Choosing Your 3 Liter Coke Bottle: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 3 liter coke bottle

In an increasingly competitive global market, sourcing the right 3 liter Coke bottle can be a daunting challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for Coca-Cola products remains robust, driven by the beverage’s popularity across diverse cultures and occasions. However, navigating the complexities of supplier selection, cost management, and logistics can pose significant hurdles. This guide aims to demystify the process, offering a thorough exploration of the various types of 3 liter Coke bottles available, their applications in different markets, and strategies for effectively vetting suppliers.

Understanding the nuances of this market is essential for making informed purchasing decisions. From identifying reliable suppliers to negotiating favorable terms, this comprehensive resource empowers businesses to enhance their procurement strategies. We delve into critical aspects such as product specifications, pricing trends, and the importance of quality assurance, ensuring that buyers can confidently source Coca-Cola products that meet their operational needs. By leveraging this guide, B2B buyers can streamline their purchasing process, mitigate risks, and ultimately drive profitability in their beverage offerings. Whether you are looking to expand your product line or optimize your supply chain, this guide serves as a valuable tool for achieving your business objectives in the global marketplace.

Understanding 3 liter coke bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Coca-Cola Classic | Iconic flavor, 3-liter size, traditional branding | Retail distribution, events, catering | Pros: Strong brand recognition; Cons: Higher price compared to generic options. |

| Coca-Cola Diet | Sugar-free variant, same 3-liter size | Health-focused retailers, cafes | Pros: Appeals to health-conscious consumers; Cons: Limited audience compared to classic. |

| Coca-Cola Zero Sugar | Zero-calorie, similar taste to classic | Restaurants, convenience stores | Pros: Popular among diet-conscious buyers; Cons: May not appeal to traditional Coke drinkers. |

| Coca-Cola Flavored Variants | Includes flavors like Cherry and Vanilla in 3 liters | Specialty stores, promotional events | Pros: Attracts diverse consumer preferences; Cons: Niche market, may have lower demand. |

| Coca-Cola Multi-Pack | Bundled 3-liter bottles for bulk purchasing | Wholesale distributors, supermarkets | Pros: Cost-effective for bulk buyers; Cons: Requires larger storage space. |

What Are the Key Characteristics of Coca-Cola Classic in 3-Liter Bottles?

Coca-Cola Classic is the flagship product of the brand, known for its distinctive taste that has been cherished since 1886. This 3-liter bottle is ideal for family gatherings, parties, and retail environments, where larger quantities are beneficial. B2B buyers should consider the strong brand loyalty associated with Coca-Cola Classic, which can drive sales in retail settings. However, pricing may be higher compared to private label options, which could affect margins.

Why Choose Coca-Cola Diet for Health-Conscious Markets?

Coca-Cola Diet offers the same iconic flavor without the calories, making it a popular choice among health-conscious consumers. Its 3-liter bottle format is suitable for restaurants and cafes that want to provide low-calorie options. B2B buyers should focus on markets that prioritize health and wellness, as demand is steadily increasing. However, the niche appeal means that it may not sell as well in all demographics, potentially leading to inventory challenges.

How Does Coca-Cola Zero Sugar Appeal to Modern Consumers?

Coca-Cola Zero Sugar is designed to mimic the classic taste while being calorie-free. This product is gaining traction in various sectors, including restaurants and convenience stores, due to the growing trend of healthier beverage choices. B2B buyers should consider the popularity of this variant among younger consumers, as it can help attract a broader audience. The challenge lies in balancing stock levels, as traditional Coke drinkers may still prefer the classic version.

What Are the Advantages of Coca-Cola Flavored Variants?

Coca-Cola offers flavored variants like Cherry and Vanilla in 3-liter bottles, which cater to diverse consumer tastes. These products are particularly suitable for specialty stores and promotional events, where unique offerings can drive foot traffic. B2B buyers should assess the local market preferences before stocking these variants, as they may attract niche audiences. However, the demand may fluctuate, leading to potential overstocking issues.

Why Consider Coca-Cola Multi-Pack Options for Bulk Purchasing?

Coca-Cola Multi-Pack options allow for bulk purchasing of 3-liter bottles, making them ideal for wholesalers and supermarkets. This approach is cost-effective for businesses looking to maximize profit margins. B2B buyers should evaluate their storage capabilities since multi-packs require more space. While they offer better pricing per unit, the initial investment may be substantial, making it essential to analyze sales forecasts and inventory turnover rates.

Key Industrial Applications of 3 liter coke bottle

| Industry/Sector | Specific Application of 3 liter coke bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Bulk distribution for events and gatherings | Cost-effective serving size for large groups | Ensure compliance with local health regulations and sustainability standards. |

| Retail | In-store promotions and displays | Attracts customers with visually appealing packaging | Evaluate supplier reliability and shelf-life of the product. |

| Hospitality | Mini-bar offerings in hotels and resorts | Enhances guest experience with familiar brands | Consider logistics for timely delivery and product availability. |

| Manufacturing & Packaging | Repackaging for local distribution | Reduces waste and optimizes supply chain efficiency | Assess the recyclability of bottles and compatibility with local packaging norms. |

| Sports & Entertainment | Sponsorships and product placement at events | Increases brand visibility and market reach | Negotiate bulk purchasing agreements for competitive pricing. |

How is the 3 Liter Coke Bottle Used in the Food & Beverage Industry?

