Chiller Cycle: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for chiller cycle

In the fast-evolving landscape of global trade, sourcing efficient chiller cycle systems poses a significant challenge for B2B buyers across diverse industries. As businesses in sectors like food preservation, pharmaceuticals, and healthcare strive for optimal operational efficiency, the demand for reliable cooling solutions is paramount. This guide delves into the intricate world of chiller cycles, providing a comprehensive overview of various types, applications, and the critical components that define their performance.

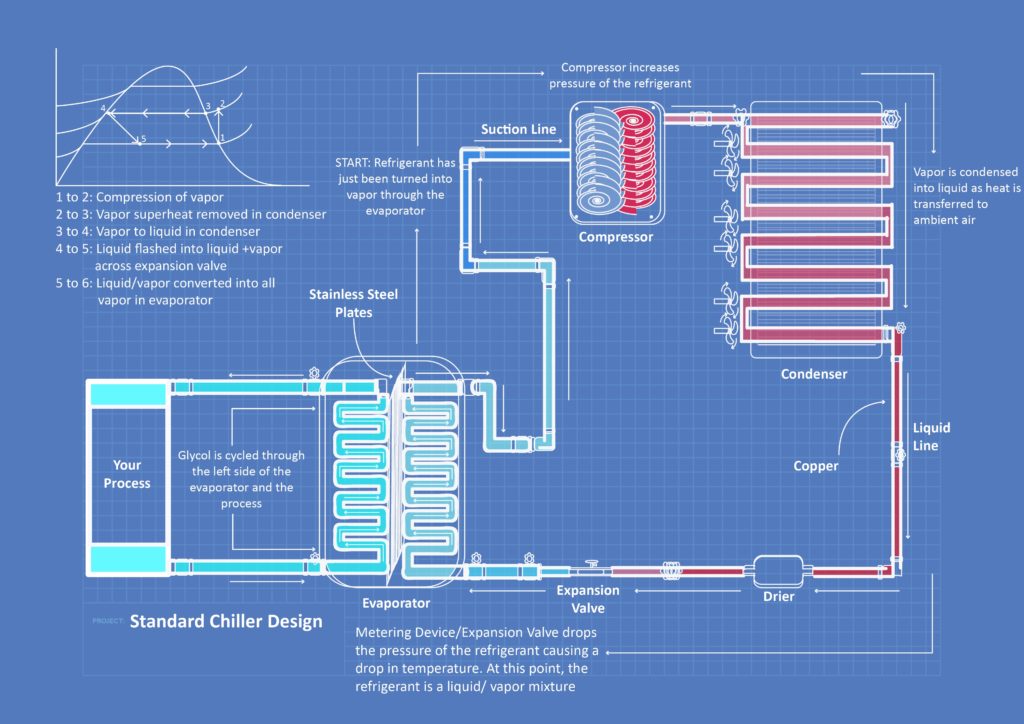

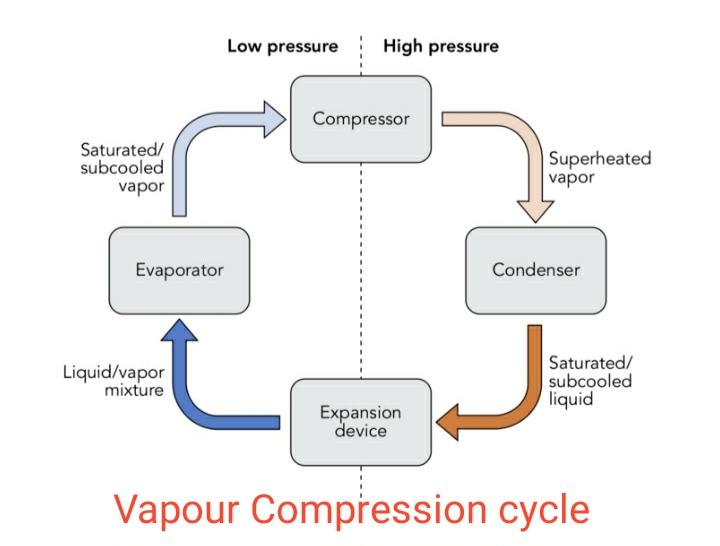

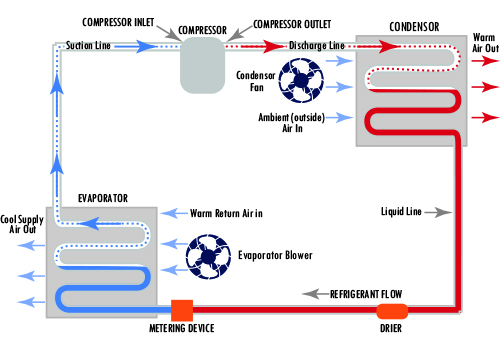

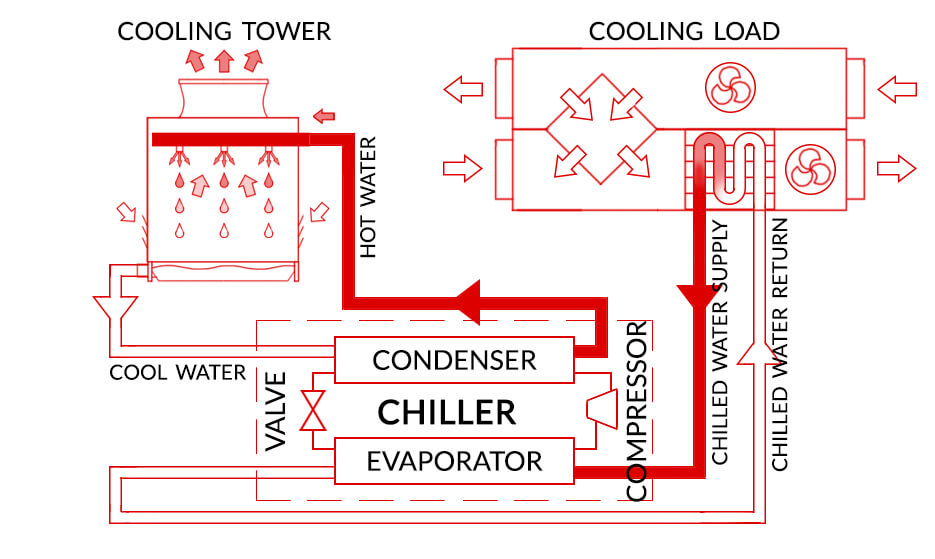

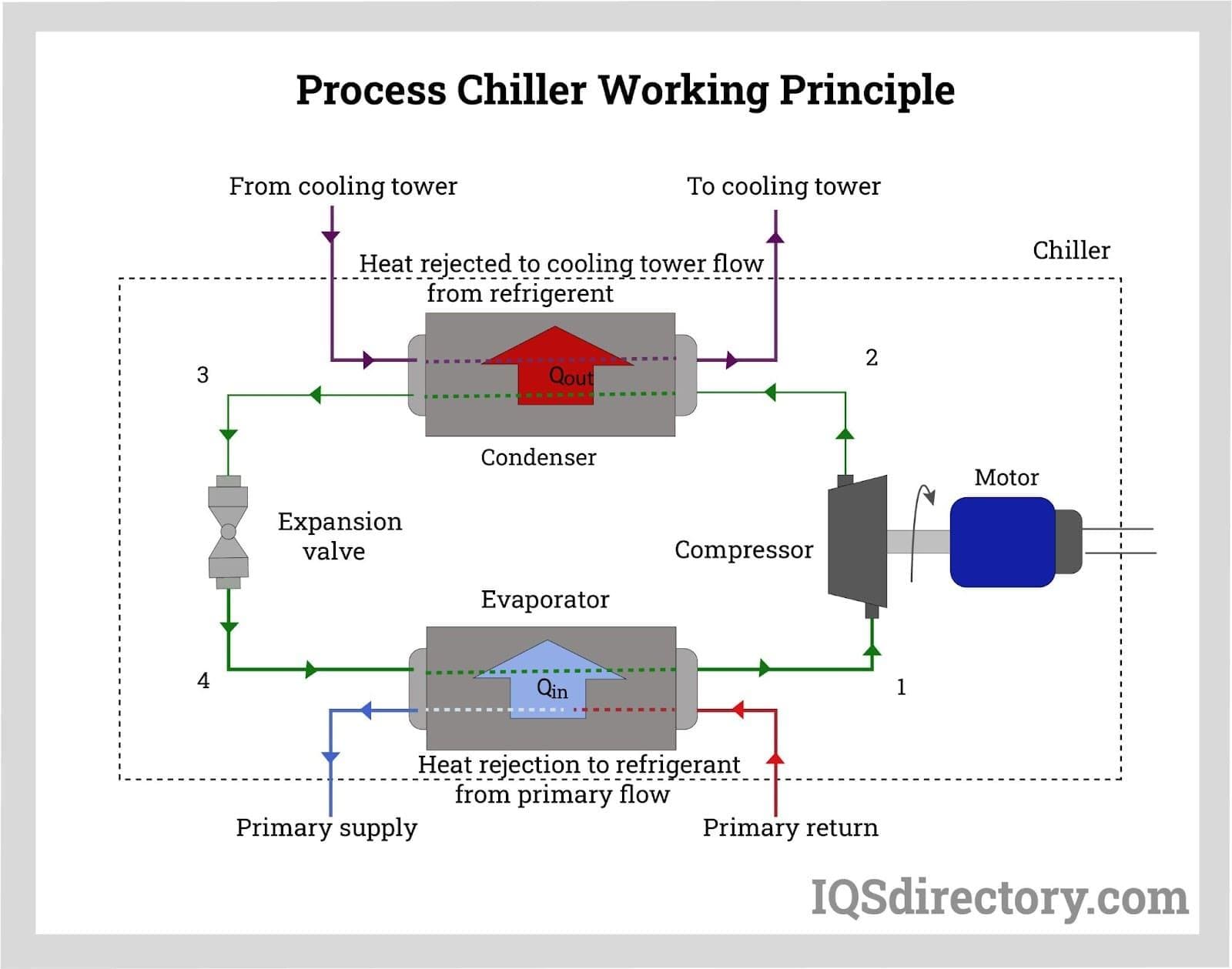

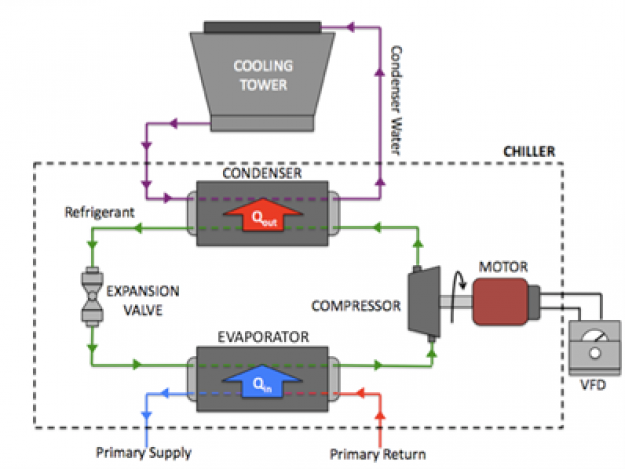

Understanding the refrigeration cycle is essential for making informed purchasing decisions, particularly in regions such as Africa, South America, the Middle East, and Europe, where market dynamics and regulatory environments can differ markedly. From evaluating the specific needs of your operations to vetting suppliers and assessing cost implications, this