Choosing Your 2017 Jeep Renegade Altitude R Side Fenders Replacement: Key Specs to…

Introduction: Navigating the Global Market for 2017 jeep renegade altitude r side fenders replacement

In the dynamic landscape of automotive parts procurement, sourcing reliable replacement fenders for the 2017 Jeep Renegade Altitude R can pose significant challenges for international B2B buyers. With the vehicle’s unique design and specific fitment requirements, ensuring the quality and compatibility of replacement parts is paramount. This comprehensive guide delves into the intricacies of the global market for fender replacements, providing valuable insights into various types, applications, and the critical process of supplier vetting.

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—will find this guide indispensable. It empowers decision-makers with essential information on cost considerations, material quality, and lead times, facilitating informed purchasing decisions. The guide also highlights how to identify reputable suppliers, ensuring that businesses can secure high-quality fenders that meet OEM specifications.

By navigating through the complexities of sourcing fenders for the 2017 Jeep Renegade Altitude R, this resource aims to streamline the procurement process, enhance operational efficiency, and ultimately support the success of B2B buyers in a competitive automotive parts market. With a focus on actionable insights and practical advice, this guide equips businesses with the tools necessary to make strategic purchasing choices that align with their operational needs and market demands.

Understanding 2017 jeep renegade altitude r side fenders replacement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Replacement Fenders | Manufactured to original specifications | Auto repair shops, dealerships | Pros: Perfect fit, high durability. Cons: Higher cost compared to aftermarket. |

| Aftermarket Fiberglass Fenders | Lightweight, customizable designs | Custom shops, performance enhancement | Pros: Weight reduction, aesthetic options. Cons: May require additional modifications. |

| Aftermarket Steel Fenders | Increased durability and off-road capability | Off-road vehicle modifications | Pros: Enhanced strength, better protection. Cons: Heavier than OEM, may affect fuel efficiency. |

| Fenders with Integrated Flare | Built-in flare for tire coverage and styling | Customization shops, body shops | Pros: Improved aesthetics, better tire coverage. Cons: Limited color options, installation complexity. |

| Reconditioned OEM Fenders | Used fenders restored to OEM quality | Budget-conscious repair facilities | Pros: Cost-effective, environmentally friendly. Cons: Potential for wear, limited availability. |

What Are the Key Characteristics of OEM Replacement Fenders for the 2017 Jeep Renegade Altitude R?

OEM replacement fenders are designed to meet the original equipment manufacturer’s specifications, ensuring a seamless fit and finish. These fenders are ideal for auto repair shops and dealerships that prioritize quality and reliability. When purchasing OEM parts, B2B buyers should consider the warranty offered, as it reflects the manufacturer’s confidence in the product’s durability. While they tend to be more expensive, the longevity and compatibility often justify the investment, particularly for businesses focused on customer satisfaction.

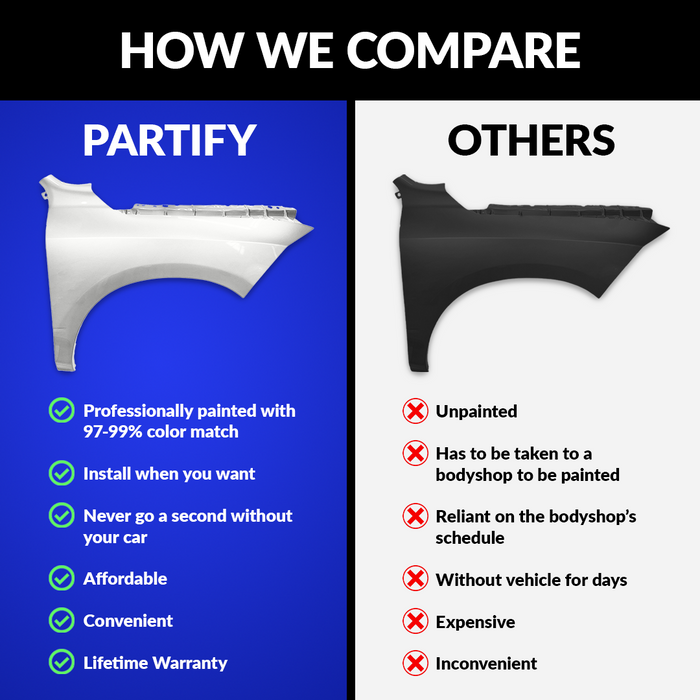

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

How Do Aftermarket Fiberglass Fenders Differ from Other Options?

Aftermarket fiberglass fenders provide a lightweight alternative that can be customized for aesthetic appeal. They are popular among customization shops and performance enhancement specialists looking to reduce vehicle weight for improved handling. Buyers should consider the potential need for additional modifications during installation, which can increase labor costs. While these fenders offer unique styling options, their durability may not match that of OEM or steel counterparts, making them a suitable choice for those prioritizing appearance over ruggedness.

What Advantages Do Aftermarket Steel Fenders Offer for Off-Road Applications?

Aftermarket steel fenders are built for durability and are particularly beneficial for off-road applications. They provide enhanced protection against debris and impacts, making them a preferred choice for off-road vehicle modifications. B2B buyers in the off-road sector should evaluate the fenders’ weight, as heavier options may affect vehicle performance and fuel efficiency. However, the investment in steel fenders is often justified by their resilience and ability to withstand harsh conditions, appealing to businesses focused on rugged vehicle performance.

