Choosing Your 16 Fat Tires Inner Tube: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 16 fat tires inner tube

In the rapidly evolving landscape of the global market, sourcing reliable 16 fat tire inner tubes presents a significant challenge for B2B buyers. With the rise in demand for electric bikes, scooters, and other fat-tire vehicles, the need for durable and high-quality inner tubes is more pressing than ever. This comprehensive guide delves into the various types of 16 fat tire inner tubes available, their diverse applications, and critical considerations for supplier vetting. By exploring cost factors, material specifications, and performance ratings, this resource equips international buyers—particularly those in regions like Africa, South America, the Middle East, and Europe (including countries such as Saudi Arabia and Brazil)—with the knowledge necessary to make informed purchasing decisions.

Navigating the complexities of sourcing inner tubes can be daunting, especially when considering the wide array of options and potential suppliers. This guide not only highlights the key attributes to look for in a quality inner tube but also offers actionable insights into establishing trustworthy supplier relationships. With a focus on empowering buyers to identify the best products for their specific needs, this resource serves as a vital tool for businesses aiming to enhance their product offerings while ensuring customer satisfaction. By leveraging the information provided, B2B buyers can confidently navigate the global market for 16 fat tire inner tubes, optimizing both their supply chain and their bottom line.

Understanding 16 fat tires inner tube Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Butyl Tube | Made from butyl rubber, durable, and cost-effective | General cycling, e-bikes | Pros: Affordable, widely available. Cons: Heavier than alternatives. |

| Thorn Resistant Tube | Enhanced wall thickness for puncture protection | Off-road cycling, rugged terrains | Pros: Increased durability, reduces maintenance. Cons: Slightly higher cost. |

| Lightweight Tubes | Made from advanced materials for reduced weight | Competitive cycling, racing | Pros: Enhances performance, easy to carry. Cons: More expensive, may sacrifice durability. |

| Schrader Valve Tube | Features a standard Schrader valve for easy inflation | General use, e-bikes, scooters | Pros: Universally compatible with pumps. Cons: Slightly bulkier than Presta valves. |

| Presta Valve Tube | Fitted with a Presta valve for high-pressure applications | Road cycling, high-performance bikes | Pros: Lightweight, better for high-pressure tires. Cons: Requires specific pumps. |

What are the characteristics of Standard Butyl Tubes for 16 Fat Tires?

Standard butyl tubes are the most commonly used inner tubes for 16 fat tires, primarily due to their affordability and availability. Made from a synthetic rubber compound, these tubes are known for their durability and ability to retain air pressure effectively. They are suitable for various applications, including general cycling and e-bikes, making them a versatile choice for B2B buyers. However, their weight can be a concern for performance-oriented customers.

Why choose Thorn Resistant Tubes for off-road cycling?

Thorn resistant tubes are designed with added wall thickness to prevent punctures, making them ideal for off-road cycling and rugged terrains. These tubes are particularly valuable for businesses in regions with challenging road conditions, as they reduce maintenance costs associated with frequent punctures. While they come at a slightly higher price point, the investment is justified by their long-lasting durability and reduced downtime, which is critical for businesses relying on consistent vehicle operation.

What advantages do Lightweight Tubes offer for competitive cycling?

Lightweight tubes are constructed from advanced materials that significantly reduce weight, making them a preferred choice for competitive cycling and racing. These tubes enhance overall bike performance by minimizing rolling resistance and improving handling. While they may be more expensive than standard options, their benefits in terms of speed and agility make them attractive for B2B buyers in the cycling industry who cater to performance-focused customers.

How do Schrader Valve Tubes compare to Presta Valve Tubes?

Schrader valve tubes are equipped with a standard valve type that is universally compatible with most pumps, making them convenient for general use, including e-bikes and scooters. Their bulkier design may not be suitable for high-performance applications, where Presta valves are often preferred due to their lighter weight and ability to handle higher pressures. B2B buyers should consider their target market’s needs when choosing between these valve types.

What are the benefits of using Presta Valve Tubes in high-performance biking?

Presta valve tubes are specifically designed for high-pressure applications, making them ideal for road cycling and high-performance bikes. Their lightweight nature and superior air retention capabilities cater to competitive cyclists looking to optimize their ride. However, they require specific pumps, which may limit their convenience for some users. B2B buyers should assess their clientele’s preferences and the types of bikes they service when deciding on inventory.

Key Industrial Applications of 16 fat tires inner tube

| Industry/Sector | Specific Application of 16 fat tires inner tube | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-Bike Manufacturing | Used in electric bicycles for urban commuting and leisure | Enhances ride comfort and stability; caters to growing e-bike market | Quality assurance, compatibility with tire specifications, pricing |

| Recreational Vehicle Rentals | Essential for all-terrain vehicles and scooters | Improves durability and performance on varied terrains | Bulk purchasing options, reliable supply chain, local regulations |

| Agriculture & Farming | Applicable in utility vehicles for agricultural tasks | Supports efficient transport of goods and personnel on farms | Resistance to punctures, availability of replacement tubes, cost |

| Logistics & Delivery | Used in cargo bikes for last-mile delivery solutions | Facilitates efficient urban logistics with eco-friendly options | Sourcing speed, tire compatibility, and logistical support |

| Sporting Goods Retail | Essential for fat tire bicycles in sports and recreation | Attracts customers seeking high-performance outdoor activities | Trends in consumer demand, seasonal stock levels, and pricing |

How Are 16 Fat Tires Inner Tubes Utilized in E-Bike Manufacturing?

