China Mini Excavator: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for china mini excavator

Navigating the global market for Chinese mini excavators presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With the growing demand for cost-effective machinery that delivers reliable performance, sourcing quality mini excavators from China can be daunting. Buyers often grapple with concerns regarding product quality, supplier credibility, and the overall total cost of ownership. This guide aims to address these challenges by providing a comprehensive overview of the mini excavator landscape, including various types, applications, and essential considerations for vetting suppliers.

Throughout this guide, you will discover how to identify the right mini excavator for your specific needs, from compact models suited for urban projects to robust machines designed for more demanding tasks. We will delve into key factors such as pricing structures, warranty options, and maintenance requirements to empower you to make informed purchasing decisions. Additionally, this resource will offer insights into best practices for supplier evaluation, ensuring that you partner with reputable manufacturers who adhere to international quality standards.

By equipping B2B buyers with actionable insights and strategic recommendations, this guide seeks to simplify the procurement process, ultimately enabling you to invest confidently in Chinese mini excavators that meet your operational needs while maximizing your return on investment.

Understanding china mini excavator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compact Mini Excavator | Lightweight, small size, and maneuverability | Landscaping, small construction projects | Pros: Cost-effective, easy to transport. Cons: Limited power for heavy-duty tasks. |

| Standard Mini Excavator | Moderate weight with a balance of power and versatility | Utility installations, roadwork, agriculture | Pros: Versatile attachments available. Cons: May lack the reach of larger models. |

| Zero-Tail Swing Excavator | Compact design allows operation in tight spaces | Urban construction, residential projects | Pros: Ideal for confined spaces. Cons: Reduced stability compared to larger models. |

| Tracked Mini Excavator | Equipped with tracks for enhanced stability and traction | Excavation in uneven terrain, demolition | Pros: Superior ground grip and stability. Cons: More expensive maintenance due to track wear. |

| Wheeled Mini Excavator | Features wheels instead of tracks for faster movement | Roadwork, landscaping, and light excavation | Pros: Faster transport over hard surfaces. Cons: Less stability on soft or uneven ground. |

What are the Characteristics of Compact Mini Excavators?

Compact mini excavators are designed for light-duty applications, making them ideal for landscaping and small construction projects. Their lightweight and small size facilitate easy transportation and maneuverability in tight spaces. B2B buyers should consider their limited power, which may not suit heavy-duty tasks. However, their cost-effectiveness makes them a popular choice for businesses that require a versatile machine for less demanding projects.

How Do Standard Mini Excavators Differ from Others?

Standard mini excavators strike a balance between power and versatility, making them suitable for utility installations, roadwork, and agricultural tasks. They typically offer various attachment options, enhancing their usability across different applications. When purchasing, B2B buyers should evaluate their specific needs, as these models may lack the reach of larger excavators while still providing sufficient power for a range of tasks.

Why Choose Zero-Tail Swing Excavators for Urban Projects?

Zero-tail swing excavators are particularly advantageous for urban construction and residential projects, where space is often limited. Their compact design allows for operation in confined areas without the risk of hitting obstacles. However, buyers should be aware of their reduced stability compared to larger models, which can affect performance on uneven ground. This type is ideal for businesses focused on urban development and renovation.

What Advantages Do Tracked Mini Excavators Offer?

Tracked mini excavators are designed for stability and traction, making them suitable for excavation in uneven terrain and demolition projects. Their tracks provide superior grip, allowing for effective operation in challenging conditions. However, B2B buyers should consider the higher maintenance costs associated with track wear. These machines are ideal for businesses that frequently work in rugged environments.

When Should You Consider Wheeled Mini Excavators?

Wheeled mini excavators are equipped with wheels, enabling faster movement across hard surfaces. They are particularly useful for roadwork, landscaping, and light excavation tasks. While they offer speed and efficiency, buyers should note that their stability may be compromised on soft or uneven ground. This type is best suited for businesses that require mobility and efficiency on solid surfaces.

Key Industrial Applications of china mini excavator

| Industry/Sector | Specific Application of china mini excavator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site preparation and foundation digging | Reduces labor costs and improves project timelines | Assess machine size and weight capacity for terrain |

| Agriculture | Land clearing and trenching for irrigation systems | Enhances land usability and increases crop yields | Evaluate attachment options for specific farming tasks |

| Landscaping | Grading and digging for landscape features | Creates aesthetically pleasing outdoor spaces efficiently | Check for versatility in attachments for landscaping |

| Utility Installation | Installing underground utilities like water and power | Streamlines installation processes, reducing downtime | Ensure compliance with local regulations and standards |

| Mining and Quarrying | Material handling and site excavation | Increases operational efficiency and reduces costs | Consider durability and maintenance support options |

How is the China Mini Excavator Used in Construction Projects?

In the construction industry, mini excavators are essential for site preparation and foundation digging. These machines can navigate tight spaces, making them ideal for urban construction sites. By using a china mini excavator, businesses can significantly reduce labor costs and complete projects more efficiently. For international buyers, especially those in Africa and South America, it is crucial to assess the machine’s size and weight capacity to ensure it is suitable for the local terrain and project requirements.

