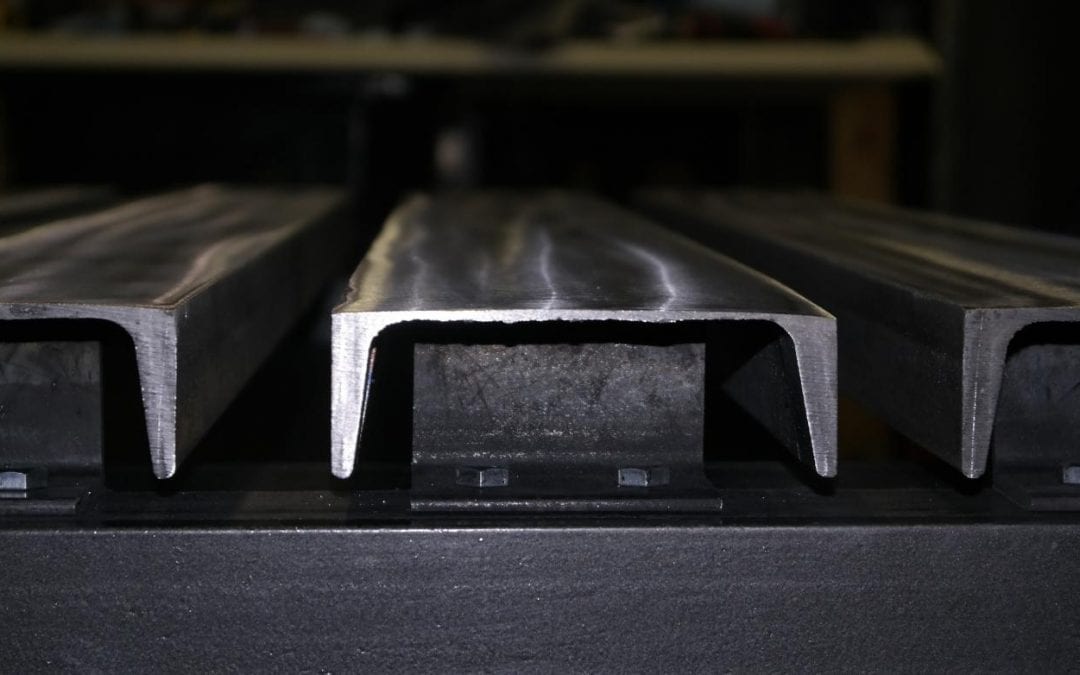

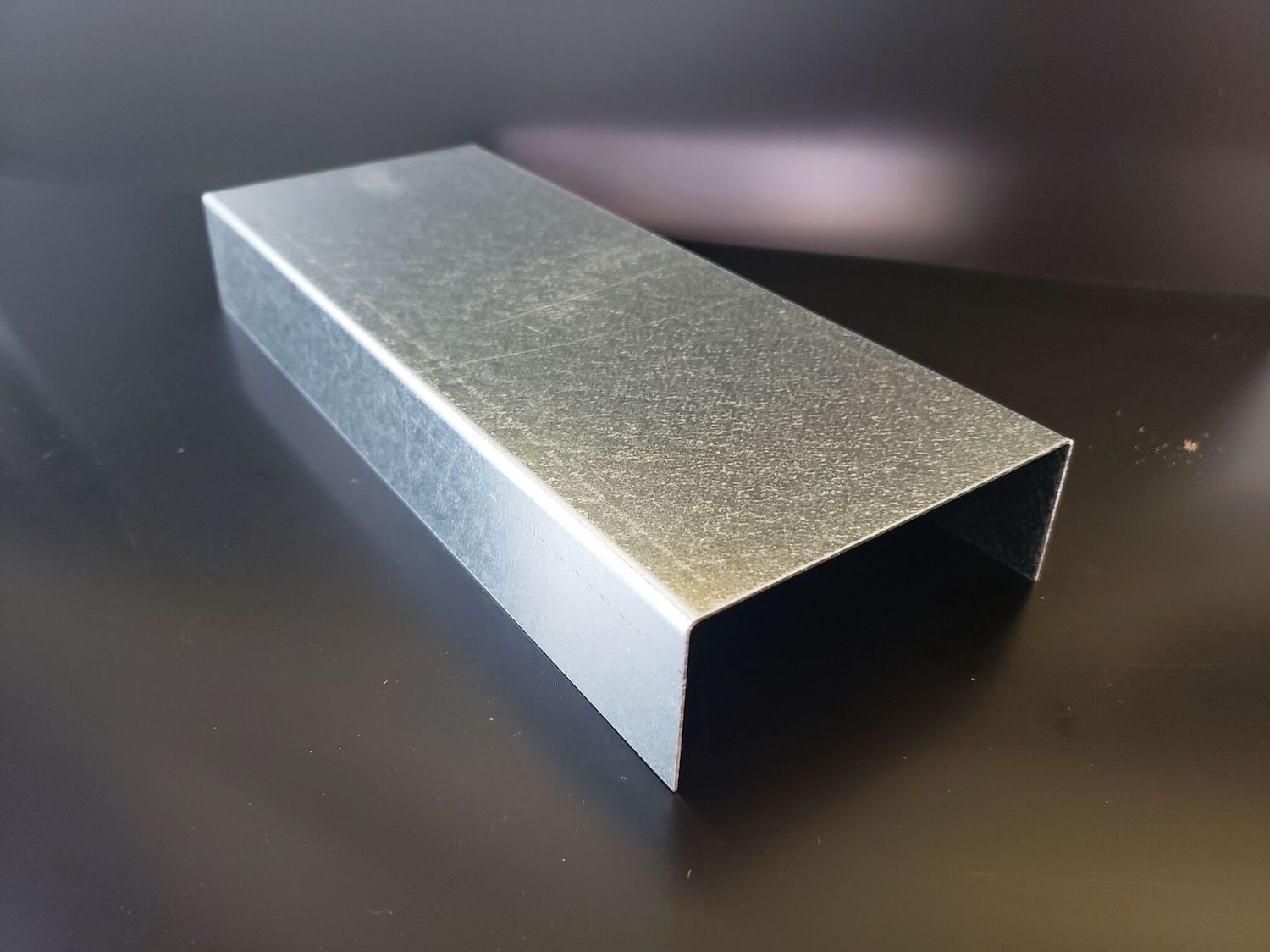

Illustrative image related to c channle

Why is c channel significant in automotive manufacturing?

In the automotive industry, c channel is integral to the production of vehicle components and assembly lines. It contributes to improved production speed and product quality by providing a stable framework for assembly operations. For B2B buyers, especially those in emerging markets like Brazil and Vietnam, understanding precision engineering requirements and sourcing materials that meet automotive standards is essential for maintaining competitiveness in the market.

3 Common User Pain Points for ‘c channle’ & Their Solutions

Scenario 1: Sourcing the Right C-Channel Specifications for Project Needs

The Problem: B2B buyers often struggle to source the correct specifications for C-channels, which can lead to project delays and increased costs. When dealing with projects that require specific dimensions, thicknesses, and materials, the challenge intensifies, especially if suppliers do not have clear product information or if buyers are unfamiliar with technical specifications. This can result in purchasing the wrong type or size of C-channel, causing delays in construction timelines and additional expenses for returns or reordering.

The Solution: To overcome this challenge, buyers should first conduct a thorough needs assessment by collaborating with their engineering teams. Identify the exact specifications required for the project, including dimensions, weight capacity, and material grade. Utilize reputable suppliers who provide detailed product catalogs with specifications, including load ratings and material certifications. Moreover, leveraging technology such as 3D modeling software can help visualize how different C-channels will fit within the overall structure, ensuring that the chosen specifications will meet the project’s requirements. Finally, consider establishing a preferred vendor list based on reliability and product quality to streamline future sourcing.

Scenario 2: Navigating Supply Chain Disruptions for C-Channel Deliveries

The Problem: International B2B buyers, particularly in emerging markets, often face significant supply chain disruptions that can delay the delivery of C-channels. Factors such as geopolitical tensions, port congestion, and fluctuating freight costs can impact the timely arrival of materials, which in turn affects project schedules and budgets. This unpredictability can also lead to a lack of trust in suppliers and increased financial strain on businesses that rely heavily on timely deliveries.

