Choosing Your Air Flow Switch: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for air flow switch

The global market for air flow switches presents a unique challenge for B2B buyers seeking to optimize their ventilation and HVAC systems. As industries across Africa, South America, the Middle East, and Europe increasingly prioritize energy efficiency and operational safety, sourcing the right air flow switch becomes critical. This guide offers a comprehensive overview of the various types of air flow switches available, their applications across different sectors, and essential considerations for supplier vetting and cost analysis.

In navigating this complex landscape, international buyers will benefit from detailed insights into the specifications and performance standards that define quality air flow switches. From adjustable paddle switches suitable for HVAC systems to pressure sensing devices tailored for industrial applications, this guide addresses the diverse needs of buyers in regions like Germany and Nigeria. Moreover, it underscores the importance of compliance with local regulations and standards to ensure that the selected products not only meet operational requirements but also enhance safety and efficiency.

By equipping B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to facilitate the procurement process, ultimately leading to improved operational performance and reduced costs. Whether you are looking to upgrade existing systems or implement new solutions, understanding the nuances of air flow switches will empower your business to thrive in today’s competitive marketplace.

Understanding air flow switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adjustable Air Flow Switch | Stainless steel vane, minimal calibration required | HVAC systems, industrial applications | Pros: Versatile, easy to install. Cons: Calibration may be needed for precise settings. |

| Duct Air Flow Switch | Monitors duct air flow with adjustable output settings | Air handling units, fan and filter monitoring | Pros: Reliable performance, adjustable settings. Cons: Limited to duct applications. |

| Air Flow Pressure Switch | Senses pressure drops, can be fixed or adjustable | Commercial kitchens, HVAC systems | Pros: Accurate pressure monitoring. Cons: Installation can be complex. |

| Compact Flow Switch | Weatherproof design, suitable for various pipe sizes | Liquid and gas monitoring in harsh environments | Pros: Durable, compact. Cons: May require specific pipe fittings. |

| Thermal Dispersion Flow Switch | LED indicators, adjustable flow rates, designed for multiple outputs | Boilers, chillers, liquid transfer systems | Pros: Visual feedback, versatile. Cons: More expensive than basic models. |

What are the characteristics of Adjustable Air Flow Switches?

Adjustable air flow switches are designed with a stainless steel vane, making them robust and reliable for detecting air flow in HVAC systems. Their minimal calibration requirement allows for quick installation and adjustment, making them ideal for various industrial applications. Buyers should consider the flexibility in settings and ease of installation when selecting this type.

Why are Duct Air Flow Switches suitable for specific applications?

Duct air flow switches are specifically engineered to monitor air flow within duct systems. Their adjustable output settings provide versatility in applications such as air handling units and filter monitoring. B2B buyers should focus on the reliability and performance of these switches, especially in environments where consistent air flow is critical for operational efficiency.

How do Air Flow Pressure Switches function in commercial settings?

