Choosing Your 4 Port Solenoid Valve: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 4 port solenoid valve

In an increasingly competitive global market, sourcing the right components like 4 port solenoid valves can pose significant challenges for B2B buyers. Whether you’re in the automotive, medical, or packaging industries, understanding the nuances of these valves is crucial to ensuring optimal performance in your systems. This comprehensive guide delves into the diverse types of 4 port solenoid valves, their myriad applications, and the vital considerations for supplier vetting. From cost analysis to performance specifications, we equip international buyers—especially those from Africa, South America, the Middle East, and Europe (including Saudi Arabia and Nigeria)—with the insights needed to make informed purchasing decisions.

Navigating this landscape requires a blend of technical knowledge and market awareness, which is precisely what this guide offers. By addressing key factors such as valve functionality, installation requirements, and maintenance practices, we empower buyers to select the best solutions tailored to their specific needs. Furthermore, we highlight emerging trends and innovative technologies in the solenoid valve market, ensuring that your procurement strategies are aligned with current industry standards. As you explore this guide, you will gain the confidence to choose the right 4 port solenoid valves that not only meet your operational demands but also contribute to your overall business success.

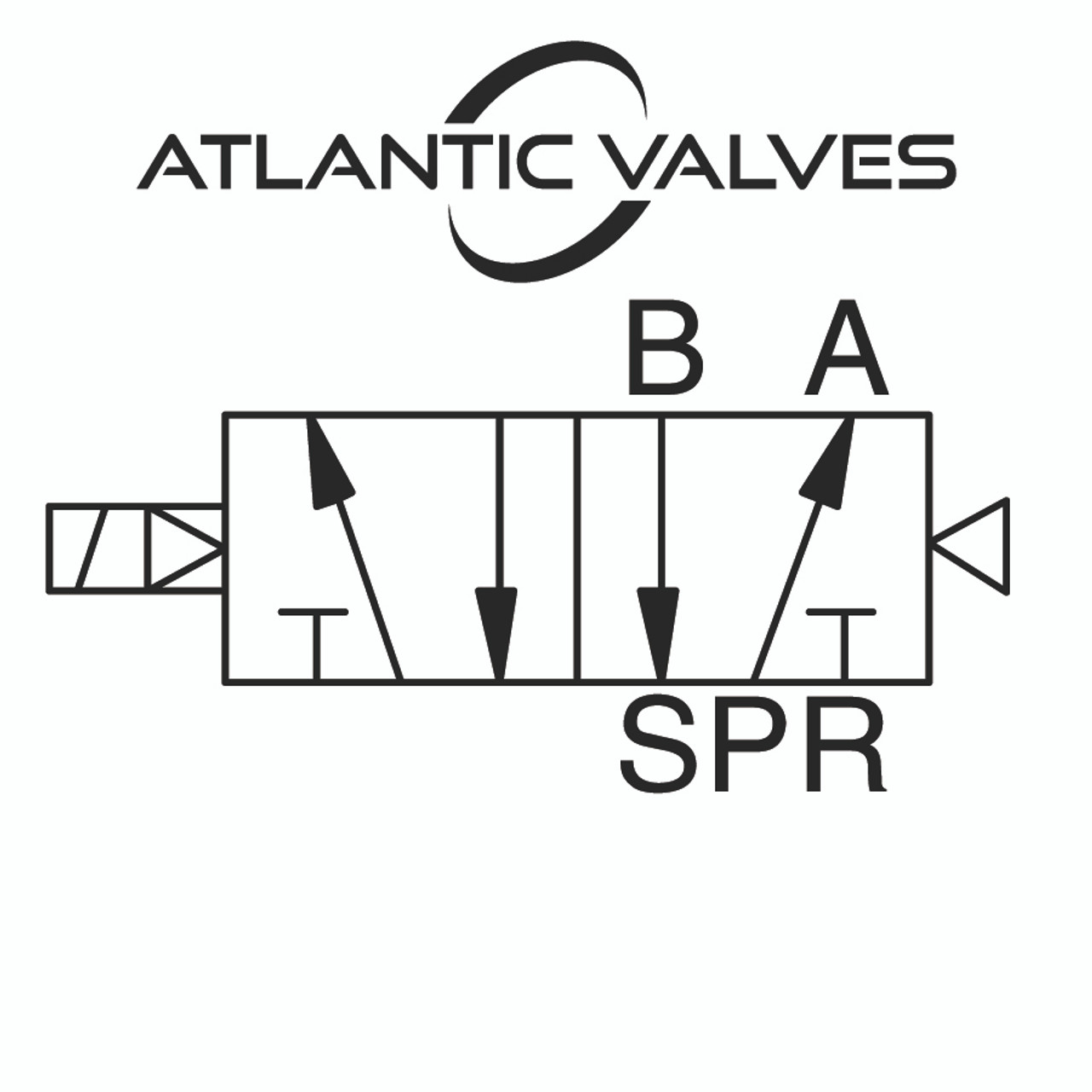

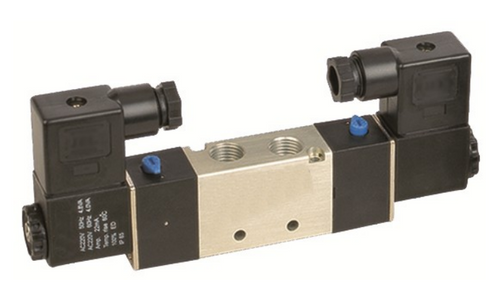

Understanding 4 port solenoid valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Balanced Valves | Compact design, high flow rates, IP67 construction | Automation, HVAC, Packaging | Pros: Space-saving, efficient; Cons: Limited to specific applications. |

| Classic Diaphragm Poppet | Rugged construction, air pilot-operated, leak-proof | Pneumatics, Industrial Equipment | Pros: Durable, reliable; Cons: Slower response times. |

| High Flow Direct Acting | 1/4″ pipe size, multi-purpose design, integral flow control | Automotive, Robotics, Manufacturing | Pros: Versatile, high flow; Cons: Higher initial cost. |

| Clean Design Manifolds | Crevice-free, easy to clean, IP69K rated | Food processing, Pharmaceuticals | Pros: Sanitary, suitable for harsh environments; Cons: More expensive. |

| Intrinsically Safe Valves | Designed for hazardous locations, energy-limiting features | Oil & Gas, Mining, Chemical Processing | Pros: Safety compliant; Cons: Requires additional setup for barriers. |

What are the Key Characteristics of Balanced Valves?

Balanced valves are designed for compactness and versatility, making them ideal for a range of applications in automation, HVAC, and packaging industries. Their high flow rates and optional IP67 rating for dust and moisture resistance enhance their reliability in challenging environments. When purchasing, consider their efficiency and space-saving capabilities, but be mindful of their limitations in specific applications.

How Do Classic Diaphragm Poppet Valves Perform?

Classic diaphragm poppet valves are known for their rugged construction and air pilot operation, ensuring they are leak-proof and can withstand high demands. They are primarily used in pneumatic applications and industrial equipment. Buyers should appreciate their durability and reliability, although they may experience slower response times compared to other types, which could affect performance in fast-paced environments.

