Choosing Your Bottle Brush Wire: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for bottle brush wire

In today’s competitive landscape, sourcing quality bottle brush wire can pose significant challenges for international B2B buyers. With diverse applications ranging from industrial cleaning to household use, understanding the nuances of this product is crucial. This comprehensive guide delves into the various types of bottle brush wire, including materials like stainless steel, brass, and high carbon steel, each tailored for specific cleaning tasks, from automotive parts to delicate glassware.

Our aim is to equip B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—countries like Vietnam and Brazil—with the knowledge needed to make informed purchasing decisions. We will explore essential factors such as supplier vetting, cost considerations, and the importance of sustainability in sourcing practices. By addressing these key areas, this guide empowers businesses to navigate the global market effectively, ensuring they select the right products that meet their operational needs while also aligning with eco-friendly practices.

As you progress through this guide, you will gain insights into how to optimize your procurement strategy, ultimately enhancing your business’s efficiency and sustainability in the long run. Whether you are a manufacturer seeking reliable suppliers or a distributor looking to expand your product line, this resource will serve as an invaluable tool in your quest for quality bottle brush wire.

Understanding bottle brush wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Wire Tube Brushes | Available in brass, high carbon steel, and stainless steel; spiral design for effective cleaning | Cleaning tubes, valves, automotive and aircraft parts | Pros: Durable, versatile; Cons: May rust if not stainless steel |

| Natural Fiber Brushes | Made from sustainable materials; biodegradable and compostable; soft bristles | Eco-friendly cleaning for bottles, vases, and delicate items | Pros: Environmentally friendly; Cons: Less durable compared to metal options |

| Twisted-In-Wire Brushes | Bristles twisted into wire for enhanced durability; various sizes available | Industrial cleaning, food processing equipment | Pros: High durability; Cons: Limited to specific applications |

| Power Tube Brushes | Designed for power tools; heavy-duty construction for aggressive cleaning | Heavy machinery, industrial applications | Pros: Efficient for tough jobs; Cons: Higher cost |

| Specialty Bottle Brushes | Unique designs for specific bottle shapes; may include cotton ends for delicate surfaces | Cleaning specialty glassware, laboratory equipment | Pros: Tailored for specific needs; Cons: Limited use cases |

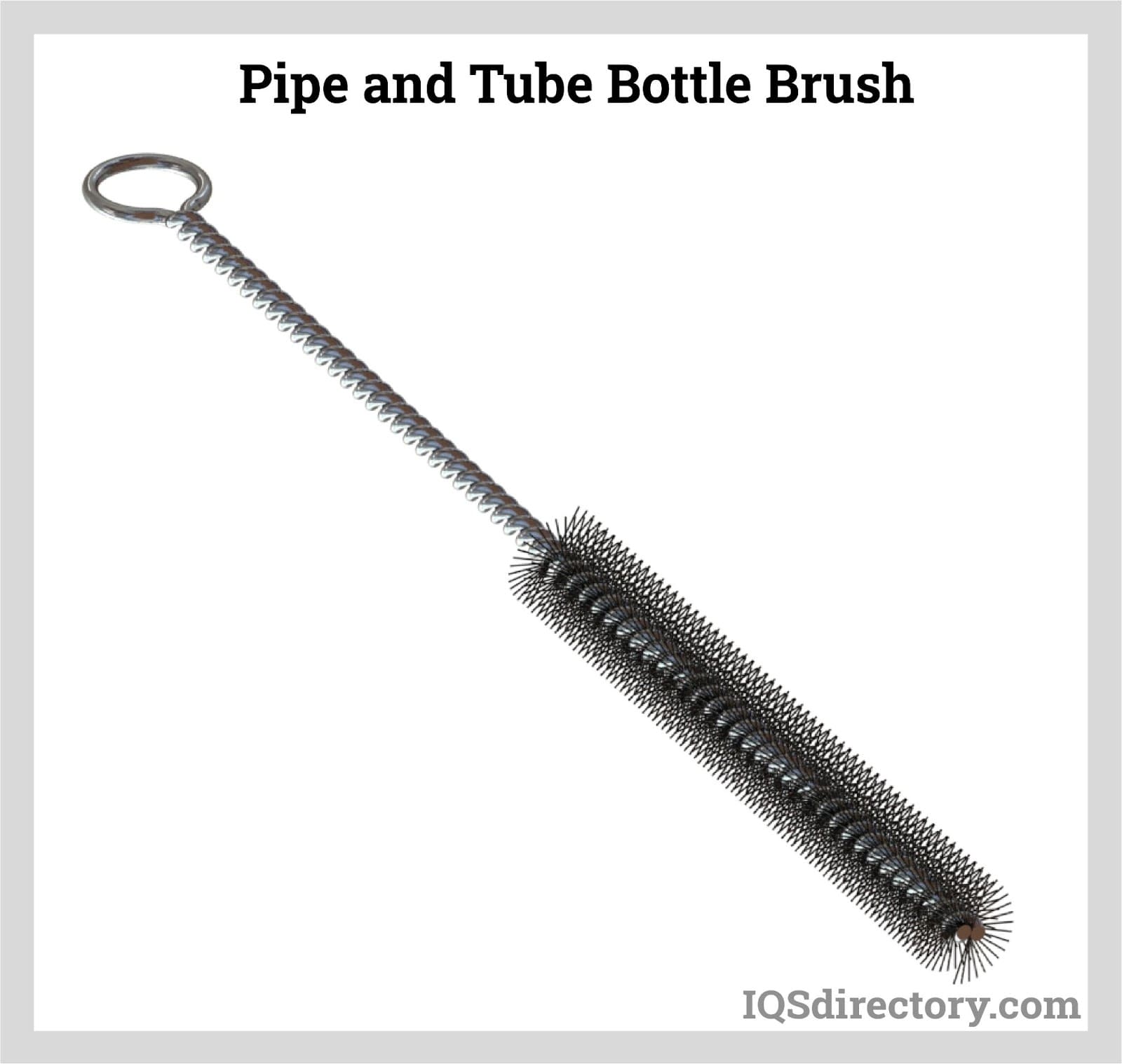

What Are Metal Wire Tube Brushes and Their Key Applications?

