Chemi Coatings: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for chemi coatings

Navigating the complexities of sourcing high-quality chemi coatings can be a daunting challenge for international B2B buyers, especially in dynamic markets across Africa, South America, the Middle East, and Europe. As industries increasingly demand durable and innovative coating solutions to enhance product performance and longevity, understanding the nuances of the chemi coatings market becomes essential. This guide delves into various types of chemi coatings, their applications across different sectors, and the critical factors to consider when vetting suppliers.

In addition to outlining the diverse functionalities of chemi coatings—from industrial lubricants to electronic cleaners—this comprehensive resource equips buyers with actionable insights on pricing structures, quality certifications, and sourcing strategies. By addressing common pain points, such as ensuring product reliability and compliance with regional regulations, this guide empowers international B2B buyers to make informed purchasing decisions.

With a focus on building long-term partnerships with reputable suppliers, this guide offers a roadmap for navigating the global market. By leveraging the information within, businesses can enhance their procurement strategies, ultimately leading to improved operational efficiencies and competitive advantages in their respective markets. Whether you are based in Brazil, Nigeria, or elsewhere, understanding the landscape of chemi coatings is crucial to unlocking new opportunities for growth and innovation.

Understanding chemi coatings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Epoxy Coatings | High adhesion, chemical resistance, durable | Industrial flooring, machinery protection | Pros: Excellent durability; Cons: Longer curing time. |

| Polyurethane Coatings | Flexible, UV resistant, aesthetic options | Automotive, furniture, and exterior surfaces | Pros: Versatile finish; Cons: Can be more expensive. |

| Acrylic Coatings | Quick-drying, easy to apply, water-based | Commercial buildings, signage, and art | Pros: Fast application; Cons: Less chemical resistance. |

| Zinc-Rich Coatings | Corrosion resistance, galvanic protection | Metal structures, pipelines, and marine | Pros: Effective against rust; Cons: Requires careful application. |

| Thermal Spray Coatings | High-temperature resistance, thick application | Aerospace, automotive, and energy sectors | Pros: Excellent thermal protection; Cons: Surface preparation is critical. |

What are the Characteristics and Suitability of Epoxy Coatings for B2B Buyers?

Epoxy coatings are known for their superior adhesion and chemical resistance, making them ideal for industrial applications. They are commonly used in environments that require durability, such as factory floors and machinery protection. When considering epoxy coatings, B2B buyers should note their longer curing times, which may affect project timelines. However, their exceptional strength and resistance to wear make them a preferred choice for high-traffic areas.