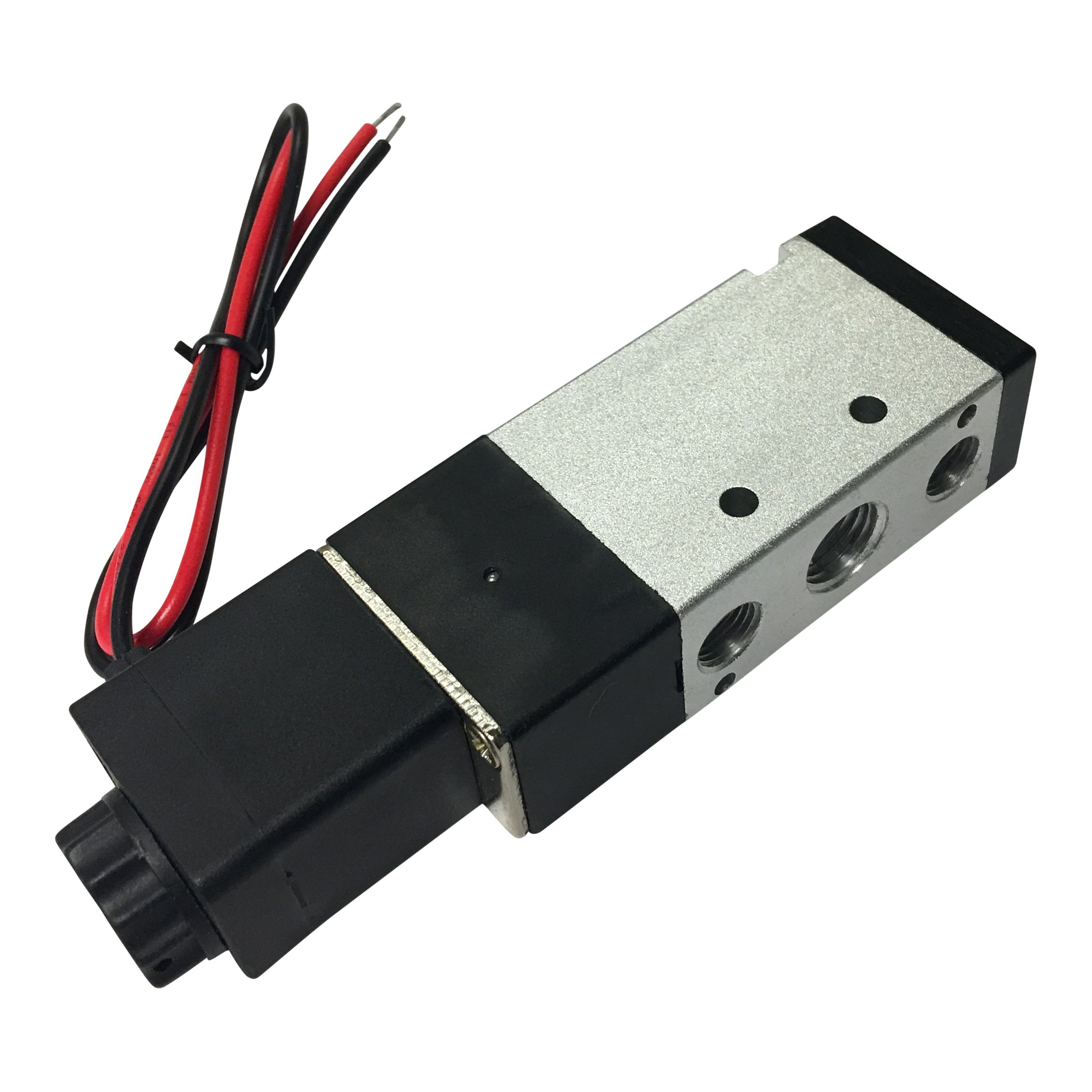

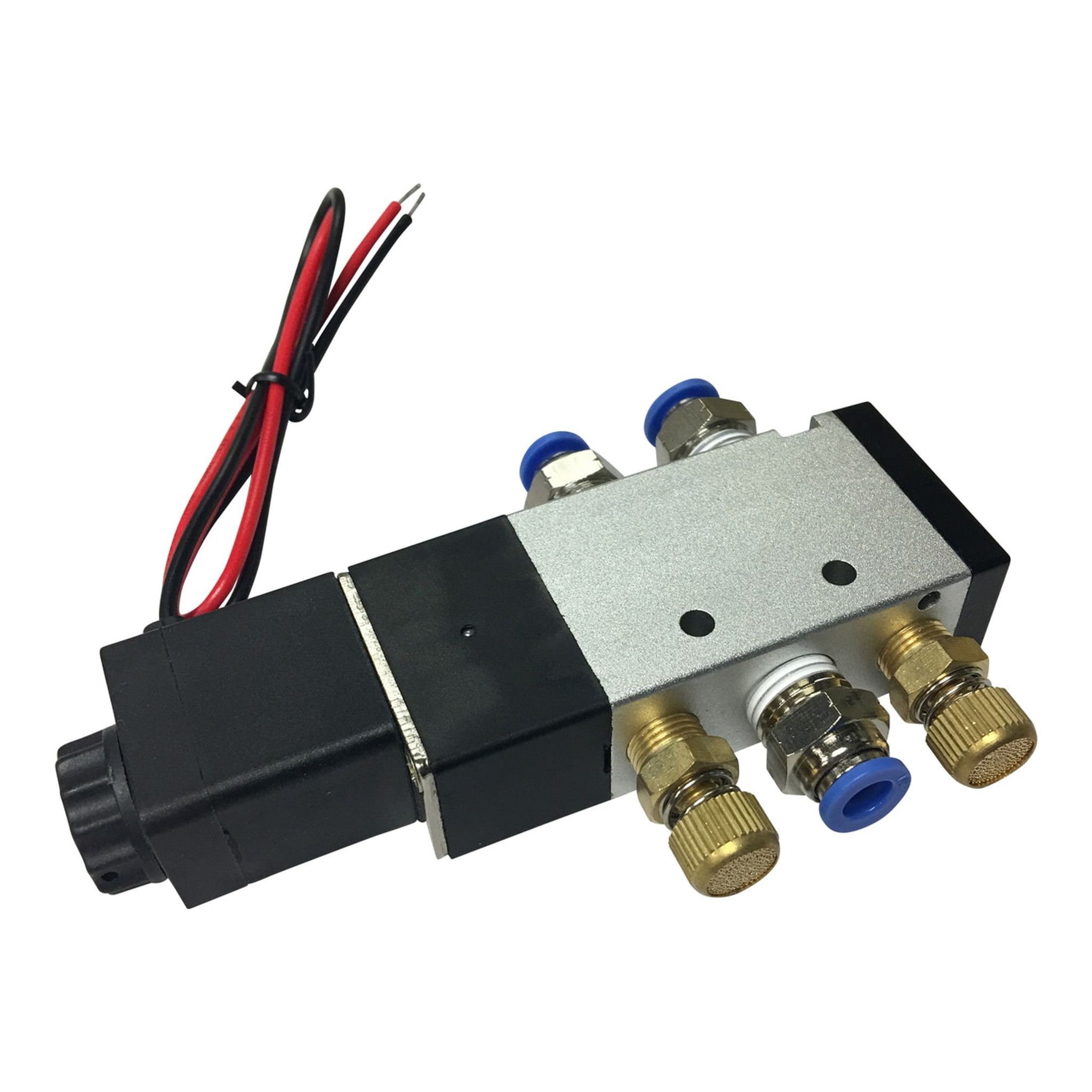

Illustrative image related to 4 port solenoid valve

What Makes High Flow Direct Acting Valves Versatile?