In the burgeoning e-bike market, the 16 fat tires inner tube is a critical component that provides enhanced comfort and stability. Manufacturers leverage these tubes to ensure their electric bicycles can handle various terrains, making them ideal for urban commuting and recreational use. Buyers in this sector must focus on quality assurance and compatibility with existing tire specifications to avoid performance issues. Additionally, competitive pricing can significantly influence purchasing decisions, especially in regions like Africa and South America, where cost-effectiveness is key.

What Role Do 16 Fat Tires Inner Tubes Play in Recreational Vehicle Rentals?

Recreational vehicle rental companies utilize 16 fat tires inner tubes in all-terrain vehicles and scooters to improve performance and durability. These tubes are designed to withstand the rigors of outdoor activities, providing a safer and more reliable experience for customers. For businesses in this sector, sourcing these tubes in bulk can lead to significant cost savings. Moreover, understanding local regulations regarding vehicle safety and maintenance is crucial for ensuring compliance and customer satisfaction.

How Are 16 Fat Tires Inner Tubes Essential in Agriculture & Farming?

In agriculture, 16 fat tires inner tubes are vital for utility vehicles that transport goods and personnel across farms. Their robust construction allows them to navigate rough terrains, reducing the risk of punctures and downtime. Buyers in this sector should prioritize tubes that offer excellent resistance to punctures and ensure a steady supply of replacements to minimize disruptions in operations. Cost considerations are also important, particularly in regions where farming budgets are tight.

Why Are 16 Fat Tires Inner Tubes Important for Logistics & Delivery?

In the logistics sector, particularly for last-mile delivery, the 16 fat tires inner tube is integral to cargo bikes. These tubes enhance the performance of bikes designed for urban environments, ensuring they can efficiently navigate city streets. For B2B buyers, sourcing speed and compatibility with existing tire systems are essential factors. Additionally, businesses must consider logistical support and availability of replacement tubes to maintain operational efficiency.

How Do Sporting Goods Retailers Benefit from 16 Fat Tires Inner Tubes?

Sporting goods retailers stock 16 fat tires inner tubes to cater to the growing demand for fat tire bicycles in recreational and competitive sports. These tubes attract customers who seek high-performance options for outdoor activities, enhancing their overall experience. Retailers should stay informed about trends in consumer demand and maintain appropriate stock levels to meet seasonal fluctuations. Competitive pricing strategies can also help capture a larger market share in this vibrant sector.

3 Common User Pain Points for ’16 fat tires inner tube’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Suppliers for 16 Fat Tire Inner Tubes

The Problem: B2B buyers often struggle to find reliable suppliers that offer quality 16 fat tire inner tubes. This challenge is particularly pronounced in regions like Africa and South America, where access to dependable logistics and consistent product quality can be limited. Buyers face the risk of purchasing inferior products that could lead to high return rates, increased operational costs, and ultimately dissatisfied customers. Inconsistent supply chains can also lead to delays in fulfilling customer orders, impacting business reputation and profitability.

The Solution: To effectively source reliable suppliers, buyers should conduct thorough market research to identify manufacturers with a strong track record in producing 16 fat tire inner tubes. Utilizing platforms like Alibaba or industry-specific trade shows can help in connecting with reputable suppliers. Buyers should prioritize suppliers that offer transparent information about their production processes, quality control measures, and certifications. Additionally, establishing direct communication with suppliers can help clarify product specifications and build trust. Requesting samples before placing bulk orders is a prudent strategy to assess the quality firsthand. This proactive approach will not only ensure product quality but also foster long-term supplier relationships.

Scenario 2: Ensuring Compatibility with Diverse E-Bike Models

The Problem: Another common pain point for B2B buyers is ensuring that the 16 fat tire inner tubes they purchase are compatible with a variety of e-bike models. Given the rapid evolution of e-bike technology and the variety of specifications across different brands, buyers often find themselves with tubes that do not fit the intended applications. This can lead to additional costs related to returns, wastage, and the need for additional inventory to meet diverse customer needs.

The Solution: To mitigate compatibility issues, buyers should invest time in understanding the specifications required by different e-bike models. This includes knowing the tire dimensions, valve types (Schrader vs. Presta), and pressure requirements. Creating a comprehensive compatibility chart that outlines these specifications can serve as a valuable reference when sourcing inner tubes. Buyers should also engage with manufacturers who can provide detailed product information and compatibility guides. Establishing partnerships with local bike shops can provide insights into popular e-bike models in the region, enabling buyers to make informed purchasing decisions.

Scenario 3: Managing Inventory and Avoiding Overstock Situations

The Problem: Managing inventory levels effectively is a significant challenge for B2B buyers in the tire and tube sector. Overstocking 16 fat tire inner tubes can lead to increased holding costs and cash flow issues, while understocking can result in missed sales opportunities. This balance is particularly hard to achieve when demand fluctuates due to seasonal trends or market changes, leading to uncertainty in inventory management.