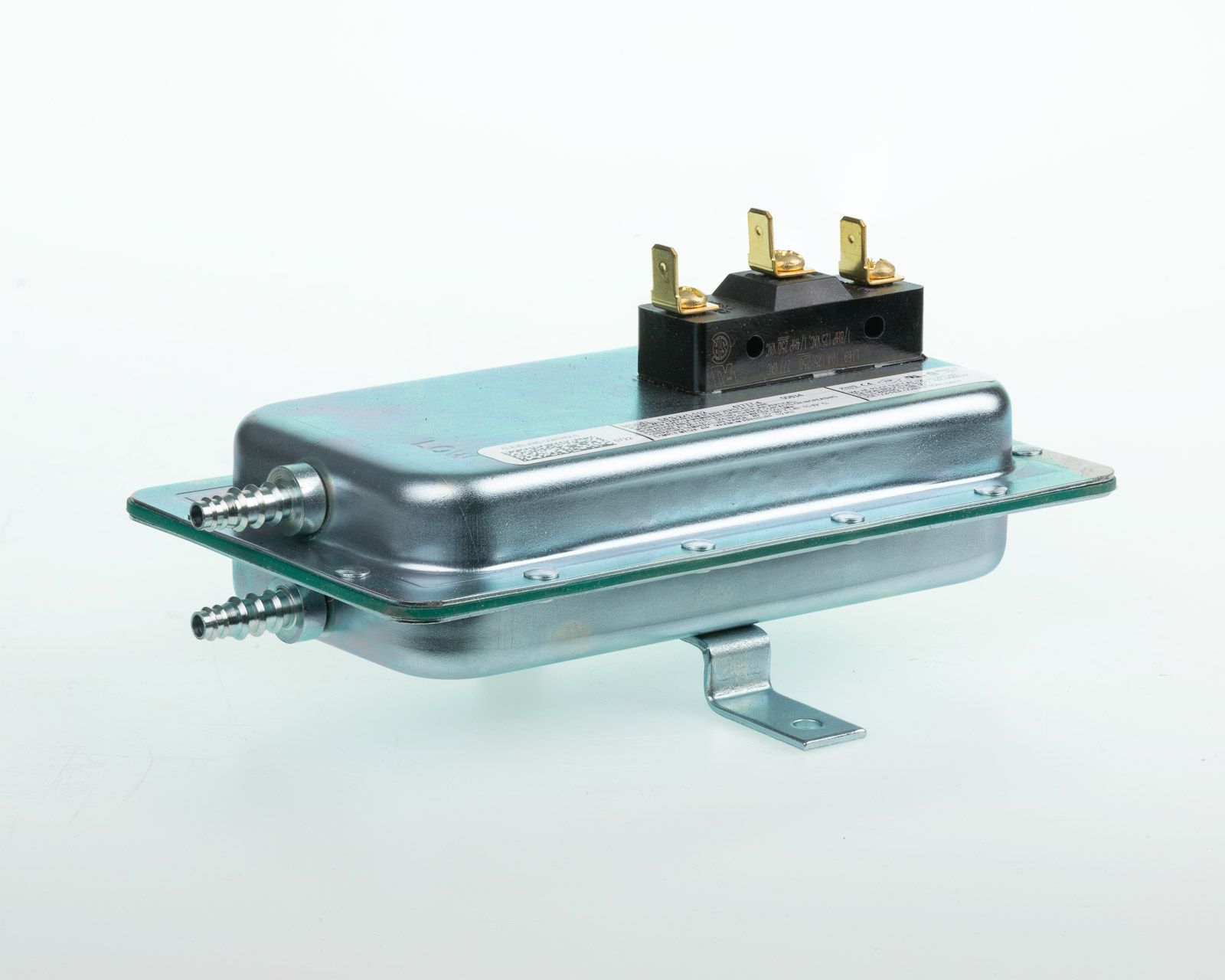

Air flow pressure switches are pivotal in monitoring pressure drops across systems, particularly in commercial kitchens and HVAC applications. They can be configured to have fixed or adjustable set points, allowing for precise control over air flow conditions. Buyers must evaluate the complexity of installation and the accuracy of the pressure monitoring features to ensure compatibility with their systems.

What advantages do Compact Flow Switches offer in challenging environments?

Compact flow switches are designed for durability and can withstand harsh environmental conditions, making them suitable for monitoring liquids and gases. Their weatherproof design and compatibility with various pipe sizes enhance their utility in diverse applications. B2B buyers should consider the specific pipe fittings required and the switch’s resilience when making purchasing decisions.

Why choose Thermal Dispersion Flow Switches for versatile applications?

Thermal dispersion flow switches offer adjustable flow rates and come equipped with LED indicators for easy monitoring. They are particularly beneficial in applications like boilers and chillers, where real-time flow visibility is essential. While these switches may come at a higher price point, their versatility and visual feedback capabilities make them a valuable investment for B2B buyers seeking reliability and performance.

Key Industrial Applications of air flow switch

| Industry/Sector | Specific Application of air flow switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Monitoring air flow in heating and cooling systems | Ensures system efficiency and prevents equipment damage | Consider durability, temperature range, and compatibility with system components |

| Industrial Manufacturing | Air flow monitoring in dust collection systems | Enhances safety by preventing hazardous dust build-up | Look for adjustable settings and compliance with local safety regulations |

| Food Processing | Ensuring proper airflow in refrigeration units | Maintains product quality and extends shelf life | Focus on hygienic design and materials that comply with food safety standards |

| Oil & Gas | Monitoring ventilation in extraction facilities | Prevents explosive environments and enhances safety | Ensure robustness against harsh conditions and environmental factors |

| Environmental Control | Air flow monitoring in pollution control systems | Supports regulatory compliance and environmental sustainability | Assess accuracy and responsiveness to varying air quality conditions |

How is an air flow switch used in HVAC systems and what problems does it solve?

In HVAC applications, air flow switches are critical for monitoring the air flow in heating and cooling systems. They detect any changes in air flow, which can indicate blockages or failures in the system. By ensuring optimal air flow, these switches help prevent equipment damage and enhance energy efficiency. For international buyers, especially in regions like Europe and Africa, it is essential to consider the switch’s durability and compatibility with local HVAC standards to ensure reliable operation.

What role do air flow switches play in industrial manufacturing dust collection systems?

In industrial manufacturing, air flow switches are vital for monitoring air flow in dust collection systems. They help prevent hazardous dust build-up, which can pose serious safety risks, including fire and health hazards. By providing real-time feedback, these switches facilitate timely maintenance and operational adjustments. Buyers from South America and the Middle East should prioritize switches that offer adjustable settings and adhere to local safety regulations to ensure compliance and safety in their operations.

How do air flow switches ensure product quality in food processing?

In food processing, air flow switches are used to monitor airflow in refrigeration units, ensuring that products are kept at the optimal temperature. This monitoring helps maintain product quality and extends shelf life by preventing spoilage. For businesses in the food industry, particularly in regions with strict food safety regulations, it is crucial to source switches made from hygienic materials that comply with food safety standards to avoid contamination.

Why are air flow switches essential in oil and gas extraction facilities?

In the oil and gas sector, air flow switches are essential for monitoring ventilation systems in extraction facilities. These switches help prevent the creation of explosive environments by ensuring adequate air flow, thereby enhancing safety. Buyers in this industry should seek robust switches that can withstand harsh environmental conditions and provide reliable operation under extreme temperatures and pressures.

How do air flow switches support environmental control systems?

Air flow switches play a significant role in environmental control systems, particularly in pollution control applications. By monitoring air flow, they help ensure compliance with environmental regulations and support sustainability initiatives. For businesses looking to source these switches, it is important to assess their accuracy and responsiveness to varying air quality conditions, especially in regions with strict environmental standards.

3 Common User Pain Points for ‘air flow switch’ & Their Solutions

Scenario 1: Inconsistent Air Flow Readings Compromise System Performance

The Problem: B2B buyers often face challenges with air flow switches that provide inconsistent or inaccurate readings. This issue can stem from improper installation, environmental factors, or even equipment wear and tear. For instance, HVAC systems depend heavily on accurate air flow measurements to optimize performance and ensure energy efficiency. When an air flow switch fails to deliver reliable data, it can lead to system inefficiencies, increased energy costs, and ultimately, equipment damage.

The Solution: To mitigate this issue, buyers should prioritize the selection of high-quality air flow switches that are compatible with their specific systems. When sourcing these devices, consider features such as adjustable set points and robust calibration options. It’s advisable to consult with manufacturers about the best practices for installation and maintenance. Regularly scheduled inspections can also help identify early signs of wear or malfunction. Additionally, utilizing air flow switches with built-in diagnostic features can provide real-time alerts, enabling proactive maintenance before issues escalate.

Scenario 2: Difficulty in Integration with Existing Systems

The Problem: Many businesses encounter integration challenges when attempting to implement air flow switches in existing HVAC or industrial systems. Compatibility issues may arise due to variations in system design, electrical specifications, or communication protocols. This can result in operational delays, increased costs, and frustration among teams tasked with system upgrades.

