Choosing Your Boston Gear: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for boston gear

In the fast-paced world of industrial manufacturing, sourcing reliable and high-performance Boston gear components can present significant challenges for B2B buyers. With the growing demand for efficient power transmission solutions across diverse sectors, including food processing, material handling, and packaging, understanding the intricacies of Boston gear products is crucial. This guide is designed to navigate the complexities of the global market, offering insights into various types of gearing solutions such as speed reducers, gear drives, and custom-engineered options tailored to specific applications.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe—especially Saudi Arabia and Germany—seek dependable suppliers, this comprehensive resource will empower them to make informed purchasing decisions. We will delve into critical aspects such as product specifications, application versatility, supplier vetting processes, and cost considerations, ensuring that buyers can confidently identify the best solutions for their operational needs. By leveraging this guide, companies can enhance their procurement strategies and secure the performance advantages that Boston gear products are renowned for, ultimately driving operational efficiency and reliability in their respective industries.

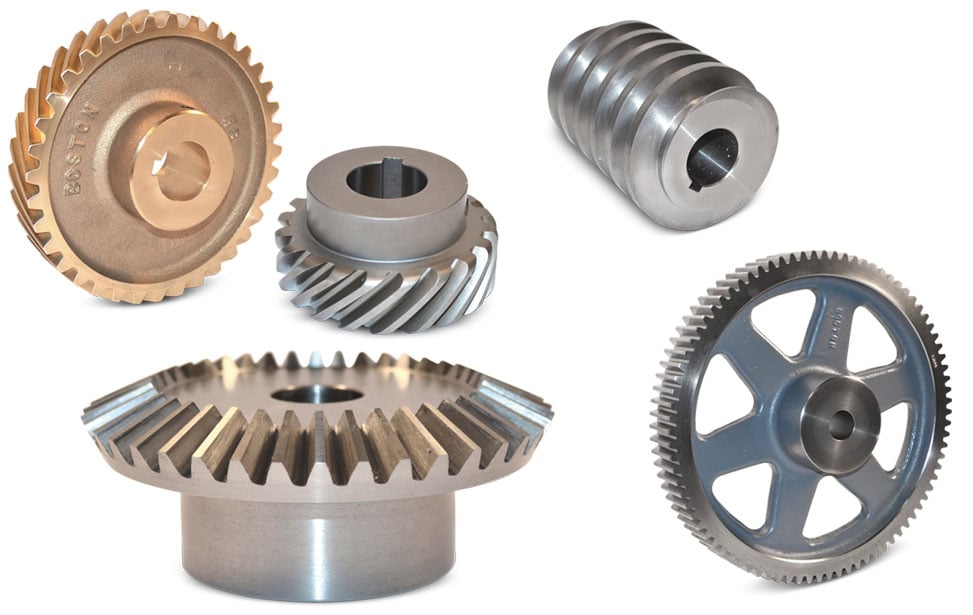

Understanding boston gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Worm Gear Reducers | High torque output, low speed ratio, compact design | Food processing, packaging, material handling | Pros: High efficiency, self-locking. Cons: Limited speed range. |

| Helical Gear Drives | Smooth operation, higher load capacity, efficient power transmission | Industrial machinery, automotive applications | Pros: Quiet operation, high efficiency. Cons: More complex design. |

| Bevel Gearboxes | Right-angle configuration, versatile mounting options | Robotics, conveyor systems, power transmission | Pros: Space-saving, adaptable. Cons: Potential for lower efficiency. |

| Planetary Gearheads | Compact design, high torque density, multiple gear stages | Aerospace, automotive, robotics | Pros: High efficiency, robust performance. Cons: Higher cost. |

| Custom Gearing Solutions | Tailored design to specific application needs | Specialized machinery, unique industrial applications | Pros: Optimized performance, flexibility. Cons: Longer lead times, potentially higher costs. |

What are the Key Characteristics of Worm Gear Reducers?

Worm gear reducers are characterized by their unique design that allows for high torque output with a low speed ratio. This makes them particularly suitable for applications requiring significant power reduction in a compact footprint. They are widely used in food processing and packaging industries due to their self-locking feature, which prevents back-driving. When purchasing, buyers should consider the operational speed and load requirements, as these reducers have a limited speed range.

How Do Helical Gear Drives Stand Out?

Helical gear drives are known for their smooth operation and higher load capacity compared to other gear types. Their design allows for efficient power transmission, making them ideal for industrial machinery and automotive applications. Buyers should evaluate the noise levels and efficiency ratings, as these gears tend to operate more quietly and efficiently than spur gears. However, the complexity of their design may lead to higher maintenance needs.

Why Choose Bevel Gearboxes for Right-Angle Applications?

Bevel gearboxes are distinct due to their ability to transmit power at right angles, offering versatile mounting options. This feature is particularly beneficial in robotics and conveyor systems where space is at a premium. Buyers should consider the application’s specific torque and speed requirements, as bevel gears may have lower efficiency compared to other types. Their adaptability and compact design make them a popular choice in various industrial settings.

What Advantages Do Planetary Gearheads Offer?

Planetary gearheads are renowned for their compact design and high torque density, making them suitable for demanding applications in aerospace and robotics. They feature multiple gear stages that enhance efficiency and provide robust performance. When considering planetary gearheads, buyers should assess the required torque and speed specifications, as well as the overall cost, which can be higher than other gear types due to their advanced engineering.