The Solution: To optimize inventory management, buyers should implement a robust inventory tracking system that utilizes data analytics to forecast demand accurately. By analyzing past sales data, buyers can identify trends and adjust their purchasing strategy accordingly. Additionally, establishing a just-in-time (JIT) inventory system can help maintain lower inventory levels while ensuring that products are available as needed. Collaborating with suppliers to create flexible ordering options, such as smaller, more frequent shipments, can also alleviate the pressure of overstocking. Regularly reviewing inventory performance and adjusting procurement strategies in response to market conditions will enable buyers to maintain a more efficient inventory system, reducing costs and enhancing profitability.

Strategic Material Selection Guide for 16 fat tires inner tube

What Are the Common Materials Used for 16 Fat Tires Inner Tubes?

When selecting materials for 16 fat tire inner tubes, manufacturers typically consider several options, each with distinct properties and applications. Understanding these materials can help international B2B buyers make informed decisions that align with their market requirements and operational needs.

Illustrative image related to 16 fat tires inner tube

How Does Butyl Rubber Perform in Inner Tubes?

Butyl rubber is one of the most common materials used for inner tubes, particularly in fat tire applications. It boasts excellent air retention properties, making it suitable for maintaining tire pressure over extended periods. Butyl rubber can withstand a temperature range of -40°C to 100°C and has a moderate pressure rating, typically around 30-50 PSI for fat tires.

Pros: Butyl rubber is durable and resistant to aging, UV radiation, and ozone, which enhances its lifespan. It is also relatively cost-effective, making it an attractive choice for manufacturers.

Cons: However, butyl rubber has limited flexibility compared to other materials, which can affect ride comfort. Additionally, its manufacturing process can be complex, requiring specialized machinery.

Impact on Application: Butyl rubber is compatible with various media, including air and some gases, but may not perform well with certain chemicals, which could be a consideration for specific regional applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards (e.g., ASTM, DIN) for rubber products. In countries with extreme temperatures, the performance of butyl rubber under high heat should be evaluated.

What Advantages Does Latex Offer for Inner Tubes?

Latex is another material option for inner tubes, known for its superior elasticity and lightweight properties. It can handle high pressures, often exceeding 60 PSI, and is effective in providing a smooth ride due to its ability to absorb shocks.

Pros: The primary advantage of latex is its low rolling resistance, which improves overall bike performance. It also has excellent air retention, though not as effective as butyl.

Cons: On the downside, latex tubes are more prone to punctures and require more frequent inflation. They are also typically more expensive than butyl rubber options.

Impact on Application: Latex is suitable for applications where performance is prioritized over durability, such as racing or high-performance biking.

Considerations for International Buyers: Buyers in Europe, where performance standards are stringent, may prefer latex for competitive cycling. However, they should be aware of the higher costs and maintenance requirements.

How Does TPU Compare as a Material for Inner Tubes?

Thermoplastic polyurethane (TPU) is increasingly being used in the production of inner tubes, offering a balance between flexibility and durability. TPU can typically withstand temperatures from -30°C to 80°C and has excellent abrasion resistance.

Pros: TPU is lightweight and can be manufactured with varying thicknesses, allowing for customization based on specific performance needs. It is also recyclable, which appeals to environmentally conscious buyers.

Cons: The primary disadvantage of TPU is its higher cost compared to traditional materials like butyl rubber. Additionally, it can be less effective in retaining air compared to butyl and latex.

Impact on Application: TPU is compatible with air and some gases, making it suitable for various applications, but its performance in extreme conditions should be evaluated.

Considerations for International Buyers: Buyers in the Middle East, where temperatures can soar, should assess the thermal stability of TPU in their specific applications. Compliance with recycling standards may also be a factor in purchasing decisions.

Illustrative image related to 16 fat tires inner tube

What Role Do Synthetic Rubber Blends Play in Inner Tube Manufacturing?

Synthetic rubber blends, often combining various polymers, are also utilized in inner tube production. These blends can be engineered to enhance specific properties like flexibility, durability, and resistance to environmental factors.

Pros: The versatility of synthetic blends allows manufacturers to tailor the material properties to meet specific performance criteria, such as increased puncture resistance or improved air retention.

Cons: However, the complexity of manufacturing synthetic blends can lead to higher production costs and variability in quality.

Impact on Application: These materials can be designed to work effectively in diverse environments, making them suitable for various markets, including those with harsh conditions.

Considerations for International Buyers: Buyers should ensure that synthetic blends meet local and international standards for safety and performance, particularly in regions with strict regulatory requirements.

Illustrative image related to 16 fat tires inner tube

Summary Table of Material Selection for 16 Fat Tires Inner Tube

| Material | Typical Use Case for 16 Fat Tires Inner Tube | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Butyl Rubber | General-purpose inner tubes | Excellent air retention | Limited flexibility | Low |

| Latex | High-performance cycling | Low rolling resistance | Prone to punctures | High |

| Thermoplastic Polyurethane (TPU) | Custom applications for durability | Lightweight and recyclable | Higher cost and air retention issues | Medium |

| Synthetic Rubber Blends | Versatile applications in diverse markets | Tailored properties for specific needs | Higher production complexity | Medium |

This comprehensive analysis of materials will aid B2B buyers in making informed decisions tailored to their regional requirements and product specifications.

In-depth Look: Manufacturing Processes and Quality Assurance for 16 fat tires inner tube

What Are the Key Manufacturing Processes for 16 Fat Tires Inner Tubes?

The manufacturing of 16 fat tires inner tubes involves several critical stages that ensure the final product meets the required quality and performance standards. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Are Materials Prepared for Inner Tube Production?