In the food and beverage sector, the 3-liter Coke bottle serves as a practical solution for bulk distribution during events, parties, and gatherings. This format allows businesses to serve a large number of customers efficiently, thus reducing the cost per serving. For international buyers, especially in regions like Africa and South America, it’s crucial to ensure that the bottles meet local health and safety standards, as well as sustainability practices to appeal to environmentally conscious consumers.

What Role Does the 3 Liter Coke Bottle Play in Retail Promotions?

Retailers utilize 3-liter Coke bottles in promotional campaigns to attract customers through eye-catching displays. This larger format not only enhances visibility but also encourages impulse buying, particularly during holiday seasons or special events. For businesses in Europe and the Middle East, sourcing considerations should include the reliability of suppliers and the shelf-life of products, ensuring that they remain fresh throughout the promotional period.

Why is the 3 Liter Coke Bottle Important for Hospitality?

In the hospitality industry, hotels and resorts often stock 3-liter Coke bottles in mini-bars to provide guests with familiar beverage options. This enhances the overall guest experience, contributing to customer satisfaction and repeat business. For buyers in these sectors, logistics are paramount; timely delivery and consistent product availability are essential to maintain service quality and meet guest expectations.

How Does the 3 Liter Coke Bottle Benefit Manufacturing & Packaging?

Manufacturers in the beverage industry may choose to repackage 3-liter Coke bottles for local distribution, thereby minimizing waste and optimizing supply chain efficiency. This approach allows companies to adapt to regional preferences while maximizing resource utilization. Buyers should assess the recyclability of these bottles and their compatibility with local packaging regulations to ensure compliance and sustainability.

In What Ways Can the 3 Liter Coke Bottle Enhance Sports & Entertainment Events?

Sponsorship and product placement at sports and entertainment events often feature the 3-liter Coke bottle, increasing brand visibility and connecting with a diverse audience. This strategic use not only promotes the product but also enhances the event experience for attendees. For B2B buyers, negotiating bulk purchasing agreements can provide competitive pricing and ensure a steady supply for large-scale events.

3 Common User Pain Points for ‘3 liter coke bottle’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions for Coca-Cola Bottles

The Problem: B2B buyers often face significant challenges when sourcing 3-liter Coca-Cola bottles, particularly in regions like Africa and South America where supply chain reliability can be inconsistent. Delays in shipments, unexpected price hikes, and limited availability can disrupt businesses that rely on these products for retail or event planning. This unpredictability not only affects inventory management but can also lead to missed sales opportunities and dissatisfied customers.

The Solution: To mitigate supply chain disruptions, B2B buyers should establish relationships with multiple suppliers across different regions. By diversifying sourcing options, businesses can ensure a more consistent supply of 3-liter Coca-Cola bottles. Furthermore, utilizing advanced inventory management software can help track stock levels in real-time, allowing for timely reorders before supplies run low. Additionally, consider entering into long-term contracts with suppliers to lock in prices and ensure priority access during peak demand periods.

Scenario 2: Ensuring Product Quality and Authenticity

The Problem: In the global marketplace, the risk of counterfeit products or subpar quality is a genuine concern for B2B buyers. When purchasing 3-liter Coca-Cola bottles, especially from unfamiliar suppliers, there is a fear of receiving inferior products that do not meet the brand’s quality standards. This issue can lead to customer dissatisfaction and potential harm to the buyer’s reputation.

The Solution: To ensure product quality and authenticity, B2B buyers should conduct thorough due diligence on potential suppliers. This includes requesting samples of the product to assess quality before making a bulk purchase. Additionally, verifying the supplier’s credentials, such as their relationship with Coca-Cola and their compliance with local regulations, can provide further assurance. Implementing a quality control process, including regular inspections of incoming shipments, can also help maintain high standards and protect brand integrity.