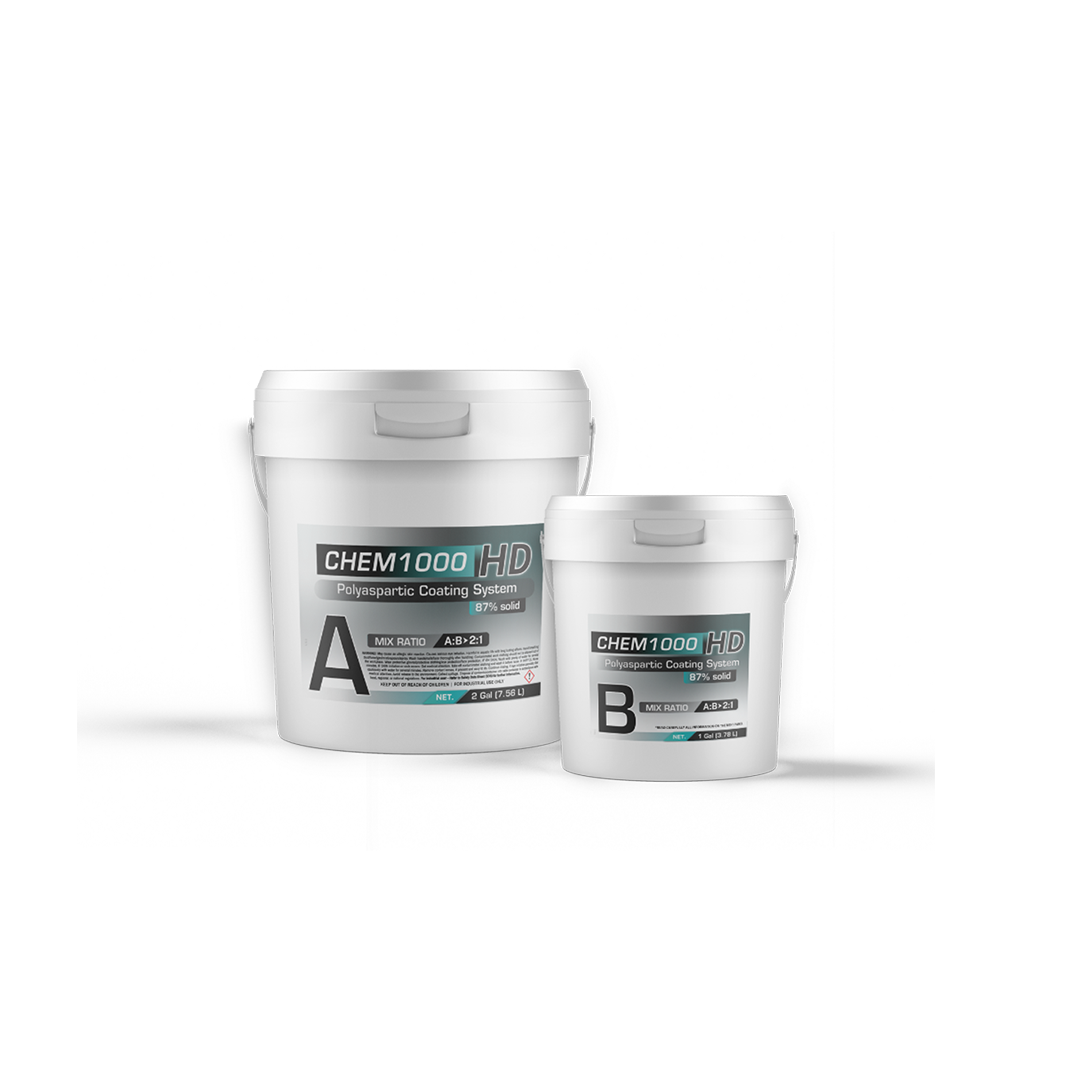

Illustrative image related to chemi coatings

How Do Polyurethane Coatings Stand Out in the Market?

Polyurethane coatings offer flexibility and UV resistance, making them suitable for a variety of applications, including automotive finishes and outdoor furniture. They provide an aesthetically pleasing finish and are available in numerous colors and gloss levels. B2B buyers should consider their cost, as polyurethane coatings can be more expensive than other options. However, their versatility and durability often justify the investment, particularly for high-end products.

What Advantages Do Acrylic Coatings Provide for Quick Applications?

Acrylic coatings are water-based and known for their quick-drying properties, making them easy to apply across various surfaces. They are commonly used for commercial buildings, signage, and artistic applications. B2B buyers should be aware that while acrylics are easy to work with and environmentally friendly, they may not offer the same level of chemical resistance as epoxy or polyurethane options. This makes them suitable for applications where rapid turnaround is essential.

Why Are Zinc-Rich Coatings Important for Corrosion Protection?

Zinc-rich coatings provide excellent corrosion resistance and are often used in metal structures, pipelines, and marine environments. They work through galvanic protection, which helps prevent rust and extends the lifespan of metal surfaces. Buyers should consider the application process, as zinc-rich coatings require careful handling to ensure proper adhesion and effectiveness. Their long-term benefits in corrosion prevention can significantly reduce maintenance costs.

Illustrative image related to chemi coatings

What are the Key Considerations for Thermal Spray Coatings in High-Temperature Applications?

Thermal spray coatings are engineered for high-temperature resistance and are commonly used in aerospace, automotive, and energy sectors. They create a thick protective layer that can withstand extreme conditions. B2B buyers must focus on surface preparation, as it is critical for achieving optimal adhesion and performance. While these coatings provide outstanding thermal protection, the complexity of their application can be a barrier for some businesses, making expertise in this area essential.

Key Industrial Applications of chemi coatings

| Industry/Sector | Specific Application of chemi coatings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Protective coatings for automotive parts | Enhanced durability and resistance to corrosion | Compliance with regional regulations and environmental standards |

| Food & Beverage | Sanitary coatings for food processing equipment | Improved hygiene and easier cleaning | Certification for food safety and resistance to chemicals |

| Construction & Infrastructure | Industrial floor coatings | Increased safety and longevity of flooring systems | Compatibility with local climate conditions and materials used |

| Electronics | Coatings for circuit boards and components | Protection against moisture and environmental factors | Precision in application and adherence to electrical standards |

| Oil & Gas | Corrosion-resistant coatings for pipelines | Extended lifespan of infrastructure and reduced downtime | Resistance to harsh chemicals and environmental conditions |

How Are Chemi Coatings Used in the Automotive Industry?

In the automotive sector, chemi coatings are employed to protect various components from corrosion, wear, and environmental damage. These coatings can be applied to engine parts, chassis, and exterior surfaces, significantly extending their lifespan and maintaining aesthetics. For international buyers, particularly in regions like Africa and South America, sourcing coatings that meet local environmental regulations is crucial. Additionally, the coatings should be compatible with the materials used in manufacturing, ensuring optimal performance and durability.

What Role Do Chemi Coatings Play in Food and Beverage Processing?

In the food and beverage industry, chemi coatings are essential for ensuring hygiene and safety in processing equipment. These coatings are designed to be non-toxic, resistant to harsh cleaning agents, and easy to maintain, which helps in meeting stringent food safety regulations. For buyers in the Middle East and Europe, it’s vital to ensure that these coatings are certified for food contact and can withstand the specific cleaning protocols of their facilities. This not only improves operational efficiency but also protects brand integrity.

How Are Chemi Coatings Beneficial in Construction and Infrastructure?

Chemi coatings serve a critical role in the construction and infrastructure sectors by providing durable floor coatings that enhance safety and longevity. These coatings can withstand heavy foot traffic, resist chemicals, and prevent slips, making them ideal for industrial and commercial spaces. Buyers from diverse climates must consider the specific performance characteristics of these coatings, including UV resistance and temperature tolerance, to ensure they meet local environmental conditions and standards.