Metal wire tube brushes are constructed using materials such as brass, high carbon steel, or stainless steel, which provide durability and resistance to wear. The spiral design of these brushes allows for thorough cleaning of various surfaces, making them ideal for applications in industries like automotive, aerospace, and plumbing. When considering a purchase, B2B buyers should evaluate the material based on their specific cleaning requirements, as stainless steel options will provide longevity in moist environments, while brass may be preferable for softer surfaces.

Why Choose Natural Fiber Brushes for Eco-Friendly Solutions?

Natural fiber brushes, often made from sustainable materials, offer a biodegradable alternative for cleaning tasks. Their soft bristles make them suitable for cleaning delicate items like antique vases or sensitive laboratory equipment. B2B buyers focused on sustainability will find these brushes appealing due to their compostable nature. However, they may not withstand heavy-duty tasks as effectively as metal brushes, making it essential to consider the intended application before purchasing.

How Do Twisted-In-Wire Brushes Stand Out in Industrial Cleaning?

Twisted-in-wire brushes are designed for heavy-duty applications, featuring bristles that are securely twisted into the wire for increased durability. They are commonly used in food processing and industrial cleaning environments where robust cleaning tools are required. Buyers should consider the specific size and bristle type needed for their applications, as these brushes can effectively remove tough residues but may not be suitable for delicate surfaces.

What Advantages Do Power Tube Brushes Offer for Heavy Machinery?

Power tube brushes are engineered for use with power tools, providing a heavy-duty option for cleaning tasks in industrial settings. Their robust construction allows for efficient cleaning of heavy machinery and equipment. B2B buyers should assess the compatibility of these brushes with their existing tools and consider the investment in terms of efficiency gains versus cost, as they may be pricier than standard brushes.

How Do Specialty Bottle Brushes Cater to Specific Needs?

Specialty bottle brushes are designed for unique shapes and applications, often featuring cotton ends or specific dimensions to accommodate various types of bottles. They are particularly useful in laboratory settings or for cleaning specialty glassware. Buyers should evaluate their specific cleaning needs and the types of bottles they frequently use to ensure they select the right brush, as these options may have limited versatility compared to more general-purpose brushes.

Key Industrial Applications of bottle brush wire

| Industry/Sector | Specific Application of bottle brush wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Cleaning and maintenance of bottling equipment | Ensures hygiene and compliance with health standards | Durability, resistance to corrosion, and compliance with food safety regulations |

| Automotive | Cleaning of fuel and oil lines | Enhances performance and longevity of vehicle components | Material compatibility with specific fluids and temperatures |

| Manufacturing | Maintenance of machinery and equipment | Reduces downtime through effective cleaning | Custom sizes and shapes to fit various machinery components |

| Healthcare | Sterilization of laboratory glassware | Maintains sterile environments critical for patient safety | Non-reactive materials to avoid contamination |

| Environmental Services | Cleaning and maintenance of recycling equipment | Supports sustainability initiatives and efficiency | Eco-friendly materials and biodegradable options |

In the Food and Beverage sector, bottle brush wire is essential for cleaning bottling equipment, ensuring that all surfaces are free from contaminants. This application is crucial for compliance with health regulations and maintaining product quality. Buyers should consider the durability and corrosion resistance of the wire, as well as compliance with food safety standards, especially in regions with stringent regulations.

In the Automotive industry, bottle brush wire is used to clean fuel and oil lines, which can accumulate debris and contaminants over time. Regular maintenance using these brushes helps enhance the performance and longevity of vehicle components, reducing the risk of costly repairs. Buyers must ensure that the brushes are made from materials compatible with specific fluids and can withstand high temperatures.

Within Manufacturing, bottle brush wire plays a vital role in the maintenance of various machinery and equipment. By effectively cleaning internal components, these brushes help reduce downtime and improve operational efficiency. Buyers should look for custom sizes and shapes that can accommodate the specific machinery used in their operations to maximize cleaning effectiveness.

In the Healthcare sector, bottle brush wire is utilized for the sterilization of laboratory glassware, which is critical for maintaining sterile environments essential for patient safety. Non-reactive materials are a key consideration for buyers to prevent contamination during cleaning processes, particularly in regions with varying healthcare standards.