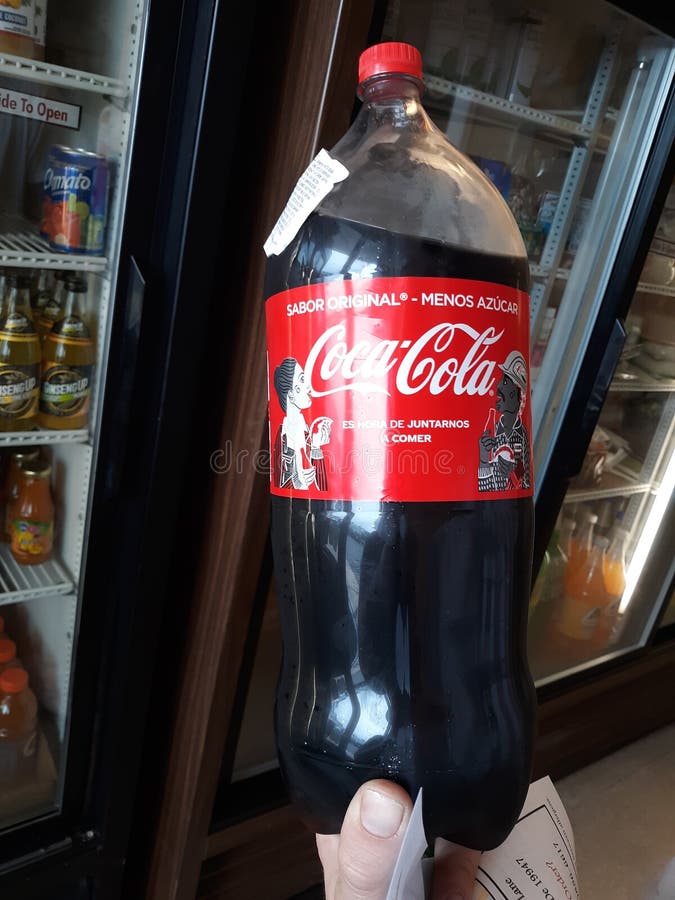

Illustrative image related to 3 liter coke bottle

Scenario 3: Managing Inventory and Storage Challenges

The Problem: Storing large quantities of 3-liter Coca-Cola bottles can present logistical challenges for B2B buyers, particularly in terms of space and inventory management. Retailers and distributors may struggle to find adequate storage solutions that maintain product integrity while also optimizing space. Poor inventory management can lead to overstocking or stockouts, both of which can hurt a business’s bottom line.

The Solution: To effectively manage inventory and storage, B2B buyers should invest in efficient shelving systems and temperature-controlled storage environments if applicable. An inventory management system that uses barcoding or RFID technology can streamline tracking and ordering processes, reducing the risk of overstocking or running out of popular items. Additionally, consider implementing a just-in-time inventory strategy, which allows for a more responsive supply chain that minimizes excess stock while ensuring availability when demand spikes. Regularly reviewing sales data can also help buyers anticipate trends and adjust their inventory levels accordingly.

By addressing these common pain points with actionable strategies, B2B buyers can enhance their operations, ensure customer satisfaction, and ultimately drive growth in their business while dealing with 3-liter Coca-Cola bottles.

Strategic Material Selection Guide for 3 liter coke bottle

When selecting materials for a 3-liter Coke bottle, it is essential to consider various factors that can influence product performance, manufacturing processes, and market compliance. The following analysis examines four common materials used in the production of beverage bottles, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of PET (Polyethylene Terephthalate) for Beverage Bottles?

PET is the most widely used material for soft drink bottles, including the 3-liter Coke bottle. It boasts excellent clarity, lightweight properties, and high strength-to-weight ratio, making it ideal for packaging carbonated beverages. PET is resistant to impact and has good barrier properties, which help maintain carbonation and flavor integrity. It can withstand temperatures up to 60°C, making it suitable for various storage conditions.

Pros & Cons: The advantages of PET include its low production cost, recyclability, and resistance to breakage. However, it has limitations in terms of heat resistance and can degrade under prolonged exposure to UV light, potentially affecting the product’s quality.

Impact on Application: PET is compatible with carbonated beverages, ensuring that the integrity of the drink is maintained throughout its shelf life. This material is particularly relevant for markets in Africa and South America, where the demand for affordable, lightweight packaging is high.

How Does Glass Compare as a Material for 3-Liter Coke Bottles?

Glass bottles are known for their premium feel and excellent barrier properties against gases and moisture. They can withstand high temperatures, making them suitable for pasteurization processes. Glass is fully recyclable and does not leach chemicals into the beverage, which is a significant advantage for health-conscious consumers.

Pros & Cons: The primary advantage of glass is its ability to preserve the taste and quality of beverages over time. However, glass is heavier and more fragile than plastic, leading to higher shipping costs and increased risk of breakage during transport. This can be a significant consideration for international buyers.

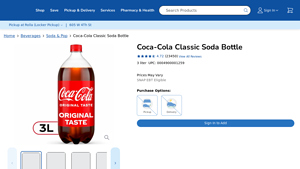

Illustrative image related to 3 liter coke bottle

Impact on Application: In markets like Europe, where consumers often prefer premium packaging, glass can enhance brand perception. However, the cost implications and logistics of handling glass bottles may deter buyers in regions with less developed infrastructure.

What Role Does HDPE (High-Density Polyethylene) Play in Beverage Packaging?

HDPE is another material that can be used for beverage bottles, characterized by its high strength and resistance to impact and chemicals. It is suitable for a variety of temperatures and is known for its durability.

Pros & Cons: HDPE is cost-effective and offers good resistance to environmental stress cracking. However, it has lower clarity compared to PET and may not provide the same level of barrier protection against gases, which can affect carbonation in soft drinks.

Impact on Application: While HDPE is less common for carbonated beverages, its use could be considered in markets where cost is a significant factor. Buyers in regions like the Middle East may appreciate the durability and cost-effectiveness of HDPE in harsh environments.

Why is Aluminum a Viable Option for Beverage Bottles?

Aluminum is increasingly being used for beverage packaging, particularly in cans. It is lightweight, strong, and provides excellent barrier properties against light and oxygen, which helps maintain beverage quality.

Illustrative image related to 3 liter coke bottle

Pros & Cons: Aluminum bottles are recyclable and can be easily transported due to their lightweight nature. However, they can be more expensive to produce than plastic options and may require additional coatings to prevent interaction with the beverage.

Impact on Application: In regions like Brazil, where sustainability is becoming a priority, aluminum can align with consumer preferences for eco-friendly packaging. However, the initial investment may be a barrier for some buyers.