Why Are Chemi Coatings Important in Electronics Manufacturing?

In electronics manufacturing, chemi coatings are used to protect circuit boards and components from moisture, dust, and other environmental factors that could compromise performance. These coatings ensure the reliability and longevity of electronic devices, which is crucial in a competitive market. International buyers should focus on sourcing coatings that comply with specific electrical standards and can be applied with precision to avoid interference with the functionality of sensitive components.

How Do Chemi Coatings Enhance Oil and Gas Operations?

In the oil and gas industry, chemi coatings are vital for protecting pipelines and equipment from corrosion caused by harsh chemicals and environmental conditions. These coatings not only extend the lifespan of assets but also reduce maintenance costs and downtime associated with repairs. Buyers in this sector, particularly from regions with extreme weather or corrosive environments, must prioritize sourcing coatings that are specifically formulated to withstand such challenges, ensuring operational efficiency and safety.

3 Common User Pain Points for ‘chemi coatings’ & Their Solutions

Scenario 1: Inconsistent Coating Performance Across Different Environments

The Problem: B2B buyers often face the challenge of inconsistent coating performance when using chemi coatings across various environments. For instance, a manufacturing facility in Brazil may experience high humidity, which can affect the adhesion and durability of the coatings used on equipment. Similarly, in colder climates like parts of Europe, the same coatings may not cure properly, leading to premature failure and necessitating costly reapplications.

Illustrative image related to chemi coatings

The Solution: To address this issue, it is crucial for buyers to conduct a thorough assessment of the specific environmental conditions where the coatings will be applied. This includes factors such as temperature fluctuations, humidity levels, and exposure to chemicals. B2B buyers should collaborate with manufacturers to choose specialized chemi coatings that are formulated for their specific environmental challenges. For example, selecting a coating that offers superior adhesion in high humidity or one that cures effectively at lower temperatures can significantly enhance performance. Additionally, conducting a small-scale pilot test of the selected coating under actual working conditions can provide insights into its effectiveness before a full-scale application.

Scenario 2: Difficulty in Compliance with Industry Standards

The Problem: Many B2B buyers in industries such as food processing or pharmaceuticals encounter strict regulatory standards that their chemi coatings must meet. Non-compliance can lead to severe penalties, product recalls, or reputational damage. For instance, if a coating contains harmful VOCs (volatile organic compounds), it may violate environmental regulations, causing production delays and financial losses.

The Solution: To ensure compliance, buyers should prioritize sourcing chemi coatings from reputable manufacturers that provide clear documentation regarding their products’ compliance with relevant industry standards. This includes certifications such as ISO, FDA, or EPA approvals, depending on the industry. B2B buyers should also invest time in understanding the specific regulations applicable to their operations and engage with suppliers to verify that the selected coatings meet these standards. Regular training for procurement teams on compliance requirements can further mitigate risks. Establishing a robust relationship with suppliers who are knowledgeable about regulatory issues can also streamline the compliance process, ensuring that the coatings used are not only effective but also legally compliant.

Scenario 3: High Costs of Application and Maintenance

The Problem: Another significant pain point for B2B buyers is the high costs associated with the application and maintenance of chemi coatings. This could arise from labor-intensive application processes, the need for multiple coats, or frequent maintenance due to premature wear. For instance, a company in Nigeria may find that its existing coating requires reapplication every few months, leading to increased downtime and labor costs.

Illustrative image related to chemi coatings

The Solution: To tackle high application and maintenance costs, buyers should consider investing in high-performance chemi coatings designed for long-lasting durability and reduced maintenance needs. Conducting a cost-benefit analysis can help buyers identify coatings that, while potentially higher in upfront cost, offer significant savings in terms of longevity and reduced labor for maintenance. Furthermore, employing advanced application techniques, such as spray-on or electrostatic coating methods, can enhance coverage and adhesion, reducing the need for multiple coats. Buyers should also explore training opportunities for their staff on proper application techniques to maximize the effectiveness of the coatings and minimize waste. Engaging with suppliers who offer ongoing support and recommendations on best practices for maintenance can further optimize costs over the product lifecycle.

Strategic Material Selection Guide for chemi coatings

What Are the Key Materials Used in Chemi Coatings?

When selecting materials for chemi coatings, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in chemi coatings, focusing on their performance characteristics and implications for international B2B buyers.

Epoxy Resins: A Versatile Choice for Industrial Applications

Epoxy resins are widely recognized for their excellent adhesion, chemical resistance, and durability. They can withstand high temperatures (up to 150°C) and provide exceptional protection against corrosion, making them suitable for various industrial environments. However, they can be more expensive than other options, and their manufacturing process can be complex, requiring precise mixing and curing conditions.

For international buyers, especially in regions like Africa and South America, it is crucial to ensure compliance with local regulations regarding VOC emissions and safety standards. Epoxy coatings often meet ASTM and DIN standards, which can facilitate their acceptance in diverse markets.

