Choosing Your 12 Volt Solenoid: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 12 volt solenoid

In the dynamic landscape of international trade, sourcing reliable 12 volt solenoids presents a unique challenge for B2B buyers. With varying specifications, applications, and quality standards across regions, ensuring a seamless procurement process can feel daunting. This guide serves as a comprehensive resource, addressing critical aspects such as the types of 12 volt solenoids available, their diverse applications in industries ranging from automotive to agricultural, and essential criteria for vetting suppliers. By equipping buyers with insights on pricing trends, quality certifications, and supplier reliability, we empower decision-makers to navigate the complexities of the global market with confidence.

For businesses operating in Africa, South America, the Middle East, and Europe—regions characterized by distinct market demands and regulatory environments—understanding the nuances of 12 volt solenoid sourcing is crucial. Whether you are looking to enhance your manufacturing capabilities or ensure the reliability of your machinery, this guide will provide actionable strategies and best practices tailored to your specific needs. With a focus on informed purchasing decisions, we aim to bridge the gap between suppliers and buyers, ultimately fostering successful partnerships that drive efficiency and innovation.

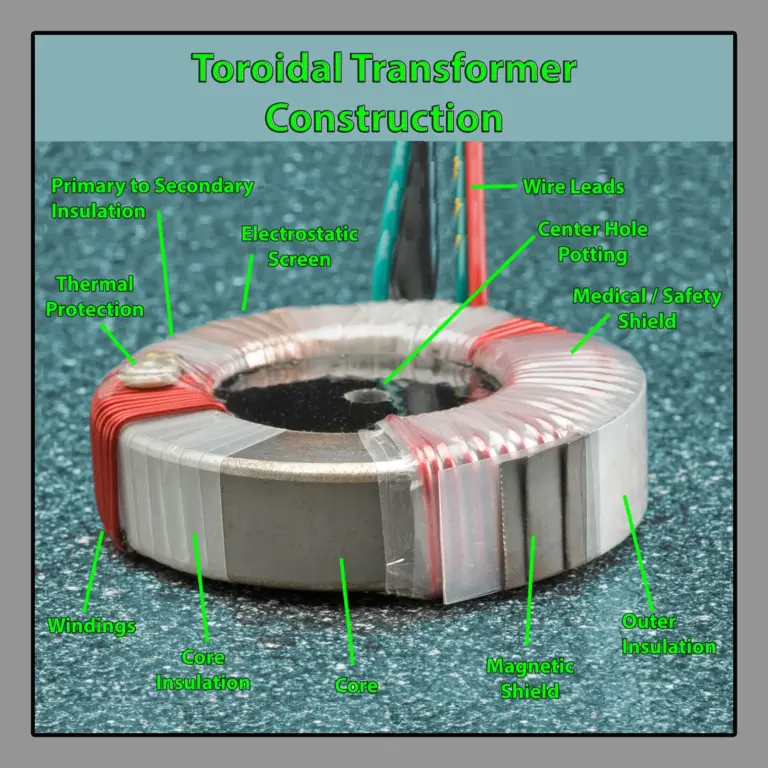

Understanding 12 volt solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Normally Closed Solenoid | Remains closed when not energized; ideal for safety | Water control systems, HVAC applications | Pros: Energy-efficient, reliable. Cons: Limited flow in standby mode. |

| Normally Open Solenoid | Opens when energized; allows for immediate flow | Irrigation systems, pneumatic applications | Pros: Fast response, allows flow when activated. Cons: May require constant power. |

| Pull Type Solenoid | Pulls a rod or lever when energized; compact design | Automotive, industrial machinery | Pros: Space-saving, versatile. Cons: Limited stroke length. |

| Push Type Solenoid | Pushes a rod or lever when energized; often used for locking | Locking mechanisms, safety devices | Pros: Strong actuation force, reliable. Cons: Requires precise installation. |

| High Power Solenoid | Designed for heavy-duty applications; handles high current | Automotive starters, industrial equipment | Pros: Durable, capable of high loads. Cons: More expensive, requires careful handling. |

What Are the Characteristics of Normally Closed Solenoids?

Normally closed solenoids are designed to remain in a closed position when not powered, making them ideal for applications where safety is paramount, such as in water control systems and HVAC systems. When energized, they open to allow fluid or gas flow. B2B buyers should consider the energy efficiency and reliability of these solenoids, as they are often used in critical systems that require fail-safe operations. However, the limitation of maintaining flow only when energized can be a drawback in certain applications.

How Do Normally Open Solenoids Function?

Normally open solenoids function by allowing flow when energized and closing when power is cut. This design is beneficial for applications like irrigation systems and pneumatic tools where immediate flow is necessary. B2B buyers should note the quick response times and ease of integration into systems that require frequent activation. However, the constant need for power to maintain flow can lead to increased energy consumption, which may impact operational costs.

Why Choose Pull Type Solenoids for Your Applications?

Pull type solenoids are compact and designed to pull a lever or rod when energized. Their space-saving design makes them suitable for automotive and industrial machinery applications where space is limited. Buyers should consider their versatility and ease of installation. However, they typically have a limited stroke length, which may restrict their use in applications requiring longer travel distances.

What Are the Advantages of Push Type Solenoids?

Push type solenoids operate by pushing a rod or lever when energized, making them ideal for locking mechanisms and safety devices. Their strong actuation force provides reliable operation in security applications. B2B buyers should evaluate the strength and reliability of these solenoids, but must also ensure precise installation to avoid malfunction, which can be a potential downside.

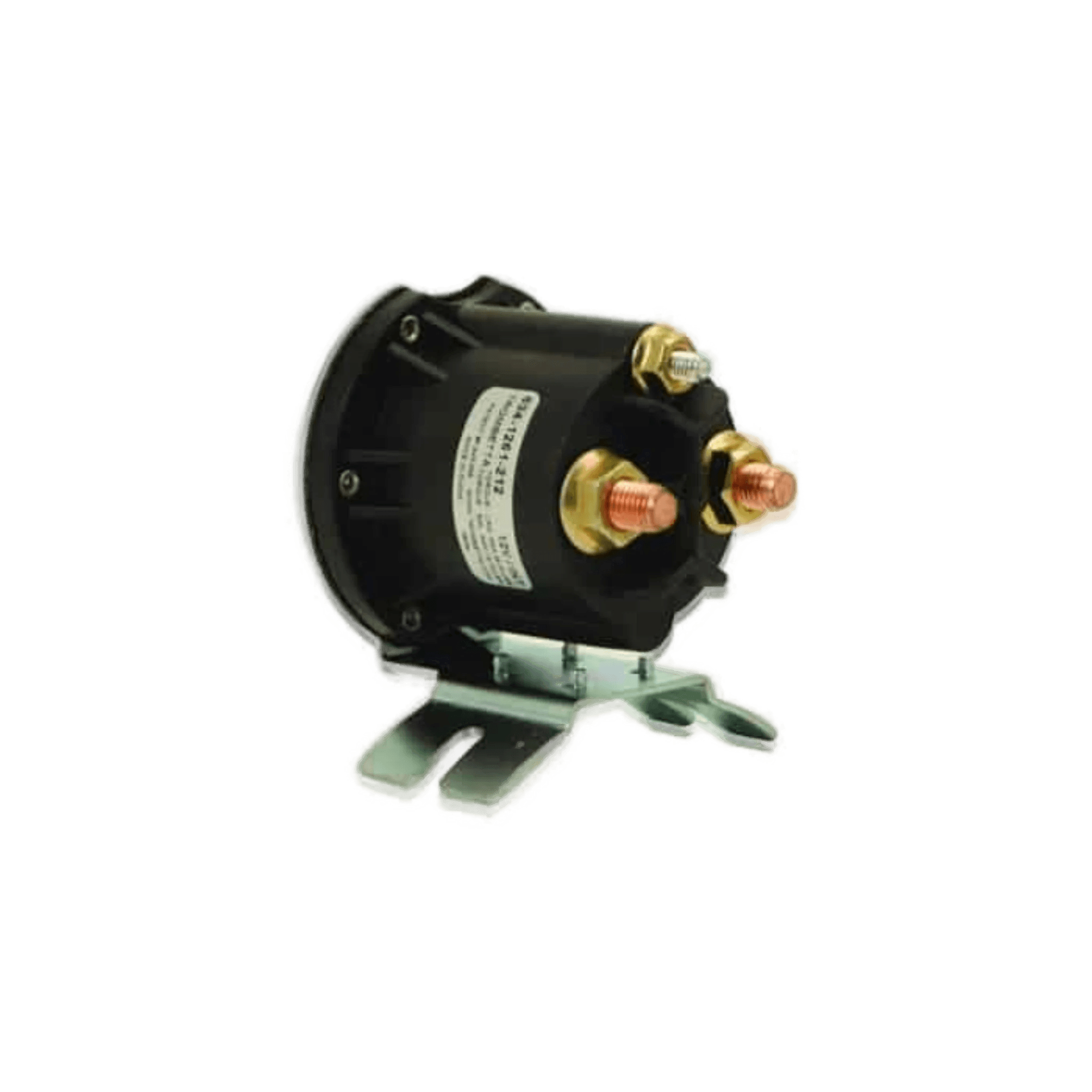

When to Use High Power Solenoids?