The Solution: To mitigate supply chain risks, buyers should diversify their sourcing strategy by establishing relationships with multiple suppliers across different regions. This not only reduces reliance on a single source but also provides alternatives in case of disruptions. Additionally, implementing just-in-time inventory management practices can help balance stock levels with project needs, minimizing excess inventory costs. Engage in proactive communication with suppliers to gain insights into potential delays and proactively adjust project timelines as necessary. Utilizing supply chain management software can also enhance visibility into order statuses and shipping times, enabling better planning and resource allocation.

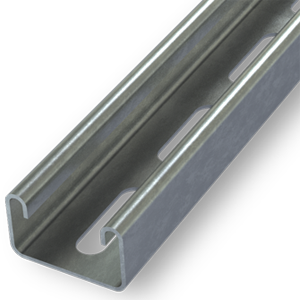

Illustrative image related to c channle

Scenario 3: Ensuring Quality and Compliance in C-Channel Purchases

The Problem: Quality control is a critical concern for B2B buyers when purchasing C-channels, especially in industries where structural integrity is paramount. Buyers may encounter issues with substandard materials that do not meet regulatory compliance or industry standards, leading to safety hazards and costly rework. This is particularly concerning in markets where quality assurance processes may not be as stringent, resulting in potential liability issues for buyers.

The Solution: To ensure quality and compliance, buyers should prioritize working with suppliers who can provide clear documentation of material certifications and compliance with international standards (e.g., ASTM, ISO). Implementing a robust quality assurance process, including material testing and third-party inspections, can further safeguard against subpar products. Establishing criteria for supplier evaluation, such as past performance, certifications, and customer reviews, can also help in selecting trustworthy suppliers. Regular audits of supplier practices and ongoing training for procurement teams on compliance standards can enhance the overall quality of purchased materials, ensuring that all C-channels meet the necessary safety and regulatory requirements.

Strategic Material Selection Guide for c channle

What Are the Key Materials for C Channel and Their Properties?

When selecting materials for C channel applications, it is essential to consider various factors such as mechanical properties, environmental resistance, and cost implications. Below, we analyze four common materials used for C channels: Carbon Steel, Stainless Steel, Aluminum, and Galvanized Steel. Each material offers distinct advantages and limitations that can significantly impact the performance and suitability for specific applications.