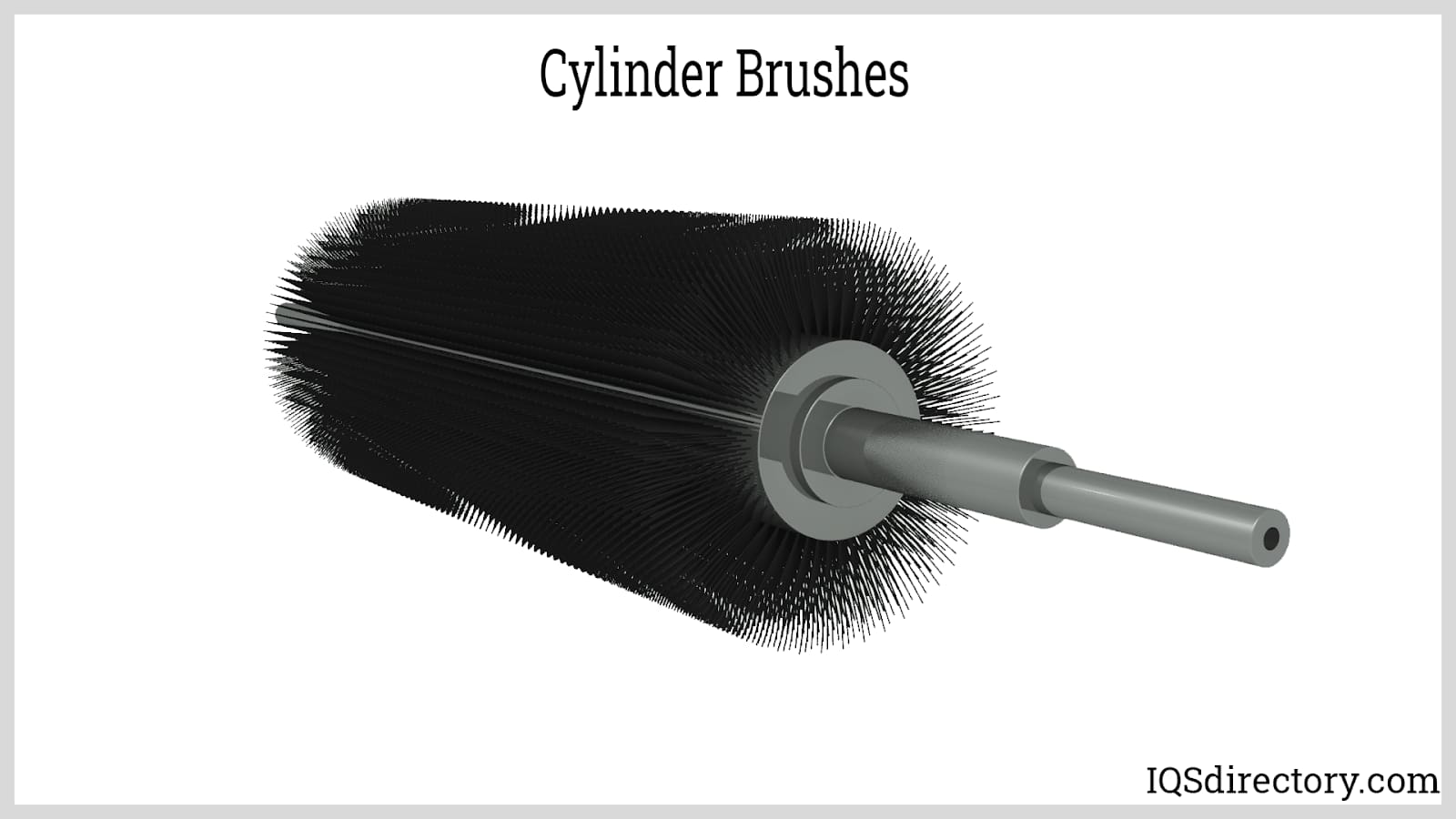

Illustrative image related to bottle brush wire

Lastly, in Environmental Services, bottle brush wire is employed for cleaning and maintaining recycling equipment. This application supports sustainability initiatives by ensuring that equipment operates efficiently and effectively. Buyers should prioritize eco-friendly materials, including biodegradable options, to align with environmental goals and regulations, particularly in markets focused on sustainability.

3 Common User Pain Points for ‘bottle brush wire’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Bottle Brush Wire for Specific Applications

The Problem: B2B buyers often face challenges when trying to find the right type of bottle brush wire that meets their specific cleaning needs. Many suppliers offer generic options that may not withstand the rigorous demands of industrial applications such as automotive cleaning, plumbing, or food processing. This can lead to inefficiencies, increased costs, and the frustration of having to frequently replace subpar products.

The Solution: To effectively source durable bottle brush wire, buyers should look for suppliers that specialize in industrial-grade products. When evaluating options, consider the material of the wire (e.g., stainless steel, brass, or high carbon steel) based on the intended application. For instance, stainless steel is preferable for environments prone to corrosion, while brass may be ideal for softer surfaces. Additionally, request detailed specifications and performance data from suppliers to ensure that the brushes will meet operational requirements. Engaging in bulk purchasing can also lead to better pricing and consistent quality, so consider establishing long-term relationships with reliable manufacturers.

Scenario 2: Inadequate Cleaning Performance Leading to Operational Inefficiencies

The Problem: Many businesses, especially in manufacturing or food service, encounter inefficiencies due to inadequate cleaning performance of bottle brush wire. Brushes that do not properly reach all areas of equipment or have bristles that wear out quickly can lead to unsatisfactory cleaning results, potentially causing contamination or malfunctions in machinery.

The Solution: To enhance cleaning performance, buyers should opt for bottle brushes with a design that includes a variety of bristle lengths and thicknesses. This allows the brush to effectively clean narrow spaces and complex geometries. It is also beneficial to select brushes with reinforced wire that can withstand rigorous scrubbing without losing shape or effectiveness. Additionally, conducting regular assessments of the brushes in use will help identify when replacements are necessary, ensuring that cleaning standards are consistently met. Consider implementing a maintenance schedule to rotate brushes and monitor their condition.

Scenario 3: Environmental Concerns and Sustainability of Cleaning Products

The Problem: As businesses increasingly prioritize sustainability, B2B buyers are often challenged by the lack of eco-friendly options in the bottle brush wire market. Many traditional brushes are made from plastic or non-recyclable materials, which can conflict with a company’s sustainability goals and contribute to environmental waste.

The Solution: Buyers should actively seek out suppliers that offer eco-friendly bottle brush wire options. Look for brushes made from natural, biodegradable materials such as sisal or other sustainable fibers. Many modern manufacturers are now producing brushes that not only have compostable bristles but also use recycled metal for the wire. When sourcing, request certifications or documentation that verify the sustainability claims of the products. Additionally, consider the lifecycle of the product; opting for reusable and recyclable options can significantly reduce environmental impact while aligning with corporate social responsibility goals. By championing sustainability in procurement practices, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Strategic Material Selection Guide for bottle brush wire

What Are the Key Materials Used for Bottle Brush Wire?

When selecting materials for bottle brush wire, it is essential to consider various factors that impact performance, durability, and suitability for specific applications. Here, we analyze four common materials: Brass, Stainless Steel, High Carbon Steel, and Natural Fibers. Each material has unique properties that cater to different cleaning needs and environments.