Summary Table of Material Selection for 3-Liter Coke Bottles

| Material | Typical Use Case for 3 liter coke bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET | Common for carbonated soft drinks | Lightweight and recyclable | Limited heat resistance | Low |

| Glass | Premium packaging for beverages | Excellent taste preservation | Heavy and fragile | High |

| HDPE | Alternative for various beverages | Cost-effective and durable | Lower clarity and gas barrier | Med |

| Aluminum | Eco-friendly option, often for cans | Strong barrier properties | Higher production costs | High |

This guide provides a comprehensive overview of the materials commonly used for 3-liter Coke bottles, enabling international B2B buyers to make informed decisions based on performance, cost, and regional market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 liter coke bottle

What Are the Main Stages in the Manufacturing Process of a 3 Liter Coke Bottle?

The manufacturing process of a 3 liter Coke bottle involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the bottle is produced efficiently and meets quality standards.

How Is Material Prepared for the Production of 3 Liter Coke Bottles?

The primary material used for manufacturing Coke bottles is polyethylene terephthalate (PET), known for its strength, lightweight properties, and recyclability. The process begins with the preparation of PET resin, which is typically in the form of pellets. These pellets are dried to remove any moisture, ensuring optimal processing conditions. Once dried, the PET resin is melted and extruded into preforms, which are small, test-tube-like structures that will later be expanded into full-sized bottles.

What Techniques Are Employed in Forming the Bottles?

The preforms are heated and then blow-molded into the final bottle shape using a blow molding technique. This involves placing the preform into a mold and injecting high-pressure air to expand it to the mold’s shape. This method ensures uniform thickness and structural integrity, critical for holding carbonated beverages. Advanced blow molding machines are equipped with precise controls to regulate temperature and pressure, ensuring consistency across all bottles produced.

What Quality Control Measures Are Implemented During Production?

Quality control (QC) is integral to the manufacturing process, ensuring that each bottle meets international standards and is safe for consumer use. Various checkpoints are established throughout the production process to monitor quality.

Which International Standards Govern the Quality of 3 Liter Coke Bottles?

Manufacturers typically adhere to international standards such as ISO 9001, which provides a framework for quality management systems. This certification ensures that organizations consistently meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking and API specifications may apply, depending on the region and market.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control is implemented at several critical checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting the raw materials, such as PET resin, before they enter the production process. Suppliers must provide certificates of conformity to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators monitor parameters such as temperature and pressure in real-time. Random sampling of bottles is conducted to check for defects like uneven thickness or improper sealing.

-

Final Quality Control (FQC): After production, bottles undergo comprehensive testing. This includes pressure testing to ensure they can withstand internal carbonation pressure and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are effective strategies to ensure compliance and quality:

What Auditing Processes Should Buyers Consider?

Buyers should request detailed quality assurance reports from suppliers, including results from IQC, IPQC, and FQC stages. Conducting regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. This can involve on-site inspections or reviewing third-party audit reports.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services offers an unbiased assessment of a supplier’s QC processes. These organizations can verify compliance with international standards, check production methods, and evaluate the overall quality of the bottles produced. This is particularly beneficial for buyers in regions with diverse regulatory requirements, ensuring that products meet local and international standards.

What Testing Methods Are Commonly Used for Quality Assurance?

Several testing methods are routinely applied to assess the quality of 3 liter Coke bottles:

-

Pressure Testing: Bottles are subjected to internal pressure tests to ensure they can withstand the carbonation process without bursting.

-

Drop Testing: This assesses the durability of the bottle by dropping it from various heights to check for breakage or deformation.

-

Visual Inspection: Automated systems often conduct visual inspections to identify surface defects, such as scratches, discoloration, or deformities.

-

Chemical Testing: Bottles may also undergo chemical testing to ensure they do not leach harmful substances, maintaining safety for consumers.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

Understanding the nuances of quality control in the context of international trade is essential for B2B buyers. Different regions may have varying regulations regarding packaging materials, which can affect compliance. For instance, the European Union has stringent regulations regarding food contact materials, while standards in some African countries may be less defined.

How Do Regional Differences Impact Quality Assurance?

Buyers must be aware of local market requirements and ensure that their suppliers can meet these standards. This may include obtaining certifications that validate compliance with specific regulations. Engaging with local experts or consultants can provide valuable insights into navigating these complexities.

In summary, the manufacturing processes and quality assurance measures for 3 liter Coke bottles are intricate and multifaceted. By understanding these processes, international B2B buyers can make informed decisions, ensuring they source high-quality products that meet their market’s demands.

Illustrative image related to 3 liter coke bottle

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 liter coke bottle’

The procurement of 3-liter Coca-Cola bottles requires a strategic approach to ensure quality, compliance, and profitability. This guide provides a practical checklist to assist international B2B buyers in navigating the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establish clear specifications for the 3-liter bottle. Consider factors such as bottle design, material (PET vs. glass), and labeling requirements. Understanding these specifications upfront helps streamline the sourcing process and ensures that the products meet your market’s regulatory standards.

- Material considerations: Assess whether the bottles need to be recyclable or have specific durability standards.

- Labeling requirements: Different regions may have specific regulations regarding nutritional information and ingredient listings.

Step 2: Research Market Demand and Trends

Conduct thorough market research to understand demand. Analyze consumption patterns in your target regions, including Africa, South America, the Middle East, and Europe. This data will guide your purchasing decisions and help you anticipate market fluctuations.

- Consumer preferences: Identify preferences for flavors, packaging styles, or promotional offers that could influence purchasing.

- Seasonal trends: Be aware of peak seasons where demand may increase, such as holidays or major events.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making commitments. Request company profiles, check for industry certifications, and ask for references from other businesses that have sourced similar products. A reliable supplier is crucial for maintaining product quality and timely delivery.