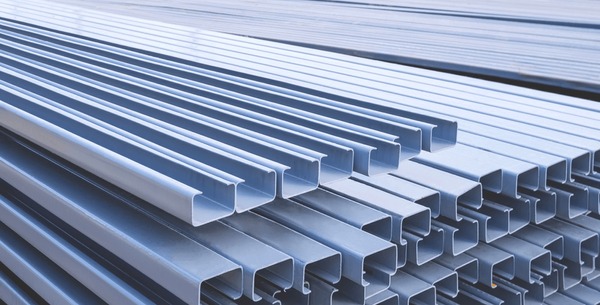

Illustrative image related to c channle

How Does Carbon Steel Perform in C Channel Applications?

Carbon steel is a widely used material for C channels due to its excellent strength-to-weight ratio and cost-effectiveness. Key properties include high tensile strength and good ductility, making it suitable for structural applications. However, carbon steel is prone to corrosion, especially in humid or marine environments, which can limit its lifespan unless adequately protected.

Pros:

– High strength and durability.

– Cost-effective for large-scale applications.

– Easy to fabricate and weld.

Cons:

– Requires protective coatings to prevent rust.

– Limited performance in corrosive environments.

For international buyers, compliance with standards such as ASTM A36 is crucial, especially in regions like Africa and South America, where structural integrity is paramount. Buyers should also consider the availability of carbon steel in their local markets to ensure timely procurement.

What Advantages Does Stainless Steel Offer for C Channels?

Stainless steel is known for its superior corrosion resistance, making it an excellent choice for C channels exposed to harsh environments. Key properties include high tensile strength and the ability to maintain structural integrity at elevated temperatures. However, stainless steel is generally more expensive than carbon steel.

Pros:

– Exceptional corrosion resistance.

– High durability and aesthetic appeal.

– Suitable for high-temperature applications.

Cons:

– Higher material costs.

– More complex fabrication processes.

For buyers in the Middle East and Europe, adherence to standards like ASTM A240 or EN 10088 is essential. The preference for stainless steel is often driven by the need for longevity and low maintenance in industrial applications.

Why Is Aluminum a Popular Choice for C Channels?

Aluminum C channels are lightweight yet strong, making them ideal for applications where weight reduction is critical. Key properties include excellent corrosion resistance and good thermal conductivity. However, aluminum is not as strong as steel, which may limit its use in heavy-load applications.

Pros:

– Lightweight and easy to handle.

– Excellent corrosion resistance.

– Good thermal and electrical conductivity.

Cons:

– Lower strength compared to steel.

– Typically higher cost per unit of strength.

International buyers, particularly in regions like Brazil and Vietnam, should consider the availability of aluminum C channels and compliance with standards such as ASTM B221. The lightweight nature of aluminum can be advantageous for shipping and handling in these markets.

What Role Does Galvanized Steel Play in C Channel Applications?

Galvanized steel combines the strength of carbon steel with a protective zinc coating, enhancing its corrosion resistance. This material is particularly beneficial in applications exposed to moisture or chemicals. Key properties include good mechanical strength and a longer lifespan compared to untreated carbon steel.

Pros:

– Enhanced corrosion resistance due to zinc coating.

– Cost-effective compared to stainless steel.

– Good structural integrity.

Cons:

– The coating can be damaged during fabrication.

– Limited performance in extreme temperatures.

For B2B buyers in Africa and the Middle East, it is crucial to ensure that galvanized steel meets relevant standards such as ASTM A123. Understanding local environmental conditions will also guide the selection of galvanized steel for specific applications.

Summary Table of Material Selection for C Channel

| Material | Typical Use Case for C Channel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural frameworks and supports | High strength and durability | Prone to corrosion without coating | Low |

| Stainless Steel | Marine and chemical processing applications | Exceptional corrosion resistance | Higher material costs | High |

| Aluminum | Lightweight structures and HVAC systems | Lightweight and corrosion-resistant | Lower strength than steel | Med |

| Galvanized Steel | Outdoor structures and industrial applications | Enhanced corrosion resistance | Coating damage during fabrication | Med |

This analysis provides a comprehensive overview of the materials commonly used for C channels, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for c channle

What Are the Main Stages in the Manufacturing Process of C-Channel?

Manufacturing C-channels involves several critical stages that ensure the product meets the specific requirements of various industries.

Material Preparation

The process begins with material selection, where suppliers typically choose high-quality steel or aluminum, often conforming to standards such as A36 for carbon steel. The material is cut to size based on the specifications of the final product. This may involve large sheets of metal that are processed through saws or laser cutting machines. Material quality is assessed through visual inspections and measurements to ensure compliance with industry standards.

Forming Techniques

After preparation, the next step is forming the C-channel shape. This is often achieved using a combination of methods such as hot rolling, cold rolling, or extrusion. Hot rolling involves heating the metal above its recrystallization temperature, allowing it to be shaped more easily. Cold rolling, on the other hand, occurs at room temperature, resulting in a stronger, more precise product. The choice of method depends on the desired mechanical properties and the specific application of the C-channel.

Assembly and Fabrication

In some cases, C-channels may be fabricated into more complex structures. This could involve welding, cutting, or bending additional components to create a finished product that meets specific engineering requirements. This stage may also include the application of coatings or treatments to enhance corrosion resistance and longevity.

Finishing Processes

Finishing processes are crucial for enhancing the durability and aesthetic appeal of C-channels. Common techniques include painting, galvanizing, or powder coating. These processes not only provide a protective layer but can also meet specific industry standards for appearance and performance. Each finishing method has its own set of advantages and may be selected based on end-user requirements.

