Choosing Your Aircon Dc: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for aircon dc

In the increasingly competitive landscape of global commerce, sourcing efficient air conditioning solutions, particularly DC-powered units, presents a significant challenge for B2B buyers. With rising temperatures and energy costs, businesses in Africa, South America, the Middle East, and Europe are seeking reliable and eco-friendly air conditioning options that deliver optimal performance without straining budgets. This guide serves as an essential resource for international buyers, providing a comprehensive overview of various aircon DC systems, including their types, applications, and the latest technological advancements.

From marine applications to telecommunications and off-grid living, the versatility of DC air conditioning systems is unparalleled. This guide will delve into the critical factors to consider when selecting a supplier, including product quality, warranty terms, and customer support. Additionally, we will explore cost implications, helping businesses make informed purchasing decisions that align with their operational needs and sustainability goals.

By equipping B2B buyers with actionable insights and detailed evaluations of aircon DC units, this guide empowers organizations to navigate the complexities of the global market. Whether you are based in Saudi Arabia, Nigeria, or elsewhere, understanding these key aspects will enable you to invest wisely in cooling solutions that enhance comfort and efficiency, ultimately driving business success.

Understanding aircon dc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Marine DC Air Conditioners | Designed for marine environments; resistant to corrosion; high efficiency | Boats, yachts, and marine vehicles | Pros: Durable, efficient cooling in harsh conditions. Cons: Higher initial investment. |

| Micro DC Air Conditioners | Ultra-compact design; low vibration; battery-driven; energy-efficient | Telecom cabinets, EV battery cooling, portable shelters | Pros: Space-saving, eco-friendly. Cons: Limited cooling capacity for larger spaces. |

| Battery-Powered DC Air Conditioners | Operates directly from batteries; eco mode for energy savings; low power consumption | Off-grid living, RVs, and mobile applications | Pros: No fuel costs, versatile. Cons: May require larger battery systems for extended use. |

| Direct Current Split Systems | Split design for easier installation; variable speed compressors | Commercial buildings, residential applications | Pros: Flexibility in installation, efficient cooling. Cons: Potential complexity in setup. |

| Portable DC Air Conditioners | Lightweight and portable; plug-and-play setup; designed for tight spaces | Temporary cooling solutions, emergency response units | Pros: Easy transport and setup. Cons: Limited power and cooling capacity. |

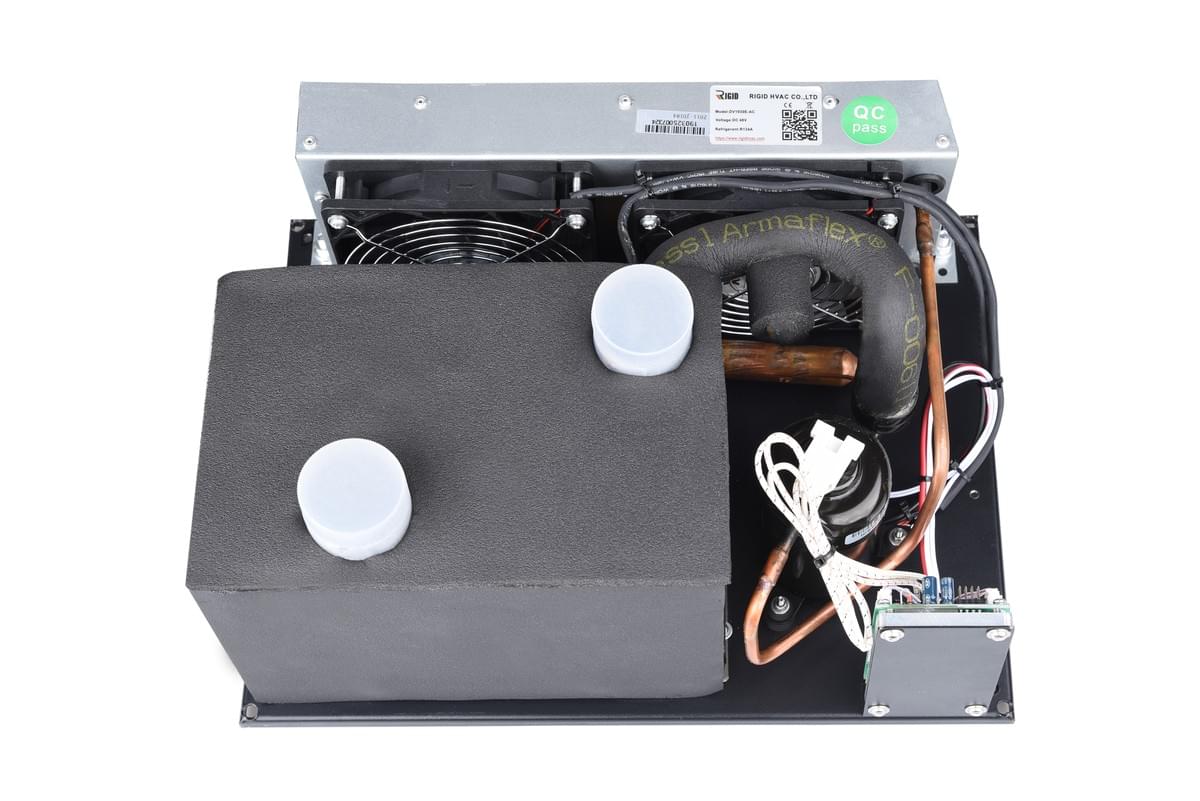

What Are Marine DC Air Conditioners and Their Key B2B Applications?