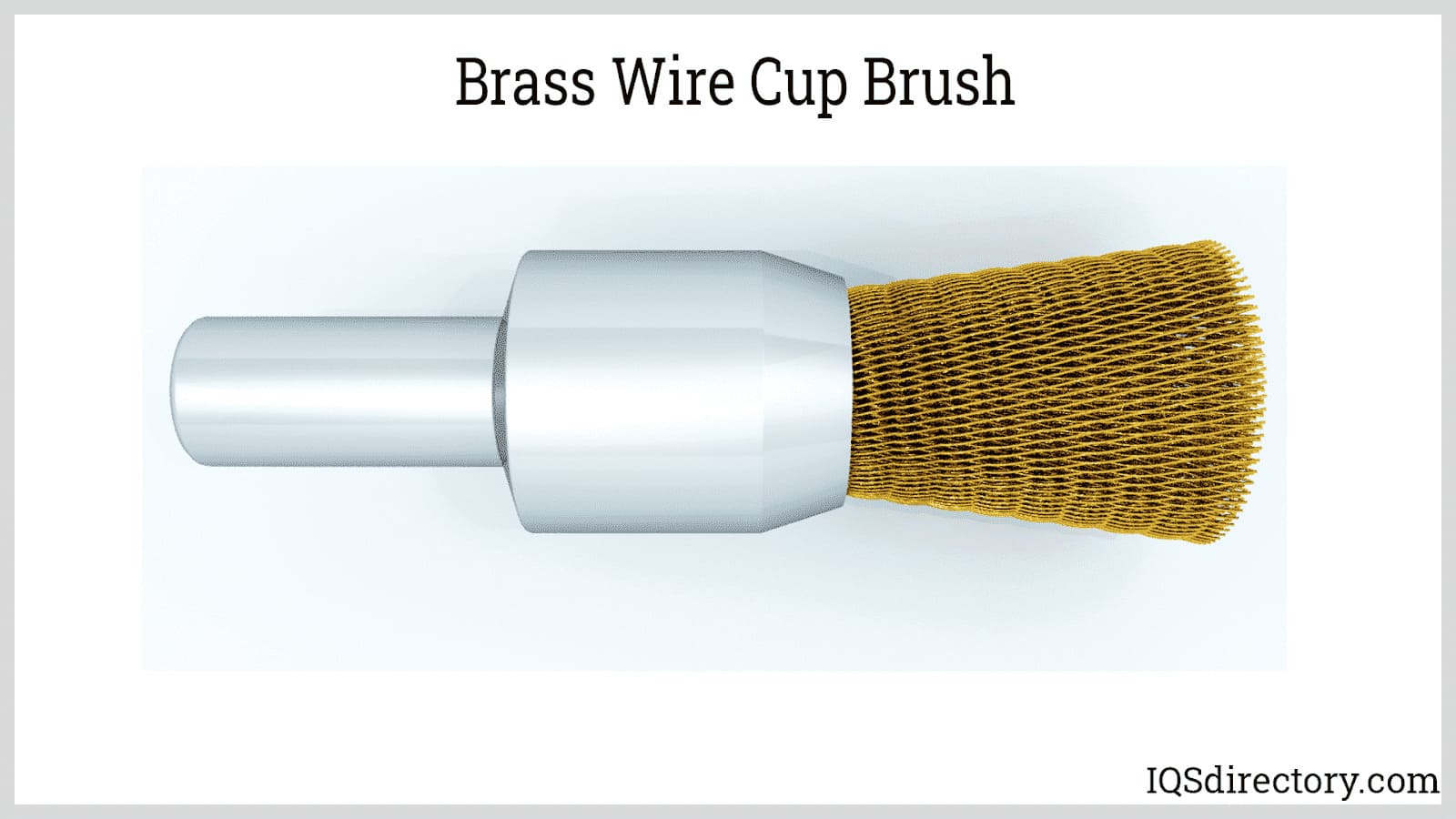

Illustrative image related to bottle brush wire

How Does Brass Perform as a Bottle Brush Wire Material?

Brass is an alloy composed primarily of copper and zinc, known for its excellent corrosion resistance and moderate strength. It performs well in applications where chemical exposure is minimal, making it suitable for cleaning tasks in non-corrosive environments.

Pros: Brass offers good durability and resistance to rust, making it ideal for long-term use. Its aesthetic appeal is also beneficial for consumer-facing products.

Cons: However, brass can be more expensive than other materials and may not withstand high temperatures or harsh chemicals, limiting its use in industrial applications.

Impact on Application: Brass is often used in cleaning delicate surfaces or items that require a gentler touch, such as glassware or certain plastics.

Illustrative image related to bottle brush wire

Considerations for International Buyers: Compliance with standards such as ASTM B36 for brass products is crucial, especially in regions like Europe and the Middle East, where quality regulations are stringent.

What Are the Advantages of Stainless Steel for Bottle Brush Wire?

Stainless steel is a popular choice for bottle brush wire due to its exceptional strength and corrosion resistance. It is particularly well-suited for environments that involve exposure to moisture or harsh chemicals.

Pros: The durability of stainless steel makes it ideal for heavy-duty applications, such as cleaning industrial tanks or automotive parts. It also maintains its integrity at high temperatures.

Cons: On the downside, stainless steel brushes can be more expensive than other options, and they may not be as flexible, which can affect their usability in certain applications.

Illustrative image related to bottle brush wire

Impact on Application: Stainless steel is compatible with a wide range of media, including oils, solvents, and acids, making it versatile for various cleaning tasks.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international standards such as DIN EN 10088, particularly in regions like South America and Europe, where quality assurance is critical.

Why Choose High Carbon Steel for Bottle Brush Wire?

High carbon steel is known for its hardness and strength, making it a suitable option for applications requiring aggressive cleaning and abrasion.

Pros: Its high tensile strength allows for effective scrubbing, making it ideal for removing rust and debris from tough surfaces.

Cons: However, high carbon steel is prone to corrosion if not properly maintained, which can limit its lifespan in wet environments.

Impact on Application: This material is often used in industrial settings, such as manufacturing and automotive, where robust cleaning tools are necessary.

Considerations for International Buyers: Compliance with standards like ASTM A228 is essential, particularly in regions with stringent manufacturing regulations, such as Europe and the Middle East.

How Do Natural Fibers Compare for Bottle Brush Wire?

Natural fibers, such as sisal or cotton, are gaining popularity due to their eco-friendly properties. These materials are biodegradable and often used in consumer products aimed at sustainability.

Pros: Natural fiber brushes are non-toxic and safe for use on delicate surfaces, making them suitable for household cleaning tasks.

Cons: However, they may not offer the same level of durability or effectiveness in heavy-duty applications compared to metal options.

Impact on Application: They are best suited for light cleaning tasks, such as kitchenware or delicate glass items.

Considerations for International Buyers: Buyers should look for certifications related to sustainability and ethical manufacturing practices, particularly in markets that prioritize eco-friendly products, such as Europe and parts of South America.