What Role Does the China Mini Excavator Play in Agriculture?

In agriculture, the china mini excavator is used for land clearing and trenching to establish irrigation systems. This capability not only enhances land usability but also increases crop yields by ensuring proper water management. Buyers should evaluate attachment options, such as trenching buckets or augers, to meet specific farming tasks. For buyers from regions like the Middle East, understanding the machine’s adaptability to various soil types is essential for effective agricultural operations.

How Can Landscaping Professionals Benefit from China Mini Excavators?

Landscaping professionals utilize china mini excavators for grading and digging to create various landscape features. The compact size of these machines allows for efficient work in residential and commercial landscaping projects. By using a mini excavator, businesses can enhance outdoor spaces while saving time and labor costs. Buyers should prioritize versatility in attachments to accommodate different landscaping needs, ensuring they can tackle diverse projects effectively.

Why are China Mini Excavators Important for Utility Installation?

In the utility installation sector, mini excavators are invaluable for installing underground utilities such as water and power lines. Their ability to dig trenches quickly and efficiently streamlines the installation process, reducing downtime significantly. International buyers must ensure that the excavators comply with local regulations and standards to avoid any legal issues during installations. Additionally, understanding the machine’s hydraulic capabilities is critical for maximizing its utility in various installation tasks.

How Do China Mini Excavators Support Mining and Quarrying Operations?

In mining and quarrying, china mini excavators facilitate material handling and site excavation. Their efficiency contributes to increased operational productivity and reduced costs, making them a vital asset in these industries. For B2B buyers, considering the durability and maintenance support options of the excavator is crucial, especially in challenging environments. Companies operating in Europe and other industrialized regions should also assess the machine’s compliance with safety standards to ensure worker protection during operations.

3 Common User Pain Points for ‘china mini excavator’ & Their Solutions

Scenario 1: Balancing Cost and Quality in Procurement of Chinese Mini Excavators

The Problem:

International buyers often face the dilemma of balancing cost and quality when sourcing mini excavators from China. Many are tempted by the significantly lower prices compared to established brands. However, concerns about durability, reliability, and after-sales support can lead to hesitation. Buyers fear that a poor-quality excavator could result in unexpected maintenance costs and project delays, ultimately negating the initial savings. This is particularly pressing in regions like Africa and South America, where infrastructure and service support may be limited.

The Solution:

To mitigate these concerns, buyers should prioritize comprehensive due diligence when selecting suppliers. Start by researching manufacturers with a solid reputation and positive customer feedback. Look for certifications that indicate adherence to international quality standards, such as ISO 9001. Engage with suppliers directly to discuss their warranty policies, spare parts availability, and customer service responsiveness. It’s advisable to request references from previous clients in similar markets to gauge their experiences. Additionally, consider visiting the manufacturing facility or utilizing third-party inspection services to assess the quality of the machinery before purchase. By ensuring that the selected mini excavator meets both budgetary constraints and quality expectations, buyers can confidently make an investment that supports their operational needs.

Scenario 2: Understanding the Technical Specifications of Mini Excavators

The Problem:

Another common challenge for B2B buyers is navigating the technical specifications of Chinese mini excavators. With numerous models available, each boasting different features and capabilities, it can be overwhelming to determine which machine is best suited for specific applications. Misunderstanding specs like hydraulic power, digging depth, and weight capacity can lead to purchasing a machine that is either underpowered or unsuitable for the intended tasks, resulting in inefficiencies and additional costs.

The Solution:

To overcome this technical hurdle, buyers should engage in a thorough analysis of their project requirements before making a purchase. Create a checklist of essential specifications based on the intended use—whether it’s trenching, landscaping, or demolition. Consult with industry experts or experienced users to gain insights into the most effective models for specific tasks. Leverage online resources, including product comparison websites and forums, to gather data on performance metrics. Many manufacturers also provide detailed specifications and user manuals, which can be invaluable for understanding operational limits. By aligning the excavator’s features with the project’s demands, buyers can select a machine that enhances productivity and minimizes downtime.

Scenario 3: Navigating After-Sales Support and Maintenance Challenges

The Problem:

After-sales support is a significant concern for buyers of Chinese mini excavators, especially in regions where local service networks may be sparse. Buyers often report difficulties in obtaining spare parts, receiving timely technical support, and finding qualified technicians for repairs. This can lead to prolonged machine downtime, impacting project timelines and overall productivity, which is particularly detrimental in competitive markets.

The Solution:

To ensure reliable after-sales support, buyers should prioritize sourcing from manufacturers that have established a network of local distributors or service centers. Before finalizing a purchase, inquire about the availability of spare parts and service support in the buyer’s region. It’s beneficial to confirm the lead times for parts and the responsiveness of customer service channels. Additionally, buyers can consider investing in training for local technicians to ensure they have the necessary skills to maintain and repair the equipment. Establishing a proactive maintenance schedule can also help prevent issues before they arise, reducing the likelihood of costly downtime. By taking these steps, buyers can enhance their operational resilience and ensure their mini excavator remains a valuable asset for years to come.