Marine DC air conditioners are specifically engineered for use in marine environments, ensuring resistance to corrosion and mold, which is crucial for maintaining air quality on boats and yachts. They feature high static pressure ball bearings and copper antimicrobial evaporators for enhanced heat transfer. B2B buyers in the marine sector should consider these units for their durability and efficiency, although the higher upfront cost can be a deterrent.

How Do Micro DC Air Conditioners Stand Out in the Market?

Micro DC air conditioners are designed for confined spaces, offering low vibration and remarkable energy efficiency. These units are particularly suitable for applications like telecom cabinet cooling and EV battery management, where precise temperature control is essential. The compact design allows for easy integration into various equipment, making them a valuable choice for B2B buyers looking to optimize performance in limited spaces.

Why Choose Battery-Powered DC Air Conditioners for Off-Grid Solutions?

Battery-powered DC air conditioners are ideal for off-grid living, RVs, and mobile applications, operating directly from batteries without the need for fuel. These units often include eco modes that reduce power consumption during non-peak cooling times. While they offer versatility and cost savings in fuel, businesses must evaluate the capacity of their battery systems to ensure sufficient performance over extended periods.

What Are the Benefits of Direct Current Split Systems for Commercial Use?

Direct current split systems provide flexibility in installation and are equipped with variable speed compressors to optimize cooling efficiency. They are commonly used in commercial buildings and residential applications, offering tailored solutions to meet specific cooling needs. However, the complexity of installation can be a challenge for some buyers, necessitating careful planning and professional assistance.

How Do Portable DC Air Conditioners Meet Temporary Cooling Needs?

Portable DC air conditioners are lightweight and designed for easy transport and setup, making them suitable for temporary cooling solutions and emergency response units. Their plug-and-play nature allows for quick deployment in various settings. However, buyers should be aware of their limited power and cooling capacity, which may restrict their effectiveness in larger spaces or prolonged use.

Key Industrial Applications of aircon dc

| Industry/Sector | Specific Application of aircon dc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Cooling for Telecom Cabinets | Ensures optimal performance and longevity of sensitive equipment. | Compatibility with existing infrastructure; energy efficiency ratings. |

| Electric Vehicles | Battery Cooling Systems | Maintains safe operating temperatures, enhancing battery life. | Voltage specifications; integration with existing vehicle systems. |

| Marine and Offshore | Climate Control in Marine Vessels | Provides reliable cooling in harsh environments, preventing equipment failure. | Corrosion resistance; compliance with marine standards. |

| Medical Equipment | Cooling for Portable Medical Devices | Protects sensitive medical equipment and ensures patient safety. | Portability; energy consumption; ease of maintenance. |

| Off-Grid Living | Air Conditioning for RVs and Mobile Homes | Offers comfort in remote locations without reliance on traditional power sources. | Power source compatibility; compact design for limited space. |

How is Aircon DC Used in Telecommunications?

In the telecommunications sector, DC air conditioning systems are essential for cooling telecom cabinets. These cabinets house sensitive equipment that can overheat, leading to failures and service disruptions. By utilizing aircon DC, companies can ensure efficient thermal management, which not only prolongs the lifespan of their equipment but also enhances performance. For B2B buyers, it’s crucial to consider compatibility with existing infrastructure and energy efficiency ratings, especially in regions with high energy costs, such as Africa and South America.

What Role Does Aircon DC Play in Electric Vehicles?

Electric vehicles (EVs) require effective thermal management systems to maintain optimal battery temperatures. Aircon DC units are increasingly used in these applications, providing precise cooling that can extend battery life and enhance performance. Buyers in this sector should focus on voltage specifications and the integration capabilities of these cooling systems with existing vehicle components. This is particularly important in regions like the Middle East, where temperatures can soar, putting additional strain on battery systems.

How Does Aircon DC Benefit Marine and Offshore Operations?

In marine and offshore industries, maintaining a stable climate is critical for both crew comfort and equipment functionality. Aircon DC systems are designed to withstand harsh environments and provide reliable cooling for vessels. These units help prevent overheating and equipment failure, which can be costly in terms of repairs and downtime. When sourcing these systems, businesses should prioritize corrosion resistance and compliance with marine standards, ensuring durability in challenging conditions, especially in regions like Saudi Arabia and Nigeria.

What is the Importance of Aircon DC in Medical Equipment Cooling?

Portable medical devices, including those used in mobile clinics, require efficient cooling solutions to protect sensitive equipment. Aircon DC units offer the necessary thermal management, ensuring that devices operate safely and effectively. For B2B buyers in the medical sector, factors such as portability, energy consumption, and ease of maintenance are critical. This is particularly relevant in regions with limited access to stable power sources, where reliable cooling solutions are essential for patient safety.

How is Aircon DC Used for Off-Grid Living?

Aircon DC systems are ideal for off-grid living scenarios, such as RVs and mobile homes, providing essential cooling without reliance on conventional power sources. These systems are designed to be energy-efficient, allowing users to maintain comfort while minimizing power consumption. Buyers should consider power source compatibility and the compact design of these units, especially in regions with limited space and resources. This makes aircon DC a valuable investment for those in remote areas across Africa and South America.

3 Common User Pain Points for ‘aircon dc’ & Their Solutions

Scenario 1: Inconsistent Cooling in Remote Locations

The Problem: B2B buyers in regions such as Africa and South America often face the challenge of ensuring consistent cooling for sensitive equipment, particularly in remote locations with limited power supply. For instance, telecom companies need to maintain optimal temperatures for their servers and battery cabinets to prevent overheating, which can lead to equipment failure and costly downtime. Traditional AC systems may be inefficient or impractical in such settings, leading to frustration and potential loss of service reliability.