The initial step in manufacturing inner tubes is the preparation of raw materials, predominantly butyl rubber, which is known for its excellent air retention properties. Manufacturers typically source high-quality rubber compounds that are blended with additives to enhance performance characteristics such as durability and flexibility.

Once the rubber is prepared, it undergoes a quality check to ensure that it meets the specified standards. This step may involve testing the rubber’s viscosity and elasticity. Furthermore, other materials, such as nylon fabric for reinforcement, are also prepared during this stage.

Illustrative image related to 16 fat tires inner tube

What Techniques Are Used in the Forming Stage?

In the forming stage, the prepared rubber is shaped into tubes using specialized machinery. The extrusion process is commonly used, where the rubber compound is forced through a die to create long, continuous tubes. This method allows for precise control over the tube’s dimensions, ensuring uniformity across products.

Following extrusion, the tubes are cut to the required lengths, typically 16 inches for fat tires. The ends of the tubes are then processed to create valve stems, which are essential for inflation. This step may involve attaching Schrader or Presta valves, depending on the design specifications.

How Is the Assembly Process Conducted?

The assembly process involves integrating various components of the inner tube. For example, if the inner tube includes a puncture-resistant layer or a specialized valve, these elements are added during this stage. Quality assurance protocols dictate that each assembly step is closely monitored to prevent defects.

After assembly, the inner tubes undergo an initial inflation test to detect any leaks or weaknesses. This test is crucial, as it helps identify potential issues before the tubes proceed to the finishing stage.

What Finishing Techniques Are Employed?

Finishing techniques include curing, where the assembled tubes are subjected to heat to vulcanize the rubber, enhancing its strength and elasticity. This process typically occurs in large autoclaves that maintain precise temperature and pressure conditions.

Once cured, the inner tubes are visually inspected for surface defects and measured for dimensional accuracy. They may also undergo additional tests, such as burst testing, to ensure they can withstand the required pressure levels.

Illustrative image related to 16 fat tires inner tube

What Quality Assurance Standards Are Relevant for Inner Tubes?

Quality assurance is a vital aspect of inner tube manufacturing, especially for international B2B buyers who require reliable products. Adherence to recognized standards such as ISO 9001 is critical, as it ensures that manufacturers maintain a quality management system that meets customer and regulatory requirements.

Which International and Industry-Specific Standards Should B2B Buyers Consider?

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for compliance with European health and safety standards, and API (American Petroleum Institute) standards for certain materials, may also be relevant. These certifications demonstrate a commitment to quality and safety, which is particularly important for buyers from regions like Europe and the Middle East.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that products meet the necessary specifications. These checkpoints typically include:

Illustrative image related to 16 fat tires inner tube

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility to verify their compliance with quality standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, various tests are performed to monitor the quality of the products as they are being produced. This may include dimensional checks, visual inspections, and functional tests.

-

Final Quality Control (FQC): At the end of the production process, finished products undergo comprehensive testing to ensure they meet all specifications. This includes pressure testing and leak detection.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify a supplier’s quality control practices. One effective method is to conduct audits of the manufacturing facility. This allows buyers to assess the supplier’s adherence to quality standards and their overall production capabilities.

Additionally, requesting quality assurance reports can provide insight into the supplier’s QC processes and testing results. Third-party inspections can also be beneficial, as they offer an unbiased assessment of the supplier’s operations and product quality.

What Are the QC Nuances for International B2B Buyers?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Different regions may have varying regulatory requirements, which can affect product specifications and compliance.

Buyers should familiarize themselves with local regulations and standards in their target markets. Furthermore, establishing strong communication with suppliers about quality expectations can help mitigate misunderstandings and ensure that the products delivered meet the necessary criteria.

Conclusion

The manufacturing processes and quality assurance practices for 16 fat tires inner tubes are integral to delivering high-quality products that meet international standards. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive reliable and durable inner tubes for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’16 fat tires inner tube’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure 16-inch fat tire inner tubes. As the demand for bicycles and electric bikes grows in various global markets, understanding how to effectively source quality inner tubes is essential. This checklist will help you navigate the complexities of procurement, ensuring that you secure products that meet your technical requirements and business needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the inner tubes you need. Consider factors such as size (16 x 4 inches), valve type (Schrader or Presta), and pressure ratings (e.g., 20 PSI or 30 PSI). Precise specifications help in narrowing down suppliers and ensuring compatibility with your tire selection.

- Size and Compatibility: Ensure that the dimensions match your fat tire requirements.

- Pressure Ratings: Different applications may require varying pressure tolerances.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers for the inner tubes. Use online platforms, trade shows, and industry contacts to compile a list of reliable manufacturers and distributors.

- Supplier Reputation: Look for suppliers with positive reviews and a strong market presence.

- Product Range: Ensure they offer a variety of inner tube options to cater to diverse needs.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and adhere to industry standards. This step is vital for ensuring product quality and safety.

- ISO Certifications: Suppliers with ISO 9001 certification demonstrate a commitment to quality management.

- Compliance with Local Regulations: Ensure that their products meet the standards required in your target market, particularly in regions like Europe or South America.

Step 4: Request Product Samples

Before making bulk purchases, request samples of the inner tubes. This allows you to assess the quality and suitability of the products firsthand.

- Quality Assessment: Inspect the materials, valve types, and overall craftsmanship.