Summary Table of Material Selection for Bottle Brush Wire

| Material | Typical Use Case for bottle brush wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Cleaning delicate surfaces | Excellent corrosion resistance | Limited high-temperature use | Medium |

| Stainless Steel | Heavy-duty industrial cleaning | Exceptional strength and durability | Higher cost | High |

| High Carbon Steel | Rust and debris removal in industrial | High tensile strength | Prone to corrosion | Medium |

| Natural Fibers | Household cleaning tasks | Eco-friendly and biodegradable | Less durable for heavy-duty use | Low |

This comprehensive analysis of materials for bottle brush wire provides B2B buyers with actionable insights to make informed purchasing decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bottle brush wire

What Are the Main Stages of the Manufacturing Process for Bottle Brush Wire?

The manufacturing process for bottle brush wire encompasses several key stages, each crucial for producing a high-quality product that meets the diverse needs of B2B buyers. Understanding these stages can help businesses ensure they partner with manufacturers who prioritize quality and efficiency.

Illustrative image related to bottle brush wire

Material Preparation: What Raw Materials Are Used?

The first step in the manufacturing process is material preparation. Bottle brushes are typically made from various types of wire, including stainless steel, brass, and high carbon steel. Each material offers different properties, such as corrosion resistance or flexibility, that can affect the brush’s performance and longevity. Manufacturers often source these materials from trusted suppliers, and they undergo stringent inspections to ensure compliance with industry standards.

How Is Wire Formed into Brush Shapes?

Once the materials are prepared, the next stage is forming. This involves cutting the wire to the required lengths and shaping it into the desired brush form. The wire is twisted, bent, or looped to create the brush’s bristles, which are then securely attached to a handle. Techniques such as twisting-in-wire or the use of specialized machinery ensure that the bristles remain firmly in place, providing durability during use.

What Does the Assembly Process Look Like?

After forming, the assembly process takes place. This stage involves attaching the bristles to the handle, which may also be made of metal or other materials. Quality manufacturers ensure that the handles are ergonomically designed for ease of use, which is particularly important for commercial applications. The assembly line may include automated systems for efficiency, but skilled workers often perform final checks to ensure that each product meets quality standards.

What Finishing Techniques Are Commonly Used?

The finishing stage includes various treatments to enhance the brush’s performance and aesthetics. Common techniques involve coating the metal to prevent rust, applying anti-corrosive finishes, or polishing the brush to remove any rough edges. Some manufacturers also offer customization options, such as branding or unique color finishes, which can be attractive to B2B buyers looking to differentiate their products.

How Is Quality Assurance Implemented in Bottle Brush Wire Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets both regulatory and customer standards. For B2B buyers, understanding the QA measures in place can provide confidence in the reliability of their suppliers.

Which International Standards Should Manufacturers Follow?

Manufacturers of bottle brush wire often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) or API (American Petroleum Institute) may be relevant depending on the intended application of the brushes.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process. Key stages include:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to identify and rectify any deviations from quality standards.

- Final Quality Control (FQC): Conducting thorough inspections of finished products to ensure they meet all requirements before shipment.

These checkpoints help minimize defects and ensure that only high-quality products reach B2B buyers.

What Testing Methods Are Commonly Used?

Testing methods for bottle brush wire can vary depending on the material and intended use. Common methods include tensile strength tests, corrosion resistance tests, and visual inspections for defects. Manufacturers may also employ advanced testing technologies, such as fatigue testing, to assess the longevity and durability of the brushes under stress.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability and compliance with international standards. Here are several strategies buyers can employ:

What Role Do Audits Play in Quality Assurance?

Conducting audits of potential suppliers is an effective way to assess their manufacturing processes and quality control measures. Audits can be performed by the buyers themselves or through third-party organizations specializing in supplier assessments. During an audit, buyers should look for documentation of quality control procedures, certifications, and records of previous inspections.

How Important Are Quality Control Reports?

Quality control reports provide valuable insights into a manufacturer’s performance and adherence to quality standards. Buyers should request access to these reports, which should include details about inspection results, testing methodologies, and corrective actions taken in case of defects. Reviewing these reports can help buyers make informed decisions about their suppliers.

What Are the Benefits of Third-Party Inspections?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These services can conduct thorough inspections and provide certifications that validate the quality of the products. For B2B buyers, particularly those in regions with less stringent local regulations, third-party inspections can serve as an added layer of assurance.

Illustrative image related to bottle brush wire

What Unique QC Considerations Exist for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing bottle brush wire. These may include:

- Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers should ensure that their suppliers are compliant with the relevant regulations in their target markets.

- Cultural Differences: Communication styles and business practices can vary significantly across regions. Understanding these differences can aid in establishing effective partnerships and ensuring that quality expectations are clearly communicated.

- Logistics and Shipping: Quality control also extends to the shipping process. Buyers should verify that suppliers have robust logistics systems in place to prevent damage during transport and ensure timely delivery of products.

By thoroughly understanding the manufacturing processes and quality assurance measures associated with bottle brush wire, B2B buyers can make informed decisions and establish strong partnerships with reliable suppliers. This knowledge not only enhances product quality but also fosters trust in the supply chain, ultimately leading to greater business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle brush wire’

The following guide provides a structured approach for B2B buyers aiming to source bottle brush wire effectively. By following this checklist, you can ensure that your procurement process is thorough and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for sourcing the right bottle brush wire. Consider the intended application—whether for cleaning tubes, bottles, or other components. Specify material types (e.g., stainless steel, brass, or high carbon steel) and dimensions, including length and diameter, to ensure compatibility with your equipment and processes.

Step 2: Identify Reliable Suppliers

Research and compile a list of potential suppliers who specialize in bottle brush wire. Look for manufacturers with a proven track record in your industry. Utilize online directories, trade shows, and industry associations to find reputable companies. Assess their experience with international shipping to your region, as this will affect lead times and logistics.

Illustrative image related to bottle brush wire

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier, it is crucial to verify their certifications. Check for quality assurance standards (such as ISO certifications) that indicate adherence to international manufacturing practices. Additionally, ensure that suppliers can provide safety data sheets and compliance documentation, particularly if your operations are subject to strict regulatory requirements.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the bottle brush wire. Testing samples allows you to assess quality, durability, and performance in real-world applications. Evaluate the bristle integrity, flexibility, and overall construction to ensure they meet your operational standards.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with selected suppliers to secure favorable pricing and terms. Consider factors such as minimum order quantities, payment terms, and shipping costs. Ensure that all agreed terms are documented in a contract to avoid misunderstandings later in the process.