The Solution: To address this issue, businesses should consider investing in DC air conditioning systems specifically designed for off-grid applications. These systems, like RIGID’s Micro DC Aircon, are battery-driven and engineered for energy efficiency. B2B buyers should look for units that offer features such as variable speed compressors and eco-friendly refrigerants, which not only reduce energy consumption but also adapt to the cooling needs of the environment. When sourcing these systems, prioritize suppliers that provide comprehensive technical support and installation guidance to ensure seamless integration into existing setups, thereby minimizing operational interruptions.

Scenario 2: High Energy Costs Impacting Profit Margins

The Problem: Companies operating in regions with extreme climates, such as the Middle East and Europe, often struggle with high energy costs associated with traditional air conditioning systems. This is particularly relevant for industries that require continuous cooling, such as food storage and medical services. The excessive energy consumption can significantly impact profit margins, making it essential for businesses to find more cost-effective cooling solutions without compromising performance.

The Solution: One effective approach is to transition to high-efficiency DC air conditioning units that operate on direct current, reducing energy consumption and lowering operational costs. For example, solutions offered by manufacturers like Cruise N Comfort utilize advanced compressor technologies that optimize power usage based on cooling demand. Buyers should conduct a thorough analysis of their cooling needs and seek systems that offer features such as eco modes and smart controls. Additionally, implementing a regular maintenance schedule can enhance the longevity and efficiency of these units, further reducing energy expenditures over time.

Scenario 3: Difficulty in Sizing and Specifying the Right System

The Problem: Many B2B buyers encounter challenges in accurately sizing and specifying the appropriate air conditioning systems for their unique applications. This often leads to over- or under-sizing, which can result in inefficient cooling and increased wear on equipment. Industries such as maritime and construction, where space and weight constraints are prevalent, particularly feel the repercussions of this issue, leading to dissatisfaction and potential financial losses.

The Solution: To mitigate these challenges, buyers should engage with suppliers that provide detailed sizing charts and application-specific guidance. For instance, companies like Mabru Power Systems offer comprehensive resources that help clients determine the best BTU ratings based on their specific environments and cooling requirements. It’s advisable for buyers to involve HVAC professionals during the specification process to ensure that all variables, including ambient temperature fluctuations and equipment heat loads, are considered. Additionally, investing in modular DC systems allows for scalable solutions that can be adjusted as operational needs evolve, thereby optimizing performance and resource allocation.

Strategic Material Selection Guide for aircon dc

What Are the Key Materials Used in Aircon DC Systems?

When selecting materials for air conditioning systems powered by direct current (DC), several factors come into play, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in aircon DC systems, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Copper Enhance Aircon DC Performance?

Copper is a prevalent choice for components such as evaporators and condensers in aircon DC systems due to its excellent thermal conductivity. This property allows for efficient heat transfer, which is crucial for maintaining optimal cooling performance. Copper also exhibits good corrosion resistance, particularly when treated with antimicrobial coatings, making it suitable for environments prone to mold and bacteria.

Pros: Copper’s durability and high thermal efficiency contribute to reduced energy consumption and improved system performance. Its relatively easy fabrication allows for complex designs.

Cons: The primary drawback is the higher cost compared to alternatives like aluminum. Additionally, copper is heavier, which may impact applications where weight is a critical factor.

Impact on Application: Copper is highly compatible with various refrigerants and is often preferred in marine and industrial applications where reliability is paramount.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards regarding copper’s use in HVAC systems, as well as consider sourcing from suppliers who adhere to quality certifications like ASTM.

Why Is Aluminum a Popular Choice for Aircon DC Systems?

Aluminum is widely used in aircon DC systems for components such as housings and heat exchangers. Its lightweight nature and good corrosion resistance make it an attractive option for portable and mobile applications.

Pros: Aluminum’s lower cost compared to copper and its ease of manufacturing make it a popular choice. Its lightweight properties are advantageous in applications requiring mobility, such as RVs and portable shelters.

Cons: While aluminum is corrosion-resistant, it is less durable than copper and may not perform as well under extreme temperature variations. It also has lower thermal conductivity than copper, which can affect overall system efficiency.

Impact on Application: Aluminum is suitable for various refrigerants but may require additional coatings or treatments for specific applications, especially in humid environments.

Considerations for International Buyers: Buyers should be aware of local regulations regarding aluminum usage and ensure that their suppliers meet international standards for quality and performance.

How Does Stainless Steel Contribute to Durability in Aircon DC Systems?

Stainless steel is often used in the construction of aircon DC units, particularly for components exposed to harsh environments, such as marine applications. Its excellent corrosion resistance and strength make it ideal for long-lasting performance.

Pros: Stainless steel’s durability ensures a longer lifespan for air conditioning units, reducing maintenance costs. Its resistance to corrosion is particularly beneficial in humid or saline environments.

Cons: The primary disadvantage is the higher cost compared to aluminum. Additionally, stainless steel can be more challenging to fabricate, which may lead to increased manufacturing complexity.

Impact on Application: Stainless steel is highly compatible with various refrigerants and is often used in high-performance applications, including military and aerospace.

Considerations for International Buyers: Buyers must ensure compliance with international standards for stainless steel grades and consider sourcing from manufacturers with a reputation for quality.