guide equips international buyers with actionable insights. By exploring the nuances of chiller systems, including evaporators, compressors, condensers, and expansion devices, you will be empowered to select the right solution that meets your unique requirements and enhances your operational efficiency.

Navigating the complexities of the chiller market need not be daunting. With the knowledge gained from this guide, B2B buyers can confidently approach their sourcing decisions, ensuring that they invest in technology that not only meets their cooling needs but also supports sustainable business practices.

Understanding chiller cycle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

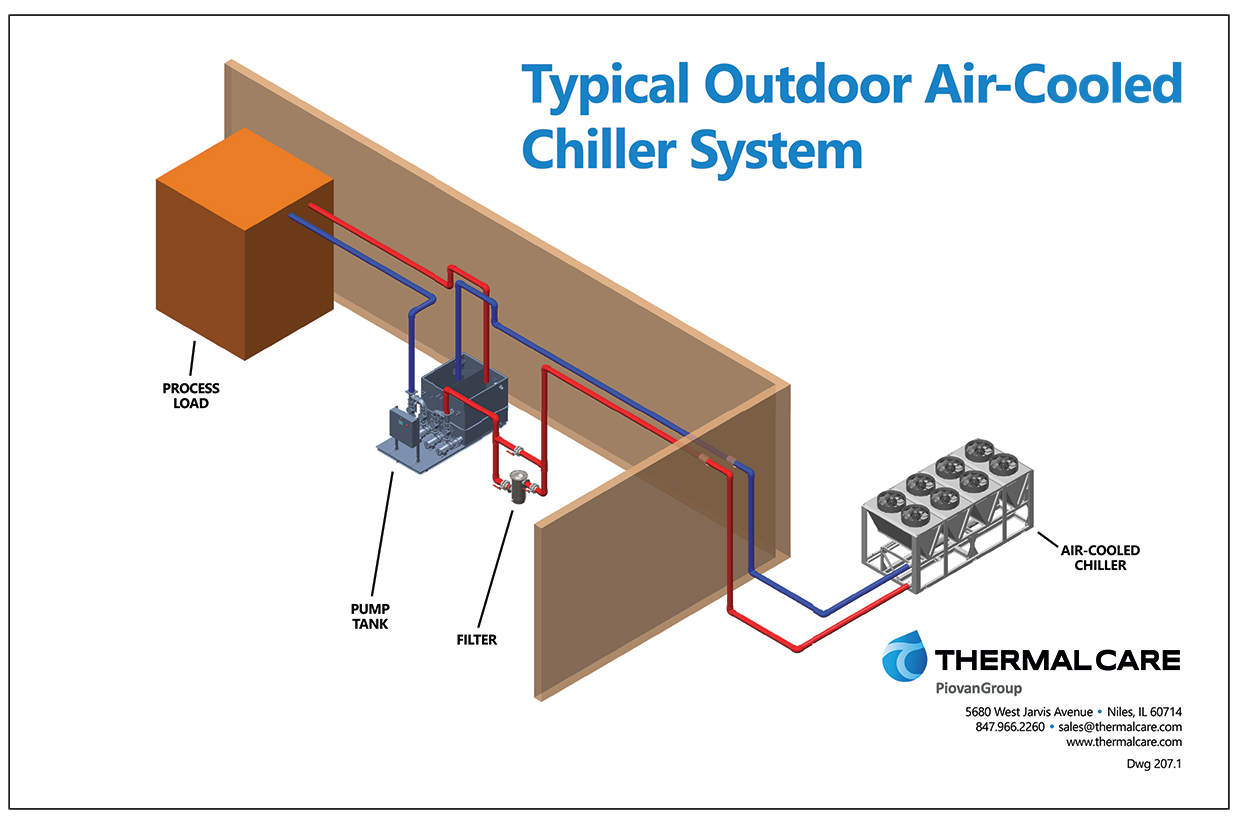

| Air-Cooled Chillers | Uses air as a cooling medium; compact design; easier installation | Commercial buildings, food processing | Pros: Lower installation cost; easier maintenance. Cons: Less efficient in high ambient temperatures. |

| Water-Cooled Chillers | Utilizes water for cooling; higher efficiency; larger footprint | Industrial applications, HVAC systems | Pros: More efficient; better for large-scale operations. Cons: Requires water supply and more complex installation. |