Strategic Material Selection Guide for china mini excavator

What Are the Key Materials Used in China Mini Excavators?

When selecting materials for China mini excavators, several factors come into play, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Steel: The Backbone of Mini Excavators

Key Properties: Steel is known for its high tensile strength and durability, making it ideal for structural components. It can withstand high temperatures and pressures, ensuring reliability under heavy loads.

Pros & Cons: Steel’s primary advantage is its strength and longevity. However, it can be prone to corrosion if not properly treated, which may lead to increased maintenance costs. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application: Steel components are essential for the frame and arm of the excavator, where structural integrity is critical. However, exposure to moisture or corrosive environments can compromise performance.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN for steel grades. In regions like Africa and South America, where environmental conditions may vary, corrosion-resistant coatings might be necessary.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for components that require reduced weight without sacrificing strength.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which enhances fuel efficiency and maneuverability. However, it is generally less strong than steel, making it unsuitable for high-stress applications. The manufacturing process can be more complex due to the need for specialized techniques.

Impact on Application: Aluminum is often used for non-structural components, such as covers or panels, where weight savings are crucial. Its corrosion resistance makes it ideal for use in humid or coastal environments.

Considerations for International Buyers: Compliance with international aluminum standards, such as JIS or EN, is vital. Buyers in Europe and the Middle East may prefer aluminum for its lightweight properties, especially in urban applications where maneuverability is important.

High-Strength Polymer: Innovative and Versatile

Key Properties: High-strength polymers are lightweight, resistant to corrosion, and have good impact resistance. They can perform well in a variety of temperatures.

Pros & Cons: These materials offer excellent weight savings and flexibility in design. However, their long-term durability under extreme conditions may be a concern, and they can be more expensive than traditional materials.

Illustrative image related to china mini excavator

Impact on Application: Polymers are often used for components like seals and hoses, where flexibility and resistance to environmental factors are essential. They are also used in non-load-bearing structures.

Considerations for International Buyers: Buyers should consider the specific polymer grades and their compliance with international standards. In regions with extreme temperatures, selecting the right polymer type is crucial to ensure performance.

Cast Iron: Strength and Stability

Key Properties: Cast iron is known for its excellent compressive strength and wear resistance, making it suitable for heavy-duty applications.

Pros & Cons: The main advantage of cast iron is its durability and resistance to deformation under load. However, it is heavier than other materials and can be brittle, leading to potential failures under impact.

Impact on Application: Cast iron is commonly used in the manufacturing of engine blocks and heavy-duty components where strength is paramount. Its weight can be a disadvantage in applications requiring high mobility.

Considerations for International Buyers: Buyers should verify that cast iron components meet relevant international standards, as variations in quality can affect performance. In regions like Africa and South America, where rugged terrain is common, the durability of cast iron can be a significant advantage.

Summary Table of Material Selection for China Mini Excavators

| Material | Typical Use Case for china mini excavator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Covers and panels | Lightweight and corrosion-resistant | Less strong than steel | Medium |

| High-Strength Polymer | Seals and hoses | Excellent flexibility and weight savings | Durability concerns under stress | High |

| Cast Iron | Engine blocks and heavy-duty components | Excellent compressive strength | Heavy and brittle | Medium |

This guide provides essential insights into material selection for China mini excavators, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for china mini excavator

What Are the Key Stages in the Manufacturing Process of Chinese Mini Excavators?

The manufacturing of mini excavators in China involves several critical stages, each designed to ensure that the final product meets both performance and quality standards. Understanding these stages can help B2B buyers assess the reliability of potential suppliers.

Material Preparation: What Raw Materials Are Used?

The first stage in manufacturing involves sourcing high-quality raw materials, primarily steel and various alloys. These materials are selected based on their strength-to-weight ratio, corrosion resistance, and suitability for heavy machinery applications. Suppliers typically follow stringent procurement guidelines to ensure that the materials meet international standards.

After sourcing, the materials undergo quality checks to verify their specifications. This may involve chemical analysis and tensile strength tests. B2B buyers should inquire about the types of materials used and request certifications to ensure they meet industry standards.

Forming: How Are Mini Excavator Components Shaped?

Once the raw materials are prepared, they are subjected to various forming processes, including cutting, bending, and welding. Advanced machinery like CNC (Computer Numerical Control) machines are often employed to achieve precise dimensions.

Key components such as the boom, arm, and chassis are crafted during this stage. Manufacturers may utilize techniques like hydroforming for complex shapes or laser cutting for high precision. It’s essential for buyers to understand the forming techniques used, as these can significantly impact the machine’s durability and performance.

Assembly: What Does the Assembly Process Involve?