What Role Does Plastic Play in Aircon DC Systems?

Plastic materials, particularly high-performance polymers, are increasingly used in aircon DC systems for components like fan housings and insulation. Their lightweight and insulating properties make them suitable for various applications.

Pros: Plastics are generally lower in cost and provide excellent insulation, which can enhance energy efficiency. They are also lightweight, making them ideal for portable applications.

Cons: The main limitation is their lower durability compared to metals, as plastics can degrade over time, especially when exposed to UV light or extreme temperatures.

Impact on Application: Plastics are suitable for non-structural components and can be used in various environments, but their performance may vary based on specific conditions.

Considerations for International Buyers: Buyers should verify that the plastics used meet local and international standards for durability and safety, especially in regions with extreme climates.

Summary Table of Material Selection for Aircon DC

| Material | Typical Use Case for aircon dc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Evaporators, condensers | Excellent thermal conductivity | Higher cost, heavier weight | High |

| Aluminum | Housings, heat exchangers | Lightweight, cost-effective | Less durable, lower thermal conductivity | Medium |

| Stainless Steel | Marine applications, high-performance units | Corrosion resistance, durability | Higher cost, manufacturing complexity | High |

| Plastic | Fan housings, insulation | Lightweight, good insulation | Lower durability, potential degradation | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for aircon dc

What Are the Key Stages in the Manufacturing Process of DC Air Conditioners?

The manufacturing process for DC air conditioners involves several critical stages that ensure the final product meets both performance and quality standards.

-

Material Preparation: This initial stage focuses on sourcing high-quality materials, including specialized metals like copper for evaporators and stainless steel for chassis, which are essential for durability and efficiency. Materials must be inspected for quality, ensuring they meet specified standards before proceeding to the next stage.

-

Forming: In this phase, raw materials are shaped into components using techniques such as stamping, bending, and machining. For instance, the fabrication of the compressor and heat exchangers is crucial as these parts significantly impact the unit’s efficiency and cooling capacity. Advanced manufacturing technologies, including CNC machining and laser cutting, are often employed to ensure precision.

-

Assembly: This stage involves integrating all the components, including the compressor, evaporators, and control systems, into a cohesive unit. Skilled technicians follow detailed assembly protocols to ensure each part is correctly installed. Automation is increasingly used in this stage to enhance efficiency and reduce human error.

-

Finishing: The final stage includes surface treatment and assembly checks. Components may undergo processes such as powder coating or anodizing to enhance corrosion resistance. This stage also involves the installation of insulation materials to improve energy efficiency and noise reduction.

How Is Quality Assurance Implemented in the Manufacturing of DC Air Conditioners?

Quality assurance (QA) is critical throughout the manufacturing process of DC air conditioners to ensure reliability and performance. The following outlines the QA measures typically employed:

-

Adherence to International Standards: Manufacturers often comply with international quality standards such as ISO 9001, which sets out criteria for a quality management system. Additionally, industry-specific certifications like CE (for compliance with European health, safety, and environmental protection standards) and API (for the petroleum and natural gas industry) are essential for global market access.

-

Quality Control Checkpoints: Effective QA processes include multiple checkpoints:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process, with random sampling and testing of components at various stages.

– Final Quality Control (FQC): Before shipping, finished products undergo rigorous testing to verify performance against specifications. -

Common Testing Methods: Various testing methods are employed to ensure product reliability, including:

– Performance Testing: Units are tested for cooling efficiency, energy consumption, and operational noise levels.

– Durability Testing: Products may undergo stress tests to evaluate their performance under extreme conditions.

– Safety Testing: Compliance with electrical safety standards is verified through electrical insulation and leakage tests.

What Should B2B Buyers Know About Verifying Supplier Quality Control?

B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, should take specific steps to verify the quality control processes of potential suppliers.

-

Conducting Audits: Regular audits of the manufacturing facilities can provide insights into the operational standards and practices. Buyers should consider third-party audits for an unbiased assessment of compliance with international quality standards.

-

Requesting Quality Reports: Suppliers should be able to provide documented evidence of their quality control measures, including IQC, IPQC, and FQC results. These reports should detail testing methods, results, and corrective actions taken for any issues identified.

-

Third-Party Inspections: Engaging third-party inspection services can offer an additional layer of verification. These services can conduct comprehensive evaluations of the manufacturing processes and the final products to ensure they meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control in international transactions can be complex due to varying regulations and standards across regions. Here are some considerations for B2B buyers:

-

Understanding Regional Standards: Buyers should familiarize themselves with the relevant quality standards in their regions. For example, compliance with CE marks is crucial for products entering the European market, while different certifications may apply in Africa or South America.

-

Cultural and Operational Differences: Be aware that manufacturing practices and quality expectations can differ significantly by region. Establishing clear communication channels and expectations with suppliers can help bridge these gaps.

-

Supply Chain Transparency: Given the global nature of supply chains, buyers should seek transparency from suppliers about their sourcing and manufacturing processes. This includes understanding where materials are sourced and how they are processed, as it can impact the final product’s quality.

-

Flexibility in Specifications: Be prepared to adapt specifications based on regional practices and standards. This flexibility can facilitate smoother transactions and ensure that products meet local requirements.

