Choosing Your 3 Point Plug: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 3 point plug

In the competitive landscape of agricultural and landscaping equipment, sourcing a reliable 3 point plug can be a daunting task for international B2B buyers. The challenge lies not only in identifying high-quality products that meet specific operational needs but also in navigating the complexities of global supply chains, varying regulations, and diverse market demands. This comprehensive guide aims to address these challenges by providing an in-depth analysis of the 3 point plug market, including various types of plugger aerators, their applications, and critical factors for supplier vetting.

Throughout this guide, buyers will discover essential insights into the performance and durability of different 3 point plugs, as well as their roles in enhancing soil health and improving agricultural efficiency. We will explore cost considerations, shipping logistics, and the importance of understanding local market conditions, particularly for buyers in Africa, South America, the Middle East, and Europe—regions where the demand for effective soil management tools is on the rise.

By equipping buyers with actionable knowledge and practical tips, this guide empowers them to make informed purchasing decisions, ensuring they select the right 3 point plug that aligns with their operational requirements and budget constraints. Whether you are looking to enhance productivity or invest in sustainable farming practices, understanding the global market dynamics of 3 point plugs is crucial for achieving long-term success in your business endeavors.

Understanding 3 point plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Plugger Aerator | Utilizes ¾” coring tines; designed for compacted soils. | Landscaping, agriculture, sports field maintenance | Pros: Effective for soil aeration; reduces compaction. Cons: May require additional weight for optimal performance. |

| Heavy-Duty Plugger Aerator | Built with high-strength steel; designed for rugged terrains. | Large farms, commercial landscaping, golf courses | Pros: Durable and long-lasting; handles tough conditions. Cons: Higher initial investment. |

| Compact Plugger Aerator | Smaller size; ideal for residential lawns and limited spaces. | Residential landscaping, small parks, community gardens | Pros: Easy to maneuver; suitable for tight areas. Cons: Limited capacity for large-scale operations. |

| Quick Hitch Compatible Plugger | Designed for quick attachment and detachment; versatile use. | Mixed-use agricultural operations | Pros: Saves time during equipment changes; increases productivity. Cons: May not fit all tractor models without adapters. |

| Weighted Plugger Aerator | Incorporates a weight tray; enhances penetration in tough soils. | Heavy-duty lawn care, athletic fields | Pros: Improved soil penetration; reduces need for multiple passes. Cons: Additional weight may affect transportability. |

What are the Characteristics of a Standard Plugger Aerator?

Standard plugger aerators are essential tools for effective soil aeration, featuring ¾” coring tines specifically engineered to alleviate soil compaction. They are commonly used in landscaping and agricultural settings, particularly for maintaining sports fields and lawns. B2B buyers should consider the aerator’s compatibility with various tractor models and its ability to enhance soil health, leading to improved plant growth. While they are effective, buyers may need to add weight for optimal performance, which could increase operational complexity.

How Does a Heavy-Duty Plugger Aerator Stand Out?

Heavy-duty plugger aerators are constructed with high-strength steel, making them ideal for rugged terrains and extensive agricultural applications. They are designed to withstand challenging conditions, making them suitable for large farms, commercial landscaping, and golf courses. B2B buyers should evaluate the durability and long-term investment potential, as these aerators offer longevity and reliability. However, the initial cost is higher, which might be a consideration for budget-conscious buyers.

Why Choose a Compact Plugger Aerator for Smaller Spaces?

Compact plugger aerators are tailored for residential lawns and smaller landscaping projects, offering ease of maneuverability in tight spaces. Their design makes them perfect for community gardens and small parks, where larger equipment may be impractical. When purchasing, B2B buyers should assess the aerator’s capacity and suitability for specific projects, as they may not be ideal for large-scale operations. While they excel in residential applications, their limited capacity is a notable drawback for larger tasks.

What Benefits Do Quick Hitch Compatible Pluggers Offer?

Quick hitch compatible plugger aerators are designed for rapid attachment and detachment from tractors, enhancing operational efficiency in mixed-use agricultural settings. This feature allows for quicker transitions between different tasks, saving time and increasing productivity. B2B buyers should consider their existing equipment compatibility when selecting this type of aerator. While the convenience is significant, some models may require additional adapters to fit various tractor models, which could complicate the purchasing decision.

How Does a Weighted Plugger Aerator Improve Performance?

Weighted plugger aerators come equipped with a weight tray that allows users to add weight for deeper soil penetration, making them particularly effective in tough soil conditions. This feature is advantageous for heavy-duty lawn care and athletic field maintenance, as it minimizes the number of passes required for effective aeration. B2B buyers should focus on the aerator’s ability to improve efficiency and effectiveness in soil treatment. However, the added weight may impact transportability, which could be a consideration for businesses with limited transport options.

Key Industrial Applications of 3 point plug

| Industry/Sector | Specific Application of 3 point plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Soil aeration for crop fields | Enhances soil health, improves crop yields | Durability, compatibility with tractors, and weight options |

| Landscaping | Lawn and turf maintenance | Promotes lush growth, reduces compaction | Build quality, ease of use, and maintenance requirements |

| Sports Facilities | Aeration of athletic fields | Ensures optimal playing conditions, improves grass health | Weight capacity, size options, and ease of transport |

| Golf Course Management | Aerating greens and fairways | Enhances drainage, promotes healthy turf | Precision engineering, compatibility with existing equipment |

| Environmental Services | Restoration of degraded land | Improves soil structure, supports ecological health | Environmental impact, material sourcing, and warranty terms |

How is the 3 Point Plug Used in Agriculture to Enhance Crop Yields?