Why Consider Fenders with Integrated Flare for Customization Projects?

Fenders with integrated flares are designed to enhance the vehicle’s aesthetics while providing better tire coverage. This type of fender is commonly sought after by customization and body shops aiming to offer a unique look for their clients. Buyers should be aware of the installation complexity, as these fenders may require precise fitting and additional hardware. While they enhance visual appeal and functionality, the limited color options might restrict some customization opportunities, necessitating careful consideration by B2B buyers.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

What Are the Benefits of Choosing Reconditioned OEM Fenders?

Reconditioned OEM fenders present a cost-effective solution for budget-conscious repair facilities. These used parts are restored to meet OEM quality standards, offering a sustainable choice for businesses looking to minimize waste. Buyers should assess the condition and warranty of reconditioned parts, as the potential for wear may affect performance. While availability can be limited, the environmental benefits and lower price point make reconditioned fenders an attractive option for many B2B buyers seeking to balance cost and quality.

Key Industrial Applications of 2017 jeep renegade altitude r side fenders replacement

| Industry/Sector | Specific Application of 2017 Jeep Renegade Altitude R Side Fenders Replacement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair & Services | Replacement for damaged fenders due to accidents or wear and tear | Enhances vehicle aesthetics and safety, leading to customer satisfaction | Ensure compatibility with specific Jeep models and OEM standards |

| Automotive Parts Retail | Selling replacement parts to consumers and garages | Generates revenue through part sales and fosters customer loyalty | Consider inventory management and shipping logistics |

| Fleet Management | Maintaining company-owned Jeep Renegades for transportation services | Reduces downtime and repair costs, ensuring operational efficiency | Look for bulk purchasing options and warranty terms |

| Off-road Vehicle Customization | Upgrading fenders for improved performance and aesthetics | Attracts off-road enthusiasts, enhancing brand reputation | Assess material quality and customization options |

| Insurance & Claims Management | Providing replacement parts for vehicles involved in insurance claims | Streamlines claims processing and repair timelines | Verify part authenticity and compliance with insurance standards |

How Do Automotive Repair & Services Benefit from 2017 Jeep Renegade Altitude R Side Fenders Replacement?

In the automotive repair sector, the replacement of side fenders for the 2017 Jeep Renegade Altitude R is crucial for restoring vehicles after accidents or wear and tear. These fenders not only improve the vehicle’s aesthetics but also play a vital role in safety by protecting internal components from debris and damage. Repair shops need to ensure that they source high-quality, OEM-compatible parts to maintain customer trust and satisfaction. International buyers, particularly from regions with varying vehicle regulations, must also consider compliance with local standards.

What Role Does Automotive Parts Retail Play in the Replacement Market?

Automotive parts retailers can capitalize on the demand for replacement fenders by stocking parts compatible with the 2017 Jeep Renegade. By offering these parts, retailers can cater to DIY enthusiasts and professional garages alike, creating a diverse customer base. The ability to provide expedited shipping options is vital, especially for international buyers from Africa and South America, where delivery times can significantly impact customer satisfaction. Retailers should also focus on inventory management to avoid stockouts and ensure a steady supply of popular parts.

How Can Fleet Management Benefit from Efficient Fender Replacement?

For fleet management companies that operate a fleet of Jeep Renegades, timely replacement of damaged side fenders is essential for maintaining operational efficiency. Keeping vehicles in top condition minimizes downtime, which can lead to increased productivity and reduced repair costs. Fleet managers should consider bulk purchasing agreements to secure favorable pricing and ensure a consistent supply of parts. Additionally, they must assess warranty terms to protect their investment in replacement components.

What Are the Advantages of Off-road Vehicle Customization?

Off-road vehicle customization is a growing niche where enthusiasts seek to enhance their Jeep Renegades for performance and aesthetics. Upgrading to aftermarket fenders can improve tire clearance and overall vehicle capability, appealing to a dedicated customer base. Businesses in this sector should prioritize high-quality materials that withstand harsh conditions and provide customization options to attract more customers. Understanding the preferences of international buyers from regions with diverse terrains can also help tailor offerings effectively.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

How Does Insurance & Claims Management Utilize Replacement Parts?

In the insurance sector, providing replacement parts like the 2017 Jeep Renegade Altitude R side fenders is integral to managing claims efficiently. Quick access to quality parts can expedite the repair process, leading to faster claim resolutions and higher customer satisfaction. Insurance companies must ensure that the parts meet authenticity and compliance standards to avoid complications during the claims process. Working with reliable suppliers who understand the intricacies of international shipping and regulations can streamline operations significantly.

3 Common User Pain Points for ‘2017 jeep renegade altitude r side fenders replacement’ & Their Solutions

Scenario 1: Sourcing Quality Replacement Fenders in Diverse Markets

The Problem: B2B buyers often face challenges when sourcing high-quality replacement fenders for the 2017 Jeep Renegade Altitude R. This issue is exacerbated in international markets, where availability, shipping logistics, and local regulations can complicate the procurement process. Buyers may struggle to find OEM (Original Equipment Manufacturer) parts that meet the required specifications for durability and fit, risking their reputation and customer satisfaction if they opt for lower-quality alternatives.