Conclusion

The manufacturing processes and quality assurance measures for DC air conditioners are integral to delivering reliable and efficient products. For B2B buyers, understanding these processes and implementing robust verification strategies can significantly enhance their procurement decisions, ensuring they source high-quality air conditioning solutions tailored to their specific regional needs. By taking a proactive approach to quality assurance and supplier verification, businesses can better navigate the complexities of international trade in the air conditioning sector.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aircon dc’

To assist B2B buyers in sourcing DC air conditioning units, this guide provides a structured approach to ensure informed decision-making. The checklist outlines critical steps that will help you identify reliable suppliers and select the most suitable products for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for aligning your procurement with operational requirements. Consider factors such as cooling capacity (BTU), voltage (12V, 24V, 48V), and the environment in which the air conditioning unit will operate (e.g., marine, telecom, or off-grid applications). Defining these parameters will streamline your search and help you avoid purchasing incompatible units.

Step 2: Research Market Trends and Technologies

Stay informed about the latest developments in DC air conditioning technology. Innovations such as energy efficiency, eco-friendly refrigerants, and compact designs are gaining traction. Understanding these trends can provide leverage during negotiations and ensure that you invest in systems that offer long-term operational benefits.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, product specifications, and references from clients in similar industries or geographical areas. Pay attention to their experience with specific applications, such as marine or mobile cooling, to ensure they have the expertise to meet your needs.

- Check Certifications: Ensure that the suppliers have relevant certifications (e.g., ISO, CE) that demonstrate compliance with international standards for quality and safety.

- Assess Customer Support: Inquire about warranty terms, support services, and spare parts availability to gauge the supplier’s reliability.

Step 4: Request Product Samples or Demonstrations

Whenever possible, request samples or arrange demonstrations of the DC air conditioning units. This allows you to assess the performance, noise levels, and ease of installation firsthand. It’s particularly important for compact systems designed for specialized applications, as the unit’s effectiveness can significantly influence overall operational efficiency.

Step 5: Analyze Cost vs. Value

Evaluate the pricing of the air conditioning units in relation to their features and long-term value. Consider the total cost of ownership, including installation, maintenance, and energy consumption. A higher upfront cost may be justified if the unit offers superior energy efficiency or durability, leading to lower operational costs over time.

Step 6: Negotiate Terms and Conditions

Once you identify a suitable supplier, engage in negotiations to finalize terms and conditions. Discuss pricing, delivery timelines, payment terms, and any potential discounts for bulk purchases. Clear agreements on these points will prevent misunderstandings and ensure a smoother procurement process.

Step 7: Plan for Installation and Maintenance

Develop a comprehensive plan for the installation and ongoing maintenance of the DC air conditioning units. Assess whether your team has the technical expertise for installation or if you need to hire external professionals. Establish a maintenance schedule to ensure optimal performance and longevity of the units.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for DC air conditioning units, ensuring they select the right products from reputable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for aircon dc Sourcing

What Are the Key Cost Components in Aircon DC Sourcing?

When sourcing air conditioning systems that operate on direct current (DC), understanding the cost structure is crucial for B2B buyers. The primary cost components include:

- Materials: Quality components, such as copper evaporators and stainless steel chassis, directly impact pricing. Higher-grade materials typically yield better durability and efficiency but can also increase the initial cost.

- Labor: Labor costs can vary significantly based on the region of production. Skilled labor in regions with higher living costs may lead to elevated manufacturing expenses.

- Manufacturing Overhead: This includes utilities, rent, and other indirect costs associated with production. Efficient manufacturing processes can mitigate these costs, affecting the overall pricing.

- Tooling: For custom designs or modifications, tooling costs can be substantial. Investment in specialized tools is necessary for high-quality production but can lead to increased upfront costs.

- Quality Control (QC): Rigorous QC processes ensure that the final product meets industry standards. This can be a significant expense, particularly for buyers requiring certifications for specific markets.

- Logistics: Shipping and handling costs vary based on destination, weight, and volume. Buyers should consider these factors when evaluating total costs.

- Margin: Supplier margins can differ based on market positioning and competition. High-quality or specialized products may carry higher margins.

How Do Price Influencers Affect Aircon DC Pricing?

Several factors influence the pricing of air conditioning systems:

- Volume/MOQ: Minimum Order Quantity (MOQ) discounts can significantly affect pricing. Bulk purchases generally lead to lower per-unit costs, making it advantageous for larger buyers.

- Specifications and Customization: Custom features or specifications can lead to increased costs. Buyers should carefully assess whether custom options are necessary for their applications.

- Materials: The choice of materials can greatly affect both performance and price. Eco-friendly refrigerants or advanced compressor technology may come at a premium but can lead to lower operating costs over time.

- Quality and Certifications: Products that meet international quality standards or have additional certifications may command higher prices. For buyers in regulated markets, these certifications can be critical.

- Supplier Factors: Supplier reputation, reliability, and past performance can influence pricing. Established suppliers may charge more due to their proven track record but can offer better support and product consistency.

- Incoterms: The terms of shipping (Incoterms) impact costs. Understanding who is responsible for shipping, insurance, and duties can influence the overall budget.

What Buyer Tips Can Help Optimize Cost-Efficiency in Aircon DC Sourcing?

To maximize cost-efficiency in sourcing air conditioning units, consider the following strategies:

- Negotiation: Always engage in negotiations with suppliers. Understanding the cost structure can empower buyers to seek better terms, especially for larger orders.

- Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term operating costs, including energy efficiency and maintenance. A higher upfront investment in a more efficient unit can lead to significant savings over time.

- Pricing Nuances for International Buyers: For buyers from regions like Africa, South America, the Middle East, and Europe, currency fluctuations and local tariffs can affect pricing. It’s essential to account for these factors when budgeting.

- Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and support. Consider long-term partnerships that can yield volume discounts or favorable terms.

- Market Research: Conduct thorough market research to understand competitive pricing and product availability. This knowledge can aid in making informed purchasing decisions and leveraging competitive offers.

Conclusion

Understanding the comprehensive cost and pricing analysis for aircon DC sourcing is essential for B2B buyers. By considering the key cost components, price influencers, and strategic buying tips, businesses can make informed decisions that align with their budget and operational needs. Always remember that indicative prices may vary based on several factors, and it’s prudent to conduct ongoing evaluations of supplier offerings.

Alternatives Analysis: Comparing aircon dc With Other Solutions

Exploring Alternatives for Aircon DC Solutions

In the quest for effective cooling systems, businesses often seek alternatives to standard air conditioning solutions. This section provides a comparative analysis of aircon DC systems against other viable technologies, helping B2B buyers make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Aircon DC | Rigid Micro DC Air Conditioner | Cruise N Comfort HD Series |

|---|---|---|---|

| Performance | High efficiency, suitable for various environments | Ultra-compact, efficient for confined spaces | Robust performance in harsh conditions |

| Cost | $5,200 – $5,800 per unit | $580 – $830 per unit | Starting around $1,500 per unit |

| Ease of Implementation | Moderate; requires space for installation | High; plug-and-play design | Moderate; requires proper mounting |

| Maintenance | Low; minimal upkeep needed | Low; designed for easy servicing | Low; built for longevity and durability |

| Best Use Case | Marine and industrial applications | Telecom, EV battery cooling, portable setups | Off-grid living, heavy equipment |

What Are the Advantages and Disadvantages of Rigid Micro DC Air Conditioner?

The Rigid Micro DC Air Conditioner is designed for confined spaces, making it ideal for applications such as telecom cabinets and mobile vehicles. Its plug-and-play design allows for easy installation, which is a significant advantage for businesses needing quick deployment. Additionally, it operates quietly and efficiently, ensuring minimal disruption in sensitive environments. However, its compact size may limit cooling capacity for larger spaces, making it less suitable for extensive industrial applications.

How Does the Cruise N Comfort HD Series Compare?

The Cruise N Comfort HD Series is built to withstand harsh environments, making it a great option for off-road vehicles and heavy equipment. Its construction from durable materials ensures longevity, while the Eco Mode technology helps reduce power consumption. However, the higher starting price may be a concern for budget-conscious buyers. Moreover, while installation is straightforward, it may require more space compared to ultra-compact alternatives.

Conclusion: How Should B2B Buyers Choose the Right Cooling Solution?

When selecting a cooling solution, B2B buyers must consider several factors, including performance requirements, budget constraints, and specific application needs. Aircon DC systems offer high efficiency and durability, making them suitable for marine and industrial contexts. In contrast, alternatives like the Rigid Micro DC and Cruise N Comfort HD Series provide unique benefits tailored to specific environments. Ultimately, understanding the operational context and evaluating the pros and cons of each solution will empower buyers to make the best choice for their businesses.

Essential Technical Properties and Trade Terminology for aircon dc

What Are the Key Technical Properties of Aircon DC Systems?

Understanding the essential technical properties of DC air conditioning units is critical for B2B buyers looking to invest in reliable and efficient cooling solutions. Here are some of the most important specifications to consider:

-

Cooling Capacity (BTU)

Measured in British Thermal Units (BTU), cooling capacity indicates the amount of heat an air conditioning unit can remove from a space in one hour. Common capacities for DC units range from 5,000 to 12,000 BTU. Selecting the right capacity ensures optimal performance and energy efficiency, crucial for operational costs in commercial settings. -

Voltage Compatibility

DC air conditioners typically operate on 12V, 24V, or 48V systems. Understanding voltage compatibility is vital for integration into existing power systems, especially in mobile or off-grid applications. Choosing the correct voltage helps prevent operational failures and enhances energy efficiency. -

Material Grade

The construction materials used in aircon DC units, such as stainless steel and copper, significantly impact durability and performance. For example, copper evaporators enhance heat transfer and resist corrosion, while stainless steel chassis offer longevity in harsh environments. Buyers should prioritize units with high-grade materials to ensure longevity and reduce maintenance costs. -

Energy Efficiency Ratio (EER)

The EER measures a unit’s cooling output divided by its power consumption. A higher EER indicates better energy efficiency, which is essential for reducing operational costs and minimizing environmental impact. Buyers should consider EER ratings when selecting units to align with sustainability goals. -

Noise Level (Decibels)

Noise level is a crucial factor for environments requiring low ambient sound, such as offices and hospitals. DC air conditioners are generally quieter than traditional AC units, making them suitable for noise-sensitive applications. Understanding noise specifications helps buyers select the right unit for their specific needs. -

Warranty and Service Support

Warranties, such as a 2-year warranty on the unit and a lifetime warranty on the compressor, are essential indicators of product reliability. Comprehensive service support ensures that buyers have access to assistance and replacement parts, reducing downtime and maintenance costs.

What Are Common Trade Terms Used in the Aircon DC Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to aircon DC systems:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess product quality and reliability, as reputable OEMs often have stringent quality control measures. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for businesses looking to stock air conditioning units in bulk. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. Buyers should prepare RFQs to receive competitive pricing and detailed information on specifications, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps buyers understand shipping costs, liability, and delivery responsibilities, which are crucial for international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for planning project timelines and ensuring that air conditioning units arrive when needed. -

After-Sales Support

This term encompasses the services provided to customers following their purchase, including installation, maintenance, and troubleshooting. Strong after-sales support is vital for ensuring customer satisfaction and long-term operational efficiency.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing air conditioning solutions tailored to their specific needs.