In the agriculture sector, the 3 point plug is primarily used for soil aeration in crop fields. By removing plugs of soil, it alleviates compaction, allowing air, water, and nutrients to penetrate deeper into the ground. This process is crucial for root development and overall crop health, leading to improved yields. Buyers in regions like Africa and South America should consider the durability of the aerator, as well as its compatibility with local tractor models, to ensure efficient and effective use.

What Role Does the 3 Point Plug Play in Landscaping Maintenance?

Landscaping professionals utilize the 3 point plug for maintaining lawns and turf areas. The aerator helps relieve soil compaction, which is essential for promoting healthy grass growth. By facilitating better water drainage and nutrient absorption, landscaping businesses can ensure lush, vibrant outdoor spaces. Buyers must focus on the build quality and ease of use, as these factors directly impact the efficiency and effectiveness of lawn care operations.

How Can Sports Facilities Benefit from Using a 3 Point Plug?

In sports facilities, the 3 point plug is vital for aerating athletic fields. Regular aeration ensures optimal playing conditions by promoting healthy grass and reducing surface compaction. This leads to better drainage and a more resilient playing surface, which is essential for athlete safety and performance. When sourcing, facility managers should consider the weight capacity and size of the aerator to match the scale of their fields and ensure ease of transport and setup.

Why is the 3 Point Plug Essential for Golf Course Management?

Golf course management relies heavily on the 3 point plug for aerating greens and fairways. This practice enhances drainage and promotes healthy turf, critical for maintaining the aesthetics and playability of the course. Golf course operators should prioritize precision engineering in the equipment they purchase, as this ensures that aeration is effective without damaging the delicate turf. Compatibility with existing maintenance equipment is also a key consideration for seamless operations.

How Does the 3 Point Plug Aid Environmental Services in Land Restoration?

Environmental services use the 3 point plug to restore degraded land by improving soil structure and promoting ecological health. Aeration can enhance the soil’s ability to retain moisture and support vegetation, which is vital in restoration projects. Buyers in this sector should evaluate the environmental impact of the materials used in the aerator, as well as warranty terms, to ensure long-term sustainability and reliability in their restoration efforts.

3 Common User Pain Points for ‘3 point plug’ & Their Solutions

Scenario 1: Ensuring Compatibility with Existing Equipment

The Problem: B2B buyers often face challenges in ensuring that the 3-point plug they intend to purchase is compatible with their existing tractors or agricultural machinery. This is particularly critical for businesses in diverse regions like Africa and South America, where the availability of specific tractor models can vary widely. Incompatibility can lead to significant downtime and financial losses, as buyers may need to return or modify the equipment, incurring additional costs and delays.

The Solution: To avoid compatibility issues, buyers should take the time to understand the specifications of their tractors, including the category of their 3-point hitch (Category I or Category II). Before purchasing a 3-point plug, check the manufacturer’s details to confirm that the plug is designed for the same hitch category. Additionally, buyers can consult with suppliers for advice on the best attachments for their specific tractor models, ensuring a seamless integration. It’s also beneficial to consider attachments that feature adjustable mounting options to enhance compatibility with various equipment. This proactive approach can save both time and money while ensuring that the equipment performs optimally.

Scenario 2: Addressing Soil Compaction Issues

The Problem: Many agricultural businesses struggle with soil compaction, which can severely impact crop yields and soil health. This issue often arises from heavy machinery usage or frequent foot traffic in agricultural fields. B2B buyers recognize that their operations need effective solutions to aerate and rejuvenate the soil, yet they may be unsure about the right approach or equipment to effectively address this problem.

The Solution: Investing in a high-quality 3-point plug aerator can significantly alleviate soil compaction. These devices work by removing cores of soil, allowing air, water, and nutrients to penetrate deeper into the ground, thus fostering healthier root systems. Buyers should look for plug aerators that offer adjustable weights for added penetration and are built from durable materials to withstand tough soil conditions. Additionally, scheduling regular aeration sessions—ideally during peak growing seasons—will enhance the long-term health of the soil. By incorporating this practice into their maintenance routines, agricultural businesses can see substantial improvements in soil structure and crop productivity.

Scenario 3: Managing Aeration Timing and Frequency

The Problem: B2B buyers often find it challenging to determine the appropriate timing and frequency for aerating their fields, which can vary based on climate conditions, soil type, and crop types. Inconsistent or poorly timed aeration can lead to ineffective results, wasting both time and resources. This is particularly crucial for businesses in regions with distinct growing seasons, such as Europe and the Middle East, where environmental factors can dictate agricultural practices.

Illustrative image related to 3 point plug

The Solution: To optimize aeration practices, buyers should consider conducting soil tests to evaluate compaction levels and nutrient profiles before determining the best times for aeration. Generally, spring and fall are ideal for aeration, as this aligns with the growing seasons for many crops. Buyers can also benefit from creating an annual aeration schedule based on weather patterns and soil conditions, adjusting as necessary for local climate variations. Furthermore, using a plug aerator with a built-in depth adjustment feature allows for customized aeration based on specific field conditions, maximizing effectiveness. Regularly reviewing and refining aeration strategies based on observed results will enhance long-term soil health and crop yields, ensuring a more productive agricultural operation.

Strategic Material Selection Guide for 3 point plug

What Are the Key Materials Used in 3 Point Plugs?

When selecting materials for 3 point plugs, it is essential to consider properties that affect performance, durability, and cost. Below, we analyze four common materials used in the manufacturing of 3 point plugs, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

How Does Steel Perform as a Material for 3 Point Plugs?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It typically has a temperature rating that can withstand significant mechanical stress and environmental conditions.

Pros & Cons: The primary advantage of steel is its strength and ability to handle heavy loads without deformation. However, steel is susceptible to corrosion, especially in humid or saline environments, which can lead to increased maintenance costs. While it is generally more affordable than other materials, the need for protective coatings can add to the overall expense.