High power solenoids are engineered for heavy-duty applications, handling significant current loads typical in automotive starters and industrial equipment. Their durability and capacity for high loads make them a preferred choice for demanding environments. However, buyers should be aware of their higher cost and the need for careful handling to prevent damage, which can be critical in procurement decisions.

Key Industrial Applications of 12 volt solenoid

| Industry/Sector | Specific Application of 12 volt solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation Control Systems | Automates water flow, improving efficiency and crop yield | Durability against weather conditions, ease of integration with existing systems |

| Automotive | Engine Start/Stop Mechanisms | Enhances vehicle reliability and performance | Compatibility with various vehicle models and voltage specifications |

| Manufacturing | Automated Material Handling | Increases operational efficiency and reduces labor costs | Reliability and response time under heavy loads |

| HVAC Systems | Airflow Control in Ducts | Optimizes energy consumption and enhances comfort | Noise levels, size constraints, and power requirements |

| Oil & Gas | Valve Actuation in Pipeline Systems | Ensures safety and efficiency in fluid control | Resistance to corrosive substances and extreme temperatures |

How is a 12 Volt Solenoid Used in Agriculture Irrigation Control Systems?

In agriculture, 12 volt solenoids are pivotal in automating irrigation systems. They control the opening and closing of valves, allowing for precise water management. This automation not only saves water but also enhances crop yields by ensuring consistent moisture levels. Buyers in this sector should consider the solenoid’s durability against varying weather conditions and its compatibility with existing irrigation infrastructure, particularly in regions like Africa and South America where agriculture is crucial for economic stability.