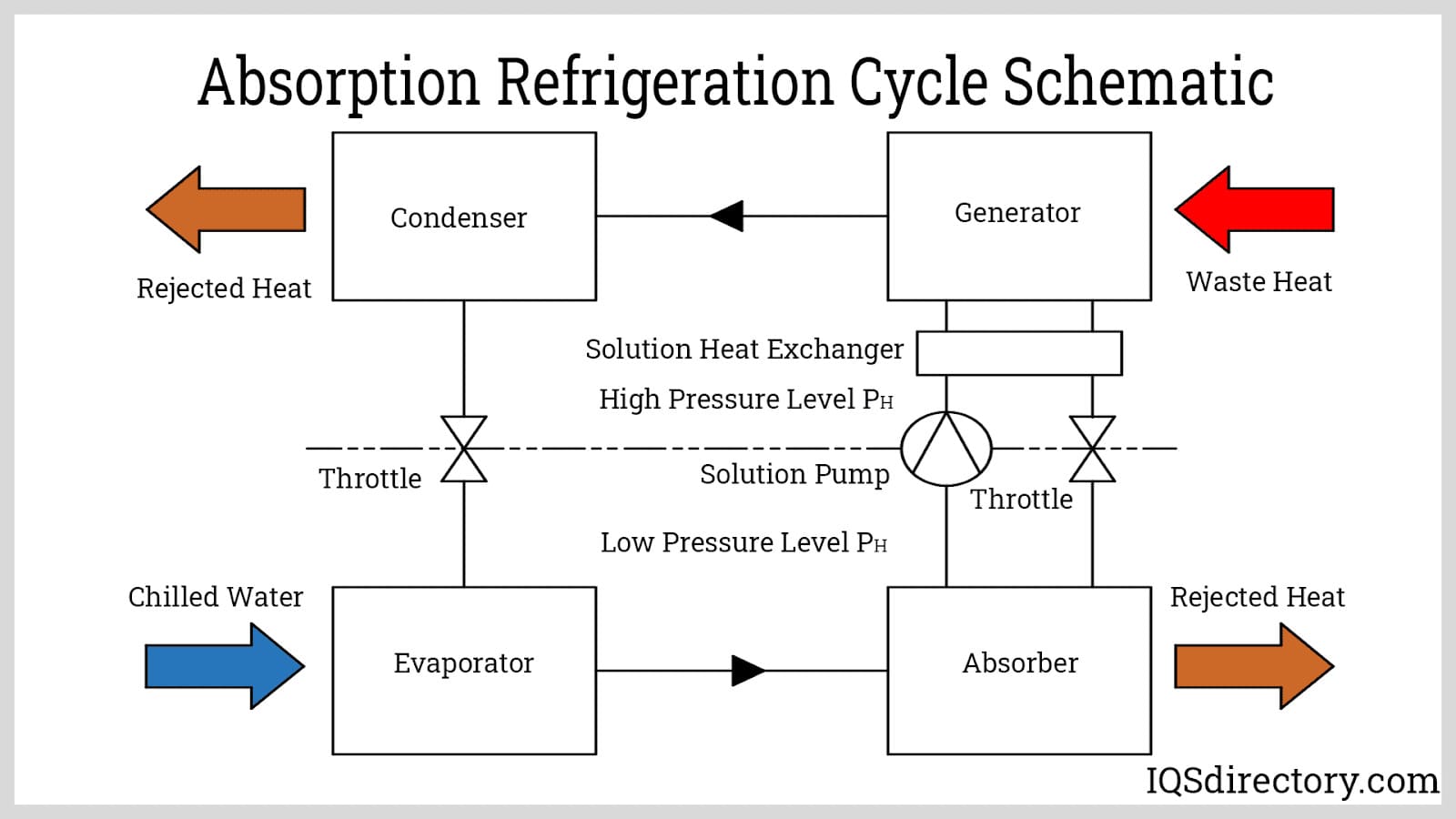

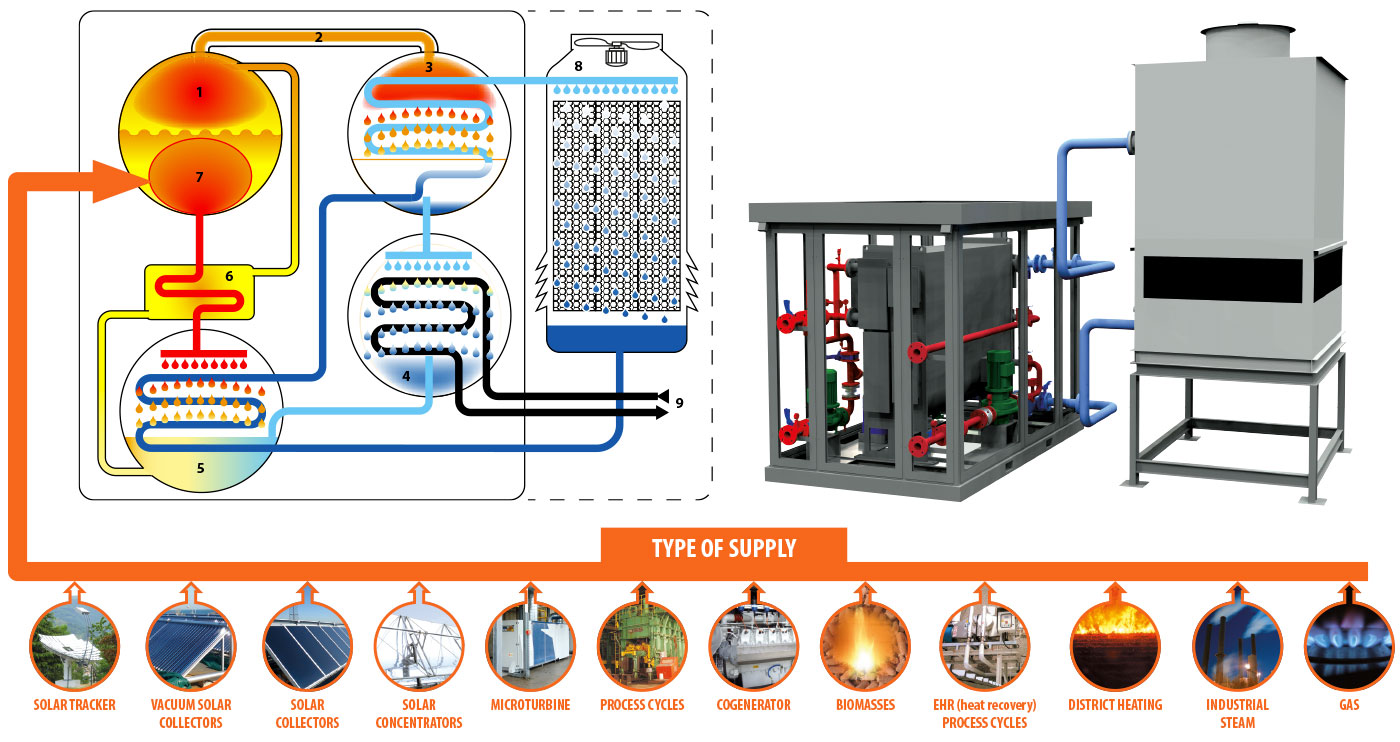

| Absorption Chillers | Operates on thermal energy instead of electricity; uses refrigerants like water or ammonia | Industrial cooling, district cooling systems | Pros: Can utilize waste heat; lower electricity costs. Cons: Higher initial investment; requires more space. |

| Screw Chillers | Employs screw compressors; ideal for large cooling capacities | Manufacturing, chemical processing | Pros: High efficiency; reliable for continuous operation. Cons: Higher upfront costs; more complex maintenance. |

| Centrifugal Chillers | Utilizes centrifugal force for refrigerant compression; suitable for large systems | Large commercial buildings, data centers | Pros: High efficiency; suitable for high-capacity needs. Cons: Higher noise levels; sensitive to fluctuating loads. |

What Are the Key Characteristics of Air-Cooled Chillers?

Air-cooled chillers are designed to use ambient air for cooling, making them a popular choice for many commercial applications. Their compact size allows for easier installation and less space consumption compared to water-cooled systems. These chillers are particularly effective in environments where water availability is limited. However, they may struggle with efficiency in extremely high ambient temperatures, which can impact performance. Buyers should consider their local climate and installation space when opting for air-cooled chillers.

How Do Water-Cooled Chillers Stand Out?

Water-cooled chillers are recognized for their efficiency and performance, utilizing water as the cooling medium. They are typically larger and more complex than air-cooled models, requiring a constant water supply, which can be a limiting factor in certain regions. These chillers excel in industrial applications where large cooling capacities are needed, making them ideal for HVAC systems and manufacturing processes. Buyers should evaluate their water availability and long-term operational costs when considering water-cooled options.

What Makes Absorption Chillers Unique?

Absorption chillers operate differently from traditional electric chillers, relying on thermal energy sources such as natural gas or steam. This makes them particularly attractive for industries looking to utilize waste heat or reduce electricity consumption. While they can significantly lower operational costs, absorption chillers typically require a higher initial investment and more space. Businesses should assess their energy sources and budget constraints to determine if absorption chillers are a suitable fit for their cooling needs.

Why Choose Screw Chillers for Large Applications?

Screw chillers are designed for high-capacity cooling and are known for their reliability and efficiency. They employ screw compressors, which offer continuous operation and are ideal for large manufacturing and chemical processing environments. While they come with a higher upfront cost and may require more intricate maintenance, their efficiency can translate to lower long-term energy expenses. Companies should consider their cooling demands and operational budget when exploring screw chiller options.

What Are the Advantages of Centrifugal Chillers?

Centrifugal chillers utilize centrifugal force to compress refrigerant, making them suitable for large-scale cooling applications such as data centers and commercial buildings. They are highly efficient and can handle large cooling loads, but they may produce higher noise levels and are sensitive to load fluctuations. When considering centrifugal chillers, buyers should evaluate their specific cooling needs, budget, and the potential impact of noise on their operations.