Step 6: Review Logistics and Delivery Options

Understand the logistics involved in sourcing bottle brush wire, especially for international shipping. Discuss delivery timelines and shipping methods with your supplier to align with your operational schedules. Investigate any potential customs duties or import regulations that could impact the final cost and delivery time.

Step 7: Establish a Quality Control Process

Once you have sourced your bottle brush wire, implement a quality control process to monitor the products received. This should include inspections upon delivery to verify that the products meet your specifications. Establish a protocol for addressing any discrepancies or quality issues with the supplier promptly.

By following these steps, B2B buyers can navigate the sourcing process for bottle brush wire with confidence, ensuring that they procure high-quality materials that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for bottle brush wire Sourcing

What Are the Key Cost Components for Sourcing Bottle Brush Wire?

When analyzing the cost structure for sourcing bottle brush wire, several critical components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Materials: The choice of wire material (e.g., brass, stainless steel, high carbon steel) significantly impacts costs. Stainless steel, for instance, is generally more expensive than high carbon steel due to its corrosion resistance and durability.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can come with trade-offs in terms of quality and consistency.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: The initial setup for production, including molds and dies, is a one-time cost that can affect pricing. Customization often requires additional tooling, which can increase upfront expenses.

-

Quality Control (QC): Investing in QC ensures product reliability and compliance with international standards. This is particularly crucial for international buyers who may require specific certifications.

-

Logistics: Shipping costs can vary based on the destination, shipping method, and volume. Understanding Incoterms is essential for clarifying responsibilities and cost implications in international shipping.

-

Margin: Suppliers typically add a margin to cover their costs and desired profit. This margin can vary based on competition, market demand, and the perceived value of the product.

How Do Price Influencers Affect Bottle Brush Wire Sourcing?

Several factors influence the pricing of bottle brush wire, affecting overall sourcing costs:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes generally lead to lower per-unit costs. Suppliers often provide discounts for bulk purchases, making it advantageous for buyers with larger needs.

-

Specifications and Customization: Customized products may incur additional costs due to unique specifications, requiring special materials or manufacturing processes. Buyers should balance their need for customization with the associated costs.

-

Quality and Certifications: Products that meet international quality standards or possess certifications (like ISO) may command higher prices. However, they often provide assurance of quality and reliability, which can justify the investment.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: The chosen Incoterms can significantly influence total costs by defining who is responsible for shipping, insurance, and tariffs. Understanding these terms is vital for accurate pricing during negotiations.

What Are the Best Practices for Negotiating Bottle Brush Wire Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can enhance cost-efficiency:

-

Research and Benchmarking: Gather information on market rates and competitors’ pricing to establish a baseline for negotiations. This knowledge empowers buyers to negotiate confidently.

-

Total Cost of Ownership (TCO): Consider all associated costs beyond the initial purchase price, including shipping, handling, and potential quality issues. A slightly higher upfront cost may lead to lower TCO if the product is of higher quality and requires less frequent replacement.

-

Building Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships may yield discounts or favorable payment terms.

-

Flexibility in Order Size: If possible, negotiate on order quantities to achieve better pricing. Sometimes, ordering slightly more than the immediate need can reduce per-unit costs.

-

Timing and Market Conditions: Be aware of market trends and seasonal fluctuations that may impact pricing. Timing your orders strategically can lead to cost savings.

Conclusion

Sourcing bottle brush wire requires a comprehensive understanding of the cost structure and pricing influencers. By analyzing these components and employing strategic negotiation practices, international B2B buyers can optimize their purchasing decisions and enhance their supply chain efficiency. Always remember that prices may vary widely based on the factors discussed, so it is essential to conduct thorough research and due diligence before finalizing any agreements.

Alternatives Analysis: Comparing bottle brush wire With Other Solutions

Exploring Alternative Solutions to Bottle Brush Wire

When evaluating cleaning solutions for industrial and commercial applications, it’s essential to consider various alternatives to bottle brush wire. Different products may offer distinct benefits depending on the specific requirements of the task, such as cleaning efficiency, cost-effectiveness, and ease of use. Below, we compare bottle brush wire with two viable alternatives: nylon bristle brushes and foam cleaning pads.

Comparison Table

| Comparison Aspect | Bottle Brush Wire | Nylon Bristle Brush | Foam Cleaning Pad |

|---|---|---|---|

| Performance | Highly effective for narrow and hard-to-reach spaces; durable for tough cleaning tasks | Good for general cleaning; less effective in tight spaces | Excellent for smooth surfaces; limited in tight spaces |

| Cost | Moderate ($5 – $10 per unit) | Generally lower ($3 – $8 per unit) | Varies widely ($2 – $15 per unit) |

| Ease of Implementation | Easy to use; can be cumbersome in very tight spaces | User-friendly; flexible in application | Very simple; often single-use or disposable |

| Maintenance | Minimal; requires rinsing and drying | Low; occasional replacement needed | Low; single-use; no maintenance required |

| Best Use Case | Ideal for cleaning bottles, tubes, and intricate machinery | Suitable for general-purpose cleaning in various settings | Best for smooth surfaces and light cleaning tasks |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Nylon Bristle Brushes?

Nylon bristle brushes are a popular alternative for many cleaning tasks due to their versatility. They are effective for general cleaning and can adapt to various shapes and surfaces. However, their performance diminishes in tight spaces, where bottle brush wire excels. Additionally, while nylon brushes are typically less expensive, they may require more frequent replacements, leading to higher long-term costs.

How Do Foam Cleaning Pads Compare?

Foam cleaning pads provide a gentle cleaning option, particularly effective on smooth surfaces. They are user-friendly and often designed for single-use, making them ideal for quick clean-up tasks. However, foam pads lack the durability and effectiveness of bottle brush wire in challenging cleaning scenarios, such as reaching deep into narrow bottles or tubes. Their cost can also vary significantly based on quality, which can affect bulk purchasing decisions.