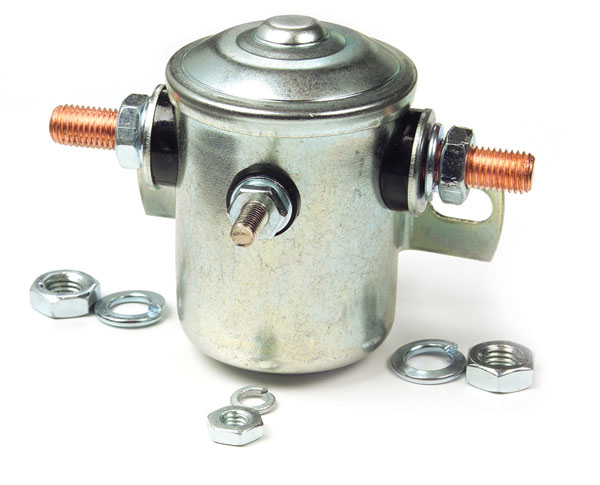

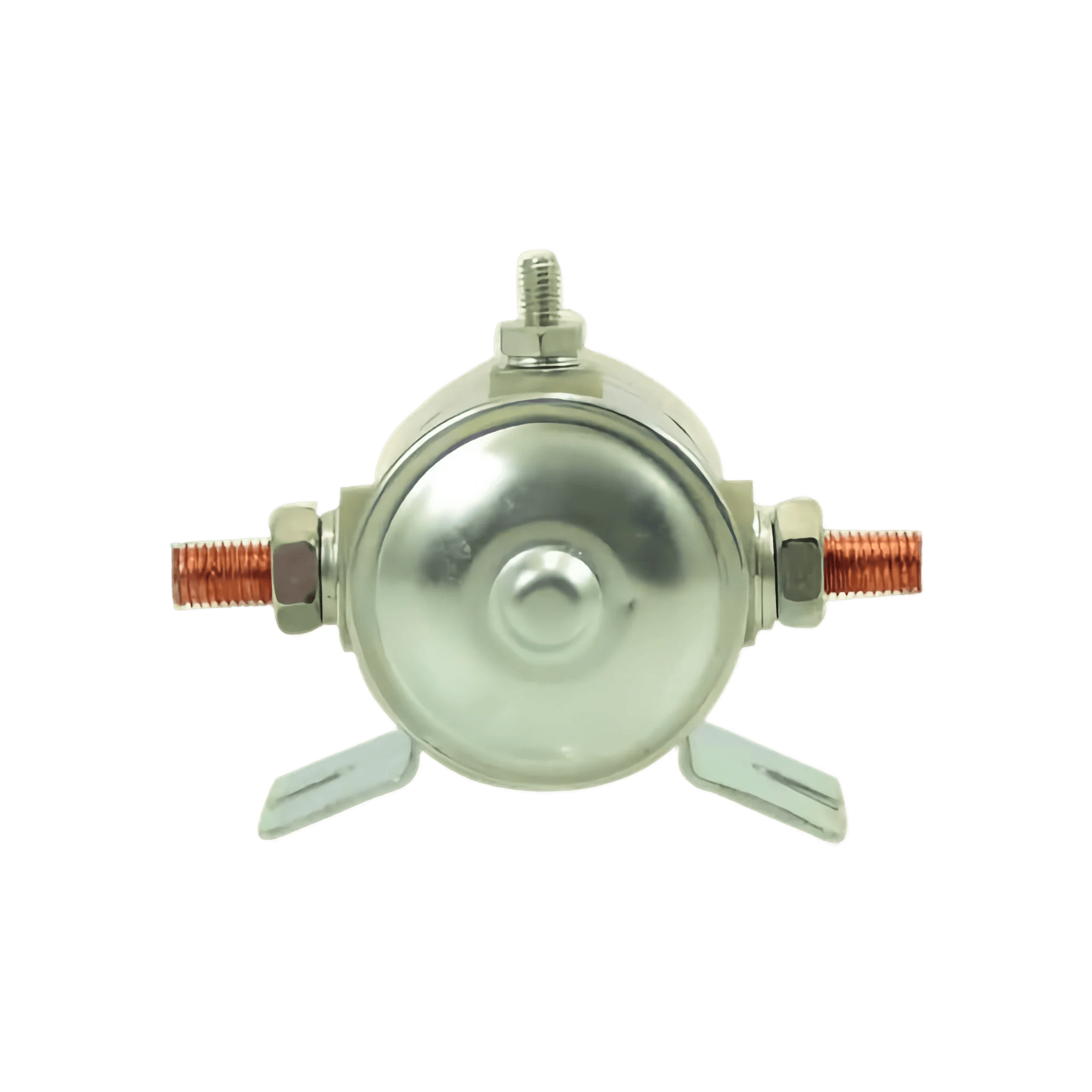

Illustrative image related to 12 volt solenoid

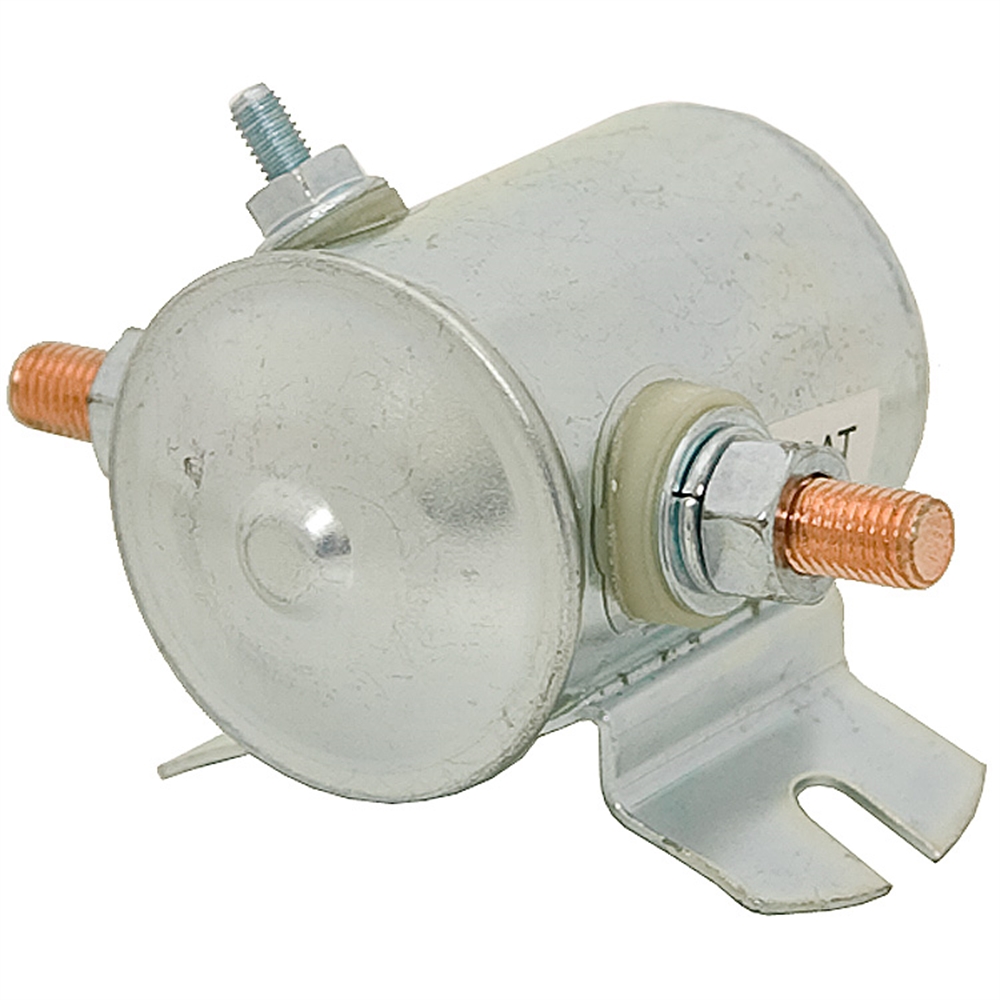

What Role Does a 12 Volt Solenoid Play in Automotive Applications?

In the automotive industry, 12 volt solenoids are often utilized in start/stop mechanisms for engines, enhancing vehicle reliability. They provide a quick response to electrical signals, ensuring efficient engine operation. For international buyers, especially in the Middle East and Europe, sourcing solenoids that meet specific vehicle model requirements and voltage specifications is vital to avoid compatibility issues, thus ensuring optimal performance in diverse driving conditions.

How Do 12 Volt Solenoids Enhance Manufacturing Efficiency?

Within manufacturing, 12 volt solenoids are integral to automated material handling systems. They facilitate the movement of materials through conveyor belts and robotic arms, significantly increasing operational efficiency. Businesses benefit from reduced labor costs and improved throughput. Buyers should prioritize solenoids that demonstrate reliability and swift response times, particularly in high-demand environments, ensuring that they can withstand the rigors of continuous operation.

In What Ways Do HVAC Systems Utilize 12 Volt Solenoids?

In HVAC systems, 12 volt solenoids control airflow in ducts, enabling precise temperature regulation in commercial and residential buildings. By automating airflow, these solenoids help optimize energy consumption, leading to cost savings. Buyers must consider factors such as noise levels, size constraints, and power requirements, particularly in European markets where energy efficiency standards are stringent.

What is the Importance of 12 Volt Solenoids in Oil & Gas Applications?

In the oil and gas sector, 12 volt solenoids are essential for valve actuation in pipeline systems, ensuring safe and efficient fluid control. They help prevent leaks and maintain pressure, which is critical in high-stakes environments. Buyers should focus on sourcing solenoids that are resistant to corrosive substances and can operate under extreme temperatures, especially in regions like the Middle East where such conditions are prevalent.

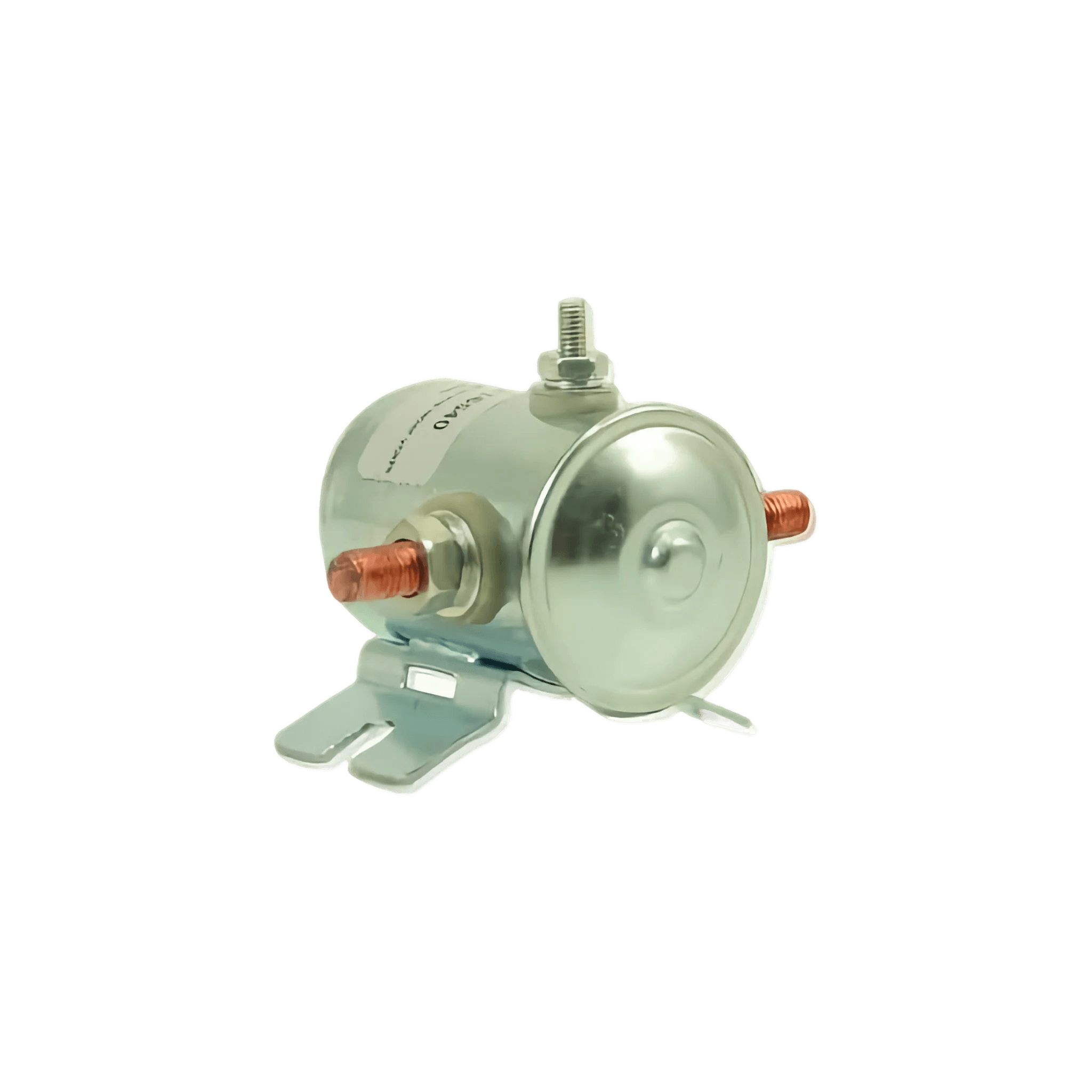

Illustrative image related to 12 volt solenoid

3 Common User Pain Points for ’12 volt solenoid’ & Their Solutions

Scenario 1: Incompatibility with Power Sources

The Problem: Many B2B buyers encounter issues when integrating 12-volt solenoids into existing systems due to compatibility challenges with power sources. For instance, a company in the agricultural sector may have equipment designed for 24V systems, leading to confusion when sourcing solenoids that are only rated for 12V. This not only complicates the procurement process but can also lead to operational downtime and increased costs if the wrong components are purchased.