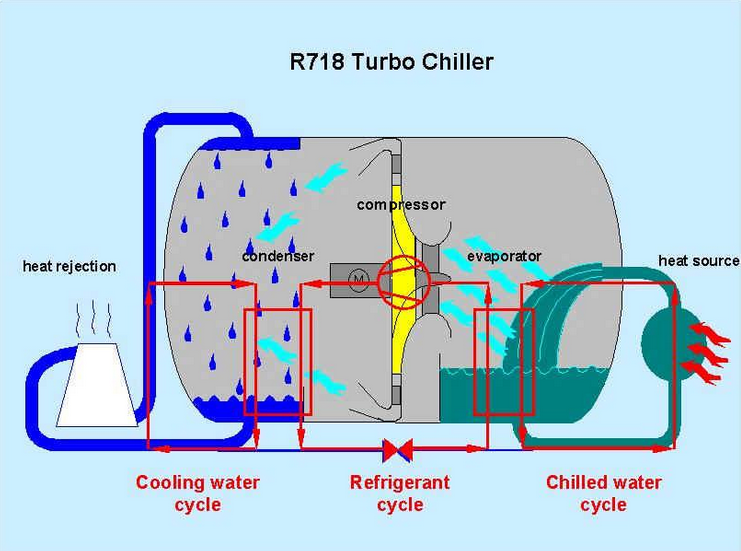

Illustrative image related to chiller cycle

Key Industrial Applications of chiller cycle

| Industry/Sector | Specific Application of chiller cycle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Cold storage for perishable goods | Extends shelf life, maintains quality and safety | Energy efficiency, capacity requirements, local regulations |

| Pharmaceuticals | Temperature-controlled storage for drugs | Ensures efficacy, compliance with regulations | Reliability, precision in temperature control, scalability |

| Medical Imaging | Cooling systems for MRI machines | Improves imaging quality, protects equipment | Compatibility with existing systems, maintenance support |

| Data Centers | Cooling for server rooms | Prevents overheating, enhances operational efficiency | Energy consumption, redundancy features, environmental impact |

| Chemical Processing | Process cooling in chemical reactions | Enhances reaction efficiency, ensures product quality | Material compatibility, safety standards, process scalability |

How is the chiller cycle applied in the food and beverage industry?

In the food and beverage sector, chillers are crucial for cold storage and transportation of perishable items. They maintain optimal temperatures to extend the shelf life of products like dairy, meat, and vegetables. This application addresses challenges such as spoilage and food safety compliance. For international buyers, especially in regions with varying climate conditions like Africa and South America, sourcing chillers with high energy efficiency and reliability is essential to minimize operational costs and meet local food safety regulations.

What role does the chiller cycle play in pharmaceuticals?

Chillers are vital in the pharmaceutical industry for the temperature-controlled storage of drugs and vaccines. They ensure that products are kept within specified temperature ranges, preserving their efficacy and complying with stringent regulatory standards. Problems such as degradation of sensitive materials are mitigated through effective cooling solutions. Buyers should consider the reliability and precision of temperature control systems, as well as the ability to scale operations based on demand, especially in emerging markets like Nigeria and Vietnam.

How does the chiller cycle enhance medical imaging technology?

In medical imaging, chillers are used to cool MRI machines and other imaging equipment. Efficient cooling is necessary to prevent overheating, which can affect imaging quality and damage sensitive components. This application helps healthcare providers deliver accurate diagnostics while ensuring equipment longevity. Buyers in the healthcare sector must prioritize compatibility with existing systems and the availability of maintenance support to ensure uninterrupted operations, particularly in regions with limited technical resources.

Illustrative image related to chiller cycle

Why is the chiller cycle critical for data centers?

Data centers utilize chillers to regulate temperature in server rooms, preventing overheating of critical IT infrastructure. This cooling is essential for maintaining operational efficiency and protecting against downtime, which can lead to significant financial losses. For international buyers, especially in hot climates, sourcing energy-efficient cooling solutions is vital to manage operational costs and environmental impact. Redundancy features are also crucial to ensure continuous cooling, even during equipment failures.

How is the chiller cycle utilized in chemical processing?

In chemical processing, chillers provide necessary cooling for various reactions, enhancing efficiency and ensuring product quality. By controlling temperatures, they help prevent unwanted reactions and maintain consistency in production. Buyers in this sector must consider material compatibility with chemicals, adherence to safety standards, and scalability of the cooling solution to accommodate varying production volumes, particularly in rapidly developing regions.

3 Common User Pain Points for ‘chiller cycle’ & Their Solutions

Scenario 1: Inconsistent Cooling Leading to Product Spoilage

The Problem: In industries such as food processing and pharmaceuticals, maintaining a consistent temperature is critical. A B2B buyer might experience issues with their chiller cycle where fluctuations in cooling lead to product spoilage. For example, a frozen food distributor may notice that their products are thawing unexpectedly, resulting in significant financial losses and reputational damage. This inconsistency can stem from various factors, including faulty sensors, poor maintenance practices, or inadequate system design.

The Solution: To address this challenge, buyers should prioritize the implementation of a comprehensive monitoring and maintenance program. This includes investing in advanced temperature sensors that provide real-time data on the cooling process. Collaborating with a reliable chiller manufacturer can help buyers design a system tailored to their specific needs, ensuring optimal performance. Additionally, establishing a regular maintenance schedule with qualified technicians can help identify and resolve potential issues before they escalate. By proactively managing the chiller system, buyers can maintain consistent cooling, thereby safeguarding their products and minimizing financial risk.

Illustrative image related to chiller cycle

Scenario 2: High Energy Costs Due to Inefficient Chiller Operation

The Problem: Many businesses face skyrocketing energy costs associated with running their chiller systems. A manufacturing facility may discover that its energy bills have increased dramatically, impacting profit margins. Inefficiencies could arise from outdated equipment, improper sizing of the chiller, or lack of optimization in the refrigeration cycle. These inefficiencies not only drain resources but can also lead to equipment failure, further compounding operational costs.

The Solution: To combat high energy costs, buyers should conduct an energy audit of their chiller systems. This audit can help identify inefficiencies and suggest improvements. For instance, upgrading to variable speed drives on compressors can enhance efficiency by adjusting motor speed according to the cooling demand. Furthermore, investing in energy-efficient chillers designed with advanced technologies can yield significant long-term savings. Buyers should also consider implementing a chiller management system that optimizes the refrigeration cycle dynamically based on real-time data, thereby reducing unnecessary energy consumption. By prioritizing energy efficiency, businesses can lower operational costs and enhance their bottom line.

Scenario 3: Complexity in Chiller System Integration

The Problem: For many B2B buyers, integrating a new chiller system with existing infrastructure can be a daunting task. Companies involved in industrial processes may struggle with compatibility issues, leading to downtime and operational disruptions. This challenge is often compounded when dealing with older systems or when attempting to implement advanced technologies that require specific configurations or upgrades.

The Solution: To streamline integration, buyers should engage with vendors who offer comprehensive engineering support and consultation services. A thorough assessment of the current system is essential before making any changes. Collaborating with experienced professionals can help identify potential integration challenges and design a phased implementation strategy that minimizes downtime. Additionally, selecting chillers that are designed with modular components can facilitate easier integration and future upgrades. Buyers should also ensure that their staff is adequately trained on the new system to maximize efficiency and minimize disruptions. By approaching integration thoughtfully, businesses can enhance their operational capabilities without sacrificing productivity.

Strategic Material Selection Guide for chiller cycle

What Are the Key Materials Used in Chiller Cycles?

When selecting materials for chiller cycles, several factors must be considered, including thermal conductivity, corrosion resistance, and mechanical strength. The following analysis covers four common materials used in chiller systems, providing insights into their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Copper Perform in Chiller Applications?

Copper is widely recognized for its excellent thermal conductivity, making it a preferred choice for heat exchangers and evaporators in chiller systems. With a temperature rating of up to 200°C and good pressure resistance, copper can efficiently transfer heat, enhancing the overall performance of the chiller.

Pros: Copper’s durability and resistance to corrosion, especially in water-cooled systems, make it suitable for long-term use. It is also relatively easy to fabricate and join, allowing for versatile design options.

Cons: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, copper is susceptible to pitting corrosion in certain water conditions, necessitating careful consideration of water chemistry.

Impact on Application: Copper is compatible with various refrigerants, but its performance can be affected by the presence of certain impurities in the fluid. Buyers should ensure that the selected refrigerant is compatible with copper to avoid issues.

Illustrative image related to chiller cycle

Considerations for International Buyers: Compliance with standards such as ASTM B280 for copper tubes is crucial. Buyers from regions like Africa and South America should also consider local availability and pricing fluctuations, which can impact overall project costs.

What Role Does Aluminum Play in Chiller Systems?

Aluminum is another popular material used in chiller applications, particularly for condensers and evaporators. Its lightweight nature and good thermal conductivity make it an attractive alternative to copper, with a temperature rating of approximately 150°C.

Pros: Aluminum is generally more cost-effective than copper, making it a budget-friendly option for large-scale installations. It also exhibits good corrosion resistance, especially when anodized or treated.

Cons: While aluminum is durable, it is less robust than copper and can be more prone to mechanical failure under high-stress conditions. Additionally, its thermal conductivity is lower than that of copper, which may affect efficiency in some applications.