Impact on Application: Steel 3 point plugs are ideal for agricultural and landscaping applications where soil compaction is a concern. However, in regions with high humidity or saltwater exposure, such as coastal areas in Africa or South America, corrosion-resistant treatments are necessary.

Illustrative image related to 3 point plug

Considerations for International Buyers: Buyers from regions like Germany and Nigeria should ensure that the steel used complies with international standards such as ASTM or DIN. Additionally, understanding local environmental conditions can help in selecting the right type of steel.

What Role Does Aluminum Play in 3 Point Plug Manufacturing?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically performs well in environments that require frequent handling or transport.

Pros & Cons: The main advantage of aluminum is its resistance to corrosion, which reduces maintenance needs. However, it is not as strong as steel, making it less suitable for heavy-duty applications. The manufacturing process can also be more complex, potentially leading to higher costs.

Impact on Application: Aluminum 3 point plugs are suitable for lighter applications or where weight reduction is critical, such as in portable equipment. However, they may not perform well under extreme loads or in applications requiring significant penetration into compacted soil.

Considerations for International Buyers: Buyers should verify that the aluminum used meets relevant international standards. In regions with strict compliance requirements, such as Europe, ensuring adherence to quality certifications is crucial.

How Does High-Strength Composite Material Compare?

Key Properties: High-strength composites offer excellent strength-to-weight ratios and are resistant to corrosion and UV degradation. They can perform well under a variety of environmental conditions.

Pros & Cons: The key advantage of composites is their lightweight nature and resistance to environmental factors, which can lead to lower maintenance costs. However, they can be more expensive and may require specialized manufacturing processes, increasing lead times.

Impact on Application: Composites are ideal for applications where weight and corrosion resistance are priorities, such as in agricultural settings with high moisture levels. However, their performance under heavy loads may not match that of steel.

Considerations for International Buyers: Buyers must ensure that composite materials meet local standards and certifications. In regions with varying levels of infrastructure, such as parts of Africa and South America, understanding the local supply chain for composite materials is essential.

What About Galvanized Steel for 3 Point Plugs?

Key Properties: Galvanized steel combines the strength of steel with a protective zinc coating, enhancing corrosion resistance. It performs well in various environmental conditions, making it a versatile choice.

Illustrative image related to 3 point plug

Pros & Cons: The main advantage of galvanized steel is its durability and resistance to rust, which extends the lifespan of the product. However, it can be more expensive than untreated steel, and the galvanization process can complicate manufacturing.

Impact on Application: Galvanized steel 3 point plugs are suitable for outdoor applications, especially in regions with high moisture or saline conditions. They provide a good balance between strength and corrosion resistance.

Considerations for International Buyers: Buyers should look for compliance with international standards and certifications, particularly in Europe and the Middle East, where quality assurance is critical. Understanding local regulations regarding galvanized materials can also be beneficial.

Summary Table of Material Selection for 3 Point Plugs

| Material | Typical Use Case for 3 Point Plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty agricultural applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight or portable equipment | Corrosion-resistant | Lower strength than steel | High |

| High-Strength Composite | Environments requiring weight reduction | Excellent strength-to-weight ratio | Higher cost and complex manufacturing | High |

| Galvanized Steel | Outdoor applications in moist areas | Enhanced corrosion resistance | More expensive than untreated steel | Medium to High |

This analysis provides a comprehensive overview of the materials used in 3 point plugs, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 point plug

What Are the Main Stages of Manufacturing Processes for 3 Point Plugs?

Manufacturing a 3-point plug involves several critical stages, each designed to ensure the final product meets stringent performance and durability standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in 3 Point Plug Manufacturing?

The first step in manufacturing 3-point plugs is selecting high-quality raw materials. Typically, manufacturers use high-strength steel, such as Grade 50, which offers exceptional durability and load-bearing capacity. The materials are often sourced from reputable suppliers to ensure consistency and reliability. Once the materials are procured, they undergo rigorous quality checks to confirm their specifications and integrity.

How Are 3 Point Plugs Formed During Manufacturing?

The forming stage utilizes various techniques such as cutting, bending, and welding to shape the raw materials into the desired components. Advanced machinery like CNC (Computer Numerical Control) machines may be employed to achieve precise cuts and angles, ensuring that each part fits together seamlessly. The welding process is particularly crucial, as it bonds different components, contributing to the overall strength of the plug.

What Assembly Techniques Are Commonly Used?

During the assembly phase, the formed components are meticulously put together. This may involve using bolts, nuts, and other fastening techniques to ensure structural integrity. For 3-point plugs, compatibility with different tractor hitch systems (like Category I and II) is vital, so assembly must ensure that the plug can easily attach and detach from various tractors without compromising safety.

What Finishing Processes Are Important for 3 Point Plugs?

Finishing processes involve surface treatments such as painting, galvanizing, or powder coating to enhance corrosion resistance and durability. These processes not only improve the aesthetic appeal but also extend the product’s lifespan in harsh working conditions. Quality manufacturers often use eco-friendly coatings to meet environmental standards, appealing to buyers conscious of sustainability.

How Is Quality Assurance Implemented in 3 Point Plug Manufacturing?

Quality assurance is crucial in ensuring that 3-point plugs perform reliably in various applications. It encompasses several international and industry-specific standards, such as ISO 9001, which establishes a framework for quality management systems. Compliance with these standards assures B2B buyers that the products have undergone rigorous testing and meet global quality benchmarks.

What Are the Key Quality Control Checkpoints?

Quality control in manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Suppliers must provide certification that materials meet specified standards.