Navigating Market Dynamics and Sourcing Trends in the aircon dc Sector

What Are the Key Market Dynamics and Trends in the Aircon DC Sector?

The aircon DC sector is witnessing substantial growth driven by several global factors, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The increasing demand for energy-efficient cooling solutions is a primary driver, as businesses seek to lower operational costs and reduce their carbon footprint. The rise of off-grid and mobile applications, especially in remote areas, has amplified the need for compact, battery-operated air conditioning systems. Furthermore, advancements in technology have led to the development of direct current (DC) air conditioners that are not only more efficient but also quieter and easier to integrate into existing systems.

Another significant trend is the shift towards customizable solutions that cater to specific industry needs. For instance, sectors like telecommunications, electric vehicles, and medical applications are increasingly utilizing specialized air conditioning systems to maintain optimal temperatures. Manufacturers are now focusing on creating versatile products that can be tailored to various applications, enhancing their market appeal. Additionally, the push for renewable energy sources has spurred interest in solar-powered DC air conditioning units, particularly in regions with abundant sunlight. This trend aligns with the growing consumer preference for sustainable solutions, allowing businesses to align their operations with eco-friendly practices.

How Is Sustainability and Ethical Sourcing Shaping the Aircon DC Market?

Sustainability is becoming a cornerstone of the aircon DC sector, with B2B buyers increasingly prioritizing environmentally friendly products and ethical sourcing practices. The production of air conditioning units has a significant environmental impact, from resource extraction to manufacturing and disposal. Therefore, companies are investing in sustainable materials and processes to minimize their carbon footprints. For instance, manufacturers are opting for eco-friendly refrigerants and recyclable materials in their designs, which not only comply with international regulations but also appeal to eco-conscious consumers.

Ethical sourcing is also gaining traction, as businesses are scrutinizing their supply chains to ensure fair labor practices and responsible resource management. Certifications such as LEED (Leadership in Energy and Environmental Design) and ENERGY STAR are becoming essential for suppliers, as they demonstrate a commitment to sustainability. B2B buyers are encouraged to engage with suppliers who can provide transparency regarding their sourcing practices and environmental impact. This focus on sustainability not only enhances brand reputation but can also lead to operational efficiencies and cost savings in the long run.

What Is the Historical Context of Aircon DC Systems and Their Evolution?

The evolution of air conditioning technology has roots dating back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially, air conditioning systems were predominantly AC (alternating current) based, which limited their efficiency and application in specific environments. However, the emergence of DC (direct current) systems has revolutionized the sector, offering solutions that are particularly advantageous for off-grid and mobile applications.

From the late 2000s onward, innovations in compressor technology, coupled with the rise of renewable energy sources, have facilitated the development of compact and efficient DC air conditioning units. These systems have become increasingly popular in niche markets such as telecommunications and electric vehicles, where traditional air conditioning solutions are impractical. The continuous improvement of battery technology has further propelled the adoption of DC air conditioning systems, enabling them to meet the demands of modern applications while aligning with the global push towards sustainability. This historical context underscores the importance of innovation in shaping the future of the aircon DC sector, providing B2B buyers with a clearer understanding of the market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of aircon dc

-

How do I choose the right DC air conditioner for my application?

Choosing the right DC air conditioner depends on several factors, including the specific cooling needs of your application, the operating environment, and power source availability. Consider the BTU capacity required for your space, as well as the unit’s efficiency ratings. Look for features like compact size, low noise levels, and the ability to operate in harsh conditions. It’s also crucial to evaluate whether the unit can be powered by renewable energy sources, especially in off-grid situations. Consulting with manufacturers can provide tailored solutions based on your requirements. -

What are the key benefits of using DC air conditioning systems?

DC air conditioning systems offer several advantages over traditional AC units. They are more energy-efficient, often resulting in lower operational costs, especially in off-grid applications. Their compact design makes them suitable for confined spaces, and they operate quietly, which is beneficial in residential or sensitive environments. Additionally, DC systems typically have longer lifespans due to fewer mechanical components, and they can effectively maintain precise temperature control, enhancing comfort and equipment protection. -

What should I know about international shipping for DC air conditioners?

When sourcing DC air conditioners internationally, it’s important to understand shipping logistics, including customs regulations and import duties specific to your country. Ensure that your supplier can provide necessary documentation, such as shipping manifests and certificates of origin. Consider the shipping method (air vs. sea) based on urgency and cost. Additionally, confirm that the products are adequately packaged to prevent damage during transit, and discuss insurance options to protect your investment. -

What are typical minimum order quantities (MOQ) for DC air conditioners?

Minimum order quantities (MOQ) for DC air conditioners can vary significantly based on the manufacturer and product type. Many suppliers have an MOQ ranging from 5 to 50 units for bulk orders, which can provide cost savings. However, for specialized or custom units, the MOQ might be higher. It’s advisable to negotiate with suppliers, especially if you are just starting or testing the market, to find a mutually beneficial arrangement. -

How can I ensure quality assurance (QA) in my DC air conditioning purchase?

To ensure quality assurance in your purchase, request detailed product specifications and performance certifications from suppliers. Look for units that comply with international standards such as ISO or CE certifications. Ask about the manufacturer’s quality control processes, including testing procedures and warranty terms. Additionally, consider requesting samples before making a large order to assess the product’s performance and build quality firsthand. -

What payment terms should I expect when purchasing DC air conditioners?