Illustrative image related to 3 liter coke bottle

- Certifications to verify: Look for ISO certifications or local food safety standards that indicate compliance with health regulations.

- Supplier reviews: Seek feedback from other B2B buyers to gauge the supplier’s reliability and service quality.

Step 4: Request Samples and Conduct Quality Checks

Always request product samples before placing large orders. This step allows you to assess the quality of the bottles firsthand and verify that they meet your specifications.

- Quality benchmarks: Check for consistency in bottle design, clarity, and labeling accuracy.

- Taste tests: If applicable, conduct taste tests to ensure the product maintains its flavor integrity.

Step 5: Negotiate Pricing and Payment Terms

Engage in negotiations to secure favorable pricing and payment terms. Understanding market pricing can provide leverage during negotiations. Aim for terms that align with your cash flow needs and minimize risks.

- Bulk purchasing discounts: Inquire about discounts for larger orders or long-term contracts.

- Payment flexibility: Explore options for staggered payments or credit terms to better manage your finances.

Step 6: Understand Import Regulations and Compliance

Familiarize yourself with import regulations specific to your target markets. Each region may have unique regulations regarding the importation of food and beverage products, which can affect your ability to sell the product.

- Documentation requirements: Ensure you have all necessary import permits and customs documentation ready.

- Tariffs and duties: Be aware of any tariffs or duties that may apply to your shipments, as these can impact overall costs.

Step 7: Establish Logistics and Distribution Channels

Plan your logistics and distribution strategy early in the process. Efficient logistics can significantly reduce costs and improve delivery times, ensuring that you meet market demand promptly.

- Shipping options: Evaluate different shipping methods based on cost and delivery speed.

- Local distribution partners: Consider partnering with local distributors who understand the regional market dynamics and can facilitate smoother entry into your target market.

By following this checklist, B2B buyers can navigate the complexities of sourcing 3-liter Coca-Cola bottles with confidence, ensuring a successful procurement process that meets both quality and market demands.

Comprehensive Cost and Pricing Analysis for 3 liter coke bottle Sourcing

When considering the sourcing of 3-liter Coca-Cola bottles, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers. This analysis will delve into the key cost components, price influencers, and provide actionable tips to enhance negotiation outcomes for international buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing 3-Liter Coca-Cola Bottles?

The cost structure for sourcing 3-liter Coca-Cola bottles can be broken down into several fundamental components:

-

Materials: The primary costs arise from the raw materials used in bottle production, which typically include PET (polyethylene terephthalate) for the bottle itself and other materials for the labeling and packaging. The price of these materials can fluctuate based on global oil prices and supply chain dynamics.

-

Labor: Labor costs involve the wages paid to workers involved in the manufacturing process. These costs vary significantly by region, influenced by local wage standards, labor laws, and the skill level of the workforce.

-

Manufacturing Overhead: This includes utilities, maintenance, and other indirect costs associated with production facilities. Efficient operations can help mitigate these costs, but they remain a critical factor in pricing.

-

Tooling: Initial setup costs for manufacturing lines, such as molds for bottle production, can be significant. Customization or specific branding requirements can further increase these costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures the product meets safety and quality standards. This can add to the overall cost but is vital for maintaining brand integrity.

-

Logistics: The costs associated with transporting the bottles to buyers, including warehousing, shipping, and handling. These costs can be affected by distance, fuel prices, and regulatory fees.

-

Margin: Suppliers will incorporate a profit margin into their pricing. This margin can vary based on the supplier’s market position, perceived value, and competitive landscape.

What Influences the Pricing of 3-Liter Coca-Cola Bottles?

Several factors can influence the pricing of 3-liter Coca-Cola bottles:

-

Volume/MOQ: Suppliers often have a minimum order quantity (MOQ). Higher volumes can lead to price reductions, making it essential for buyers to assess their needs and negotiate bulk pricing.

-

Specifications/Customization: Unique branding or design requirements can lead to higher costs. Buyers should consider whether customization is essential or if standard offerings are sufficient.

-

Materials and Quality Certifications: The quality of materials used can significantly impact price. Bottles that meet specific certifications (e.g., ISO standards) may command a premium.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established brands with a proven track record may charge more but offer greater assurance of quality and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) affect shipping responsibilities and costs. Buyers must understand these terms to avoid unexpected expenses.

How Can Buyers Negotiate for Better Pricing?

For B2B buyers, especially from diverse regions, effective negotiation strategies can lead to cost savings:

Illustrative image related to 3 liter coke bottle

-

Understand Total Cost of Ownership (TCO): Consider all associated costs, including shipping, storage, and potential waste. This holistic view aids in making informed purchasing decisions.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet or exceed MOQs, thereby unlocking volume-based pricing advantages.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can foster better terms and pricing over time. Loyal customers may receive preferential pricing or first access to new products.

-

Research Regional Pricing Nuances: Pricing can vary significantly based on geographical location due to local market conditions, tariffs, and logistics costs. Understanding these nuances can provide leverage in negotiations.

-

Stay Informed on Market Trends: Being aware of fluctuations in raw material costs or changes in international trade policies can help buyers time their purchases effectively.