After the components are formed, they move to the assembly line. This stage involves the meticulous assembly of the excavator, where each part is fitted together, often using automated robotic systems for efficiency and accuracy.

During assembly, manufacturers often implement a modular approach, allowing for easier repairs and upgrades in the future. B2B buyers should look for suppliers that offer detailed assembly documentation, as this can aid in maintenance and troubleshooting.

Finishing: How Is the Final Product Prepared for Sale?

The finishing stage includes painting, coating, and final quality checks. This is where the excavator is painted with durable, weather-resistant coatings that not only enhance its appearance but also protect it from rust and corrosion.

Manufacturers may also conduct surface treatments like shot blasting or powder coating to improve durability. Buyers should ask about the types of finishes used and their expected longevity, as this can influence the total cost of ownership.

Illustrative image related to china mini excavator

What Quality Assurance Measures Are Implemented in Mini Excavator Manufacturing?

Quality assurance is a critical component in the manufacturing of mini excavators, ensuring that each machine meets both national and international standards. Understanding these measures can help B2B buyers make informed purchasing decisions.

What International Standards Are Relevant to Mini Excavators?

Most Chinese manufacturers adhere to international quality standards such as ISO 9001, which outlines a framework for quality management systems. Compliance with these standards indicates that the manufacturer has implemented effective processes for quality control and continuous improvement.

Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the intended use of the excavators. B2B buyers should request copies of these certifications to ensure compliance.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process ensure that components meet specifications and standards.

- Final Quality Control (FQC): This final inspection occurs once the assembly is complete, confirming that the excavator meets all performance and safety standards.

B2B buyers should ask suppliers for detailed reports on these quality control processes, including any issues encountered and corrective actions taken.

What Common Testing Methods Are Used?

Testing methods can vary, but common practices include:

- Performance Testing: Assessing the excavator’s functionality under various load conditions.

- Durability Testing: Subjecting the machine to extreme conditions to evaluate its resilience.

- Safety Testing: Ensuring that all safety features, such as emergency shut-offs, function correctly.

Buyers can verify the robustness of these testing methods by requesting test reports and certifications from third-party testing agencies.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that a supplier adheres to high-quality standards is crucial for B2B buyers, especially when purchasing from international markets. Here are several ways to verify supplier quality control:

What Should Buyers Look for in Supplier Audits?

Conducting audits of potential suppliers can provide valuable insights into their quality control processes. Buyers should look for:

- Third-Party Audits: Independent assessments can validate a manufacturer’s adherence to quality standards.

- Factory Visits: Visiting the manufacturing facility can provide firsthand insight into production practices and quality control measures.

What Types of Reports Should Buyers Request?

Buyers should request various reports from suppliers, including:

- Quality Management System Reports: These documents outline the supplier’s adherence to ISO 9001 or other relevant standards.

- Inspection Reports: Detailed reports from IQC, IPQC, and FQC can provide transparency about the quality of the manufacturing process.

- Testing Certifications: Certifications from accredited testing agencies validate the performance and safety of the excavators.

What Nuances Should International Buyers Consider?

When engaging with Chinese manufacturers, international buyers should be aware of certain nuances that may affect the purchasing process:

- Cultural Differences: Understanding business practices and communication styles can facilitate smoother negotiations.

- Regulatory Compliance: Buyers must ensure that the excavators comply with local regulations in their respective countries, such as emissions standards or safety regulations.

- Logistics and Shipping: Consideration of logistics, including customs regulations and shipping times, is essential for timely delivery.

By taking these factors into account, B2B buyers can make informed decisions when purchasing mini excavators from Chinese manufacturers, ensuring they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘china mini excavator’

To assist international B2B buyers in sourcing Chinese mini excavators, this practical sourcing guide provides a step-by-step checklist. This guide aims to ensure you make informed decisions, optimize your procurement process, and ultimately select the best mini excavator for your needs.

Illustrative image related to china mini excavator

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical specifications required for your project. Consider factors such as the excavator’s size, weight, engine power, digging depth, and attachment compatibility. Defining these parameters will help you narrow down your options and ensure you select a machine that meets your operational needs.

Step 2: Research Reputable Manufacturers

Identifying reliable manufacturers is essential to ensure product quality and after-sales support. Look for companies with a proven track record in the mini excavator market and positive reviews from previous buyers. Utilize industry-specific forums, trade shows, and online platforms to gather insights about potential manufacturers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. Request company profiles, case studies, and references from buyers in your region or industry. Pay attention to their production capacity, quality control processes, and customer service responsiveness, as these factors can significantly impact your purchasing experience.

Illustrative image related to china mini excavator

- Ask for Certifications: Ensure the supplier holds relevant quality certifications, such as ISO9001, to confirm adherence to international standards.

- Inquire About Warranty and Support: Understand the warranty terms and after-sales support options available to protect your investment.

Step 4: Assess Pricing and Payment Terms

Compare pricing across different suppliers to find a competitive rate without compromising quality. Consider not only the upfront cost but also potential hidden fees such as shipping, customs duties, and installation charges. Negotiating favorable payment terms can also enhance cash flow management.