Illustrative image related to chemi coatings

Polyurethane Coatings: Flexibility and Aesthetic Appeal

Polyurethane coatings offer a unique combination of flexibility and hardness, making them ideal for applications requiring abrasion resistance and UV stability. They are often used in automotive and architectural finishes due to their aesthetic qualities and ability to maintain color over time. However, they typically have a lower temperature resistance compared to epoxy resins, withstanding up to 80-100°C.

International buyers should consider the specific environmental conditions of their regions, such as humidity and temperature fluctuations, as these can impact the performance of polyurethane coatings. Additionally, understanding local compliance with standards like JIS can help ensure product suitability.

Acrylic Coatings: Quick-Drying and Cost-Effective Solutions

Acrylic coatings are known for their rapid drying times and ease of application, making them a popular choice in various sectors, including construction and automotive. They offer decent chemical resistance and can be formulated for both indoor and outdoor use. However, their durability may not match that of epoxy or polyurethane coatings, particularly in harsh environments.

For B2B buyers in the Middle East and Europe, it is essential to evaluate the specific application requirements, as acrylic coatings may not perform well under extreme conditions. Compliance with local standards, such as EN or ISO, is also crucial to ensure product acceptance in different markets.

Silicone Coatings: High-Temperature Resilience

Silicone coatings are particularly valued for their ability to withstand extreme temperatures (up to 300°C) and their excellent weather resistance. They are often used in applications requiring thermal insulation and protection against UV radiation. However, silicone coatings can be more expensive and may require specialized application techniques, which can complicate the manufacturing process.

Illustrative image related to chemi coatings

For international buyers, especially in regions with high-temperature environments, understanding the performance characteristics of silicone coatings is critical. Compliance with international standards such as ASTM can help facilitate market entry and acceptance.

Summary Table of Material Selection for Chemi Coatings

| Material | Typical Use Case for chemi coatings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Epoxy Resins | Industrial machinery and equipment | Excellent adhesion and corrosion resistance | Higher cost and complex manufacturing | High |

| Polyurethane | Automotive and architectural finishes | Flexibility and UV stability | Lower temperature resistance | Medium |

| Acrylic | Construction and automotive | Quick-drying and cost-effective | Moderate durability in harsh environments | Low |

| Silicone | High-temperature applications | Exceptional heat and weather resistance | Higher cost and specialized application required | High |

This guide provides a comprehensive overview of the materials commonly used in chemi coatings, helping international B2B buyers make informed decisions based on their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for chemi coatings

What Are the Key Stages in the Manufacturing Process of Chemi Coatings?

The manufacturing process for chemi coatings is a multi-faceted operation that typically involves several critical stages, including material preparation, forming, assembly, and finishing. Each of these stages plays a vital role in ensuring that the final product meets the high standards required by various industries.

Material Preparation: How Are Raw Materials Processed?

The first step in the manufacturing process is material preparation. This phase involves sourcing high-quality raw materials, such as resins, pigments, and solvents. Suppliers should prioritize materials that comply with international safety and environmental regulations. The materials are then subjected to rigorous quality checks to ensure they meet the required specifications before moving to the next stage.

Forming: What Techniques Are Used to Create Coatings?

Once the materials are prepared, they undergo forming processes. This can include mixing, blending, and emulsifying the components to create a uniform coating solution. Techniques such as high-shear mixing and ultrasonic dispersion may be employed to achieve the desired viscosity and consistency. Understanding these techniques is crucial for B2B buyers, as they can impact the performance and application of the coatings.

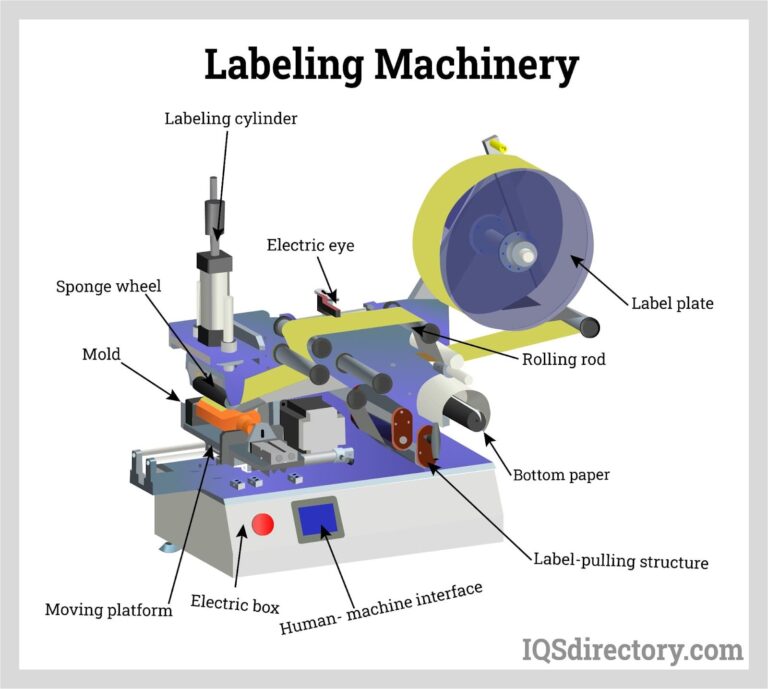

Assembly: How Are Coatings Packaged and Prepared for Distribution?