The Solution: To navigate this complexity, buyers should establish relationships with reputable suppliers who specialize in OEM parts for international markets. Utilize platforms that focus on B2B automotive parts, ensuring that suppliers provide detailed product specifications, including fitment data and material quality. Implement a systematic approach to vet suppliers by checking for certifications, customer reviews, and warranty policies. Additionally, consider leveraging local distributors in key regions to streamline shipping and reduce lead times, thus ensuring that parts arrive promptly and meet local compliance standards. By prioritizing quality over cost, businesses can enhance their service offerings and maintain a competitive edge.

Scenario 2: Installation Challenges and Technical Support

The Problem: Even with the right fender, installation can pose significant challenges for mechanics and automotive shops. The 2017 Jeep Renegade Altitude R’s fender replacement requires specific tools and techniques to ensure a proper fit and finish. Mechanics may find themselves encountering difficulties with the fender flare clips or aligning the fender with existing body panels, leading to increased labor costs and potential rework.

The Solution: To mitigate installation issues, B2B buyers should invest in comprehensive technical support from suppliers. This includes obtaining detailed installation guides, instructional videos, and access to technical support teams who can provide real-time assistance. Additionally, conducting training sessions for staff on best practices for fender installation can significantly reduce errors. Encourage shops to familiarize themselves with the vehicle’s body structure and common pitfalls through hands-on workshops. By prioritizing training and access to resources, businesses can enhance operational efficiency, reduce turnaround times, and improve customer satisfaction.

Scenario 3: Managing Inventory and Reducing Downtime

The Problem: Many automotive businesses struggle with maintaining adequate inventory levels for replacement parts like the 2017 Jeep Renegade Altitude R fenders. Excessive downtime due to out-of-stock parts can lead to lost sales and dissatisfied customers. This issue is particularly pressing for businesses operating in regions with fluctuating demand, where predicting inventory needs becomes a complex task.

The Solution: Implementing an effective inventory management system can help businesses anticipate demand for fenders and other parts. Utilize data analytics tools to track sales trends and seasonal fluctuations, allowing for more accurate forecasting. Establish a just-in-time inventory strategy to minimize excess stock while ensuring that critical components are readily available when needed. Additionally, consider forming strategic partnerships with suppliers to create a consignment inventory model, where parts are delivered as needed without the upfront investment. This approach not only reduces holding costs but also enhances the ability to respond swiftly to customer needs, thereby increasing overall business agility and profitability.

Strategic Material Selection Guide for 2017 jeep renegade altitude r side fenders replacement

What Materials Are Commonly Used for 2017 Jeep Renegade Altitude R Side Fenders Replacement?

When selecting materials for the replacement of side fenders on the 2017 Jeep Renegade Altitude R, it is essential to consider factors such as durability, cost, and manufacturing complexity. Below, we analyze four common materials used in the automotive industry for this application: steel, aluminum, plastic (polypropylene), and fiberglass.

How Does Steel Perform as a Material for Jeep Renegade Fenders?

Steel is a traditional choice for automotive body parts due to its strength and durability. It typically offers excellent impact resistance and can withstand high temperatures and pressures. However, steel is prone to corrosion unless treated with protective coatings, which can add to the cost and complexity of manufacturing.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

Pros and Cons: Steel fenders are generally more durable than their counterparts but are heavier, which can affect vehicle performance and fuel efficiency. The manufacturing process is well-established, making it a cost-effective option for mass production. However, the need for corrosion protection can increase overall costs.

International Considerations: Buyers in regions with high humidity or exposure to saltwater, such as coastal areas in Africa or Brazil, should prioritize corrosion-resistant treatments. Compliance with ASTM standards for steel quality is crucial for ensuring product reliability.

What Are the Benefits of Using Aluminum for Fenders?

Aluminum is gaining popularity in automotive applications due to its lightweight nature and resistance to corrosion. It can be easily formed into complex shapes, making it suitable for modern vehicle designs. Aluminum fenders can also improve fuel efficiency by reducing overall vehicle weight.

Pros and Cons: While aluminum fenders are lightweight and resistant to rust, they can be more expensive than steel. The manufacturing process for aluminum can be more complex, requiring specialized equipment. However, the longevity and performance benefits often justify the higher initial costs.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

International Considerations: Buyers should ensure that aluminum parts meet international standards such as DIN and JIS, particularly in Europe and the Middle East, where quality assurance is paramount.

How Does Plastic (Polypropylene) Compare for Fenders?

Plastic, particularly polypropylene, is commonly used for automotive fenders due to its flexibility and resistance to impact. It is lightweight and can be produced at a lower cost compared to metal options. Plastic fenders can also be molded into various shapes, allowing for unique designs.

Pros and Cons: While plastic fenders are resistant to rust and corrosion, they may not offer the same level of durability as metal options. They can be less effective in high-temperature environments and may require reinforcement for added strength. However, their lower cost and ease of manufacturing make them an attractive option for budget-conscious buyers.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

International Considerations: Buyers should verify that the plastic materials comply with environmental regulations in their region, particularly in Europe, where stringent standards for material safety and recyclability exist.

What Advantages Does Fiberglass Offer for Fenders?

Fiberglass is another material option for fenders, known for its lightweight and high strength-to-weight ratio. It is resistant to corrosion and can be molded into complex shapes, making it suitable for custom designs.

Pros and Cons: Fiberglass fenders are durable and can withstand harsh environmental conditions. However, they can be more expensive and require a more complex manufacturing process. Additionally, fiberglass can be brittle, making it prone to cracking under impact.

