Choosing Your 2Jz Motor For Sale: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 2jz motor for sale

In an increasingly competitive landscape, sourcing a reliable 2JZ motor for sale can pose significant challenges for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. As businesses seek high-performance engines for applications ranging from automotive racing to performance upgrades, understanding the nuances of the global supply chain becomes critical. This comprehensive guide addresses key considerations such as types of 2JZ motors available, their specific applications, supplier vetting processes, and pricing structures.

By delving into the intricacies of the 2JZ motor market, this guide equips buyers with actionable insights necessary for making informed purchasing decisions. It highlights the importance of quality assurance, compatibility with existing vehicle frameworks, and the potential for long-term partnerships with trusted suppliers. Readers will learn how to effectively assess the reliability of suppliers, navigate international shipping logistics, and understand the implications of warranty and after-sales support.

Whether you are a seasoned automotive professional or a newcomer to the industry, this resource will empower you to successfully navigate the global market for 2JZ motors, ensuring that your investments yield maximum performance and reliability.

Understanding 2jz motor for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2JZ-GTE VVTI | Twin-turbo, inline-6, VVTi technology, high horsepower potential | Performance tuning, motorsport applications | Pros: High performance, reliability; Cons: Higher cost, requires skilled installation. |

| 2JZ-GE | Naturally aspirated, less complex, lower horsepower | Everyday vehicles, basic performance builds | Pros: Simpler installation, cost-effective; Cons: Lower power output compared to GTE. |

| 2JZ-GTE Non-VVTI | Turbocharged, lacks variable valve timing, robust aftermarket support | Racing, performance upgrades | Pros: Strong performance, availability of parts; Cons: Older technology, less efficiency. |

| Turnkey 2JZ Engine Packages | Pre-tuned, complete systems ready for installation | Racing teams, enthusiasts, custom builds | Pros: Easy installation, optimized performance; Cons: Higher upfront cost, limited customization. |

| 2JZ-GTE JDM Imports | Imported engines with low mileage, complete drivetrain options | Specialty builds, restorations | Pros: Authentic parts, potential for high performance; Cons: Import regulations, variable quality. |

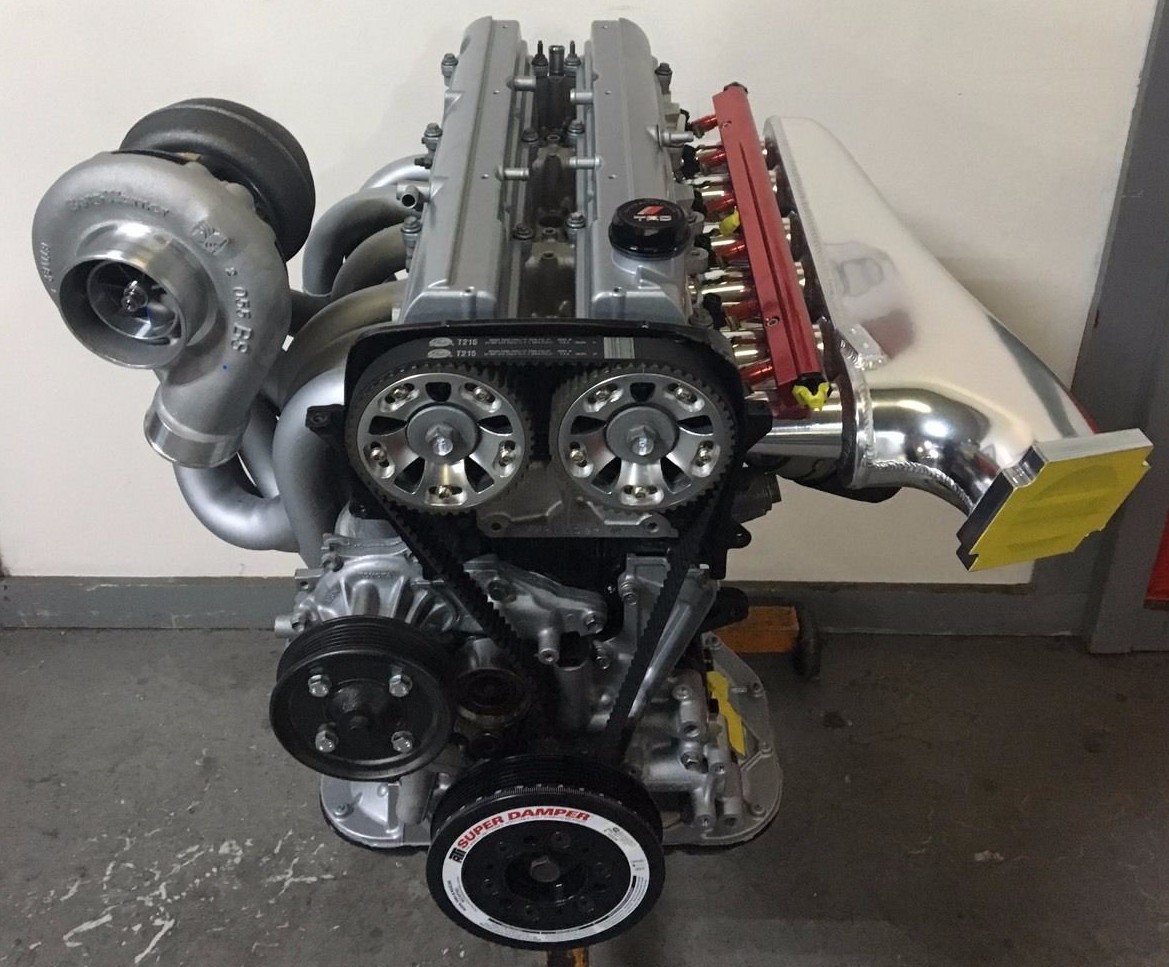

What Are the Key Characteristics of the 2JZ-GTE VVTI Engine?