- Request Detailed Quotations: Ensure quotations include all costs associated with the purchase, including delivery timelines.

- Consider Bulk Purchase Discounts: If you plan to acquire multiple units, inquire about discounts for bulk purchases.

Step 5: Inspect Samples or Visit the Manufacturing Facility

Whenever possible, inspect samples or visit the manufacturing facility to assess product quality firsthand. This step allows you to evaluate the construction quality, operational performance, and overall reliability of the mini excavator. It also provides an opportunity to establish rapport with the supplier.

Step 6: Review Logistics and Delivery Options

Understanding the logistics involved in transporting the excavator to your location is crucial. Discuss delivery timelines, shipping methods, and any potential delays that may arise. Make sure the supplier can accommodate your preferred delivery schedule and provides tracking information for shipments.

Illustrative image related to china mini excavator

Step 7: Finalize the Contract

Once you have selected a supplier, ensure all agreed-upon terms are documented in a formal contract. The contract should outline product specifications, pricing, payment terms, delivery schedules, and warranty details. Having a clear agreement helps mitigate risks and provides legal recourse in case of disputes.

By following this checklist, B2B buyers can streamline the procurement process for Chinese mini excavators, ensuring they select the right equipment to meet their operational needs while minimizing risks associated with international sourcing.

Comprehensive Cost and Pricing Analysis for china mini excavator Sourcing

What Are the Key Cost Components in Sourcing Chinese Mini Excavators?

When sourcing mini excavators from China, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel, hydraulic components, and engines (often sourced from reputable brands) contribute to durability but can raise the price. Opting for standard materials can lower costs but may affect the machine’s lifespan and performance.

-

Labor: Labor costs in China are generally lower than in Western countries, contributing to competitive pricing. However, skilled labor is necessary for tasks such as assembly and quality control, which can influence the final cost.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient factories with high output can spread these costs over a larger production volume, potentially lowering the unit price.

-

Tooling and Equipment: Initial setup costs for specialized tools and machinery can be significant. Buyers should consider these costs when evaluating prices, as they can vary widely depending on the manufacturer’s capabilities.

-

Quality Control (QC): Investing in quality assurance processes ensures that the mini excavators meet international standards. This may add to the upfront costs but can save buyers from costly repairs and replacements down the line.

-

Logistics: Shipping costs can vary based on the Incoterms agreed upon. Freight, insurance, and handling fees need to be factored into the total cost. Additionally, customs duties can add unexpected expenses for international buyers.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the average margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Chinese Mini Excavator Costs?

Several factors influence the pricing of mini excavators:

-

Volume/MOQ: Bulk orders often attract lower prices per unit. Buyers should assess their needs and consider purchasing more units if it results in significant savings.

-

Specifications and Customization: Customized machines with specific attachments or features can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Machines that meet international quality standards (ISO, CE) may cost more but offer enhanced reliability and safety. Buyers should evaluate whether these certifications are essential for their operations.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established manufacturers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterm (e.g., FOB, CIF) determines the responsibilities of the buyer and seller, impacting the total cost. Understanding these terms can help buyers negotiate better shipping arrangements.

What Are Essential Buyer Tips for Sourcing Chinese Mini Excavators?

To maximize value when sourcing mini excavators, consider the following strategies:

-

Negotiation: Engage in negotiations with suppliers to secure the best pricing. Having multiple quotes can strengthen your position and encourage suppliers to offer competitive rates.

-

Cost-Efficiency: Look beyond the initial purchase price. Assess the Total Cost of Ownership (TCO), which includes maintenance, operational costs, and potential resale value. A cheaper machine may incur higher long-term costs.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of exchange rates, import tariffs, and local regulations that can affect pricing. Researching local market conditions can provide insights into expected costs.

-

Due Diligence: Conduct thorough research on suppliers, including their production capabilities, customer reviews, and after-sales support. This can mitigate risks associated with purchasing inferior products.

Disclaimer

Prices mentioned for Chinese mini excavators are indicative and can fluctuate based on market conditions, supplier negotiations, and changes in material costs. Always seek updated quotes and conduct comprehensive market research before making purchasing decisions.

Alternatives Analysis: Comparing china mini excavator With Other Solutions

Introduction to Alternative Solutions for Mini Excavation

When considering excavation needs, the market offers various solutions beyond the popular China mini excavator. Each alternative has unique attributes that can cater to specific project requirements, budget constraints, and operational efficiencies. This analysis will compare the China mini excavator with two viable alternatives: a traditional skid steer loader and a compact track loader. Understanding the strengths and weaknesses of each option is essential for B2B buyers aiming to make informed purchasing decisions.