How Can Custom Gearing Solutions Benefit Specific Applications?

Custom gearing solutions are tailored to meet the unique requirements of specialized machinery and industrial applications. These solutions can optimize performance and enhance efficiency in ways that standard products may not achieve. Buyers should be aware that while custom solutions offer significant advantages, they may also involve longer lead times and potentially higher costs. Understanding the specific application needs is crucial for making informed purchasing decisions.

Key Industrial Applications of boston gear

| Industry/Sector | Specific Application of Boston Gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Speed reducers for conveyor systems | Enhanced efficiency and reliability in product handling | Compliance with food safety standards; corrosion-resistant materials |

| Material Handling | Gear drives for automated storage and retrieval systems | Improved operational efficiency and reduced downtime | Customization options for specific load capacities and configurations |

| Packaging Equipment | Gearboxes in filling and sealing machines | Increased accuracy and speed in packaging processes | Need for high torque and speed reduction ratios for heavy loads |

| Corrugating Machinery | Worm gears in corrugators | Consistent performance under heavy-duty conditions | Availability of durable, high-performance gear solutions |

| Automotive Manufacturing | Gearing solutions for assembly line machinery | Streamlined production and reduced operational costs | Technical support for integration and maintenance requirements |

How is Boston Gear Utilized in Food Processing Applications?

In the food processing industry, Boston Gear’s speed reducers are critical for conveyor systems that transport products from one stage of production to another. These reducers are designed to handle the rigorous demands of food handling, ensuring that products are moved efficiently and without contamination. For international buyers, particularly in regions with stringent food safety regulations, sourcing products that meet these standards is essential. Additionally, the use of corrosion-resistant materials in Boston Gear’s offerings enhances longevity and minimizes maintenance, making them a preferred choice in this sector.

What Role Does Boston Gear Play in Material Handling Systems?

Boston Gear’s gear drives are extensively utilized in automated storage and retrieval systems, which are vital for enhancing operational efficiency in warehouses and distribution centers. These systems rely on precise power transmission to ensure that goods are moved quickly and accurately. For businesses in Africa and South America, investing in reliable gear solutions can significantly reduce downtime and improve throughput. Buyers should consider customization options that cater to specific load capacities and configurations to optimize performance.

How Does Boston Gear Enhance Packaging Equipment Efficiency?

In the packaging industry, Boston Gear’s gearboxes are used in filling and sealing machines, where precision and speed are paramount. The ability to achieve high torque and speed reduction ratios ensures that these machines operate smoothly, enhancing productivity. For international B2B buyers, particularly in Europe and the Middle East, understanding the compatibility of these gearboxes with existing machinery is crucial. Ensuring that the selected components meet the specific operational needs can lead to significant improvements in packaging accuracy and efficiency.

What Advantages Do Boston Gear Solutions Offer in Corrugating Machinery?

Boston Gear’s worm gears are integral to the operation of corrugators, providing consistent performance in the production of corrugated materials. These gears are designed to withstand heavy-duty conditions, making them ideal for the demands of the corrugating industry. Buyers from regions with robust manufacturing sectors should prioritize sourcing durable and high-performance gear solutions to ensure uninterrupted production processes. The ability to maintain consistent quality under high stress is a critical factor for manufacturers in this field.

How Can Automotive Manufacturers Benefit from Boston Gear’s Gearing Solutions?

In automotive manufacturing, Boston Gear’s gearing solutions play a pivotal role in the operation of assembly line machinery. These components streamline production processes, thereby reducing operational costs and increasing output. For international buyers, particularly in regions like Saudi Arabia and Germany, it is essential to consider the technical support available for integrating these solutions into existing systems. Ensuring that the selected gears align with specific production requirements can lead to enhanced efficiency and reliability in automotive manufacturing operations.

3 Common User Pain Points for ‘boston gear’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Gear Drive for Unique Applications

The Problem:

B2B buyers often face the challenge of selecting the most appropriate gear drive for their specific applications, particularly when the requirements are unique or specialized. For instance, a manufacturer in the food processing sector may require a stainless steel speed reducer that can withstand corrosive environments while providing high torque. Without a clear understanding of the different types of gear drives available, such as worm, helical, or bevel gearboxes, buyers may struggle to find the right fit, leading to performance issues or even costly equipment failures.

The Solution:

To overcome this challenge, buyers should engage with Boston Gear’s technical support and application engineers early in the selection process. By providing detailed information about the application, including load requirements, environmental conditions, and space constraints, buyers can receive tailored recommendations. Additionally, leveraging Boston Gear’s extensive catalog, which includes over 30,000 standard products, can help in identifying suitable options quickly. Custom engineering services are also available for those who need a solution that deviates from standard offerings. This proactive approach ensures that the chosen gear drive not only meets operational demands but also enhances overall system efficiency.

Scenario 2: Concerns Over Product Reliability and Maintenance

The Problem:

Many B2B buyers are apprehensive about the reliability of gear systems, especially in industries where downtime can lead to significant financial losses. For example, a logistics company utilizing conveyor systems for material handling may experience frequent breakdowns if the gear drives are not robust enough to handle heavy loads over extended periods. This fear can lead to hesitation in making purchasing decisions, as buyers weigh the costs of potential maintenance and repairs against the initial investment.