-

In-Process Quality Control (IPQC): During production, operators conduct routine checks to ensure that processes are adhering to established guidelines. This includes monitoring machinery and evaluating the quality of work in progress.

-

Final Quality Control (FQC): Before shipping, finished products undergo a comprehensive evaluation to confirm that they meet design specifications and performance requirements. This often includes testing for strength, durability, and compatibility.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to validate the quality of 3-point plugs. Common techniques include:

- Load Testing: Assessing the plug’s ability to withstand heavy loads without deformation or failure.

- Corrosion Testing: Evaluating the effectiveness of protective coatings through exposure to harsh environments.

- Dimensional Inspection: Using calipers and gauges to ensure that all components conform to specified dimensions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and quality assurance processes directly.

-

Quality Reports: Requesting detailed quality reports can provide insight into the supplier’s quality metrics, including defect rates and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and final products, ensuring they meet specified quality standards.

What Are the QC and Certification Nuances for International Buyers?

For buyers from diverse regions like Africa, South America, the Middle East, and Europe, understanding local regulations and certifications is crucial. For example, CE marking is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. In contrast, buyers in Africa or South America may need to consider regional certifications that ensure products meet local regulations.

Illustrative image related to 3 point plug

Additionally, different countries may have varying expectations for quality and performance. Buyers should engage with suppliers familiar with these nuances to ensure compliance and satisfaction. Establishing clear communication about expectations can help mitigate risks associated with international procurement.

Conclusion: Why Is Quality Assurance Critical for 3 Point Plug Buyers?

In conclusion, the manufacturing processes and quality assurance protocols for 3-point plugs are designed to ensure that buyers receive durable, high-performing products. Understanding these processes allows B2B buyers to make informed decisions, ensuring they partner with suppliers that prioritize quality. By leveraging effective quality control measures and certifications, buyers can safeguard their investments and maintain operational efficiency in their respective industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 point plug’

Introduction

Sourcing a high-quality 3-point plug is essential for businesses in agriculture, landscaping, and land management. This guide provides a practical checklist to assist B2B buyers in making informed procurement decisions. By following these steps, you can ensure that you select a reliable supplier, secure the right product, and optimize your investment.

Step 1: Define Your Technical Specifications

Before beginning your search, outline the specific requirements for the 3-point plug you need. Consider factors such as size, weight capacity, and compatibility with existing equipment. Understanding your technical needs will help streamline the sourcing process and ensure that the equipment meets your operational demands.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in 3-point plugs. Look for companies with a strong track record in your region, and check their online presence, customer reviews, and ratings. A supplier’s reputation can significantly impact your purchasing experience and the quality of the product you receive.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold the necessary certifications and comply with industry standards. Certifications such as ISO, CE, or local compliance marks can indicate product quality and reliability. This step is crucial as it helps mitigate risks associated with subpar equipment that could lead to operational inefficiencies.

Step 4: Request Detailed Product Information

Once you’ve shortlisted suppliers, request detailed product specifications and documentation. This should include technical sheets, warranty information, and maintenance guidelines. Understanding the product’s features, materials, and expected lifespan will enable you to make a more informed decision.

Illustrative image related to 3 point plug

Step 5: Assess Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures. Look beyond the initial cost and consider total ownership costs, including shipping, installation, and maintenance. Additionally, review payment terms to ensure they align with your budget and cash flow needs.

Step 6: Inquire About After-Sales Support

After-sales support is a critical factor in your purchasing decision. Inquire about warranty coverage, parts availability, and customer service responsiveness. A supplier that offers robust support can save you time and money in the long run, as issues may arise during the product’s lifecycle.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier and agreed on terms, ensure that all details are documented in a formal purchase agreement. This should include product specifications, pricing, delivery timelines, and payment terms. A clear agreement protects both parties and minimizes misunderstandings during the transaction.

By following this step-by-step checklist, B2B buyers can effectively navigate the procurement of 3-point plugs, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for 3 point plug Sourcing

What Are the Key Cost Components in Sourcing 3 Point Plugs?

When sourcing 3 point plugs, understanding the cost structure is vital for effective budgeting and pricing strategy. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to 3 point plug

-

Materials: The choice of materials significantly impacts the overall cost. High-strength steel, commonly used for durable 3 point plugs, can be more expensive than lower-grade alternatives. Additionally, sourcing locally can mitigate costs related to import tariffs and shipping.

-

Labor: Labor costs vary widely by region. In countries with a higher cost of living, such as Germany, labor costs will be higher compared to regions like Nigeria. This can influence the final pricing of the product.

-

Manufacturing Overhead: This includes the costs associated with the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, allowing for more competitive pricing.

-

Tooling: The initial investment in tooling for manufacturing 3 point plugs is a significant cost. Custom designs or specific features will require specialized tooling, increasing upfront costs but potentially improving product differentiation.

-

Quality Control: Ensuring that products meet international quality standards is crucial. This includes testing and certification, which can add to the costs but ultimately enhances product reliability and buyer trust.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the chosen Incoterms. Freight costs can be substantial, especially when importing to regions like Africa or South America.

-

Margin: Suppliers typically add a margin to cover their costs and achieve profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect the Cost of 3 Point Plugs?

Several factors influence the pricing of 3 point plugs beyond the fundamental cost components. These include:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it essential for buyers to consider their procurement strategy.

-

Specifications and Customization: Custom features, such as specific sizes or additional functionalities, can increase the price. Buyers should balance the need for customization against the potential increase in costs.

-

Material Quality and Certifications: Products with higher quality materials or those that meet specific certifications (e.g., ISO standards) will command a premium price. Buyers should assess whether these certifications align with their market requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and service quality can also impact pricing. Established suppliers may charge more due to perceived value, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the chosen Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total cost.