Impact on Application: Aluminum is compatible with a wide range of refrigerants but can be affected by certain chemical reactions, particularly with ammonia. Proper selection of materials is essential to avoid degradation.

Considerations for International Buyers: Aluminum components must comply with standards such as ASTM B221. Buyers in Europe and the Middle East should be aware of the varying regulations regarding aluminum quality and treatment processes.

Why is Stainless Steel a Preferred Material for Chillers?

Stainless steel is often selected for its exceptional corrosion resistance and mechanical strength, making it ideal for high-pressure applications in chiller systems. Its temperature rating can exceed 300°C, allowing for a wide operational range.

Pros: The durability of stainless steel ensures a long lifespan, reducing maintenance costs over time. It is also highly resistant to various chemicals, making it suitable for diverse applications.

Cons: Stainless steel is generally more expensive than both copper and aluminum, which can impact budget considerations. Additionally, its weight may require more robust support structures in installation.

Impact on Application: Stainless steel is compatible with most refrigerants and is particularly effective in environments where corrosion is a significant concern. Its robustness ensures reliable performance in demanding conditions.

Illustrative image related to chiller cycle

Considerations for International Buyers: Compliance with standards such as ASTM A312 for stainless steel pipes is essential. Buyers from regions like Africa should consider the availability of certified stainless steel to ensure quality.

How Does Plastic Material Fit into Chiller Applications?

Plastic materials, such as PVC and polyethylene, are increasingly being used in chiller systems for certain components, particularly in applications where corrosion resistance is paramount. These materials can withstand temperatures up to 80°C.

Pros: Plastics are lightweight, cost-effective, and resistant to corrosion and chemical reactions, making them suitable for various environments. They also offer excellent insulation properties.

Cons: Plastics have lower mechanical strength compared to metals and may not withstand high-pressure applications. Their thermal conductivity is also significantly lower, which can affect overall system efficiency.

Impact on Application: While plastics are compatible with many refrigerants, their use may be limited in high-temperature or high-pressure scenarios. Buyers must evaluate the specific application requirements before selecting plastic components.

Illustrative image related to chiller cycle

Considerations for International Buyers: Compliance with standards such as ASTM D1784 for PVC is critical. Buyers in regions like South America should be aware of local regulations regarding plastic materials and their certifications.

Summary Table of Material Selection for Chiller Cycles

| Material | Typical Use Case for chiller cycle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Heat exchangers, evaporators | Excellent thermal conductivity | High cost, pitting corrosion risk | High |

| Aluminum | Condensers, evaporators | Cost-effective, lightweight | Lower mechanical strength | Medium |

| Stainless Steel | High-pressure applications | Exceptional corrosion resistance | Higher cost, heavier weight | High |

| Plastic | Non-pressurized components | Corrosion resistant, lightweight | Lower strength, limited temperature range | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the chiller industry, enabling informed decisions that align with specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for chiller cycle

What Are the Key Stages in the Manufacturing Process of Chiller Cycles?

The manufacturing process of chillers is complex and involves several key stages that ensure the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Chiller Manufacturing?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality materials such as steel, aluminum, and specialized alloys that can withstand the pressures and temperatures of the refrigeration cycle. Suppliers are often vetted based on their ability to provide materials that comply with international standards like ISO 9001, which ensures quality management systems are in place.

Once materials are sourced, they undergo various treatments to enhance their properties. For instance, steel components may be galvanized or coated to prevent corrosion, which is crucial for the longevity of chillers in diverse environments, from humid climates in Africa to arid regions in the Middle East.

Illustrative image related to chiller cycle

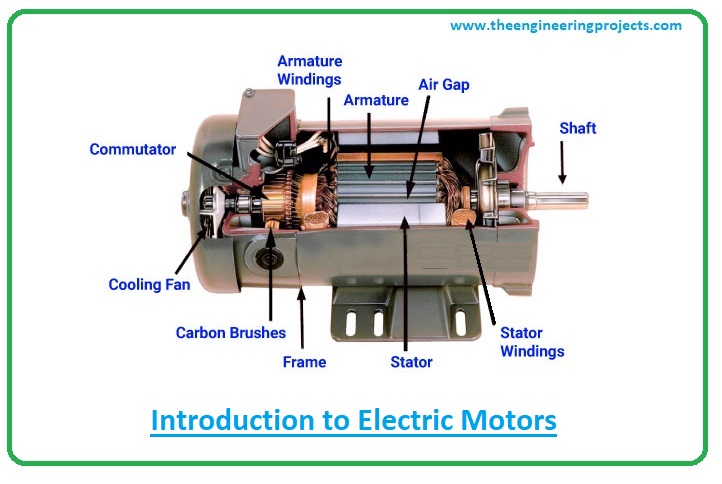

What Forming Techniques Are Commonly Used in Chiller Manufacturing?

The next stage is forming, where raw materials are shaped into the required components of the chiller. Techniques such as welding, machining, and bending are commonly employed.

- Welding: Used to join different metal components securely. Automated welding techniques, including MIG and TIG, enhance precision and reduce human error.

- Machining: This includes processes like turning and milling to achieve exact dimensions. Precision is critical, as any miscalculation can lead to inefficiencies in the chiller’s performance.

- Bending: Used for pipes and ducts that carry refrigerants. Advanced CNC bending machines ensure that bends are uniform, thus optimizing flow and reducing the risk of leaks.

How Does the Assembly Process Work for Chillers?

The assembly stage is where all the components come together. This involves a systematic approach where each part, from the compressor to the evaporator, is assembled in a clean and controlled environment to minimize contamination.

During assembly, quality control checkpoints are established. These include:

- Incoming Quality Control (IQC): Verification of incoming materials and components against specifications.

- In-Process Quality Control (IPQC): Monitoring during assembly to ensure each component is installed correctly and functions as intended.

- Final Quality Control (FQC): A thorough inspection of the assembled chiller, including functional testing to ensure that it operates efficiently under simulated conditions.

What Finishing Techniques Are Applied to Chillers?

The final stage of the manufacturing process is finishing, which includes surface treatments and testing. Surface treatments may involve painting or coating to enhance aesthetic appeal and corrosion resistance.

Additionally, chillers undergo rigorous testing to ensure they meet performance specifications. Common tests include:

- Pressure Testing: To ensure that the system can handle the operational pressures without leaks.

- Thermal Performance Testing: To verify that the chiller maintains the required temperature under load conditions.

What Are the International Standards for Quality Assurance in Chiller Manufacturing?

Quality assurance in chiller manufacturing is crucial for ensuring reliability and performance. International standards, such as ISO 9001, provide a framework for quality management systems, ensuring that manufacturers adhere to best practices throughout the production process.

In addition to ISO standards, industry-specific certifications play a significant role. For example:

- CE Marking: Required for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for chillers used in the oil and gas sector, ensuring equipment is suitable for demanding applications.

What Are the Key Quality Control Checkpoints in Chiller Manufacturing?

Quality control (QC) is integral to the manufacturing process. Various checkpoints ensure that each stage meets the required standards:

Illustrative image related to chiller cycle

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch any deviations early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to confirm it meets all performance and safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some actionable steps:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should look for documentation of compliance with international standards.

- Requesting Quality Reports: Suppliers should provide quality assurance documentation, including test results and certifications, demonstrating compliance with industry standards.

- Third-Party Inspections: Engaging independent inspection bodies can offer an unbiased assessment of the manufacturing processes and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must be aware of the nuances in quality control and certification that can affect purchasing decisions. For instance, certain certifications may be more valued in specific regions. In Europe, CE marking is critical, while in the Middle East, compliance with local regulations may take precedence.

Additionally, understanding the logistics of transporting chillers across borders can introduce challenges related to compliance with import regulations. Buyers should ensure that their suppliers are knowledgeable about these requirements and can provide the necessary documentation.

In conclusion, the manufacturing processes and quality assurance measures for chillers are intricate and essential for ensuring optimal performance and reliability. B2B buyers must prioritize suppliers who adhere to international standards and demonstrate rigorous quality control practices to secure the best products for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chiller cycle’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure a chiller cycle system. As chillers play a crucial role in various industries, understanding the procurement process can help ensure you select a solution that meets your operational needs while maximizing efficiency and reliability.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to clarify your technical requirements. Consider the cooling capacity needed, the type of refrigerant to be used, and the specific application for which the chiller will be employed.

– Cooling Capacity: Assess the heat load requirements of your facility to determine the appropriate chiller size.

– Refrigerant Type: Choose between traditional refrigerants and more environmentally friendly options, as regulations may influence your decision.

Step 2: Research Supplier Reputation

Investigate potential suppliers to gauge their credibility and reliability. Look for suppliers with a proven track record in your industry or region.