- Testing: If possible, conduct tests to verify durability and performance under various conditions.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to determine pricing, payment terms, and shipping conditions. This step is crucial for maximizing your cost-effectiveness and ensuring favorable contractual agreements.

- Bulk Discounts: Inquire about pricing structures for larger orders.

- Payment Flexibility: Seek terms that align with your cash flow and financial strategy.

Step 6: Establish Clear Communication Channels

Set up clear lines of communication with your chosen supplier. Effective communication can prevent misunderstandings and ensure smooth transactions.

- Point of Contact: Identify a dedicated representative for your account.

- Regular Updates: Schedule periodic check-ins to monitor order progress and address any concerns promptly.

Step 7: Monitor Supply Chain Logistics

Once the order is placed, keep an eye on the logistics involved in shipping and delivery. Understanding the supply chain helps in managing expectations and preparing for any potential delays.

- Tracking Systems: Utilize tracking tools to monitor shipment status.

- Contingency Planning: Have a plan in place to address any supply chain disruptions.

By following this checklist, B2B buyers can streamline their procurement process for 16-inch fat tire inner tubes, ensuring they secure quality products that meet their operational needs.

Illustrative image related to 16 fat tires inner tube

Comprehensive Cost and Pricing Analysis for 16 fat tires inner tube Sourcing

What Are the Key Cost Components in Sourcing 16 Fat Tires Inner Tubes?

When analyzing the cost structure for sourcing 16 fat tires inner tubes, several components play a crucial role. The primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The type and quality of rubber used significantly impact the cost. Higher-quality materials, such as butyl rubber, are often more expensive but provide better durability and performance. Custom specifications may lead to increased material costs.

-

Labor: Labor costs can vary based on the region of production. For instance, countries with lower labor costs may offer more competitive pricing, but this can also affect the quality of workmanship.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and maintenance. Efficient production processes can lower these costs and, consequently, the price of the inner tubes.

-

Tooling: The initial investment in molds and tooling for custom sizes or designs can be significant. However, this cost is typically amortized over larger production runs, making it more economical for bulk orders.

-

Quality Control (QC): Robust QC measures are essential to ensure product reliability. This can add to costs but is crucial for maintaining customer satisfaction and reducing returns.

-

Logistics: Shipping costs can vary significantly based on the chosen Incoterms and the distance to the buyer’s location. International logistics can introduce complexities that affect overall pricing.

-

Margin: Suppliers will include a profit margin, which can vary based on market competition and perceived value. Understanding the market landscape is vital for negotiating favorable terms.

How Do Price Influencers Affect the Cost of 16 Fat Tires Inner Tubes?

Several factors influence the pricing of 16 fat tires inner tubes, making it essential for buyers to understand these nuances:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often lead to lower per-unit costs, making bulk purchasing an attractive option for businesses.

-

Specifications and Customization: Custom specifications may entail additional costs for tooling and materials. Buyers should weigh the benefits of customization against the potential price increase.

-

Quality and Certifications: Products that meet international quality standards or possess certifications (e.g., ISO) may command higher prices. Buyers should consider the long-term benefits of investing in quality.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge a premium but often provide better service and product assurance.

-

Incoterms: Understanding the implications of Incoterms on shipping responsibilities and costs is crucial. Different terms can lead to variations in total landed costs.

What Buyer Tips Can Help Negotiate Better Pricing for 16 Fat Tires Inner Tubes?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can benefit from strategic negotiation and cost-efficiency practices:

-

Negotiation: Establishing a strong relationship with suppliers can lead to better pricing. Open communication about requirements and expectations fosters trust and can lead to concessions on pricing or terms.

-

Cost-Efficiency: Buyers should calculate the total cost of ownership, including shipping, duties, and potential returns. A lower initial price may not always equate to the best overall value.

-

Pricing Nuances: Understanding regional market dynamics and currency fluctuations can help buyers negotiate better terms. Being aware of seasonal demand fluctuations can also provide leverage during negotiations.

-

Long-Term Partnerships: Building long-term relationships with suppliers can result in better pricing and priority service. Consider engaging in contracts for consistent orders to secure favorable rates.

-

Local Regulations: Buyers should be aware of import regulations and tariffs in their respective countries. Compliance with local laws can prevent unexpected costs and delays.

In conclusion, understanding the comprehensive cost structure and pricing influencers is vital for B2B buyers of 16 fat tires inner tubes. By employing strategic negotiation tactics and considering the total cost of ownership, businesses can optimize their sourcing strategies effectively.

Alternatives Analysis: Comparing 16 fat tires inner tube With Other Solutions

Exploring Alternatives to 16 Fat Tires Inner Tubes

In the world of cycling and electric bikes, the inner tube is a crucial component that significantly affects performance and rider experience. While the 16 fat tires inner tube serves specific needs, there are alternatives that may better suit different applications or preferences. This analysis compares the 16 fat tires inner tube against two viable alternatives: tubeless tire systems and solid rubber tires. Understanding these options can help international B2B buyers make informed decisions based on their unique requirements.

| Comparison Aspect | 16 Fat Tires Inner Tube | Tubeless Tire System | Solid Rubber Tires |

|---|---|---|---|

| Performance | High puncture resistance, good shock absorption | Lower rolling resistance, customizable pressure | Excellent durability, no punctures |

| Cost | Moderate ($30 – $65) | Higher initial investment ($70 – $150) | Higher upfront costs ($50 – $100) |

| Ease of Implementation | Simple installation, requires basic tools | Requires sealant, additional setup time | Easy installation, no air required |

| Maintenance | Regular checks needed for punctures | Minimal maintenance, occasional sealant top-up | Virtually no maintenance required |

| Best Use Case | Recreational biking, moderate terrains | Off-road biking, racing, varied terrains | Urban commuting, heavy loads |

What Are the Pros and Cons of a Tubeless Tire System?

