Choosing Your Brick Anchors: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for brick anchors

In the evolving landscape of global construction and manufacturing, sourcing high-quality brick anchors presents a significant challenge for B2B buyers. Whether your projects span the bustling cities of Brazil or the architectural marvels of Saudi Arabia, understanding the diverse types and applications of brick anchors is crucial for ensuring structural integrity and safety. This comprehensive guide delves into the various categories of brick anchors, including their specific uses in masonry and concrete settings, helping you make informed decisions tailored to your local market needs.

Our exploration extends beyond just product specifications; we will also cover critical aspects such as supplier vetting, cost analysis, and logistical considerations. With insights into the best practices for selecting reliable manufacturers and understanding pricing trends across different regions, this guide empowers international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to navigate the complexities of the brick anchor market. By leveraging this information, you can confidently procure the right products that meet regulatory standards and project requirements, ensuring your investments yield optimal results.

As you embark on your sourcing journey, let this guide be your trusted resource in making strategic purchasing decisions that support your business objectives.

Understanding brick anchors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Expansion Anchors | Expand within the brick upon installation, providing a secure hold. | Heavy-duty shelving, machinery mounting. | Pros: High load capacity, reliable hold. Cons: Requires precise installation. |

| Sleeve Anchors | Feature a sleeve that expands against the brick when tightened. | Securing fixtures, wall-mounted items. | Pros: Versatile, suitable for various materials. Cons: May not suit all brick types. |

| Wedge Anchors | Use a wedge mechanism for strong anchorage in solid substrates. | Structural applications, outdoor fixtures. | Pros: Excellent for heavy loads. Cons: Limited to solid brick or concrete. |

| Tapcon Screws | Self-tapping screws designed specifically for masonry. | Fastening brackets, light fixtures. | Pros: Easy installation, no pre-drilling needed. Cons: Limited to lighter applications. |

| Nylon Plug Anchors | Use a nylon plug that expands when a screw is inserted. | Light-duty applications, decorative items. | Pros: Cost-effective, easy to use. Cons: Not suitable for heavy loads. |

What Are Expansion Anchors and Their Applications in B2B?

Expansion anchors are designed to expand within the brick upon installation, offering a secure hold for heavy-duty applications such as shelving and machinery mounting. Their ability to support significant weight makes them ideal for industrial settings where safety and reliability are paramount. When purchasing, consider the load capacity and the specific brick type, as improper installation can compromise effectiveness.

How Do Sleeve Anchors Function and Where Are They Used?

Sleeve anchors feature a sleeve that expands against the brick when tightened, making them suitable for securing fixtures or wall-mounted items. Their versatility allows them to be used in various materials, including concrete and masonry. Buyers should evaluate the specific requirements of their projects, such as load and environmental conditions, before selecting sleeve anchors to ensure optimal performance.

What Are Wedge Anchors and Their Key Advantages?

Wedge anchors utilize a wedge mechanism to provide strong anchorage in solid substrates, making them ideal for structural applications and outdoor fixtures. Their design allows for excellent load-bearing capabilities, which is crucial in construction and heavy industrial contexts. However, buyers must ensure they are used with solid brick or concrete, as they may not perform well in softer materials.

Why Choose Tapcon Screws for Masonry Applications?

Tapcon screws are self-tapping screws specifically designed for masonry, making them a popular choice for fastening brackets and light fixtures. Their ease of installation—requiring no pre-drilling—saves time and labor costs, making them attractive for contractors. However, their application is limited to lighter loads, so buyers should assess the weight requirements of their projects before selection.

What Are the Benefits of Using Nylon Plug Anchors?

Nylon plug anchors are designed to expand when a screw is inserted, making them suitable for light-duty applications like decorative items. Their cost-effectiveness and ease of use make them appealing for smaller projects or temporary installations. However, these anchors are not suitable for heavy loads, so businesses should carefully consider the expected weight of the items being secured to avoid failures.

Key Industrial Applications of brick anchors

| Industry/Sector | Specific Application of Brick Anchors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Securing structural elements in masonry buildings | Ensures stability and safety of structures, reducing liability risks | Compliance with local building codes and standards |

| Infrastructure | Mounting signage and barriers on brick surfaces | Enhances visibility and safety, improving user experience | Weather resistance and load capacity of anchors |

| Residential Renovation | Installing shelves and cabinetry in brick walls | Maximizes space efficiency while maintaining aesthetic appeal | Compatibility with various shelf designs and weights |

| Commercial Facilities | Fixing HVAC systems to exterior brick walls | Optimizes energy efficiency and operational reliability | Thermal resistance and corrosion protection of materials |

| Outdoor Landscaping | Securing garden structures, such as trellises | Enhances landscape aesthetics and functionality | Durability against weather conditions and soil types |

How Are Brick Anchors Used in Construction Projects?

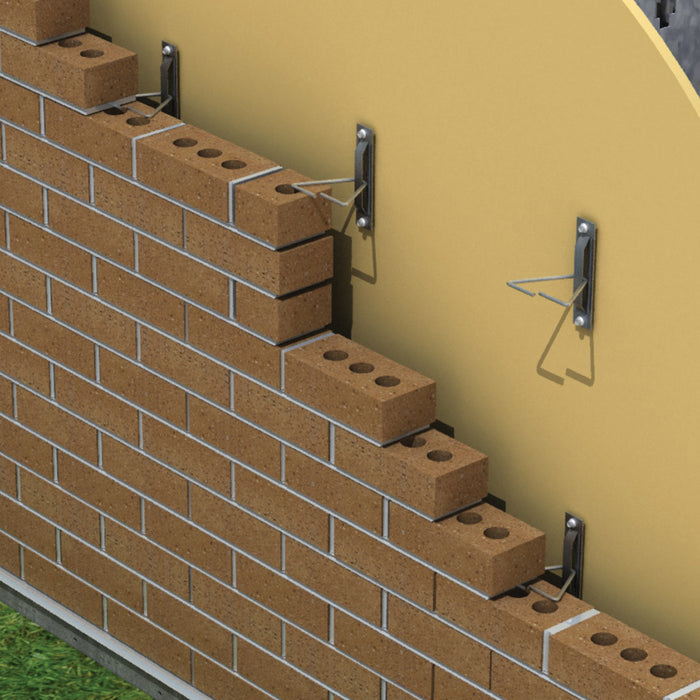

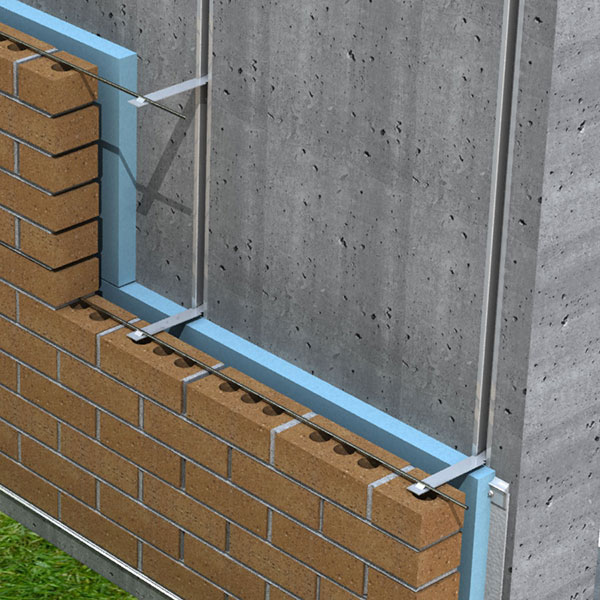

In the construction industry, brick anchors are essential for securing structural elements like beams, walls, and facades to masonry buildings. They provide the necessary support to ensure the integrity and safety of structures, thereby minimizing liability risks for builders and contractors. Buyers in this sector must prioritize compliance with local building codes and standards, ensuring that the selected anchors meet the specific load-bearing requirements of their projects.