International Considerations: Buyers should ensure that fiberglass products meet the relevant safety and quality standards in their respective regions, particularly in Europe and the Middle East, where compliance is strictly monitored.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

Summary of Material Selection for 2017 Jeep Renegade Altitude R Side Fenders

| Material | Typical Use Case for 2017 Jeep Renegade Altitude R Side Fenders Replacement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Replacement fenders for durability and strength | High impact resistance | Prone to corrosion | Medium |

| Aluminum | Lightweight fenders for improved fuel efficiency | Corrosion-resistant | Higher manufacturing costs | High |

| Plastic | Cost-effective fenders for mass production | Lightweight and flexible | Less durable than metal options | Low |

| Fiberglass | Custom fenders for unique designs | High strength-to-weight ratio | Brittle and can crack under impact | Medium to High |

This strategic material selection guide provides B2B buyers with actionable insights into the various materials available for the 2017 Jeep Renegade Altitude R side fenders replacement, allowing for informed purchasing decisions that align with regional requirements and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for 2017 jeep renegade altitude r side fenders replacement

What Are the Key Manufacturing Processes for 2017 Jeep Renegade Altitude R Side Fenders?

The manufacturing of replacement fenders for the 2017 Jeep Renegade Altitude R involves several critical stages that ensure the final product meets both performance and aesthetic standards. The typical manufacturing process includes material preparation, forming, assembly, and finishing.

How Is Material Prepared for Fender Manufacturing?

The first stage in the manufacturing process is material preparation. High-quality steel or plastic composites are commonly used due to their durability and resistance to corrosion. Materials are sourced from certified suppliers who adhere to international quality standards. Upon arrival at the manufacturing facility, materials undergo inspection to verify compliance with specifications. This is a crucial step, as any defect at this stage could compromise the entire manufacturing process.

What Techniques Are Used in Forming the Fender?

After material preparation, the forming stage commences. The chosen material is cut into sheets and subjected to processes such as stamping or injection molding. Stamping is prevalent for metal fenders, where large sheets are pressed into shape using high-tonnage presses. For plastic fenders, injection molding techniques are employed, allowing for intricate designs and lightweight structures. Each method requires precision machinery and skilled operators to ensure that the fenders are shaped accurately, meeting OEM specifications for fitment.

How Are Fenders Assembled and Finished?

Once formed, the next step is assembly. This phase may involve the attachment of components such as fender flares or internal supports, which enhance structural integrity. Assembly is often conducted using robotic arms for consistency and efficiency, followed by manual inspections to ensure that all parts fit correctly.

The finishing stage includes surface treatment, painting, and coating. Fenders are often subjected to processes such as priming and painting to achieve a high-quality finish that matches the vehicle’s original color. This not only improves aesthetics but also provides an additional layer of protection against environmental factors.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

What Quality Assurance Measures Are Implemented in Fender Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each fender meets international and industry-specific standards. Manufacturers typically adhere to ISO 9001, which outlines the requirements for a quality management system (QMS). This standard focuses on consistent quality and customer satisfaction, making it essential for B2B buyers who prioritize reliability in their supply chain.

What Are the Relevant International Standards for Fender Quality Assurance?

In addition to ISO 9001, specific certifications such as CE marking may be required for compliance in European markets, while other regions might have their own standards. For instance, in countries like Brazil, compliance with local automotive regulations is crucial. Understanding these standards helps B2B buyers gauge the credibility of suppliers.

How Are QC Checkpoints Integrated Throughout the Manufacturing Process?

Quality Control (QC) checkpoints are established at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection verifies that incoming materials meet required specifications.

- In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to ensure that the production process adheres to defined parameters.

- Final Quality Control (FQC): After assembly, a thorough inspection is performed to confirm that the fenders meet all quality and performance standards before shipping.

Common testing methods include dimensional checks, visual inspections, and functional tests to assess durability and resistance to impact.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is crucial to ensuring product quality. Here are some methods to achieve this:

-

Supplier Audits: Conducting regular audits of suppliers helps assess their compliance with quality standards. These audits can focus on manufacturing processes, employee training, and adherence to safety regulations.

-

Quality Reports: Requesting detailed quality reports, including test results and QC metrics, allows buyers to evaluate a supplier’s performance over time.

-

Third-Party Inspections: Engaging third-party inspection services offers an unbiased assessment of the manufacturing process, ensuring that products meet specified quality standards before shipment.

-

Certification Verification: Buyers should verify that suppliers possess relevant certifications, which can be confirmed through official documentation.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from different regions may encounter unique challenges related to quality control. For instance, varying regulations and standards across countries can complicate compliance. Buyers should be aware of local automotive regulations and ensure that their suppliers are compliant with both local and international standards.

Additionally, language barriers and cultural differences can affect communication regarding quality expectations. Establishing clear specifications and maintaining open lines of communication can mitigate these issues.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for the 2017 Jeep Renegade Altitude R side fenders is essential for B2B buyers. By focusing on quality control practices and compliance with international standards, buyers can ensure that they receive durable, high-quality replacement parts that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2017 jeep renegade altitude r side fenders replacement’

Introduction

This guide is designed to assist B2B buyers in sourcing replacement side fenders for the 2017 Jeep Renegade Altitude R. Whether you’re a parts distributor, auto body shop, or fleet manager, understanding the procurement process can streamline your operations and ensure you get the best quality parts. Follow this checklist to make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the fenders you need. This includes the model year (2017), compatibility with the Jeep Renegade Altitude R, and any color or finish specifications.