Comparison Table

| Comparison Aspect | China Mini Excavator | Skid Steer Loader | Compact Track Loader |

|---|---|---|---|

| Performance | High digging capability, suitable for tight spaces | Versatile for various attachments, good lifting capacity | Excellent traction, stability, and performance on uneven terrain |

| Cost | Low initial cost (around $8,900) | Moderate cost (starting at $15,000) | Higher cost (starting at $25,000) |

| Ease of Implementation | Simple operation, quick setup | Requires operator training for effective use | Needs specialized training for optimal operation |

| Maintenance | Low maintenance, readily available parts | Moderate maintenance costs; parts may vary by brand | Generally higher maintenance due to complexity |

| Best Use Case | Residential projects, landscaping, small site work | Construction sites, landscaping, snow removal | Heavy-duty landscaping, site preparation on rough terrain |

Detailed Breakdown of Alternatives

Skid Steer Loader

Skid steer loaders are versatile machines that can handle a variety of tasks by switching attachments like buckets, forks, and sweepers. Their compact size allows for maneuverability in tight spaces, making them ideal for urban construction sites. However, the initial investment can be significant, often starting at around $15,000. Maintenance costs can vary based on the brand and the complexity of the attachments, which may require specialized knowledge for repairs. While skid steers excel in lift capacity and versatility, they may not be as efficient in digging operations compared to excavators.

Compact Track Loader

Compact track loaders offer enhanced stability and traction on uneven or soft ground due to their wider tracks. They are particularly effective in landscaping and site preparation where ground conditions are challenging. Starting prices for compact track loaders are generally higher, around $25,000, which may deter budget-conscious buyers. The complexity of these machines often leads to higher maintenance requirements and the need for specialized operator training. While they deliver superior performance on rugged terrain, their cost may not justify their use for smaller projects where a mini excavator would suffice.

Conclusion: Choosing the Right Excavation Solution

For B2B buyers, selecting the right excavation solution depends on several factors, including budget, project type, and operational needs. The China mini excavator stands out for its affordability and suitability for smaller projects, making it an attractive option for buyers looking for a cost-effective solution. On the other hand, skid steer loaders and compact track loaders provide versatility and performance for more demanding tasks but come with higher costs and maintenance considerations. Ultimately, understanding the specific requirements of each project will guide buyers in making the most informed choice that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for china mini excavator

What Are the Key Technical Specifications for a China Mini Excavator?

When considering a mini excavator from China, several critical specifications play a significant role in determining the machine’s efficiency, durability, and suitability for specific tasks. Here are some essential technical properties:

-

Operating Weight

The operating weight of a mini excavator typically ranges from 1 to 6 tons. This specification affects the machine’s stability, lifting capacity, and transportation logistics. For B2B buyers, understanding the operating weight is crucial for compliance with local regulations and for ensuring that the excavator can handle the intended workload without compromising safety. -

Engine Power (HP)

Engine power, measured in horsepower (HP), is a key indicator of the excavator’s performance. Mini excavators usually feature engines ranging from 13 HP to 50 HP. Higher engine power translates to better digging and lifting capabilities, making it essential for buyers to match the engine’s power with the tasks at hand, especially in challenging terrains. -

Digging Depth

The digging depth typically varies between 1.5 meters and 3 meters for mini excavators. This specification directly impacts the machine’s ability to perform tasks such as trenching, foundation work, or landscaping. For B2B buyers, knowing the digging depth helps in assessing whether the machine is suitable for specific projects, particularly in construction and agricultural applications. -

Hydraulic Flow Rate

Measured in liters per minute (L/min), the hydraulic flow rate indicates the efficiency of the hydraulic system in powering attachments like buckets and augers. A higher flow rate allows for quicker operation and better performance of hydraulic attachments. This is vital for B2B buyers who require versatility in their machinery, as it affects productivity and the range of tasks the excavator can perform. -

Bucket Capacity

Bucket capacity is often expressed in cubic meters or liters and typically ranges from 0.02 to 0.1 cubic meters for mini excavators. This specification determines how much material can be moved in a single load, impacting the overall efficiency of operations. Buyers should consider the bucket capacity in relation to their project requirements to optimize performance and reduce operational costs.

What Are the Common Trade Terms Related to China Mini Excavators?

Understanding industry jargon can greatly enhance communication and negotiation processes in B2B transactions. Here are some common trade terms associated with mini excavators:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the original products. In the context of mini excavators, an OEM produces the machine and its components. For buyers, purchasing from reputable OEMs ensures quality and reliability, which is crucial for long-term operational success. -

MOQ (Minimum Order Quantity)

MOQ specifies the minimum number of units a buyer must order to complete a transaction. Understanding MOQ is essential for international buyers, as it affects inventory management and overall costs. Buyers should negotiate MOQs that align with their project needs while ensuring cost-effectiveness. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting price quotes for specific products. In the mini excavator market, an RFQ allows buyers to compare prices, specifications, and delivery terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to understand their liabilities and ensure smooth transactions when importing mini excavators. -

Lead Time

This term refers to the time taken from placing an order to receiving the product. In the context of mini excavators, lead time can vary based on manufacturing schedules and shipping logistics. Buyers should account for lead times when planning projects to avoid delays in operations. -

Warranty Period

The warranty period indicates the duration during which the manufacturer guarantees the product against defects. For B2B buyers, understanding warranty terms is vital for risk management, as it provides assurance regarding the machine’s reliability and performance over time.