– Customer Reviews: Check online reviews and testimonials to understand other customers’ experiences.

– Industry Presence: A supplier with a long-standing presence in the market is often more reliable, showcasing stability and experience.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Case Studies: Ask for examples of previous projects that are comparable to your requirements to assess their capabilities.

– References: Speaking directly with past clients can provide insights into the supplier’s service quality and reliability.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you consider comply with international and local standards. This step is vital to avoid potential legal or operational issues down the line.

– Certifications: Look for ISO certifications or other relevant industry-specific credentials that affirm the supplier’s adherence to quality standards.

– Regulatory Compliance: Confirm that their products meet local environmental regulations, particularly concerning refrigerants.

Step 5: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals outlining their offerings. This should include specifications, pricing, and delivery timelines.

– Comparison Metrics: Use a standardized format to compare proposals side-by-side, ensuring all relevant factors are considered.

– Service Agreements: Pay attention to warranty and service terms, as these can significantly impact long-term operational costs.

Step 6: Conduct Site Visits and Inspections

If possible, conduct site visits to the supplier’s manufacturing facility or recent installation sites. This hands-on approach can provide valuable insights into their operational capabilities.

– Quality Control: Observe their quality control processes to ensure that they meet your standards.

– Technical Support: Engage with their technical team to understand the support services they offer post-purchase.

Step 7: Negotiate Terms and Finalize the Purchase

Once you are satisfied with a supplier, enter into negotiations to finalize the purchase terms. Ensure clarity on all aspects, including payment terms, delivery schedules, and after-sales support.

– Flexible Terms: Seek terms that allow for adjustments based on your operational needs.

– Documentation: Ensure that all agreements are documented to avoid misunderstandings in the future.

By following this checklist, B2B buyers can effectively navigate the procurement process for a chiller cycle, ensuring they select the best solution for their operational needs.

Comprehensive Cost and Pricing Analysis for chiller cycle Sourcing

Understanding the cost structure and pricing dynamics in chiller cycle sourcing is essential for B2B buyers looking to optimize their investments. This analysis highlights the key cost components, price influencers, and practical tips for negotiating and ensuring cost-efficiency, particularly for international buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Chiller Cycle Manufacturing?

A comprehensive cost structure for chiller cycles encompasses several critical elements:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality refrigerants, metals for the evaporator and condenser, and insulation materials are essential for performance and durability. Opting for eco-friendly refrigerants may incur higher initial costs but can lead to long-term savings through efficiency.

-

Labor: Labor costs vary by region and skill level. Skilled technicians are required for assembly and quality control. Regions with lower labor costs may offer competitive pricing, but it’s crucial to ensure that quality isn’t compromised.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: Depending on the complexity of the chiller design, tooling costs can be significant. Custom tooling for specialized components will increase initial investment but can enhance production efficiency.

-

Quality Control (QC): Stringent quality control measures are necessary to ensure that chillers meet industry standards and certifications. This can add to the cost but is essential for minimizing failures and warranty claims.

-

Logistics: Transportation and handling costs should not be overlooked, particularly for international shipments. These costs can vary significantly based on distance, mode of transport, and customs duties.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition, brand reputation, and perceived value.

How Do Price Influencers Affect Chiller Cycle Costs?

Several factors influence the pricing of chiller cycles:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in bulk pricing discounts. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Customized solutions tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or environmental standards) can drive up costs. Buyers should assess the value of these certifications against their operational needs.

-

Supplier Factors: Supplier reputation, reliability, and past performance can influence pricing. Established suppliers may charge a premium but often provide better support and warranty services.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance, which can significantly affect total costs.

What Are Effective Buyer Tips for Negotiating Chiller Cycle Prices?

-

Negotiate Based on Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, energy consumption, and potential downtime costs. This approach can lead to better long-term savings.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs or negotiate long-term contracts for better pricing.

-

Request Multiple Quotes: Engaging multiple suppliers can provide leverage in negotiations and help identify competitive pricing.

-

Assess Quality vs. Cost: While lower prices are attractive, compromising on quality can lead to higher operational costs and risks. Ensure that the chosen supplier meets required quality standards.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, tariffs, and local regulations that may affect pricing. Establishing a clear understanding of these factors can help mitigate unexpected costs.

Conclusion

Navigating the cost structure and pricing landscape of chiller cycle sourcing requires careful consideration of various factors. By understanding the components that contribute to costs and leveraging effective negotiation strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. It is essential to approach sourcing with a holistic view, focusing on long-term value rather than just initial expenditure.

Alternatives Analysis: Comparing chiller cycle With Other Solutions

Exploring Alternative Cooling Solutions for Industrial Applications

When considering cooling solutions for industrial applications, it’s essential to evaluate various options to determine the best fit for specific needs. The chiller cycle is a widely recognized method for temperature control, but alternatives exist that may offer distinct advantages depending on the context. This analysis compares the chiller cycle to two viable alternatives: evaporative cooling systems and thermoelectric cooling systems.

| Comparison Aspect | Chiller Cycle | Evaporative Cooling System | Thermoelectric Cooling System |

|---|---|---|---|

| Performance | High efficiency, effective for large-scale applications | Effective in hot, dry climates; lower efficiency in humid areas | Best for small-scale applications with precise temperature control |

| Cost | Higher upfront and operational costs | Lower initial investment; cost-effective for large areas | Moderate initial cost; higher operational costs due to energy consumption |

| Ease of Implementation | Requires professional installation and setup | Generally easier to install; can be DIY for small units | Straightforward installation; no moving parts required |

| Maintenance | Regular maintenance required; can be complex | Minimal maintenance; requires water supply and occasional cleaning | Low maintenance; solid-state design reduces wear and tear |

| Best Use Case | Industrial manufacturing, HVAC systems, medical imaging | Agricultural applications, cooling large outdoor areas | Electronics cooling, precision instruments, small-scale refrigeration |

Understanding Evaporative Cooling Systems

Evaporative cooling systems utilize the natural process of water evaporation to cool the air. This method is particularly effective in hot, dry climates where the humidity is low. The primary advantage of evaporative cooling is its cost-effectiveness, both in terms of initial investment and operational expenses. However, its efficiency diminishes significantly in humid environments, limiting its applicability. Maintenance requirements are minimal, but ensuring a consistent water supply is crucial for optimal performance.

Exploring Thermoelectric Cooling Systems

Thermoelectric cooling systems operate on the principle of the Peltier effect, where electricity is used to create a temperature differential. These systems are compact and can be easily integrated into small devices, making them ideal for electronics cooling and applications requiring precise temperature control. While their initial costs can be moderate, operational expenses may rise due to higher energy consumption, especially in larger setups. The solid-state design of thermoelectric systems means they require minimal maintenance, with no moving parts to wear out.

Choosing the Right Cooling Solution for Your Needs

Selecting the appropriate cooling solution involves assessing various factors, including performance requirements, budget constraints, and the specific environment in which the system will operate. The chiller cycle remains a robust choice for large-scale industrial applications due to its high efficiency and versatility. However, for less demanding cooling needs or specific environmental conditions, evaporative and thermoelectric systems may provide a more suitable and cost-effective solution.

Ultimately, B2B buyers should conduct a thorough analysis of their operational requirements and consult with industry experts to make informed decisions that align with their long-term goals and sustainability initiatives.

Essential Technical Properties and Trade Terminology for chiller cycle

What Are the Essential Technical Properties of Chiller Cycles?

Understanding the technical specifications of chiller cycles is crucial for B2B buyers, especially those involved in industries requiring precise temperature control. Here are several critical technical properties to consider:

-

Cooling Capacity (kW or BTU/hr)

Cooling capacity refers to the amount of heat a chiller can remove from a process or space within a specified time. It is typically measured in kilowatts (kW) or British Thermal Units per hour (BTU/hr). For B2B buyers, selecting a chiller with the appropriate cooling capacity is vital to ensure optimal performance and energy efficiency, ultimately impacting operational costs. -

Energy Efficiency Ratio (EER)

The Energy Efficiency Ratio measures a chiller’s cooling output relative to its energy consumption. A higher EER indicates a more efficient chiller. This metric is essential for businesses looking to minimize energy costs and adhere to environmental regulations. Understanding EER can lead to substantial savings over the lifecycle of the equipment. -

Refrigerant Type

The choice of refrigerant affects both the environmental impact and efficiency of the chiller. Common refrigerants include R-410A, R-134A, and ammonia. Buyers should be aware of regulations regarding refrigerants, as some substances may be phased out due to their ozone-depleting potential. Selecting a chiller with an environmentally friendly refrigerant can enhance a company’s sustainability profile. -

Operating Temperature Range

This specification defines the minimum and maximum temperatures at which a chiller can efficiently operate. Knowing the operating temperature range is crucial for buyers, as it ensures that the chiller can meet specific industrial needs without risking equipment failure or inefficiency. -

Material Grade

The construction materials of a chiller, including the type of metals and coatings used, can affect its durability and maintenance needs. For instance, stainless steel is often preferred for its corrosion resistance. Buyers should consider material grade to ensure longevity and reliability in varying environmental conditions.