- Key considerations: Ensure that the fenders meet OEM specifications for proper fit and durability. This will prevent potential issues during installation and maintain vehicle integrity.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in automotive parts, particularly those with experience in Jeep components.

- What to look for: Focus on suppliers with a solid reputation, positive customer reviews, and a history of timely delivery. Utilize trade directories and automotive forums to gather insights about potential partners.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your potential suppliers have the necessary certifications.

- Why it matters: Certifications can indicate compliance with industry standards and quality assurance. Look for ISO certifications or equivalent, which can provide peace of mind regarding the quality of the parts.

Step 4: Request Samples or Specifications

Once you’ve narrowed down your options, request samples or detailed specifications of the fenders.

- Importance of this step: This allows you to assess the quality and confirm that the parts match your requirements. Inspect for material quality, fitment accuracy, and finish consistency.

Step 5: Compare Pricing Structures

Obtain quotes from multiple suppliers to compare pricing structures.

- What to consider: Look beyond the base price; consider shipping costs, bulk order discounts, and payment terms. A lower initial price may not always lead to the best overall value if additional fees are incurred later.

Step 6: Assess Logistics and Delivery Options

Review the logistics options available from your chosen suppliers.

- Key factors: Ensure they can accommodate your delivery timelines and have a reliable shipping process. Delays in receiving parts can impact your operations, so prioritize suppliers with proven logistics capabilities.

Step 7: Establish a Long-term Relationship

Once you have successfully sourced your fenders, consider establishing a long-term relationship with your supplier.

- Benefits of a partnership: A reliable supplier can provide consistent quality and may offer better pricing or priority service for future orders. Building a rapport can also facilitate smoother communication and quicker problem resolution.

By following this comprehensive checklist, B2B buyers can ensure they are making informed decisions when sourcing replacement side fenders for the 2017 Jeep Renegade Altitude R, ultimately supporting their business operations effectively.

Comprehensive Cost and Pricing Analysis for 2017 jeep renegade altitude r side fenders replacement Sourcing

What Are the Key Cost Components in Sourcing 2017 Jeep Renegade Altitude R Side Fenders?

When analyzing the cost structure for sourcing replacement side fenders for the 2017 Jeep Renegade Altitude R, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary component of the cost is the raw materials used in manufacturing the fenders. High-quality automotive-grade plastic or steel is typically utilized, with prices varying based on supplier and material specifications. For example, the cost for a driver side fender like the CH1240284 model is around $176.99, reflecting the quality and durability required for automotive parts.

-

Labor: Labor costs can vary significantly depending on the region and the production facility’s operational efficiency. Skilled labor is essential for both manufacturing and quality assurance processes. Manufacturers in regions with higher labor costs may charge more, impacting the final price to international buyers.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and general administrative expenses. Manufacturers often distribute these costs over the volume of parts produced, meaning larger orders can lead to lower per-unit costs.

-

Tooling: Initial tooling costs for producing specific fender designs can be substantial. These costs are amortized over the production run, so larger volume orders can mitigate the impact of these expenses on individual part pricing.

-

Quality Control: Ensuring that fenders meet OEM specifications is critical. Quality control processes can add to the cost but are essential for maintaining product integrity and reducing returns. Certifications related to quality standards can also influence pricing.

-

Logistics: Shipping and handling costs vary based on the origin and destination. International buyers should consider Incoterms, which define responsibilities for shipping, risk, and insurance. For instance, CIF (Cost, Insurance, and Freight) terms might be preferable for buyers seeking to minimize risk during transit.

-

Margin: Finally, suppliers will add a margin to cover their costs and profit. This margin can vary based on market demand, competition, and the supplier’s positioning.

What Factors Influence Pricing for International Buyers of Jeep Renegade Fenders?

Several factors can influence the pricing for international B2B buyers when sourcing side fenders:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for larger orders. Buyers should evaluate their inventory needs to take advantage of bulk pricing.

-

Specifications and Customization: Custom specifications or unique requirements can increase costs. Standard parts are typically less expensive than customized options.

-

Material Quality and Certifications: Higher quality materials and certifications may raise the initial cost but can lead to reduced maintenance and replacement costs over time, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Establishing long-term relationships with trustworthy suppliers may lead to better pricing and service.

How Can Buyers Negotiate and Optimize Costs?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield significant savings:

-

Research and Benchmarking: Understand market prices and competitor offerings to negotiate better terms. Having data on hand can strengthen your negotiating position.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with parts, including installation, maintenance, and potential downtime. Presenting this analysis to suppliers can justify requests for lower prices or better terms.

-

Flexible Payment Terms: Negotiating payment terms can enhance cash flow. Suppliers may offer discounts for upfront payments or longer payment terms for large orders.

-

Consider Alternate Suppliers: Don’t hesitate to explore multiple suppliers and compare offers. This competition can lead to better pricing and terms.

Conclusion

In summary, understanding the comprehensive cost structure and pricing influencers for sourcing replacement side fenders for the 2017 Jeep Renegade Altitude R is crucial for B2B buyers. By considering the various cost components, negotiating effectively, and leveraging volume purchases, international buyers can optimize their sourcing strategy and improve their bottom line. Always remember to assess the Total Cost of Ownership to ensure long-term value from your purchases.

