Choosing Your Aircraft Cables: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for aircraft cables

In the ever-evolving landscape of aviation and related industries, sourcing high-quality aircraft cables poses a significant challenge for international B2B buyers. As a critical component in various applications—from rigging and winch lines to safety systems—understanding the nuances of aircraft cables is essential for ensuring safety and compliance. This guide serves as a comprehensive resource, addressing key aspects such as types of aircraft cables, their specific applications, supplier vetting processes, and cost considerations.

For buyers in regions like Africa, South America, the Middle East, and Europe—including emerging markets such as Brazil and Saudi Arabia—this guide empowers you to make informed purchasing decisions. It offers insights into the differences between galvanized and stainless steel cables, the importance of breaking strength ratings, and how to evaluate suppliers based on quality and compliance with international standards. By navigating the complexities of the global market for aircraft cables with this guide, you can enhance your procurement strategy, mitigate risks, and ultimately secure reliable products that meet your operational needs.

With actionable insights and expert recommendations, this resource not only demystifies the aircraft cable market but also equips you with the knowledge to optimize your sourcing efforts in a competitive global landscape.

Understanding aircraft cables Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 7×19 Galvanized Aircraft Cable | Constructed with 7 strands of wire in 19 configurations; corrosion-resistant | Winch lines, rigging, fencing | Pros: Cost-effective, good corrosion resistance. Cons: Less durable than stainless steel in marine environments. |

| 7×19 Stainless Steel Aircraft Cable | Offers higher corrosion resistance; available in Type 304 and Type 316 | Marine applications, high-moisture areas | Pros: Superior durability, excellent rust resistance. Cons: Higher cost compared to galvanized options. |

| Rotation-Resistant Wire Rope | Designed to minimize rotation during lifting; typically larger in diameter | Heavy lifting, cranes, construction | Pros: Reduces twisting, enhances safety. Cons: More expensive, requires specific handling. |

| Swaged & Compacted Wire Rope | Compact design for increased strength; swaged ends for secure fittings | Industrial lifting, rigging applications | Pros: High strength-to-weight ratio, versatile. Cons: May require specialized fittings, higher upfront cost. |

| Cable Laid Wire Rope | Constructed by twisting multiple strands together; flexible yet strong | Marine rigging, mooring lines | Pros: Flexibility, good load distribution. Cons: Can be bulkier, may require more storage space. |

What are the characteristics of 7×19 Galvanized Aircraft Cable?

The 7×19 Galvanized Aircraft Cable is a widely used general-purpose wire rope, ideal for various applications such as winch lines and rigging. Its construction features 7 strands of wire arranged in 19 configurations, providing a balance of flexibility and strength. B2B buyers should consider this option for projects where cost-effectiveness is essential, but note that while it offers decent corrosion resistance, it may not withstand harsh marine environments as effectively as stainless steel options.

When should you choose 7×19 Stainless Steel Aircraft Cable?

The 7×19 Stainless Steel Aircraft Cable is available in both Type 304 and Type 316, making it an excellent choice for applications requiring superior corrosion resistance, particularly in marine or high-moisture environments. This cable is characterized by its strength and durability, making it suitable for demanding applications like marine rigging. Although the initial investment is higher, its longevity and resistance to rust often justify the expense for B2B buyers.

What makes Rotation-Resistant Wire Rope a safe choice?

Rotation-Resistant Wire Rope is engineered to minimize twisting and rotation during lifting operations, enhancing safety and stability. Typically larger in diameter, this type of wire rope is commonly used in heavy lifting applications, such as cranes and construction. B2B purchasers should weigh the benefits of increased safety against the higher cost and specialized handling requirements that may come with this option.

How does Swaged & Compacted Wire Rope enhance performance?

Swaged & Compacted Wire Rope features a compact design that increases its strength, making it highly suitable for industrial lifting and rigging. The swaged ends provide secure fittings, ensuring reliability in high-stress applications. While it offers a high strength-to-weight ratio, B2B buyers should be prepared for potentially higher upfront costs and the need for specialized fittings.

What are the advantages of Cable Laid Wire Rope for flexibility?

Cable Laid Wire Rope is constructed by twisting multiple strands together, offering excellent flexibility while maintaining strength. This type is particularly effective in marine rigging and mooring lines. Its flexibility allows for good load distribution, but B2B buyers should consider storage space and potential bulkiness when selecting this option for their operations.

Key Industrial Applications of aircraft cables

| Industry/Sector | Specific Application of aircraft cables | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Support cables for scaffolding and temporary structures | Ensures safety and stability during building projects | Compliance with local regulations, tensile strength, and corrosion resistance |

| Marine & Offshore | Rigging for sailboats and mooring lines | Provides reliable performance in harsh marine environments | Material selection (stainless steel vs. galvanized), length and diameter specifications |

| Transportation | Suspension cables for bridges and elevated roads | Enhances structural integrity and load-bearing capacity | Sourcing from certified manufacturers, adherence to safety standards |

| Agriculture | Tensioning cables for greenhouse structures | Supports crop production while maximizing space | UV resistance, weather durability, and ease of installation |

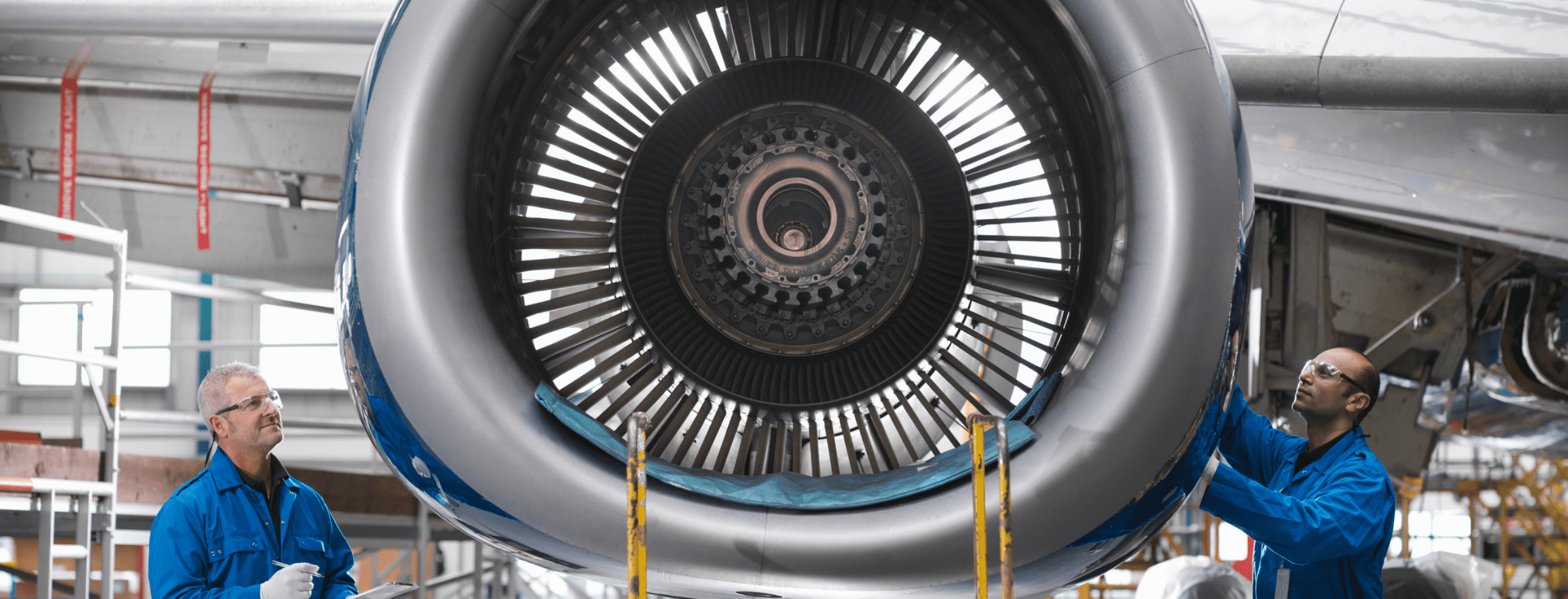

| Aviation | Non-load bearing applications in aircraft handling | Facilitates safe and efficient aircraft operations | Ensure compliance with aviation safety regulations, weight considerations |

How Are Aircraft Cables Used in Construction Projects?

In the construction industry, aircraft cables are commonly utilized as support cables for scaffolding and temporary structures. Their high tensile strength ensures that the scaffolding remains stable and secure, which is critical for worker safety. International buyers, particularly from regions like Africa and South America, should consider local regulations regarding materials used in construction to ensure compliance. They should also evaluate the cable’s corrosion resistance, especially in areas with high humidity or saline environments.