Disclaimer on Indicative Prices

Prices for 3-liter Coca-Cola bottles can vary widely based on the factors discussed. The information provided serves as a guideline, and buyers should conduct thorough market research and obtain quotes from multiple suppliers to ensure they secure the best possible pricing for their needs.

Alternatives Analysis: Comparing 3 liter coke bottle With Other Solutions

Understanding Alternatives to the 3 Liter Coke Bottle

When considering beverage packaging solutions, particularly for soft drinks like Coca-Cola, it’s essential to explore various alternatives that can meet similar needs. This analysis compares the iconic 3 liter Coke bottle with two viable alternatives: multi-pack cans and bag-in-box systems. Each option has unique attributes that may appeal to different B2B buyers, depending on their market, distribution channels, and consumer preferences.

Comparison Table

| Comparison Aspect | 3 Liter Coke Bottle | Multi-Pack Cans | Bag-in-Box System |

|---|---|---|---|

| Performance | High carbonation retention; suitable for quick consumption. | Good portability; ideal for sharing. | Excellent for large volumes; minimizes waste. |

| Cost | Moderate price point; competitive in the soft drink market. | Slightly higher unit cost; discounts available for bulk purchases. | Higher initial investment; cost-effective for high volume sales. |

| Ease of Implementation | Simple to store and distribute; requires minimal handling. | Requires more shelf space; can be challenging to stack. | Complex setup; requires specialized dispensing equipment. |

| Maintenance | Low maintenance; easy to recycle. | Moderate; cans must be disposed of properly. | Requires regular cleaning and maintenance of dispensing units. |

| Best Use Case | Retail sales and casual consumption. | Events and gatherings, where portability is key. | Restaurants and catering services needing large quantities. |

Detailed Breakdown of Alternatives

Multi-Pack Cans

Multi-pack cans, typically sold in 6 or 12-packs, offer a portable option that is popular for social gatherings and events. These cans are easier to transport and store, making them a favorite for consumers on the go. However, they come at a slightly higher unit cost compared to the 3 liter bottle. Additionally, cans have a shorter shelf life once opened, which may lead to more waste if not consumed quickly. For B2B buyers targeting event organizers or retail outlets with limited space, multi-pack cans could provide a practical solution.

Bag-in-Box System

The bag-in-box (BIB) system is designed for high-volume dispensing, commonly used in restaurants and catering services. This system allows for easy pouring and minimizes waste due to its airtight packaging, which preserves the beverage’s freshness for an extended period. Although the initial investment for a BIB system can be significant due to the need for specialized dispensing equipment, it offers long-term savings for high-volume users. However, the complexity of setup and maintenance might deter smaller businesses or those with limited resources.

Conclusion: How to Choose the Right Beverage Solution

When selecting the most appropriate beverage packaging solution, B2B buyers must consider their specific operational needs and target market. The 3 liter Coke bottle is ideal for casual consumption and retail environments, while multi-pack cans offer convenience for events. On the other hand, the bag-in-box system is suited for establishments that require large quantities and efficient dispensing. Evaluating factors such as cost, ease of implementation, and maintenance will help buyers make informed decisions tailored to their unique business models and customer preferences.

Essential Technical Properties and Trade Terminology for 3 liter coke bottle

What Are the Key Technical Properties of a 3 Liter Coca-Cola Bottle?

Understanding the essential technical properties of a 3-liter Coca-Cola bottle is critical for B2B buyers, especially those looking to optimize their supply chain and ensure product quality. Here are some key specifications to consider:

-

Material Grade: The 3-liter Coca-Cola bottle is primarily made from PET (Polyethylene Terephthalate), known for its excellent barrier properties, lightweight nature, and recyclability. For buyers, selecting bottles made from high-quality PET ensures durability during transportation and storage, reducing the likelihood of breakage and product loss.

-

Volume Tolerance: The nominal volume of a 3-liter bottle is crucial for compliance with packaging regulations in various regions. A tolerance of ±5% is generally acceptable in the industry, meaning the actual volume can vary slightly without affecting consumer satisfaction. Understanding this tolerance helps buyers ensure they meet legal requirements and customer expectations.

-

Capping System: The bottle is typically equipped with a screw cap designed to provide an airtight seal, preserving carbonation and freshness. The effectiveness of this sealing mechanism is vital for maintaining product quality during distribution. Buyers should consider the compatibility of caps with their filling and packaging systems to prevent leaks or spoilage.

-

Labeling Specifications: Compliance with local labeling regulations is essential for international trade. Each bottle must have clear, legible labeling that includes nutritional information, ingredient lists, and recycling symbols. Buyers should ensure their suppliers adhere to these specifications to avoid customs issues and enhance brand reputation.

-

Weight and Dimensions: The standard weight and dimensions of a 3-liter Coca-Cola bottle (approximately 1.3 kg and 30 cm in height) are significant for shipping and storage efficiency. Understanding the weight helps buyers calculate shipping costs, while dimensions influence palletization and shelf space in retail environments.

What Are Common Trade Terminology and Concepts Relevant to the 3 Liter Coca-Cola Bottle?

Familiarity with industry terminology is essential for B2B buyers to navigate the procurement process effectively. Here are some common terms relevant to the trade of 3-liter Coca-Cola bottles:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of beverage packaging, understanding OEM relationships can help buyers identify reliable suppliers of bottles and closures that meet specific quality standards.