Illustrative image related to brick anchors

What Role Do Brick Anchors Play in Infrastructure Development?

Infrastructure projects often require the installation of signage and barriers on brick surfaces. Brick anchors are used to mount these elements securely, enhancing visibility and safety for pedestrians and vehicles. For international buyers, especially in regions with varying weather conditions, it is crucial to consider the weather resistance and load capacity of the anchors, ensuring they withstand environmental stresses while maintaining structural integrity.

How Can Brick Anchors Optimize Residential Renovation Projects?

In residential renovations, brick anchors are utilized for installing shelves, cabinetry, and other fixtures on brick walls. This application maximizes space efficiency and enhances aesthetic appeal without compromising safety. Buyers should focus on the compatibility of the anchors with various shelf designs and weight capacities, ensuring that their installations are both functional and visually pleasing.

Why Are Brick Anchors Important for Commercial Facilities?

For commercial facilities, brick anchors are vital for securing HVAC systems to exterior brick walls. This application not only optimizes energy efficiency but also ensures the operational reliability of heating and cooling systems. Buyers should consider the thermal resistance and corrosion protection of the anchors, as these factors significantly impact the longevity and performance of the installations in various climates.

How Do Brick Anchors Enhance Outdoor Landscaping Projects?

In outdoor landscaping, brick anchors are used to secure garden structures such as trellises, providing stability and enhancing the overall aesthetic of the landscape. This application contributes to the functionality of outdoor spaces, allowing for creative designs that integrate greenery and architectural elements. When sourcing brick anchors for landscaping, durability against weather conditions and compatibility with different soil types are critical considerations for international buyers.

3 Common User Pain Points for ‘brick anchors’ & Their Solutions

Scenario 1: Ensuring Structural Integrity in Heavy Loads

The Problem: B2B buyers in construction often face the challenge of ensuring that the brick anchors they select can support heavy loads, particularly in commercial applications like shelving, machinery installations, or even architectural features. The risk of failure can lead to costly damages, safety hazards, and project delays. Buyers frequently struggle with identifying the correct anchor size and type based on the specific load requirements and the characteristics of the brick being used.

The Solution: To effectively address this issue, B2B buyers should conduct a thorough assessment of both the load requirements and the properties of the brick substrate. Begin by calculating the total weight the anchor will need to support, including any dynamic loads that may occur during usage. Utilize manufacturer specifications and load capacity tables to identify the appropriate anchor size and type, such as wedge anchors or sleeve anchors, designed for brick applications. Furthermore, consulting with engineering professionals or suppliers who specialize in masonry can provide additional insights tailored to specific projects. Implementing a detailed installation guide, including proper drilling techniques and the use of appropriate tools, will ensure that the anchors are set correctly, maximizing their load-bearing capacity and minimizing the risk of failure.

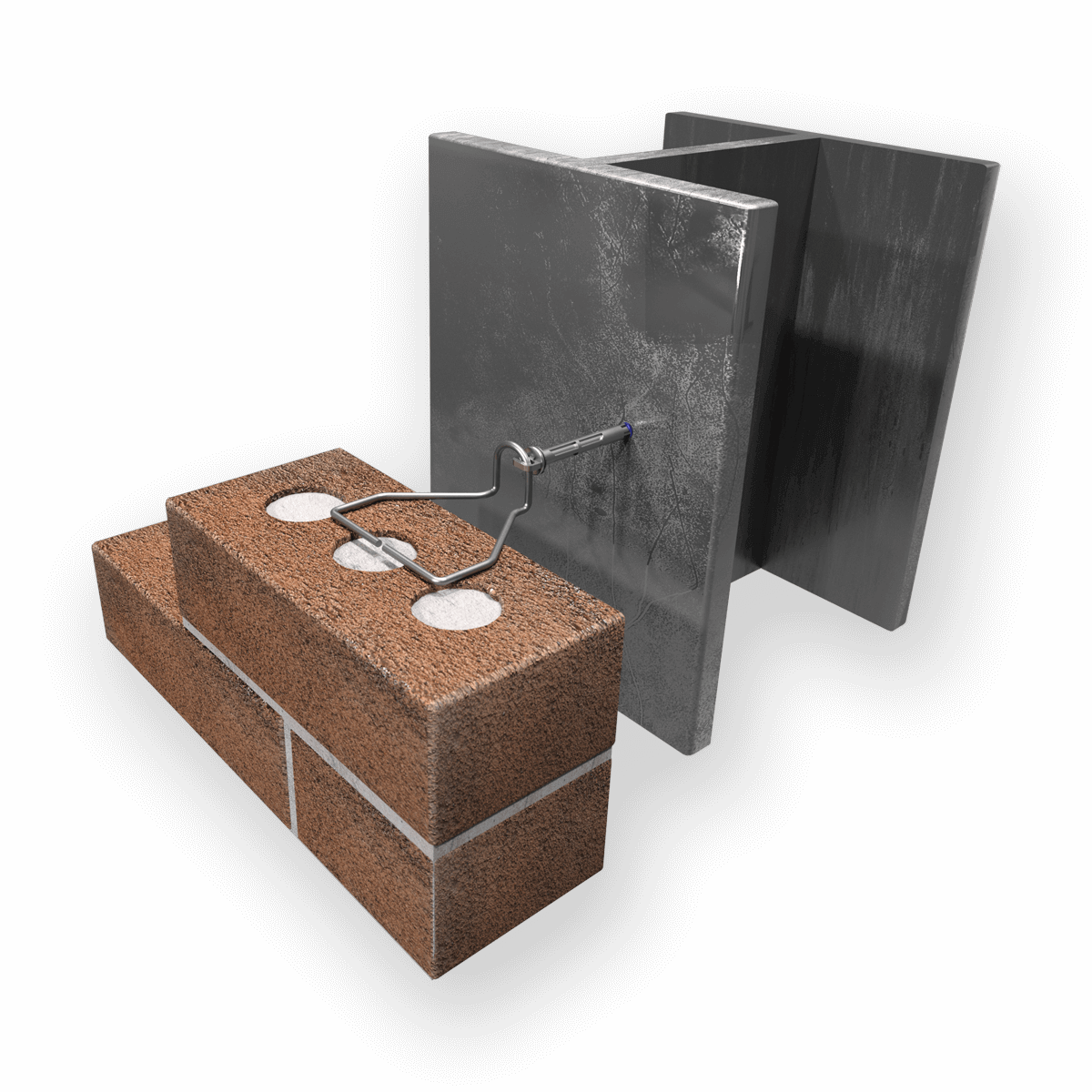

Scenario 2: Navigating Compatibility Issues with Different Brick Types

The Problem: Buyers often encounter compatibility issues when trying to use standard brick anchors on various types of bricks, such as soft brick, hard brick, or even reclaimed materials. Different brick types have unique densities and structures, which can significantly impact the effectiveness of the anchors. This lack of compatibility can result in inadequate anchoring, causing fixtures to loosen over time or fail entirely.

The Solution: To mitigate these compatibility challenges, it is crucial for B2B buyers to understand the specific characteristics of the brick type they are working with. Conduct a material analysis to determine the density and compressive strength of the brick. Based on this information, choose anchors specifically designed for that brick type. For instance, use expansion anchors for softer bricks that require a more aggressive grip, while opting for high-strength concrete screws for harder materials. Additionally, suppliers often provide technical data sheets that detail the compatibility of their anchors with various masonry types. Implementing a trial installation phase on a small scale can also help identify any potential issues before full-scale deployment.

Scenario 3: Overcoming Moisture and Environmental Challenges

The Problem: In regions with high humidity or frequent rain, B2B buyers must consider the impact of moisture on the longevity and performance of brick anchors. Corrosion can weaken anchors over time, leading to structural failures. This issue is particularly prevalent in coastal areas or regions with extreme weather conditions, where salt and other environmental factors accelerate deterioration.