What Role Do Aircraft Cables Play in Marine and Offshore Applications?

In the marine sector, aircraft cables are essential for rigging sailboats and mooring lines. Their ability to withstand harsh marine conditions makes them a reliable choice for securing vessels. Buyers from the Middle East, where marine activities are prevalent, should prioritize materials that offer excellent corrosion resistance, such as stainless steel. Additionally, they must consider the specific lengths and diameters required for their applications to ensure optimal performance.

How Are Aircraft Cables Beneficial for Transportation Infrastructure?

Transportation infrastructure, particularly in the construction of bridges and elevated roads, benefits from the use of aircraft cables as suspension cables. These cables enhance the structural integrity and load-bearing capacity of the infrastructure, ensuring safety for users. For European buyers involved in large-scale transport projects, sourcing from certified manufacturers is crucial to adhere to safety standards. They should also consider the cable’s tensile strength and durability against environmental factors.

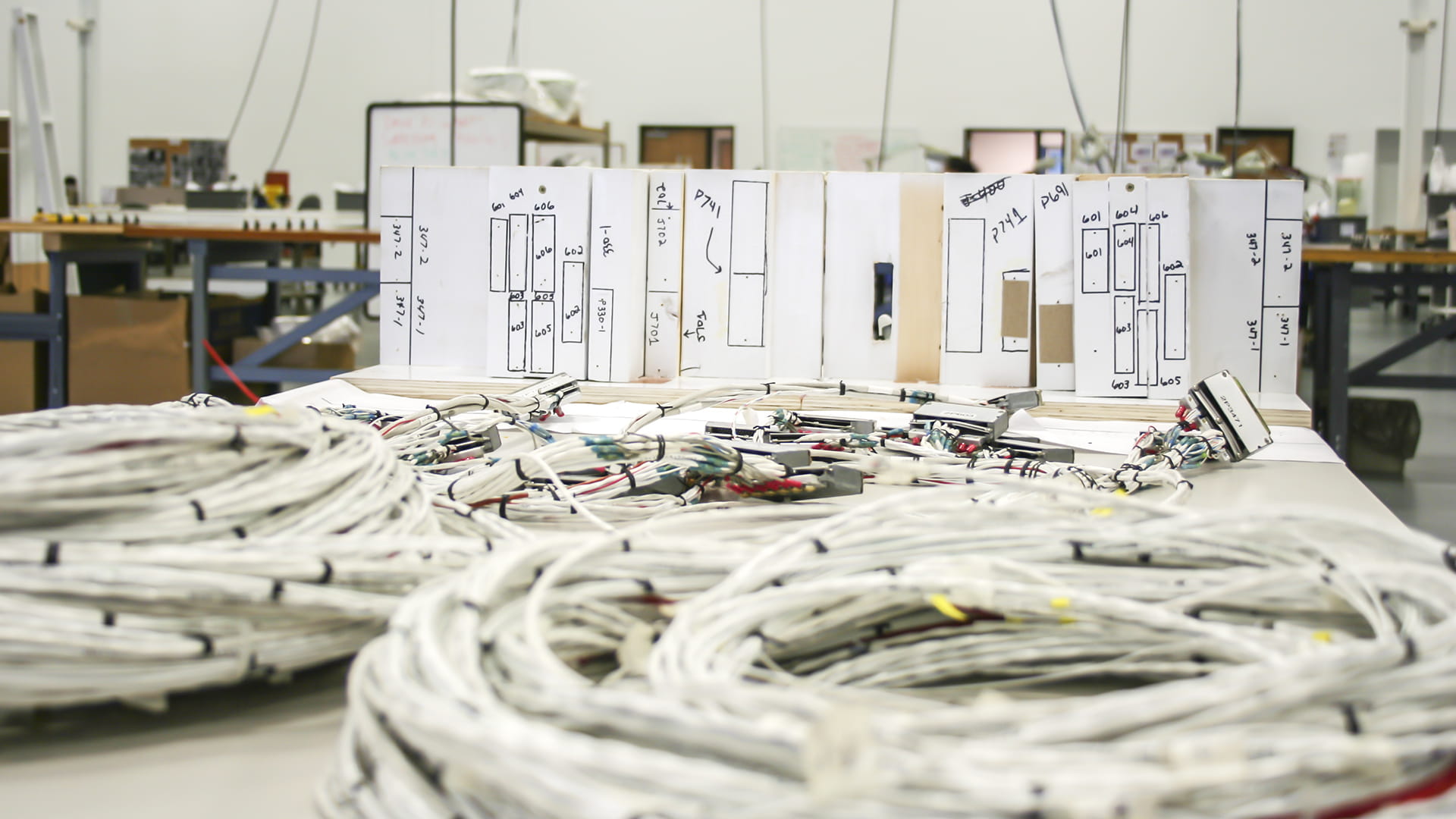

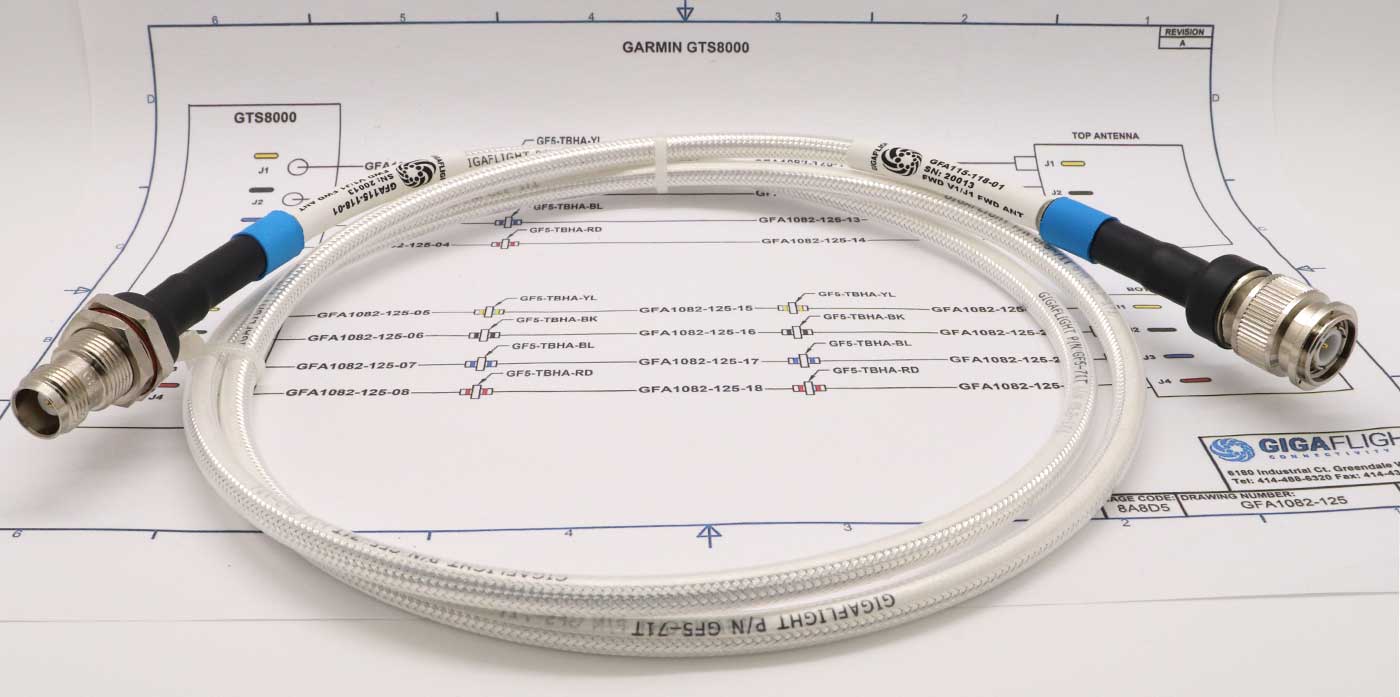

Illustrative image related to aircraft cables

How Do Aircraft Cables Support Agricultural Operations?

In agriculture, aircraft cables serve as tensioning cables for greenhouse structures, allowing for better crop production while maximizing available space. They help maintain the integrity of the structure against wind and other environmental stresses. Buyers from regions like South America should focus on cables with UV resistance and weather durability to ensure long-lasting performance in diverse climates. Ease of installation is another key consideration for agricultural applications.

What Are the Non-Load Bearing Uses of Aircraft Cables in Aviation?

In the aviation sector, aircraft cables are often used for non-load bearing applications, such as in aircraft handling and ground support systems. They facilitate safe and efficient operations, contributing to the overall safety of flight operations. Buyers in this industry need to ensure that the cables comply with aviation safety regulations and take into account weight considerations to avoid impacting aircraft performance.