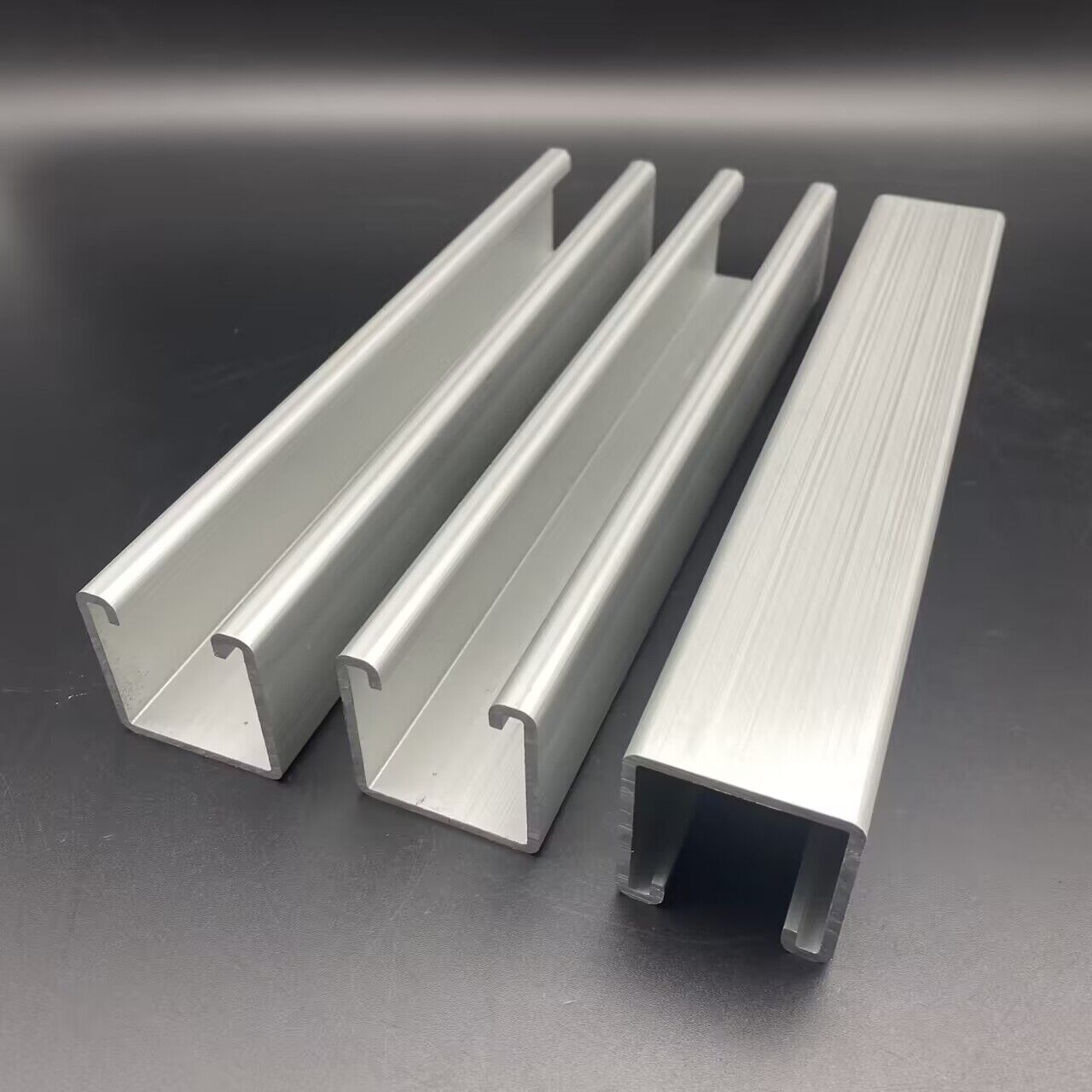

Illustrative image related to c channle

How Is Quality Assurance Implemented in C-Channel Manufacturing?

Quality assurance (QA) is vital in ensuring that manufactured C-channels meet both international standards and customer expectations.

What International and Industry-Specific Standards Are Relevant?

Manufacturers typically adhere to various international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE marking (for products sold within the European Economic Area) or API standards (for petroleum and natural gas industry products) may apply. These certifications help ensure that the products are safe, reliable, and of high quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. Any defective materials are rejected or returned to the supplier.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted at various stages to monitor compliance with specifications. This may involve measuring dimensions, checking material properties, and ensuring proper adherence to manufacturing protocols.

-

Final Quality Control (FQC): Once production is complete, a final inspection is performed to verify that the C-channels meet all specifications before they are shipped. This includes a thorough review of finishing and packaging.

What Common Testing Methods Are Used for C-Channels?

Several testing methods are utilized to ensure the integrity and quality of C-channels:

-

Tensile Testing: This method evaluates the strength and ductility of the material.

-

Dimensional Inspection: Tools such as calipers and micrometers measure dimensions to ensure they align with specifications.

-

Visual Inspection: A thorough visual examination checks for surface defects, such as cracks, rust, or inconsistencies in coating.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic or magnetic particle testing are used to identify internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some effective strategies:

Illustrative image related to c channle

-

Audits: Conducting regular audits of suppliers can provide insight into their quality management systems and manufacturing processes. This can help identify any potential issues before they affect product quality.

-

Quality Assurance Reports: Requesting detailed QA reports can give buyers a comprehensive overview of the supplier’s QC processes, including results from inspections and testing.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control measures and product reliability.