Which Common Trade Terms Should B2B Buyers Know in Chiller Cycles?

Familiarity with industry jargon can greatly enhance communication and negotiation processes. Here are some common terms relevant to chiller cycles:

Illustrative image related to chiller cycle

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the chiller industry, knowing the OEM can help buyers assess the quality and reliability of the equipment being purchased. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to plan their purchases effectively and avoid excess inventory or under-ordering. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. Crafting a clear RFQ can streamline the procurement process and ensure that buyers receive accurate and competitive quotes from multiple vendors. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping responsibilities, risks, and costs associated with transporting chillers. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. Understanding lead time is critical for B2B buyers to manage project timelines and ensure that chillers arrive when needed to avoid disruptions in operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting chillers, ultimately enhancing operational efficiency and aligning with business objectives.

Navigating Market Dynamics and Sourcing Trends in the chiller cycle Sector

What are the Current Market Dynamics and Key Trends in the Chiller Cycle Sector?

The global chiller cycle market is experiencing robust growth driven by rising demand across various sectors, including pharmaceuticals, food and beverage, and industrial manufacturing. As industries increasingly recognize the critical role of temperature control in enhancing product quality and operational efficiency, chillers have become indispensable. Key trends include the adoption of advanced technologies such as IoT and smart monitoring systems, which allow for real-time temperature management and predictive maintenance.

Moreover, energy efficiency has emerged as a significant consideration for buyers, with many opting for chillers that meet stringent energy performance standards. In regions like Africa, South America, and the Middle East, the push for sustainable and efficient cooling solutions is particularly pronounced, given the rising temperatures and energy costs. International buyers from these regions are also focusing on securing reliable supply chains and sourcing partnerships that can offer flexible solutions tailored to local conditions, such as varying climate challenges and infrastructure limitations.

Emerging markets are increasingly investing in eco-friendly refrigerants, aligning with global regulatory shifts aimed at reducing greenhouse gas emissions. As regulations evolve, businesses must stay informed about compliance requirements to avoid penalties and ensure market access.

How is Sustainability and Ethical Sourcing Influencing the Chiller Cycle Sector?

Sustainability is no longer an optional consideration; it is a fundamental aspect of sourcing in the chiller cycle sector. The environmental impact of refrigerants, particularly those with high global warming potential, has prompted a shift toward more eco-friendly alternatives. Buyers are prioritizing chillers that utilize refrigerants with lower environmental footprints, such as hydrofluoroolefins (HFOs) or natural refrigerants like ammonia and CO2.

Ethical sourcing practices are also gaining traction. International B2B buyers are increasingly scrutinizing their supply chains to ensure that materials are sourced responsibly, with minimal impact on local ecosystems. Certifications such as ISO 14001 for environmental management systems and the Global GreenTag certification for sustainable materials are becoming critical differentiators for suppliers.

Furthermore, companies that demonstrate a commitment to ethical labor practices and sustainable operations are more likely to build trust with buyers. This trend emphasizes the importance of transparency in the supply chain, enabling buyers to make informed decisions that align with their sustainability goals.

Illustrative image related to chiller cycle

How Has the Chiller Cycle Sector Evolved Over Time?

The evolution of the chiller cycle sector reflects broader technological advancements and changing market needs. Initially, chillers relied on simple mechanical systems, but advancements in refrigerant technology and digital monitoring systems have significantly enhanced performance and efficiency. The introduction of variable speed drives and advanced compressors has allowed for greater energy savings and operational flexibility.

Historically, the focus was primarily on cooling efficiency; however, as environmental concerns became more prominent, the industry shifted towards sustainable practices and refrigerants. Today, the sector is at the forefront of innovation, integrating smart technologies that offer predictive analytics and remote monitoring capabilities. This evolution not only enhances operational efficiency but also positions the chiller cycle sector as a key player in global sustainability efforts, appealing to a growing base of eco-conscious buyers.

The ongoing trend towards digitization and sustainability will continue to shape the future of the chiller cycle market, providing ample opportunities for B2B buyers to engage with suppliers who prioritize efficiency, reliability, and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of chiller cycle

-

How do I determine the right chiller for my industry?

To select the most suitable chiller for your industry, assess your specific cooling requirements, including the desired temperature range, cooling capacity, and application type. Consider factors such as the ambient environment, energy efficiency, and compatibility with existing systems. Consulting with manufacturers or industry experts can provide insights into the best chiller types, whether air-cooled, water-cooled, or evaporative, ensuring that your choice meets operational demands and regulatory standards. -