3 Common User Pain Points for ‘aircraft cables’ & Their Solutions

Scenario 1: Ensuring Compliance with Industry Standards

The Problem: B2B buyers in the aviation and transportation sectors often face challenges ensuring that their aircraft cables meet specific industry standards. Regulations can vary significantly between regions, and non-compliance can lead to serious safety hazards and financial penalties. For example, an international buyer might be unsure if the cables sourced from a particular supplier meet the ASTM A1023 standards or federal specifications, especially when sourcing from different countries like Brazil or Saudi Arabia.

The Solution: To overcome this compliance challenge, buyers should prioritize suppliers who provide clear documentation of their products’ certifications and compliance with relevant standards. Before making a purchase, request detailed specifications, including test results and certification documents, to verify compliance with industry standards such as RR-W-410. Additionally, establishing a relationship with reputable manufacturers or suppliers who are well-versed in the local regulations of the regions they operate in can help ensure that the products are compliant. Regular training for procurement teams on the latest standards and regulations can further mitigate risks associated with non-compliance.

Scenario 2: Selecting the Right Material for Diverse Environments

The Problem: Another common pain point for B2B buyers is the difficulty in selecting the appropriate material for aircraft cables that will be used in various environmental conditions. For instance, cables used in high-moisture environments, such as coastal areas in South America, require different properties than those used in dry, arid regions of the Middle East. Many buyers may struggle to understand the differences between galvanized and stainless steel cables and the implications of these choices on durability and performance.

The Solution: To ensure the right material is selected, buyers should conduct a thorough analysis of the environmental conditions in which the aircraft cables will be utilized. For marine or high-humidity environments, stainless steel, particularly Type 316, is recommended due to its superior corrosion resistance. In contrast, galvanized cables may suffice in less demanding conditions but may not perform well in high-moisture scenarios. Buyers can benefit from consulting with materials experts or utilizing detailed product guides that outline the advantages and limitations of each type of cable. Furthermore, conducting field tests and pilot projects can provide insights into the performance of different materials before committing to large-scale purchases.

Scenario 3: Managing Supply Chain Disruptions

The Problem: B2B buyers are often confronted with supply chain disruptions that can lead to delays in the procurement of essential components like aircraft cables. Geopolitical issues, transportation challenges, and unexpected demand spikes can create uncertainty in the availability of specific cable types. For instance, a buyer in Europe might experience a delay in receiving a critical shipment of aircraft cables due to port congestion or regulatory changes impacting import processes.

The Solution: To mitigate supply chain risks, it is essential for buyers to develop a diversified sourcing strategy. This includes establishing relationships with multiple suppliers across different regions to create a safety net against potential disruptions. Implementing inventory management systems that allow for real-time tracking of stock levels and lead times can also help in anticipating shortages. Buyers should also consider keeping a buffer stock of high-demand cables and regularly reviewing and updating their procurement strategies based on market trends and geopolitical developments. Engaging with logistics partners who have a deep understanding of international trade can further streamline the import process and reduce the impact of unforeseen supply chain issues.

Strategic Material Selection Guide for aircraft cables

What Are the Key Materials Used in Aircraft Cables?

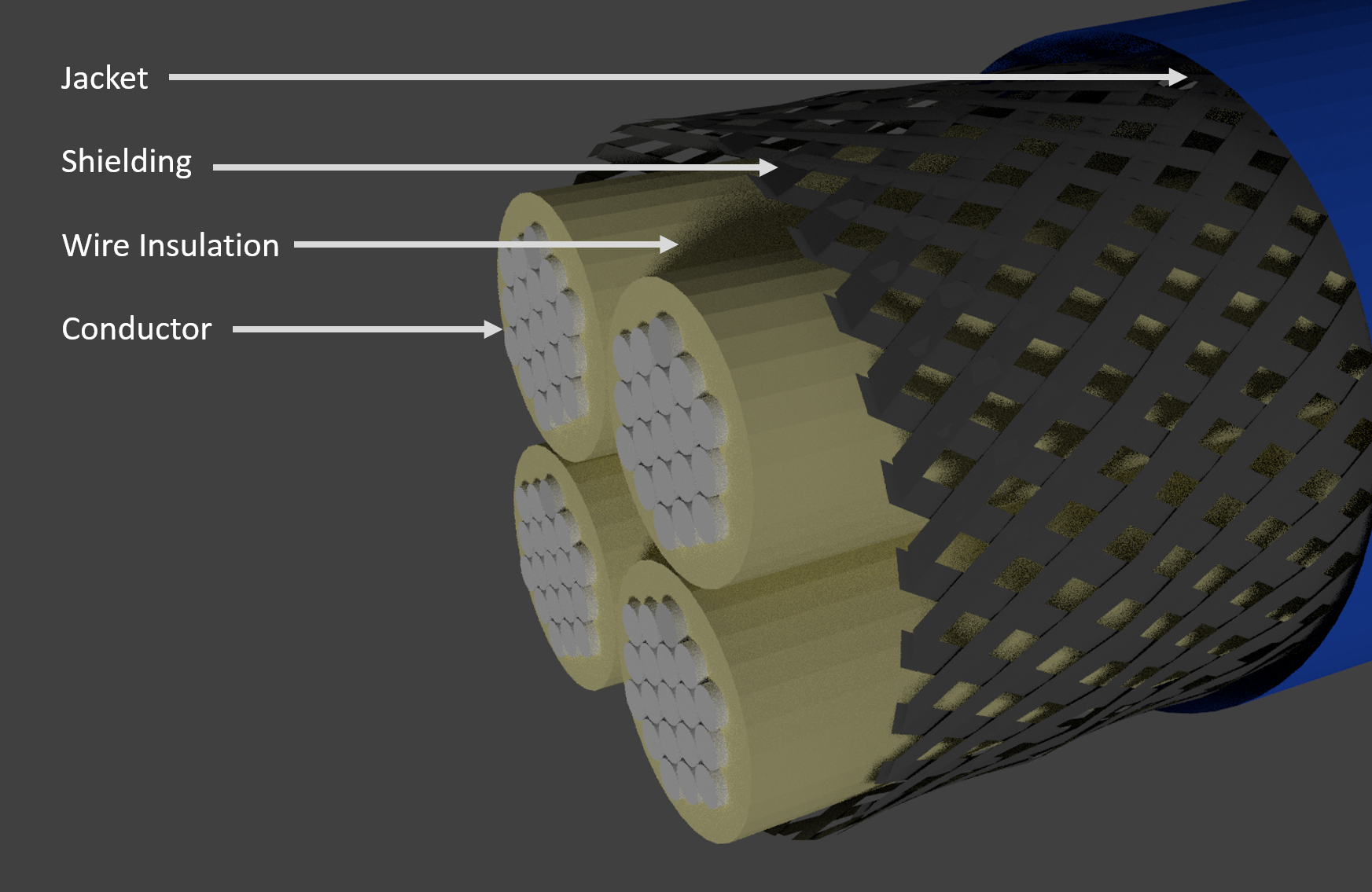

Selecting the right material for aircraft cables is critical for ensuring safety, performance, and compliance with international standards. Below are analyses of four common materials used in aircraft cables, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Stainless Steel Enhance Aircraft Cable Performance?

Key Properties: Stainless steel aircraft cables, particularly those made from Type 304 and Type 316, offer excellent corrosion resistance, high tensile strength, and good temperature tolerance. Type 316, which contains molybdenum, is particularly suited for marine environments due to its superior resistance to rust.

Pros & Cons: The primary advantage of stainless steel is its durability and long lifespan, making it ideal for applications exposed to harsh conditions. However, it is more expensive than other materials, which can be a consideration for budget-conscious buyers. Additionally, manufacturing processes can be complex, requiring specialized equipment.

Impact on Application: Stainless steel cables are particularly suitable for environments with high moisture or corrosive elements, such as coastal regions or industrial settings. They are often used in applications requiring high strength and reliability, such as rigging and suspension systems.