What Nuances Should International Buyers Be Aware of Regarding QC Certifications?

When dealing with international suppliers, particularly in regions like Africa and South America, it’s essential to understand the nuances of QC certifications:

-

Regional Compliance: Some regions may have unique regulatory requirements that differ from international standards. Buyers should familiarize themselves with these local regulations to ensure compliance.

-

Documentation: Ensure that all certifications and quality documents are up-to-date and verifiable. This includes certificates of compliance, inspection reports, and any relevant testing data.

-

Communication: Establishing clear lines of communication with suppliers about quality expectations can help mitigate misunderstandings and ensure that products meet required standards.

Conclusion

For B2B buyers, particularly those operating in diverse international markets, understanding the manufacturing processes and quality assurance measures for C-channels is critical. By focusing on material preparation, forming techniques, and comprehensive quality control checkpoints, buyers can ensure they partner with reliable suppliers who deliver high-quality products. Taking proactive steps to verify QC practices and certifications will further enhance the reliability of supply chains and product integrity.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘c channle’

In the competitive landscape of B2B procurement, sourcing C-channel products effectively is essential for ensuring quality and cost-efficiency. This guide provides a structured checklist that will help international buyers streamline their sourcing process, particularly focusing on the needs of businesses in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the C-channel you need is the foundation of effective sourcing. This includes dimensions, material type (e.g., steel, aluminum), and any specific standards (like ASTM or ISO) relevant to your application. Detailed specifications not only help suppliers understand your requirements but also ensure that the products meet your project standards.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers who specialize in C-channel products. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. Pay attention to suppliers who have experience in your specific market region, as they will be more familiar with local regulations and logistical challenges.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that your shortlisted suppliers hold the necessary certifications. Look for ISO 9001 for quality management and any industry-specific certifications relevant to C-channel manufacturing. Certifications ensure that the supplier adheres to recognized standards, minimizing the risk of quality issues later in the procurement process.

Step 4: Request Samples and Product Specifications

Always request samples of the C-channel products you are considering. This step allows you to physically assess the quality and ensure they meet your specifications. Alongside samples, ask for detailed product specifications, including material properties and load-bearing capabilities, to confirm they align with your project needs.

Step 5: Compare Pricing and Payment Terms

Gather detailed quotes from multiple suppliers, ensuring you compare not just the prices but also the payment terms and conditions. Consider factors such as bulk discounts, shipping costs, and payment flexibility. Understanding the total cost of ownership will help you make a more informed decision and potentially save on overall expenses.

Step 6: Conduct Supplier Audits

If possible, perform audits or site visits to the facilities of your top suppliers. This step is crucial for assessing their production capabilities, quality control processes, and overall reliability. A direct evaluation can provide insights that go beyond what is presented in documents and help build a stronger partnership.

Step 7: Establish Clear Communication Channels

Once you select a supplier, establish clear communication channels and protocols. Define points of contact for different issues, including order updates, quality concerns, and logistical coordination. Effective communication is key to ensuring smooth operations and addressing any issues that may arise during the sourcing process.

By following this checklist, B2B buyers can navigate the complexities of sourcing C-channel products with confidence, ensuring they select the right suppliers and products for their needs.

Comprehensive Cost and Pricing Analysis for c channle Sourcing

What Are the Key Cost Components in C Channel Sourcing?

When sourcing C channels, understanding the cost structure is paramount for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of steel—such as A36 carbon steel, stainless steel, or aluminum—directly influences material costs. Prices can fluctuate based on global market conditions and local availability. Buyers should consider sourcing from regions with lower raw material costs.

-

Labor: Labor costs vary significantly by region. In countries with higher wage standards, such as those in Europe, labor will comprise a larger percentage of the overall cost. Conversely, sourcing from regions like Southeast Asia may offer lower labor costs but could involve trade-offs in quality.

-

Manufacturing Overhead: This encompasses the costs related to factory operations, including utilities, equipment depreciation, and indirect labor. Efficient manufacturing processes can reduce overhead costs, which can be beneficial for bulk orders.

-

Tooling: Custom tooling for unique specifications can add to the upfront costs. However, investing in the right tooling can lead to long-term savings through improved production efficiency.

-

Quality Control (QC): Ensuring that C channels meet required specifications and certifications can incur additional QC costs. Buyers should prioritize suppliers with robust quality assurance processes to mitigate risks.

-

Logistics: Transportation costs can vary widely based on the origin of the materials, shipping methods, and delivery locations. Understanding the total logistics costs, including tariffs and taxes, is crucial for accurate budgeting.

-

Margin: Suppliers typically add a margin that reflects their operating expenses and profit goals. This margin can vary based on market conditions and the supplier’s pricing strategy.

How Do Price Influencers Affect C Channel Sourcing?

Several factors influence the pricing of C channels, and being aware of these can help buyers negotiate better deals.

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Suppliers are more willing to offer discounts for bulk purchases, which can significantly reduce overall expenses.

-

Specifications and Customization: Customized C channels tailored to specific applications may incur additional costs. Buyers should carefully assess their needs to avoid unnecessary customization that can inflate prices.

-

Materials: The choice of material impacts not only the cost but also the performance and lifespan of the product. For instance, while aluminum may be more expensive, it offers benefits such as corrosion resistance that can justify the price.