The Solution:

To address reliability concerns, buyers should consider Boston Gear’s reputation for producing long-lasting and high-performance power transmission components. Engaging in thorough discussions with the sales team about warranty options and maintenance services can also provide peace of mind. Buyers should request detailed information on product testing and performance metrics to better understand the durability of selected products. Implementing a regular maintenance schedule, as recommended by Boston Gear, can further enhance reliability, ensuring that gear systems operate efficiently and that any issues are caught early, minimizing downtime.

Scenario 3: Navigating Customization and Modifications

The Problem:

B2B buyers often encounter challenges when their applications require customized gearing solutions that are not available off-the-shelf. For instance, a manufacturer may need a specific speed reducer that fits within a confined space while also providing unique torque specifications. This need for customization can lead to frustration if suppliers do not offer adequate support or if the modification process is unclear, delaying project timelines and increasing costs.

The Solution:

To streamline the customization process, buyers should leverage Boston Gear’s engineering capabilities. By initiating a dialogue with their engineering team, buyers can discuss their specific requirements and explore various options for customization, such as modifications to existing designs or entirely new solutions tailored to their needs. It’s crucial to provide comprehensive details about the application, including dimensions, load capacity, and operational environment, to facilitate effective design adjustments. Additionally, utilizing the company’s resources, such as their online configurators or design tools, can help visualize the final product and ensure alignment with operational expectations, resulting in a smoother implementation process.

Strategic Material Selection Guide for boston gear

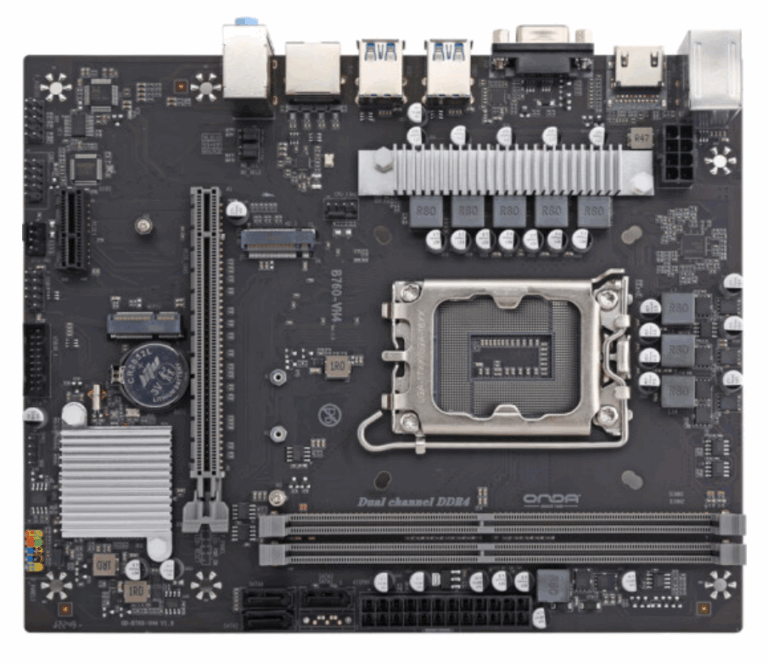

What Are the Key Materials Used in Boston Gear Products?

When selecting materials for Boston Gear products, understanding the properties and applications of various materials is crucial for ensuring optimal performance in specific environments. Below, we analyze four common materials used in Boston Gear’s offerings, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Stainless Steel Impact Performance in Boston Gear Products?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures. It typically has a temperature rating up to 800°F (427°C) and is resistant to rust and staining, making it suitable for harsh environments.

Pros & Cons: The durability of stainless steel is a significant advantage, especially in food processing and chemical applications where hygiene is paramount. However, it tends to be more expensive than other materials and can require more complex manufacturing processes, which may increase lead times.

Impact on Application: Stainless steel is particularly suitable for applications involving corrosive substances, such as in the food and beverage industry. Its compatibility with various media ensures longevity and reliability in performance.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 for stainless steel. The cost of stainless steel may vary significantly based on local market conditions, which should be factored into procurement strategies.

What Role Does Aluminum Play in Boston Gear Applications?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a temperature rating typically around 400°F (204°C). Its strength-to-weight ratio makes it an attractive choice for applications where weight savings are essential.

Pros & Cons: The primary advantage of aluminum is its low weight, which can lead to reduced shipping costs and easier installation. However, it is less durable than stainless steel and may not perform well in high-temperature applications, limiting its use in specific environments.

Impact on Application: Aluminum is ideal for applications requiring lightweight components, such as in material handling systems. Its resistance to corrosion makes it suitable for use in environments with moisture but less so in highly corrosive settings.

Considerations for International Buyers: Buyers in Africa and South America should consider local availability and pricing of aluminum, as well as compliance with international standards like ASTM B221. Understanding the specific environmental conditions of the application will be critical in material selection.

How Does Bronze Enhance Boston Gear Products?

Key Properties: Bronze is known for its excellent wear resistance and low friction properties, making it suitable for bearing applications. It can handle temperatures up to 600°F (316°C) and has good corrosion resistance, particularly against seawater.

Pros & Cons: The durability and self-lubricating properties of bronze are significant advantages, particularly in applications involving high friction. However, bronze can be more expensive than other materials and may require specialized machining techniques.

Impact on Application: Bronze is particularly effective in applications involving moving parts, such as bearings and bushings, where reduced friction is essential for performance. Its compatibility with various lubricants enhances its functionality.