The assembly stage involves packaging the chemi coatings into appropriate containers, such as aerosol cans or bulk drums. This process must adhere to specific guidelines to ensure the integrity and safety of the products during transportation and storage. Companies often utilize automated filling systems to enhance efficiency and minimize human error, which can be a concern in manual operations.

Finishing: What Final Touches Are Applied to Ensure Quality?

Finishing touches include labeling, applying safety information, and conducting final inspections. This stage is critical, as it ensures that the product is ready for the market and complies with local regulations. Packaging must also be designed to protect the product from environmental factors, such as UV exposure and moisture, which could compromise the quality.

Illustrative image related to chemi coatings

What Quality Control Measures Are Essential in Chemi Coatings Manufacturing?

Quality assurance in the manufacturing of chemi coatings is paramount. B2B buyers should be aware of the various international standards and industry-specific certifications that suppliers may adhere to, such as ISO 9001, CE, and API standards. These certifications indicate a commitment to quality management systems and product safety.

What International Standards Should Buyers Look For?

ISO 9001 is a widely recognized standard that specifies requirements for a quality management system (QMS). Compliance with this standard ensures that suppliers consistently provide products that meet customer and regulatory requirements. Buyers should confirm that their suppliers have been certified by an accredited body and request copies of the certificates for verification.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that quality is maintained. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, samples may be taken for testing to identify any deviations from quality standards.

- Final Quality Control (FQC): Before products are shipped, they undergo a final inspection to ensure they meet all specifications and quality standards.

What Testing Methods Are Commonly Used for Chemi Coatings?

Common testing methods in the chemi coatings industry include:

- Adhesion Tests: To determine how well the coating bonds to the substrate.

- Chemical Resistance Tests: To evaluate how the coating performs when exposed to various chemicals.

- Durability Tests: To assess the longevity and wear resistance of the coating.

These tests help in validating the performance characteristics of the coatings and are essential for B2B buyers to understand.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying the quality control processes of potential suppliers is a crucial step for B2B buyers. Here are some actionable strategies:

Illustrative image related to chemi coatings

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits can provide insights into the operational and quality assurance practices of a manufacturer. Buyers should consider:

- On-site Audits: Visiting the manufacturing facility to observe processes and QC practices.

- Document Reviews: Examining quality control documents, including procedures, test results, and compliance certifications.

How Can Buyers Access QC Reports and Third-Party Inspections?

Requesting quality control reports from suppliers can provide additional assurance of their commitment to quality. Furthermore, engaging third-party inspection services can offer an unbiased assessment of the manufacturer’s quality processes. These services can conduct random checks and provide detailed reports on compliance with international standards.

What Are the Unique Quality Control Considerations for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, there are additional nuances to consider:

- Regulatory Compliance: Different regions may have varying regulations regarding chemical coatings. Buyers should ensure that suppliers comply with local regulations in their respective markets.

- Cultural Differences: Understanding cultural differences in business practices can affect negotiations and supplier relationships. Establishing clear communication channels is essential.

- Logistical Challenges: Shipping coatings internationally may pose challenges, such as customs regulations and import/export restrictions. Buyers should work with suppliers who have experience in international logistics to navigate these complexities.

Conclusion: How Can Buyers Ensure Quality in Chemi Coatings?

In conclusion, understanding the manufacturing processes and quality assurance measures in chemi coatings is crucial for B2B buyers. By focusing on the key stages of production, adhering to international standards, implementing rigorous QC checkpoints, and conducting thorough supplier evaluations, buyers can ensure they are sourcing high-quality chemi coatings that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chemi coatings’

Introduction

In the competitive landscape of industrial coatings, procuring high-quality chemi coatings is essential for ensuring product durability and performance. This guide aims to provide B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, with a practical checklist to streamline their sourcing process. By following these steps, businesses can make informed decisions and establish strong partnerships with reliable suppliers.

Illustrative image related to chemi coatings

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for chemi coatings. This includes understanding the specific materials you need to coat, environmental conditions the coatings will face, and any regulatory compliance standards applicable in your region.

- Consider factors such as:

- Temperature resistance

- Chemical exposure levels

- Desired finish and aesthetics

Step 2: Conduct Market Research on Suppliers

Take the time to research potential suppliers in the chemi coatings market. Investigate their product offerings, industry reputation, and geographical reach.

- Key elements to evaluate include:

- Customer reviews and testimonials

- Industry certifications (e.g., ISO, ASTM)

- Their experience with similar applications

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request detailed company profiles, case studies, and references from buyers in your industry or region.

- Look for:

- Evidence of successful projects

- Responsiveness to inquiries

- Willingness to provide samples or trial products

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers hold relevant certifications that validate their quality control processes and product performance. Certifications can indicate compliance with international standards and best practices.

Illustrative image related to chemi coatings

- Important certifications to check include:

- ISO 9001 for quality management

- Environmental certifications (e.g., ISO 14001)

- Specific industry-related certifications

Step 5: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of their chemi coatings. Testing samples allows you to assess the product’s performance against your specifications before making a bulk order.