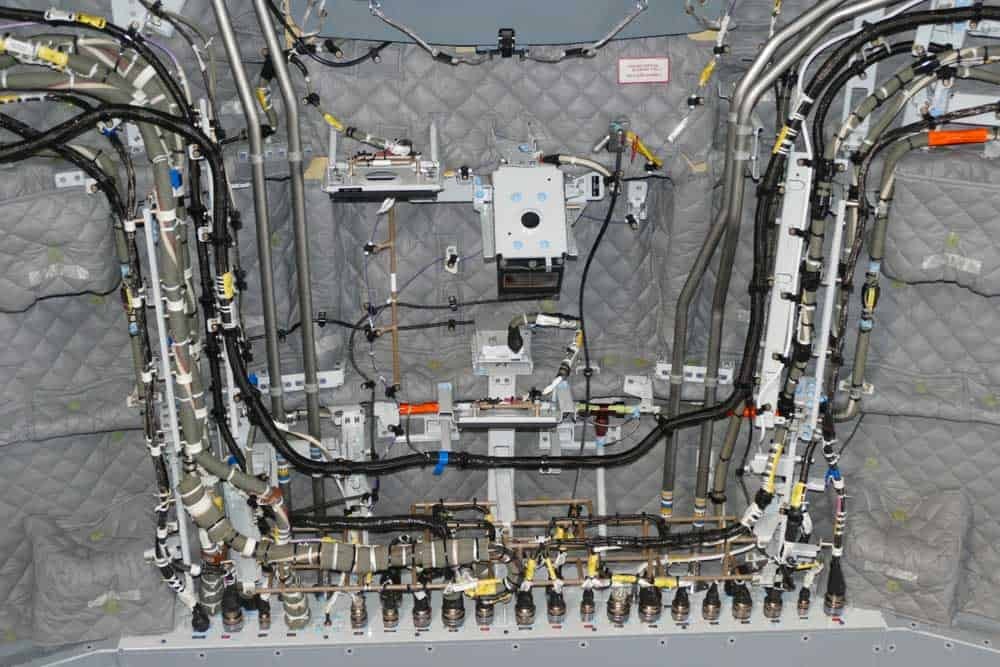

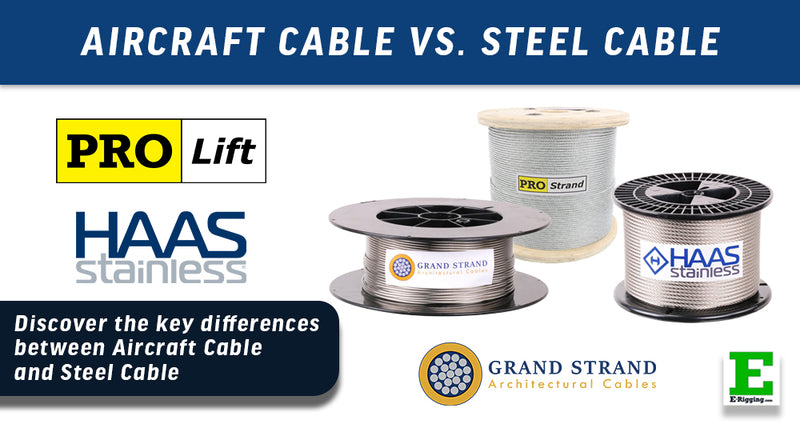

Illustrative image related to aircraft cables

Considerations for International Buyers: Compliance with international standards such as ASTM A313 and DIN 3060 is essential. Buyers from regions like the Middle East and Europe should ensure that the stainless steel grades meet local regulations and preferences for corrosion resistance.

What Advantages Do Galvanized Steel Aircraft Cables Offer?

Key Properties: Galvanized steel cables are coated with zinc to enhance corrosion resistance. They typically exhibit good strength and flexibility, making them suitable for various applications.

Pros & Cons: The main advantage of galvanized cables is their cost-effectiveness compared to stainless steel. They perform well in moderate environments but may not withstand extreme conditions as effectively. The zinc coating can wear off over time, leading to potential corrosion issues.

Impact on Application: These cables are commonly used in construction, agriculture, and general rigging applications where cost is a significant factor. However, they may not be suitable for marine environments or areas with high humidity.

Illustrative image related to aircraft cables

Considerations for International Buyers: Buyers should check for compliance with ASTM A475 standards and consider the specific environmental conditions of their location. For example, regions like South America may have varying humidity levels that could affect the longevity of galvanized cables.

How Do Vinyl-Coated Aircraft Cables Perform?

Key Properties: Vinyl-coated aircraft cables are typically made from galvanized or stainless steel and are covered with a layer of vinyl for added protection. This coating provides additional corrosion resistance and enhances grip.

Pros & Cons: The vinyl coating offers improved aesthetics and reduces wear on surfaces that the cable may contact. However, this coating can be susceptible to damage, which might expose the underlying metal to corrosion. Additionally, the coating can add to the overall cost of the cable.

Impact on Application: Vinyl-coated cables are ideal for applications where aesthetics are important, such as railings and decorative installations. They also provide better handling characteristics, making them easier to work with.

Considerations for International Buyers: Ensure that the vinyl coating meets local standards for safety and durability. Buyers should also consider the impact of temperature fluctuations on the vinyl, particularly in regions with extreme climates like parts of Africa.

Illustrative image related to aircraft cables

What Role Does Fiber Core Play in Aircraft Cable Construction?

Key Properties: Aircraft cables with a fiber core provide additional flexibility and cushioning, which can help absorb shocks and vibrations. This construction can enhance the overall performance of the cable under dynamic loads.

Pros & Cons: The primary advantage of a fiber core is increased flexibility, making it easier to handle and install. However, fiber cores may not provide the same level of strength as steel cores and can be less durable over time.

Impact on Application: Fiber core cables are suitable for applications where flexibility is crucial, such as in winching and lifting operations. However, they may not be appropriate for high-load applications where maximum strength is required.

Illustrative image related to aircraft cables

Considerations for International Buyers: Compliance with relevant standards such as ASTM A1023 is important. Buyers should evaluate the specific requirements of their applications, particularly in regions with diverse industrial practices like Europe and the Middle East.

Summary of Material Properties for Aircraft Cables

| Material | Typical Use Case for aircraft cables | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine rigging, high-strength applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Galvanized Steel | General rigging, construction | Cost-effective and good strength | Susceptible to corrosion over time | Medium |

| Vinyl-Coated Steel | Decorative railings, handling applications | Improved aesthetics and grip | Coating can be damaged, increasing risk | Medium |

| Fiber Core | Winching, lifting operations | Enhanced flexibility | Lower strength compared to steel cores | Low |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, helping them make informed decisions based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for aircraft cables

What Are the Key Manufacturing Stages for Aircraft Cables?

The manufacturing process of aircraft cables is a complex procedure that demands precision and quality at every stage. The process typically includes material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers looking to ensure the integrity and reliability of the products they procure.

How Is Material Prepared for Aircraft Cables?