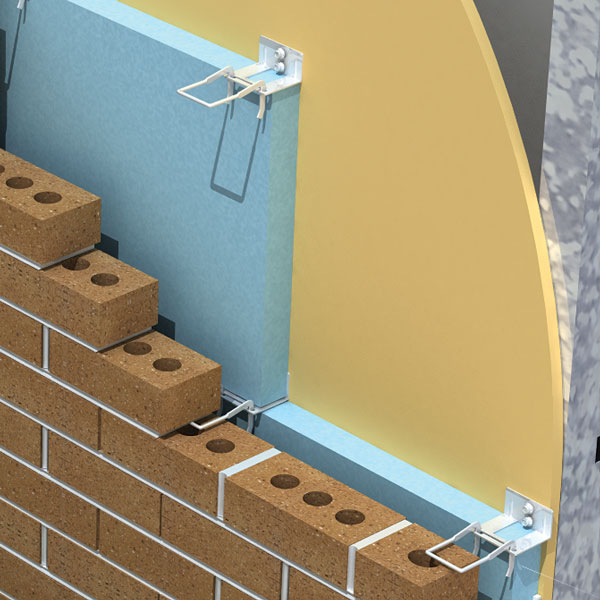

Illustrative image related to brick anchors

The Solution: To combat moisture-related challenges, buyers should prioritize selecting corrosion-resistant materials for their brick anchors. Stainless steel and galvanized options are excellent choices for environments prone to moisture. Additionally, applying a waterproof sealant around the anchor during installation can further protect against water infiltration. It’s also advisable to design the installation in a way that minimizes water accumulation around the anchor points, such as ensuring proper drainage or using angled installations. Regular maintenance checks should be scheduled to assess the condition of the anchors and the surrounding brickwork, allowing for timely replacements if signs of corrosion are detected. By taking these proactive steps, buyers can significantly enhance the durability and reliability of their anchoring solutions.

Strategic Material Selection Guide for brick anchors

What Are the Key Materials Used for Brick Anchors?

When selecting brick anchors, understanding the materials used is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials—steel, stainless steel, nylon, and aluminum—focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform as a Material for Brick Anchors?

Steel is a widely used material for brick anchors due to its high tensile strength and durability. It typically has a temperature rating that can withstand significant heat, making it suitable for various applications. However, steel is prone to corrosion, especially in humid or coastal environments, which can compromise its integrity over time.

Pros: Steel anchors are cost-effective and offer excellent load-bearing capabilities. They are relatively easy to manufacture and can be produced in various shapes and sizes.

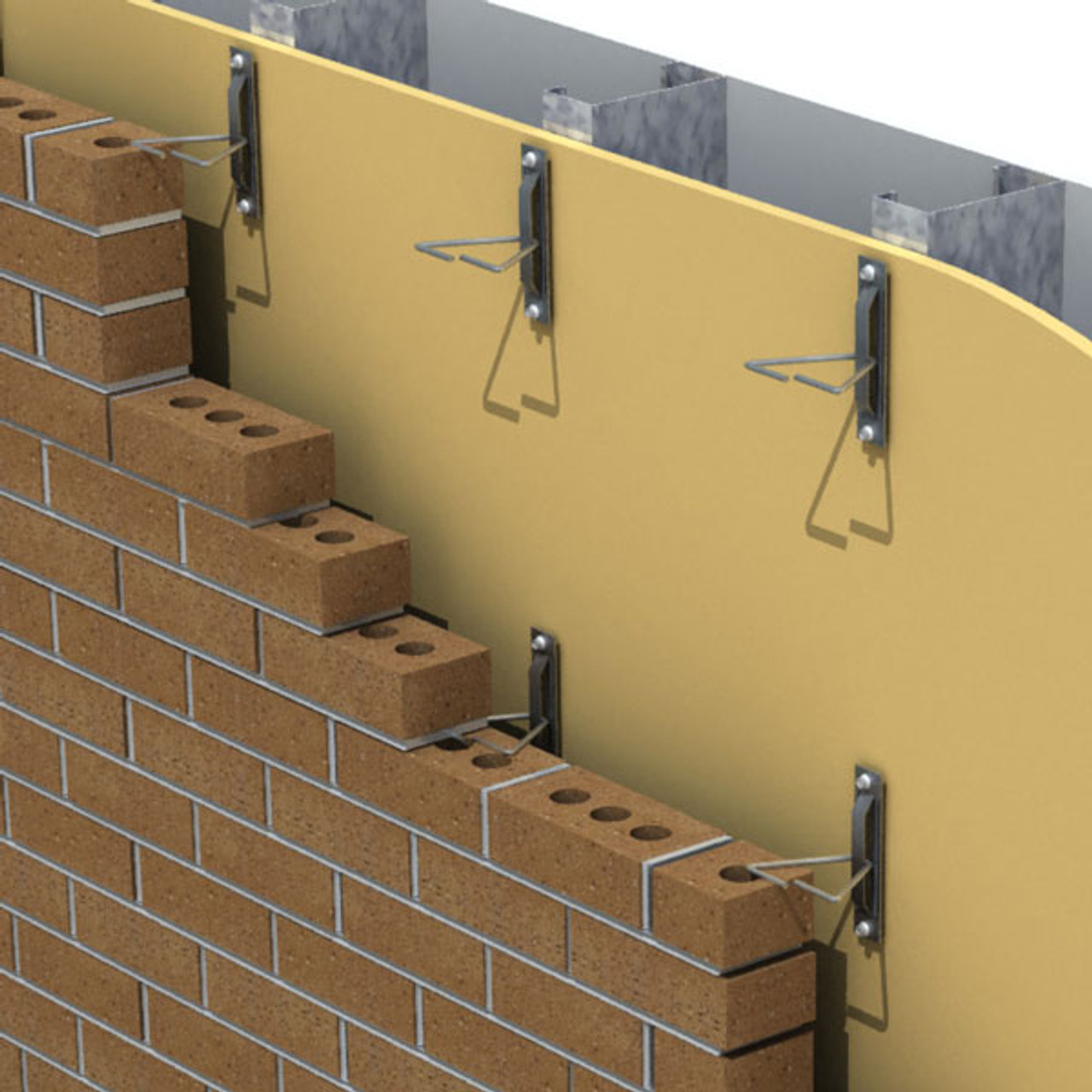

Illustrative image related to brick anchors

Cons: The primary limitation of steel is its susceptibility to rust and corrosion, necessitating protective coatings or treatments for outdoor applications.

Impact on Application: Steel anchors are ideal for heavy-duty applications, such as securing structural components in buildings. However, in regions with high humidity or saline environments, their longevity may be compromised.

Considerations for International Buyers: Compliance with standards like ASTM A307 for carbon steel is essential. Buyers in regions like Brazil and Saudi Arabia should prioritize corrosion-resistant coatings to enhance durability.

What Advantages Does Stainless Steel Offer for Brick Anchors?

Stainless steel is another popular choice for brick anchors, known for its superior corrosion resistance and aesthetic appeal. It can withstand high temperatures and is less likely to rust compared to traditional steel.

Illustrative image related to brick anchors

Pros: The primary advantage of stainless steel anchors is their longevity and low maintenance requirements, making them ideal for outdoor and marine applications.

Cons: The main drawback is the higher cost compared to regular steel, which can impact budget-sensitive projects.

Impact on Application: Stainless steel anchors are suitable for environments where corrosion is a significant concern, such as coastal areas or industrial settings with exposure to chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM A276 is crucial. Buyers should also consider the availability of stainless steel grades like 304 or 316, which may vary by region.

How Does Nylon Compare as a Material for Brick Anchors?

Nylon anchors are often used for lighter applications, particularly in interior settings. They are resistant to corrosion and can perform well in various environmental conditions.

Pros: Nylon anchors are lightweight, easy to install, and resistant to moisture, making them suitable for non-load-bearing applications.

Cons: They have lower load-bearing capacity compared to metal anchors and are not ideal for heavy-duty applications.