High flow direct acting valves, typically in a 1/4″ pipe size, offer a multi-purpose design that is particularly beneficial in automotive, robotics, and manufacturing sectors. Their integral flow control features allow for precise regulation, making them a popular choice. While they provide great versatility and high flow capabilities, the higher initial cost can be a consideration for budget-conscious buyers.

Why Choose Clean Design Manifolds?

Clean design manifolds are engineered for applications where hygiene is paramount, such as food processing and pharmaceuticals. With a crevice-free exterior and IP69K rating, these valves are easy to clean and maintain. While they offer superior sanitary features, the cost may be higher than standard options, necessitating careful evaluation of budget versus hygiene requirements.

What are the Benefits of Intrinsically Safe Valves?

Intrinsically safe valves are specially designed for use in hazardous locations, featuring energy-limiting technologies that prevent ignition. They are widely utilized in oil and gas, mining, and chemical processing industries. While they ensure safety compliance, buyers must consider the additional setup required for energy barriers, which can complicate installation and increase costs.

Key Industrial Applications of 4 port solenoid valve

| Industry/Sector | Specific Application of 4 port solenoid valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Boost control systems in turbocharged engines | Enhances engine performance and efficiency | Reliability, temperature resistance, and compatibility with various engine types. |

| Packaging | Control of pneumatic actuators in automated packaging | Increases speed and accuracy in packaging | Flow rate specifications, compact design, and ease of integration into existing systems. |

| Medical Devices | Operation of fluid delivery systems in medical devices | Ensures precise control in critical applications | Compliance with medical regulations, reliability, and ease of cleaning. |

| Semiconductor Manufacturing | Control of gas flow in processing equipment | Improves production efficiency and yield | High flow rates, low power consumption, and resistance to contaminants. |

| Robotics | Directional control in robotic arms and end-effectors | Enhances precision and responsiveness | Compact design, quick response times, and compatibility with various control systems. |

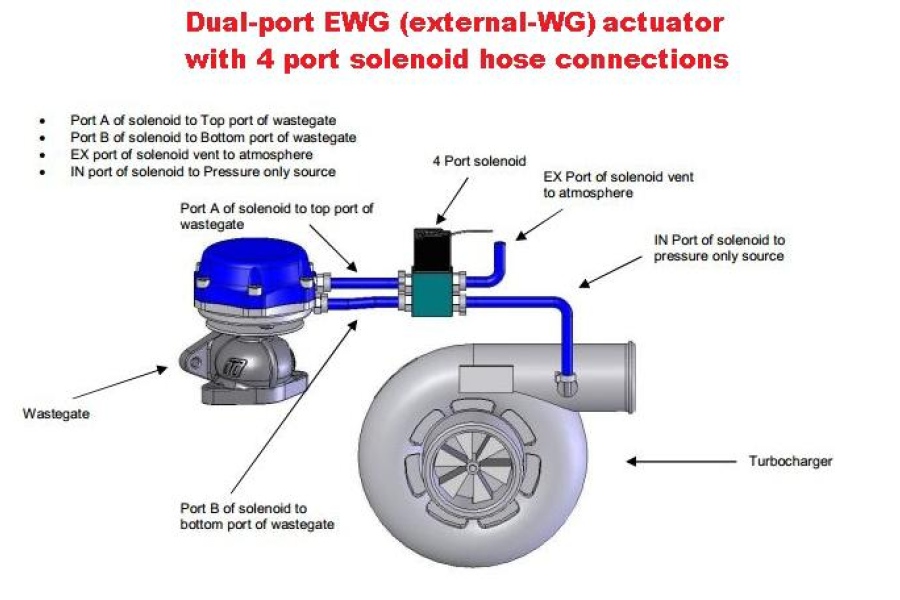

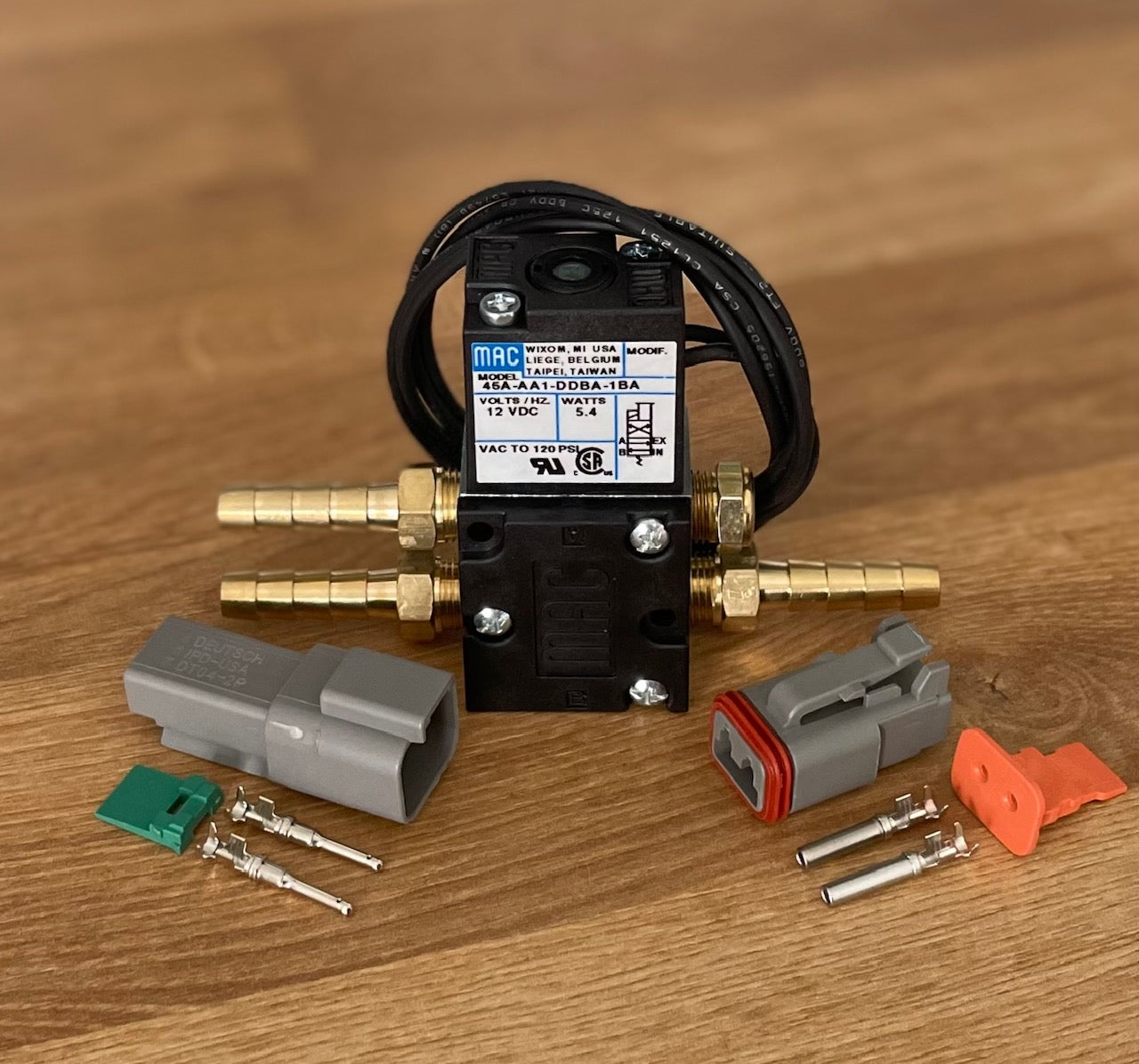

How are 4 Port Solenoid Valves Used in Automotive Applications?