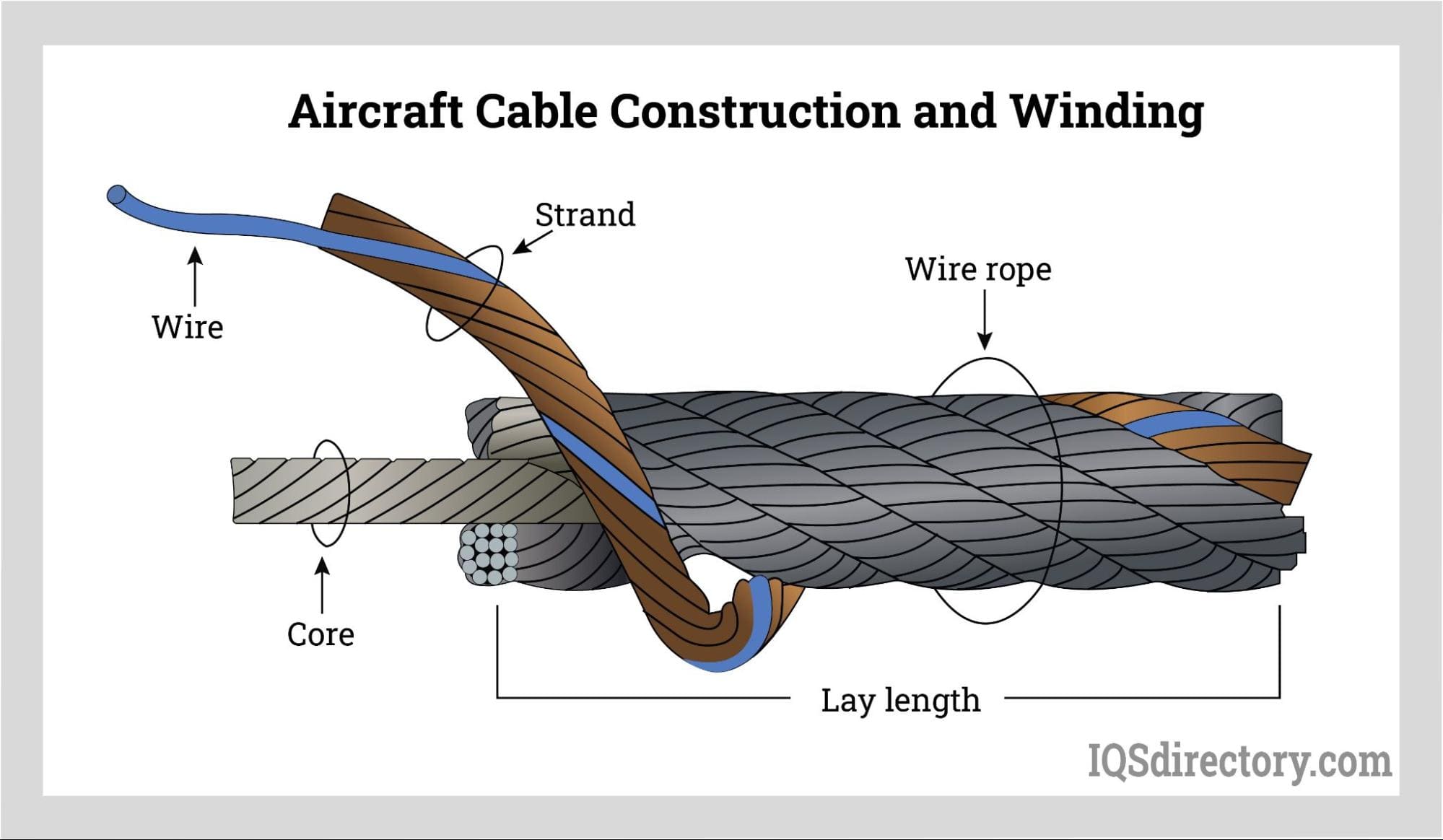

The first stage in the manufacturing process involves selecting high-quality raw materials. Aircraft cables are usually made from high-strength steel, which can be galvanized or stainless steel, depending on the intended application and environmental conditions.

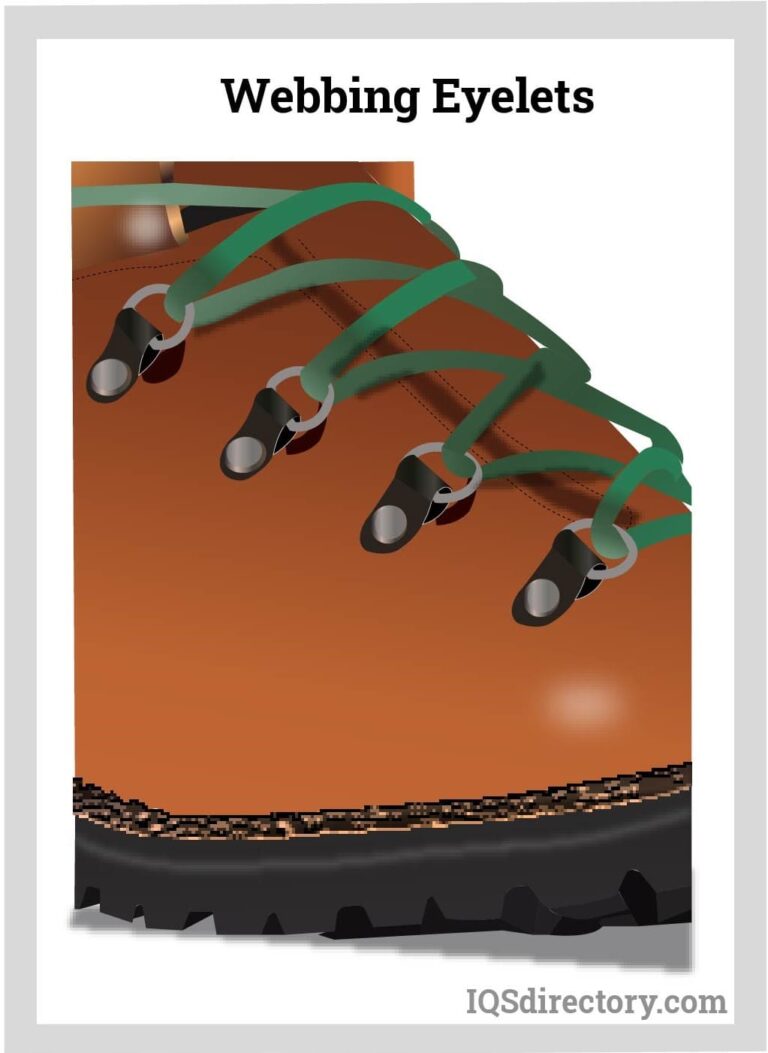

The steel is then processed to achieve the desired diameter and tensile strength. This may involve drawing the steel into thinner wires, which are then bundled together to form strands. The typical constructions include 7×19, which consists of seven outer wires twisted around a core of one wire, offering high flexibility and strength.

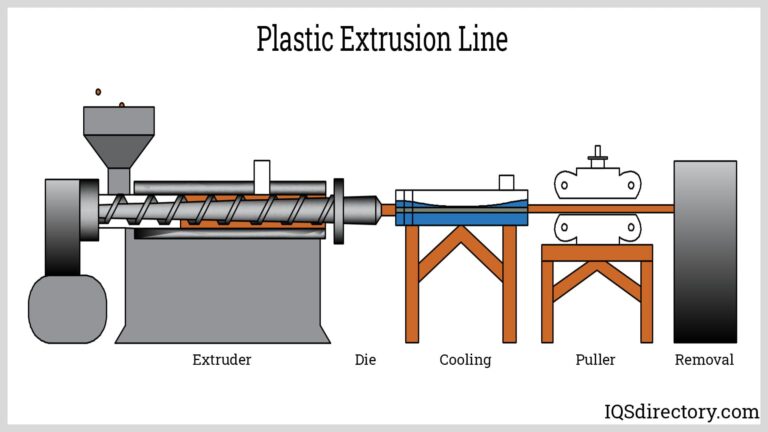

What Techniques Are Used in the Forming Stage?

Once the material is prepared, the forming stage begins. This involves twisting the strands together to create the cable. Techniques such as swaging and compacting can be employed during this stage to enhance the cable’s durability and performance.

Swaging involves compressing the wire strands to create a denser and more robust cable, while compacting arranges the wire strands in a way that reduces the cable’s overall diameter without compromising strength. This is particularly important for applications requiring lightweight and high-strength cables.

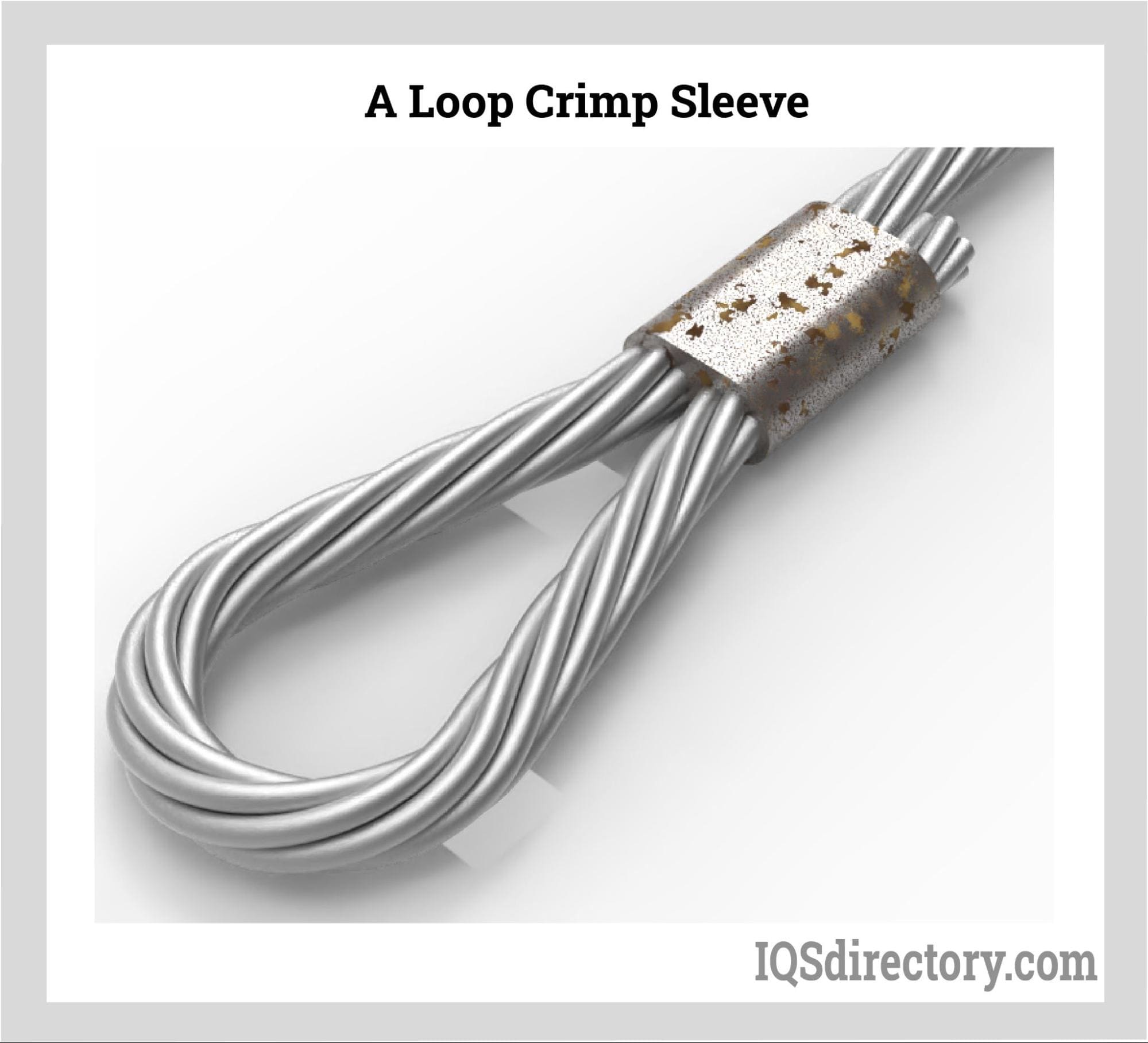

How Are Aircraft Cables Assembled and Finished?