By grasping these technical specifications and trade terms, international buyers can make informed decisions, optimize their procurement strategies, and enhance operational efficiency in their projects.

Navigating Market Dynamics and Sourcing Trends in the china mini excavator Sector

What Are the Current Market Dynamics and Key Trends in the China Mini Excavator Sector?

The global market for mini excavators, particularly those manufactured in China, is experiencing significant growth driven by infrastructure development, urbanization, and rising demand for efficient construction machinery. With a focus on affordability and functionality, Chinese mini excavators are increasingly appealing to international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The competitive pricing—often significantly lower than Western counterparts—combined with adequate performance features makes these machines an attractive option for cost-conscious buyers.

Illustrative image related to china mini excavator

Emerging technologies are reshaping the sourcing landscape. Buyers are increasingly leveraging digital platforms for procurement, facilitating greater transparency and efficiency in transactions. Online marketplaces and direct-to-consumer models are becoming standard, allowing buyers to compare specifications, prices, and after-sales services easily. Additionally, advancements in manufacturing processes and materials are enhancing the durability and operational efficiency of these excavators, making them suitable for diverse applications, from agriculture to construction.

Furthermore, the integration of smart technologies—such as IoT connectivity for maintenance tracking and operational efficiency—has started to penetrate the mini excavator market. These innovations are particularly attractive to international buyers looking to optimize fleet management and reduce downtime, thereby increasing overall productivity.

How Is Sustainability and Ethical Sourcing Addressed in the Mini Excavator Sector?

As environmental concerns gain prominence globally, the sourcing and manufacturing of mini excavators in China are increasingly scrutinized for sustainability and ethical practices. The importance of environmentally friendly operations cannot be overstated; buyers are now demanding machines that not only meet performance expectations but also align with sustainable practices.

Illustrative image related to china mini excavator

Chinese manufacturers are beginning to adopt greener production techniques, such as using recyclable materials and reducing waste during manufacturing. Additionally, certifications related to environmental management—like ISO 14001—are becoming more prevalent among reputable manufacturers. These certifications assure international buyers that the products they are sourcing come from facilities that adhere to environmental regulations and sustainable practices.

Moreover, ethical sourcing is critical in establishing a trustworthy supply chain. Buyers are encouraged to partner with manufacturers that prioritize fair labor practices and transparency in their operations. This commitment to ethical sourcing not only enhances brand reputation but also aligns with the increasing consumer demand for corporate responsibility in the construction sector.

What Is the Brief Evolution of the China Mini Excavator Market?

The evolution of the mini excavator market in China can be traced back to the late 1990s when the demand for compact construction equipment began to rise. Initially, the focus was on replicating Western models, but over the years, Chinese manufacturers have invested significantly in research and development. This investment has led to innovations that cater to both local and international markets, focusing on versatility and performance.

By the mid-2000s, the Chinese mini excavator market saw rapid expansion, driven by urbanization and infrastructure projects. As manufacturers gained experience and improved their production techniques, the quality of Chinese mini excavators began to rival that of established brands. Today, with a diverse range of models and enhanced technological features, Chinese mini excavators are not only a viable alternative but often preferred for their cost-effectiveness and adaptability to various terrains and applications.

In conclusion, navigating the China mini excavator sector requires an understanding of market dynamics, sustainability considerations, and the historical context that shapes current offerings. For international B2B buyers, aligning with reputable manufacturers that prioritize both performance and ethical practices will be essential for making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of china mini excavator

-

How do I evaluate the quality of a Chinese mini excavator before purchasing?

To assess the quality of a Chinese mini excavator, start by researching the manufacturer’s reputation and history in the industry. Look for reviews from previous buyers, focusing on durability, performance, and customer service. Request detailed specifications, including engine type, hydraulic system, and safety features. If possible, arrange for a factory visit or third-party inspection to ensure compliance with international standards. Additionally, consider testing the excavator in real work conditions to gauge its capabilities. -

What are the key features to consider when selecting a mini excavator for my business?

When choosing a mini excavator, consider factors such as size, weight, and operating capacity to match your project needs. Key features include digging depth, reach, and hydraulic power. Evaluate attachments available for versatility, such as buckets, augers, and thumbs. Fuel efficiency, ease of maintenance, and operator comfort are also crucial. Lastly, ensure the model complies with local safety regulations and standards, especially if you’re operating in regions with stringent requirements. -

What payment terms should I expect when sourcing mini excavators from China?

Payment terms can vary significantly among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer letter of credit (L/C) options, especially for larger orders. It’s essential to negotiate terms that protect your interests, such as escrow services or trade assurance programs. Always clarify currency preferences and ensure that all terms are documented in your purchase agreement to avoid misunderstandings. -

What are the minimum order quantities (MOQs) for Chinese mini excavators?