Illustrative image related to boston gear

Considerations for International Buyers: Buyers from regions like Saudi Arabia and Germany should ensure compliance with relevant standards such as ASTM B505. The availability and cost of bronze can vary, impacting project budgets.

What Advantages Does Plastic Offer in Boston Gear Products?

Key Properties: Engineering plastics, such as nylon and acetal, are lightweight and have good chemical resistance. They can typically withstand temperatures up to 200°F (93°C) and are non-corrosive, making them suitable for various applications.

Pros & Cons: The primary advantage of plastic components is their low weight and cost-effectiveness. However, they may not withstand high loads or temperatures as well as metals, which limits their application scope.

Impact on Application: Plastic is ideal for applications where weight savings are critical, such as in small machinery or consumer products. Their chemical resistance makes them suitable for various environments, but they may not be appropriate for heavy-duty applications.

Considerations for International Buyers: Buyers should be aware of the specific chemical compatibility of the plastic used in their applications, especially in industries like food processing. Compliance with standards such as FDA regulations for food contact materials is essential.

Illustrative image related to boston gear

Summary Table of Material Selection for Boston Gear Products

| Material | Typical Use Case for Boston Gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical applications | High corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Material handling, lightweight systems | Lightweight and cost-effective | Less durable than stainless steel | Medium |

| Bronze | Bearings, bushings | Excellent wear resistance | Higher cost and specialized machining | High |

| Plastic | Small machinery, consumer products | Lightweight and cost-effective | Limited load and temperature capacity | Low |

This guide provides a comprehensive overview of material selection for Boston Gear products, equipping international B2B buyers with the insights needed to make informed decisions tailored to their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for boston gear

What Are the Key Stages in Boston Gear’s Manufacturing Process?

Boston Gear employs a meticulous manufacturing process that ensures high-quality power transmission products. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing journey begins with the selection of high-grade materials, such as stainless steel and specialized alloys. This choice is crucial, particularly for products like the SS700 series, which are designed to withstand harsh environments. Materials undergo rigorous testing to confirm their properties, ensuring they meet the necessary specifications before advancing to the next stage.

-

Forming: This stage involves various techniques such as machining, forging, and casting to create the desired shapes and components. Advanced CNC (Computer Numerical Control) machines are utilized for precision cutting and shaping, allowing for tight tolerances essential in gear manufacturing. The use of automated processes enhances consistency and reduces human error, which is vital for maintaining product integrity.

-

Assembly: The assembly process is where individual components come together to form complete gear systems. Skilled technicians utilize specialized tools and fixtures to ensure that each part is correctly aligned and securely fitted. This stage often incorporates automated systems for efficiency, particularly in high-volume production runs. Each assembly undergoes preliminary inspections to catch any potential issues early in the process.

-

Finishing: The final stage includes surface treatments, coating, and testing to enhance durability and performance. Techniques such as anodizing, painting, or applying corrosion-resistant finishes are common. Additionally, products are subjected to functional tests to ensure they meet performance standards. This thorough finishing process is essential, especially for applications in the food and beverage industry, where hygiene and resistance to contamination are paramount.

How Does Boston Gear Ensure Quality Control in Manufacturing?

Quality assurance is integral to Boston Gear’s operations, with a structured approach to maintaining high standards throughout the manufacturing process. The company adheres to international standards such as ISO 9001, which outlines requirements for a quality management system.

-

International and Industry-Specific Standards: Compliance with ISO 9001 ensures that Boston Gear maintains consistent quality across its products. Additionally, certifications like CE mark for products sold in Europe and API standards for oil and gas applications demonstrate their commitment to industry-specific quality benchmarks.

-

Quality Checkpoints: Boston Gear implements a multi-tiered quality control system that includes several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the production process, identifying deviations before they escalate.

– Final Quality Control (FQC): Finished products undergo comprehensive testing to verify performance and durability. This includes stress testing, dimensional checks, and functional assessments. -

Common Testing Methods: The company employs various testing methodologies, including load testing, torque testing, and vibration analysis. These tests help ensure that products will perform reliably under expected operational conditions.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For B2B buyers, particularly those in international markets like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers like Boston Gear is crucial. Here are some best practices:

-

Supplier Audits: Conducting audits of the manufacturing facility can provide insights into the quality control processes in place. Buyers should look for evidence of adherence to ISO standards and other relevant certifications. Audits can help identify any potential gaps in quality assurance that could impact product reliability.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline testing procedures, results, and any corrective actions taken. These documents can demonstrate a supplier’s commitment to quality and transparency.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly important for international buyers who may not have the capacity to conduct on-site inspections.

-

Understanding QC/CERT Nuances: Different regions may have specific quality certifications that are recognized locally. For instance, in Germany, compliance with the German Institute for Standardization (DIN) may be important, while in Saudi Arabia, local standards may apply. B2B buyers should familiarize themselves with these nuances to ensure their suppliers meet local requirements.

How Does Boston Gear’s Commitment to Innovation Impact Quality Assurance?

Boston Gear’s emphasis on innovation plays a significant role in enhancing quality assurance. The company invests in research and development to improve existing products and develop new solutions. This commitment leads to the incorporation of advanced materials and manufacturing techniques that enhance product performance and longevity.

-

Continuous Improvement: Through ongoing R&D, Boston Gear identifies opportunities to refine manufacturing processes. This can include adopting new technologies that improve efficiency and reduce waste, contributing to better overall product quality.