The Solution: To ensure seamless integration, it’s crucial to conduct a thorough compatibility assessment before purchasing an air flow switch. Buyers should engage with suppliers who provide comprehensive technical specifications and support for their products. Look for air flow switches that offer flexible installation options and can accommodate various mounting orientations and electrical connections. Furthermore, investing in solutions that feature standardized communication protocols can facilitate easier integration with existing automation systems. Collaboration with the supplier during the installation phase can also ensure that the air flow switch operates effectively within the broader system context.

Scenario 3: Lack of Real-Time Monitoring and Alerts

The Problem: Many businesses operate without real-time monitoring capabilities for air flow switches, which can lead to delayed responses to critical changes in air flow conditions. This lack of monitoring can result in hazardous situations, particularly in applications involving sensitive processes, such as in pharmaceutical manufacturing or food service. Consequently, companies may face compliance issues or even jeopardize product quality due to inadequate air flow management.

The Solution: To address this pain point, B2B buyers should consider air flow switches equipped with advanced monitoring and alerting functionalities. These devices can provide immediate feedback on air flow conditions and trigger alarms when parameters fall outside acceptable ranges. When selecting an air flow switch, prioritize models that offer digital interfaces and remote monitoring capabilities, allowing for integration with existing facility management systems. Additionally, implementing a centralized monitoring system can help teams stay informed about air flow status in real-time, enabling quick action to rectify any deviations. Regular training sessions for staff on using monitoring systems can further enhance responsiveness and ensure compliance with safety standards.

Strategic Material Selection Guide for air flow switch

What Are the Key Properties of Common Materials Used in Air Flow Switches?

When selecting materials for air flow switches, it is essential to consider their physical and chemical properties, which directly impact performance, durability, and compatibility with various media. Below, we analyze four common materials used in air flow switches: stainless steel, aluminum, plastic, and brass.

1. Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance, excellent strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures exceeding 150 psi.

Pros & Cons: The durability of stainless steel makes it suitable for harsh environments, including industrial applications. However, its higher cost compared to other materials can be a drawback for budget-sensitive projects. Manufacturing complexity can also increase due to the need for specialized machining.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive gases and liquids, making it ideal for HVAC systems and industrial applications.

International Considerations: Buyers from regions like Europe and the Middle East may prefer stainless steel due to its compliance with standards such as DIN and ASTM. However, the higher cost may be a consideration in developing markets like Nigeria and South America.

2. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and is suitable for moderate temperature applications, typically up to 400°F (204°C). It is also relatively easy to machine and fabricate.

Pros & Cons: The low weight of aluminum makes it an excellent choice for portable applications, and its cost is generally lower than that of stainless steel. However, it may not perform well in high-temperature or high-pressure environments, limiting its applications.

Impact on Application: Aluminum is suitable for air flow switches in less demanding environments, such as residential HVAC systems. However, it may not be suitable for applications involving corrosive substances.

International Considerations: In regions with stringent environmental regulations, aluminum’s recyclability can be a significant advantage. However, buyers must ensure compliance with local standards to avoid issues in procurement.

3. Plastic

Key Properties: Plastics, such as polycarbonate or PVC, offer excellent corrosion resistance and are lightweight. They typically have a lower temperature rating, around 180°F (82°C), and lower pressure ratings compared to metals.

Pros & Cons: The primary advantage of plastic is its cost-effectiveness and ease of manufacturing. However, plastics may not be suitable for high-temperature or high-pressure applications, limiting their use in industrial settings.

Impact on Application: Plastic air flow switches are ideal for residential applications or environments where chemical exposure is minimal. They are often used in HVAC systems and other low-stress applications.

International Considerations: Buyers should verify the chemical compatibility of plastic materials with specific media, especially in regions with diverse industrial applications. Compliance with international standards like ISO for plastics may also be necessary.

4. Brass

Key Properties: Brass is known for its good corrosion resistance and ability to withstand moderate temperatures and pressures, typically rated up to 300°F (149°C) and 150 psi.

Pros & Cons: The aesthetic appeal of brass can be advantageous for applications where visibility is essential. However, its cost can be higher than that of plastics and aluminum, and it may not be suitable for highly corrosive environments.

Impact on Application: Brass is often used in air flow switches for HVAC systems and plumbing applications due to its durability and resistance to corrosion from water and air.

International Considerations: Brass components must comply with regional regulations regarding lead content, especially in Europe, where standards are stringent. Buyers in developing regions should consider the cost implications of sourcing brass components.

Summary Table of Material Selection for Air Flow Switches

| Material | Typical Use Case for air flow switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial HVAC systems | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Residential HVAC systems | Lightweight and cost-effective | Limited high-temperature performance | Medium |

| Plastic | Low-stress residential applications | Cost-effective and easy to manufacture | Not suitable for high temperatures/pressures | Low |

| Brass | HVAC and plumbing applications | Good corrosion resistance and aesthetics | Higher cost and lead content regulations | Medium |

This strategic material selection guide aims to equip B2B buyers with critical insights into the properties, advantages, limitations, and considerations of various materials used in air flow switches, enabling informed purchasing decisions tailored to specific regional needs and standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air flow switch

What Are the Key Stages in the Manufacturing Process of Air Flow Switches?

Manufacturing air flow switches involves several critical stages, each requiring specific techniques and quality checks to ensure a reliable end product. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Quality Control

The first step in manufacturing air flow switches is sourcing high-quality materials that can withstand various environmental conditions. Common materials include stainless steel, plastic, and various alloys, chosen for their durability and compatibility with the intended application. Quality checks during this stage often involve verifying supplier certifications and conducting incoming quality control (IQC) inspections to ensure materials meet predefined specifications.