Conclusion: How to Choose the Right Cleaning Solution for Your Needs

For B2B buyers, the choice between bottle brush wire and its alternatives largely depends on the specific cleaning requirements of their operations. If the primary need is to clean intricate machinery or narrow containers, bottle brush wire is the superior option. Conversely, for general cleaning tasks, nylon bristle brushes may suffice, especially when cost is a critical factor. Foam cleaning pads can be ideal for quick, light cleaning on smooth surfaces but fall short in versatility. Ultimately, understanding the unique needs of your application will guide you in selecting the most effective cleaning solution.

Illustrative image related to bottle brush wire

Essential Technical Properties and Trade Terminology for bottle brush wire

What Are the Key Technical Properties of Bottle Brush Wire?

Understanding the technical properties of bottle brush wire is essential for B2B buyers seeking reliable and effective cleaning solutions. Here are several critical specifications that should be considered:

-

Material Composition

Bottle brush wires are commonly made from materials such as brass, stainless steel, and high carbon steel. The choice of material affects durability, corrosion resistance, and suitability for various cleaning applications. For instance, stainless steel is ideal for high-moisture environments, while brass may be preferred for its softer texture, which is less likely to scratch delicate surfaces. -

Wire Diameter

The diameter of the wire used in bottle brushes can vary significantly, typically ranging from 0.008 inches to 0.016 inches. A thicker wire provides more stiffness and cleaning power, making it suitable for heavy-duty applications. Conversely, a thinner wire allows for flexibility, which can be advantageous in intricate cleaning tasks. -

Brush Length and Diameter

The overall length and diameter of the brush directly impact its cleaning efficiency and versatility. Longer brushes are better for reaching deep or narrow spaces, while wider brushes cover more surface area. Standard sizes usually include lengths from 6 inches to 18 inches and diameters ranging from 1/2 inch to 1 1/2 inches. -

Filament Type

The type of filament—whether twisted wire, natural bristles, or synthetic fibers—affects the brush’s cleaning capability and durability. Twisted wire brushes are often more durable and effective for scrubbing tough surfaces, while natural bristles may be more suitable for delicate cleaning tasks. -

Bristle Density

The density of the bristles influences the brush’s cleaning effectiveness. A higher density often translates to better dirt and debris removal, making it crucial for industries requiring thorough cleaning, such as food processing and pharmaceuticals. -

Resistance to Chemicals

Depending on the application, resistance to various chemicals can be a vital property. For example, brushes used in automotive or industrial settings may need to withstand harsh solvents or cleaning agents without degrading.

What Are Common Trade Terms in the Bottle Brush Wire Industry?

Familiarity with industry terminology can streamline communication and negotiations in B2B transactions. Here are key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bottle brush wire, OEMs may provide specialized brushes tailored to specific industrial applications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to assess whether a supplier’s terms align with their purchasing needs and budget. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for pricing and terms on specified products. Submitting an RFQ is a standard practice for businesses looking to compare offers before making a purchasing decision. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms helps businesses understand shipping costs, risk transfer, and insurance responsibilities when sourcing from international suppliers. -

Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is essential for managing inventory and ensuring that operations continue smoothly without interruptions. -

Bulk Pricing

Bulk pricing refers to reduced rates offered when purchasing large quantities. Negotiating bulk pricing can significantly lower costs for businesses, making it an important consideration for B2B buyers looking to optimize their budgets.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing bottle brush wire, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the bottle brush wire Sector

What Are the Current Market Dynamics and Key Trends Affecting the Bottle Brush Wire Sector?

The bottle brush wire sector is experiencing significant growth driven by several global factors. The increasing demand for cleaning tools across various industries—such as automotive, food and beverage, and healthcare—has prompted manufacturers to diversify their product offerings. In regions like Africa, South America, the Middle East, and Europe, the rise of e-commerce platforms has also facilitated greater access to a wider range of products. These platforms enable international B2B buyers to source products more efficiently, with options for bulk purchasing and customized solutions.

Emerging technologies, such as automation in manufacturing processes, are reshaping the supply chain dynamics. Companies are leveraging data analytics to forecast demand, streamline inventory management, and enhance customer engagement. For instance, the integration of AI-driven tools allows suppliers to optimize their production lines, ensuring timely delivery and reduced costs. Additionally, the move towards digital marketplaces is fostering competition, driving prices down, and improving service offerings, which is particularly beneficial for buyers in price-sensitive markets.

Illustrative image related to bottle brush wire

As sustainability becomes a focal point in business operations, manufacturers are increasingly adopting eco-friendly practices. This trend is particularly pronounced in Europe and North America, where regulations on waste management and sustainability are stringent. Consequently, B2B buyers are encouraged to consider suppliers that prioritize environmentally responsible manufacturing processes and materials.

How Important Is Sustainability and Ethical Sourcing in the Bottle Brush Wire Sector?

Sustainability and ethical sourcing have become paramount in the bottle brush wire sector, influencing purchasing decisions among B2B buyers. The environmental impact of cleaning products, including the materials used in brushes, has garnered attention. For instance, brushes made from biodegradable and recycled materials are gaining traction, aligning with global sustainability goals and reducing plastic waste.

Ethical supply chains are also critical, as buyers increasingly demand transparency regarding the sourcing of materials. Certifications such as Fair Trade and organic labeling are now sought after, providing assurance that products are produced under ethical labor conditions. Suppliers who can demonstrate compliance with these standards are likely to gain a competitive edge, especially in markets sensitive to corporate social responsibility.

Moreover, the shift towards ‘green’ materials is evident, with manufacturers exploring alternatives like natural fibers and recyclable metals. This not only addresses consumer concerns about the environmental footprint but also opens up new market opportunities in regions prioritizing eco-friendly products.

How Has the Bottle Brush Wire Sector Evolved Over Time?

The evolution of the bottle brush wire sector reflects broader trends in manufacturing and consumer behavior. Initially, wire brushes were primarily used in industrial applications, but as consumer awareness about hygiene and cleanliness increased, their use expanded into household products. This shift spurred innovation, leading to the development of specialized brushes that cater to specific cleaning needs, such as those for narrow vases or intricate machinery.