-

Quality and Certifications: Products that meet international quality standards or hold specific certifications may come at a premium. Buyers should weigh the importance of certifications against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and location can significantly influence pricing. Establishing relationships with trusted suppliers can lead to better pricing terms and conditions.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) determine who bears responsibility for shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs.

What Buyer Tips Can Enhance Cost Efficiency in C Channel Sourcing?

To maximize value when sourcing C channels, B2B buyers should consider several strategies:

-

Negotiate Effectively: Leverage volume discounts and long-term contracts to negotiate better pricing. Open communication about budget constraints can also yield favorable terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and lifecycle costs. A lower upfront cost may result in higher long-term expenses if quality is compromised.

-

Understand Pricing Nuances for International Transactions: Buyers from regions like Africa, South America, and the Middle East should be aware of import duties, taxes, and potential currency fluctuations that can affect final costs. Engaging local representatives can provide insights into these complexities.

-

Stay Informed About Market Trends: Regularly monitoring market trends and price fluctuations can help buyers make informed purchasing decisions. Networking with industry peers can also provide insights into best practices and sourcing strategies.

Disclaimer

The prices referenced in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to obtain accurate and competitive pricing.

Alternatives Analysis: Comparing c channle With Other Solutions

In the competitive landscape of structural solutions, understanding the alternatives to ‘C Channel’ is crucial for making informed decisions. ‘C Channel’, a versatile product used in various construction and manufacturing applications, faces competition from several alternatives. This analysis delves into how ‘C Channel’ stacks up against other viable solutions, helping B2B buyers assess their options effectively.

Illustrative image related to c channle

| Comparison Aspect | C Channel | Steel I-Beam | Aluminum Channel |

|---|---|---|---|

| Performance | High strength-to-weight ratio; suitable for various loads | Excellent load-bearing capacity; optimal for heavy loads | Lightweight; corrosion-resistant; less load capacity |

| Cost | Moderate; varies by size and material | Higher initial cost due to manufacturing complexity | Generally higher than steel but lower than I-beams |

| Ease of Implementation | Straightforward; can be easily cut and welded | Requires specialized equipment for installation | Easy to handle but requires specific tools for cutting |

| Maintenance | Low maintenance; rust prevention needed in harsh environments | Low maintenance; durable but can corrode | Minimal maintenance; resistant to corrosion |

| Best Use Case | General construction, framing, and bracing | Heavy construction, bridges, and high-load applications | Lightweight structures, marine applications, and decorative uses |

What Are the Advantages and Disadvantages of Using Steel I-Beams as an Alternative to C Channel?

Steel I-Beams are renowned for their exceptional load-bearing capacity, making them ideal for heavy-duty applications such as bridges and skyscrapers. Their design allows for efficient distribution of weight, which is crucial in structural integrity. However, the higher initial cost and the need for specialized installation equipment can be prohibitive for smaller projects. Additionally, while they require minimal maintenance, they can suffer from corrosion if not properly treated, which may lead to increased long-term costs.

How Does an Aluminum Channel Compare to C Channel in Terms of Versatility and Cost?

Aluminum Channels offer a lightweight alternative to C Channels, ideal for applications where weight is a significant consideration, such as in aerospace or marine industries. Their corrosion resistance makes them suitable for outdoor and marine environments without the need for extensive protective coatings. However, they typically have a lower load capacity compared to steel options, which may limit their use in heavy construction. While their initial cost is generally higher than C Channels, they can offer savings in maintenance and longevity.

Conclusion: How Can B2B Buyers Choose the Right Structural Solution for Their Needs?

When selecting the right structural solution, B2B buyers must evaluate their specific project requirements, including load capacity, environmental conditions, and budget constraints. ‘C Channel’ offers a balance of strength and cost-effectiveness for many applications, but alternatives like Steel I-Beams and Aluminum Channels may be better suited for specialized needs. By carefully considering performance metrics, costs, and implementation ease, buyers can make informed choices that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for c channle

What Are the Key Technical Properties of C Channel?

When sourcing C channel products for construction, manufacturing, or other industrial applications, understanding the critical technical specifications is essential. These properties determine the performance, compatibility, and overall suitability of the material for your project needs.

Illustrative image related to c channle

-

Material Grade

– The most common material grade for C channel is A36, which is a low carbon steel known for its good weldability and machinability. Understanding the material grade is crucial as it affects the channel’s strength, weight, and corrosion resistance. For international buyers, specifying the correct material grade ensures compliance with local building codes and standards. -

Dimensions and Tolerances

– C channels come in various dimensions, typically denoted by their height, width, and thickness (e.g., C 4 x 5.4). Tolerances refer to the permissible limits of variation in these dimensions. Accurate dimensions and tolerances are vital for ensuring proper fit and structural integrity in applications. Buyers should pay close attention to these specifications to avoid costly rework or safety issues. -

Weight per Unit Length

– The weight of the C channel per unit length (e.g., pounds per foot) is an important property that affects shipping costs and handling. This metric helps buyers estimate total weight for transport and handling logistics. It also plays a role in the structural load calculations necessary for safe and effective design. -

Finish Type

– The finish type, such as galvanized or painted, impacts the channel’s resistance to corrosion and environmental factors. A galvanized finish, for instance, offers superior protection in outdoor or humid conditions. Buyers must consider the finish type based on the intended application environment to ensure long-term durability. -

Yield Strength

– Yield strength is the amount of stress a material can withstand before it deforms permanently. Knowing the yield strength of a C channel is crucial for engineers and designers to ensure that the selected channel can safely support the expected loads without failure.