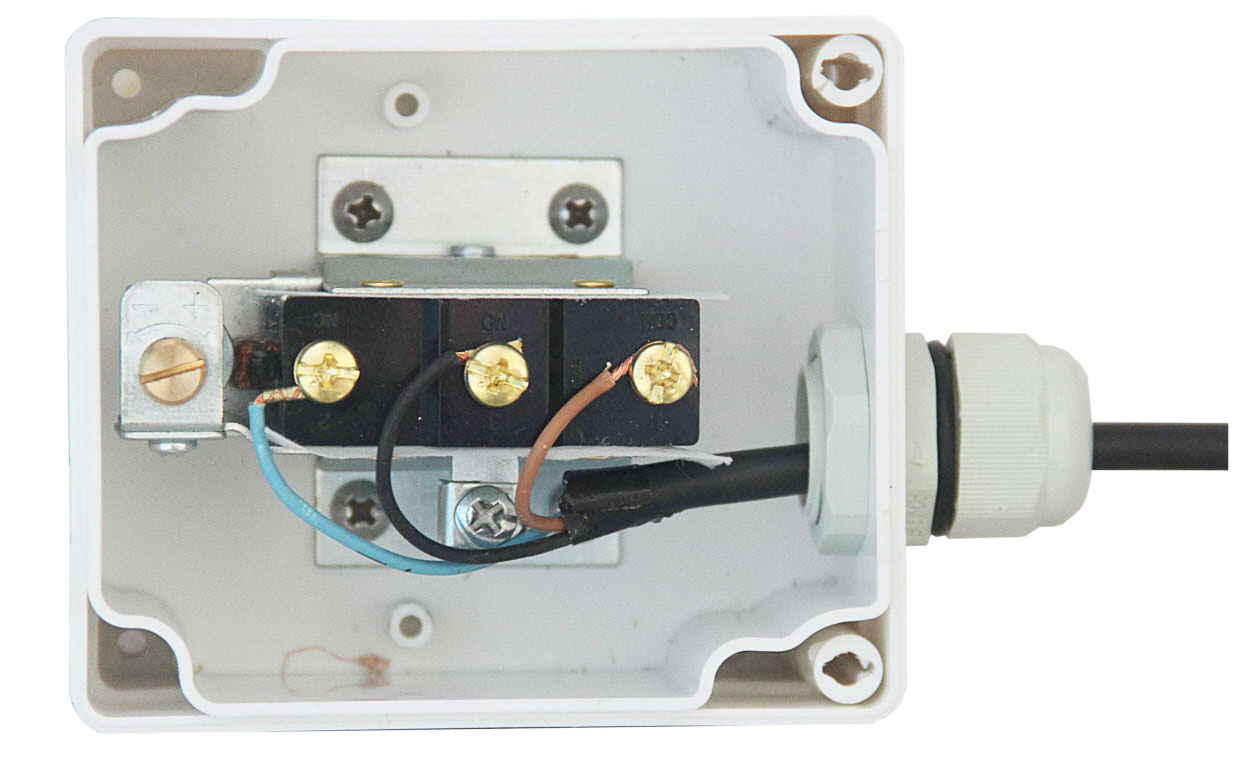

Illustrative image related to air flow switch

Forming: Techniques for Precision Manufacturing

Once materials are prepared, they undergo forming processes, which may include machining, stamping, and molding. CNC machining is widely used to achieve high precision in components like vanes and housings. For plastic parts, injection molding is a common technique, allowing for complex shapes with minimal waste. Each forming technique requires adherence to strict tolerances, and manufacturers often utilize computer-aided design (CAD) software to optimize designs before production.

Assembly: Ensuring Functionality and Reliability

The assembly stage is where the individual components come together. This process often involves both manual and automated techniques, depending on the complexity of the switch. Automated assembly can enhance efficiency and reduce human error, while manual assembly allows for more intricate adjustments. During this phase, manufacturers typically conduct in-process quality control (IPQC) to ensure that each component fits correctly and functions as intended.

Finishing: Final Touches for Performance and Aesthetics

The final stage of manufacturing is finishing, which may include surface treatments, painting, or coating to enhance durability and aesthetics. For example, anodizing or powder coating can provide additional protection against corrosion. Quality assurance during this stage often includes testing for surface defects and ensuring compliance with industry standards.

How Is Quality Assurance Implemented in Air Flow Switch Manufacturing?

Quality assurance (QA) is crucial for ensuring that air flow switches meet industry standards and customer expectations. Various international and industry-specific standards guide the QA process, including ISO 9001 for general quality management systems, CE marking for compliance in Europe, and API standards for applications in the petroleum industry.

What Are the Key International Standards for Air Flow Switches?

-

ISO 9001: This standard outlines requirements for a quality management system, emphasizing customer satisfaction and continuous improvement. Manufacturers seeking ISO 9001 certification demonstrate their commitment to quality processes.

-

CE Marking: In Europe, CE marking indicates that a product meets health, safety, and environmental protection standards. Air flow switches intended for the European market must comply with relevant directives to obtain CE certification.

-

API Standards: For applications in the oil and gas sectors, adherence to API standards ensures that air flow switches meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated at various stages of the manufacturing process to catch defects early and ensure compliance with standards. These checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production process.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks the assembly and functionality of components at various stages, helping to identify issues before they escalate.

-

Final Quality Control (FQC): The final checkpoint before shipping, FQC involves comprehensive testing of the finished product to ensure it meets all specifications and standards. Common tests include pressure testing, flow rate measurement, and electrical safety assessments.

What Testing Methods Are Commonly Used for Air Flow Switches?

Testing is a vital part of the quality assurance process for air flow switches, ensuring that they operate reliably under specified conditions. Common testing methods include:

- Functional Testing: Verifying that the switch activates and deactivates as intended at specified flow rates.

- Pressure Testing: Ensuring that the switch can withstand the operational pressures without failure.

- Environmental Testing: Assessing performance under various environmental conditions, such as extreme temperatures or humidity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to source air flow switches should ensure that their suppliers maintain robust quality control practices. Here are several actionable steps:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes reviewing their certifications, production capabilities, and quality control measures.