Impact on Application: Nylon anchors are best suited for securing lightweight fixtures or panels in dry environments. They may not be appropriate for structural applications.

Considerations for International Buyers: Compliance with standards such as ISO 527 for plastic materials is important. Buyers should ensure that the nylon used is UV-stabilized for outdoor applications.

What Role Does Aluminum Play in Brick Anchor Applications?

Aluminum anchors are lightweight and resistant to corrosion, making them suitable for various applications, especially where weight is a concern.

Pros: The lightweight nature of aluminum allows for easy handling and installation. It also has good corrosion resistance, making it suitable for outdoor use.

Cons: Aluminum has a lower tensile strength compared to steel, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum anchors are ideal for securing lightweight structures or fixtures, particularly in environments where rust is a concern.

Illustrative image related to brick anchors

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum is essential. Buyers should evaluate the specific alloy used, as this can affect performance in different environments.

Summary of Material Selection for Brick Anchors

| Material | Typical Use Case for brick anchors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty structural applications | High load-bearing capacity | Susceptible to corrosion | Low |

| Stainless Steel | Outdoor and marine applications | Superior corrosion resistance | Higher cost | High |

| Nylon | Lightweight fixtures in dry environments | Lightweight and easy to install | Low load-bearing capacity | Medium |

| Aluminum | Lightweight structures and fixtures | Corrosion-resistant and lightweight | Lower tensile strength | Medium |

This guide provides an overview of the strategic material selection for brick anchors, enabling international B2B buyers to make informed decisions based on performance, application suitability, and regional compliance requirements.

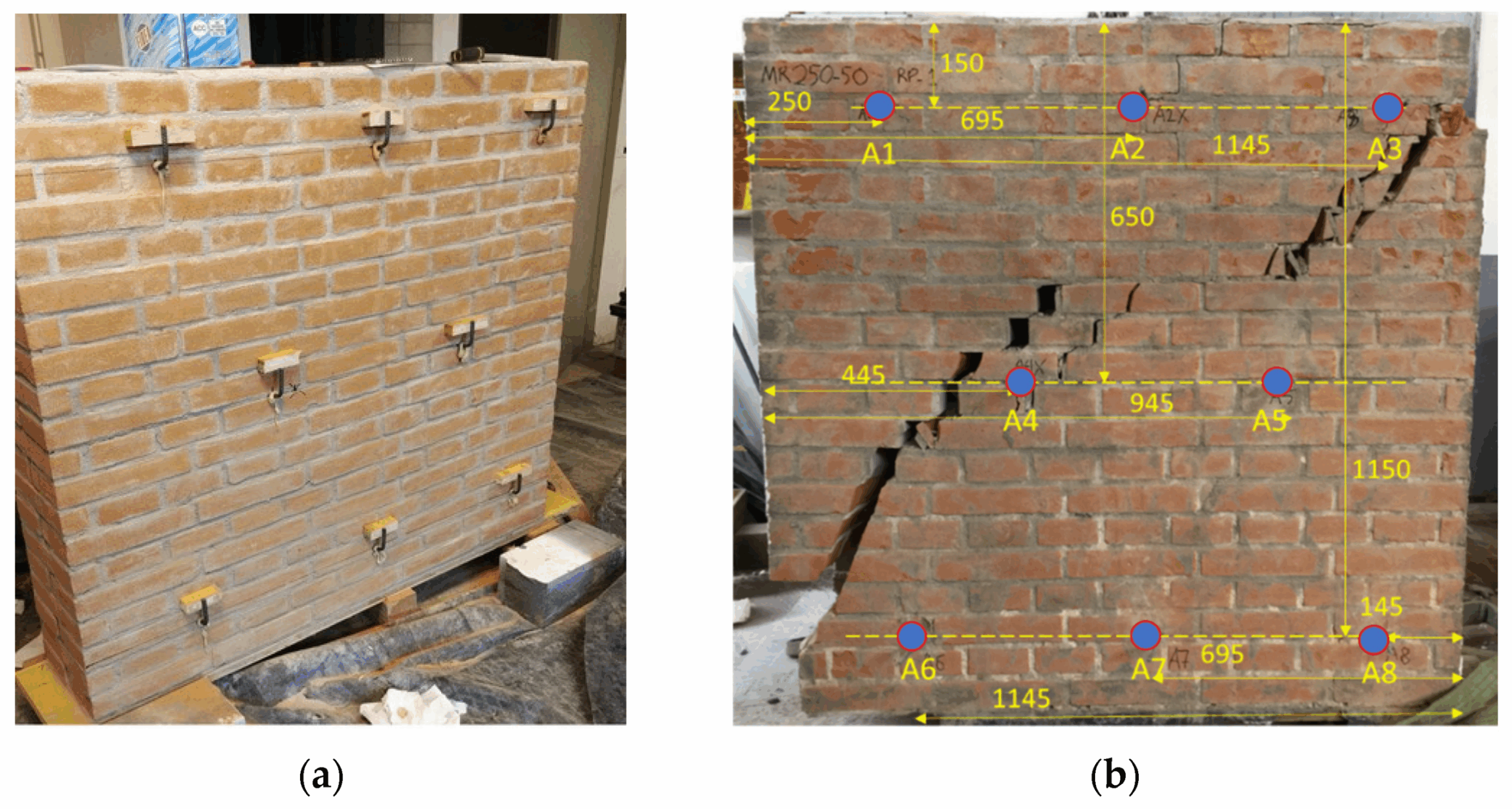

In-depth Look: Manufacturing Processes and Quality Assurance for brick anchors

What Are the Main Stages of Manufacturing Brick Anchors?

The manufacturing process for brick anchors involves several critical stages that ensure the final product meets both performance and safety standards.

Material Preparation

The first step in manufacturing brick anchors is material selection and preparation. Common materials used include carbon steel, stainless steel, and, in some cases, nylon or aluminum. These materials are chosen based on their mechanical properties, such as tensile strength and corrosion resistance. The raw materials are often sourced from certified suppliers to ensure quality. Before proceeding, manufacturers conduct tests to verify the material composition and properties, ensuring they meet required specifications.

Forming Techniques

Once the materials are prepared, they undergo forming processes. This typically involves techniques such as stamping, forging, or machining, depending on the design and specifications of the brick anchor.

- Stamping: This technique is often used for creating flat components or washers that are part of the anchor assembly.

- Forging: This method is frequently employed for high-strength anchors, where the material is shaped under high pressure to improve its structural integrity.

- Machining: Precision machining may be used to create threaded portions or other intricate designs.

These processes are essential for achieving the precise dimensions and structural characteristics required for effective anchoring in brick materials.

Assembly of Components

After forming, the next step involves assembling various components of the brick anchor. This may include integrating the anchor body with nuts, washers, or other fittings. Manufacturers often employ automated assembly lines to enhance efficiency and consistency.

Quality control during assembly is vital; any misalignment or improper fitting can compromise the anchor’s performance. Each assembly line is monitored closely to ensure that components fit together as intended.

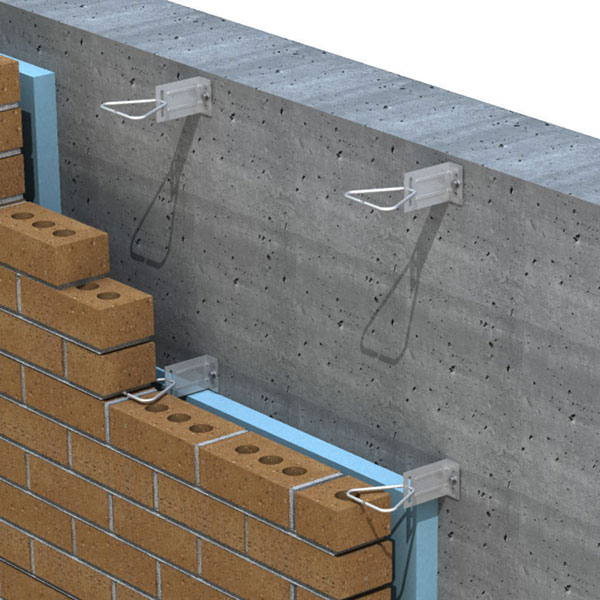

Illustrative image related to brick anchors

Finishing Processes

The final stage involves finishing processes that may include surface treatments such as galvanization, powder coating, or passivation. These treatments are crucial for enhancing the anchor’s resistance to corrosion and environmental degradation, particularly for applications in harsh climates.