-

Feedback Loops: Boston Gear actively seeks feedback from clients and uses this information to inform product enhancements. By addressing customer needs and concerns, the company can adapt its quality control measures accordingly.

-

Training and Development: The company prioritizes training for its workforce, ensuring that employees are well-versed in the latest manufacturing techniques and quality standards. This investment in human capital is critical for sustaining high-quality output.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance for B2B Buyers

For international B2B buyers, understanding the manufacturing processes and quality assurance measures of suppliers like Boston Gear is essential. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, Boston Gear demonstrates its commitment to delivering reliable and high-performance power transmission products. B2B buyers should leverage audits, quality reports, and third-party inspections to ensure their suppliers uphold the highest standards of quality and performance. This due diligence not only mitigates risks but also fosters long-term partnerships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘boston gear’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring Boston Gear products, including speed reducers and other drivetrain components. By following this step-by-step checklist, buyers can ensure they make informed decisions, select the right products, and establish reliable supplier relationships.

1. Identify Your Application Requirements

Before engaging with suppliers, clearly define your application needs. Consider factors such as load capacity, speed reduction ratios, and environmental conditions. This information will guide your selection process and ensure that the products you choose will perform effectively in your specific context.

2. Define Your Technical Specifications

Establish detailed technical specifications for the Boston Gear products you require. This includes the type of gear (e.g., worm, helical, bevel), dimensions, and material preferences. Accurate specifications help eliminate miscommunication with suppliers and reduce the risk of receiving incorrect or unsuitable products.

3. Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential suppliers that offer Boston Gear products. Look for manufacturers and distributors with a strong reputation and experience in your industry. Create a shortlist based on factors such as product range, customization options, and geographical reach, especially if you are operating in diverse markets like Africa or Europe.

4. ✅ Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications and comply with international quality standards. This is crucial for maintaining product reliability and safety, especially in sectors such as food processing and material handling. Look for certifications like ISO 9001 or industry-specific accreditations.

5. Request Product Samples and Technical Data

Before making a bulk purchase, request samples and detailed technical data sheets for the Boston Gear products you are considering. Evaluating samples allows you to assess quality and compatibility with your application. Technical data sheets provide insights into performance metrics, installation requirements, and maintenance procedures.

6. Evaluate Pricing and Payment Terms

Compare pricing structures and payment terms across shortlisted suppliers. While cost is an important factor, consider the total cost of ownership, which includes installation, maintenance, and potential downtime. Negotiate payment terms that align with your cash flow and project timelines to enhance financial planning.

7. Establish Communication Channels and Support

Finally, set up clear communication channels with your selected supplier. Ensure they provide comprehensive customer support, including technical assistance during installation and ongoing maintenance. A responsive supplier can significantly impact the success of your projects by addressing issues promptly and effectively.

By following this checklist, B2B buyers can streamline their sourcing process for Boston Gear products, ensuring they meet their operational needs while fostering strong supplier partnerships.

Comprehensive Cost and Pricing Analysis for boston gear Sourcing

What Are the Key Cost Components for Sourcing Boston Gear Products?

When evaluating the cost structure for sourcing Boston Gear products, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts costs. Boston Gear utilizes high-quality materials such as stainless steel for its speed reducers, especially in food and beverage applications, which can increase the base cost.

-

Labor: Labor costs vary based on the complexity of the product. Custom solutions may require specialized labor, which can inflate the overall price.

-

Manufacturing Overhead: This includes expenses related to factory operations that are not directly tied to production, such as utilities and facility maintenance. A well-optimized manufacturing process can help mitigate these costs.

-

Tooling: For custom or specialized products, tooling costs can be substantial. Initial investments in tooling may be amortized over larger production runs, influencing unit costs.

-

Quality Control: Ensuring that products meet industry standards involves costs related to testing and certification. Boston Gear’s commitment to high-quality standards means that these expenses are factored into the pricing.

-

Logistics: Shipping and handling costs can vary based on the destination. For international buyers, understanding Incoterms and logistics arrangements is crucial for accurate cost estimation.

-

Margin: Manufacturers typically apply a profit margin over the total cost of production. This margin can vary based on market conditions and competitive positioning.

How Do Pricing Influencers Affect Boston Gear Product Costs?

Several factors influence the pricing of Boston Gear products, particularly for B2B buyers in international markets:

Illustrative image related to boston gear

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Understanding MOQ requirements can help buyers strategize their purchasing.

-

Specifications and Customization: Custom engineering services can lead to increased costs. Buyers should balance their need for customization against the potential for higher pricing.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or FDA compliance) can raise costs but may be necessary for specific applications, especially in regulated industries.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers with a track record of quality may command higher prices, but they often provide better assurance of product performance.

-

Incoterms: The choice of Incoterms affects the overall cost of acquisition. Buyers should understand who bears the responsibility for shipping, insurance, and tariffs, as these factors impact total expenses.

What Tips Can Help International Buyers Optimize Costs?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, optimizing costs involves strategic negotiation and understanding pricing nuances:

-

Negotiation: Engage suppliers in discussions about pricing flexibility, especially for larger orders. Leveraging long-term relationships can yield better pricing and terms.

-

Cost-Efficiency Analysis: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also operational costs like maintenance, downtime, and energy consumption over the product’s lifespan.