The 2JZ-GTE VVTI is a standout choice for B2B buyers looking for high-performance engines. This twin-turbo, inline-6 engine features Variable Valve Timing (VVTi), enhancing efficiency and power. It is ideal for motorsport applications and performance tuning, making it popular among racing teams and car enthusiasts. When considering this engine, buyers should evaluate the installation complexity and the need for skilled technicians, as its advanced features may require specialized knowledge.

How Does the 2JZ-GE Engine Differ from the GTE?

The 2JZ-GE is naturally aspirated, making it less complex and more accessible for everyday vehicles and basic performance builds. While it offers lower horsepower compared to its turbocharged counterpart, its simplicity translates to easier installation and reduced costs. B2B buyers should consider the intended application; for those seeking reliable performance without the need for extreme horsepower, the 2JZ-GE serves as a practical option.

What Advantages Does the 2JZ-GTE Non-VVTI Offer?

The 2JZ-GTE Non-VVTI variant is turbocharged but lacks the variable valve timing feature. Despite being an older technology, it is well-regarded for its robust aftermarket support, making it a favorite among racers and performance enthusiasts. B2B buyers can benefit from the availability of parts and proven performance; however, they should be aware of potential efficiency drawbacks compared to newer models.

Why Consider Turnkey 2JZ Engine Packages?

Turnkey 2JZ engine packages are pre-tuned systems that offer a hassle-free installation experience. These complete systems are optimized for performance, making them ideal for racing teams and custom builds. While they come at a higher upfront cost, the ease of installation and immediate performance readiness can be advantageous for businesses looking to minimize downtime. Buyers should assess their budget against the potential performance gains.

What Should Buyers Know About 2JZ-GTE JDM Imports?

The 2JZ-GTE JDM imports are often sourced from low-mileage donor vehicles, offering authenticity and high performance. These engines typically come with complete drivetrain options, which can be beneficial for specialty builds or restorations. However, B2B buyers must navigate import regulations and ensure quality assurance when purchasing these engines, as the standards can vary significantly.

Key Industrial Applications of 2jz motor for sale

| Industry/Sector | Specific Application of 2jz motor for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Performance Tuning | High-performance upgrades for sports cars | Enhanced vehicle performance and competitive edge in racing markets | Ensure compatibility with existing systems and local regulations |

| Motorsport | Engine swaps for racing vehicles | Increased horsepower and reliability during competitive events | Verify engine specifications and performance benchmarks |

| Custom Vehicle Manufacturing | Custom builds for classic car restorations | Ability to modernize classic vehicles while maintaining originality | Assess availability of supporting components and aftermarket parts |

| Off-Road Vehicles | Powering off-road and adventure vehicles | Improved torque and durability for challenging terrains | Evaluate environmental regulations and emissions standards |

| Export Markets | Supply for international automotive markets | Access to a globally recognized engine with strong performance history | Consider shipping logistics and local market demand |

How is the 2JZ Motor Applied in Automotive Performance Tuning?

In the automotive performance tuning sector, the 2JZ motor is frequently used for high-performance upgrades in sports cars, particularly the Toyota Supra. Buyers seek this engine for its ability to significantly enhance horsepower and torque, making it a favorite among enthusiasts aiming for competitive racing. International B2B buyers must consider the compatibility of the 2JZ with their existing systems, as well as any local regulations regarding engine modifications.

What Role Does the 2JZ Motor Play in Motorsport?

In the motorsport industry, the 2JZ motor is a common choice for engine swaps in racing vehicles. Its robust design allows for substantial power increases, which is critical for success in various racing formats. Businesses involved in motorsport must verify the engine specifications, ensuring they meet performance benchmarks required for competitive racing. Additionally, sourcing a reliable engine from reputable suppliers can mitigate risks associated with performance failures.

How is the 2JZ Motor Used in Custom Vehicle Manufacturing?

Custom vehicle manufacturers often utilize the 2JZ motor in restoring classic cars, allowing them to modernize performance without compromising the vehicle’s original aesthetic. This application appeals to buyers interested in creating unique, high-performance vehicles that stand out in the market. When sourcing the 2JZ, businesses should assess the availability of supporting components and aftermarket parts to ensure a successful build.

Why is the 2JZ Motor Ideal for Off-Road Vehicles?

The 2JZ motor is also popular in the off-road vehicle sector, where it powers trucks and SUVs designed for rugged terrains. Its high torque output and durability make it well-suited for off-road challenges, providing businesses with a competitive advantage in this niche market. International buyers should evaluate environmental regulations and emissions standards in their regions, as these can impact the use of high-performance engines in off-road applications.

How Does the 2JZ Motor Benefit Export Markets?

Finally, the 2JZ motor holds significant value in export markets, particularly in regions where performance vehicles are in high demand. Its reputation for reliability and power makes it a sought-after option for automotive businesses looking to cater to enthusiasts. Buyers in this sector must consider shipping logistics and local market demand when sourcing the 2JZ, ensuring they can meet customer expectations effectively.

3 Common User Pain Points for ‘2jz motor for sale’ & Their Solutions

Scenario 1: Difficulty in Verifying Engine Quality and Authenticity

The Problem: B2B buyers often face challenges in ensuring the quality and authenticity of 2JZ motors available for sale. With numerous suppliers in the market, buyers may encounter counterfeit or subpar engines that do not meet performance expectations. This can lead to significant financial losses, wasted time, and potential damage to their business reputation if they fail to deliver reliable products to their customers.