Alternatives Analysis: Comparing 2017 jeep renegade altitude r side fenders replacement With Other Solutions

The automotive market is increasingly diverse, and when it comes to replacement parts for vehicles like the 2017 Jeep Renegade Altitude R, buyers often seek alternatives that can meet their specific needs. This section explores viable options for replacing side fenders, comparing the direct replacement parts with alternative solutions. Understanding these options is crucial for B2B buyers, especially in regions where supply chains may vary.

| Comparison Aspect | 2017 Jeep Renegade Altitude R Side Fenders Replacement | Aftermarket Fender Replacement | DIY Fender Repair Kits |

|---|---|---|---|

| Performance | High durability, OEM specifications | Varies by manufacturer | Depends on skill and materials |

| Cost | Approximately $176.99 | $100-$150 | $50-$100 |

| Ease of Implementation | Requires professional installation recommended | Moderate, may require some adjustments | High, suitable for DIY enthusiasts |

| Maintenance | Minimal, designed for longevity | Varies, may require periodic checks | Depends on repairs made |

| Best Use Case | Ideal for maintaining vehicle value and aesthetics | Cost-effective for repairs | Suitable for quick fixes or budget constraints |

What Are the Benefits and Drawbacks of Aftermarket Fender Replacement?

Aftermarket fender replacements can offer significant cost savings compared to OEM parts, typically ranging from $100 to $150. However, the quality and fit can vary widely depending on the manufacturer. While some aftermarket options provide a good fit and finish, others may not adhere to the same durability standards as OEM parts, potentially leading to issues over time. B2B buyers should carefully assess the reputation of aftermarket suppliers to ensure they are getting reliable products.

How Do DIY Fender Repair Kits Compare to Professional Replacements?

DIY fender repair kits offer a budget-friendly alternative, usually priced between $50 and $100. These kits typically include materials needed to fix minor damages, such as clips, adhesives, and paints. The main advantage is cost savings and the flexibility to conduct repairs at one’s convenience. However, this option requires a certain level of DIY skill and can be time-consuming. For buyers who prefer quick fixes and have the necessary expertise, these kits can be a practical solution, but they may not restore the vehicle’s aesthetics to the original standard.

How Do Replacement Parts for the 2017 Jeep Renegade Altitude R Maintain Vehicle Value?

Choosing the original replacement fender for the 2017 Jeep Renegade Altitude R is often the best option for those looking to maintain the vehicle’s value and aesthetic integrity. Priced at approximately $176.99, these parts are manufactured to meet OEM specifications, ensuring a perfect fit and finish. While they may represent a higher upfront cost, the durability and reliability of OEM parts can justify the investment for businesses focused on long-term vehicle performance and resale value.

Conclusion: Which Solution Should B2B Buyers Choose?

When selecting a replacement solution for the 2017 Jeep Renegade Altitude R side fenders, B2B buyers must consider their budget, the importance of maintaining vehicle aesthetics, and the level of skill available for repairs. OEM replacements are ideal for those prioritizing quality and longevity, while aftermarket options may suit cost-sensitive buyers willing to compromise on fit and finish. DIY kits serve as a practical solution for minor repairs but require adequate expertise. Ultimately, evaluating these alternatives based on the specific needs of the business will guide buyers to the most appropriate choice.

Essential Technical Properties and Trade Terminology for 2017 jeep renegade altitude r side fenders replacement

What Are the Key Technical Properties for 2017 Jeep Renegade Altitude R Side Fender Replacement?

When considering a replacement for the 2017 Jeep Renegade Altitude R side fender, several technical specifications are critical to ensure compatibility, durability, and performance. Understanding these properties can help B2B buyers make informed decisions.

-

Material Grade

The fender is typically made from high-quality steel or plastic composites, which are essential for durability and resistance to corrosion. A high-grade material ensures the fender can withstand environmental stressors, such as UV rays and moisture, which is particularly important in regions with extreme weather conditions. -

OEM Specifications

Original Equipment Manufacturer (OEM) specifications refer to standards set by the vehicle manufacturer. An OEM fender will match the original part in fit, finish, and functionality. For B2B buyers, sourcing OEM parts guarantees compatibility with the vehicle, minimizing issues during installation and ensuring long-term performance. -

Tolerance Levels

Tolerance levels indicate the acceptable variation in dimensions during manufacturing. For fenders, maintaining tight tolerances is crucial for proper alignment and fitment. A fender with precise tolerances will reduce the risk of gaps or misalignment, enhancing both aesthetics and functionality. -

Finish and Coating

The finish of the fender, whether it’s primed, painted, or unpainted, affects its appearance and protection. A properly finished fender will resist scratches and rust, essential for maintaining the vehicle’s visual appeal and structural integrity over time. Buyers should consider the finish based on their customer base’s preferences and regional environmental factors. -

Weight

The weight of the fender can influence installation and overall vehicle performance. Lighter materials may reduce the vehicle’s overall weight, contributing to better fuel efficiency. B2B buyers should evaluate the trade-off between weight and durability, especially for off-road applications common in regions like Africa and South America. -

Compatibility

Ensuring the fender is compatible with various Jeep Renegade models (2015-2023) is vital. Compatibility information should include details about model variations and any necessary modifications required for installation. This is particularly useful for distributors who cater to a wide range of Jeep owners.

What Are Common Trade Terms in the Automotive Replacement Parts Industry?