-

Requesting Quality Reports: Buyers should ask suppliers for quality reports, including data on defect rates, testing results, and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes and product reliability.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality control:

-

Understanding Local Regulations: Different regions have varying compliance requirements. Buyers should familiarize themselves with local regulations, such as CE marking in Europe or specific safety standards in their target market.

-

Cultural Considerations: Communication and business practices can vary significantly across cultures. Establishing clear expectations regarding quality standards and testing procedures is essential to avoid misunderstandings.

-

Logistical Challenges: Shipping and logistics can impact product quality. Buyers should ensure that suppliers have robust packaging and handling procedures to protect products during transit.

By understanding the manufacturing processes and quality assurance practices for air flow switches, B2B buyers can make informed decisions, ensuring they source reliable and compliant products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air flow switch’

In the competitive landscape of B2B procurement, sourcing the right air flow switch is vital for ensuring system efficiency and safety. This guide provides a practical checklist to help international buyers navigate the procurement process effectively, focusing on critical aspects that influence decision-making.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of sourcing the right air flow switch. Consider factors such as the switch type (e.g., paddle, pressure sensing), operating temperature range, and air flow rate requirements. Understanding these parameters will help you filter suppliers and products that meet your operational needs.

Step 2: Identify Application Requirements

Different applications have unique requirements for air flow switches. Whether for HVAC systems, industrial processes, or commercial kitchens, it’s essential to clarify the context in which the switch will operate. Identify specific functionalities, such as alarm settings for low or high flow rates, and ensure the chosen switch can handle the intended media, whether air, gas, or other particulates.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies relevant to your industry. Consider reaching out for references from previous buyers to gauge their satisfaction with both the product and the supplier’s service. This step minimizes risks associated with quality and reliability.

Illustrative image related to air flow switch

Step 4: Verify Compliance and Certifications

Ensure that the air flow switches comply with relevant industry standards and certifications. Depending on your region, look for certifications such as CE, UL, or ISO to ensure product safety and reliability. Compliance not only guarantees quality but also facilitates smoother import processes across different countries.

Step 5: Assess Customization Options

Consider whether you require customized solutions for your air flow switch needs. Some suppliers offer configurable options to meet specific operational requirements, such as unique mounting solutions or specialized materials for harsh environments. Assessing these options early can save time and costs in the long run.

Step 6: Inquire About Support and Maintenance

After selecting a supplier, inquire about the support and maintenance services they offer. A reliable supplier should provide installation guidance, calibration services, and ongoing technical support. Understanding the maintenance requirements will ensure the longevity and optimal performance of the air flow switch in your application.

Step 7: Review Pricing and Payment Terms

Finally, review pricing structures and payment terms carefully. Compare quotes from multiple suppliers while considering factors like warranty offers and after-sales service. Make sure to clarify any additional costs, such as shipping or duties, which could affect the total investment.

By following these steps, B2B buyers can strategically navigate the sourcing process for air flow switches, ensuring they select the best options for their operational needs while mitigating risks associated with procurement.

Comprehensive Cost and Pricing Analysis for air flow switch Sourcing

What are the Key Cost Components in Air Flow Switch Sourcing?

When sourcing air flow switches, understanding the cost structure is crucial for B2B buyers. The primary components influencing costs include:

-

Materials: The choice of materials significantly affects the price of air flow switches. Common materials include stainless steel for durability, plastics for lightweight options, and specialized alloys for high-performance applications. Higher-quality materials may incur additional costs but can lead to enhanced longevity and reliability.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. In regions with higher labor costs, such as parts of Europe, the overall pricing may reflect these expenses. Conversely, sourcing from regions with lower labor costs can provide savings, but it is essential to assess the quality of workmanship.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, and utilities. Manufacturers with advanced production technologies may charge a premium, but this can result in improved efficiency and product quality.

-

Tooling: Custom tooling for specific applications can add to the initial investment. If a buyer requires specialized designs or features, these costs should be factored into the total price.

-

Quality Control (QC): A robust QC process ensures that the air flow switches meet performance specifications. Suppliers investing in comprehensive QC measures may charge higher prices, but this can mitigate risks related to product failures.

-

Logistics: Transportation costs can vary based on the mode of shipping, distance, and the Incoterms agreed upon. Buyers should consider potential tariffs and duties, especially for international shipments.

-

Margin: Supplier margins can vary widely based on market competition, brand reputation, and product differentiation. Understanding the typical margins in your target market can aid in negotiations.

How Do Price Influencers Affect Air Flow Switch Costs?

Several factors can influence the pricing of air flow switches, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract discounts due to economies of scale. Buyers should assess their needs to determine the optimal order quantity to negotiate better pricing.

-

Specifications and Customization: Customized solutions tailored to specific applications may incur additional costs. Buyers must weigh the benefits of customization against the associated price increases.

-

Quality and Certifications: Products meeting international standards (e.g., ISO, CE) may come at a premium. However, such certifications often reflect a commitment to quality and reliability, which can be critical for operational efficiency.

-

Supplier Factors: Supplier reliability, reputation, and service capabilities can influence pricing. Established suppliers may charge more but often provide better support and product guarantees.

-

Incoterms: The chosen Incoterms affect the distribution of costs and responsibilities between buyer and seller. Understanding these terms can help avoid unexpected expenses.

What Tips Can Buyers Use for Cost-Efficiency in Air Flow Switch Sourcing?

To enhance cost-efficiency in sourcing air flow switches, consider the following strategies:

-

Negotiation: Leverage your position as a buyer by negotiating terms, especially for bulk orders. Establishing long-term relationships with suppliers can also lead to better pricing and service.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but the total cost of ownership, which includes maintenance, operational costs, and potential downtimes. Selecting higher-quality switches may result in lower TCO over time.

-

Pricing Nuances for International Buyers: International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of regional pricing strategies. Currency fluctuations, import duties, and local market conditions can significantly affect total costs.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices and features across suppliers. This knowledge can provide leverage during negotiations and help identify the best value for your investment.