The Solution: To mitigate these risks, it is crucial for buyers to establish strong relationships with reputable suppliers. Start by researching suppliers with a proven track record in the automotive industry, particularly those specializing in JDM (Japanese Domestic Market) engines like the 2JZ. Look for certifications, customer testimonials, and case studies that demonstrate their expertise and reliability. Before finalizing any purchase, request detailed documentation of the engine’s history, including maintenance records and warranty information. Additionally, consider utilizing services that offer engine inspections or dyno testing to confirm performance specifications. This proactive approach not only helps ensure the quality of the engine but also fosters trust and transparency between buyers and suppliers.

Scenario 2: Challenges in Engine Compatibility and Installation

The Problem: Many B2B buyers struggle with the compatibility of the 2JZ motor with their existing vehicle setups or aftermarket modifications. Misalignment in specifications can lead to increased installation costs, delays, and frustration. Buyers may also lack the technical expertise to determine if additional components are necessary for a seamless integration, complicating the installation process further.

The Solution: To address compatibility concerns, buyers should conduct thorough research and communicate openly with suppliers about their specific vehicle models and intended applications. Providing detailed information about the existing setup, such as the vehicle’s make, model, and any previous modifications, can help suppliers recommend the right engine package and any necessary additional components. Additionally, consider investing in a comprehensive installation guide or workshop manual that outlines the installation process and required parts. Collaborating with experienced mechanics or automotive engineers can also streamline the installation, ensuring that all components work harmoniously together. By taking these steps, buyers can minimize compatibility issues and facilitate a smoother installation process.

Scenario 3: Navigating Import Regulations and Compliance Issues

The Problem: International buyers, especially from regions like Africa, South America, and the Middle East, often encounter regulatory hurdles when importing automotive parts, including the 2JZ motor. Different countries have varying import regulations and emissions standards, which can complicate the purchasing process and lead to delays or additional costs. Without proper guidance, buyers may inadvertently purchase engines that are not compliant with local laws, resulting in potential legal issues.

The Solution: To navigate these complex regulations effectively, buyers should familiarize themselves with the import laws and emissions requirements specific to their countries. Consulting with customs brokers or legal experts who specialize in automotive imports can provide valuable insights and help ensure compliance with all necessary regulations. Before making a purchase, verify that the supplier can provide all required documentation, such as certificates of conformity and emissions compliance statements. Additionally, consider sourcing engines that are specifically designed for international markets or that meet the standards of the buyer’s country. By being proactive and informed, buyers can minimize the risk of regulatory challenges and ensure a smooth import process.

Strategic Material Selection Guide for 2jz motor for sale

What Materials Are Commonly Used in 2JZ Motors?

When selecting materials for the 2JZ motor, it is crucial to consider the properties that directly affect performance, durability, and overall application suitability. Here, we analyze four common materials used in the construction of the 2JZ engine, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum Alloys

Aluminum alloys are extensively used in engine blocks and cylinder heads due to their lightweight and excellent thermal conductivity. Key properties include a temperature rating up to 400°C and good resistance to corrosion, particularly when treated with anodizing.

Pros: Aluminum alloys provide significant weight savings, which can improve vehicle performance and fuel efficiency. They are relatively easy to machine, allowing for complex designs.

Cons: While durable, aluminum alloys can be less resistant to wear compared to steel, particularly under high-stress conditions. They also tend to be more expensive than cast iron.

Impact on Application: Aluminum’s lightweight nature makes it ideal for applications requiring speed and agility. However, it may not be suitable for high-torque applications without additional reinforcement.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider the availability of aluminum alloys in their regions, as supply chains can vary.

Cast Iron

Cast iron is often used for engine blocks due to its excellent wear resistance and ability to withstand high temperatures and pressures. It has a temperature rating of approximately 600°C and offers good corrosion resistance.

Pros: Cast iron is highly durable and has a lower cost compared to aluminum, making it a popular choice for budget-conscious buyers. Its excellent vibration-damping characteristics also contribute to a smoother engine operation.

Cons: The weight of cast iron can negatively impact performance and fuel efficiency. Additionally, it is more challenging to machine than aluminum, which can increase manufacturing complexity.

Impact on Application: Cast iron is suitable for high-torque applications and can handle significant stress, making it ideal for performance builds. However, its weight may limit its use in lightweight racing applications.

Considerations for International Buyers: Buyers should be aware of the different grades of cast iron and their compliance with local standards. Additionally, the shipping costs may be higher due to the material’s weight.

Steel Alloys

Steel alloys are commonly used for components such as crankshafts and connecting rods due to their high strength and durability. They can withstand high temperatures and pressures, with a temperature rating often exceeding 600°C.

Pros: Steel alloys offer superior tensile strength and fatigue resistance, making them ideal for high-performance applications. They are also widely available and can be sourced easily.

Cons: The cost of high-strength steel alloys can be significant, and they may require specialized machining processes, increasing manufacturing complexity.

Impact on Application: Steel’s strength makes it suitable for high-performance builds, particularly in applications where high torque is expected. However, the added weight may be a drawback for lightweight applications.

Considerations for International Buyers: Buyers should consider the specific steel grade required for their application and ensure compliance with international standards. Additionally, they should assess local availability and potential tariffs on imported steel products.

Composite Materials

Composite materials, such as carbon fiber and fiberglass, are increasingly being used for engine components like intake manifolds and covers. They offer excellent strength-to-weight ratios and can withstand high temperatures.

Pros: Composites are lightweight and can be molded into complex shapes, providing design flexibility. They also exhibit good resistance to corrosion and fatigue.