In the automotive sector, 4 port solenoid valves are primarily utilized in boost control systems for turbocharged engines. These valves regulate the flow of air and fuel, significantly enhancing engine performance and efficiency. For international buyers, particularly in regions like the Middle East and South America, the reliability of these valves is crucial, as they must withstand extreme temperatures and varying fuel qualities. Buyers should consider sourcing valves that offer high durability and compatibility with diverse engine types to ensure optimal performance.

What Role Do 4 Port Solenoid Valves Play in Packaging Automation?

In the packaging industry, 4 port solenoid valves are integral to controlling pneumatic actuators used in automated packaging lines. They facilitate the precise movement of packaging materials, ensuring speed and accuracy in filling, sealing, and labeling processes. For B2B buyers in Africa and Europe, it is essential to select valves that meet specific flow rate requirements and have a compact design for seamless integration into existing machinery. Reliability and ease of maintenance are also key factors, as downtime can lead to significant losses in production.

Illustrative image related to 4 port solenoid valve

How Are 4 Port Solenoid Valves Essential in Medical Device Applications?

4 port solenoid valves are crucial in the medical device sector, particularly in fluid delivery systems, where they ensure precise control over the flow of medications and other fluids. This precision is vital in critical applications such as infusion pumps and diagnostic equipment. International buyers, especially from regions with stringent medical regulations, should prioritize sourcing valves that comply with health standards and are easy to clean. Reliability and long operational life are also significant considerations, as they directly impact patient safety and device performance.

Why Are 4 Port Solenoid Valves Important in Semiconductor Manufacturing?

In semiconductor manufacturing, 4 port solenoid valves control the flow of gases used in various processing steps, such as etching and deposition. These valves help improve production efficiency and yield by ensuring consistent gas delivery. For B2B buyers in this industry, particularly in technologically advanced regions like Europe, sourcing valves that provide high flow rates and low power consumption is critical. Additionally, the ability to resist contaminants is essential to maintain the integrity of the semiconductor fabrication process.

How Do Robotics Utilize 4 Port Solenoid Valves for Enhanced Performance?

In robotics, 4 port solenoid valves are employed for directional control in robotic arms and end-effectors, allowing for precise movements and quick response times. This is particularly beneficial in applications requiring high levels of accuracy, such as assembly lines and automated manufacturing. Buyers from regions with growing automation sectors, like Africa and South America, should look for valves that are compact and compatible with various control systems to maximize efficiency. The quick actuation and reliability of these valves can significantly enhance overall robotic performance.

3 Common User Pain Points for ‘4 port solenoid valve’ & Their Solutions

Scenario 1: Inconsistent Performance in High-Pressure Applications

The Problem: B2B buyers often encounter issues with solenoid valves that fail to perform consistently under high-pressure conditions. This inconsistency can lead to operational delays, increased maintenance costs, and potential safety hazards. For industries such as automotive or manufacturing, where precision and reliability are paramount, a malfunctioning solenoid valve can disrupt entire production lines or processes, resulting in financial losses and reputational damage.

The Solution: To mitigate this issue, buyers should prioritize sourcing high-quality, robust 4 port solenoid valves specifically designed for high-pressure applications. When specifying a solenoid valve, consider the valve’s material construction, as materials like stainless steel or durable polymers can enhance performance under stress. Furthermore, look for valves with built-in pressure regulation features and those rated for higher flow rates to ensure consistent performance. Establishing a relationship with reputable manufacturers who provide extensive testing data and certifications can also help ensure reliability. Regular maintenance checks and the use of filters to prevent foreign materials from entering the valve can significantly extend its lifespan and maintain performance.

Illustrative image related to 4 port solenoid valve

Scenario 2: Difficulties in Installation and Integration

The Problem: Many B2B buyers face challenges during the installation and integration of 4 port solenoid valves into existing systems. Complexities arise due to differing sizes, mounting configurations, and the need for compatible connectors. This often leads to extended downtime as teams troubleshoot and modify systems to accommodate new components, which can be particularly frustrating in fast-paced environments.

The Solution: To streamline the installation process, buyers should opt for solenoid valves that offer flexible mounting options and compatibility with standard connectors. Prior to purchasing, conducting a thorough assessment of the existing system and consulting with manufacturers can provide insights into the best fit for the application. Many suppliers also offer detailed installation guides and video tutorials, which can be invaluable resources during setup. Additionally, investing in modular systems can simplify future upgrades and integrations, allowing for quicker adjustments as operational needs evolve. Engaging with experienced technicians during the initial installation can also help ensure that the integration is seamless and efficient.

Scenario 3: High Energy Consumption and Operating Costs

The Problem: In many industrial applications, the energy consumption of solenoid valves can significantly impact operational costs. Buyers may find themselves facing high electricity bills due to inefficient solenoid designs that draw excessive power during operation. This is especially concerning for businesses aiming to enhance sustainability and reduce their carbon footprint, as energy efficiency becomes a critical consideration in procurement decisions.

Illustrative image related to 4 port solenoid valve

The Solution: To address energy consumption concerns, buyers should focus on selecting 4 port solenoid valves that are designed for low power consumption and have energy-efficient features. Look for models with advanced coil designs that minimize energy use while maintaining performance, such as those with pulse-width modulation (PWM) capabilities. Conducting a life-cycle cost analysis when evaluating solenoid valves can also help identify potential savings over time. Furthermore, implementing smart controls and automation systems can optimize the operation of solenoid valves, ensuring they only draw power when necessary. Regular monitoring and analysis of valve performance can provide insights for further optimization, contributing to reduced energy costs and improved operational efficiency.

Strategic Material Selection Guide for 4 port solenoid valve

What Are the Key Materials Used in 4 Port Solenoid Valves?

When selecting a 4 port solenoid valve, the choice of materials significantly influences performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in the construction of these valves, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Brass Perform in 4 Port Solenoid Valves?

Brass is a popular choice for solenoid valve bodies due to its excellent machinability and corrosion resistance. It typically has a temperature rating of up to 200°C and can withstand moderate pressure levels.

Pros: Brass is durable, relatively inexpensive, and offers good resistance to corrosion, especially in water and air applications. Its ease of machining allows for complex designs, making it suitable for various configurations.

Cons: However, brass is not ideal for harsh chemical environments, as it can corrode when exposed to certain acids and chlorides. Additionally, its mechanical properties can degrade at elevated temperatures.

Illustrative image related to 4 port solenoid valve

Impact on Application: Brass is often used in applications involving water, air, and non-corrosive gases. Buyers should ensure compatibility with the specific media they intend to control.

International Considerations: Compliance with standards such as ASTM B283 for brass fittings is crucial. Buyers in regions like Africa and South America may prefer brass due to its cost-effectiveness.

What Are the Benefits of Stainless Steel in 4 Port Solenoid Valves?

Stainless steel is renowned for its strength and corrosion resistance, making it suitable for demanding applications. It can handle temperatures up to 250°C and high-pressure environments.

Pros: Its durability ensures a long service life, even in corrosive environments. Stainless steel also maintains structural integrity under high temperatures and pressures, making it ideal for industrial applications.

Cons: The main drawback is the higher cost compared to brass. Additionally, stainless steel can be more challenging to machine, which may increase manufacturing complexity.