Understanding industry jargon is essential for effective communication and negotiations in the B2B sector. Here are key terms relevant to fender replacements:

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

-

OEM (Original Equipment Manufacturer)

Refers to parts produced by the manufacturer of the original vehicle. OEM parts are preferred for their guaranteed fit and quality, making them a critical consideration for buyers looking to maintain vehicle integrity. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps B2B buyers manage inventory and cash flow, particularly when dealing with larger automotive parts. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. It is a vital step in the procurement process, allowing buyers to compare pricing and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

These are a series of international sales terms that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is essential for negotiating shipping costs and determining liability during transport. -

Aftermarket

This term refers to parts not made by the OEM but intended for use in vehicles. Aftermarket parts can offer cost savings and customization options, appealing to buyers in markets with diverse vehicle modification trends. -

Freight Terms

These terms specify how shipping costs are handled, including who pays for transport and at what point ownership transfers. Clarity on freight terms is crucial for B2B transactions to avoid misunderstandings and additional costs.

By understanding these technical properties and trade terminology, B2B buyers can make more informed purchasing decisions when sourcing replacement fenders for the 2017 Jeep Renegade Altitude R.

Navigating Market Dynamics and Sourcing Trends in the 2017 jeep renegade altitude r side fenders replacement Sector

What Are the Current Market Dynamics and Key Trends in the Replacement Sector for 2017 Jeep Renegade Altitude R Side Fenders?

The market for replacement parts, including side fenders for the 2017 Jeep Renegade Altitude R, is influenced by several global drivers, particularly in the B2B sector. The increasing number of vehicles on the road, particularly in emerging markets like Africa and South America, has led to a heightened demand for quality replacement parts. Additionally, the rising trend of vehicle customization and modification is creating opportunities for suppliers to offer unique and high-quality aftermarket components.

Technological advancements in manufacturing, such as the adoption of 3D printing and automation, are streamlining production processes and reducing lead times. B2B buyers are increasingly leveraging digital platforms for sourcing, enabling them to compare prices, assess supplier reliability, and facilitate faster transactions. Furthermore, the trend of online marketplaces is reshaping traditional distribution channels, providing international buyers easier access to parts that were previously hard to source locally.

Illustrative image related to 2017 jeep renegade altitude r side fenders replacement

Region-specific dynamics also play a crucial role. In Europe, particularly Germany, the market is driven by stringent quality standards and preferences for OEM (Original Equipment Manufacturer) parts, while in the Middle East, the demand is often influenced by off-road vehicle enthusiasts who seek durable and aesthetically pleasing replacements. Understanding these regional nuances can help international buyers tailor their sourcing strategies effectively.

How Does Sustainability and Ethical Sourcing Impact the Replacement Parts Industry?

In recent years, sustainability has emerged as a vital consideration for B2B buyers in the automotive replacement parts sector. The environmental impact of manufacturing processes and materials used in parts, such as the side fenders for the 2017 Jeep Renegade, is under scrutiny. Buyers are increasingly seeking suppliers that prioritize eco-friendly practices, from material sourcing to production methods.

Ethical sourcing is also becoming a key differentiator in the market. Buyers are more inclined to partner with manufacturers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade standards are becoming essential criteria for evaluation.

Moreover, the use of recycled materials in the production of replacement parts can significantly reduce environmental footprints. Companies that incorporate ‘green’ materials not only contribute to sustainability but also appeal to a growing base of environmentally-conscious consumers and businesses. By aligning with suppliers that prioritize sustainability, B2B buyers can enhance their brand reputation while meeting regulatory requirements and customer expectations.

What is the Brief Evolution of the Replacement Parts Market?

The evolution of the replacement parts market for vehicles like the 2017 Jeep Renegade has been marked by significant transformations over the past few decades. Initially dominated by OEM parts, the market has seen a gradual shift towards aftermarket solutions, driven by the need for cost-effective alternatives and consumer preferences for customization.

The rise of the internet revolutionized how parts are sourced and sold, enabling businesses to reach a broader audience without geographical constraints. E-commerce platforms have facilitated the growth of niche suppliers who can cater to specific vehicle models and customization trends. Additionally, the increasing complexity of vehicle technologies has led to more specialized replacement parts, requiring suppliers to invest in knowledge and expertise to meet evolving consumer demands.

As the market continues to mature, the focus is shifting towards providing not only functional parts but also enhancing the overall vehicle experience through quality, design, and sustainability. Understanding this evolution is crucial for B2B buyers as they navigate the competitive landscape of the automotive replacement parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 2017 jeep renegade altitude r side fenders replacement

-

How do I solve issues with fender fitment for the 2017 Jeep Renegade Altitude R?

To address fitment issues with the fenders, ensure that you are sourcing parts with the correct OEM specifications, specifically part number CH1240284 for the driver side fender. It’s advisable to verify compatibility with your vehicle’s make and model before purchasing. If problems persist, consider consulting with a professional mechanic or body shop, as they can provide insights on installation techniques and any necessary adjustments. -

What are the best suppliers for replacement fenders for the 2017 Jeep Renegade?

Look for suppliers with a strong reputation in the automotive parts industry, particularly those specializing in Jeep components. Check for certifications and customer reviews to gauge reliability. Suppliers that offer warranties on their parts and have a transparent return policy can also add value. It’s beneficial to engage with manufacturers or distributors that have experience in international shipping, particularly to your region. -

What customization options are available for the 2017 Jeep Renegade fenders?

Many suppliers offer customization options such as color matching, additional protective coatings, or modifications for wider tires. When sourcing, inquire specifically about available finishes and materials. Customization may involve additional lead time and costs, so it’s essential to communicate your requirements upfront to ensure that your needs are met without delays. -

What is the minimum order quantity (MOQ) for fender replacements?