Disclaimer

The prices and cost structures discussed in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek multiple quotes and conduct due diligence before finalizing procurement decisions.

Illustrative image related to air flow switch

Alternatives Analysis: Comparing air flow switch With Other Solutions

Exploring Alternatives to Air Flow Switches

In the quest for efficient airflow management in various industrial and commercial applications, businesses often consider multiple solutions. While air flow switches are widely used for monitoring and ensuring optimal airflow, alternatives exist that may better fit specific operational needs or budget constraints. This section compares air flow switches with two viable alternatives: air flow pressure switches and flow meters. Each solution has unique advantages and potential drawbacks, making it essential for buyers to understand their options.

| Comparison Aspect | Air Flow Switch | Air Flow Pressure Switch | Flow Meter |

|---|---|---|---|

| Performance | Monitors airflow, ensuring system safety and efficiency. | Detects pressure variations, indicating airflow indirectly. | Measures actual flow rate, providing precise data. |

| Cost | Moderate; typically lower than flow meters. | Generally lower to moderate; varies by specifications. | Higher initial investment but offers extensive data. |

| Ease of Implementation | Straightforward installation with minimal calibration. | Simple setup, often factory-calibrated. | More complex installation; may require additional equipment. |

| Maintenance | Low maintenance; periodic checks recommended. | Low to moderate; requires calibration checks. | Higher maintenance due to moving parts and calibration needs. |

| Best Use Case | Ideal for HVAC systems and applications needing flow detection. | Suited for systems where pressure drop indicates airflow. | Best for processes requiring precise flow measurements, such as in manufacturing. |

Understanding Air Flow Pressure Switches

Air flow pressure switches are designed to sense pressure changes across a system, providing an indirect method of monitoring airflow. They are generally cost-effective and easy to implement, making them suitable for applications where budget constraints are a primary concern. However, they may lack the precision of direct airflow measurements, which can be a drawback in systems requiring tight control. Their primary advantage lies in their simplicity and reliability, particularly in HVAC systems where a pressure drop can signal airflow issues.

Evaluating Flow Meters

Flow meters offer a direct measurement of airflow, providing real-time data that can enhance operational efficiency and safety. While they tend to have a higher upfront cost compared to air flow switches and pressure switches, the detailed insights they provide can lead to significant savings and improved performance over time. However, their installation can be more complex, often requiring specialized knowledge and additional equipment. Maintenance can also be more demanding due to the potential for wear and tear on moving parts. Flow meters are best suited for environments where precise flow control is critical, such as in manufacturing processes or laboratory settings.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right airflow management solution, B2B buyers should carefully consider their specific operational requirements, including performance needs, budget constraints, and ease of maintenance. Air flow switches offer a reliable and cost-effective option for most HVAC and industrial applications, while air flow pressure switches can serve as a budget-friendly alternative with indirect measurement capabilities. For those needing precise flow data, flow meters may be the best choice despite their higher costs and maintenance requirements. By evaluating these factors, businesses can make informed decisions that align with their operational goals and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for air flow switch

Understanding the critical specifications and terminology associated with air flow switches is essential for making informed purchasing decisions in the B2B sector. This guide aims to clarify the key technical properties and common trade terms relevant to air flow switches, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Technical Specifications for Air Flow Switches?

1. Material Grade

The material of an air flow switch directly impacts its durability and compatibility with various environments. Common materials include stainless steel, plastic, and die-cast aluminum. For instance, stainless steel offers superior corrosion resistance, making it suitable for harsh conditions, while plastic may be more cost-effective for less demanding applications. Selecting the right material is crucial for ensuring longevity and reliability, especially in industrial applications.

2. Operating Temperature Range

Air flow switches come with specified maximum and minimum operating temperatures, typically expressed in degrees Celsius or Fahrenheit. This specification is vital for applications exposed to extreme heat or cold. Choosing a switch with an appropriate temperature range ensures optimal functionality and prevents premature failure, which can lead to costly downtime.

3. Air Flow Rate

The air flow rate is usually measured in feet per minute (FPM) or cubic feet per minute (CFM). This specification indicates the minimum and maximum air flow the switch can effectively monitor. Understanding the required air flow rate for your system is essential for selecting a switch that can accurately detect changes, thereby ensuring system efficiency and safety.