Cons: The cost of composite materials can be high, and they may require specialized manufacturing techniques. Additionally, their performance can vary based on the specific resin or fiber used.

Impact on Application: Composites are ideal for applications where weight reduction is critical, such as in racing scenarios. However, they may not be suitable for load-bearing components without proper engineering.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards and are aware of the specific manufacturing capabilities available in their region.

Summary Table

| Material | Typical Use Case for 2JZ Motor for Sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Engine blocks, cylinder heads | Lightweight, excellent thermal conductivity | Less wear-resistant than steel | Medium |

| Cast Iron | Engine blocks | Highly durable, cost-effective | Heavier, more challenging to machine | Low |

| Steel Alloys | Crankshafts, connecting rods | Superior strength and fatigue resistance | Higher cost, specialized machining needed | High |

| Composite Materials | Intake manifolds, engine covers | Excellent strength-to-weight ratio | High cost, variable performance | High |

This analysis provides a comprehensive understanding of the materials commonly used in 2JZ motors, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for 2jz motor for sale

What Are the Main Stages of Manufacturing a 2JZ Motor for Sale?

The manufacturing of a 2JZ engine, particularly for B2B markets, involves several critical stages that ensure the final product meets high-performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Quality Control

Material preparation is the foundational stage where high-quality raw materials are sourced. For a 2JZ motor, critical components such as aluminum for the engine block and steel for the crankshaft must meet stringent specifications. Reputable suppliers often provide certificates of compliance to ensure materials conform to international standards like ISO 9001. This documentation is crucial for B2B buyers, especially when importing components from various countries.

Forming: Precision Engineering Techniques

Once materials are sourced, the forming stage involves precision engineering techniques. Advanced machining processes such as CNC (Computer Numerical Control) machining are used to create intricate engine components with high accuracy. This process is vital for parts like the cylinder head and engine block, where even minor deviations can lead to performance issues. Additionally, casting methods may be employed for parts that require complex shapes, ensuring strength and durability.

Assembly: Ensuring Compatibility and Functionality

The assembly stage is where all individual components are brought together. Skilled technicians perform this process, often utilizing jigs and fixtures to maintain alignment and accuracy. During assembly, attention is given to torque specifications and sealant applications to prevent leaks. It’s also common to incorporate automated assembly systems that enhance efficiency and reduce human error, which is particularly important for larger orders.

Finishing: Quality Surface Treatment

The finishing stage typically includes surface treatments such as anodizing or powder coating to enhance durability and aesthetics. This step also involves thorough cleaning and inspection to ensure all components are free from contaminants. Additionally, balancing the engine components is critical to reduce vibrations during operation, further ensuring the longevity of the motor.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a crucial aspect of the manufacturing process for 2JZ motors. It involves systematic measures to ensure that each engine meets both regulatory and performance standards.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards signifies that manufacturers have established processes to ensure product quality consistently. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are essential for engines sold in Europe and North America, respectively. These certifications reassure B2B buyers that the products meet specific safety and environmental standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at various stages of the manufacturing process through defined checkpoints:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival to ensure they meet required specifications.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect any deviations from quality standards. This may include measuring tolerances and ensuring proper assembly techniques.

-

Final Quality Control (FQC): Before shipment, each 2JZ motor undergoes a comprehensive inspection, which includes performance testing and verification against specifications. This ensures that the engine is operational and meets the expected quality before reaching the customer.

What Testing Methods Are Commonly Used for 2JZ Motors?

Testing methods are vital in validating the performance and reliability of a 2JZ engine. Common techniques include:

-

Dyno Testing: This involves running the engine on a dynamometer to measure horsepower and torque under various conditions, ensuring it performs as expected.

-

Leak Testing: This method checks for oil and coolant leaks, critical for engine longevity and reliability.

-

Vibration Analysis: This test identifies any imbalances that could lead to premature wear or failure, ensuring the engine operates smoothly.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of suppliers is essential to ensure the integrity of their purchases. Here are several strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting audits and quality assurance reports from suppliers can provide insights into their manufacturing practices. These documents should detail compliance with international standards and any certifications held. Buyers should also inquire about the frequency and results of internal audits, as well as corrective actions taken in response to quality issues.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct on-site inspections and testing, providing unbiased reports on the quality of the engines being manufactured. This approach is particularly beneficial for buyers in regions with varying local standards, as it ensures that the products meet the buyer’s requirements.

What Are the Nuances of Quality Control for International B2B Buyers?

Quality control nuances can vary significantly based on the buyer’s location. For instance, European buyers may have stricter emissions standards compared to those in Africa or South America. Understanding these regional differences is crucial for B2B buyers when negotiating contracts and setting expectations with suppliers.

Additionally, buyers should be aware of the potential for language barriers and differing business practices in international transactions. Establishing clear communication and ensuring that all quality expectations are documented can mitigate misunderstandings and ensure a smooth purchasing process.

Conclusion

In conclusion, the manufacturing processes and quality assurance measures for 2JZ motors are intricate and vital for ensuring that these high-performance engines meet the expectations of B2B buyers. Understanding these processes not only helps buyers make informed purchasing decisions but also fosters long-term partnerships with reliable suppliers across the globe. By prioritizing quality control and verification, buyers can confidently invest in 2JZ motors that will perform reliably in various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2jz motor for sale’

Introduction

Sourcing a 2JZ motor for sale can be a complex task, especially for international B2B buyers navigating various suppliers and regulations. This guide provides a practical checklist to streamline the procurement process, ensuring that you make informed decisions and secure high-quality engines that meet your performance needs.