What Buyer Tips Can Help in Negotiating Prices for 3 Point Plugs?

To ensure cost-effectiveness when sourcing 3 point plugs, international buyers should consider the following tips:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for larger orders. Suppliers may be willing to negotiate terms, particularly if they value a long-term partnership.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO), which encompasses not just the purchase price but also maintenance, durability, and potential resale value. A lower upfront cost may not always equate to better value in the long run.

-

Understand Pricing Nuances: International buyers should be aware of potential hidden costs, such as tariffs or customs fees, which can affect the final price. Researching local regulations can help avoid unexpected expenses.

-

Leverage Local Relationships: Building relationships with local distributors can provide insights into market trends and pricing strategies, enabling better negotiation leverage.

-

Evaluate Supplier Performance: Regularly assess supplier performance in terms of delivery times, product quality, and service. This can inform future purchasing decisions and strengthen negotiation positions.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier policies, and regional factors. Always consult with multiple suppliers to obtain accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing 3 point plug With Other Solutions

Exploring Alternatives to the 3 Point Plug

When considering soil aeration solutions, the 3-point plug aerator stands out for its efficiency and effectiveness. However, buyers should evaluate other viable options that may better suit their specific agricultural or landscaping needs. Below, we compare the 3-point plug with two popular alternatives: spike aerators and manual aeration methods.

Illustrative image related to 3 point plug

Comparison Table

| Comparison Aspect | 3 Point Plug | Spike Aerator | Manual Aeration |

|---|---|---|---|

| Performance | Excellent; removes soil plugs for optimal aeration | Good; punctures soil but compacts surrounding area | Fair; labor-intensive and time-consuming |

| Cost | $1,965 – $2,451 | $500 – $1,500 | $50 – $200 (tools only) |

| Ease of Implementation | Requires tractor with 3-point hitch | Can be used with smaller equipment | Requires physical effort and time |

| Maintenance | Minimal; occasional cleaning needed | Moderate; tines may need replacement | High; tools must be maintained regularly |

| Best Use Case | Large areas like farms or sports fields | Residential lawns and small gardens | Small patches or areas with limited access |

Detailed Breakdown of Alternatives

Spike Aerators

Spike aerators are designed to perforate the soil surface with sharp spikes, allowing water and nutrients to penetrate. While they are often more affordable and suitable for smaller areas, their effectiveness is limited compared to plug aerators. The primary drawback is that they compact the surrounding soil, which can negate some benefits of aeration. They are best suited for residential lawns where budget constraints are a priority, but for larger areas, they may not provide the desired results.

Manual Aeration

Manual aeration tools, such as garden forks or hand-held aerators, offer a hands-on approach to soil aeration. They are the least expensive option and allow for targeted aeration in small areas. However, this method is labor-intensive and can be time-consuming, making it impractical for large-scale applications. Manual aeration is ideal for small gardens or areas where machinery cannot reach, but it may not be feasible for businesses aiming for efficiency and productivity.

Conclusion: Choosing the Right Aeration Solution

When selecting an aeration method, B2B buyers should assess their specific requirements, including the size of the area to be aerated, budget constraints, and the desired level of efficiency. The 3-point plug aerator is optimal for large-scale applications, particularly in agriculture or sports field maintenance, where soil health is critical. In contrast, spike aerators and manual methods may suit smaller, residential projects or budgets. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational goals.

Illustrative image related to 3 point plug

Essential Technical Properties and Trade Terminology for 3 point plug

What Are the Essential Technical Properties of a 3 Point Plug?

Understanding the technical specifications of a 3 point plug is crucial for B2B buyers who seek durability, efficiency, and compatibility with their existing agricultural equipment. Here are some key properties:

-

Material Grade

The material used in manufacturing a 3 point plug is fundamental to its performance and longevity. High-strength steel, such as Grade 50, is commonly employed due to its exceptional yield strength of 50 ksi. This property ensures that the plug can withstand heavy loads and harsh operating conditions, making it essential for buyers in agriculture and landscaping who require reliable equipment for demanding tasks. -

Coring Tine Specifications

The coring tines, typically made from heat-treated steel, are designed to penetrate the soil effectively. Standard lengths of 7.5 inches and diameters of ¾ inch are common. These dimensions are critical as they affect the aeration effectiveness and the ability to alleviate soil compaction. Buyers should consider these specifications to ensure optimal performance in various soil types. -

Drum Capacity and Weight

Many 3 point plugs come with a drum that can be filled with water or weights for increased penetration. The drum’s design often includes a fitting for easy filling and draining. This feature is particularly important for B2B buyers who work in varying soil conditions, as additional weight can significantly enhance aeration results. -

Compatibility with Hitch Systems

A 3 point plug must be compatible with specific hitch categories (e.g., Category I or II). This compatibility ensures that the plug can be easily attached to different tractors, which is vital for businesses that own multiple machines. Buyers should verify compatibility to avoid additional costs related to modifications or purchasing new equipment. -

Warranty and Support

A robust warranty (e.g., one year) provides peace of mind for buyers, assuring them of the product’s quality and durability. This is particularly significant in B2B transactions, where investments are substantial. Understanding warranty coverage can influence purchasing decisions, especially in regions with challenging operating conditions.

What Are Common Trade Terms Related to 3 Point Plugs?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B contexts. Here are some common terms related to 3 point plugs:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify the quality and compatibility of replacement parts, ensuring they source reliable components for their equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to know, as it can affect inventory management and cost efficiency. Suppliers may set MOQs based on production costs, and understanding this can aid buyers in planning their purchases. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other relevant details for a specific quantity of goods. Utilizing RFQs can streamline the procurement process, allowing businesses to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms helps businesses understand shipping responsibilities, risks, and costs, which is crucial for effective logistics management. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for B2B buyers, especially those operating in agricultural sectors where timing is essential for planting and harvesting cycles.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure successful procurement of 3 point plugs.