-

MOQ (Minimum Order Quantity): MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For buyers, knowing the MOQ for 3-liter bottles is crucial in managing inventory levels and cash flow. It allows businesses to plan purchases effectively while negotiating favorable terms with suppliers.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing 3-liter Coca-Cola bottles, issuing an RFQ can help buyers compare options, negotiate better prices, and ensure they receive the best value for their purchase.

-

Incoterms (International Commercial Terms): These are a series of pre-defined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is essential for buyers to clarify shipping responsibilities, risk transfer, and cost allocation when importing 3-liter bottles.

-

Lead Time: This term refers to the time it takes for an order to be fulfilled from the moment it is placed until it is delivered. Understanding lead times for 3-liter Coca-Cola bottle orders helps buyers plan inventory levels, manage customer expectations, and avoid stockouts.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure compliance in the global beverage packaging market.

Navigating Market Dynamics and Sourcing Trends in the 3 liter coke bottle Sector

What Are the Current Market Dynamics and Key Trends Affecting the 3 Liter Coke Bottle Sector?

The global beverage market is experiencing a significant shift, driven by evolving consumer preferences and technological advancements. In the 3-liter Coke bottle sector, international B2B buyers are witnessing a rise in demand, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key trends include an increasing preference for larger packaging sizes, which cater to family consumption and social gatherings, especially in regions like Brazil and Saudi Arabia, where communal dining is prevalent.

Moreover, the integration of e-commerce platforms is reshaping sourcing strategies. B2B buyers are leveraging digital marketplaces to procure products efficiently, enabling them to compare prices, access bulk discounts, and streamline logistics. The rise of data analytics tools also allows businesses to forecast demand more accurately and optimize inventory management. In this context, understanding local market dynamics—such as regional tastes and purchasing behaviors—becomes crucial for successful sourcing.

Another emerging trend is the focus on health-conscious alternatives. While traditional Coke remains a staple, buyers are also exploring variations like Coke Zero and Coca-Cola Life, which cater to health-conscious consumers. This shift necessitates a versatile sourcing strategy that accommodates diverse product lines while maintaining quality and brand integrity.

How Is Sustainability and Ethical Sourcing Impacting the 3 Liter Coke Bottle Sector?

Sustainability is becoming a non-negotiable aspect of B2B procurement, particularly in the beverage industry. The environmental impact of plastic waste has led to increased scrutiny from consumers and regulatory bodies alike. For international B2B buyers, sourcing 3-liter Coke bottles involves ensuring that suppliers adhere to sustainable practices. This includes using recycled materials and exploring alternative packaging solutions, such as biodegradable or reusable bottles.

Ethical supply chains are gaining importance, with buyers increasingly seeking partners who demonstrate a commitment to reducing their carbon footprint. Certifications such as ISO 14001 (Environmental Management) and the Forest Stewardship Council (FSC) label can serve as indicators of a supplier’s commitment to sustainable practices. By prioritizing suppliers with ‘green’ certifications, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation in a market that increasingly values corporate responsibility.

Furthermore, companies are exploring ways to implement circular economy principles, encouraging the recycling and reuse of bottles. Engaging in partnerships with organizations focused on recycling initiatives can also create a positive impact and foster community goodwill. This dual focus on sustainability and ethical sourcing is not just a trend but a strategic imperative for long-term success in the 3-liter Coke bottle market.

How Has the 3 Liter Coke Bottle Evolved Over Time?

The 3-liter Coke bottle has a rich history that reflects broader trends in consumer behavior and packaging innovation. Introduced as part of Coca-Cola’s effort to accommodate family consumption and larger gatherings, the 3-liter bottle quickly became a staple in many households. Its evolution mirrors changes in packaging technology, with advancements that enhance product preservation and convenience.

Initially, glass bottles dominated the market, but the shift to lightweight, recyclable plastic has significantly reduced transportation costs and environmental impact. This transition aligns with consumer demands for convenience and portability, making the 3-liter bottle an attractive option for buyers looking to meet diverse consumer needs.

Today, the 3-liter Coke bottle stands as a testament to Coca-Cola’s adaptability and commitment to innovation, positioning itself as a key player in the global beverage landscape. As international B2B buyers navigate this sector, understanding its historical context can provide valuable insights into current market dynamics and future opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 liter coke bottle

-

How do I ensure the quality of the 3-liter Coke bottles I am sourcing?

To ensure quality, establish strict quality assurance (QA) protocols with your supplier. Request samples before placing a bulk order to assess taste, carbonation, and packaging integrity. Additionally, inquire about the supplier’s certifications, such as ISO or HACCP, which indicate adherence to industry standards. Conducting third-party inspections can further validate product quality and compliance with safety regulations in your target market. -

What are the most important factors to consider when choosing a supplier for Coca-Cola products?

When selecting a supplier for Coca-Cola products, prioritize their experience in beverage distribution, reputation in the market, and ability to meet your specific volume requirements. Verify their logistics capabilities, including shipping times and methods, to ensure timely delivery. It’s also essential to assess their customer service responsiveness and willingness to accommodate custom orders or packaging options. -

What are the minimum order quantities (MOQ) for 3-liter Coke bottles?

Minimum order quantities for 3-liter Coke bottles can vary significantly based on the supplier and your location. Typically, MOQs range from a few pallets to several containers. Discuss your needs with potential suppliers to negotiate an MOQ that aligns with your business model while ensuring they can meet your demand without compromising on product availability. -

What payment terms are commonly offered for international B2B transactions?