Step 1: Define Your Technical Specifications

Start by clearly defining the technical specifications required for your application. Consider factors such as engine type (e.g., 2JZ-GTE or 2JZ-GE), horsepower requirements, and compatibility with existing systems. This step is crucial to ensure that the engine fits your vehicle or project specifications and meets performance expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in 2JZ motors. Look for suppliers with a strong online presence, customer reviews, and case studies. This research will help you compile a list of potential partners who have a proven track record in delivering quality products.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify the certifications and credentials of your shortlisted suppliers. Check for industry-standard certifications such as ISO, which reflect quality management practices. Supplier certifications can significantly impact the reliability and performance of the engines you procure.

Step 4: Request Detailed Product Information

Engage with suppliers to obtain detailed product specifications, including mileage, condition, and included components. Ask for information on warranties and return policies. This step is vital to understand what you are purchasing and to ensure that the engine meets your performance and reliability standards.

Step 5: Assess Pricing and Payment Terms

Request quotes from multiple suppliers to compare pricing structures. Ensure that you understand the payment terms, including deposit requirements and payment methods accepted. This evaluation will help you find the best value while maintaining financial security throughout the transaction.

Step 6: Check Logistics and Shipping Options

Inquire about the logistics of shipping the 2JZ motor to your location. Confirm the shipping costs, delivery timelines, and whether the supplier offers any tracking services. Understanding these logistics is essential for planning and ensuring that your engine arrives safely and on time.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, draft a purchase agreement that outlines all terms and conditions, including product specifications, pricing, payment terms, and delivery schedules. This formal contract helps protect both parties and ensures that everyone is on the same page regarding the transaction.

By following these steps, you can navigate the complexities of sourcing a 2JZ motor efficiently and effectively, ensuring that you secure a quality product that meets your operational needs.

Comprehensive Cost and Pricing Analysis for 2jz motor for sale Sourcing

What Are the Key Cost Components in Sourcing a 2JZ Motor?

When considering the acquisition of a 2JZ motor, various cost components must be analyzed to form a comprehensive understanding of the pricing structure. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials significantly affects the final price. The 2JZ engine requires high-quality components, including aluminum for the block, steel for the crankshaft, and various alloys for pistons and valves. Premium materials lead to better performance and longevity, justifying higher prices.

-

Labor: Skilled labor is essential for the precision assembly of the 2JZ motor. Labor costs can vary significantly based on the geographic location of the manufacturer. In regions with a higher cost of living, labor expenses can increase the overall cost.

-

Manufacturing Overhead: This encompasses expenses related to facility maintenance, utilities, and equipment depreciation. Efficient production processes can help reduce overhead costs, impacting the final pricing.

-

Tooling: The cost of specialized tools and equipment necessary for engine production is a crucial component. Investing in advanced machinery can enhance production efficiency and quality, but it also raises initial costs.

-

Quality Control: Ensuring that each engine meets strict performance and safety standards adds to the overall cost. Rigorous QC processes are essential, especially for high-performance engines like the 2JZ, which must adhere to specific tolerances.

-

Logistics: The cost of transporting the engine from the manufacturer to the buyer can vary based on distance and shipping methods. International logistics can add complexity and costs, especially if customs duties and taxes are involved.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can fluctuate based on market demand, competition, and supplier reputation.

How Do Price Influencers Affect the Cost of a 2JZ Motor?

Several factors can influence the pricing of a 2JZ motor, making it essential for buyers to understand these dynamics.

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQs), and larger purchases may reduce per-unit costs.

-

Specifications and Customization: Custom-built engines or those with enhanced specifications (such as increased horsepower or specific performance features) will typically command higher prices due to the additional engineering and materials involved.

-

Materials and Quality Certifications: The use of certified materials and components can influence pricing. Engines with certifications for performance and emissions may be priced higher but provide assurance of quality and compliance.

-

Supplier Factors: The reputation, experience, and reliability of the supplier can affect pricing. Established suppliers with a track record of quality and service may charge more but offer greater peace of mind.

-

Incoterms: Understanding the terms of shipment (Incoterms) is crucial for international buyers. These terms dictate who is responsible for shipping costs, insurance, and customs clearance, which can impact the total landed cost of the engine.

What Buyer Tips Can Help Optimize Costs When Sourcing a 2JZ Motor?

To achieve cost efficiency when sourcing a 2JZ motor, buyers should consider the following tips:

-

Negotiation: Engage in negotiations with suppliers to secure better pricing. Highlighting long-term partnerships or potential bulk purchases can provide leverage.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operational efficiency, and potential resale value. Investing in a higher-quality engine may result in lower long-term costs.

-

Explore Multiple Suppliers: Conduct thorough market research to compare prices and offerings from various suppliers. This can help identify competitive pricing and better terms.

-

Stay Informed About Pricing Trends: Keep abreast of market trends and fluctuations in material costs, which can impact engine pricing. Awareness of seasonal demand can also help in timing purchases effectively.

-

Understand Regional Market Nuances: Different regions may have varying pricing structures due to local demand, supply chain logistics, and economic conditions. Tailoring your sourcing strategy based on regional insights can yield better cost outcomes.

Disclaimer on Indicative Prices

Prices for 2JZ motors can vary widely based on the factors discussed above. Buyers are encouraged to conduct their due diligence, verify current pricing, and consider all cost components to make informed purchasing decisions.

Alternatives Analysis: Comparing 2jz motor for sale With Other Solutions

Exploring Alternatives to the 2JZ Motor for Sale: A Comparative Analysis

In the dynamic automotive market, particularly for performance engines, buyers often seek alternatives that can meet their specific needs. The 2JZ motor, renowned for its reliability and power, is a popular choice among enthusiasts and professionals alike. However, understanding viable alternatives can help B2B buyers make informed decisions that align with their operational goals, budget, and performance requirements.