After forming, the assembly stage combines various components, such as end fittings and connectors, to create a complete aircraft cable system. The assembly process is critical, as the integrity of the connections can significantly affect the overall performance of the cable.

Illustrative image related to aircraft cables

Finishing processes, which include coating and corrosion protection, are also crucial. Galvanization provides a protective layer against rust, while vinyl coatings can offer additional protection in specific environments. It’s essential for buyers to understand the finishing options available to select the right cable for their specific applications.

What Quality Assurance Standards Are Relevant for Aircraft Cables?

Quality assurance (QA) is paramount in the manufacturing of aircraft cables, as these components are critical for safety in aviation and other heavy-duty applications. International standards, such as ISO 9001, provide a framework for ensuring consistent quality and customer satisfaction.

In addition to general ISO standards, there are industry-specific certifications, including CE marking for products sold within the European Economic Area and API standards relevant to the oil and gas industry. These certifications indicate that the manufacturer meets stringent quality and safety requirements.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process. The primary checkpoints typically include:

-

Incoming Quality Control (IQC): This stage checks the raw materials for compliance with specifications before production begins. It ensures that only high-quality materials are used in manufacturing.

-

In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to identify and rectify any deviations from quality standards. This includes monitoring the forming and assembly processes.

-

Final Quality Control (FQC): The final product undergoes rigorous testing to ensure it meets all specifications and standards. This may include tensile strength tests, corrosion resistance evaluations, and dimensional checks.

What Testing Methods Are Commonly Used for Aircraft Cables?

B2B buyers should be aware of the various testing methods utilized to verify the quality of aircraft cables. Common testing methods include:

-

Tensile Testing: Measures the strength and ductility of the cable under stress. It ensures that the cable can withstand the forces it will encounter in real-world applications.

-

Fatigue Testing: Evaluates the cable’s performance under repeated loading cycles, which is crucial for applications involving dynamic loads.

-

Corrosion Resistance Testing: Assesses the cable’s ability to resist rust and degradation in various environments, particularly for cables intended for marine or high-moisture applications.

-

Visual Inspections: Regular inspections for any visible defects, such as fraying or corrosion, are essential to maintain safety and performance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is critical to ensure the reliability of aircraft cables. Here are some effective strategies:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and QC practices. This includes reviewing their compliance with international standards and certifications.

-

Request Quality Reports: Suppliers should provide detailed quality assurance reports that outline their processes, testing methods, and results. This transparency can help buyers assess the reliability of the supplier.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s QC practices. These inspectors can conduct audits and testing to ensure compliance with international standards.

What Are the QC and Certification Nuances for International Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, must navigate various certification nuances. Different regions may have specific regulations and standards that impact the certification of aircraft cables.

Illustrative image related to aircraft cables

For example, while CE marking is essential for European buyers, other regions may require compliance with local standards. Buyers should familiarize themselves with the certification requirements of their respective markets to ensure compliance and avoid potential legal issues.

In summary, understanding the manufacturing processes and quality assurance practices for aircraft cables is essential for B2B buyers. By focusing on the critical stages of manufacturing, relevant QC standards, and verification methods, buyers can make informed decisions and ensure they procure high-quality, reliable products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aircraft cables’

To assist B2B buyers in procuring aircraft cables effectively, this step-by-step checklist is designed to streamline the sourcing process and ensure that all critical factors are considered.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify the technical requirements of the aircraft cables you need. Consider factors such as diameter, material (galvanized vs. stainless steel), construction type (e.g., 7×19), and the specific applications (like rigging or winching) where the cables will be used. Having precise specifications will help you communicate your needs clearly to potential suppliers.

Illustrative image related to aircraft cables

Step 2: Research Regulatory Standards and Compliance

Understanding the relevant industry regulations is crucial for ensuring product safety and quality. Different regions may have specific standards, such as ASTM or ISO certifications, that aircraft cables must meet. Verify that the products adhere to these standards to avoid compliance issues that could arise during importation or use.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from previous buyers, especially those in similar markets or industries. This due diligence helps to assess the supplier’s reliability, product quality, and customer service.

Step 4: Request and Compare Quotes

Once you have a shortlist of suppliers, request detailed quotes that include pricing, delivery timelines, and payment terms. Compare these quotes not just on price, but also on the total cost of ownership, which includes shipping fees, potential duties, and the reliability of the delivery schedule. This comprehensive comparison will help you make a well-informed decision.

Illustrative image related to aircraft cables

Step 5: Confirm Quality Assurance Processes

Inquire about the quality assurance measures implemented by the suppliers. Ensure that they have robust testing procedures and certifications for their products. Look for details on how they handle defects and returns, as a reliable quality assurance process can save you from future complications.

Step 6: Negotiate Terms and Finalize Contracts

Negotiation is key to securing favorable terms. Discuss not only pricing but also delivery schedules, warranty conditions, and after-sales support. Ensure that all agreed terms are documented in a contract to protect both parties and clarify expectations.

Step 7: Plan for Logistics and Customs Clearance

Finally, consider the logistics involved in importing aircraft cables to your location. Check the required documentation for customs clearance and factor in shipping times and costs. Collaborating with a logistics expert or a freight forwarder can help streamline this process and ensure timely delivery.

By following this checklist, B2B buyers can navigate the complexities of sourcing aircraft cables with greater confidence and efficiency, leading to successful procurement outcomes.

Illustrative image related to aircraft cables

Comprehensive Cost and Pricing Analysis for aircraft cables Sourcing

What Are the Key Components of Aircraft Cable Costs?

When sourcing aircraft cables, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Galvanized steel is generally less expensive than stainless steel, but the latter offers superior corrosion resistance, making it ideal for marine or high-moisture environments. The specific type of stainless steel (Type 304 vs. Type 316) also influences cost, with Type 316 typically being more expensive due to its enhanced properties.

-

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but it’s essential to assess the quality of workmanship. Skilled labor is necessary for producing high-quality cables, which can drive up costs.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Suppliers with advanced manufacturing processes may have higher overheads, which could be reflected in their pricing.

-

Tooling: Custom tooling for specialized cable designs or specifications can increase initial costs. However, these costs may be amortized over larger production runs, affecting the per-unit price.

-

Quality Control (QC): Rigorous QC processes ensure that the cables meet safety and performance standards. Suppliers who adhere to international standards may charge more, but this investment can lead to long-term reliability and reduced failure rates.

-

Logistics: Shipping and handling costs, including customs duties and tariffs, are vital considerations for international buyers. Understanding Incoterms is essential, as they dictate who bears the costs and risks during transportation.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary based on market conditions, competition, and the supplier’s business model.

How Do Volume and Specifications Affect Aircraft Cable Pricing?

Pricing is heavily influenced by several factors:

-

Volume/MOQ: Many manufacturers offer tiered pricing based on order volume. Higher quantities can lead to significant discounts, making it beneficial for buyers to consolidate orders whenever possible.

-

Specifications and Customization: Custom cables tailored to specific applications or performance requirements may incur additional costs. Standardized products are generally more affordable due to economies of scale.

-

Quality and Certifications: Cables that meet industry certifications (e.g., ASTM standards) tend to be priced higher due to the assurance of quality and compliance. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and service may charge a premium, while newer entrants might offer lower prices to gain market share.

What Negotiation Strategies Can B2B Buyers Use for Cost Efficiency?