-

Understand Local Market Dynamics: Pricing can vary significantly based on local market conditions. Researching regional supply chains and competitive pricing will provide leverage during negotiations.

-

Shipping and Import Duties: For international buyers, understanding shipping costs and potential import duties is essential. Seek suppliers who can offer competitive logistics solutions.

-

Stay Informed on Currency Fluctuations: Currency exchange rates can affect pricing for international transactions. Keeping an eye on these fluctuations can help in budgeting and negotiating prices.

Disclaimer for Indicative Prices

It is essential to note that pricing for Boston Gear products can vary widely based on the aforementioned factors. Buyers are encouraged to request quotes directly from suppliers for the most accurate and up-to-date pricing information tailored to their specific needs.

Alternatives Analysis: Comparing boston gear With Other Solutions

Understanding the Importance of Comparing Alternatives in Power Transmission Solutions

In the competitive landscape of power transmission solutions, it’s crucial for B2B buyers to evaluate various options to find the most suitable products for their specific applications. Boston Gear has established itself as a leader in manufacturing reliable speed reducers and drivetrain components. However, it’s beneficial to compare its offerings with alternative solutions to make informed purchasing decisions. This section provides a comparative analysis of Boston Gear against two notable alternatives: DieQua Corporation and Vortex Speed Reducers.

Comparison Table

| Comparison Aspect | Boston Gear | DieQua Corporation | Vortex Speed Reducers |

|---|---|---|---|

| Performance | High efficiency, durable designs | Excellent torque and speed ratio | Compact, lightweight designs |

| Cost | Moderate to high pricing | Competitive pricing | Affordable options available |

| Ease of Implementation | Requires technical expertise | User-friendly installation | Simple integration |

| Maintenance | Low maintenance with support | Requires periodic checks | Minimal upkeep required |

| Best Use Case | Heavy-duty applications in food and beverage | Custom applications in industrial settings | Light to medium-duty applications |

Detailed Breakdown of Alternatives

DieQua Corporation

DieQua Corporation offers a diverse range of power transmission products, including speed reducers and gearboxes. Known for their robust performance, DieQua products excel in applications requiring high torque and speed reduction ratios. Their competitive pricing makes them an attractive option for businesses aiming to minimize costs without compromising quality. However, DieQua may require periodic maintenance checks, which could add to operational downtime. Overall, DieQua is best suited for custom applications in industrial settings where performance is paramount.

Vortex Speed Reducers

Vortex Speed Reducers are recognized for their compact and lightweight designs, making them ideal for applications where space is a constraint. They are cost-effective, providing affordable options for businesses that need reliable power transmission solutions without a hefty price tag. The ease of installation and minimal maintenance required are significant advantages for companies looking to streamline operations. However, Vortex may not provide the same level of performance in heavy-duty applications as Boston Gear or DieQua, making it more suitable for light to medium-duty tasks.

Conclusion: How to Choose the Right Power Transmission Solution

When selecting a power transmission solution, B2B buyers should assess their specific needs, including application type, budget constraints, and required performance levels. Boston Gear excels in heavy-duty applications with a focus on durability and reliability, while DieQua offers a balance of performance and cost-effectiveness for industrial environments. Vortex, on the other hand, is ideal for businesses seeking compact, budget-friendly solutions for lighter applications. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational requirements and strategic goals.

Essential Technical Properties and Trade Terminology for boston gear

What Are the Essential Technical Properties of Boston Gear Products?

When considering Boston Gear products, it’s crucial to understand specific technical properties that can impact their performance and suitability for various applications. Here are some critical specifications:

Illustrative image related to boston gear

-

Material Grade

Boston Gear products are often made from high-grade materials such as stainless steel, which enhances their durability and resistance to corrosion. This is particularly important in industries like food processing, where sanitation is a priority. Selecting the right material grade ensures long-lasting performance and minimizes maintenance costs. -

Torque Rating

The torque rating indicates the maximum load the gear system can handle without failure. For B2B buyers, understanding torque ratings is essential for matching the gear to the machinery’s requirements. A mismatch can lead to equipment failure or inefficiencies, resulting in costly downtime. -

Speed Reduction Ratio

This specification denotes the ratio of input speed to output speed. A higher reduction ratio means slower output speed but increased torque. Buyers need to evaluate this ratio to ensure that the gear reducer meets the specific operational demands of their applications, such as conveyor systems or packaging machinery. -

Efficiency Rating

Efficiency ratings indicate how much input energy is converted to output energy, often expressed as a percentage. Higher efficiency translates to lower operational costs and reduced energy consumption. For B2B buyers, selecting products with high efficiency ratings is essential for improving overall productivity and sustainability. -

Dimensional Tolerances

Tolerances refer to the permissible limit or limits of variation in a physical dimension. Precise tolerances are crucial for ensuring the proper fit and function of gear assemblies. Understanding dimensional tolerances helps buyers avoid installation issues and ensures optimal performance in their specific applications.

What Are Common Trade Terms Used in the Boston Gear Industry?