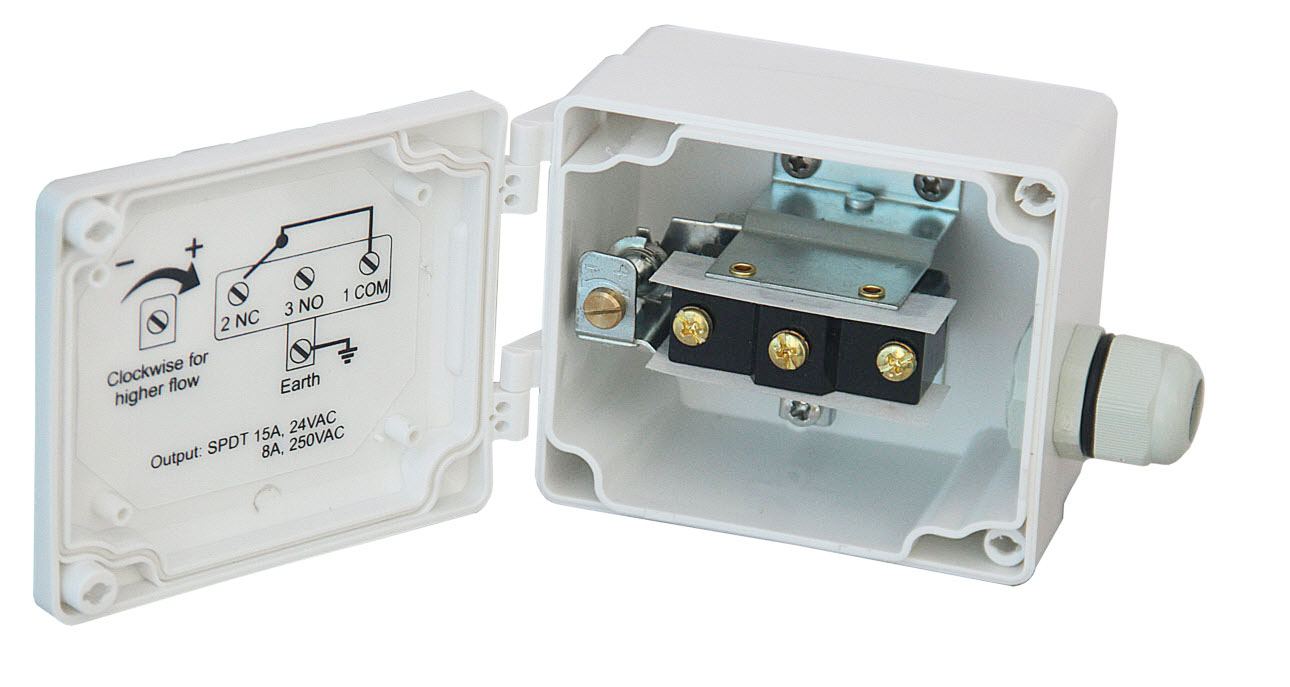

4. Electrical Connection Type

Different air flow switches feature various electrical connection types, such as SPST (Single Pole Single Throw) or SPDT (Single Pole Double Throw). The choice of electrical connection affects how the switch integrates with existing systems. Knowing the connection type is crucial for ensuring compatibility with controllers and alarms, which can simplify installation and maintenance.

5. Switch Rating

The switch rating, which indicates the maximum voltage and current the switch can handle, is critical for ensuring safety and compliance with local regulations. Ratings are typically expressed in volts and amps. A switch with an appropriate rating will help prevent electrical failures and enhance the overall reliability of the system.

What Are Common Trade Terms Related to Air Flow Switches?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that may be marketed by another manufacturer. Understanding OEM products is essential for buyers looking for customized solutions that meet specific operational requirements.

Illustrative image related to air flow switch

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is particularly relevant for B2B buyers who need to understand bulk purchasing requirements to optimize inventory levels and cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. Utilizing RFQs can streamline the procurement process, ensuring that buyers receive competitive offers and can make well-informed decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms helps businesses manage shipping costs, risks, and delivery timelines effectively.

5. NEMA Ratings (National Electrical Manufacturers Association)

NEMA ratings classify enclosures based on their ability to protect against environmental conditions such as dust, water, and corrosion. Understanding these ratings is essential for ensuring that the air flow switch can operate effectively in its intended environment.

By familiarizing yourself with these essential technical specifications and trade terminologies, you can make informed decisions when sourcing air flow switches, ultimately enhancing the performance and reliability of your systems.

Navigating Market Dynamics and Sourcing Trends in the air flow switch Sector

What Are the Key Market Dynamics and Trends Influencing the Air Flow Switch Sector?

The air flow switch sector is experiencing significant growth driven by several global factors, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. A major driver is the increasing demand for energy-efficient HVAC systems, which utilize air flow switches to optimize performance and reduce energy consumption. Additionally, the rise in industrial automation is leading to a greater reliance on air flow switches for monitoring and controlling air flow in manufacturing processes.

Current B2B tech trends include the integration of smart technologies, such as IoT-enabled air flow switches that provide real-time monitoring and analytics. This capability is particularly appealing to international buyers looking to enhance operational efficiency and predictive maintenance in their facilities. Moreover, sustainability is becoming a critical consideration; buyers are increasingly favoring products that demonstrate environmental responsibility and energy efficiency.

International buyers, especially from regions like Germany and Nigeria, are also navigating regulatory changes that mandate stricter compliance with safety and environmental standards. This has led to a surge in demand for air flow switches that meet these compliance requirements, making it essential for buyers to source products that not only fulfill operational needs but also adhere to local and international regulations.

How Important Is Sustainability and Ethical Sourcing in the Air Flow Switch Sector?

Sustainability and ethical sourcing have become paramount in the air flow switch sector as businesses increasingly recognize their environmental impact. The production of air flow switches often involves materials and processes that can contribute to carbon footprints and resource depletion. As a result, buyers are now prioritizing products made from sustainable materials and those that are manufactured using environmentally friendly processes.

Illustrative image related to air flow switch

Ethical supply chains are also gaining traction. Buyers are urged to scrutinize their suppliers’ practices to ensure fair labor conditions and minimal environmental harm. Certifications such as ISO 14001 for environmental management systems or LEED for sustainable building practices are becoming key indicators of a supplier’s commitment to sustainability.

Incorporating ‘green’ certifications into sourcing decisions not only enhances a company’s brand reputation but also aligns with the growing consumer and regulatory demand for environmentally responsible products. This trend is particularly relevant for international buyers in Europe, where sustainability regulations are stringent, but it is increasingly influencing purchasing decisions in Africa and South America as well.

What Has Been the Evolution of Air Flow Switches in the B2B Context?

The evolution of air flow switches has been characterized by advancements in technology and a growing focus on efficiency and safety. Initially, air flow switches were simple mechanical devices designed to detect air flow in HVAC systems. Over the years, they have transformed into sophisticated electronic devices that provide precise measurements and real-time data analytics.

The introduction of digital technologies, such as IoT connectivity, has further expanded their capabilities, allowing for remote monitoring and automated alerts. This evolution has made air flow switches indispensable in various sectors, including HVAC, industrial automation, and energy management. Today’s air flow switches not only enhance operational efficiency but also contribute to energy savings and compliance with stringent safety regulations, making them a vital component of modern industrial systems.

In summary, the air flow switch sector is witnessing dynamic changes shaped by technological advancements, sustainability imperatives, and evolving market demands. International buyers must stay informed and adapt their sourcing strategies to leverage these trends effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of air flow switch

-

How do I solve airflow issues in my HVAC system?