The Solution: To avoid such incompatibility issues, it is crucial to conduct a thorough assessment of the existing electrical systems before sourcing solenoids. Buyers should look for solenoids with a voltage rating that aligns with their equipment’s specifications, ideally those that offer a range of input voltages (such as 9-24V). Engaging with suppliers who provide detailed product specifications, including compatibility information, is essential. Additionally, leveraging technical support services from manufacturers can assist in confirming the right match for your system’s requirements. This proactive approach helps ensure seamless integration and optimal functionality.

Scenario 2: Limited Knowledge of Solenoid Types

The Problem: B2B buyers often struggle with the vast array of solenoid types available, each designed for specific applications. For instance, a manufacturing firm may need a solenoid for controlling fluid flow but lacks clarity on whether to select a normally closed or normally open type. This confusion can lead to purchasing errors, resulting in equipment malfunctions and increased repair costs.

The Solution: Buyers should invest time in understanding the specific applications of different solenoid types. Collaborating with suppliers that provide extensive educational resources or product guides can significantly enhance decision-making. It’s advisable to create a detailed requirements list that includes factors such as the desired action (open/close), application environment (temperature, pressure), and medium being controlled (air, water, oil). Furthermore, reaching out to technical support teams for guidance can clarify which type of solenoid will best meet operational needs, reducing the risk of costly mistakes.

Scenario 3: Durability Concerns in Harsh Environments

The Problem: In sectors like construction or agriculture, solenoids are frequently exposed to harsh conditions, including extreme temperatures, moisture, and dust. A company may find that their solenoids fail prematurely due to these environmental factors, leading to costly downtimes and repairs. This issue is particularly pronounced in regions with extreme climates, such as the Middle East or parts of Africa, where durability is a critical concern.

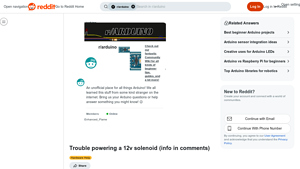

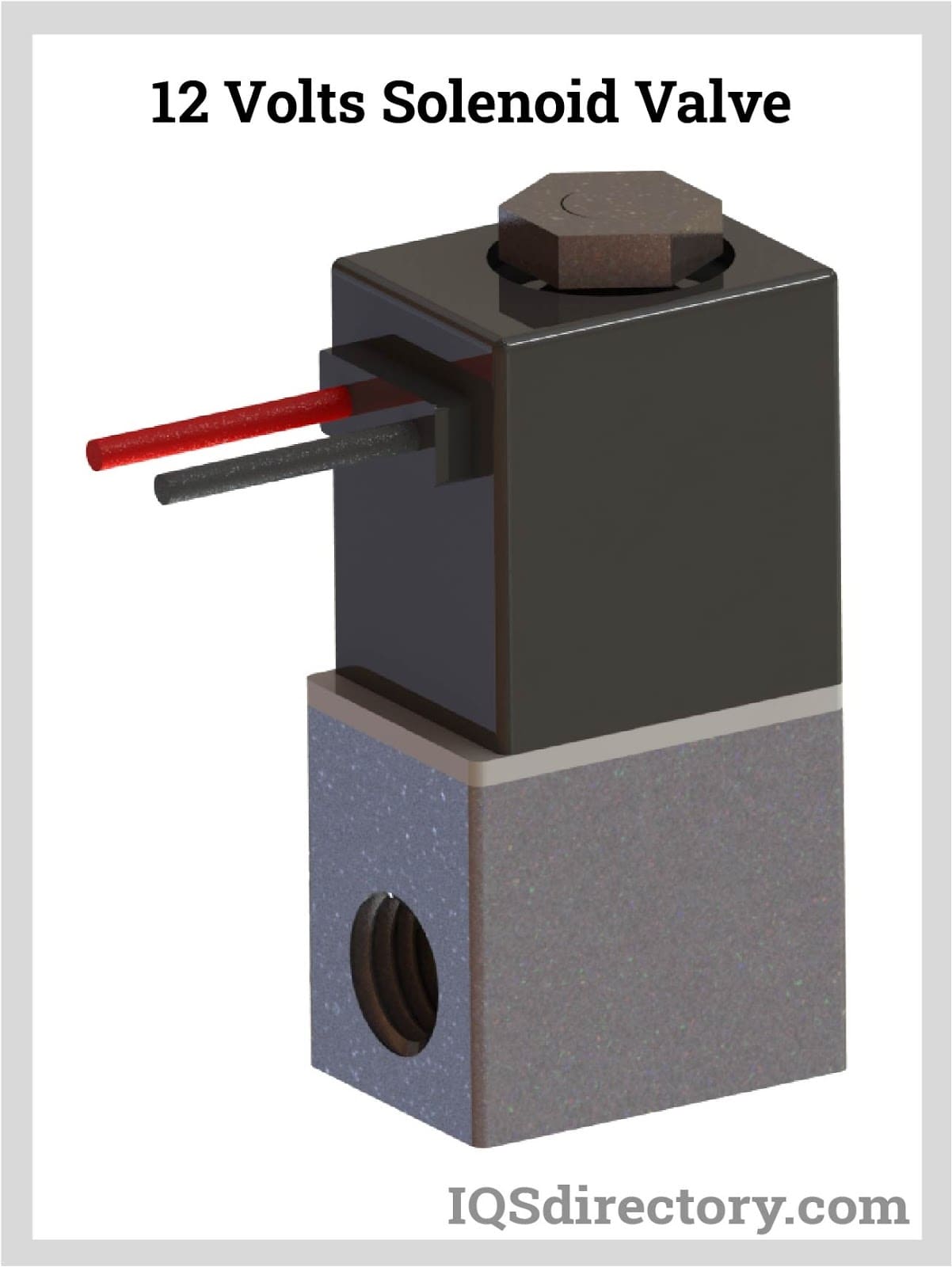

Illustrative image related to 12 volt solenoid

The Solution: To ensure longevity and reliability, B2B buyers should prioritize sourcing solenoids specifically designed for harsh environments. Look for products that feature robust construction materials such as stainless steel or brass, and that are rated for high temperature and moisture resistance. Additionally, consider solenoids with protective coatings or seals, such as Viton or NBR, to enhance resilience against environmental stresses. Consulting with manufacturers about the environmental ratings of their products can also provide insights into which solenoids are best suited for specific applications. Implementing these strategies not only increases the lifespan of solenoids but also enhances overall operational efficiency.

Strategic Material Selection Guide for 12 volt solenoid

What Are the Key Materials Used in 12 Volt Solenoids?

When selecting materials for 12 volt solenoids, it is crucial to consider the specific requirements of the application, including environmental conditions and the type of media being controlled. Here, we analyze four common materials used in the construction of solenoids: brass, stainless steel, plastic (Nylon), and aluminum.

How Does Brass Perform in 12 Volt Solenoids?

Brass is a popular choice for solenoid valves due to its excellent corrosion resistance and good thermal conductivity. It typically has a temperature rating of up to 200°C and can handle moderate pressure levels, making it suitable for various applications, including water and air control.

Pros: Brass solenoids are durable and provide a reliable seal, which is essential for preventing leaks. They are also relatively easy to machine, which simplifies manufacturing processes.

Cons: The main drawback of brass is its higher cost compared to plastic alternatives. Additionally, it may not be suitable for highly corrosive environments, such as those involving strong acids or bases.

Impact on Application: Brass solenoids are compatible with water, air, and some oils, making them versatile for many applications.

Considerations for International Buyers: Brass solenoids must comply with international standards such as ASTM B36. Buyers from regions like Africa and South America should consider local availability and import tariffs on brass components.