Minimum order quantities for Chinese mini excavators typically range from one unit to several units, depending on the manufacturer and model. Smaller suppliers may accommodate lower MOQs, while larger manufacturers may require bulk orders to optimize production costs. When negotiating, consider your budget and storage capacity. If you’re uncertain about committing to a large order, discuss options for sample units or pilot orders to evaluate the product before scaling up. -

How can I ensure reliable logistics and shipping for my mini excavator purchase?

To ensure reliable logistics, partner with a reputable freight forwarder experienced in handling heavy machinery. Discuss shipping methods, such as container shipping or roll-on/roll-off (RoRo), to determine the best option based on your budget and timeline. Obtain detailed shipping schedules and customs clearance procedures to avoid delays. Additionally, ensure that the supplier provides necessary export documentation and insurance coverage for the shipment to protect your investment during transit. -

What are the common customization options available for mini excavators?

Many manufacturers offer customization options for mini excavators, including engine type, color, and attachments. You can often specify features such as cab designs, hydraulic systems, and safety enhancements based on your operational needs. Discuss any specific requirements with the supplier to ensure they can meet your expectations. Customization may impact lead times and costs, so factor these into your procurement planning. -

How do I vet suppliers of Chinese mini excavators effectively?

To effectively vet suppliers, start by verifying their business licenses and certifications. Use platforms like Alibaba or Global Sources to check ratings and reviews from previous customers. Request references and follow up with past clients about their experiences. Conduct video calls or in-person visits to assess the manufacturing facilities. Additionally, consider engaging third-party inspection services to evaluate product quality before shipment, ensuring you receive what you expect. -

What quality assurance measures should I implement when sourcing mini excavators?

Implement a comprehensive quality assurance process that includes pre-shipment inspections, testing of machinery, and adherence to international standards. Develop a checklist of specifications that the excavator must meet, including safety features and performance metrics. Work closely with the supplier to establish clear quality benchmarks and timelines. Regular communication and updates during the production phase will also help ensure that any issues are addressed promptly, reducing the risk of receiving subpar products.

Top 3 China Mini Excavator Manufacturers & Suppliers List

1. Chinese Mini Excavator – 1-Ton Class

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: Chinese mini excavator, 1-ton class, priced at $8900. Features a 13 hp Briggs engine, well-built with clean welds, plenty of digging depth. Capable of turning itself over if not careful, requires additional counterweight. Comes with a quick-change mount for attachments. Hydraulic auger attachment available, capable of sinking a 24″ deep post hole in sandy soil. Initial use included digging a 300′ …

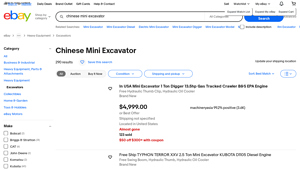

2. Chinese Mini Excavator – Listings Overview

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Chinese Mini Excavator listings on eBay include various models and specifications. Key details extracted include: 1. **Condition**: New and Used options available. 2. **Price Range**: Listings range from under $4,700 to over $6,600. 3. **Popular Models**: Examples include a 2 Ton New Mini Excavator with EPA certified KUBOTA Diesel D902 engine priced at $10,415.07, a 1 Ton Digger with 13.5hp Gas Tr…

3. Yufan Machinery – Mini Excavators

Domain: yufanmachinery.com

Registered: 2022 (3 years)

Introduction: Best Chinese Mini Excavators | 2024 Hot Selling Models

Key Product Details:

– Type: Crawler excavators

– OEM customization: Support

– Appearance: Tailored body color and logos available

– Weight range: 0.8 ton to 3.5 ton

– Applications: Construction, utility work, forestry, etc.

– Payment options: T/T, LC, Paypal, West Union, credit card, etc.

Mini Excavator Models:

1. YFT08: Engine: Koop192F, P…

Strategic Sourcing Conclusion and Outlook for china mini excavator

As the market for mini excavators continues to evolve, strategic sourcing from China presents a valuable opportunity for international B2B buyers. The affordability and versatility of Chinese mini excavators, such as those available for less than $10,000, make them an attractive alternative to more expensive brands. Buyers should focus on key factors such as quality assurance, supplier reliability, and after-sales support when evaluating potential partnerships.

Illustrative image related to china mini excavator

Understanding the unique requirements of various markets in Africa, South America, the Middle East, and Europe is crucial. Local conditions, regulatory standards, and buyer expectations can significantly influence procurement strategies. By leveraging insights from user experiences and product performance, companies can make informed decisions that align with their operational needs.

Looking ahead, the demand for cost-effective, efficient machinery will likely increase, especially in emerging markets. International buyers are encouraged to explore partnerships with reputable Chinese manufacturers, ensuring they capitalize on the benefits of innovation and competitive pricing. By acting now, businesses can position themselves advantageously in a growing sector, ultimately enhancing their operational capabilities and market presence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to china mini excavator