Finishing not only improves durability but also can affect aesthetic qualities, which may be relevant for certain applications. Manufacturers must ensure that the finish meets both functional and aesthetic standards.

How Is Quality Assurance Implemented in Brick Anchor Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, particularly in sectors where safety and reliability are paramount.

What International Standards Are Applicable?

To ensure quality, manufacturers often adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard demonstrates a commitment to continuous improvement and customer satisfaction.

Additionally, region-specific certifications, like CE marking in Europe or API standards for specific applications, may be relevant. These certifications verify that the products meet specific safety and performance criteria, which is critical for B2B buyers in international markets.

What Are the Key Quality Control Checkpoints?

Quality control in brick anchor manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before they enter the production process. Suppliers must provide certificates of compliance to validate material quality.

-

In-Process Quality Control (IPQC): During production, various tests and inspections are performed to ensure that the manufacturing processes are being followed correctly. This may include dimensional checks and verification of forming techniques.

-

Final Quality Control (FQC): After manufacturing, the finished products undergo rigorous testing to confirm that they meet design specifications and performance standards. Common tests include tensile strength testing, pull-out tests, and corrosion resistance tests.

What Common Testing Methods Are Used for Brick Anchors?

Testing methods for brick anchors can vary based on the intended application, but some common techniques include:

-

Tensile Testing: This method measures the anchor’s strength by applying a force until the anchor fails. It helps determine if the anchor can withstand the required load.

-

Shear Testing: This test evaluates how much force the anchor can resist before it shears off, which is crucial for applications where lateral forces may be applied.

-

Pull-Out Testing: This is often conducted in a laboratory setting to simulate the conditions under which the anchor will be used. It helps ensure that the anchor will not pull out under load.

-

Corrosion Testing: For anchors intended for outdoor use, manufacturers may conduct salt spray tests to assess the corrosion resistance of the anchor’s finish.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in diverse international markets, verifying a supplier’s quality control processes is essential. Here are some actionable strategies:

Audits and Inspections

Conducting audits of the supplier’s manufacturing facility can provide insight into their quality management practices. Buyers should look for:

- ISO Certification: Verify that the supplier holds valid ISO certifications, which indicate adherence to international quality standards.

- Internal Audit Reports: Request access to recent audit reports to understand how the supplier addresses quality issues.

Quality Control Reports

Suppliers should provide detailed QC reports that outline testing results for products. These documents should include:

- Test Methods: A clear description of the testing methods used.

- Results: Summary of results, including any failures and corrective actions taken.

- Traceability: Information on batch numbers or production lots for tracking purposes.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s products. This is particularly important for buyers in regions where local regulations may differ from international standards.

Illustrative image related to brick anchors

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate a complex landscape of quality control and certification requirements, particularly when dealing with suppliers from different regions.

Regional Regulations

Understanding regional regulations is crucial. For instance, buyers in Europe must ensure that products comply with CE marking requirements, while those in the Middle East may need to consider local certification standards.

Language and Documentation

Language barriers can complicate the verification process. It is advisable for buyers to request documentation in their preferred language and ensure that all specifications and certifications are clearly defined.

Cultural Considerations

Cultural differences may impact communication styles and business practices. Establishing strong relationships with suppliers can facilitate smoother negotiations and enhance trust regarding quality commitments.

Conclusion

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for brick anchors is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing processes, along with robust quality control measures, buyers can ensure they select reliable suppliers. Verifying supplier quality through audits, QC reports, and third-party inspections will further safeguard against potential risks, making for a successful procurement process in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brick anchors’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure brick anchors, ensuring that you make informed decisions tailored to your specific needs. Brick anchors are essential for securing fixtures in masonry and brick structures, and selecting the right type can significantly impact the integrity of your projects. Follow these steps to streamline your sourcing process and enhance your procurement strategy.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the brick anchors meet your project requirements. Consider factors such as anchor diameter, length, and load capacity based on the materials you’ll be working with. This will help you narrow down your options and communicate effectively with suppliers.

- Load Capacity: Determine the maximum weight the anchors need to support.

- Material Compatibility: Ensure the anchors are suitable for the type of brick or masonry you are using.

Step 2: Research Available Types of Brick Anchors

Understanding the different types of brick anchors available will enable you to select the most suitable option for your application. Common types include wedge anchors, sleeve anchors, and concrete screws, each designed for specific purposes and environments.

- Wedge Anchors: Ideal for heavier loads and outdoor applications.

- Sleeve Anchors: Versatile for both solid and hollow materials.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is essential to conduct thorough evaluations. Request detailed company profiles, product samples, and references from previous clients to assess their reliability and quality.

- Case Studies: Look for examples of similar projects they have completed.

- Industry Experience: Ensure the supplier has a proven track record in your specific industry.

Step 4: Verify Compliance and Certifications

Ensure that the brick anchors you plan to purchase comply with relevant industry standards and certifications. This is crucial for maintaining safety and quality in your projects, especially in international markets where regulations may vary.

- ISO Certification: Check if the supplier has ISO or similar certifications.

- Local Regulations: Understand any specific compliance requirements in your region.

Step 5: Request Samples for Testing

Before making a large order, it is prudent to request samples of the brick anchors for testing. This allows you to evaluate their performance and suitability for your specific applications, reducing the risk of costly mistakes.

- Performance Testing: Assess how the anchors perform under load and environmental conditions.

- Installation Trials: Test the ease of installation to ensure efficiency.

Step 6: Negotiate Terms and Conditions

Engage in discussions to negotiate pricing, payment terms, and delivery timelines. Establishing favorable terms can improve your cash flow and ensure timely project execution.

- Bulk Discounts: Inquire about pricing breaks for larger orders.

- Delivery Options: Discuss logistics to ensure timely delivery, especially for international shipments.

Step 7: Establish a Long-term Relationship

Finally, consider building a long-term relationship with your selected supplier. This can lead to better pricing, priority service, and insights into new products that could benefit your future projects.

- Feedback Loop: Provide regular feedback to help the supplier improve their services.

- Collaborative Opportunities: Explore joint ventures or promotional opportunities that could enhance both businesses.

By following these steps, you can ensure a strategic approach to sourcing brick anchors that aligns with your project goals and enhances your operational efficiency.

Comprehensive Cost and Pricing Analysis for brick anchors Sourcing

What Are the Key Cost Components for Sourcing Brick Anchors?

When sourcing brick anchors, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of materials used significantly influences the cost of brick anchors. Common materials include stainless steel, carbon steel, and nylon. Stainless steel anchors generally command higher prices due to their durability and corrosion resistance, making them suitable for exterior applications.

-

Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. Regions with higher wage standards may see increased costs, while manufacturers in countries with lower labor costs can offer competitive pricing.

-

Manufacturing Overhead: This includes costs associated with the production process such as utilities, factory rent, and equipment maintenance. Efficient operations can reduce these overheads, which can positively affect pricing.

-

Tooling: Specific tooling is required for the production of various anchor types. Custom tooling can lead to higher initial costs, but if utilized for larger production runs, it can reduce the per-unit cost.

-

Quality Control: Rigorous quality control measures ensure the reliability of brick anchors, particularly for structural applications. The costs associated with QC can vary, influencing the overall price of the anchors.

-

Logistics: Shipping costs can significantly affect the final price, especially for international buyers. Factors like distance, shipping method, and volume impact logistics costs. Bulk purchasing can often mitigate some of these expenses.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary widely based on market demand, competition, and perceived value.