Navigating Market Dynamics and Sourcing Trends in the 3 point plug Sector

What Are the Key Market Drivers and Trends in the 3 Point Plug Sector?

The global market for 3-point plugs, particularly in the aeration segment, is witnessing significant growth driven by several factors. One of the primary drivers is the increasing focus on sustainable agriculture and landscape maintenance. As soil health becomes a priority for farmers and landscapers alike, the demand for efficient aeration tools, such as plugger aerators, is on the rise. These tools not only alleviate soil compaction but also promote better nutrient absorption, which is crucial in regions with intensive farming practices.

Emerging technologies are also shaping the sourcing landscape. Automation and precision agriculture tools are becoming more prevalent, allowing for enhanced efficiency in land management. For international buyers, particularly in Africa, South America, the Middle East, and Europe, leveraging these technologies can lead to improved yield and reduced operational costs. Furthermore, the rise of e-commerce and digital platforms has made sourcing more accessible, enabling buyers to connect with manufacturers and suppliers directly, ensuring competitive pricing and better negotiation opportunities.

In terms of market dynamics, understanding regional preferences is essential. For instance, European markets may prioritize high-quality, durable products, while African buyers may focus on cost-effectiveness and ease of use. This variation necessitates a tailored approach to sourcing, ensuring that products meet local needs while maintaining global standards.

How Does Sustainability and Ethical Sourcing Impact the 3 Point Plug Market?

Sustainability is becoming increasingly important in the B2B landscape, particularly in the agricultural sector. For buyers of 3-point plugs, considering the environmental impact of their purchases is crucial. Many manufacturers are now adopting sustainable practices, such as using recycled materials or eco-friendly production processes, to minimize their carbon footprint. This shift not only appeals to environmentally conscious buyers but also enhances brand reputation and marketability.

Ethical sourcing is another critical aspect. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and products made from sustainably sourced materials can serve as indicators of a supplier’s commitment to ethical practices. By choosing products that meet these standards, international buyers can contribute to sustainable development in their regions while also benefiting from the increased demand for eco-friendly products.

Moreover, the integration of sustainability into product design, such as creating 3-point plugs with longevity in mind, can reduce waste and promote a circular economy. As buyers increasingly seek out sustainable options, manufacturers who prioritize these values will likely gain a competitive edge in the market.

What is the Historical Context Behind the Development of 3 Point Plugs?

The evolution of 3-point plugs can be traced back to the early 20th century when mechanization began to transform agriculture. Initially, these tools were rudimentary, designed primarily for basic soil management. Over time, as agricultural practices advanced, so did the technology behind these implements. The introduction of durable materials and innovative designs in the mid-20th century enhanced their effectiveness and usability.

Today, 3-point plugs, particularly aerators, have evolved to incorporate advanced materials like high-strength steel and features that improve their efficiency and ease of use. This evolution reflects a broader trend in agriculture towards greater efficiency, sustainability, and productivity. Understanding this historical context not only provides insight into the current market dynamics but also informs future purchasing decisions, emphasizing the importance of investing in high-quality, reliable equipment.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 point plug

-

How do I solve soil compaction issues in my agricultural fields?

To address soil compaction, using a 3-point plug aerator is highly effective. This equipment removes soil plugs, allowing air, water, and nutrients to penetrate deeper into the soil, promoting root growth. Regular aeration, particularly before planting seasons or after heavy foot traffic, can significantly improve soil health. For optimal results, consider the soil type and moisture levels; aerating when the soil is moist but not overly wet will enhance the effectiveness of the aeration process. -

What is the best 3-point plugger aerator for my region’s soil conditions?

Selecting the best 3-point plugger aerator depends on your specific soil conditions. For heavy clay soils, a robust model with deeper tines is advisable to ensure effective aeration. Conversely, sandy soils may require a lighter aerator. Additionally, consider the size of your tractor and the aerator’s compatibility with your equipment. Researching local suppliers and seeking recommendations from agricultural experts in your region can also help you make an informed decision. -

What factors should I consider when vetting suppliers of 3-point plugger aerators?

When vetting suppliers, consider their reputation, product quality, and customer service. Look for suppliers with positive reviews and testimonials from previous buyers. Additionally, inquire about their manufacturing processes, warranty policies, and whether they provide after-sales support. It’s beneficial to request samples or visit the manufacturing facility if possible. Lastly, ensure that they can meet your specific requirements, such as customization options and reliable shipping times. -

What customization options are available for 3-point plugger aerators?

Many manufacturers offer customization options for 3-point plugger aerators to suit specific needs. This can include variations in tine length, frame size, and weight capacity. Some suppliers may also allow for branding or unique color choices to align with your company’s identity. When reaching out to suppliers, clearly communicate your requirements and ask about available customization options that can enhance the functionality or aesthetic appeal of the aerator. -

What is the minimum order quantity (MOQ) for 3-point plugger aerators?

The MOQ for 3-point plugger aerators can vary significantly among suppliers. Typically, it ranges from one unit for smaller manufacturers to larger quantities for bulk orders from major brands. When negotiating with suppliers, inquire about their MOQ and whether they can accommodate smaller orders, especially if you are testing the market or have limited storage capacity. Some suppliers may offer flexible terms for first-time buyers or for larger orders in the future. -

What payment terms are commonly offered by international suppliers?

International suppliers often provide a range of payment terms, including upfront payments, letters of credit, or installment payments. It’s crucial to discuss and agree on payment terms before finalizing your order to avoid any misunderstandings. Some suppliers may also accept payment via escrow services to ensure security for both parties. Always confirm the preferred payment methods and any associated fees that may apply, particularly for international transactions. -

How do I ensure quality assurance for 3-point plugger aerators?