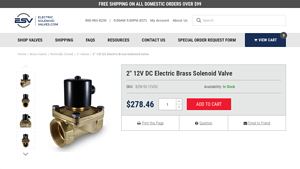

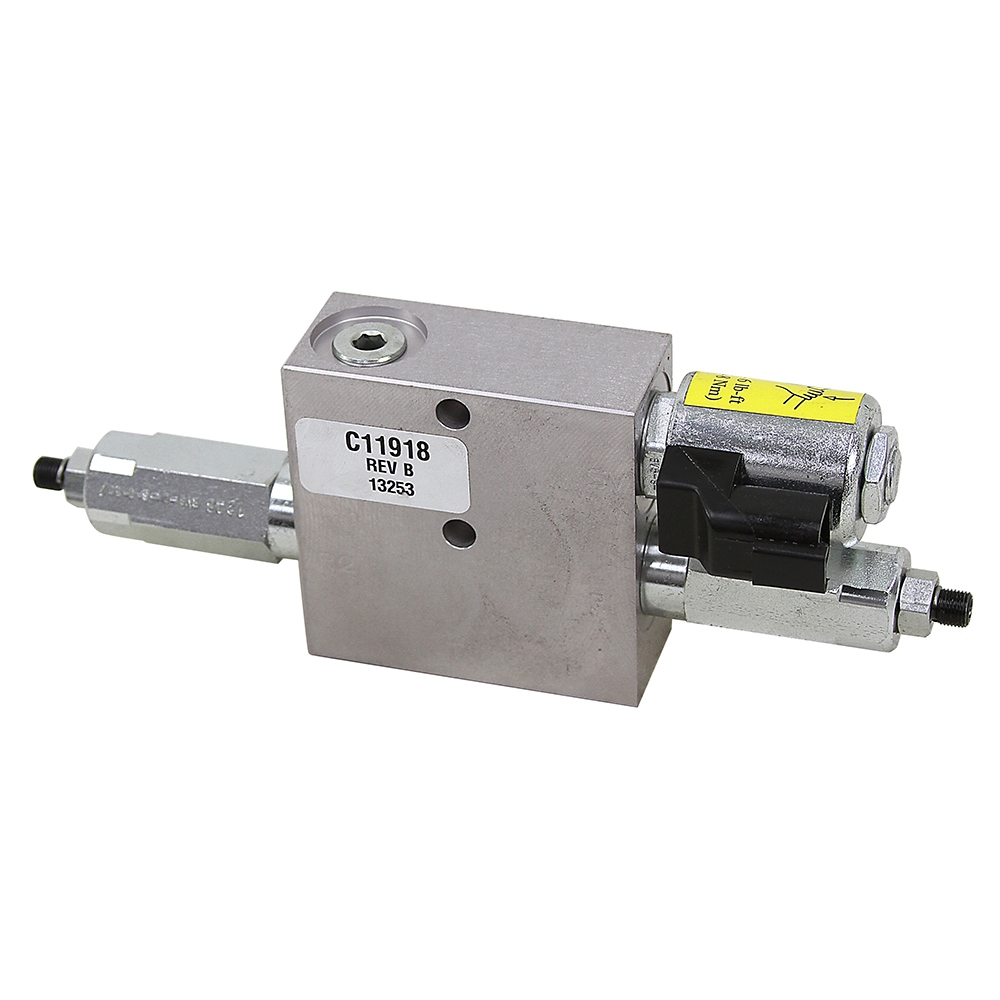

Illustrative image related to 12 volt solenoid

What Advantages Does Stainless Steel Offer for Solenoid Applications?

Stainless steel is renowned for its exceptional strength and corrosion resistance, particularly in harsh environments. It can withstand temperatures up to 300°C and is suitable for high-pressure applications.

Pros: Stainless steel solenoids are highly durable and can endure extreme conditions, making them ideal for industrial applications. They also require minimal maintenance due to their resistance to rust and corrosion.

Cons: The primary limitation is the cost, as stainless steel is generally more expensive than brass and plastic. Additionally, the manufacturing process can be more complex, leading to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including corrosive chemicals, making it suitable for industries like pharmaceuticals and food processing.

Considerations for International Buyers: Compliance with standards such as ASTM A276 is essential. Buyers in the Middle East and Europe should also ensure that the materials meet local regulations for food safety.

Why Choose Plastic (Nylon) for 12 Volt Solenoids?

Plastic, particularly Nylon, is often used for solenoids in applications where weight and cost are critical factors. It typically has a temperature rating of up to 80°C and is suitable for low-pressure applications.

Pros: Plastic solenoids are lightweight and cost-effective, making them ideal for mass production. They also offer good chemical resistance against many common solvents.

Cons: However, plastic solenoids may not withstand high temperatures or pressures, limiting their use in demanding environments. Additionally, their durability is lower compared to metal options.

Illustrative image related to 12 volt solenoid

Impact on Application: Nylon solenoids are suitable for applications involving air and water but may not be ideal for high-temperature or high-pressure scenarios.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with standards like JIS K 6725. In regions with high humidity, such as parts of Africa, the moisture resistance of the plastic should also be considered.

What Role Does Aluminum Play in Solenoid Manufacturing?

Aluminum is another material option for solenoids, known for its lightweight and good thermal conductivity. It typically has a temperature rating similar to brass and can handle moderate pressures.

Illustrative image related to 12 volt solenoid

Pros: Aluminum solenoids are easier to manufacture and can be anodized for enhanced corrosion resistance. Their lightweight nature makes them suitable for portable applications.

Cons: However, aluminum is less durable than stainless steel and can corrode in certain environments, particularly when exposed to saltwater.

Impact on Application: Aluminum solenoids are compatible with air and water but may not perform well in corrosive environments.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is necessary. Buyers from regions like South America should be aware of the availability of aluminum components and potential shipping costs.

Summary Table of Material Selection for 12 Volt Solenoids

| Material | Typical Use Case for 12 volt solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water and air control | Excellent corrosion resistance | Higher cost, limited in corrosive environments | Medium |

| Stainless Steel | Industrial applications | High durability and corrosion resistance | High cost, complex manufacturing | High |

| Plastic (Nylon) | Low-pressure applications | Lightweight and cost-effective | Limited temperature/pressure tolerance | Low |

| Aluminum | Portable applications | Lightweight and easy to manufacture | Less durable, susceptible to corrosion | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common materials used in 12 volt solenoids, enabling informed purchasing decisions tailored to specific application needs.

Illustrative image related to 12 volt solenoid

In-depth Look: Manufacturing Processes and Quality Assurance for 12 volt solenoid

What Are the Key Stages in the Manufacturing Process of 12 Volt Solenoids?

The manufacturing of 12 volt solenoids involves a series of meticulously planned stages, each critical to ensuring the final product meets performance and reliability standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with sourcing high-quality materials, such as brass, stainless steel, and various plastics. These materials are selected based on their durability, corrosion resistance, and suitability for electrical applications. Suppliers often need to verify the material specifications through certificates of conformity to ensure compliance with international standards.

Forming: Once materials are prepared, they undergo forming processes, which may include machining, stamping, or molding. For example, the body of the solenoid may be machined from solid blocks of brass, while other components like coils may be wound from copper wire. Precision in these processes is crucial, as even minor deviations can lead to performance issues.

Assembly: After forming, the components are assembled. This stage involves integrating the coil, housing, and actuator. Automated systems are commonly used to enhance consistency, but manual assembly may be necessary for complex designs. During assembly, technicians perform initial checks to ensure that all parts fit correctly and function as intended.

Illustrative image related to 12 volt solenoid

Finishing: The final stage involves applying protective coatings, such as paint or plating, to enhance corrosion resistance and aesthetics. Quality control checks are performed throughout the finishing process to ensure that the product meets the required specifications.

Which Quality Assurance Standards Are Relevant for 12 Volt Solenoids?

Quality assurance is vital in the manufacturing of 12 volt solenoids to ensure safety, reliability, and compliance with international standards. The most relevant quality standards include ISO 9001, CE marking, and industry-specific certifications such as API.

ISO 9001: This international standard focuses on quality management systems (QMS). Manufacturers seeking ISO 9001 certification must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. This certification is often a prerequisite for doing business in many international markets.

CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This marking assures B2B buyers that the solenoids meet EU directives, which is particularly important for companies importing products into Europe.

API Standards: In sectors such as oil and gas, solenoids may need to comply with standards set by the American Petroleum Institute (API). These standards focus on performance and safety in harsh environments, which is crucial for buyers in industries requiring high reliability.

Illustrative image related to 12 volt solenoid

What Are the Critical Quality Control Checkpoints in Solenoid Manufacturing?

To ensure that 12 volt solenoids meet quality standards, several checkpoints are established throughout the manufacturing process. Key checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the facility. Manufacturers test materials for compliance with specifications, ensuring that only high-quality inputs are used in production. Documentation, including certificates of analysis, is crucial at this stage.

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are performed to monitor the production line. This includes inspecting dimensions, tolerances, and assembly integrity at various stages. Continuous monitoring helps catch defects early, reducing waste and rework.

Final Quality Control (FQC): Once production is complete, FQC involves rigorous testing of finished products. Common testing methods include electrical performance testing, leak testing, and environmental stress testing. These tests confirm that the solenoids meet operational specifications and safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. There are several strategies to accomplish this.

Illustrative image related to 12 volt solenoid

Supplier Audits: Conducting audits of potential suppliers can provide insights into their quality control processes. An audit typically involves reviewing production facilities, quality management systems, and compliance with relevant standards. Buyers may also assess the supplier’s documentation practices, ensuring that all quality checks are properly recorded.

Quality Control Reports: Requesting quality control reports from suppliers can also provide valuable information. These reports should detail the results of IQC, IPQC, and FQC processes, as well as any corrective actions taken for non-conformities. Regular reporting demonstrates a commitment to maintaining high standards.

Third-Party Inspections: Engaging third-party inspection services can further validate a supplier’s quality assurance practices. These independent organizations assess compliance with international standards and provide unbiased evaluations of the manufacturer’s quality systems and product performance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances when sourcing 12 volt solenoids.

Illustrative image related to 12 volt solenoid

Regulatory Compliance: Different regions may have varying regulatory requirements. For instance, products sold in Europe must adhere to CE marking, while those in the Middle East may need to comply with local standards. Buyers should familiarize themselves with these regulations to avoid potential legal issues.

Cultural and Language Barriers: When dealing with suppliers from different countries, cultural and language differences can affect communication regarding quality expectations. Buyers should ensure that both parties have a clear understanding of specifications and quality standards to minimize misunderstandings.

Supply Chain Transparency: Ensuring transparency in the supply chain is vital for international buyers. This includes knowing where components are sourced and how they are manufactured. A transparent supply chain can help mitigate risks associated with quality issues and enhance trust between buyers and suppliers.

In conclusion, understanding the manufacturing processes and quality assurance protocols for 12 volt solenoids is essential for B2B buyers looking to source reliable products. By focusing on key manufacturing stages, relevant quality standards, critical checkpoints, and verification strategies, buyers can make informed decisions that contribute to their operational success.

Illustrative image related to 12 volt solenoid

Practical Sourcing Guide: A Step-by-Step Checklist for ’12 volt solenoid’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure 12-volt solenoids. With a variety of applications across industries—from automotive to industrial machinery—understanding the essential criteria for sourcing these components can streamline your procurement process and ensure you make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider the voltage, type (normally closed or normally open), and size of the solenoid required for your application. Understanding these parameters will help you narrow down your choices and avoid compatibility issues later.

- Voltage Requirements: Ensure that the solenoid operates effectively at 12V DC.

- Type of Solenoid: Determine if you need a pull or push type based on your application.

Step 2: Research Supplier Options

Identify potential suppliers that specialize in 12-volt solenoids. A thorough market research process will reveal manufacturers and distributors that offer quality products suited to your needs. Look for suppliers with a strong reputation in your region.

- Reputation and Reviews: Check online reviews and ratings from other businesses.

- Product Range: Ensure the supplier has a variety of solenoid types and sizes.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a detailed evaluation. Request company profiles, product catalogs, and case studies to gauge their expertise and reliability. Seek references from other buyers in similar industries or regions to validate their claims.

- Certifications: Verify if the supplier holds relevant industry certifications.

- Experience: Consider how long the supplier has been in business and their track record.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the solenoids you are considering. Testing samples in your operational environment will help ensure they meet your performance and reliability standards.

- Testing Parameters: Evaluate for operational efficiency, durability, and response time.

- Compatibility: Confirm that the solenoid integrates well with your existing systems.

Step 5: Negotiate Pricing and Terms

Once you have selected a suitable supplier, engage in negotiations to secure favorable pricing and terms. Ensure that you consider not just the unit price but also shipping costs and payment terms.

- Volume Discounts: Inquire about discounts for bulk orders.

- Payment Terms: Clarify payment methods and timelines to avoid future misunderstandings.

Step 6: Verify After-Sales Support

Assess the level of after-sales support offered by the supplier. Quality support can be crucial for troubleshooting and maintenance, particularly if you encounter issues post-purchase.

- Technical Assistance: Ensure the supplier provides technical support for installation and maintenance.

- Warranty and Returns: Understand the warranty policy and the process for returns or replacements.

Step 7: Finalize the Purchase Agreement

After confirming all details and ensuring satisfaction with the supplier, finalize the purchase agreement. Make sure all terms discussed are documented to protect both parties.

- Contract Clarity: Ensure that the contract clearly outlines all terms, including delivery timelines and penalties for non-compliance.

- Documentation: Keep all communication and documentation for future reference.

By following this checklist, B2B buyers can navigate the procurement of 12-volt solenoids efficiently, ensuring quality and reliability for their applications.

Comprehensive Cost and Pricing Analysis for 12 volt solenoid Sourcing

What Are the Key Cost Components in Sourcing 12 Volt Solenoids?

When sourcing 12 volt solenoids, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts costs. For instance, solenoids made from brass or stainless steel tend to be more expensive than those made from plastic. The quality of seals (e.g., VITON vs. NBR) also affects the material costs and the product’s longevity.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this could come at the expense of quality and reliability.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce these overheads, influencing overall pricing.

-

Tooling: Custom tooling for unique specifications can add to initial costs. Buyers should consider whether a standard product meets their needs to avoid extra expenses.

-

Quality Control (QC): Implementing rigorous QC processes is crucial for ensuring product reliability. Suppliers may charge more for products with higher QC standards, which is often justified by reduced failure rates and warranty claims.

-

Logistics: Shipping costs can vary widely based on the origin and destination of the solenoids. International buyers should factor in customs duties, taxes, and potential delays in their total cost calculations.

-

Supplier Margin: Different suppliers will have varying margins based on their market positioning, brand reputation, and service levels. It’s advisable to compare quotes from multiple suppliers to understand the market rate.

How Do Price Influencers Affect 12 Volt Solenoid Costs?

Several factors can influence the pricing of 12 volt solenoids, particularly for international B2B buyers.

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Minimum order quantities (MOQs) can also affect pricing strategies, with many suppliers offering tiered pricing based on order size.

-

Specifications and Customization: Custom specifications can drive up costs. Buyers should evaluate whether off-the-shelf solutions can meet their needs to maintain cost efficiency.

-

Materials: The choice of materials directly affects price. High-quality materials may lead to higher upfront costs but can reduce maintenance and replacement expenses over time.

-

Quality and Certifications: Certifications (like ISO or CE marking) can add to the cost but may be necessary for compliance in certain markets. These certifications often assure buyers of the product’s reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products but often provide better support and warranty options.

-

Incoterms: Understanding Incoterms is critical for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total cost of acquisition.

What Are the Best Tips for International Buyers Sourcing 12 Volt Solenoids?

-

Negotiate Wisely: Don’t hesitate to negotiate terms, especially on larger orders. Suppliers may be willing to adjust pricing or offer additional services.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and potential downtime costs.

-

Understand Pricing Nuances: Pricing can fluctuate based on market demand, currency exchange rates, and geopolitical factors. Staying informed about these changes can help in budgeting and forecasting.