Tubeless tire systems offer a modern alternative that eliminates the need for traditional inner tubes. They utilize a sealant to prevent air leaks and can run at lower pressures, enhancing traction and comfort. However, installation can be more complex, requiring special rim tape and sealant. While the initial cost is higher, the long-term savings on tube replacements and improved performance make them attractive for serious cyclists and businesses looking to invest in high-quality equipment.

What Makes Solid Rubber Tires a Good Option?

Solid rubber tires are another alternative that provides durability and eliminates the risk of punctures entirely. They are especially suitable for urban environments where glass and debris are common. The main advantages include low maintenance and the ability to handle heavy loads without the risk of flats. However, solid tires can be heavier and may compromise ride quality due to reduced shock absorption. This makes them less ideal for recreational biking on varied terrains but perfect for commercial applications such as delivery services or city commuting.

How Can B2B Buyers Choose the Right Solution?

When deciding between a 16 fat tires inner tube and its alternatives, B2B buyers should consider their specific use cases and operational needs. For businesses that prioritize performance and versatility, investing in tubeless systems could yield significant benefits in terms of reduced downtime and enhanced rider comfort. Conversely, companies focused on durability and low maintenance might find solid rubber tires more advantageous, particularly in urban settings. Ultimately, the choice will depend on balancing initial costs with long-term performance and maintenance considerations, ensuring the selected solution aligns with the intended application and rider experience.

Illustrative image related to 16 fat tires inner tube

Essential Technical Properties and Trade Terminology for 16 fat tires inner tube

What are the Essential Technical Properties of 16 Fat Tire Inner Tubes?

Understanding the technical properties of 16 fat tire inner tubes is crucial for B2B buyers who aim to ensure product quality, compatibility, and performance. Here are some critical specifications to consider:

1. Material Composition

Most inner tubes are made from butyl rubber, known for its excellent air retention and durability. Some manufacturers may offer alternatives like latex, which is lighter and provides better performance but at a higher cost. Selecting the right material impacts the tube’s lifespan and performance, especially in diverse climates found in regions like Africa and South America.

2. Wall Thickness

The wall thickness of an inner tube affects its durability and puncture resistance. Typical thickness ranges from 0.9mm to 4mm, depending on the tube’s intended use. A thicker wall provides better protection against punctures, which is vital for users in rugged terrains often encountered in the Middle East and parts of Europe.

Illustrative image related to 16 fat tires inner tube

3. Pressure Rating

Inner tubes come with specified pressure ratings, commonly ranging from 20 PSI to 30 PSI for 16 fat tire tubes. This rating is crucial for ensuring optimal performance and safety. Exceeding the recommended pressure can lead to blowouts, while under-inflation can cause handling issues. Understanding these ratings helps buyers match tubes with the intended bicycle or application.

4. Valve Type

Inner tubes typically feature either Schrader or Presta valves. Schrader valves are wider and commonly found in automotive applications, while Presta valves are narrower and often used in high-performance bicycles. The choice of valve affects compatibility with pumps and the ease of inflation, making it essential for buyers to consider their specific requirements.

5. ISO Size Designation

The ISO size designation (e.g., 16 x 4) indicates the diameter and width of the tire, ensuring compatibility with specific bicycle models. This specification is critical for B2B buyers to ensure that the tubes they order will fit the intended bicycles, thereby minimizing returns and dissatisfaction.

What are Common Trade Terms in the Inner Tube Industry?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify high-quality products that meet specific performance standards.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget-conscious buyers who need to manage inventory levels and costs effectively, especially when dealing with international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Crafting an effective RFQ can lead to better deals and clearer expectations regarding product specifications, delivery timelines, and payment terms.

4. Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, risk management, and cost allocation.

5. TPI (Threads Per Inch)

This measurement indicates the density of the threads used in the tire’s construction, impacting its strength and flexibility. A higher TPI often means a lighter and more supple tire, appealing to performance-focused buyers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 16 fat tire inner tubes, ensuring compatibility, quality, and cost-effectiveness in their supply chains.

Navigating Market Dynamics and Sourcing Trends in the 16 fat tires inner tube Sector

What Are the Global Drivers and Key Trends in the 16 Fat Tires Inner Tube Market?

The 16 fat tire inner tube market is witnessing significant growth, driven by the rising popularity of electric bikes (e-bikes) and fat tire bicycles across diverse regions. Increasing urbanization and demand for sustainable transportation solutions, particularly in urban areas of Africa, South America, the Middle East, and Europe, are pushing the adoption of these vehicles. Moreover, health consciousness and recreational cycling are fueling interest in fat tire bikes, which are favored for their stability and performance on various terrains.

Emerging B2B tech trends include the integration of e-commerce platforms that enhance the sourcing process for international buyers, allowing them to compare prices, specifications, and availability across multiple suppliers. Digital supply chain solutions and data analytics are increasingly being utilized to optimize inventory management and predict market demand. Furthermore, manufacturers are exploring direct-to-consumer models, which can significantly reduce costs and improve profit margins for B2B buyers.