To ensure quality assurance, request detailed specifications and certifications from the supplier. Many reputable manufacturers adhere to international quality standards, such as ISO certifications. Additionally, consider asking for product samples or conducting a factory audit to inspect the production processes and materials used. Establishing a clear communication channel with the supplier regarding quality expectations will also help mitigate risks associated with defects or subpar products. -

What logistics considerations should I keep in mind when importing 3-point plugger aerators?

When importing 3-point plugger aerators, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Research the best shipping options based on your budget and urgency, whether by sea or air freight. Ensure you understand the customs duties and taxes applicable to your country and factor these into your overall costs. Collaborating with a logistics provider experienced in international shipping can streamline the process and help avoid potential delays.

Top 4 3 Point Plug Manufacturers & Suppliers List

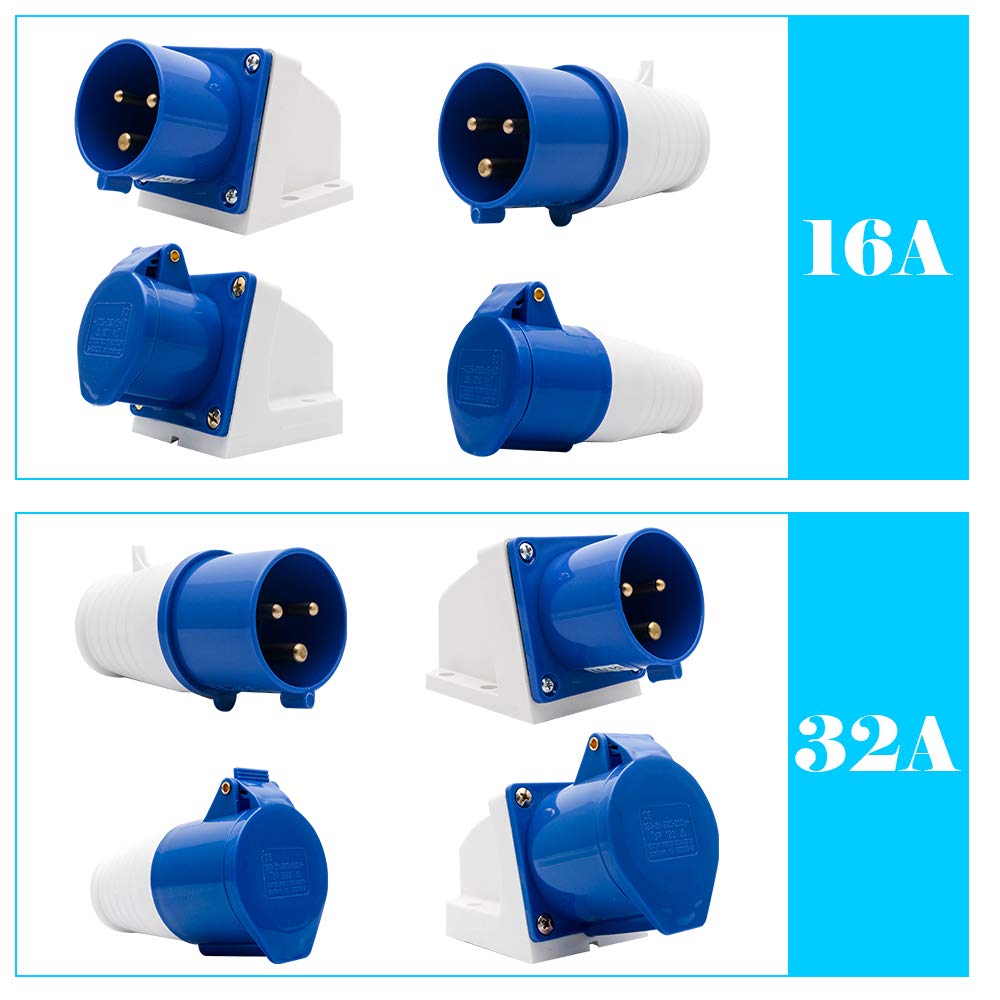

1. Koike – 3 Pin Electrical Plug (120V)

Domain: koike.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “3 Pin Electrical Plug (120V)”, “SKU”: “ZS60781”, “UPC”: “”, “MSRP”: “$22.06”, “Current Stock”: “34”, “Related Products”: [{“Name”: “3 Pin Electrical Socket (120V)”, “SKU”: “ZS30273”, “MSRP”: “$16.95”}, {“Name”: “3 Pin Power Cord Assembly (120V)”, “SKU”: “61004264”, “MSRP”: “$97.29”}, {“Name”: “5 Pin plug (To Welder)”, “SKU”: “ZS37689”, “MSRP”: “$94.31”}, {“Name”: “4 Pin Electrica…