International suppliers often offer various payment terms, including advance payment, letters of credit, and payment upon delivery. Commonly, a 30% deposit is required upfront, with the remaining balance due before shipping or upon receipt of goods. Discussing flexible terms can help establish a mutually beneficial agreement, especially for larger orders or long-term partnerships. -

How can I customize the packaging for my 3-liter Coke bottles?

Customization options for packaging can include label designs, shrink sleeves, or promotional packaging. Communicate your specific requirements to potential suppliers and inquire about their capabilities for customization. Some suppliers may offer design services, while others might require you to provide finished designs. Be aware that customization may impact lead times and costs, so factor these into your planning. -

What logistics considerations should I keep in mind when sourcing Coke bottles internationally?

Logistics play a crucial role in international sourcing. Consider shipping methods (air vs. sea), lead times, and potential customs duties or tariffs that may apply. Collaborate with your supplier to select the most efficient shipping routes and methods. Additionally, ensure that your supply chain is robust enough to handle contingencies like delays or changes in demand. -

What regulations should I be aware of when importing soft drinks like Coke into my country?

When importing soft drinks, familiarize yourself with local regulations regarding food and beverage imports, including labeling requirements, health and safety standards, and tariff classifications. Each country may have specific guidelines on ingredients, packaging, and nutritional information that must be adhered to. Consulting with a local customs broker can help navigate these regulations effectively. -

How do I handle disputes or issues with my supplier regarding the 3-liter Coke bottles?

To manage disputes effectively, maintain clear communication with your supplier from the outset. Establish a formal contract outlining terms, quality standards, and dispute resolution processes. If issues arise, address them promptly and professionally, seeking to resolve them through discussion. If necessary, consider mediation or arbitration as a means to resolve conflicts without damaging the business relationship.

Top 5 3 Liter Coke Bottle Manufacturers & Suppliers List

1. Coca-Cola – Classic Soda Bottle

Domain: kroger.com

Registered: 1993 (32 years)

Introduction: {“name”: “Coca-Cola Classic Soda Bottle”, “size”: “3 liter”, “UPC”: “0004900001259”, “average_customer_rating”: 4.72, “total_reviews”: 23450, “caffeine_content”: “34 mg per 12 fl oz serving”, “description”: “There’s nothing quite like the crisp, refreshing taste of an ice-cold coca-cola. Carefully crafted in 1886, coca-cola’s great taste has stood the test of time. This soda is the perfect compani…

2. Coca-Cola – Thirst Buster

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: In 1985, Coca-Cola introduced a 3-liter soda bottle known as the Thirst Buster.

3. Coca-Cola – Classic Soda 3L

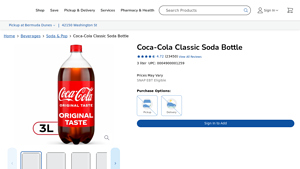

Domain: ralphs.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Coca-Cola Classic Soda Bottle”, “size”: “3 liter”, “UPC”: “0004900001259”, “caffeine_content”: “34 mg per 12 fl oz serving”, “average_customer_rating”: “4.72”, “total_reviews”: “23450”, “description”: “There’s nothing quite like the crisp, refreshing taste of an ice-cold Coca-Cola. Carefully crafted in 1886, Coca-Cola’s great taste has stood the test of time. This soda is the per…

4. Coca-Cola – Cola Soda Pop 3L

Domain: shop.fiestamart.com

Registered: 1996 (29 years)

Introduction: {“product_name”:”Coca-Cola Cola Soda Pop Bottle”,”price”:”$3.99″,”volume”:”3 L”,”price_per_100ml”:”$0.13/100ml”,”caffeinated”:”true”}

5. Coca-Cola – 3 L Soda Pop Bottle

Domain: instacart.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Coca-Cola Cola Soda Pop Bottle”, “size”: “3 L”, “delivery_info”: “$0 delivery fee on first 3 orders. Terms apply.”, “description”: “There’s nothing quite like the crisp, refreshing taste of an ice-cold Coca-Cola. Carefully crafted in 1886, Coca-Cola’s great taste has stood the test of time. This soda is the perfect companion for both special moments and everyday enjoyment. Each s…

Strategic Sourcing Conclusion and Outlook for 3 liter coke bottle

In the competitive landscape of beverage distribution, strategic sourcing of the 3-liter Coca-Cola bottle represents an opportunity for international B2B buyers to leverage strong brand recognition and consumer loyalty. Key takeaways emphasize the importance of establishing reliable supply chains that can adapt to regional demands while optimizing pricing strategies. Understanding local consumer preferences and market trends in regions such as Africa, South America, the Middle East, and Europe can enhance your purchasing decisions, driving profitability.

Additionally, the product’s versatility—suitable for both casual and celebratory occasions—positions it as an essential item for wholesalers and retailers alike. As buyers seek to differentiate themselves in the marketplace, the ability to provide a well-known and trusted product like Coca-Cola can significantly impact customer satisfaction and retention.

Looking ahead, it is crucial for B2B buyers to invest in robust sourcing strategies that not only secure quality products but also foster partnerships with reputable suppliers. By doing so, businesses can ensure a steady supply of the iconic 3-liter Coca-Cola bottle, meeting the evolving demands of consumers and capitalizing on growth opportunities across diverse markets. Embrace the potential of strategic sourcing to enhance your product offerings and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to 3 liter coke bottle

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.