Familiarity with industry terminology can significantly enhance communication and decision-making for B2B buyers. Here are some common terms associated with Boston Gear:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers as it can influence product availability and warranty considerations. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is important for buyers as it affects inventory management and cost efficiency. Knowing the MOQ can help in planning orders to avoid excess stock or shortages. -

RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers requesting a price quote for specific products. For B2B buyers, submitting an RFQ allows for comparative analysis of pricing and terms, facilitating better negotiation and purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. They are crucial for international transactions, as they clarify who is responsible for shipping, insurance, and tariffs. Understanding these terms helps buyers avoid unexpected costs and delays. -

Lead Time

Lead time is the duration between placing an order and receiving the goods. Knowing the lead time is essential for supply chain management, enabling buyers to plan their production schedules and inventory levels effectively. -

Customization Options

Customization refers to the ability to modify standard products to meet specific customer requirements. For B2B buyers, understanding available customization options can lead to tailored solutions that enhance operational efficiency and address unique challenges.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing Boston Gear products, ensuring they align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the boston gear Sector

What Are the Key Market Dynamics and Trends in the Boston Gear Sector?

The Boston Gear sector is experiencing significant growth fueled by global drivers such as industrial automation, increasing demand for energy-efficient solutions, and advancements in manufacturing technologies. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focusing on sourcing high-performance drivetrain components that ensure reliability and efficiency. Key trends include the adoption of smart manufacturing techniques, the integration of IoT technologies, and a shift towards customizable solutions to meet specific operational needs.

Emerging technologies, such as advanced materials and innovative design methodologies, are transforming product offerings. For example, the introduction of Boston Gear’s new SS700 series stainless steel speed reducers emphasizes durability and efficiency, catering to sectors like food processing and material handling. Buyers are also placing greater emphasis on suppliers that offer not only a vast array of standard products but also the capability for custom engineering, ensuring a tailored fit for their unique applications.

Furthermore, the market is witnessing a consolidation of suppliers, leading to enhanced partnerships and collaborative innovation. This trend allows buyers to access comprehensive support services and technical expertise, facilitating smoother procurement processes and long-term partnerships.

How Is Sustainability and Ethical Sourcing Impacting the Boston Gear Sector?

Sustainability and ethical sourcing are becoming pivotal considerations for B2B buyers in the Boston Gear sector. As global awareness of environmental issues rises, companies are increasingly required to demonstrate their commitment to sustainable practices. The environmental impact of manufacturing processes, particularly in the power transmission industry, necessitates a shift towards greener alternatives. This includes the use of eco-friendly materials and energy-efficient production techniques.

Buyers are now looking for suppliers that adhere to sustainability certifications and standards, such as ISO 14001, which focuses on effective environmental management systems. Additionally, the demand for ‘green’ products is influencing procurement decisions, with a preference for gear solutions made from recyclable materials or those that contribute to energy conservation.

Ethical supply chains are also gaining traction, as companies seek to ensure transparency and fairness in their sourcing practices. This is particularly relevant for international buyers who prioritize suppliers that engage in responsible labor practices and provide safe working conditions. Establishing a sustainable and ethical supply chain not only enhances brand reputation but also aligns with the growing consumer demand for corporate responsibility.

What Is the Historical Context of Boston Gear’s Evolution?

Founded in 1877, Boston Gear has evolved from a small manufacturing operation into a recognized leader in power transmission products. Over the years, the company has consistently adapted to changing market demands and technological advancements, solidifying its position as a trusted partner for industries ranging from food processing to material handling.

The introduction of innovative solutions, such as the stainless steel speed reducers, highlights Boston Gear’s commitment to addressing the specific needs of diverse applications while maintaining a focus on durability and efficiency. This historical adaptability, combined with a strong emphasis on customer service and technical support, has enabled Boston Gear to build lasting relationships with B2B buyers across the globe. As the market continues to evolve, Boston Gear remains poised to meet the challenges of modern manufacturing with an extensive product lineup and custom engineering capabilities.

Frequently Asked Questions (FAQs) for B2B Buyers of boston gear

-

How do I solve compatibility issues with Boston Gear products in my machinery?

To address compatibility issues with Boston Gear products, begin by reviewing the specifications of both the machinery and the gear components. Consult Boston Gear’s engineering support for insights on the best fit for your application, including torque requirements and mounting configurations. Additionally, consider custom engineering solutions if standard products do not meet your needs. Engaging with an authorized distributor can provide further assistance in ensuring compatibility and optimal performance in your specific application. -

What is the best type of speed reducer for heavy-duty applications?

For heavy-duty applications, worm gear speed reducers are often recommended due to their high torque capabilities and efficiency in power transmission. Boston Gear offers a range of robust options, including their stainless steel SS700 series, which is designed to withstand harsh environments. It’s essential to consider factors such as load requirements, speed reduction ratios, and environmental conditions when selecting the best speed reducer. Consulting with Boston Gear’s technical support can help you identify the ideal solution for your specific application. -

What customization options are available for Boston Gear products?

Boston Gear provides extensive customization options, including tailored designs for specific applications, modifications to stock gears for mounting flexibility, and custom speed reducers. Their engineering team is experienced in developing unique solutions that meet precise operational requirements. To initiate a customization request, contact their customer service or your local authorized distributor, and be prepared to provide detailed specifications and application information to facilitate the design process. -

What are the minimum order quantities (MOQs) for Boston Gear products?

Minimum order quantities (MOQs) for Boston Gear products can vary depending on the specific item and its customization level. Standard products may have lower MOQs, while custom-engineered solutions typically require larger orders. It’s advisable to reach out to Boston Gear directly or consult with an authorized distributor to understand the specific MOQs for the products you are interested in. This will help you plan your procurement process more effectively. -

What payment terms does Boston Gear offer for international buyers?