What Influences the Pricing of Brick Anchors?

Several factors can influence the pricing of brick anchors, making it essential for buyers to be aware of these variables:

-

Volume/MOQ: Many manufacturers offer tiered pricing based on order volume. Higher minimum order quantities (MOQs) often result in lower unit prices. This encourages bulk purchasing, which can significantly reduce costs.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized manufacturing processes or materials. Buyers should evaluate whether customization is necessary for their applications.

-

Material Quality and Certifications: Higher quality materials or those that meet specific certifications (e.g., ISO, ASTM) can increase costs. Buyers should weigh the importance of these certifications against their project requirements.

-

Supplier Factors: Supplier reliability, reputation, and geographic location can all influence pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial for international transactions. They define the responsibilities of buyers and sellers in shipping and logistics, which can impact overall costs.

What Buyer Tips Can Improve Cost-Efficiency in Sourcing Brick Anchors?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Illustrative image related to brick anchors

-

Negotiation: Engage in negotiations with suppliers to secure better pricing or payment terms. Building a long-term relationship can lead to favorable conditions.

-

Total Cost of Ownership: Consider the total cost of ownership (TCO) rather than just the purchase price. This includes installation, maintenance, and potential replacement costs, which can significantly affect the overall expenditure.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect costs when purchasing from international suppliers. Always request a detailed quote that includes these factors.

-

Supplier Audits: Conduct due diligence on suppliers to ensure they meet quality standards and can deliver on time. This can prevent costly delays and replacements.

-

Market Research: Stay informed about market trends and pricing fluctuations in the brick anchors sector. This knowledge can empower buyers to make informed purchasing decisions and time their orders for maximum savings.

Conclusion

Sourcing brick anchors involves navigating a complex landscape of costs and pricing influences. By understanding the cost components, factors affecting pricing, and employing strategic purchasing practices, international B2B buyers can optimize their sourcing processes and achieve better financial outcomes.

Alternatives Analysis: Comparing brick anchors With Other Solutions

Exploring Alternatives to Brick Anchors for B2B Applications

When selecting fastening solutions for construction and masonry projects, understanding the available alternatives to brick anchors is crucial for making informed decisions. Various fastening methods offer distinct advantages and drawbacks depending on the specific requirements of the project. This analysis will compare brick anchors with two viable alternatives: concrete screws and expansion anchors, allowing B2B buyers to evaluate their options effectively.

| Comparison Aspect | Brick Anchors | Concrete Screws | Expansion Anchors |

|---|---|---|---|

| Performance | High holding capacity in brick | Excellent for concrete applications | Good load-bearing capabilities |

| Cost | Moderate cost (typically $0.30-$2) | Generally low cost (around $0.10-$1) | Varies (usually $0.50-$3) |

| Ease of Implementation | Requires pre-drilling; moderate skill | Easy to install; self-tapping design | Requires more extensive installation |

| Maintenance | Low maintenance; durable | Low maintenance; corrosion-resistant | Moderate maintenance; check for loosening |

| Best Use Case | Ideal for wall-mounted fixtures | Suitable for heavy-duty applications | Effective for structural connections |

What Are the Advantages and Disadvantages of Concrete Screws?

Concrete screws, often made of hardened steel, are specifically designed for direct installation into concrete surfaces. Their self-tapping feature allows for quick and easy installation without the need for pre-drilling, making them an attractive option for many contractors. They generally offer a lower cost compared to brick anchors, making them a budget-friendly choice. However, concrete screws may not perform as well in softer materials like brick, limiting their versatility in mixed-material projects.

Illustrative image related to brick anchors

How Do Expansion Anchors Compare in Performance?

Expansion anchors consist of a bolt and a sleeve that expands when the bolt is tightened, creating a strong hold in masonry and concrete. They are highly effective for structural applications and can accommodate various weight loads, making them suitable for heavy fixtures. While they provide excellent holding power, installation can be more complex and time-consuming, often requiring specific tools and techniques. Additionally, expansion anchors can be more costly, especially in high-strength applications, and may require periodic inspections to ensure they remain secure.

Which Solution Should B2B Buyers Choose for Their Projects?

When choosing between brick anchors and their alternatives, B2B buyers should consider the specific requirements of their projects, including the material type, load capacity, and installation environment. Brick anchors are often the preferred choice for brick surfaces, offering reliable performance and durability. In contrast, concrete screws may serve better in concrete applications where ease of use and cost efficiency are prioritized. Expansion anchors are ideal for heavy-duty applications but come with a more complex installation process.

Ultimately, the decision should align with the project’s unique needs and the installation team’s expertise. Evaluating these factors will help ensure the selected fastening solution provides the best performance, longevity, and value for the investment.

Essential Technical Properties and Trade Terminology for brick anchors

What Are the Key Technical Properties of Brick Anchors?

When selecting brick anchors, understanding their technical properties is crucial for ensuring optimal performance and safety in construction projects. Here are some essential specifications to consider:

-

Material Composition

Brick anchors are typically made from various materials including stainless steel, carbon steel, and nylon. Stainless steel is preferred for outdoor applications due to its corrosion resistance, while carbon steel is often used for internal structures where exposure to moisture is limited. The choice of material affects durability and load-bearing capacity, making it vital for B2B buyers to align material selection with their project requirements. -

Anchor Diameter

The diameter of the anchor influences its load capacity and the type of installation tools required. Common sizes include 3/16″, 1/4″, and 3/8″. A larger diameter generally supports greater weight but may require more extensive drilling and installation processes. Understanding anchor diameter helps buyers select the appropriate product for their specific applications, ensuring structural integrity. -

Maximum Weight Capacity

Each brick anchor has a specified maximum weight capacity, which is critical for ensuring safety in construction. This specification is influenced by factors such as the anchor type, material, and installation method. Buyers must assess the load requirements of their projects to select anchors that can safely accommodate the intended weight, thereby preventing structural failures. -

Fastener Length

The length of the anchor determines how deep it can be embedded in the substrate, impacting its holding strength. Common lengths range from 1 inch to 6 inches or more. Selecting the right length is essential for achieving optimal grip and stability, particularly in applications involving heavy loads or dynamic forces. -

Tolerance and Thread Pitch

Tolerance refers to the permissible limit of variation in the anchor dimensions, while thread pitch indicates the distance between threads. These specifications are critical for ensuring compatibility with corresponding fasteners and for maintaining the structural integrity of the installation. Buyers should consider these factors to avoid potential installation issues.

What Are Common Trade Terms Related to Brick Anchors?

Familiarity with industry jargon can greatly enhance communication and negotiation in B2B transactions. Here are some common terms used in the brick anchor market:

Illustrative image related to brick anchors

-

OEM (Original Equipment Manufacturer)

An OEM produces parts and equipment that may be marketed by another manufacturer. In the context of brick anchors, partnering with an OEM can ensure high-quality components tailored to specific project requirements, providing buyers with reliable performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to plan their inventory and budget effectively. Larger orders may lead to discounts, making it advantageous to negotiate based on projected usage. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It allows buyers to compare offers and negotiate better deals. For brick anchors, submitting an RFQ can help businesses secure competitive pricing and favorable terms from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. For international buyers of brick anchors, understanding Incoterms is crucial for managing logistical costs and ensuring timely delivery. -

Load Testing

This term refers to the process of applying a load to an anchor to verify its performance and safety. Load testing is critical in construction projects to ensure that anchors can withstand expected forces, thereby minimizing the risk of failure in structural applications.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance the safety and efficacy of their construction projects involving brick anchors.