To achieve cost efficiency when sourcing aircraft cables, buyers should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with installation, maintenance, and potential replacements. A lower-priced product may lead to higher TCO if it requires frequent replacement or incurs additional maintenance costs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster trust and open doors for negotiations on pricing.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can provide insights into competitive pricing. However, prioritize quality and service alongside cost to ensure long-term value.

-

Be Aware of Pricing Nuances: International buyers, particularly from regions like Africa, South America, and the Middle East, should be mindful of currency fluctuations, import tariffs, and local market conditions that can affect overall costs. Understanding these nuances can help in making informed purchasing decisions.

Are There Any Pricing Disclaimers Buyers Should Be Aware Of?

It is essential to note that the prices for aircraft cables can fluctuate based on market dynamics, raw material costs, and geopolitical factors. Buyers should request updated quotes and be prepared for potential price changes throughout the sourcing process. Always ensure that pricing discussions are transparent and documented to avoid misunderstandings.

Illustrative image related to aircraft cables

Alternatives Analysis: Comparing aircraft cables With Other Solutions

Understanding Alternatives to Aircraft Cables for B2B Applications

When evaluating solutions for lifting, securing, or rigging applications, it’s essential to consider various options available in the market. Aircraft cables are widely recognized for their strength and versatility, but alternative solutions may offer specific benefits that can better meet the unique needs of different industries. This analysis compares aircraft cables with two viable alternatives: synthetic ropes and chain slings. Each option has its strengths and weaknesses, making it crucial for B2B buyers to understand how they align with their operational requirements.

Comparison Table

| Comparison Aspect | Aircraft Cables | Synthetic Ropes | Chain Slings |

|---|---|---|---|

| Performance | High tensile strength; flexible | Lightweight; good abrasion resistance | Very high strength; rigidity |

| Cost | Moderate to high | Generally lower | Moderate to high |

| Ease of Implementation | Requires specialized fittings | Easy to handle and install | Requires heavy-duty hardware |

| Maintenance | Regular inspections needed | Low maintenance; resistant to UV | Moderate maintenance; check for wear |

| Best Use Case | Rigging, winching, and suspension | Marine, outdoor, and lightweight applications | Heavy lifting and industrial uses |

In-Depth Analysis of Alternatives

Synthetic Ropes

Synthetic ropes, such as those made from nylon or polyester, are increasingly popular due to their lightweight nature and high strength-to-weight ratio. They are particularly advantageous in marine and outdoor environments due to their excellent resistance to UV rays and moisture. However, they may not perform as well under extreme temperatures and can be more susceptible to abrasion compared to aircraft cables. Additionally, while synthetic ropes tend to be more affordable, their performance can vary significantly based on the specific material used.

Chain Slings

Chain slings are a robust alternative commonly used for heavy lifting in industrial settings. They provide exceptional strength and durability, making them ideal for moving heavy machinery or materials. One significant advantage of chain slings is their resistance to heat and abrasion, which ensures longevity in harsh environments. However, they are heavier and less flexible than aircraft cables or synthetic ropes, which can complicate handling and installation. Additionally, the need for regular inspections to check for wear and tear can add to maintenance costs.

Illustrative image related to aircraft cables

Making the Right Choice for Your B2B Needs

Selecting the appropriate lifting or rigging solution involves understanding the specific requirements of your operations. Aircraft cables excel in applications where flexibility and high strength are paramount, especially in environments that demand precise control, such as construction and aviation. On the other hand, if your operations involve heavy lifting or require a lightweight solution for marine applications, synthetic ropes might be the better choice. Chain slings are best suited for industrial environments where maximum strength is necessary, but their weight and rigidity may limit their versatility.

Ultimately, buyers should assess their unique operational demands, including environmental factors, load requirements, and budget constraints, to choose the most effective solution.

Essential Technical Properties and Trade Terminology for aircraft cables

What Are the Key Technical Properties of Aircraft Cables?

Understanding the essential technical properties of aircraft cables is crucial for B2B buyers to ensure they select the right products for their applications. Here are some key specifications to consider:

-

Material Grade

Aircraft cables are typically made from high-strength steel, with common grades being stainless steel (Type 304 and Type 316) and galvanized steel. The choice of material affects corrosion resistance, tensile strength, and overall durability. For applications in high-moisture environments, Type 316 stainless steel is recommended due to its superior rust resistance. -

Construction Type

Aircraft cables are classified based on their construction, most commonly in configurations like 7×19 or 7×7. The “7” refers to the number of strands, while the “19” indicates the number of wires in each strand. This construction influences flexibility, strength, and suitability for various applications. For instance, 7×19 cables provide better flexibility, making them ideal for rigging and winch lines. -

Diameter and Break Strength

The diameter of aircraft cables typically ranges from 1/32 inch to 3/8 inch. Each diameter correlates with a specific break strength, which is the maximum load the cable can handle before failing. For example, a 3/8 inch 7×19 galvanized cable can have a break strength of 14,400 lbs. Understanding these specifications is vital for ensuring safety and compliance with industry standards. -

Tolerance and Coating

Tolerance refers to the allowable variation in diameter and tensile strength. This is crucial for ensuring that the cable fits within specific applications and meets safety standards. Additionally, coatings (such as vinyl or galvanized finishes) can enhance corrosion resistance and reduce friction, prolonging the cable’s lifespan and performance. -

Compliance Standards

Aircraft cables must comply with industry standards, such as ASTM A1023 and federal specifications like RR-W-410. Compliance ensures that the cables meet safety and performance benchmarks, which is particularly important for B2B buyers in regulated industries.

Which Trade Terminology Should B2B Buyers Know for Aircraft Cables?

Familiarity with industry-specific terminology can significantly enhance communication and negotiation processes. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify reliable suppliers who can provide high-quality cables that meet specific standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for buyers to manage their inventory effectively and make cost-effective purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. Including detailed specifications in the RFQ can help ensure accurate pricing and expedite the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk, and responsibilities, facilitating smoother cross-border transactions. -

Tensile Strength

This term refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure. It is a critical factor for determining the suitability of aircraft cables for specific applications. -

Lead Time

Lead time is the time taken from placing an order to the delivery of the product. Understanding lead times is essential for planning and ensuring that project timelines are met without delays.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to aircraft cables

Navigating Market Dynamics and Sourcing Trends in the aircraft cables Sector

What Are the Current Market Dynamics and Key Trends in the Aircraft Cables Sector?

The aircraft cables market is experiencing a transformative phase driven by several global trends. The increasing demand for lightweight and high-strength materials in aviation and aerospace applications is propelling the growth of aircraft cables, particularly in regions like Africa, South America, the Middle East, and Europe. Innovations in material science, such as the development of corrosion-resistant stainless steel and advanced coatings, are enhancing the performance of aircraft cables, making them suitable for a broader range of applications. Moreover, the rise of electric and hybrid aircraft is creating new opportunities for specialized cable solutions, aligning with the global trend toward sustainability and efficiency.

Emerging B2B technology trends are also reshaping sourcing strategies. Digital platforms for supply chain management are gaining traction, allowing international buyers to streamline procurement processes, compare suppliers, and ensure compliance with international standards. The integration of AI and machine learning in inventory management is optimizing stock levels and reducing lead times. Furthermore, the growing emphasis on just-in-time manufacturing practices is prompting buyers to seek suppliers that can offer flexibility and rapid response times to fluctuating demands.

How Are Sustainability and Ethical Sourcing Impacting the Aircraft Cables Sector?

Sustainability is becoming a cornerstone of procurement strategies in the aircraft cables sector. The environmental impact of sourcing materials, particularly in terms of carbon emissions and resource depletion, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. This shift is not just about compliance; it also enhances brand reputation and customer loyalty.

Ethical supply chains are crucial in ensuring that materials used in aircraft cables meet stringent environmental and social standards. Certifications such as ISO 14001 for environmental management and Oeko-Tex for sustainable textiles are gaining importance among buyers seeking ‘green’ materials. Additionally, the use of recycled materials in cable production is becoming more prevalent, aligning with global efforts to reduce waste and promote circular economies. For companies operating in the Middle East and Europe, where regulatory frameworks are becoming more stringent, investing in sustainability can lead to competitive advantages and open new market opportunities.

Illustrative image related to aircraft cables

What Is the Evolution of Aircraft Cables and Its Significance for B2B Buyers?

The evolution of aircraft cables dates back to the early days of aviation, where the need for reliable and lightweight materials was paramount. Initially made from simple steel wires, advancements in metallurgy and manufacturing processes have led to the development of high-strength cables designed to withstand extreme conditions. Modern aircraft cables, such as those made from stainless steel and specialized coatings, offer enhanced durability and performance characteristics that are critical in today’s aviation environment.