- During testing, evaluate:

- Adhesion and durability

- Resistance to chemicals and environmental factors

- Ease of application

Step 6: Negotiate Terms and Conditions

Before finalizing your order, negotiate favorable terms and conditions with your chosen supplier. This includes pricing, delivery timelines, and payment terms.

- Consider discussing:

- Volume discounts for larger orders

- Return policies for unsatisfactory products

- Warranty terms on product performance

Step 7: Establish a Communication Plan

After selecting a supplier, establish a clear communication plan to ensure smooth interactions throughout the procurement process. Regular updates and feedback can help address issues promptly and foster a collaborative relationship.

- Include in your plan:

- Scheduled check-ins for order status

- Points of contact for different queries

- Feedback mechanisms for product performance

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing chemi coatings, ensuring they partner with suppliers that align with their business needs and quality standards.

Comprehensive Cost and Pricing Analysis for chemi coatings Sourcing

What Are the Key Cost Components in Chemi Coatings Sourcing?

When sourcing chemi coatings, understanding the cost structure is essential for effective budgeting and negotiations. The primary cost components include:

Illustrative image related to chemi coatings

- Materials: The quality and type of raw materials significantly impact the price. High-performance polymers or specialized chemical formulations can lead to higher costs but may offer enhanced durability and performance.

- Labor: Skilled labor is required for both production and quality assurance. Labor costs may vary based on the region and the complexity of the coating application.

- Manufacturing Overhead: This includes utilities, equipment depreciation, and facility maintenance costs. Efficient manufacturing processes can help minimize these overheads.

- Tooling: Custom tooling for specific applications can add to initial costs but may reduce production time and improve product consistency.

- Quality Control (QC): Rigorous QC processes ensure that products meet industry standards and client specifications, which can increase costs but ultimately reduce returns and enhance customer satisfaction.

- Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as transportation mode, distance, and packaging requirements will influence overall logistics costs.

- Margin: Supplier margins vary widely based on competition and perceived value. Understanding these margins can help buyers identify the most cost-effective options.

How Do Volume and Customization Affect Chemi Coatings Pricing?

Pricing for chemi coatings is often influenced by order volume and the level of customization required.

- Volume/MOQ: Suppliers frequently offer tiered pricing models based on minimum order quantities (MOQs). Larger orders can yield significant discounts, making it advantageous for businesses with high usage rates to consolidate orders.

- Specifications and Customization: Custom formulations or specific performance characteristics can lead to higher costs. Buyers should clearly communicate their requirements to avoid unexpected charges and delays.

What Role Do Material Quality and Certifications Play in Pricing?

Material quality and certifications are crucial factors in determining the price of chemi coatings. High-quality materials that meet international standards may come at a premium but can result in superior performance and longevity. Certifications like ISO or specific industry standards can also influence costs, as they often require additional testing and validation.

How Do Supplier Factors and Incoterms Impact Total Costs?

Supplier factors, including their reputation, location, and reliability, play a significant role in pricing. A supplier with a proven track record may charge more but offer added value in terms of service and quality assurance.

- Incoterms: Understanding Incoterms is vital for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Choosing the right Incoterm can significantly affect total landed costs.

What Are Effective Negotiation Strategies for B2B Buyers?

To maximize cost-efficiency in sourcing chemi coatings, consider the following negotiation strategies:

- Research and Benchmarking: Understand market rates and competitor offerings. This knowledge empowers buyers during negotiations.

- Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Establishing trust may also result in favorable payment terms or discounts.

- Discuss Total Cost of Ownership (TCO): Highlighting the long-term value and performance of the coatings can justify higher initial costs. This perspective can be particularly persuasive when negotiating with stakeholders focused on upfront pricing.

What Are the Pricing Nuances for International Buyers?

International buyers must navigate specific pricing nuances, particularly in regions like Africa, South America, the Middle East, and Europe. Currency fluctuations, import tariffs, and local market conditions can significantly impact pricing. Understanding these variables is crucial for accurate budgeting and cost management.

Conclusion: What Should Buyers Keep in Mind?

While this analysis provides a framework for understanding costs and pricing in chemi coatings sourcing, it is essential to note that prices can vary widely based on numerous factors. Buyers should approach negotiations equipped with knowledge and flexibility to secure the best value for their specific needs. Always seek multiple quotes and be prepared to discuss the nuances of your requirements to achieve the most favorable outcomes.