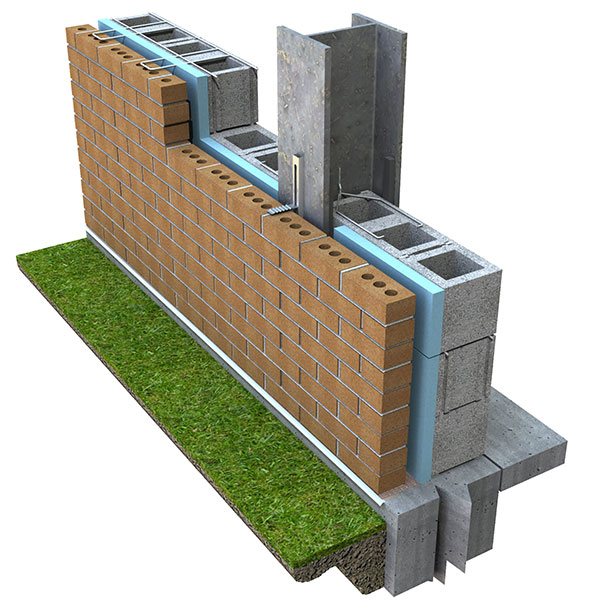

Navigating Market Dynamics and Sourcing Trends in the brick anchors Sector

What Are the Current Market Dynamics and Key Trends Impacting Brick Anchors?

The brick anchors market is experiencing significant growth driven by increased construction activities, infrastructure development, and the rising demand for robust fastening solutions in various sectors. Global urbanization trends, particularly in Africa, South America, the Middle East, and Europe, are leading to a surge in residential and commercial construction projects. This demand is further fueled by advancements in building technologies that require reliable anchoring systems for safety and durability.

Emerging B2B technology trends, such as the adoption of e-commerce platforms and digital supply chain management, are reshaping sourcing practices. International buyers are increasingly leveraging online marketplaces to find competitive pricing and diverse product offerings. Additionally, automation and data analytics are enhancing inventory management and order fulfillment processes, allowing suppliers to respond rapidly to market demands.

The market is also witnessing a shift towards specialization, with manufacturers focusing on developing anchors that cater to specific applications, such as high-load bearing or weather-resistant solutions. Buyers from regions like Brazil and Saudi Arabia are particularly interested in these innovations, as they seek products that can withstand their unique environmental conditions. Understanding these dynamics is crucial for B2B buyers to make informed sourcing decisions.

Illustrative image related to brick anchors

How Is Sustainability and Ethical Sourcing Transforming the Brick Anchors Industry?

Sustainability is becoming a critical consideration for B2B buyers in the brick anchors sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, has raised awareness about the need for sustainable practices. Buyers are increasingly favoring suppliers who demonstrate a commitment to reducing their carbon footprint through eco-friendly production methods and materials.

Ethical sourcing is equally important, as businesses seek to ensure that their supply chains are free from human rights abuses and environmental degradation. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential criteria for procurement decisions. Buyers are encouraged to verify that their suppliers adhere to these standards, as they not only align with corporate social responsibility goals but also enhance brand reputation.

Moreover, the use of ‘green’ materials in the production of brick anchors, such as recycled metals or low-VOC adhesives, is gaining traction. Buyers can differentiate themselves in the market by sourcing sustainable products, which can also lead to long-term cost savings and compliance with increasingly stringent regulations.

What Is the Historical Context Behind Brick Anchors and Their Development?

The history of brick anchors dates back to ancient construction practices, where rudimentary fastening methods were employed to secure structures. As architectural designs evolved, so did the need for more sophisticated anchoring solutions. The development of modern brick anchors can be traced to the industrial revolution, which introduced new materials and manufacturing techniques, allowing for the creation of stronger, more reliable anchors.

Throughout the 20th century, innovations such as expansion anchors and chemical anchors emerged, providing enhanced performance for various applications. Today, brick anchors are engineered to meet specific load requirements and environmental conditions, reflecting the growing complexity of construction needs. This evolution highlights the importance of understanding historical trends in order to appreciate the advancements that shape current sourcing strategies in the B2B marketplace.

By recognizing these historical developments, international buyers can better navigate the current landscape of brick anchors, ensuring they choose solutions that meet both their operational requirements and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of brick anchors

-

How do I select the right brick anchor for my project?

Selecting the appropriate brick anchor depends on several factors, including the type of brick, the weight of the object being secured, and the environmental conditions. For heavier loads, consider using wedge anchors or heavy-duty screw anchors, while lighter fixtures may be adequately supported by plastic or nylon anchors. Assess the specific requirements of your project, including load capacity and installation environment, to choose the most suitable anchor type. -

What is the best brick anchor for outdoor applications?

For outdoor applications, stainless steel or galvanized brick anchors are recommended due to their corrosion resistance. Anchors like wedge anchors or expansion anchors are ideal for securing heavier structures, while lighter-duty options such as nylon anchors may suffice for smaller fixtures. Always consider the local climate conditions, such as humidity and exposure to moisture, to ensure the longevity of the anchors used in your project. -

What are the minimum order quantities (MOQs) for brick anchors?

Minimum order quantities (MOQs) for brick anchors can vary significantly by supplier and product type. Many manufacturers offer flexible MOQs, especially for bulk purchases, which can range from 100 to 500 units. It’s advisable to confirm MOQs with suppliers during the sourcing process to negotiate better pricing and ensure alignment with your project needs. -

How do I vet suppliers for brick anchors?

To effectively vet suppliers, conduct thorough research on their reputation, certifications, and customer reviews. Request product samples to assess quality and performance. Additionally, verify their manufacturing capabilities and compliance with international quality standards. Engaging in direct communication can also provide insights into their customer service and responsiveness, which are crucial for long-term partnerships. -

What payment terms should I expect when sourcing brick anchors internationally?

Payment terms for international transactions can vary, but common practices include upfront payments, deposits, or payment upon delivery. Letters of credit and escrow services are also popular for ensuring transaction security. Always clarify payment terms before finalizing agreements to avoid misunderstandings and ensure that they align with your cash flow requirements. -

How do I ensure quality assurance (QA) for brick anchors?

Quality assurance can be ensured by requesting certifications from suppliers that demonstrate compliance with international standards, such as ISO or ASTM. Conduct factory audits, if possible, or request third-party inspections before shipment. Establishing a clear quality agreement that outlines specifications and testing methods is also essential for maintaining product integrity. -

What logistics considerations should I keep in mind when importing brick anchors?

When importing brick anchors, consider shipping costs, delivery timelines, and customs regulations. Engage with logistics partners who have experience in handling construction materials to navigate potential challenges. It’s also wise to discuss packaging and handling requirements to prevent damage during transit, ensuring that the anchors arrive in good condition. -

Can brick anchors be customized for specific applications?

Many manufacturers offer customization options for brick anchors to meet specific project needs. This can include variations in size, material, or load capacity. When discussing customization, provide detailed specifications and any relevant project requirements to the supplier. Early engagement in the design process can help ensure that the anchors meet your precise needs and performance standards.