Comparison Table of Engine Alternatives

| Comparison Aspect | 2JZ Motor For Sale | Alternative 1: RB26DETT Engine | Alternative 2: LS Swap (Chevy LS Series) |

|---|---|---|---|

| Performance | Up to 1,000 HP with modifications | Up to 800 HP; known for high-revving capability | 400-700 HP; strong torque across the range |

| Cost | $3,000 – $10,000 (depending on package) | $4,000 – $6,000 (used) | $3,000 – $10,000 (varies with configuration) |

| Ease of Implementation | Plug-and-play options available | Requires custom mounts and modifications | Generally easier with aftermarket kits |

| Maintenance | Moderate; requires quality components | Higher; parts can be expensive and rare | Generally lower; widespread parts availability |

| Best Use Case | High-performance builds, especially in Supras | Nissan enthusiasts, drift applications | Versatile for various builds, including muscle cars |

In-Depth Look at Alternatives

What Are the Advantages and Disadvantages of the RB26DETT Engine?

The RB26DETT engine, originally developed by Nissan, is celebrated for its power potential and tuning capabilities. It can reach up to 800 horsepower with proper modifications, making it a favorite among drift and performance enthusiasts. However, sourcing parts can be challenging and often expensive. Additionally, the installation process requires custom modifications, which can increase overall project costs and time.

How Does an LS Swap Compare to the 2JZ Motor?

The LS series engines from Chevrolet are known for their robust design and ease of availability. An LS swap can provide a balance of power and torque, ranging from 400 to 700 horsepower, and is often regarded as a cost-effective solution due to the abundance of aftermarket parts. The installation process is typically straightforward, especially with pre-made kits available for various chassis. However, some purists may argue that an LS engine lacks the unique character and performance pedigree of the 2JZ.

Conclusion: How to Choose the Right Engine Solution for Your Needs

Selecting the right engine solution depends on your specific performance goals, budget constraints, and project requirements. The 2JZ motor is an excellent choice for those looking for a reliable, high-performance engine with a rich history in motorsports. However, if cost, ease of installation, or specific tuning capabilities are your priority, exploring alternatives like the RB26DETT or LS swaps may provide better value. B2B buyers should carefully evaluate their needs, consider the total cost of ownership, and seek suppliers that offer comprehensive support to ensure a successful engine integration.

Essential Technical Properties and Trade Terminology for 2jz motor for sale

What Are the Key Technical Properties of the 2JZ Motor for Sale?

When considering the purchase of a 2JZ motor, understanding its technical properties is essential for making informed decisions. Here are several critical specifications that highlight the engine’s performance and compatibility:

-

Engine Code and Configuration

The 2JZ engine series, particularly the 2JZ-GTE, is known for its inline-six configuration. This design contributes to a smoother operation and better balance, making it a popular choice for high-performance applications. For B2B buyers, knowing the engine code helps in identifying the specific variant and its capabilities, ensuring compatibility with the intended vehicle or project. -

Displacement

The 2JZ-GTE has a displacement of 3.0 liters (2,997 cm³). Displacement is a crucial factor in determining an engine’s power output and efficiency. A larger displacement typically allows for more air and fuel intake, which can lead to higher horsepower and torque. Understanding this metric helps buyers assess whether the engine meets the performance requirements for their specific applications. -

Power Output and Torque

The 2JZ-GTE is rated at approximately 276 HP (206 kW) for the JDM variant and up to 320 HP (239 kW) for the North American version. Torque figures vary, with the JDM version producing around 432 Nm (318.8 ft-lb) at 3,600 RPM. These specifications are vital for B2B buyers looking to match engine performance with vehicle capabilities, particularly in racing or high-performance builds. -

Fuel System and Turbocharging

The engine features a multi-point fuel injection system and twin turbochargers (CT20 for JDM and CT12B for North America). Understanding the fuel system and turbocharging setup is essential for buyers focused on performance tuning and efficiency. This knowledge can guide decisions on supporting modifications and upgrades. -

Material Composition

The 2JZ engine block is typically made from cast iron, while the cylinder head is aluminum. These material choices impact the engine’s durability and weight. For B2B buyers, recognizing the materials used can inform decisions related to maintenance, longevity, and overall engine performance under stress. -

Dimensions and Weight

The engine weighs approximately 230 kg (507 lbs). Knowing the dimensions and weight is important for logistics and compatibility with specific vehicles or projects. This information can influence shipping costs and installation considerations, particularly in international transactions.

What Are Common Trade Terms Related to Buying a 2JZ Motor?

Understanding trade terminology is crucial for navigating the purchasing process effectively. Here are several common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts that are made by the manufacturer of the original vehicle. For 2JZ motors, OEM components are often sought for their reliability and compatibility. Buyers should look for OEM specifications to ensure they are receiving parts that meet original performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers looking to procure multiple engines or parts, as it can affect inventory levels and overall costs. -

RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to request price quotes from suppliers. When considering a 2JZ motor, submitting an RFQ can help in obtaining competitive pricing and understanding available options. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms is crucial for B2B transactions involving the import/export of 2JZ motors, as they clarify who is responsible for shipping costs, insurance, and risk during transportation. -

Turnkey Engine Package

This term refers to a complete engine assembly that is ready for installation with minimal setup. Understanding this can help buyers evaluate the ease of installation and readiness for immediate use, which is particularly appealing for businesses looking to minimize downtime. -

Dyno-Tuning

Dyno-tuning involves testing an engine’s performance on a dynamometer to optimize its settings. For buyers, knowing whether a 2JZ motor has been dyno-tuned can provide confidence in its performance capabilities and potential reliability in high-stress environments.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing a 2JZ motor, ensuring they select the right engine for their needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the 2jz motor for sale Sector

What Are the Current Market Trends Impacting the 2JZ Motor for Sale Sector?