Market dynamics are influenced by fluctuating raw material prices, particularly rubber and other composites used in inner tubes. This volatility necessitates that international buyers remain agile, monitoring market conditions closely to negotiate favorable terms. As competition intensifies, the focus on product differentiation through innovation—such as puncture-resistant technology and eco-friendly materials—will become increasingly important for suppliers looking to capture market share.

How Are Sustainability and Ethical Sourcing Practices Influencing the 16 Fat Tires Inner Tube Industry?

Sustainability is becoming a cornerstone in the sourcing strategies of B2B buyers in the 16 fat tire inner tube sector. The environmental impact of traditional manufacturing processes, including high carbon emissions and waste generation, is prompting buyers to seek out suppliers committed to ethical practices. This shift is particularly relevant for businesses aiming to align with global sustainability goals and consumer expectations for eco-friendly products.

Ethical supply chains are increasingly prioritized, with buyers looking for manufacturers that adhere to fair labor practices and sustainable sourcing of raw materials. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as critical indicators for B2B buyers when selecting partners. Moreover, the use of recycled materials in inner tube production not only reduces environmental impact but can also enhance brand reputation among environmentally conscious consumers.

In addition, the trend towards circular economy practices is gaining traction. Suppliers that offer take-back programs for used inner tubes or promote recycling initiatives are likely to attract discerning buyers. This emphasis on sustainability not only addresses regulatory pressures but also fosters customer loyalty in an increasingly eco-conscious market.

What Is the Evolution of the 16 Fat Tires Inner Tube Market?

The 16 fat tire inner tube market has evolved significantly over the past few decades, reflecting broader trends in bicycle design and consumer preferences. Initially, inner tubes were primarily designed for traditional bicycles, with limited options for specialty tires. However, the advent of fat bikes, which gained popularity in the early 2000s, necessitated the development of wider, more robust inner tubes to accommodate larger tires and varied terrains.

As cycling culture has expanded globally, particularly in regions like North America and Europe, the demand for specialized products such as fat tire inner tubes has surged. This evolution has been further accelerated by the rise of e-bikes, which have introduced new performance requirements and consumer expectations. Today, the market is characterized by a diverse range of products that cater to different riding styles and conditions, underlining the importance of innovation and adaptability in this sector.

In conclusion, the 16 fat tire inner tube market is a dynamic sector influenced by technological advancements, sustainability concerns, and evolving consumer preferences. International B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 16 fat tires inner tube

-

How do I solve issues with sourcing 16 fat tires inner tubes internationally?

To effectively address sourcing challenges for 16 fat tires inner tubes, start by identifying reliable suppliers through platforms like Alibaba, Global Sources, or regional trade directories. Conduct thorough background checks, including reviewing their business licenses, customer feedback, and product quality certifications. Establish communication to clarify your requirements, including specifications and compliance with local regulations. It’s also beneficial to request samples to evaluate product quality before placing bulk orders. Engaging with a local trade representative can further streamline the process and help navigate any regional trade laws. -

What is the best specification for 16 fat tires inner tubes for electric bikes?

For electric bikes using 16 fat tires, the ideal inner tube specification typically includes a size of 16×4 inches, compatible with the bike’s tire dimensions. Look for tubes designed to handle varying pressure ranges, such as 20-30 PSI, which provide optimal performance and durability. Brands like BLACK CAT and Innova offer robust options that ensure reliability during rides. Additionally, consider tubes that are puncture-resistant or have added features like thicker walls for enhanced durability, particularly in rugged terrains often encountered in markets like Africa and South America. -

What are the minimum order quantities (MOQs) for 16 fat tires inner tubes?

Minimum order quantities for 16 fat tires inner tubes can vary significantly depending on the supplier and production capabilities. Generally, MOQs range from 100 to 500 units. It’s advisable to negotiate terms based on your purchasing capacity and projected sales. Some suppliers may offer lower MOQs for first-time orders or sample requests. Always clarify these terms before finalizing agreements, as they can impact your inventory management and overall cost structure. -

How can I vet suppliers for 16 fat tires inner tubes?

Vetting suppliers involves several crucial steps to ensure you partner with reputable manufacturers. Start by checking online reviews and ratings on trade platforms. Request references from previous clients to gauge their experiences. Review the supplier’s certifications, such as ISO or CE, which indicate adherence to quality standards. Conduct video calls or visits (if feasible) to assess their facilities and production processes. Lastly, consider engaging third-party inspection services for quality assurance before shipment, especially when dealing with large orders. -

What payment terms should I expect when sourcing 16 fat tires inner tubes?

Payment terms for sourcing 16 fat tires inner tubes can vary by supplier and region. Common terms include a 30% deposit upfront with the balance due before shipment, or 100% payment upon order confirmation. For larger orders, you may negotiate more favorable terms, such as a letter of credit or partial payment upon delivery. It’s crucial to establish clear terms in your contract to avoid misunderstandings and ensure both parties are protected throughout the transaction. -

What logistics considerations should I keep in mind for shipping 16 fat tires inner tubes?