Illustrative image related to 4 port solenoid valve

Impact on Application: Stainless steel is well-suited for applications involving chemicals, steam, and high-temperature fluids. Buyers should consider the specific grades of stainless steel, such as 304 or 316, based on the media compatibility.

International Considerations: Adherence to standards like ASTM A276 for stainless steel is essential. In regions like the Middle East, where high temperatures are common, stainless steel valves are often preferred.

How Does Aluminum Compare for 4 Port Solenoid Valves?

Aluminum is lightweight and offers good corrosion resistance, making it a viable option for specific applications. It can typically withstand temperatures up to 150°C.

Illustrative image related to 4 port solenoid valve

Pros: The lightweight nature of aluminum allows for easy installation and reduces the overall weight of the system. It is also relatively cost-effective and offers good thermal conductivity.

Cons: However, aluminum is not as strong as brass or stainless steel and may not perform well under high-pressure conditions. It can also be susceptible to corrosion in certain environments, particularly when exposed to saltwater.

Impact on Application: Aluminum is often used in pneumatic systems and applications where weight is a critical factor. Buyers should evaluate the pressure and temperature requirements of their specific applications.

International Considerations: Compliance with standards such as ASTM B221 for aluminum extrusions is important. In regions like Europe, aluminum valves may be favored for their lightweight properties.

What Role Does Plastic Play in 4 Port Solenoid Valves?

Plastic materials, such as polyamide or PVC, are increasingly used in solenoid valves for their lightweight and corrosion-resistant properties. They can handle temperatures up to 80°C.

Pros: Plastics are highly resistant to chemical corrosion and are often less expensive than metal options. Their lightweight nature facilitates easy handling and installation.

Cons: The main limitation is their lower temperature and pressure ratings compared to metals. Plastics may also have a shorter lifespan in high-stress applications.

Impact on Application: Plastic solenoid valves are ideal for low-pressure applications and corrosive environments, such as in chemical processing. Buyers should ensure that the selected plastic is compatible with the intended media.

Illustrative image related to 4 port solenoid valve

International Considerations: Compliance with standards like ASTM D638 for plastic materials is essential. In regions with aggressive environments, such as parts of Africa, plastic valves may be a preferred choice for their chemical resistance.

Summary Table of Material Selection for 4 Port Solenoid Valves

| Material | Typical Use Case for 4 port solenoid valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water and air applications | Good machinability and corrosion resistance | Limited chemical compatibility | Low |

| Stainless Steel | Chemical and high-temperature applications | Excellent durability and corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Pneumatic systems and lightweight applications | Lightweight and cost-effective | Lower strength and pressure rating | Medium |

| Plastic | Low-pressure and corrosive environments | Chemical resistance and low cost | Limited temperature and pressure ratings | Low |

This strategic material selection guide provides insights into the various materials used in 4 port solenoid valves, helping international B2B buyers make informed decisions based on their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 4 port solenoid valve

What Are the Key Stages in the Manufacturing Process of 4 Port Solenoid Valves?

The manufacturing process of 4 port solenoid valves involves several critical stages, each designed to ensure the integrity and functionality of the final product. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for 4 Port Solenoid Valves?

Material preparation is the first step in the manufacturing process, where raw materials, typically brass, stainless steel, or various plastics, are selected based on the valve’s intended application. These materials are then cut into specific dimensions and shapes required for different components of the valve, such as the body, diaphragm, and solenoid coil. The selection of high-quality materials is crucial, as they must withstand the pressures and temperatures expected in operational environments.

What Forming Techniques Are Used in 4 Port Solenoid Valve Manufacturing?

Forming is the next stage, where the prepared materials are transformed into usable components. Common techniques include machining, die-casting, and injection molding. Machining involves precision processes to create the valve body and other components, ensuring tight tolerances. Die-casting is often used for metal parts, providing a strong, lightweight structure. For plastic components, injection molding is favored for its efficiency and ability to produce complex shapes. Each technique is selected based on the material properties and the required precision of the components.

How Are 4 Port Solenoid Valves Assembled?

Assembly follows forming and is a meticulous process that combines all individual components into a functioning solenoid valve. This stage typically requires skilled labor or automated systems to ensure proper alignment and integration of parts such as the solenoid coil, armature, and seals. Attention to detail is paramount during assembly, as any misalignment can lead to operational failures or leaks. Manufacturers often employ jigs and fixtures to aid in the assembly process, improving efficiency and accuracy.

What Finishing Processes Are Essential for Quality 4 Port Solenoid Valves?

Finishing involves surface treatments and coatings that enhance the valve’s durability and performance. Common finishing processes include anodizing, plating, and painting. Anodizing can increase corrosion resistance, while plating can provide additional protection against wear. These finishing touches not only improve the aesthetic appeal of the valve but also contribute to its longevity in demanding environments.

What Quality Assurance Practices Are Critical in 4 Port Solenoid Valve Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that each 4 port solenoid valve meets both international standards and customer specifications. Adopting a comprehensive QA strategy involves multiple checkpoints throughout the manufacturing process.

Which International Standards Should B2B Buyers Consider for Quality Assurance?

For B2B buyers, understanding relevant international standards is vital. ISO 9001 is one of the most recognized quality management standards, emphasizing consistent quality and continuous improvement. Additionally, industry-specific certifications such as CE marking (for compliance with European safety standards) and API certification (for oil and gas applications) are significant for buyers operating in specialized fields. These certifications not only validate the quality of the products but also assure compliance with safety regulations.

Illustrative image related to 4 port solenoid valve

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints play a pivotal role in maintaining the integrity of the manufacturing process. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves the inspection of raw materials and components before they enter the production process. Ensuring that only high-quality materials are used is essential for the overall quality of the finished product.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor the production process. This may include dimensional checks and functional tests to ensure components meet design specifications.

-

Final Quality Control (FQC): After assembly, a comprehensive inspection is performed to validate the functionality and safety of the solenoid valves. This often includes pressure testing, leakage tests, and electrical tests to ensure that the valves perform as intended.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for B2B buyers, especially when sourcing from international markets. Here are several strategies to ensure the supplier meets your quality expectations:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits can provide insights into a manufacturer’s quality control processes. Buyers should establish a clear audit protocol that includes:

-

Facility Inspection: Visiting the manufacturing site allows buyers to evaluate equipment, processes, and overall working conditions.

-

Document Review: Checking for certifications, quality manuals, and previous audit reports can provide a comprehensive view of the supplier’s adherence to quality standards.

-

Process Observation: Observing production processes can reveal the practical application of quality control measures, enabling buyers to assess the effectiveness of the supplier’s QA systems.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further ensure product quality. Independent inspectors can conduct thorough checks at various stages of production, providing an unbiased assessment of compliance with specified standards. These services can include:

-

Pre-shipment Inspections: Ensuring that products meet quality and quantity specifications before shipment.

-

Random Sampling: Testing a sample of products to verify that they meet performance criteria.

-

Documentation Verification: Ensuring that all necessary documentation, such as compliance certificates and test reports, is in order.

What Unique Considerations Should International Buyers Keep in Mind?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances when sourcing 4 port solenoid valves.

Illustrative image related to 4 port solenoid valve

How Do Different Regions Impact Quality Standards and Expectations?

Different regions may have varying regulatory requirements and expectations concerning quality. For instance, buyers in Europe may prioritize CE certification, while buyers in the Middle East might focus on compliance with local standards. Understanding these regional nuances can help buyers select suppliers that align with their specific market requirements.