To address airflow issues, begin by inspecting your air flow switches for proper functionality. Ensure that they are calibrated correctly and check for any obstructions in the ductwork that could impede air movement. Regular maintenance, including cleaning filters and ducts, is crucial. If problems persist, consider upgrading your air flow switch to a model with better sensitivity or adjustable settings to enhance monitoring capabilities. -

What is the best air flow switch for industrial applications?

For industrial applications, the best air flow switch often depends on specific requirements such as the media type, pressure conditions, and environmental factors. Look for switches designed for high durability and capable of handling extreme temperatures and pressures. Models with adjustable set points and robust construction, such as stainless steel options, are highly recommended for reliable performance in demanding environments. -

How can I evaluate potential suppliers for air flow switches?

When evaluating suppliers, consider their experience in the industry and the quality of their products. Request certifications and compliance documents to ensure they meet international standards. Check customer reviews and testimonials for insights into their reliability and service. Additionally, inquire about their support for international logistics and after-sales service, which is crucial for B2B transactions. -

What are the typical minimum order quantities (MOQs) for air flow switches?

Minimum order quantities for air flow switches can vary widely among suppliers. Some manufacturers may have MOQs as low as 50 units, while others may require orders of 100 or more. It’s essential to discuss your specific needs with potential suppliers to find flexibility in MOQs, especially if you are testing a new product line or entering a new market. -

What payment terms are commonly offered by suppliers of air flow switches?

Common payment terms include net 30 or net 60 days, but this can vary based on the supplier’s policies and your relationship with them. Some suppliers may offer early payment discounts or require a partial upfront payment for larger orders. Always clarify payment terms before finalizing any agreements to avoid misunderstandings and ensure smooth transactions. -

How do I ensure quality assurance for air flow switches?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Inquire about their quality control processes, including testing methods for their air flow switches. Consider conducting third-party inspections or audits, especially for large orders, to verify that the products meet your quality standards and comply with international regulations. -

What logistics considerations should I keep in mind when sourcing air flow switches internationally?

When sourcing internationally, consider shipping methods, delivery times, and customs regulations that may affect your order. Evaluate the total landed cost, including shipping fees, tariffs, and taxes, to avoid unexpected expenses. Partnering with a supplier that offers comprehensive logistics support can streamline the import process and ensure timely delivery of your products. -

Can I customize air flow switches to fit my specific requirements?

Yes, many manufacturers offer customization options for air flow switches. You can request modifications such as specific pressure ranges, materials, or electrical connections to suit your application needs. Discuss your requirements with potential suppliers, and ensure they have the capability to provide prototypes or samples before placing a larger order to confirm that the customizations meet your expectations.

Top 6 Air Flow Switch Manufacturers & Suppliers List

1. McMaster – Airflow Switches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Airflow Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Flows – Flow Switches

Domain: flows.com

Registered: 1995 (30 years)

Introduction: Flow Switches include Air Flow Switch, Insertion Flow Switch, Paddle Flow Switch, Thermal Flow Switch, and Water Flow Switch. They are used in various applications such as residential, commercial, industrial, and agricultural settings.

3. Dwyer – Air Flow Switch

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: {“product_name”: “Air Flow Switch”, “brand”: [“Dwyer”, “Omega”], “price_range”: “$50-$199.99 to $500-$999.99”, “media_compatibility”: [“Air”, “Argon”, “Nitrogen”, “Gases”], “materials_wetted”: [“ABS”, “Brass”, “Galvanized Steel”, “Polycarbonate”, “Stainless Steel”, “Titanium”], “switch_type”: [“Selectable”, “SPDT NO/NC”, “SPST NO”], “compliance”: [“CE”, “UL”, “RoHS3”], “operating_temperature_max”:…

4. Cambridge Air – Air Flow Pressure Switch

Domain: parts.cambridgeair.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Air Flow Pressure Switch”, “Part Number”: “21-193”, “Description”: “This air flow switch senses a pressure drop across the burner.”, “Set Pressure”: “.75 +/- .07 inches of water column”, “Compatibility”: “Designed for vertically mounted C1900, C2500, S1850, S2200, S3200.”, “Replaces”: “21-127”, “Manufacturer Part Number”: “8026501249”, “Lead Time”: “20”}

5. Cleveland Controls – Air Flow Pressure Sensing Switches

Domain: clevelandcontrols.com

Registered: 1998 (27 years)

Introduction: {‘product_name’: ‘Air Flow Pressure Sensing Switches’, ‘manufacturer’: ‘Cleveland Controls’, ‘features’: [‘Electrical switching action at low positive, negative, or differential pressures’, ‘Fixed and adjustable set point models up to 12” wc’, ‘Numerous features, options, and accessories’, ‘Instrumentation for installation, calibration, testing, and maintenance’], ‘industries_served’: [‘HVAC’, ‘En…

6. Grainger – Airflow Switches

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Airflow Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for air flow switch

In the evolving landscape of industrial applications, air flow switches stand out as crucial components for ensuring safety and efficiency. Their ability to monitor air flow in HVAC systems and various industrial processes not only protects equipment from damage but also optimizes performance, making them indispensable for businesses across sectors. As international B2B buyers assess their sourcing strategies, understanding the diverse applications and specifications of air flow switches is vital. Selecting the right model can lead to significant cost savings and enhanced operational reliability.

Strategic sourcing is essential in today’s competitive market. It allows businesses to leverage supplier relationships, negotiate better terms, and ensure compliance with regional standards—particularly important for buyers in regions such as Africa, South America, the Middle East, and Europe. By focusing on quality, compatibility, and service support, organizations can position themselves for success.

Looking ahead, the demand for innovative and reliable air flow switches will continue to grow. Companies are encouraged to engage with suppliers who not only provide high-quality products but also offer technical support and customization options. Investing in strategic partnerships today will pave the way for operational excellence tomorrow. Make the informed choice—prioritize quality and reliability in your sourcing strategy for air flow switches.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.