-

Evaluate Supplier Relationships: Building long-term relationships with reliable suppliers can lead to better pricing and service terms. Regular communication and feedback can enhance collaboration.

-

Conduct Due Diligence: Research potential suppliers thoroughly. Look for reviews, certifications, and case studies to assess their reliability and product quality.

Disclaimer on Indicative Prices

The prices listed in various sources for 12 volt solenoids are indicative and can vary based on market conditions, supplier pricing strategies, and specific buyer requirements. Always confirm current pricing and terms directly with the supplier before making procurement decisions.

Alternatives Analysis: Comparing 12 volt solenoid With Other Solutions

When evaluating the best solutions for automation and control systems, it’s essential to consider various alternatives to the 12-volt solenoid. This analysis focuses on comparing the 12-volt solenoid with two viable alternatives: pneumatic actuators and servo motors. Each of these solutions has unique characteristics that can influence performance, cost, and suitability for specific applications.

| Comparison Aspect | 12 Volt Solenoid | Pneumatic Actuator | Servo Motor |

|---|---|---|---|

| Performance | Quick actuation, suitable for on/off applications | High force output, good for continuous operation | Precise control and positioning |

| Cost | Moderate ($10-$100) | Varies widely ($50-$500+) | Higher ($100-$800+) |

| Ease of Implementation | Simple wiring and setup | Requires compressed air supply and plumbing | Complex wiring and control systems |

| Maintenance | Low maintenance | Regular checks for leaks and pressure | Low, but may require calibration |

| Best Use Case | Valve control, small machinery | Heavy machinery, automation systems | Robotics, CNC machines |

What Are the Advantages and Disadvantages of Pneumatic Actuators?

Pneumatic actuators utilize compressed air to create motion, making them a strong alternative to 12-volt solenoids, especially in applications requiring high force output and continuous operation. Their ability to handle heavy loads makes them ideal for industrial automation, where power and speed are essential. However, the need for a compressed air supply can complicate installation and increase operational costs. Additionally, pneumatic systems require ongoing maintenance to check for leaks and ensure proper pressure levels, which can lead to increased downtime.

How Do Servo Motors Compare to 12 Volt Solenoids?

Servo motors provide precise control over position, speed, and torque, making them an excellent choice for applications requiring intricate movements or adjustments. They are frequently used in robotics and CNC machines due to their accuracy and reliability. However, servo motors are typically more expensive than both 12-volt solenoids and pneumatic actuators. Furthermore, they often require complex control systems and programming, which can lead to longer implementation times and higher initial costs. While their maintenance needs are relatively low, they may require periodic calibration to ensure optimal performance.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right automation solution, B2B buyers should consider their specific application requirements, budget, and long-term operational goals. The 12-volt solenoid is a cost-effective choice for straightforward on/off control tasks, while pneumatic actuators excel in heavy-duty applications where high force is needed. Servo motors are best suited for precision tasks but come with a higher price tag and complexity. By evaluating these factors, buyers can make informed decisions that align with their operational needs and financial constraints, ensuring they choose the most effective solution for their projects.

Essential Technical Properties and Trade Terminology for 12 volt solenoid

What Are the Key Technical Properties of a 12 Volt Solenoid?

When evaluating 12 volt solenoids for B2B applications, understanding their technical specifications is crucial. Here are some essential properties that influence performance and compatibility:

-

Material Grade

The material of the solenoid body significantly affects durability and application suitability. Common materials include brass, stainless steel, and nylon. Brass solenoids offer excellent corrosion resistance and are ideal for fluid control applications, while stainless steel is better suited for harsher environments. Nylon is lightweight and often used for lower-pressure applications. -

Operating Voltage and Current Rating

Solenoids are designed to operate within specific voltage ranges, with 12V DC being standard for many applications. It’s essential to consider the current rating, typically expressed in Amperes (A), to ensure the solenoid can handle the required load without overheating. This specification is critical for electrical compatibility and operational safety. -

Actuation Type

Solenoids can be classified as “pull” or “push” types based on their actuation mechanism. Pull-type solenoids draw a plunger inward when energized, while push-type solenoids extend a plunger. Understanding the required actuation type is vital for meeting specific operational needs, such as in automation or valve control. -

Seal Material

The seal material, such as VITON or NBR (Nitrile Butadiene Rubber), affects the solenoid’s resistance to various fluids and environmental conditions. Choosing the right seal material is essential for applications involving chemicals, oils, or extreme temperatures, ensuring long-term reliability and preventing leaks. -

Stroke Length

The stroke length defines how far the solenoid can move its plunger. This specification is crucial for applications requiring precise movement, such as in automation or valve actuation. A longer stroke may be necessary for certain applications, while others may require a more compact design. -

IP Rating

The Ingress Protection (IP) rating indicates the level of sealing effectiveness against environmental factors like dust and moisture. A higher IP rating is essential for outdoor or industrial applications where exposure to elements is a concern. This specification can directly impact the solenoid’s longevity and reliability in challenging environments.

What Are Common Trade Terms Related to 12 Volt Solenoids?

Familiarity with industry terminology can streamline communication and negotiations in the B2B landscape. Here are key terms to know:

Illustrative image related to 12 volt solenoid

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for ensuring compatibility and quality in sourcing solenoids. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ can help businesses plan their inventory and budget effectively, especially when sourcing components like solenoids in bulk. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This is a critical step in procurement, allowing businesses to compare options and negotiate favorable terms. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers to avoid misunderstandings and ensure smooth transactions. -

Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is crucial for project planning and inventory management, particularly in industries where timing is critical. -

Certification Standards

These standards, such as ISO or CE, indicate that a product meets specific safety, quality, and environmental requirements. Certifications can be essential for compliance and can enhance the credibility of suppliers in the eyes of international buyers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 12 volt solenoids, ensuring they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the 12 volt solenoid Sector

What Are the Current Market Trends in the 12 Volt Solenoid Sector?

The global market for 12-volt solenoids is influenced by a convergence of technological advancements and increased demand across various industries. Key drivers include the expansion of the automotive sector, growth in renewable energy applications, and the need for automation in industrial processes. Emerging technologies such as IoT and smart devices are creating new opportunities for solenoid applications, especially in sectors like agriculture and HVAC systems. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. Buyers should be aware that while the price sensitivity varies by region, quality and reliability remain paramount, especially in high-temperature and high-vibration environments.

Furthermore, the increased focus on energy efficiency and miniaturization of components is pushing manufacturers to innovate. Products that offer versatility, such as solenoids compatible with multiple voltage ranges (e.g., 9-24V DC), are becoming increasingly popular. B2B buyers should also note the rising trend of automation, which is leading to higher demand for solenoids in control systems. This shift is particularly relevant in emerging markets where infrastructure development is accelerating, creating a fertile ground for solenoid applications.

Illustrative image related to 12 volt solenoid

How Can Sustainability and Ethical Sourcing Impact Your Solenoid Purchases?

As global awareness of environmental issues increases, sustainability has become a critical factor in B2B sourcing decisions. The production of 12-volt solenoids can have significant environmental impacts, including energy consumption and waste generation. Thus, sourcing from manufacturers that prioritize sustainable practices is becoming essential for businesses looking to enhance their brand reputation and meet regulatory requirements.

Buyers should seek suppliers who utilize ‘green’ certifications and materials, such as those that are recyclable or made from sustainable resources. Certifications like ISO 14001 for environmental management can provide assurance that a supplier adheres to recognized sustainability practices. Additionally, engaging in ethical sourcing not only mitigates environmental impact but also fosters stronger relationships with suppliers who share similar values.

By opting for solenoids that are designed with energy efficiency in mind—such as those featuring lower power consumption—companies can reduce their overall carbon footprint. This shift towards sustainable practices is increasingly becoming a competitive advantage, especially in markets that are prioritizing green technologies.

What Is the Historical Context of 12 Volt Solenoids in B2B Applications?

The evolution of 12-volt solenoids can be traced back to the early 20th century when they were primarily used in automotive applications for starting systems and ignition. Over the decades, advancements in materials and technology have expanded their usage across various sectors, including manufacturing, aerospace, and telecommunications.