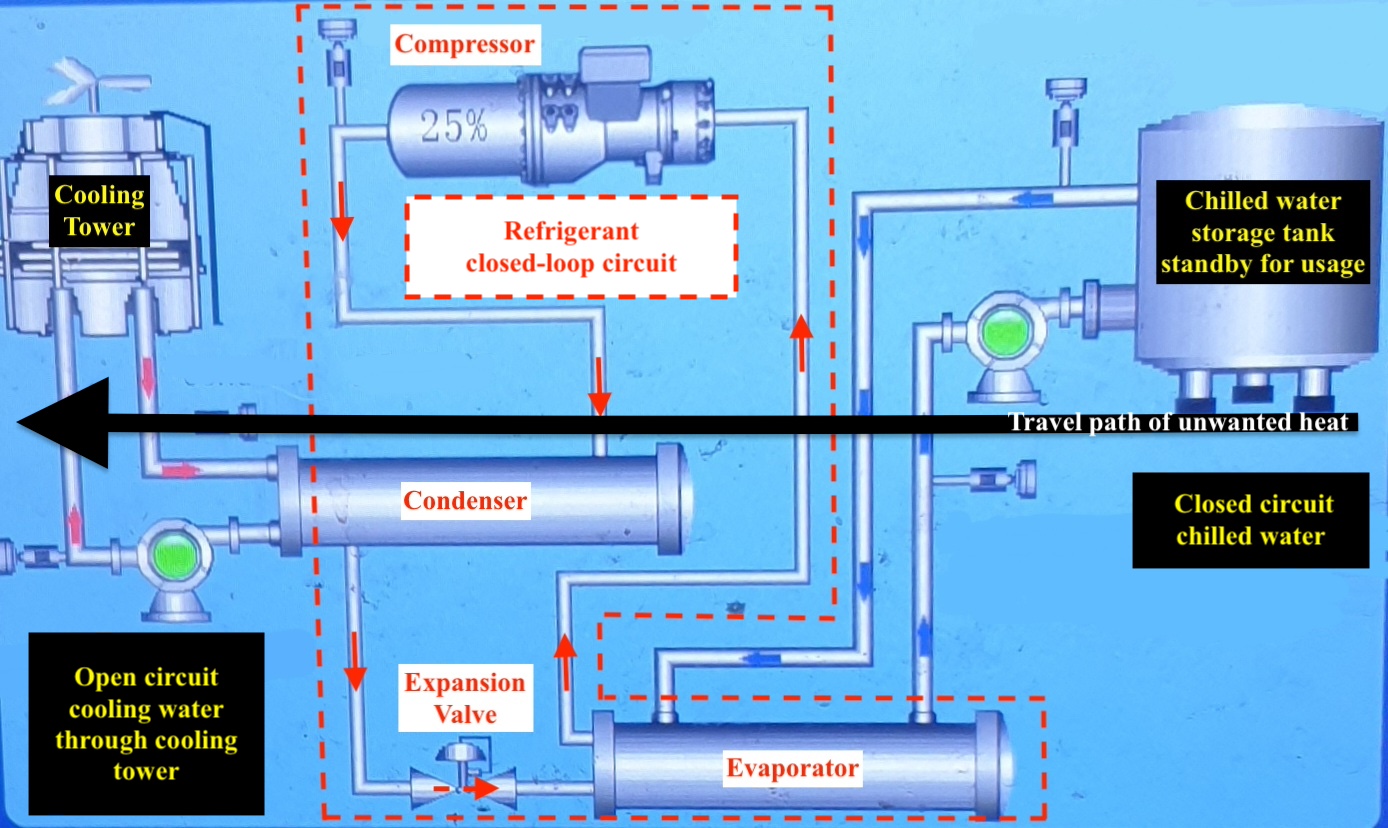

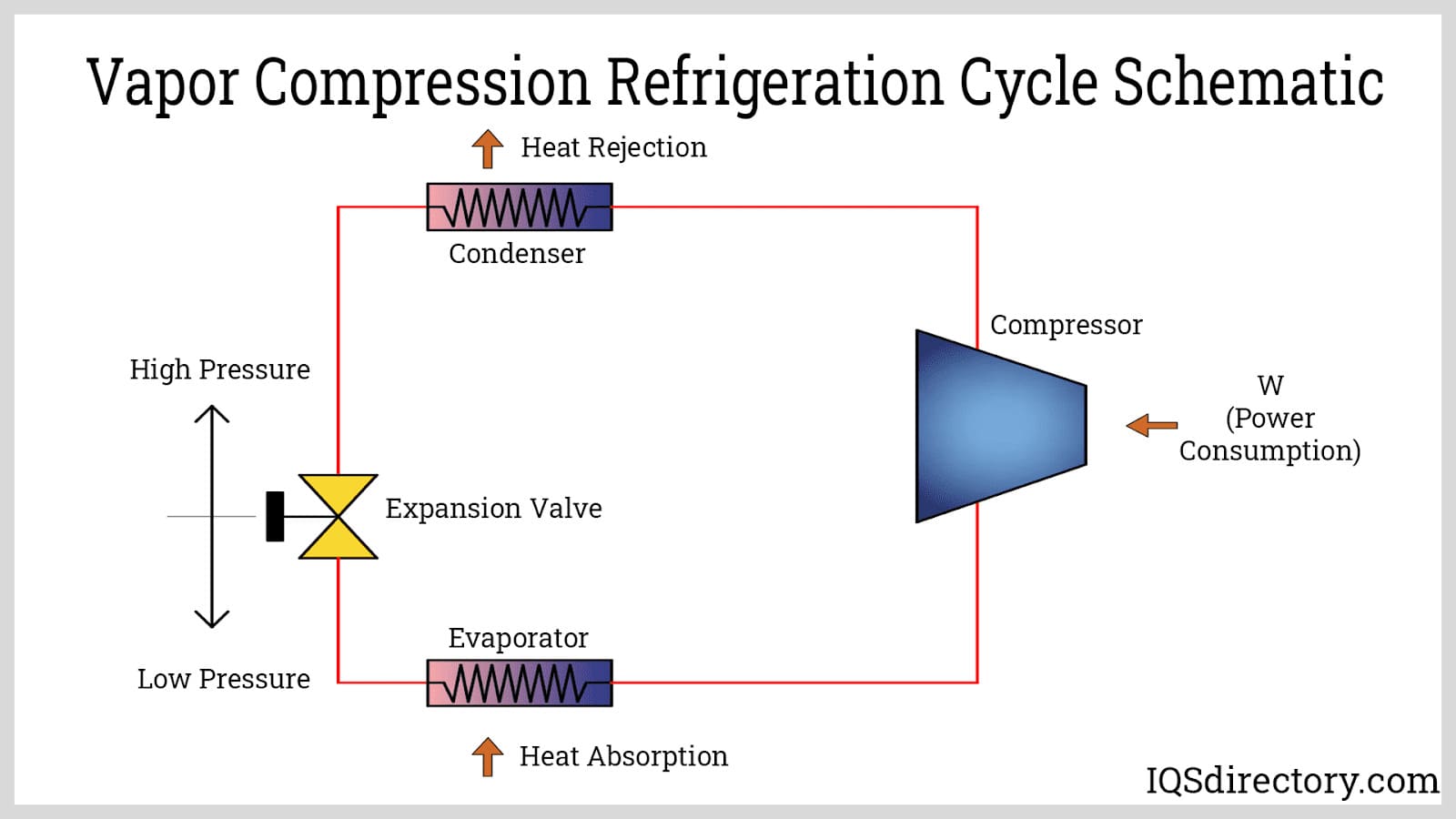

What are the key components of a chiller cycle?

The chiller cycle comprises four essential components: the evaporator, compressor, condenser, and expansion device. The evaporator absorbs heat from the process fluid, turning refrigerant into vapor. The compressor then increases the pressure and temperature of this vapor. In the condenser, heat is expelled, converting the refrigerant back into liquid form, which then passes through the expansion device to reduce pressure before re-entering the evaporator. Understanding these components helps in troubleshooting and optimizing chiller performance. -

What factors should I consider when vetting chiller suppliers?

When vetting chiller suppliers, evaluate their industry experience, reputation, and customer reviews. Check for certifications and compliance with international standards, as well as their ability to provide customized solutions that meet your specific needs. Assess their after-sales support, warranty offerings, and responsiveness to inquiries. A reliable supplier should also demonstrate transparency in pricing and terms, ensuring a trustworthy partnership for your business. -

What customization options are available for chillers?

Chillers can be customized based on various factors, including cooling capacity, energy efficiency ratings, and specific features tailored to your application. Options may include different refrigerant types, control systems, and integration with existing HVAC systems. Discussing your requirements with the manufacturer can lead to bespoke solutions that enhance performance and efficiency, ensuring that the chiller aligns with your operational goals. -

What is the minimum order quantity (MOQ) for chillers?

Minimum order quantities for chillers vary by manufacturer and depend on several factors, including the type of chiller and production capabilities. Generally, MOQs are established to ensure cost-effectiveness and production efficiency. Inquire with potential suppliers about their MOQs, as some may offer flexibility for smaller orders, especially for first-time buyers or long-term partners. Understanding MOQ helps in planning your procurement strategy and budget. -

What payment terms should I expect when purchasing chillers internationally?

Payment terms for international chiller purchases typically include options such as advance payment, letters of credit, or payment upon delivery. Suppliers may also offer flexible financing solutions, particularly for large orders. It’s crucial to clarify payment terms upfront to avoid misunderstandings and ensure a smooth transaction. Additionally, consider any currency exchange implications and transaction fees that may affect the total cost. -

How can I ensure quality assurance in chiller procurement?

To ensure quality assurance in chiller procurement, request detailed product specifications and performance certifications from the supplier. Implement a thorough inspection process upon delivery, checking for compliance with agreed-upon standards. Consider third-party testing or certification to validate product performance. Establishing a clear communication channel with the supplier for addressing any quality concerns can also help maintain high standards throughout the procurement process. -

What logistics considerations should I keep in mind for chiller shipments?

When planning logistics for chiller shipments, consider factors such as shipping methods, lead times, and customs regulations specific to your region. Ensure that the supplier has experience in international shipping and can provide proper packaging to protect the equipment during transit. Additionally, plan for potential delays at customs and ensure all necessary documentation is in place to facilitate a smooth import process. Collaborating with a logistics provider familiar with your destination can enhance efficiency and reduce risks.

Top 3 Chiller Cycle Manufacturers & Suppliers List

1. Chillers.com – Comprehensive Chiller Solutions

Domain: chillers.com

Registered: 1997 (28 years)

Introduction: Chiller types: plastics chillers, injection molding chillers, blow molding chillers, extrusion chillers, laser chillers, used chillers, brewery & winery chillers, distillery chillers, glycol chillers, anodizing and plating chillers, ice rink chillers, bakery chillers, machine tool chillers, medical MRI chillers, optical chillers, hydroponic chillers, hydraulic oil chillers, waterjet chillers, chem…

2. Johnson Controls – Chillers

Domain: johnsoncontrols.com

Registered: 1995 (30 years)

Introduction: This company, Johnson Controls – Chillers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Savree – Chiller Plant

Domain: savree.com

Registered: 2017 (8 years)

Introduction: Chiller Plant: A system that uses the vapour compression refrigeration cycle (VCRC) to cool buildings, vehicles, refrigerators, freezers, and industrial processes. Main components include: 1. Compressor: Increases refrigerant gas density and temperature; types include centrifugal, reciprocating piston, gear, lobe, and scroll designs. 2. Condenser: Cools high-pressure refrigerant gas to condense it…

Strategic Sourcing Conclusion and Outlook for chiller cycle

As global industries increasingly rely on efficient cooling systems, the strategic sourcing of chillers becomes paramount. Understanding the refrigeration cycle—comprising evaporation, compression, condensation, and expansion—allows businesses to make informed decisions that enhance operational efficiency and reduce energy costs. Selecting the right chiller not only prolongs equipment lifespan but also ensures optimal performance across diverse applications, from food preservation to medical imaging.

International buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with reputable suppliers who offer tailored solutions. Consideration of factors such as energy efficiency, maintenance support, and technological advancements will yield long-term benefits and drive competitive advantage in local markets.

Illustrative image related to chiller cycle

Looking ahead, the demand for chillers is set to grow as industries evolve and climate considerations become more pressing. By embracing strategic sourcing practices today, businesses can secure reliable cooling solutions that meet future challenges. Engage with industry experts and invest in the right chiller systems to unlock new opportunities and enhance your operational capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to chiller cycle