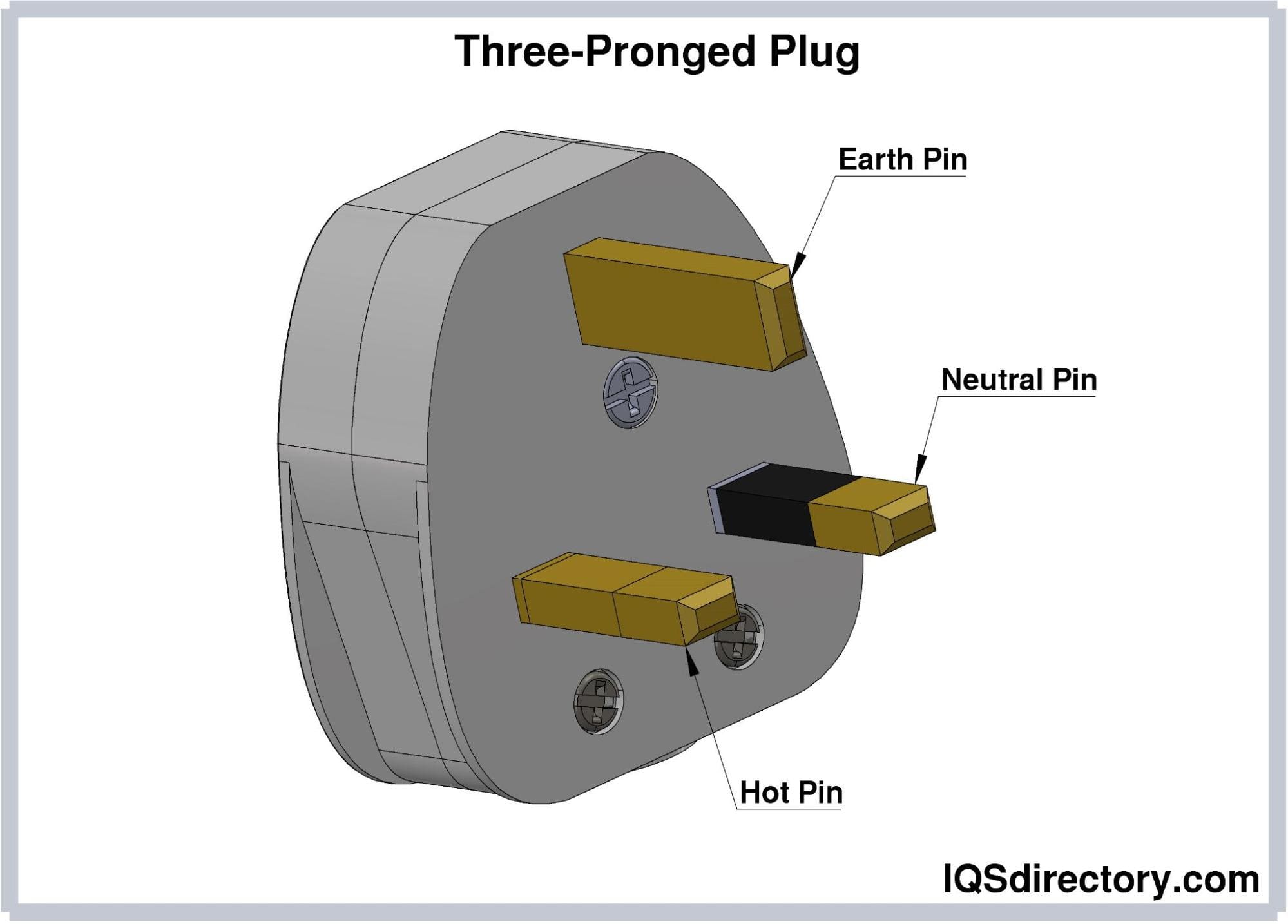

2. HowStuffWorks – Electrical Plugs Explained

Domain: electronics.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Two-prong plugs have two vertical slots (neutral and hot) and do not provide grounding, while three-prong plugs include a third round hole for grounding, which protects against electric shock. The left slot in a three-prong plug is neutral (white wire), the right slot is hot (black wire), and the ground (green wire) connects to the ground screw. Existing two-prong outlets are legal but can be repl…

3. Cattachments – Catawba 3 Point Plugger Core Aerator

Domain: cattachments.com

Registered: 2020 (5 years)

Introduction: Product Name: Catawba 3 Point Plugger Core Aerator

Price Range: $1,965.00 – $2,451.00

Customer Rating: 5.00 out of 5 based on 7 ratings

Sizes Available: 4 ft, 5 ft, 6 ft, 7 ft

Key Features:

– Robust frame made from 3″x3″x1/4″ angle iron and 2″x3/16″ square tubing

– 13″ drum made from rolled 3/16″ thick plate

– Drum can be filled with water for added weight through a 1.25″ fitting

– USA made ¾” cor…

4. AMP – 3-Pin CPC Power Plug Kit

Domain: store.agexpress.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “AMP 3-Pin CPC Plug (Power) Kit”, “SKU”: “AE1238K”, “UPC”: “”, “description”: “The AMP CPC Power Plug 3-Cavity Replacement Kit is a power adapter plug for connecting to power access ports in tractors, combines and sprayers. Male connector body with flat spade-style female contacts and locking ring. Includes connector, crimp-style terminals, and backshell/strain relief.”, “type_of_…

Strategic Sourcing Conclusion and Outlook for 3 point plug

In the ever-evolving landscape of agricultural and landscaping equipment, the strategic sourcing of 3-point plugger aerators presents a pivotal opportunity for B2B buyers. These robust tools not only facilitate soil aeration, enhancing root growth and nutrient absorption, but they also mitigate issues of compaction and thatch buildup, crucial for maintaining healthy landscapes. As international buyers from regions like Africa, South America, the Middle East, and Europe seek reliable, high-quality equipment, understanding the unique features and benefits of various models—such as those constructed from Grade 50 high-strength steel—can significantly impact purchasing decisions.

Investing in quality 3-point plugger aerators ensures long-term durability and performance, translating to improved productivity and cost-effectiveness for businesses. The ability to source these products efficiently allows buyers to strengthen their supply chains while ensuring they meet local agricultural demands.

Looking ahead, the demand for advanced soil management solutions is set to rise, driven by increased awareness of sustainable practices. As you explore your options, consider establishing partnerships with reputable manufacturers that offer both quality and support. Embrace this opportunity to elevate your operations and contribute to more resilient agricultural practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.