What Are Common Trade Terms in the C Channel Industry?

Familiarity with industry terminology is essential for effective communication and negotiation with suppliers. Here are some commonly used terms relevant to C channel transactions:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, identifying OEMs can be beneficial for sourcing high-quality, reliable C channels that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for budget planning and inventory management, particularly for international buyers who may face higher shipping costs for smaller orders. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Providing detailed specifications in an RFQ can lead to more accurate quotes and better pricing for C channels. -

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify who bears the risk and costs during transport and delivery, making them critical for international buyers to negotiate favorable terms. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is important for project scheduling and ensuring that materials arrive when needed to avoid delays. -

Certification Standards

– Certification standards refer to the qualifications that materials must meet to ensure safety and performance (e.g., ASTM, ISO). Knowledge of these standards helps buyers ensure that the C channels they source comply with regulatory requirements and industry benchmarks.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions, streamline procurement processes, and ultimately enhance their project outcomes.

Navigating Market Dynamics and Sourcing Trends in the c channle Sector

What Are the Key Market Dynamics and Sourcing Trends in the C Channel Sector?

The global market for C channels, particularly in structural steel and metal components, is influenced by several significant factors. A primary driver is the increasing demand for construction and infrastructure development across emerging economies, notably in Africa, South America, and parts of Europe. Countries like Brazil and Vietnam are investing heavily in urbanization, leading to a surge in demand for durable construction materials. Moreover, advancements in manufacturing technologies, such as automation and precision cutting, have optimized production efficiency, enabling suppliers to meet diverse client specifications quickly and cost-effectively.

Current trends in B2B sourcing indicate a shift towards digital procurement platforms. Buyers increasingly prefer online marketplaces that provide comprehensive product catalogs, competitive pricing, and transparent supply chain information. This digital transformation facilitates smoother transactions and enhances buyer-supplier interactions. Additionally, there is a noticeable trend towards customization, where buyers seek tailored solutions to meet specific project requirements, reflecting a move away from one-size-fits-all approaches.

How Is Sustainability Influencing Sourcing in the C Channel Sector?

Sustainability has become a cornerstone of sourcing strategies in the C channel sector. Environmental concerns surrounding traditional manufacturing processes have prompted many companies to adopt greener practices. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainable sourcing, including the use of recycled materials and energy-efficient production methods. This shift is not only beneficial for the environment but also enhances the brand image of companies that embrace sustainability.

Illustrative image related to c channle

The importance of ethical supply chains cannot be overstated. International buyers are increasingly scrutinizing their suppliers to ensure compliance with labor laws and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming crucial criteria in supplier selection. By opting for certified materials, companies can significantly reduce their environmental impact while also appealing to a growing consumer base that values sustainability.

What Is the Historical Context of C Channels in B2B Markets?

The C channel’s evolution can be traced back to the industrial revolution when the demand for structural materials surged. Initially, C channels were primarily utilized in heavy industries, including shipbuilding and construction, due to their strength and versatility. Over the decades, advancements in metallurgy and manufacturing techniques have led to a wider variety of channel types, including aluminum and stainless steel options, catering to diverse applications across various sectors.

As globalization progressed, the C channel market expanded, with suppliers emerging from different regions, enhancing competition and driving innovation. Today, C channels are essential components in numerous applications, from structural frames to automotive manufacturing, underscoring their significance in modern B2B supply chains. Understanding this historical context allows buyers to appreciate the evolution of C channels and the ongoing innovations that continue to shape the market.

Frequently Asked Questions (FAQs) for B2B Buyers of c channle

1. How do I solve issues with sourcing C-channel products internationally?

To effectively source C-channel products internationally, start by identifying reputable suppliers who specialize in structural steel products. Conduct thorough research on their credibility by checking reviews, certifications, and trade references. Ensure they have experience in exporting to your region, as this can simplify logistics and compliance with local regulations. Establish clear communication channels and request samples to evaluate quality before placing larger orders. Additionally, consider using trade platforms that facilitate international transactions, which can offer buyer protections and dispute resolution services.

2. What is the best type of C-channel for construction projects?

The best type of C-channel for construction projects often depends on the specific structural requirements. For most applications, A36 carbon steel C-channel is highly recommended due to its excellent strength-to-weight ratio and versatility. It’s suitable for a wide range of construction uses, including framing, bracing, and support structures. When selecting a C-channel, consider factors such as load-bearing capacity, environmental conditions, and project specifications. Consulting with a structural engineer can also ensure that you choose the appropriate material and dimensions for your project.

Illustrative image related to c channle

3. How can I vet suppliers when sourcing C-channel products internationally?

Vetting suppliers is crucial to ensure the quality and reliability of your C-channel products. Start by checking their business credentials, including registration, certifications, and industry affiliations. Request references from previous clients, especially those in similar markets. It’s also beneficial to conduct an on-site visit if possible or utilize third-party inspection services to evaluate their manufacturing processes. Additionally, consider suppliers who are members of recognized trade associations, as this often indicates adherence to industry standards and practices.

4. What customization options are available for C-channel products?

Many suppliers offer customization options for C-channel products to meet specific project needs. Common customization includes varying lengths, widths, and thicknesses, as well as finishes such as galvanization for corrosion resistance. You may also request pre-drilled holes or cut-to-size options to facilitate easier installation. When discussing customization, be clear about your specifications and deadlines, as this will help suppliers provide accurate quotes and timelines. Always confirm that the customized product meets the necessary industry standards.