Top 7 Brick Anchors Manufacturers & Suppliers List

1. Mezzanines Online – Wall Anchors for Concrete & Brick

Domain: mezzaninesonline.com

Registered: 2014 (11 years)

Introduction: Wall anchors for concrete or brick

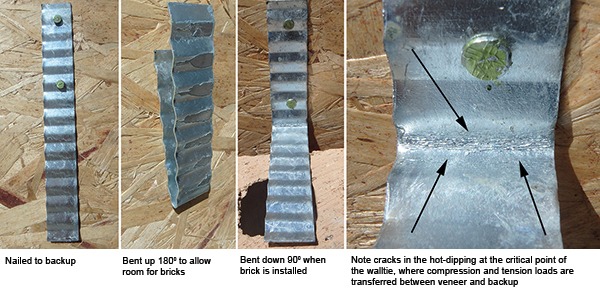

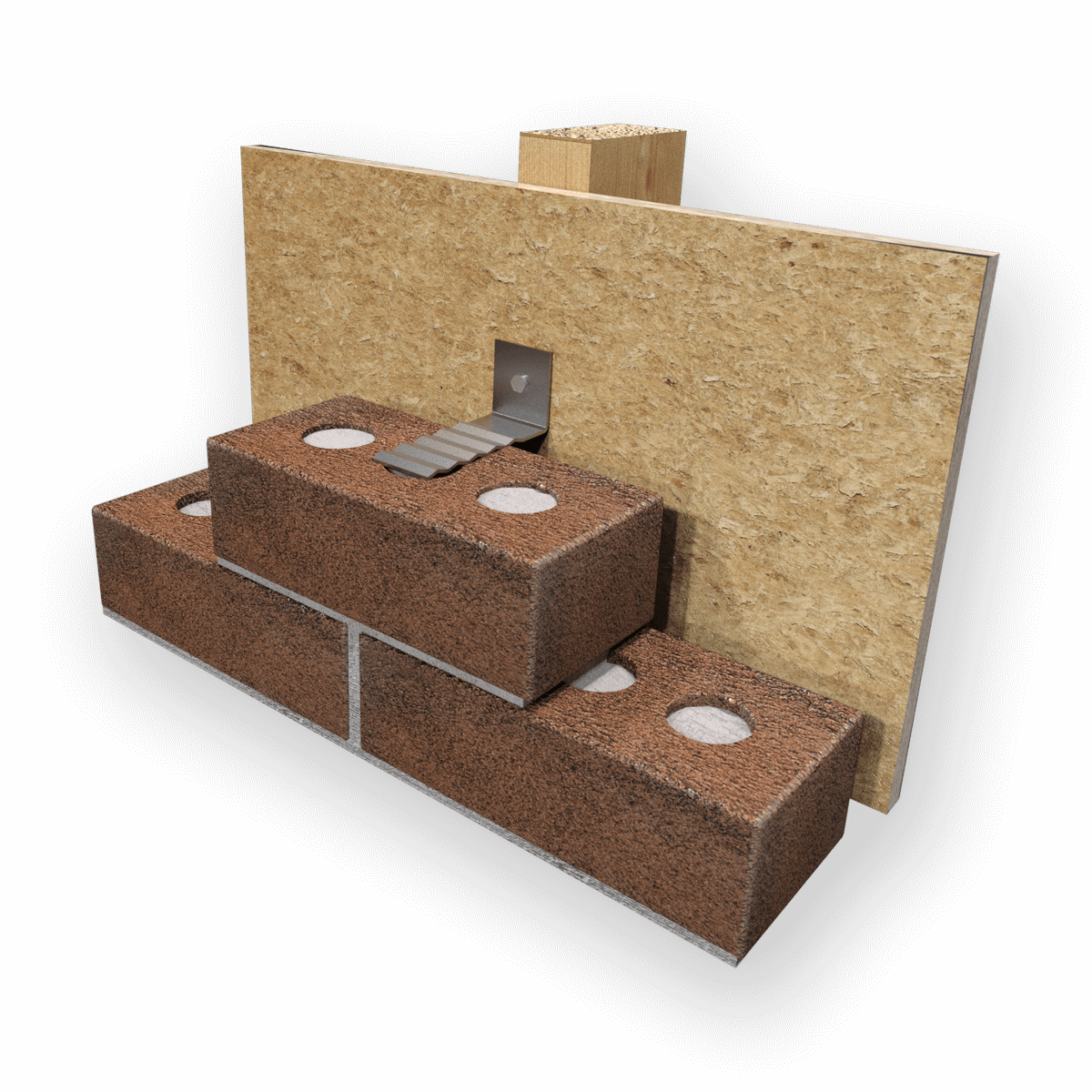

2. Hohmann & Barnard – DW-10HS Veneer Anchors

Domain: masonrydirect.com

Registered: 2017 (8 years)

Introduction: Anchors & Ties (Masonry Veneer) are essential for preventing movement, ensuring structural integrity, distributing loads evenly, and enhancing the stability and durability of masonry constructions. Key products include:

1. Hohmann & Barnard DW-10HS Veneer Anchors (250 Pieces/Box) – High-strength veneer anchor, price range $93.73 – $393.12.

2. Hohmann & Barnard Veneer Byna Ties (250 Pieces/Box) – …

3. Strongtie – Adhesive Solutions and Mechanical Anchors

Domain: strongtie.com

Registered: 1995 (30 years)

Introduction: {“Adhesive Solutions”: [“SET-3G® High-Strength Epoxy Adhesive”, “AT-3G™ High-Strength Hybrid Acrylic Adhesive”, “ET-3G™ Epoxy Adhesive”], “Mechanical Anchors”: [“Titen HD® Heavy-Duty Screw Anchor”, “Strong-Bolt® 2 Wedge Anchor”, “Titen Turbo™ Concrete and Masonry Screw Anchor”, “Drop-In (DIAB) Internally Threaded Anchor”], “Direct Fastening”: [“G3 Gas-Actuated Fastening Tool”, “PTP-27L Premium Too…

4. CONFAST – Brick Anchors

Domain: confast.com

Registered: 1998 (27 years)

Introduction: Best Brick Anchors from Concrete Fastening Systems include various types of anchors such as CONFAST® Wedge Anchors, ThunderStud Anchors, Simpson Strong-Bolt® 2 Wedge Anchors, Red Head Trubolt Wedge Anchors, and Powers Fasteners Power-Stud Sleeve Anchors. These anchors are available in different materials including Zinc Plated, Galvanized, 304 Stainless Steel, and 316 Stainless Steel. The product r…

5. Masonry Anchors – Versatile Wall Solutions

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: These anchors are suitable for use in brick and masonry walls, but are not recommended for wooden walls as wood screws alone are sufficient. They are referred to by various names including screw anchors, ribbed anchors, and drywall anchors. While they can hold light loads such as a half-ounce camera, better quality anchors exist for masonry applications, such as Tapcon screws, which do not require…

6. Tapcon – Concrete Anchors

Domain: tapcon.com

Registered: 1999 (26 years)

Introduction: Tapcon Concrete Anchors are designed for easy installation, corrosion resistance, and long-lasting quality. They feature Star and Hex heads that deliver the performance professionals demand. The Heavy-Duty Tapcon+ anchors provide heavy-duty holding power in demanding conditions. Tapcon products are suitable for concrete, block, and brick applications, offering an alternative to expansion anchors, …

7. AnchorCo – Corrugated Brick Anchor with Hole

Domain: anchorco.com

Registered: 1999 (26 years)

Introduction: Product Name: Corrugated Brick Anchor With Hole (187)

Price: $250.00

Description: Used for attaching brick veneer to wood backups.

Material: Hot-Dip Galvanized

Standard Thickness: 16 gauge x 1-1/4″

Standard Lengths: 3-1/2″ or 5-1/2″ with a 1-1/2″ bend

Hole: Centered 5/16″ diameter

Custom Sizes: Available

Box Quantity: 250

Shipping: Ships fast in 24 hours

Customer Support: Dedicated support availab…

Strategic Sourcing Conclusion and Outlook for brick anchors

In the evolving landscape of construction and industrial applications, the strategic sourcing of brick anchors presents significant opportunities for B2B buyers. By aligning with reputable suppliers and understanding product specifications, businesses can ensure the reliability and durability of their installations. Key takeaways include recognizing the importance of selecting the right type of anchor based on specific project requirements, such as weight capacity and environmental conditions. Additionally, leveraging bulk purchasing options can enhance cost efficiency, making it a strategic advantage for organizations looking to optimize their supply chain.

As international markets expand, particularly in regions like Africa, South America, the Middle East, and Europe, there is a growing demand for high-quality brick anchors. Companies should prioritize partnerships with manufacturers who offer comprehensive support, including technical assistance and flexible payment options. By doing so, businesses can not only meet current project needs but also prepare for future developments in construction methodologies.

Looking ahead, now is the time for B2B buyers to capitalize on these insights and secure their supply lines. Embrace strategic sourcing as a pathway to innovation and growth, ensuring your projects are supported by the best materials in the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to brick anchors

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.