Over the years, the introduction of diverse materials—including stainless steel, brass, and natural fibers—has enhanced the functionality and durability of these brushes. Additionally, the rise of e-commerce has transformed the way buyers access these products, allowing for greater customization and flexibility in ordering. As the sector continues to evolve, it remains crucial for B2B buyers to stay informed about market dynamics, sourcing trends, and the importance of sustainability in their purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle brush wire

-

How do I choose the right material for bottle brush wire?

When selecting the right material for bottle brush wire, consider the application and cleaning requirements. Common materials include brass, stainless steel, and high carbon steel. Brass is corrosion-resistant and ideal for delicate surfaces, while stainless steel offers durability and resistance to rust, making it suitable for heavy-duty applications. High carbon steel is best for aggressive cleaning tasks. Evaluate the environmental conditions and the type of residue to be cleaned to make an informed decision. -

What are the common applications for bottle brush wire?

Bottle brush wires are versatile tools used in various industries. They are commonly employed in cleaning narrow tubes, bottles, valves, and intricate machinery parts. Industries such as automotive, food and beverage, pharmaceuticals, and manufacturing utilize these brushes for maintenance and cleaning of equipment. Understanding your specific cleaning needs will help you identify the most suitable brush type and material. -

What are the minimum order quantities (MOQs) for bottle brush wire?

Minimum order quantities for bottle brush wire can vary widely by supplier and location. Typically, MOQs range from as low as 6 units to several hundred units, depending on the manufacturer’s production capabilities and the specific product type. When negotiating with suppliers, clarify your needs and inquire about potential flexibility in MOQs, especially if you’re looking to test a new product line. -

How can I ensure quality assurance when sourcing bottle brush wire?

To ensure quality assurance when sourcing bottle brush wire, request samples before placing a bulk order. Evaluate the material, bristle strength, and overall construction of the brush. Additionally, verify the supplier’s certifications and manufacturing processes. Establishing a quality control agreement that outlines acceptable standards and inspections can further safeguard the quality of your order. -

What payment terms should I expect when sourcing internationally?

Payment terms in international B2B transactions can vary significantly. Common terms include advance payment, letters of credit, or payment upon delivery. It’s crucial to discuss and negotiate these terms upfront with your supplier. Additionally, consider factors like currency exchange rates and transaction fees that may impact the total cost. Building a trustworthy relationship with suppliers can often lead to more favorable payment arrangements. -

What logistics considerations should I be aware of when importing bottle brush wire?

When importing bottle brush wire, consider logistics factors such as shipping methods, customs regulations, and lead times. Evaluate whether air freight or ocean freight is more suitable based on your budget and urgency. Familiarize yourself with the import duties and tariffs applicable to your country. Partnering with a reliable freight forwarder can streamline the process and help you navigate complex customs requirements. -

How can I vet suppliers for bottle brush wire effectively?

To effectively vet suppliers for bottle brush wire, conduct thorough research on their reputation and experience in the industry. Request references from past clients and review customer testimonials. Additionally, evaluate their production capabilities, certifications, and compliance with international standards. Visiting the supplier’s manufacturing facility, if possible, can provide valuable insights into their operational practices and product quality. -

Are customization options available for bottle brush wire?

Yes, many suppliers offer customization options for bottle brush wire. You can request specific dimensions, bristle types, and materials to meet your unique needs. Discuss your requirements with potential suppliers and inquire about their capabilities to accommodate custom orders. Keep in mind that custom products may require longer lead times and potentially higher costs, so plan accordingly.

Top 4 Bottle Brush Wire Manufacturers & Suppliers List

1. Justman – 18-Inch Metal Wire Tube Brushes

Domain: justmanbrush.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “18-Inch Metal Wire Tube Brushes”, “available_materials”: [“Brass”, “High Carbon Steel”, “Stainless Steel”], “length”: “18 inches”, “brush_diameter_options”: [“1/2 inch”, “9/16 inch”, “5/8 inch”, “3/4 inch”, “7/8 inch”, “1 inch”, “1 1/4 inch”, “1 1/2 inch”], “minimum_purchase”: 6, “price_range”: “$5.19 – $9.99”, “features”: [“Durable construction”, “Convenient loop for hanging or …

2. Mighty Market – Bottle Brush

Domain: mighty.market

Introduction: Bottle Brush – Wire Handle, Price: $9.00, Description: This brush can be used to clean the base and the neck of your bottles. Bristles twisted in wire.

3. Weiler – Power Tube Brushes

Domain: weilerabrasives.com

Registered: 1999 (26 years)

Introduction: This company, Weiler – Power Tube Brushes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. PELCO® – Pro Cleaning Brushes

Domain: tedpella.com

Registered: 1996 (29 years)

Introduction: Cleaning Brushes and Pads conform to many shapes. PELCO® Pro Cleaning Brushes are specially designed, high quality cleaning brushes made in the U.S.A. They are suitable for cleaning glassware, baths, ducts, pipes, hoses, ultrasonic cleaners, and instruments. Brushes are available for delicate and heavy cleaning tasks with sturdy polypropylene bristles, non-scratching cleaning with soft closed cell…

Strategic Sourcing Conclusion and Outlook for bottle brush wire

In navigating the complexities of sourcing bottle brush wire, it is essential to recognize the diverse applications and materials available, including brass, stainless steel, and high carbon steel. Each material offers unique benefits, catering to specific cleaning requirements across various industries, from automotive to food service. Understanding these nuances allows buyers to make informed decisions that align with their operational needs and sustainability goals.

Strategic sourcing not only enhances procurement efficiency but also fosters relationships with reliable suppliers, ensuring consistent quality and availability. As international markets, especially in Africa, South America, the Middle East, and Europe, continue to evolve, leveraging local suppliers can significantly mitigate logistical challenges and reduce costs.

Illustrative image related to bottle brush wire

Looking ahead, businesses should prioritize establishing partnerships with manufacturers who emphasize ethical production and sustainability. This approach not only addresses consumer demand for eco-friendly products but also positions companies as leaders in responsible sourcing practices. By embracing these strategies, B2B buyers can optimize their supply chains and enhance their competitive edge in the global market. Engage with trusted suppliers today to secure a robust sourcing strategy for your bottle brush wire needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to bottle brush wire