What Are the Risks and Challenges of Sourcing Globally?

Sourcing from international manufacturers poses risks, including potential communication barriers, cultural differences, and variations in manufacturing practices. Buyers should conduct thorough due diligence, considering factors such as supplier reputation, previous customer feedback, and financial stability. Establishing strong communication channels and clear contracts can mitigate some of these risks, ensuring a smoother procurement process.

By understanding the manufacturing processes and quality assurance practices associated with 4 port solenoid valves, B2B buyers can make informed decisions, ensuring they source reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4 port solenoid valve’

In this guide, we provide a practical checklist for B2B buyers looking to procure 4 port solenoid valves. These valves play a critical role in various applications, from automotive to industrial automation, making it essential to source the right product for your needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is crucial before sourcing a 4 port solenoid valve. Identify parameters such as flow rate, pressure ratings, and voltage requirements to ensure compatibility with your system. Document these specifications to facilitate clear communication with potential suppliers.

Illustrative image related to 4 port solenoid valve

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in solenoid valves. Look for companies with a solid track record in your industry and consider their geographical location, as local suppliers may offer advantages like quicker shipping and easier communication. Utilize platforms like trade directories and industry forums to compile a list of candidates.

Step 3: Evaluate Supplier Certifications

It’s important to verify that your chosen suppliers hold relevant certifications, such as ISO 9001 or CE marking. These certifications indicate adherence to quality management and safety standards, which can significantly reduce the risk of defects and ensure reliability in performance. Request copies of these certifications during your initial discussions.

Step 4: Request Detailed Quotations

Once you’ve shortlisted potential suppliers, request detailed quotations that outline pricing, lead times, and payment terms. Ensure that the quotes include all necessary components, such as mounting brackets or fittings, as well as shipping costs. A clear and comprehensive quotation helps prevent unexpected costs later in the procurement process.

Step 5: Assess Product Quality and Performance

Before making a decision, assess the quality and performance of the solenoid valves. Request samples if possible, or ask for performance data and case studies that demonstrate the valves’ effectiveness in similar applications. Pay attention to aspects such as response time, durability, and maintenance requirements to ensure they meet your operational needs.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a preferred supplier, engage in negotiations regarding terms and conditions. Discuss warranty policies, return procedures, and support services, as these factors can significantly impact your overall satisfaction with the purchase. Ensure that all agreements are documented to avoid misunderstandings in the future.

Step 7: Plan for Logistics and Delivery

Consider the logistics of transporting the solenoid valves to your location. Discuss shipping options and timelines with your supplier, and plan for any potential customs issues if importing from overseas. Having a clear logistics plan will help ensure that your valves arrive on time and in optimal condition.

By following this checklist, B2B buyers can streamline the sourcing process for 4 port solenoid valves, ensuring they select the right product from reliable suppliers while minimizing risks and costs.

Illustrative image related to 4 port solenoid valve

Comprehensive Cost and Pricing Analysis for 4 port solenoid valve Sourcing

When sourcing 4 port solenoid valves, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. The costs associated with these valves can be broken down into several key components, while various factors influence their pricing.

What Are the Key Cost Components for 4 Port Solenoid Valves?

-

Materials: The choice of materials significantly impacts the cost. Common materials include brass, stainless steel, and plastic, each with varying costs based on market demand and availability. Higher-quality materials often lead to enhanced durability and resistance to environmental factors, thus influencing the overall price.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, while countries with higher labor standards may lead to increased manufacturing expenses.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Companies with advanced manufacturing technologies may have lower overhead costs due to increased efficiency, which can be reflected in their pricing.

-

Tooling: Initial tooling costs can be significant, particularly for custom-designed valves. Buyers should consider whether the supplier can absorb these costs through economies of scale or if they will be passed on to the customer.

-

Quality Control (QC): Investing in rigorous QC processes ensures that the solenoid valves meet international standards, which is particularly important for industries requiring high reliability. However, these processes add to the overall cost structure.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the buyer’s destination. Incoterms play a vital role here, as they dictate who is responsible for shipping, insurance, and tariffs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business viability. This margin can fluctuate based on market competition and the perceived value of the product.

What Factors Influence the Pricing of 4 Port Solenoid Valves?

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts due to economies of scale. Buyers should negotiate to establish the best possible pricing based on their forecasted needs.

-

Specifications and Customization: Custom specifications can lead to higher costs due to additional tooling and materials required. Buyers should clearly define their requirements to avoid unexpected charges.

-

Quality and Certifications: Valves that meet specific industry standards or certifications (e.g., ISO, CE) typically come at a premium. Buyers in regulated industries should factor in these costs when budgeting.

-

Supplier Factors: The supplier’s reputation, reliability, and after-sales service can also influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Different Incoterms (e.g., FOB, CIF) can significantly affect the total landed cost. Understanding these terms can help buyers make informed decisions about shipping responsibilities and costs.

What Are the Best Practices for Negotiating Prices on 4 Port Solenoid Valves?

-

Conduct Market Research: Buyers should research current market prices and trends to understand the competitive landscape. This knowledge empowers them during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and potential downtime costs. A slightly higher upfront investment in a more reliable valve can yield significant long-term savings.

-

Leverage Volume Discounts: If planning to order in bulk, communicate this to suppliers upfront. Many suppliers are willing to negotiate better rates for larger orders.

-

Request Samples: Before making large purchases, request samples to assess quality. This step can prevent costly mistakes later.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and regional pricing strategies. Understanding these nuances can help avoid unexpected costs.

Conclusion

In summary, the cost and pricing analysis for 4 port solenoid valves involves a multifaceted approach, taking into account material selection, manufacturing processes, and logistical considerations. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, these insights are vital for making informed purchasing decisions. Always remember that the indicative prices provided are subject to change based on market conditions and other influencing factors.

Alternatives Analysis: Comparing 4 port solenoid valve With Other Solutions

When evaluating the optimal solution for controlling fluid or gas flow in industrial applications, the 4 port solenoid valve is a popular choice. However, it’s essential for B2B buyers to consider various alternatives that may offer different advantages depending on specific operational needs. This analysis compares the 4 port solenoid valve against two viable alternatives: the 3-way pneumatic valve and the proportional valve, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | 4 Port Solenoid Valve | 3-Way Pneumatic Valve | Proportional Valve |

|---|---|---|---|

| Performance | High flow rates; versatile | Good for simple applications | Precise control of flow rates |

| Cost | Moderate cost | Generally lower cost | Higher initial investment |

| Ease of Implementation | Flexible mounting options | Simple installation | Requires more setup |

| Maintenance | Low maintenance; durable | Moderate maintenance | Higher maintenance due to complexity |

| Best Use Case | Complex control systems | Basic on/off operations | Applications requiring variable flow |

What Are the Advantages and Disadvantages of a 3-Way Pneumatic Valve?

The 3-way pneumatic valve is a straightforward alternative primarily used for simple on/off control in pneumatic systems. Its advantages include a lower initial cost and ease of installation, making it suitable for basic applications such as controlling air flow in cylinders. However, it lacks the versatility of a 4 port solenoid valve, as it can only manage flow in two directions, limiting its use in more complex systems that require multiple flow paths.

How Does a Proportional Valve Compare in Precision and Control?