Boston Gear typically offers flexible payment terms for international buyers, which may include options like letters of credit, wire transfers, or payment upon delivery. The specific terms can vary based on the buyer’s location and order size. To obtain the most accurate and relevant information regarding payment terms, it’s best to engage directly with Boston Gear’s sales representatives or your distributor. They can provide guidance tailored to your specific purchasing situation. -

How does Boston Gear ensure quality assurance in their products?

Boston Gear employs stringent quality assurance processes throughout their manufacturing and engineering operations. This includes rigorous testing of materials and components, adherence to industry standards, and continuous monitoring during production. For international buyers, certification documents and quality reports can often be requested to ensure that the products meet your specific quality requirements. Engaging with customer service can provide additional information on the QA processes relevant to your order. -

What logistics support does Boston Gear provide for international shipping?

Boston Gear collaborates with various logistics partners to ensure efficient and reliable shipping for international orders. They can assist with documentation, customs clearance, and shipping options to minimize delays. When placing an order, it’s beneficial to discuss logistics requirements with your sales representative to ensure that all necessary arrangements are in place. This proactive approach helps facilitate smoother delivery, especially for time-sensitive projects. -

How can I find an authorized distributor of Boston Gear products in my region?

To locate an authorized distributor of Boston Gear products in your region, visit the official Boston Gear website or contact their customer service for recommendations. Many distributors are equipped to provide local support, product availability, and technical assistance. Additionally, they can often facilitate the procurement of customized solutions to meet your specific needs, making them valuable partners in your sourcing efforts.

Top 6 Boston Gear Manufacturers & Suppliers List

1. Boston Gear – Gen2 SS700 Stainless Steel Speed Reducer

Domain: bostongear.com

Registered: 1997 (28 years)

Introduction: Boston Gear offers a wide range of products including Enclosed Gear Drives & Motors, Open Gearing, Bearings, Clutches, Couplings, Shaft Accessories, and PT Products. Notable products include the new Gen2 SS700 Stainless Steel Speed Reducer, which features upgrades and efficiencies while maintaining the original Domed Crown TM Design. The SS700 Series Worm Gear Speed Reducers are particularly suite…

2. Boston Gear – Key Products

Domain: altramotion.com

Registered: 2004 (21 years)

Introduction: Boston Gear offers a comprehensive array of over 30,000 standard products, including:

– Speed Reducers

– Enclosed Gear Drives

– Custom Speed Reducers

– AC/DC Motors

– DC Drives

– Centric Brand Overload Clutches

– Torque Limiters

Key product categories include:

– Bearings

– Clutches

– Couplings

– Shaft Accessories & PT Products

– Micron TRUE Planetary® Gearheads

– Open Gearing

Applications span v…

3. Boston Gear – Power Transmission Components

Domain: mrosupply.com

Registered: 1998 (27 years)

Introduction: Boston Gear is a premier resource for high-performance power transmission components with over 125 years of experience. They offer more than 30,000 standard products and custom engineering solutions. Product lines include standard enclosed gear drives, custom speed reducers, AC/DC motors, DC drives, and Centric brand overload clutches and torque limiters.

4. Boston Gear – Industrial Gearboxes & Speed Reducers

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Boston Gear In Industrial Gearboxes & Speed Reducers for sale on eBay. Related products include Lead, Ball & Roller Screws, Ball & Roller Bearings, Baldor General Purpose Industrial Electric Motors, Flexible Couplings, and VEVOR Industrial Gearboxes & Speed Reducers. Best selling items include Dayton 3GD43 Speed Reducer, Lexar Industrial MRV063 Worm Gear, Dodge Tigear-2 Speed Reducer, and Lexar In…

5. Boston Gear – Power Transmission Solutions

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Boston Gear – Power Transmission Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. PMI Supplies – RF732-20-B9-G Boston 20 oz Green Plastic Bottle

Domain: pmisupplies.com

Registered: 2016 (9 years)

Introduction: {“product_name”:”RF732-20-B9-G Boston”,”brand”:”PMI Supplies”,”model_number”:”RF732-20-B9-G”,”color”:”Green”,”size”:”20 oz”,”material”:”Plastic”,”features”:”BPA-free, dishwasher safe, reusable, lightweight”,”quantity_per_case”:”24″,”price”:”$39.99″}

Strategic Sourcing Conclusion and Outlook for boston gear

In today’s competitive landscape, strategic sourcing of Boston Gear products can significantly enhance operational efficiency and reliability for international businesses. With a robust portfolio of over 30,000 standard products, including speed reducers, gear drives, and custom-engineered solutions, Boston Gear stands out as a premier partner for sectors such as food processing, material handling, and packaging.

The ability to source high-performance power transmission components is crucial for companies aiming to optimize their production capabilities and reduce downtime. Boston Gear’s commitment to innovation, demonstrated by the introduction of advanced products like the SS700 stainless steel speed reducer, addresses the evolving needs of diverse industries, particularly in harsh environments.

As you consider sourcing options, remember that partnering with a trusted supplier like Boston Gear not only ensures quality but also provides access to tailored solutions that fit your specific applications. By leveraging their expertise and customer-centric support, you can secure a competitive edge in your market.

Looking ahead, seize the opportunity to enhance your operations by integrating Boston Gear products into your supply chain. Engage with their team to explore how their solutions can meet your unique requirements and drive your business forward in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.