Alternatives Analysis: Comparing chemi coatings With Other Solutions

When evaluating coating solutions for industrial applications, it’s essential to consider various alternatives to ‘chemi coatings’. Each solution has unique benefits and drawbacks that can significantly impact operational efficiency, cost-effectiveness, and suitability for specific projects. This analysis will compare ‘chemi coatings’ with two prominent alternatives: epoxy coatings and polyurethane coatings.

| Comparison Aspect | Chemi Coatings | Epoxy Coatings | Polyurethane Coatings |

|---|---|---|---|

| Performance | Excellent chemical resistance, suitable for diverse environments | High durability, strong adhesion, and chemical resistance | Flexible, UV resistant, and abrasion-resistant |

| Cost | Moderate initial investment, long-term savings due to durability | Generally lower initial cost, but may require more frequent reapplication | Higher initial investment, but longer lifespan |

| Ease of Implementation | Requires surface preparation; application can be complex | Straightforward application, good for DIY projects | Requires skilled labor for optimal application |

| Maintenance | Low maintenance due to durability | Moderate maintenance; may need touch-ups | Low maintenance, but can be affected by harsh weather |

| Best Use Case | Industrial settings with exposure to harsh chemicals | Manufacturing floors, garages, and workshops | Automotive and outdoor applications requiring flexibility |

What are the Pros and Cons of Epoxy Coatings Compared to Chemi Coatings?

Epoxy coatings are known for their excellent bonding capabilities and durability. They provide a robust solution for environments that face heavy wear and tear, such as factory floors and warehouses. The lower initial cost makes them an attractive choice for budget-conscious projects. However, their lifespan may not match that of chemi coatings, as they can require more frequent reapplications, particularly in areas exposed to harsh chemicals or extreme conditions.

How Do Polyurethane Coatings Stack Up Against Chemi Coatings?

Polyurethane coatings offer a flexible solution that can withstand temperature fluctuations and UV exposure, making them ideal for outdoor applications. They maintain their aesthetic appeal longer than other coatings, resisting yellowing and fading. However, the application process can be complex, necessitating skilled labor to achieve the best results. The higher initial investment can deter some buyers, but their longevity can justify the cost over time.

How Can B2B Buyers Choose the Right Coating Solution for Their Needs?

Selecting the appropriate coating solution involves evaluating the specific requirements of your project, including environmental conditions, budget constraints, and desired lifespan. Buyers should consider the performance characteristics of each option, weighing factors such as chemical resistance, maintenance needs, and application complexity. Engaging with suppliers and seeking expert advice can further clarify which solution aligns best with operational goals and industry standards. Ultimately, choosing the right coating can enhance productivity and reduce long-term costs, making it a strategic investment for any business.

Illustrative image related to chemi coatings

Essential Technical Properties and Trade Terminology for chemi coatings

What Are the Key Technical Properties of Chemi Coatings?

Understanding the technical properties of chemi coatings is crucial for B2B buyers seeking to make informed purchasing decisions. Here are several critical specifications that should be considered:

1. Material Grade

Material grade refers to the classification of the coating based on its chemical composition and physical properties. High-grade materials typically offer superior resistance to wear, corrosion, and temperature variations. For B2B buyers, selecting the appropriate material grade ensures that the coating will perform effectively in its intended environment, enhancing product longevity and reducing maintenance costs.

2. Thickness Tolerance

Thickness tolerance indicates the permissible variation in the thickness of the coating. This specification is essential because it can affect the coating’s durability and performance. A tighter tolerance generally implies a more consistent and reliable application, which is critical for industries requiring precise specifications, such as automotive and aerospace. Buyers should verify thickness tolerances to ensure compliance with industry standards.

3. Adhesion Strength

Adhesion strength measures how well the coating bonds to the substrate material. This property is vital for ensuring that the coating will remain intact under stress, such as abrasion or thermal cycling. High adhesion strength minimizes the risk of delamination, which can lead to costly repairs and downtime. For B2B buyers, understanding adhesion strength can inform their choices regarding surface preparation and application methods.

4. Chemical Resistance

Chemical resistance refers to the coating’s ability to withstand exposure to various chemicals without degrading. This property is particularly important in industrial applications where coatings may come into contact with solvents, acids, or other corrosive substances. Buyers should assess the chemical resistance of a coating to ensure it meets the specific requirements of their operational environment, thus ensuring safety and compliance.

5. Thermal Stability

Thermal stability indicates how well a coating can maintain its properties under high temperatures. Coatings with excellent thermal stability are essential in environments where heat exposure is frequent, such as in manufacturing processes or automotive applications. B2B buyers must consider thermal stability to prevent premature failure of coatings, which can lead to increased operational costs.

Which Trade Terms Are Essential in the Chemi Coatings Industry?

Familiarizing yourself with industry-specific terminology can facilitate smoother transactions and better communication with suppliers. Here are some common trade terms:

Illustrative image related to chemi coatings

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the chemi coatings context, understanding OEM relationships is vital for buyers looking to source coatings that meet specific standards required by equipment manufacturers. This knowledge can influence purchasing decisions and supplier selection.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it can impact inventory management and cost efficiency. Understanding MOQs helps buyers assess whether they can meet their production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer solicits price quotes from suppliers for specific products or services. In the chemi coatings market, issuing an RFQ allows buyers to compare pricing, specifications, and terms from multiple suppliers, ensuring they make informed decisions based on competitive offers.

Illustrative image related to chemi coatings

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms is essential for B2B buyers involved in international transactions, as it defines who is responsible for shipping, insurance, and tariffs, thereby influencing overall cost and risk management.