5. What are typical minimum order quantities (MOQs) for C-channel?

Minimum order quantities (MOQs) for C-channel products can vary significantly based on the supplier and the type of channel being ordered. Generally, MOQs may range from 500 kg to several tons for standard products. However, some suppliers may accommodate smaller orders, especially if they offer a wider range of products. It’s essential to communicate your needs upfront and inquire about MOQs during the initial discussions to find a supplier that aligns with your purchasing requirements.

6. What payment terms should I expect when ordering C-channel products?

Payment terms for C-channel orders can vary widely among suppliers. Common practices include a deposit (often 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, allowing you to pay within a specified period after receiving the goods. It’s important to negotiate payment terms that are favorable and secure for both parties. Always ensure that payment methods are secure and consider using letters of credit for larger transactions to mitigate risks.

7. How does quality assurance (QA) work for C-channel products?

Quality assurance (QA) for C-channel products typically involves several stages, from material selection to final inspection. Reputable suppliers conduct tests to verify the mechanical properties of the steel, ensuring it meets specified standards. This may include tensile strength tests, dimensional checks, and surface inspections. Before shipment, suppliers often provide certificates of compliance or test reports. It’s advisable to request these documents to ensure the products meet your quality expectations and local regulatory requirements.

8. What logistics considerations should I keep in mind when importing C-channel?

When importing C-channel products, consider logistics aspects such as shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling steel products to navigate international shipping regulations. Be aware of import duties and taxes that may apply in your country, as these can significantly affect overall costs. Additionally, ensure proper packaging to prevent damage during transit. Establish clear communication with your supplier regarding shipping schedules and tracking to ensure timely delivery.

Top 6 C Channle Manufacturers & Suppliers List

1. MetalsDepot® – A36 Steel Channel

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Steel Channel Online! A36 Structural Steel Channel is a hot rolled, mild steel structural C shape with inside radius corners. Ideal for structural applications, general fabrication, manufacturing, and repairs. Widely used in industrial maintenance, agricultural implements, transportation equipment, truck beds, trailers, etc. C-shape or U-shape configuration provides added streng…

2. McMaster – C-Channels and U-Channels

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – C-Channels and U-Channels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

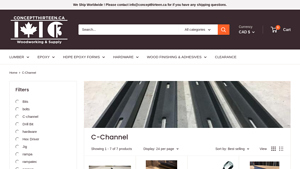

3. Concept Thirteen – C-Channel Hardware Packs

Domain: conceptthirteen.ca

Registered: 2016 (9 years)

Introduction: This company, Concept Thirteen – C-Channel Hardware Packs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Stainless Supply – Custom C-Channel 304 Stainless #4 Finish

Domain: stainlesssupply.com

Registered: 2000 (25 years)

Introduction: Custom C-Channel – 304 Stainless #4 Finish

– Material: 304 stainless steel

– Finish: #4 brushed finish

– PVC film on one side for scratch protection during fabrication and installation

– Meets criteria for #3 and #4 finish

– Length options: Up to 120″ (10 feet); over 96″ (8 feet) rated as freight shipment

– Thickness options: 24G, 22G, 20G, 18G, 16G, 14G, 12G, 11G

– Customization: Grain direction …

5. Penn Stainless – Stainless Channels

Domain: pennstainless.com

Registered: 1999 (26 years)

Introduction: Penn Stainless Products supplies stainless channels in 304/304L and 316/316L. Larger channels over 24″ can be manufactured using laser fusion technology, allowing for mixed thickness or material grades. Laser fused channels can also be supplied in Duplex 2205 and lean Duplex 2101. All channels can be cut to size and are available with a polished finish. Product variations include 304/304L, 316/316…

6. VEX Robotics – C-Channels

Domain: vexrobotics.com

Registered: 2004 (21 years)

Introduction: C-Channels (8-sizes) – VEX Robotics

– In stock

– Works with products and accessories: V5RC, VURC, VAIRC, FTC legal

– Holes on 0.500″ increments

– Excellent strength and bending resistance for building robust robots

– Multiple sizes available in two material types: cold rolled steel and 5052-H32 aluminum

– Each channel is segmented into cuttable 2.5″ pieces

Aluminum C-Channel Products:

1. 1x2x1x25…

Strategic Sourcing Conclusion and Outlook for c channle

In the evolving landscape of global trade, strategic sourcing of C channel products has become essential for businesses aiming to enhance their supply chain efficiency. By fostering relationships with reliable suppliers, companies can secure high-quality materials, reduce costs, and ensure timely deliveries. The emphasis on local sourcing in regions such as Africa, South America, the Middle East, and Europe can further create competitive advantages by reducing lead times and supporting regional economies.

As international B2B buyers navigate the complexities of sourcing C channels, it is crucial to remain informed about market trends, material specifications, and supplier capabilities. Engaging in thorough research and leveraging technology can facilitate better decision-making and sourcing strategies.

Looking ahead, businesses should prioritize building resilient supply chains that can adapt to market fluctuations and evolving customer needs. By investing in strategic sourcing now, companies not only position themselves for immediate success but also lay the groundwork for sustainable growth in the future. We encourage buyers from diverse regions to take proactive steps towards optimizing their sourcing strategies, ensuring they remain competitive in an increasingly interconnected market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.