With the rise of automation in the late 20th century, solenoids gained prominence in control systems, enabling more efficient operations across industries. The introduction of durable materials and improved design has allowed solenoids to function reliably in challenging environments, such as high-temperature and high-vibration applications.

Illustrative image related to 12 volt solenoid

Today, 12-volt solenoids represent a vital component in numerous devices, from simple valves to complex automation systems. This historical context is essential for B2B buyers as it highlights the adaptability and continuous innovation within the sector, underscoring the importance of selecting reliable and high-quality products for their specific applications.

Frequently Asked Questions (FAQs) for B2B Buyers of 12 volt solenoid

-

How do I choose the right 12 volt solenoid for my application?

Choosing the right 12 volt solenoid depends on several factors including the application requirements, operating environment, and compatibility with your system. Assess whether you need a normally closed or normally open solenoid based on the control logic of your system. Consider the solenoid’s voltage rating, size, and materials, especially if the solenoid will be exposed to harsh conditions. Consult with suppliers to determine the best options, and ask for product specifications to ensure they meet your operational standards. -

What are the common applications for 12 volt solenoids?

12 volt solenoids are commonly used in various applications such as automotive systems, irrigation systems, industrial automation, and HVAC systems. They are effective in controlling fluid flow, activating machinery, and managing pneumatic systems. In mobile and stationary equipment like generators and compressors, solenoids are essential for operational efficiency. Understanding the specific requirements of your application will help you select the right solenoid for your needs. -

What customization options are available for 12 volt solenoids?

Many manufacturers offer customization options for 12 volt solenoids to meet specific requirements. Customizations can include alterations in size, voltage ratings, materials, and sealing options to enhance durability. Additionally, you may request changes in actuator stroke length or the addition of features such as feedback sensors. Discuss your needs with potential suppliers to explore available options and ensure that the final product aligns with your application requirements. -

What are the minimum order quantities (MOQs) for 12 volt solenoids?

Minimum order quantities (MOQs) for 12 volt solenoids can vary significantly between suppliers and depend on factors such as the type of solenoid and customization requirements. Some manufacturers may have low MOQs for standard products, while customized solutions may require larger orders to justify production costs. Always inquire about MOQs when sourcing solenoids, as this can impact your purchasing strategy and inventory management. -

What payment terms should I expect when sourcing 12 volt solenoids internationally?

Payment terms for international orders of 12 volt solenoids can vary widely depending on the supplier and the country of transaction. Common terms include upfront payment, partial payment before shipment, or payment upon delivery. It is also advisable to confirm whether the supplier accepts various payment methods such as bank transfers, credit cards, or letters of credit. Understanding the payment terms beforehand can prevent misunderstandings and facilitate smoother transactions. -

How can I ensure quality assurance (QA) when sourcing solenoids?

To ensure quality assurance when sourcing 12 volt solenoids, request certifications such as ISO 9001 from your suppliers, indicating they meet international quality management standards. Ask for product samples and test reports to evaluate performance and durability. Establish a clear communication line with the supplier regarding quality expectations and inspection processes. Additionally, consider third-party inspections if ordering large quantities to further ensure product compliance. -

What logistics considerations should I be aware of for international shipments of solenoids?

When sourcing 12 volt solenoids internationally, logistics considerations include shipping methods, customs clearance, and potential tariffs. Choose a reliable shipping partner that understands the intricacies of international shipping and can provide tracking. Be aware of the import regulations in your country and ensure that all necessary documentation is in place to avoid delays. Planning for these logistics aspects can help streamline the delivery process and reduce costs. -

How do I vet suppliers for 12 volt solenoids?

Vetting suppliers for 12 volt solenoids involves researching their credibility, production capabilities, and customer reviews. Start by checking their company history, certifications, and compliance with industry standards. Request references and reach out to previous clients for feedback on their experiences. Additionally, visiting the supplier’s facility, if possible, can provide firsthand insight into their operations and product quality. A thorough vetting process will help ensure you partner with a reliable supplier.

Top 7 12 Volt Solenoid Manufacturers & Suppliers List

1. US Solid – 12V DC Solutions

2. McMaster – 12V DC Solenoids

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 12V DC Solenoids, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Sterndrive – 12 Volt Solenoids

Domain: sterndrive.cc

Registered: 2003 (22 years)

Introduction: Solenoid 12 Volt

– Used for O/B Starters & PTT Motors

– Isolated Base options available

– Multiple models and prices:

– Mercury/Mercruiser Solenoid 12V Isolated Base: $30.80, $35.20, $26.40, $36.00

– Mercury OMC Volvo Solenoid Late Model Delco 12V: $37.40

– Mercury Force 12V Solenoid Isolated Base: $35.20

– J/E 1993-Up 9.9-15 HP 12V Solenoid Isolated Base: $35.20

– OMC 12V O/B Starter So…

4. Fielect – 12V Solenoid Actuator

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Fielect DC 12V solenoid, 0.02kg pull/push, powered with a 12V 1A power supply, using a TIP-120 transistor, 1N4007 diode, and 1k resistor.

5. Electric Solenoid Valves – BZW-50-12VDC

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: {“SKU”:”BZW-50-12VDC”,”Position”:”Normally Closed”,”Port Size”:”2″ Female NPT”,”Voltage”:”12V DC”,”Body Material”:”Brass”,”Components”:”Stainless Steel”,”Seal Material”:”Viton®”,”Diaphragm Orifice Size”:”50 mm”,”Temp Range”:”15 to 250° F / -10 to 120°C”,”Pressure Range”:”Water: 0-90PSI | Air 7-90 PSI”,”Flow Rate”:”Cv 45 (Appx 345 GPM @ 60 PSI)”,”Power”:”40 Watts / 3.25 Amps”,”Coil Connection”:”Lea…

6. Wiring Products – High Power 12 Volt Solenoids

Domain: wiringproducts.com

Registered: 2004 (21 years)

Introduction: High Power 12 Volt Solenoids – Wiring Products offers a range of high power solenoids designed for automotive and industrial applications. These solenoids are typically used to control high current circuits and are essential for various electrical systems. The product line includes options for different current ratings and configurations to suit specific needs. Key features include durability, rel…

7. Woodward – 1502ES-12-C-2-U-1-B2-S1 Solenoid

Domain: acepowerparts.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “Woodward 1502ES-12-C-2-U-1-B2-S1 Solenoid”, “Type”: “12 Volt DC, Pull Type”, “Model”: “1502ES”, “Pull Force Range”: “10-12 lbs (44-53 N)”, “Hold Force Range”: “19-28 lbs (85-125 N)”, “Design”: “Dual Coils (Pull coil and Hold coil)”, “Base Mounting Style”: “Thread ?-28”, “Terminals”: “Ungrounded (3 terminals for Pull, Hold, and Common)”, “Termination Type”: “Screw type”, “Material…

Strategic Sourcing Conclusion and Outlook for 12 volt solenoid

What Are the Key Takeaways for B2B Buyers of 12 Volt Solenoids?

In summary, strategic sourcing of 12 volt solenoids offers significant advantages for international buyers. By understanding the diverse range of applications and specifications—from automotive to industrial uses—buyers can select products that meet their specific operational needs. Key considerations include compatibility with various power sources, material quality (such as brass or stainless steel), and the type of sealing used (e.g., VITON or NBR) to ensure durability and reliability.

How Can Strategic Sourcing Enhance Your Business Operations?

Investing in strategic sourcing not only reduces costs but also improves supply chain efficiency. Buyers are encouraged to establish strong relationships with manufacturers and suppliers, particularly those that offer comprehensive product support and robust warranty options. This approach ensures access to high-quality products while minimizing downtime and maintenance costs.

What’s Next for International Buyers in Emerging Markets?

Looking ahead, the demand for 12 volt solenoids is expected to grow, particularly in emerging markets like Africa, South America, the Middle East, and Europe. As industries evolve and require more sophisticated automation solutions, now is the time for B2B buyers to engage with reliable suppliers. By leveraging strategic sourcing practices, you can position your business for success in a competitive landscape. Don’t hesitate to reach out to manufacturers and distributors to explore tailored solutions that can drive your operations forward.

Illustrative image related to 12 volt solenoid

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.