The global market for the 2JZ motor is witnessing notable growth, driven by the increasing popularity of high-performance vehicles and the enduring legacy of the Toyota Supra. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, engage with this sector, several key trends emerge. First, the demand for turnkey engine packages is on the rise. Buyers prefer ready-to-install solutions that minimize downtime and complexity, facilitating smoother integrations into existing vehicle systems. Additionally, there is a shift towards sourcing engines from reputable suppliers that offer comprehensive warranties and customer support, which enhances buyer confidence and satisfaction.

Another emerging trend is the increasing use of digital platforms for sourcing and purchasing engines. Buyers are leveraging online marketplaces and manufacturer websites to compare specifications, prices, and customer reviews, enabling informed decision-making. This digital transformation is coupled with advancements in logistics technology, which streamline shipping processes and reduce lead times, critical factors for international buyers operating in diverse regions.

How Important Is Sustainability and Ethical Sourcing in the 2JZ Motor for Sale Sector?

The significance of sustainability and ethical sourcing in the automotive parts industry, including the 2JZ motor sector, cannot be overstated. As global awareness of environmental issues rises, buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes sourcing materials responsibly and minimizing waste throughout the production process. For B2B buyers, partnering with manufacturers that demonstrate a commitment to sustainability can enhance their brand reputation and appeal to environmentally conscious consumers.

Moreover, ethical supply chains are becoming a focal point for procurement strategies. Buyers are encouraged to inquire about the origins of engine components and the labor practices involved in their manufacturing. Certifications such as ISO 14001 for environmental management and adherence to fair labor practices can serve as indicators of a supplier’s commitment to ethical standards. By prioritizing sustainability and ethical sourcing, B2B buyers can align their operations with global sustainability goals, potentially opening doors to new markets and customer segments.

What Is the Historical Context of the 2JZ Engine’s Popularity?

The 2JZ engine, particularly the 2JZ-GTE variant, gained prominence in the 1990s as the powerhouse behind the legendary Toyota Supra MKIV. Initially designed for the Japanese Grand Touring Car Championship, this inline-six engine quickly became a favorite among automotive enthusiasts due to its robust performance capabilities and tunability. With a factory rating of around 276 horsepower, it has been proven to handle significantly higher power levels with relatively simple modifications, making it a popular choice for both street and race applications.

Over the years, the 2JZ engine’s reputation has been solidified through its appearances in motorsport and popular culture, notably in the “Fast and Furious” franchise. This cultural impact has further fueled demand in the aftermarket sector, leading to a thriving market for both new and used 2JZ motors. As a result, international B2B buyers are now drawn to this engine not only for its performance but also for its storied history and the community of enthusiasts that surrounds it. Understanding this evolution is crucial for buyers looking to navigate the current market landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of 2jz motor for sale

-

How do I ensure the quality of a 2JZ motor before purchasing?

To ensure the quality of a 2JZ motor, request detailed specifications and documentation from the supplier, including engine history, maintenance records, and performance testing results. Look for suppliers that offer warranties or guarantees on their engines, as this indicates confidence in their products. Additionally, consider asking for customer reviews or testimonials to gauge other buyers’ experiences. If possible, request a video demonstration of the engine running to verify its condition. -

What is the typical lead time for international orders of 2JZ motors?

Lead times for international orders of 2JZ motors can vary based on the supplier, shipping method, and destination. Generally, you can expect a lead time of 2 to 6 weeks, including processing, packaging, and shipping. To minimize delays, confirm stock availability with the supplier and discuss expedited shipping options if your project timeline is tight. Always factor in customs clearance time for your specific country when planning. -

What payment terms should I expect when buying a 2JZ motor internationally?

Payment terms can differ significantly among suppliers. Many will require a deposit upfront, typically ranging from 20% to 50% of the total cost, with the balance due before shipment. Some suppliers may offer credit terms or financing options, particularly for larger orders. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card, PayPal) and any additional fees that may apply to international transactions. -

Are there customization options available for the 2JZ motor?

Yes, many suppliers offer customization options for the 2JZ motor, including modifications for performance enhancements or compatibility with specific vehicle models. Customizations can range from tuning the engine for higher horsepower to installing specialized parts such as different turbochargers or exhaust systems. Discuss your specific requirements with the supplier, and ensure they provide a clear outline of additional costs and lead times associated with any custom modifications. -

What are the minimum order quantities (MOQs) for 2JZ motors?

Minimum order quantities (MOQs) can vary widely based on the supplier and your specific needs. Some suppliers may allow single unit purchases, while others might have an MOQ of 2-5 engines, particularly for bulk pricing discounts. When sourcing, it’s advisable to confirm MOQs early in discussions to align your purchasing strategy with your business needs and budget. -

How can I vet suppliers when sourcing a 2JZ motor?

To vet suppliers effectively, research their reputation through online reviews, ratings, and feedback from previous customers. Verify their business credentials, including registration and compliance with local laws. Request references and consider visiting their facility if feasible. Engaging in direct communication to assess their customer service and responsiveness can also provide insights into their reliability as a partner. -

What logistics considerations should I be aware of when importing a 2JZ motor?

When importing a 2JZ motor, consider the logistics involved, including shipping methods (air vs. sea freight), insurance, and customs regulations. Ensure that the supplier provides proper documentation for customs clearance, such as invoices, packing lists, and certificates of origin. Familiarize yourself with import duties and taxes applicable in your country, and factor these costs into your overall budget for the purchase. -

What are the common challenges faced when sourcing 2JZ motors internationally?