For B2B buyers, understanding this evolution is essential for making informed purchasing decisions. The transition from traditional materials to advanced composites not only reflects technological progress but also highlights the increasing demand for safety and reliability in aviation applications. Buyers who grasp these historical developments can better appreciate the value of investing in high-quality, innovative aircraft cables that meet the rigorous demands of the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of aircraft cables

-

How do I select the right type of aircraft cable for my application?

Choosing the right aircraft cable involves understanding the specific requirements of your application, such as load capacity, environmental conditions, and flexibility. Consider factors like the diameter of the cable, material (stainless steel or galvanized), and construction type (e.g., 7×19 for flexibility or rotation-resistant options). Additionally, review the break strength specifications to ensure the cable can handle the intended load. Consulting with suppliers for recommendations based on your use case can also provide valuable insights. -

What is the typical minimum order quantity (MOQ) for aircraft cables?

Minimum order quantities for aircraft cables can vary significantly among suppliers. Typically, MOQs range from 100 feet to 1,000 feet, depending on the cable type and supplier capabilities. Some manufacturers may offer flexible MOQs for smaller businesses or specific applications. It’s advisable to discuss your needs directly with suppliers to negotiate terms that suit your purchasing strategy, especially if you are testing a new product line. -

How can I ensure the quality of aircraft cables from international suppliers?

To ensure quality, request certifications and compliance documents that verify adherence to industry standards, such as ASTM and federal specifications. Conduct thorough supplier vetting, including checks on their manufacturing processes, quality control measures, and customer reviews. If possible, request samples for testing before placing large orders. Establishing a strong communication channel with the supplier can also help in monitoring quality throughout the production process. -

What payment terms should I expect when purchasing aircraft cables internationally?

Payment terms can vary by supplier and region, but common practices include upfront payments, letters of credit, or payment upon delivery. For larger orders, you may negotiate more favorable terms, such as a 30% deposit with the remainder due upon shipment. Always clarify payment methods (bank transfers, PayPal, etc.) and be aware of currency exchange implications. It’s prudent to have a clear agreement documented to avoid any misunderstandings later. -

What are the shipping options for international orders of aircraft cables?

Shipping options for aircraft cables typically include air freight for expedited delivery or ocean freight for cost-effectiveness on larger shipments. The choice depends on your budget, timeline, and the urgency of the project. Discuss logistics with your supplier to understand lead times and associated costs, and consider using freight forwarders experienced in handling industrial supplies to simplify customs clearance and documentation. -

Can I customize aircraft cables to fit my specific requirements?

Many suppliers offer customization options for aircraft cables, including varying lengths, diameters, and finishes. You can also request specific constructions, such as swaged or compacted cables, to meet unique application needs. Ensure you communicate your specifications clearly and confirm the supplier’s capability to fulfill customized orders. Be prepared for longer lead times and potentially higher costs associated with custom manufacturing. -

What are the common applications for aircraft cables in various industries?

Aircraft cables are versatile and used in various applications across industries. Common uses include rigging in construction, suspension systems for signage, winch lines in marine applications, and safety cables in entertainment setups. They are also utilized in transportation for securing loads. Understanding the specific needs of your industry can help you select the appropriate cable type and specifications. -

How do I handle customs and import regulations for aircraft cables?

Navigating customs and import regulations requires understanding the specific requirements of your destination country. This includes tariffs, import duties, and necessary documentation such as certificates of origin and compliance. Work closely with your supplier to ensure all paperwork is correctly filled out, and consider engaging a customs broker to facilitate the import process. Staying informed about regulatory changes can help prevent delays and additional costs.

Top 8 Aircraft Cables Manufacturers & Suppliers List

1. Rigging Warehouse – Aircraft Cable & Wire Rope Products

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Aircraft Cable & Wire Rope products include: 1″ 6×37 XIP Steel Core (IWRC) Bright Wire Rope, 3/16″ 1X7 Common Galvanized Strand, 3/16X1000′ 7X7 Stainless Steel Aircraft Cable T304, 3/16X500′ 7X7 Stainless Steel Aircraft Cable T304, 3/16X5000′ 7X7 Stainless Steel Aircraft Cable T304, 3/32″ x 500′ 7×19 Galvanized Aircraft Cable, 1″ 19×7 Rotation-Resistant Wire Rope, 1″ 6×25 XIP Steel Core (IWRC) Bri…

2. US Cargo Control – Aircraft Cable Options

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Aircraft Cable options include: 7×19 Galvanized Aircraft Cable, 7×19 304 Stainless Steel Aircraft Cable, 7×19 316 Stainless Steel Aircraft Cable, 7×19 Galvanized Aircraft Cable – Vinyl-Coated, 7×19 304 Stainless Steel Aircraft Cable – Vinyl-Coated. Break Strengths available range from 920 lbs to 14400 lbs.

3. Griplock® Systems – Wire Rope Aircraft Cable

Domain: griplocksystems.com

Registered: 1998 (27 years)

Introduction: Wire Rope Aircraft Cable from Griplock® Systems is available in galvanized or stainless steel. Cable assemblies are offered in 7×7 or 7×19 configurations, with medium-to-high tensile strength. The assemblies come factory fitted with various terminals including die-cast zinc, swaged aluminum, swaged copper, or swaged steel. Griplock terminals are guaranteed to the full published break-strength of t…

4. Stager Rigging Warehouse – Aircraft Cable Options

Domain: stageriggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Aircraft Cable options include: Galvanized, Black Galvanized, Stainless Steel, and Vinyl Coated. Available sizes range from 1/16″ to 3/8″ in various constructions such as 7×19 and 7×7. Lengths available include 100′, 250′, 500′, 1000′, 2500′, 5000′, and 10000′. Breaking strengths vary from 270 lbs to 9800 lbs depending on the specific cable type and size. Brands include Loos & Co and PTC Approved …

5. Bergen Cable – Aircraft Safety Cable™

Domain: bergencable.com

Registered: 1999 (26 years)

Introduction: {‘product_name’: ‘Aircraft Cable Assemblies’, ‘features’: [{‘name’: ‘Aircraft Safety Cable™’, ‘description’: ‘Introduced in 1988, replaces lockwire, safe and easy to use, simplifies repairs, lowers assembly costs, 50% faster installation.’, ‘specifications’: {‘length’: ‘6” to 24”’, ‘diameter’: ’20mm to 60mm’, ‘materials’: [‘321 stainless steel’, ‘304 stainless steel’, ‘Inconel 600’, ‘Inconel 625’]…

6. Tie – Galvanized Steel Aircraft Cable

Domain: acehardware.com

Registered: 1995 (30 years)

Introduction: – Product Types: Galvanized Steel Aircraft Cable, Vinyl Coated Galvanized Steel Aircraft Cable, Clear Vinyl Galvanized Steel Cable Sling

– Diameter Options: 1/16 in., 1/8 in., 3/16 in., 1/4 in., 3/8 in., 7/32 in.

– Length Options: 6 ft., 9 ft., 25 ft., 30 ft., 50 ft., 100 ft., 500 ft.

– Brands: Tie Down Engineering, Baron

– Material: Galvanized Steel, Vinyl Coated Galvanized Steel

– Customer Ratin…

7. Loosco – Aircraft Cable Solutions

Domain: loosco.com

Registered: 1997 (28 years)

Introduction: Aircraft Cable products manufactured and stocked to commercial and military specifications in stainless steel, galvanized carbon steel, and various alloys. Supports flight control, landing gear, emergency systems, and other critical applications. Available constructions include 1×19, 1×7, 3×19, 6×19, 6×25, 6×36, 6×37, 6×42, 7×19, 7×7, 7x7x19, 7x7x7, 3×7, 19×7. Materials include 302/304 Stainless, …

8. E-Rigging – Aircraft Cable

Domain: e-rigging.com

Registered: 2004 (21 years)

Introduction: This company, E-Rigging – Aircraft Cable, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for aircraft cables

As the global demand for aircraft cables continues to rise, strategic sourcing becomes paramount for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Understanding the specific applications and performance characteristics of various types of aircraft cables—such as galvanized and stainless steel options—enables businesses to make informed purchasing decisions that enhance safety and operational efficiency.

Illustrative image related to aircraft cables

Investing in high-quality aircraft cables not only mitigates risks associated with inferior products but also ensures compliance with international standards. The careful selection of suppliers who can provide reliable, durable cables tailored to your specific needs will lead to long-term savings and improved project outcomes.

Looking ahead, international buyers should prioritize building strong relationships with manufacturers and distributors that can offer technical support and customization options. This proactive approach will not only facilitate smoother procurement processes but also enable businesses to stay ahead in a competitive landscape. Engage with trusted suppliers today to secure the right aircraft cables that will meet your future operational demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to aircraft cables

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.