MOQs can vary significantly between suppliers, typically ranging from one unit to bulk orders depending on the manufacturer. For B2B transactions, negotiating MOQs is often possible, especially if you plan to establish a long-term purchasing relationship. Always confirm the MOQ prior to placing an order to avoid unexpected costs or delays. -

What payment terms should I expect when sourcing fenders internationally?

Payment terms can vary widely by supplier and region. Common arrangements include upfront payment, net 30, or 50% deposit with the balance upon delivery. It’s critical to clarify terms before finalizing any agreements. Consider using secure payment methods that offer buyer protection, especially for significant transactions, and be aware of any currency exchange implications. -

How can I ensure quality assurance (QA) for the fender replacements?

To ensure quality, ask potential suppliers about their QA processes, including material sourcing, testing methods, and compliance with automotive standards. Request samples if possible, and consider third-party inspections for bulk orders. Establishing clear communication about your quality expectations can help mitigate risks related to subpar parts. -

What logistics considerations should I keep in mind when ordering fenders from abroad?

International shipping can introduce complexities such as customs duties, tariffs, and shipping times. Ensure that your supplier has experience with international logistics and can provide accurate shipping estimates. It’s also wise to consider the total landed cost, including shipping and customs fees, to avoid budget overruns. -

What should I do if I encounter shipping delays or damaged parts?

In the event of shipping delays or damage, promptly contact your supplier to report the issue. Most reputable suppliers will have policies in place for handling such situations, including replacements or refunds. Documentation, such as photographs of any damage and shipping records, can be crucial for resolving disputes efficiently. Always review the supplier’s return and damage policies before completing your purchase.

Top 5 2017 Jeep Renegade Altitude R Side Fenders Replacement Manufacturers & Suppliers List

1. Jeep – Right Side Fender for Renegade 2015-2023

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_title”:”Right Side Fender Fit 2015 2016 2017 2018-2023 Jeep Renegade Front Passenger”,”price”:”US $147.00 or Best Offer”,”condition”:”New”,”shipping”:”Free 2-4 day delivery”,”returns”:”30 days returns, seller pays for return shipping”,”location”:”Brooklyn, New York, United States”,”compatibility”:”Compatible with 102 vehicle(s) including 2015-2023 Jeep Renegade models with 1.3L and 2.4L eng…

2. Partify USA – Jeep Renegade Driver Side Fender

Domain: partifyusa.com

Registered: 2024 (1 years)

Introduction: {“product_name”: “Jeep Renegade Driver Side Fender”, “part_number”: “CH1240284”, “compatible_models”: “JEEP RENEGADE 2015-2023”, “price”: “$176.99”, “quality_options”: [{“type”: “Aftermarket”, “price”: “$176.99”, “description”: “Budget-friendly alternative for vehicle repairs, dependable fit and functionality.”}, {“type”: “CAPA”, “price”: “$303.99”, “description”: “Meets or exceeds OEM standards, …

3. Jeep – Renegade Rear Fender Trim

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2017 Jeep Renegade rear plastic fender trim; installation involves clips; replacement part requires trim removal tool; installation is a simple process; may need additional clips if broken during removal.

4. QLaboratory – Flares Replacement for Jeep 2015-2017

Domain: qlaboratory.com

Registered: 2009 (16 years)

Introduction: Flares Replacement for 2015-2017 Jeep; designed for durability and style; easy installation; enhances vehicle appearance; made from high-quality materials; fits specific Jeep models.

5. Mopar – Jeep Renegade Fender Panel (Right)

Domain: parts.moparonlineparts.com

Registered: 2007 (18 years)

Introduction: {‘name’: ‘Jeep Renegade Fender Panel (Right)’, ‘part_number’: ‘68307086AA’, ‘manufacturer’: ‘Mopar’, ‘condition’: ‘New’, ‘description’: ‘Genuine OEM Mopar Fender Panel for 2017-2023 Jeep Renegade.’, ‘warranty’: ‘Minimum of 12 Months’, ‘price’: {‘msrp’: ‘$418.00’, ‘discount’: ‘$113.00’, ‘sale_price’: ‘$305.00’}, ‘engine_options’: [‘1.4l i4 multiair turbo engine’, ‘2.4l i4 multiair engine’, ‘2.4l i4…

Strategic Sourcing Conclusion and Outlook for 2017 jeep renegade altitude r side fenders replacement

In conclusion, the strategic sourcing of replacement fenders for the 2017 Jeep Renegade Altitude R presents a significant opportunity for international B2B buyers. By focusing on high-quality parts such as the Jeep Renegade Driver Side Fender (part number CH1240284), businesses can ensure both durability and compliance with OEM specifications. This alignment not only enhances customer satisfaction but also builds trust in a competitive market.

Moreover, understanding the nuances of fender installation—such as the importance of clips and screws—can empower buyers to offer value-added services, including DIY support and installation guidance. This approach can differentiate suppliers in diverse markets across Africa, South America, the Middle East, and Europe, where vehicle maintenance practices vary.

Looking ahead, businesses should embrace a proactive sourcing strategy that prioritizes quality, efficient logistics, and responsive customer service. By doing so, they can tap into the growing demand for reliable auto parts while fostering long-term relationships with their clients. Engage with us today to explore tailored solutions that meet your specific needs in the ever-evolving automotive parts landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.