Common challenges when sourcing 2JZ motors internationally include language barriers, differing quality standards, and potential delays in shipping. Additionally, customs regulations can vary significantly between countries, which may complicate the import process. To mitigate these issues, maintain clear communication with suppliers, ensure thorough documentation, and consider partnering with a logistics provider experienced in international automotive parts to streamline the process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 2Jz Motor For Sale Manufacturers & Suppliers List

1. Brangers Racing – Turnkey 2JZ Engine Packages

Domain: brangersracing.com

Registered: 2008 (17 years)

Introduction: 2JZ Engine for Sale – True Dyno Tuned Turnkey 2JZ Engine Packages. Easy installation: hook up 3 wires and go. 1000 HP 2JZ Turn-Key Engine Package and 2500 HP 2JZ BRE Compound Turbo available. Warranties provided on all products (racing parts excluded). Over 50 years of combined auto and machining experience. Designed for sanctioned off-road/competition non-emissions controlled vehicles only.

2. Toyota – 2JZ Engine Collection

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 2JZ Engine, JDM 2JZ-GE TOYOTA ARISTO GS300 VVTI ENGINE 3.0L 6 CYL MOTOR WITH 5 SPEED GEARBOX, Pre-Owned, $4,249.00, Free delivery, Located in Dallas, TX; 2JZ-GTE TWIN TURBO VVTi JDM ENGINE 2JZ 3.0L MOTOR AUTO TRANS, WIRING, ECU, Pre-Owned, $6,345.00, Free delivery, Located in Chantilly, VA; Toyota 2JZGTE Engine 3.0L DOHC Twin Turbo JDM 2jz Motor Auto Trans Aristo/ Supra, Pre-Owned, $8,500.00, Free…

3. JDM – Toyota 2JZ GTE VVTI

Domain: nwjdmmotors.com

Registered: 2022 (3 years)

Introduction: Product: JDM Toyota 2JZ GTE VVTI

Price: $3,350.00

Rating: 4.93 out of 5 based on 122 customer ratings

Mileage: 51,123 miles

Engine Code: 2JZ-GTE

Engine Layout: Inline-6 (Straight-6)

Fuel Type: Gasoline

Displacement: 3.0 L (2,997 cm³)

Fuel System: Multi-point fuel injection

Power Adders: Twin-turbochargers (CT20 for Japan market, CT12B for North America and Europe)

Max Horsepower: JDM: 280 PS (276 …

4. JDM Engine Depot – 2JZGTE Engine for Sale

Domain: jdmenginedepotinc.com

Registered: 2017 (8 years)

Introduction: 2JZGTE Engine for Sale – Price: $17,799.00 (originally $17,999.00). Includes Toyota Supra Twin Turbo VVTI Engine, 6SPD Transmission, Loom, ECU. JDM 2JZGTE engine is preferred for its availability, cost-effectiveness, performance, reliability, and enhanced design. Designed for longevity with features like under-piston oil squirters and a durable cooling system capable of handling over 1,000 hp. JDM…

5. 2JZ Engine – Key Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2JZ engine options: 2JZ-GE (non-turbo) and 2JZ-GTE (turbo). Common vehicles with 2JZ-GE include Lexus IS300, GS300, and SC300. The 2JZ-GTE is primarily found in the Toyota Supra turbo and some other models not offered in the US. Recommendations for purchasing include looking for places that import half-cuts, searching online for crates, or checking local car groups. Prices for 2JZ engines can vary…

6. High-Performance Car Enthusiasts – Engine Swaps

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, High-Performance Car Enthusiasts – Engine Swaps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

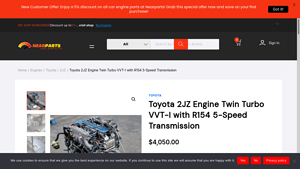

7. Toyota – 2JZ Engine Twin Turbo VVT-I with R154 Transmission

Domain: nearautosparts.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “Toyota 2JZ Engine Twin Turbo VVT-I with R154 5-Speed Transmission”, “Price”: “$4,050.00”, “Condition”: “Tested/driven and ready for a second use”, “Mileage”: “Low Mileage”, “Engine Code”: “2JZ VVT-i”, “Cylinder Arrangement”: “6”, “Gearbox”: “R154 Transmission Manual”, “Displacement”: “2,997 cc”, “Valvetrain”: “DOHC”, “Bore x Stroke”: “86mm x 86mm”, “Fuel System”: “Direct Injectio…

Strategic Sourcing Conclusion and Outlook for 2jz motor for sale

As the demand for high-performance engines continues to rise globally, particularly for the iconic 2JZ motor, B2B buyers must focus on strategic sourcing to ensure they acquire the best products at competitive prices. Key takeaways from this guide emphasize the importance of sourcing from reputable suppliers who offer turnkey solutions, comprehensive warranties, and proven performance. Buyers should consider factors such as engine specifications, compatibility with existing systems, and the supplier’s track record in customer satisfaction.

Strategic sourcing not only enhances supply chain efficiency but also mitigates risks associated with engine performance and compliance with regional regulations. Engaging with suppliers who have a solid understanding of local markets—especially in regions like Africa, South America, the Middle East, and Europe—can lead to better procurement decisions and long-term partnerships.

Looking ahead, international B2B buyers are encouraged to leverage the insights gained from this guide to make informed purchasing decisions. By focusing on quality, reliability, and supplier expertise, businesses can position themselves for success in the competitive automotive landscape. Start connecting with trusted suppliers today to ensure your operations are equipped with the best 2JZ motors available on the market.