Proportional valves are designed for applications that necessitate precise control over fluid or gas flow. They offer variable flow rates and can be adjusted to deliver specific amounts of fluid, making them ideal for complex industrial processes. However, this increased functionality comes at a higher cost and may require more maintenance due to their intricate design. Proportional valves are best suited for applications in industries such as pharmaceuticals or food and beverage, where exact measurements are critical.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right valve solution depends on a thorough understanding of specific operational requirements. For applications that demand flexibility and high performance, the 4 port solenoid valve stands out as a robust choice. Conversely, for simpler tasks where cost is a major factor, a 3-way pneumatic valve may suffice. In scenarios where precise control is paramount, investing in a proportional valve could be justified despite its higher cost. B2B buyers should carefully assess their operational needs, budget constraints, and maintenance capabilities to determine the most suitable valve solution for their applications.

Essential Technical Properties and Trade Terminology for 4 port solenoid valve

When considering the procurement of a 4-port solenoid valve, understanding its technical properties and industry terminology is crucial for making informed purchasing decisions. Below are the essential specifications and common trade terms relevant to B2B buyers.

What Are the Key Technical Properties of a 4-Port Solenoid Valve?

-

Material Grade

– The materials used in solenoid valves typically include brass, stainless steel, and various plastics. The choice of material influences durability, corrosion resistance, and suitability for different media (e.g., air, water, chemicals). For instance, stainless steel valves are ideal for corrosive environments, while brass may be sufficient for less demanding applications. Understanding the material grade is essential for ensuring the valve can withstand the operational conditions of your specific application. -

Pressure Rating

– This specification indicates the maximum pressure the valve can handle safely. It’s crucial for ensuring that the valve can operate effectively within the parameters of your system without risk of failure. For example, a valve rated for 10 bar should not be used in applications exceeding this limit, as it could lead to leaks or catastrophic failure. Selecting the correct pressure rating is vital for both safety and operational efficiency. -

Flow Rate

– Measured in liters per minute (L/min), the flow rate determines how much fluid can pass through the valve in a given time. This specification is critical for applications requiring precise control over fluid dynamics, such as in pneumatic systems. Buyers must assess their system’s requirements to choose a valve that offers an appropriate flow rate, ensuring optimal performance and energy efficiency. -

Electrical Specifications

– This includes voltage ratings (e.g., 24V DC, 110V AC) and power consumption. Understanding the electrical requirements of the solenoid valve is essential for ensuring compatibility with existing systems and avoiding electrical overloads. It’s also important to consider the power consumption for operational cost assessments, particularly in large-scale applications. -

Actuation Type

– Solenoid valves can be either direct-acting or pilot-operated. Direct-acting valves respond directly to electrical signals, while pilot-operated valves use a small pilot signal to control a larger flow. The choice between these types affects the speed of operation and the size of the valve, influencing installation space and response times. Buyers should consider the specific needs of their application when selecting the actuation type. -

IP Rating (Ingress Protection)

– This rating indicates the level of protection the valve has against dust and moisture. An IP67 rating, for example, means the valve is dust-tight and can withstand immersion in water up to a certain depth. For applications in harsh environments, selecting a valve with an appropriate IP rating is critical to ensure longevity and reliability.

What Are Common Trade Terms Related to 4-Port Solenoid Valves?

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are then marketed by another company. Understanding OEM relationships is important for B2B buyers, as it can influence pricing, warranty, and service levels. Buyers often seek OEM products for their reliability and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget-conscious buyers who need to manage inventory costs effectively. Knowing the MOQ helps in planning purchases, especially for smaller businesses that may not require large quantities. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process is essential for obtaining competitive pricing and understanding the terms of sale. B2B buyers should prepare detailed RFQs to ensure they receive accurate and comparable quotes. -

Incoterms (International Commercial Terms)

– These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for buyers to understand shipping costs, risk transfer, and delivery obligations, which can significantly impact overall procurement costs. -

Lead Time

– This refers to the time between placing an order and receiving the goods. Understanding lead times is essential for project planning and inventory management. Buyers should account for lead times when scheduling installations or production processes to avoid delays. -

Certification Standards

– Many industries require valves to meet specific certification standards (e.g., ISO, CE). Compliance with these standards can affect regulatory approval and market access. Buyers should verify that the valves they intend to purchase meet the necessary certification requirements for their industry.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding the selection and procurement of 4-port solenoid valves, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the 4 port solenoid valve Sector

What are the Current Market Dynamics and Key Trends in the 4 Port Solenoid Valve Sector?

The global market for 4 port solenoid valves is experiencing robust growth, driven by the increasing demand for automation across various industries such as automotive, manufacturing, and healthcare. Key drivers include the need for energy-efficient solutions and the rising adoption of smart technologies. As industries pivot towards automation, the demand for solenoid valves, which offer precise control over fluid and gas flow, is surging. Emerging technologies such as IoT-enabled solenoid valves are becoming prevalent, allowing for remote monitoring and control, which is particularly appealing to international B2B buyers looking to enhance operational efficiencies.

Illustrative image related to 4 port solenoid valve

In regions like Africa and South America, the market is also influenced by infrastructure development and industrialization. Countries such as Nigeria are seeing increased investment in manufacturing and processing sectors, thereby boosting the demand for reliable solenoid solutions. Meanwhile, in the Middle East, the push for sustainable energy and smart city projects is driving innovation in valve technology. European markets are increasingly focused on regulatory compliance and performance standards, leading to a preference for high-quality, certified products.

International buyers must also be aware of fluctuating supply chain dynamics, including raw material availability and geopolitical factors, which can impact pricing and sourcing strategies. Companies that prioritize flexibility in their supply chains and build relationships with multiple suppliers are better positioned to navigate these challenges.

How Can Sustainability and Ethical Sourcing Impact B2B Purchases of 4 Port Solenoid Valves?

Sustainability is becoming a critical factor in purchasing decisions for B2B buyers of 4 port solenoid valves. The environmental impact of manufacturing processes, from raw material extraction to waste generation, is under scrutiny. Buyers are increasingly seeking suppliers who demonstrate a commitment to reducing their carbon footprint through eco-friendly manufacturing practices and sustainable materials.

The importance of ethical supply chains cannot be overstated, especially in regions where labor practices may be questioned. Suppliers that adhere to ethical standards not only enhance their reputation but also attract clients who prioritize corporate social responsibility (CSR). Certifications such as ISO 14001 for environmental management and compliance with the REACH regulation in Europe are becoming essential criteria in the supplier selection process.

Moreover, the use of ‘green’ materials, such as recyclable or biodegradable components, is gaining traction. B2B buyers are encouraged to engage with suppliers who can provide transparency regarding their sourcing practices and material compositions. By aligning purchasing decisions with sustainability goals, companies can differentiate themselves in a competitive marketplace and contribute to broader environmental objectives.

Illustrative image related to 4 port solenoid valve

What is the Brief Evolution and History of 4 Port Solenoid Valves?

The evolution of solenoid valves, particularly 4 port variants, has been marked by significant technological advancements since their inception in the mid-20th century. Initially designed for simple on/off control, these valves have transformed into sophisticated devices capable of complex flow management in various applications.

The introduction of electronic controls and materials science has allowed for miniaturization, enhancing performance while reducing energy consumption. The integration of smart technologies has further revolutionized the sector, enabling remote diagnostics and automation. As industries face the dual challenge of efficiency and sustainability, the development of 4 port solenoid valves continues to align with modern demands for precision, reliability, and environmental responsibility.