When shipping 16 fat tires inner tubes, consider factors such as shipping method, cost, and delivery timelines. Sea freight is often the most economical for bulk orders but may take longer than air freight. Ensure the supplier can provide necessary shipping documents, including bills of lading and customs declarations. It’s also vital to understand the import duties and regulations in your destination country to avoid unexpected fees. Partnering with a logistics provider who has experience in your target market can streamline the shipping process and mitigate risks. -

How can I customize 16 fat tires inner tubes for my brand?

Customizing inner tubes involves working closely with your supplier to specify your branding needs. You can request features like unique color options, logos, or specific packaging designs that align with your brand identity. Discussing your requirements early in the negotiation process is essential, as customization may affect MOQs and lead times. Many manufacturers are open to customization, especially if you present a clear vision of your branding goals. Ensure that you receive samples to review the quality of the customization before mass production. -

What quality assurance practices should I implement when sourcing 16 fat tires inner tubes?

To ensure quality assurance when sourcing 16 fat tires inner tubes, establish a comprehensive QA process that includes product inspections at various stages. Request detailed product specifications and standards from your supplier. Conduct pre-shipment inspections to verify that the products meet your quality criteria. Additionally, consider implementing a warranty policy to safeguard against defects and ensure customer satisfaction. Regularly reviewing supplier performance and maintaining open communication can help address any quality issues proactively.

Top 6 16 Fat Tires Inner Tube Manufacturers & Suppliers List

1. Fat Tire House – 16×4 Bicycle Fat Tires

Domain: fattirehousela.com

Registered: 2022 (3 years)

Introduction: fat tire 16×4 options available: BLACK CAT Moped Style 16″x4″ bicycle fat Tire for Ebike (30 PSI) from $65.00; Ebike 16″x4″ bicycle fat Tire for Ebike (20 PSI) from $55.00; Innova hybrid 16×4 fat tire (thick tire) (60 TPI, 25 PSI) from $55.00; 16×4 choayang big daddy fat tire (sold out) from $50.00; BLACK CAT 16×4 tube set of 2 for $35.00; 16 x 4 Inner Tube set of 2 for $30.00.

2. Hycline – Mid-Wide Inner Tube

Domain: hyclinebike.com

Registered: 2022 (3 years)

Introduction: This company, Hycline – Mid-Wide Inner Tube, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. eBay – 16 in Bicycle Tire Tubes

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 16 in Bicycle Tire Tubes available for sale on eBay. Various brands and types include: Stop-a-flat Solid No-flat Bicycle Tube (Puncture Proof, 16 x 1.75), Bell Bicycle Inner Tube (16 Inch x 1.75 – 2.25″ Standard Valve), Specialized Inner Tubes (16 x 1.5-2.3″ 32mm Schrader Valve), Slime Self-Sealing Bicycle Tube (16 x 1.7 – 2.125″ Schrader Valve), Sunlite Inner Tube (16 x 2.125 32mm Schrader Valve …

4. Teravail – Fat Bike Tube

Domain: phattirebikeshop.com

Registered: 2010 (15 years)

Introduction: This company, Teravail – Fat Bike Tube, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

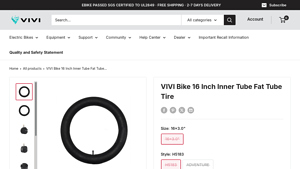

5. VIVI – 16 Inch Inner Tube Fat Tube Tire

Domain: viviebikes.com

Registered: 2022 (3 years)

Introduction: {‘product_name’: ‘VIVI Bike 16 Inch Inner Tube Fat Tube Tire’, ‘size’: ’16×3.0″‘, ‘style’: ‘H5183 ADVENTURE’, ‘price’: ‘$39.99’, ‘stock’: ‘Sold out’, ‘shipping_info’: ‘Free shipping on all orders, delivery time is 9-12 working days’, ‘compatible_bike_models’: [‘Gopina V1’, ‘Gopina V2’], ‘material’: ‘Rubber’, ‘color’: ‘Black’, ‘tire_type’: ‘Tubular’, ‘compatible_bike_type’: ‘Commuter Bike’, ‘wheel_…

6. QBP – Q Tube TU6860

Domain: bikeforums.net

Registered: 2001 (24 years)

Introduction: For fat bikes, the recommended tube size is 26×2.4-2.75. This size is lighter than traditional fat bike tubes and works well even with 4.8″ tires on 100mm rims. A popular option for purchase is the “Q Tube” from QBP, part number TU6860. Surly brand fat bike tubes and tires are also available through local bike shops.

Strategic Sourcing Conclusion and Outlook for 16 fat tires inner tube

In summary, the strategic sourcing of 16 fat tire inner tubes presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the diverse options available—ranging from varying PSI ratings to specific compatibility with different tire brands—enables buyers to tailor their sourcing strategies to meet the unique needs of their markets.

Emphasizing quality and reliability in procurement can lead to enhanced customer satisfaction and reduced operational costs. By establishing strong partnerships with manufacturers and suppliers, businesses can secure favorable pricing and ensure a steady supply of high-quality products. Moreover, staying attuned to market trends, such as the growing popularity of electric bikes and rugged terrain cycling, can further inform sourcing decisions.

As we look ahead, international buyers are encouraged to leverage the insights gained from this guide to optimize their purchasing strategies. By prioritizing strategic sourcing, businesses can not only enhance their competitive edge but also contribute to the growth of the cycling industry in their regions. Engage with suppliers today to explore innovative solutions that align with your business goals and customer expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.