Payment terms can vary among suppliers but typically include options such as upfront payments, partial payments, or payment upon delivery. It’s common for suppliers to request a deposit (20-50%) before production, with the balance due upon shipping or delivery. Always clarify payment methods accepted (e.g., wire transfer, credit card, etc.) and consider using letters of credit for larger transactions to mitigate risk. Understanding the payment terms upfront can help in budgeting and financial planning. -

Can I customize DC air conditioners to meet specific requirements?

Yes, many manufacturers offer customization options for DC air conditioners to better suit specific applications. This may include modifications to cooling capacity, size, voltage specifications, or additional features like remote control or specialized refrigerants. Discuss your needs with potential suppliers early in the negotiation process to understand what customization options are available and any associated costs or lead times. -

What are the common applications for DC air conditioning systems in various industries?

DC air conditioning systems are widely used across multiple industries due to their versatility and efficiency. Common applications include telecommunications for cooling equipment in remote areas, electric vehicles to maintain battery temperatures, and medical devices requiring precise temperature control. They are also ideal for off-grid living solutions, marine environments, and mobile applications like RVs and boats. Understanding the specific needs of your industry can help in selecting the most suitable DC air conditioning solution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Aircon Dc Manufacturers & Suppliers List

1. Mabru – Marine Air Conditioning Units

Domain: mabrustore.com

Registered: 2016 (9 years)

Introduction: This company, Mabru – Marine Air Conditioning Units, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. CoolTechX – DC Air Conditioner

Domain: cooltechx.com

Registered: 2022 (3 years)

Introduction: DC air conditioner (Aircon DC) uses direct current to cool spaces, powered by batteries or solar panels, making it suitable for areas without regular electricity. Energy savings range from 2% to 25%, with some reports indicating up to 44% savings. Key features include:

– Compressor Types: COPELAND, PANASONIC, HIGHLY, MITSUBISHI

– Operating Voltage: 12V, 24V, 48V DC

– Refrigerants: R134A, R290

…

3. Reddit – Solar-Powered DC Air Conditioners

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: DC air conditioners are designed to run on solar power, providing a more efficient cooling solution compared to traditional AC units. They can save users significant amounts on electricity bills, with potential savings of around $100 per month. The systems are self-contained, requiring no inverter or connection to the grid, and can charge batteries to extend operation into the evening. A specific …

4. Hotspot Energy – DC4812VRF Air Conditioner

Domain: hotspotenergy.com

Introduction: DC4812VRF Air Conditioner: 12,000 BTU, designed for off-grid solar and telecom applications, operates on native 48VDC or -48VDC. Features include: all-DC system for high efficiency without inverters, variable capacity and speed, SeaSpray Anti-Corrosion technology for protection against salt air corrosion, exceptionally quiet operation, and heat pump functionality for both cooling and heating. Avai…

5. DC Airco – HVAC Solutions

Domain: dcairco.com

Registered: 2001 (24 years)

Introduction: DC Airco offers a range of Heating, Venting & Cooling (HVAC) air conditioning solutions for various applications including rolling stock, electric vehicles, military equipment, and underground mining. Key product details include:

– Voltage Options: Available in 12V, 24V, 48V, 74V, 110V, 230V, 400V, 750V DC and AC.

– Applications: Designed for rolling stock, public transport, autonomous vehicles, …

6. Today’s Homeowner – DC Inverter Air Conditioners

Domain: todayshomeowner.com

Registered: 1996 (29 years)

Introduction: DC inverter air conditioners utilize motor control technology to adjust compressor power and speed, allowing for precise temperature control and energy savings. They convert AC to DC and back to control compressor operation based on cooling or heating demands. Advantages include better energy efficiency, more precise temperature control, longer lifespan, quieter operation, and use of environmental…

7. Deye – Hybrid AC/DC Solar Air Conditioner

Domain: deye.com

Registered: 1997 (28 years)

Introduction: Deye Hybrid AC/DC Solar Air Conditioner – Portable cooling system for homes, offices, and outdoor spaces. Runs on electricity and solar power, achieving 100% energy savings during the day. Features AC grid power limiter (0-600W), AC/DC auto balance, and operates without inverter, battery, or charge controller. Wide operating temperature range (-10℃ to 58℃). Key features include WiFi monitoring and…

Strategic Sourcing Conclusion and Outlook for aircon dc

In the evolving landscape of air conditioning solutions, particularly for direct current (DC) systems, strategic sourcing has emerged as a critical component for international B2B buyers. The integration of high-efficiency technologies, such as antimicrobial materials and variable speed compressors, highlights the importance of selecting reliable suppliers who prioritize innovation and sustainability. Companies like Mabru and Rigid HVAC demonstrate how advanced engineering can enhance product performance while addressing specific application needs, from marine environments to off-grid living.

As businesses in Africa, South America, the Middle East, and Europe consider their air conditioning options, it is essential to evaluate not only the cost but also the long-term value these systems offer. Investing in energy-efficient DC air conditioning solutions can significantly reduce operational costs and improve reliability in demanding environments.

Looking ahead, the demand for compact and energy-efficient cooling solutions will continue to rise, driven by trends in mobile applications and renewable energy integration. Now is the time for international buyers to engage with trusted manufacturers and explore tailored solutions that meet their unique cooling challenges. By prioritizing strategic sourcing, businesses can ensure they are well-equipped to thrive in a competitive marketplace.