In conclusion, the 4 port solenoid valve sector is characterized by rapid technological evolution, sustainability imperatives, and a dynamic market landscape that requires B2B buyers to stay informed and adaptable. Understanding these trends is essential for making strategic sourcing decisions that not only meet operational needs but also align with broader industry shifts.

Frequently Asked Questions (FAQs) for B2B Buyers of 4 port solenoid valve

-

How do I solve issues with solenoid valve performance in my application?

To address solenoid valve performance issues, first ensure that the valve is correctly installed and properly powered. Check for any obstructions or contaminants in the valve body that may hinder its operation. Regular maintenance, including cleaning and replacing seals, can also improve reliability. If problems persist, consider consulting with the manufacturer for technical support or troubleshooting guides. Additionally, evaluate if the valve specifications align with your application needs, as mismatched flow rates or pressure ratings can lead to performance failures. -

What is the best 4 port solenoid valve for pneumatic applications?

The best 4 port solenoid valve for pneumatic applications often depends on specific requirements such as flow rate, pressure range, and mounting options. For high flow demands, look for valves with robust designs, like those featuring IP67 ratings for moisture resistance. Valves from established brands, such as SMC or Humphrey, typically offer reliable performance and customizable options. Evaluate the compatibility with your existing systems, and consider factors like response time and power consumption to ensure optimal performance in your application. -

What are the typical minimum order quantities (MOQs) for 4 port solenoid valves?

Minimum order quantities for 4 port solenoid valves can vary significantly depending on the supplier and the specific model. Generally, MOQs may range from as low as 10 units for standard models to several hundred for custom specifications. When sourcing, inquire about bulk pricing options, as larger orders may lead to better pricing per unit. Additionally, some suppliers may offer flexibility in MOQs for first-time buyers or ongoing partnerships, so it’s worth negotiating based on your purchasing needs. -

How can I ensure the quality of the 4 port solenoid valves I am sourcing?

To ensure quality, choose suppliers who provide detailed product specifications, certifications, and testing data. Request samples to assess the build quality and performance before placing a larger order. Look for manufacturers who adhere to international standards, such as ISO certifications, which indicate a commitment to quality management. Additionally, consider conducting third-party quality audits or reviews to further validate the supplier’s reliability and product quality. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers but typically include options like advance payment, letter of credit, or net terms (30-90 days post-delivery). It’s crucial to discuss and agree upon payment terms before finalizing the order to avoid any misunderstandings. Evaluate the supplier’s reputation and payment flexibility, as established vendors may offer more favorable terms based on your purchasing volume and business relationship. Always ensure that payment methods are secure to mitigate risks associated with international transactions. -

What logistics considerations should I take into account when importing solenoid valves?

When importing solenoid valves, consider shipping methods, lead times, and customs clearance processes. Evaluate whether air freight or sea freight is more suitable for your needs based on urgency and cost. Understand the import regulations in your country, including any duties or taxes that may apply. Collaborating with a reputable freight forwarder can streamline logistics and ensure compliance with local laws. Additionally, confirm the supplier’s packaging standards to prevent damage during transit. -

Can I customize the specifications of a 4 port solenoid valve?

Yes, many manufacturers offer customization options for 4 port solenoid valves to meet specific application requirements. Customizations may include changes to size, materials, electrical specifications, and flow configurations. When inquiring about custom options, provide detailed requirements and any specific industry standards that must be met. Be aware that custom orders may involve longer lead times and potentially higher costs, so plan accordingly in your procurement timeline. -

What industries typically use 4 port solenoid valves?

4 port solenoid valves are widely utilized across various industries, including automotive, manufacturing, pharmaceuticals, and food processing. Their versatility makes them suitable for applications requiring precise control of air or fluid flow, such as in pneumatic systems, packaging machinery, and robotics. Understanding the specific requirements of your industry can help in selecting the right valve, as different sectors may prioritize factors like hygiene standards, material compatibility, or environmental conditions in their applications.

Top 6 4 Port Solenoid Valve Manufacturers & Suppliers List

1. Humphrey Products – 4-Way Solenoid Operated Valves

Domain: humphrey-products.com

Registered: 2000 (25 years)

Introduction: Small 4-Way Solenoid Operated Valves from Humphrey Products are compact, versatile, and economical direct solenoid valve series available in three high flow sizes. They feature balanced valves, optional IP67 construction, and come in various designs including the 410 Series (1/8 PIPE universal design with inline, stacking, and subbase mount options) and the 420 Series (high flow, 1/4 PIPE direct a…

2. Electric Solenoid Valves – 4 Way 5 Ports 2 Position

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: {“SKU”:”4V410-15″,”Valve Type”:”4 Way, 5 Ports, 2 Position”,”Suitable Media”:”Clean Air (40 Micron Filter)”,”Operation Type”:”Single Solenoid, Spring Return”,”Port Size”:”1/2″ Female NPT, Body Ported”,”Flow Rate”:”CV=2.79″,”Response Time”:”Less than 0.05 Seconds”,”Body Material”:”Aluminum Alloy”,”Seal Material”:”NBR O-Ring”,”Power”:”AC: 3.0VA / DC: 2.8 Watts”,”Insolation Class”:”Class F”,”Enclosur…

3. GFB – 4 Port Boost Control Solenoid

Domain: gofastbits.com

Registered: 2001 (24 years)

Introduction: {“name”:”GFB 4 Port Boost Control Solenoid”,”part_no”:”3845″,”price”:”US$ 169.00″,”category”:”Accessories and Spares”,”description”:”4 Port Boost Control Solenoid (Includes 4 x hose tails). As supplied with GFB electronic boost controllers G-Force II 3004, G-Force III 3005, and D-Force 3006 & 3007. MAC 45 series are the go-to solenoid valve for automotive boost control due to their exceptionally r…

4. McMaster – Four-Way Solenoid Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Four-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. SMC – Solenoid Valves

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: This company, SMC – Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Full Race – 4 Port MAC Boost Control Solenoid

Domain: full-race.com

Registered: 2001 (24 years)

Introduction: {“name”: “Full Race 4 Port MAC Boost Control Solenoid”, “SKU”: “FR-UNI-4PORT-BCSV”, “price”: “$58.49”, “description”: “Our 4-port MAC boost control solenoid valve is designed to target a clearly defined boost curve and improve boost responses, and in some cases with a soft WG spring—quicker spool. The 4-port design works equally well in low boost and high boost applications.”, “features”: [“Better…

Strategic Sourcing Conclusion and Outlook for 4 port solenoid valve

In conclusion, the strategic sourcing of 4 port solenoid valves offers significant advantages for businesses seeking efficiency and reliability in their operations. Key takeaways include the importance of selecting valves that align with specific application requirements, such as flow rates, response times, and environmental conditions. By understanding the diverse range of products available—from compact designs suitable for limited spaces to high-performance valves that meet rigorous industry standards—B2B buyers can make informed decisions that enhance operational efficiency.

Moreover, fostering strong supplier relationships and leveraging global supply chains can reduce costs while ensuring access to the latest technologies. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for versatile and reliable solenoid valves will only grow.

Looking ahead, businesses should prioritize strategic partnerships that not only meet immediate needs but also anticipate future demands. Now is the time to explore innovative solutions and engage with manufacturers who can provide tailored support. Take proactive steps in your sourcing strategy to stay ahead of the competition and ensure your operations are equipped with the best 4 port solenoid valves available.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to 4 port solenoid valve

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.