5. Lead Time

Lead time is the duration between the initiation of an order and its fulfillment. This term is critical for B2B buyers, as it impacts project timelines and production schedules. Understanding lead times allows buyers to plan their operations effectively and avoid delays in product availability.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies for chemi coatings, leading to better outcomes and more effective supply chain management.

Navigating Market Dynamics and Sourcing Trends in the chemi coatings Sector

What Are the Key Market Dynamics and Trends Influencing the Chemi Coatings Sector?

The global chemi coatings market is experiencing a significant transformation driven by advancements in technology, increasing industrialization, and rising environmental regulations. Key drivers include the demand for high-performance coatings that can withstand extreme conditions, alongside the growing need for products that enhance durability and aesthetic appeal. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, staying abreast of these trends is crucial for making informed purchasing decisions.

Emerging technologies, such as nanotechnology and smart coatings, are redefining product capabilities. These innovations offer improved resistance to corrosion, UV degradation, and chemical exposure, making them ideal for various applications, from automotive to industrial machinery. Furthermore, digital platforms for sourcing are becoming more prevalent, enabling buyers to streamline procurement processes and enhance transparency. E-commerce solutions and digital marketplaces allow buyers from diverse regions to access a wider range of products and suppliers, fostering competitive pricing and better service options.

How Is Sustainability Shaping the Chemi Coatings Industry and B2B Sourcing?

Sustainability is increasingly becoming a focal point in the chemi coatings sector, driven by regulatory pressures and consumer demand for environmentally friendly products. The environmental impact of traditional coatings, which often contain volatile organic compounds (VOCs), has led to a surge in the adoption of ‘green’ alternatives. B2B buyers are now prioritizing suppliers who offer low-VOC or water-based coatings that align with sustainable practices.

Ethical sourcing is also gaining traction, as businesses recognize the importance of responsible supply chains in their operations. This includes ensuring that raw materials are sourced from suppliers who adhere to ethical labor practices and sustainable environmental policies. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can serve as valuable indicators for buyers looking to partner with responsible manufacturers. By focusing on sustainable products, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation and meet the growing demand for sustainable solutions in their markets.

What Is the Historical Context of Chemi Coatings and Its Relevance to Current B2B Trends?

The evolution of chemi coatings can be traced back to the industrial revolution, where the need for protective finishes for machinery and structures became paramount. As technology progressed, coatings evolved from basic oil-based products to advanced formulations that incorporate polymers, resins, and additives designed for specific performance characteristics.

Over the decades, the shift towards more specialized and high-performance coatings has been notable. The introduction of eco-friendly formulations in the late 20th century marked a significant turning point, as manufacturers began to respond to environmental concerns and regulatory demands. This historical context is essential for B2B buyers to understand the trajectory of product development and the importance of innovation in meeting modern challenges. As the sector continues to evolve, understanding this history will help buyers anticipate future trends and make strategic sourcing decisions.

Illustrative image related to chemi coatings

In conclusion, navigating the chemi coatings market requires awareness of current dynamics, an emphasis on sustainability, and a comprehension of the industry’s evolution. By aligning sourcing strategies with these insights, international B2B buyers can position themselves for success in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of chemi coatings

-

How do I select the right chemi coating for my specific application?

When choosing a chemi coating, consider the specific requirements of your application, including the material to be coated, environmental conditions, and desired durability. Consult with suppliers to understand the chemical resistance, temperature tolerance, and application methods of different coatings. Additionally, request samples to test compatibility and performance before making a bulk purchase. Engaging with a knowledgeable supplier can also provide insights into industry best practices and innovations that may suit your needs. -

What are the common types of chemi coatings available for industrial use?

Chemi coatings come in various formulations, including epoxy, polyurethane, and acrylic. Each type has distinct properties: epoxies offer excellent adhesion and chemical resistance, making them ideal for harsh environments; polyurethanes provide flexibility and UV resistance, suitable for outdoor applications; and acrylics are often used for their quick-drying and easy-to-apply nature. Assess your specific requirements, such as chemical exposure and mechanical stress, to determine which type is best for your application. -

What minimum order quantities (MOQ) should I expect when sourcing chemi coatings?

Minimum order quantities for chemi coatings can vary significantly based on the supplier and the specific product. Typically, MOQs can range from a few gallons to several hundred liters. It’s essential to discuss your needs with potential suppliers to find a mutually agreeable MOQ. If your requirements do not meet the MOQ, some suppliers may offer alternatives, such as combining orders with other clients or providing smaller batches at a premium. -

What payment terms should I negotiate with suppliers of chemi coatings?

When negotiating payment terms, consider options like net 30, net 60, or upfront payments, depending on your cash flow and relationship with the supplier. Some suppliers may offer discounts for early payments or larger orders. Additionally, inquire about payment methods accepted (e.g., wire transfers, credit cards) and the possibility of escrow services for larger transactions to ensure security. Clear communication about payment terms can help avoid misunderstandings later. -

How can I ensure quality assurance (QA) in chemi coatings?

To ensure quality assurance in chemi coatings, request detailed product specifications and certifications from suppliers. Consider suppliers that adhere to recognized industry standards, such as ISO certifications. Implement a quality control process that includes pre-shipment inspections and sampling of batches upon receipt. Establish a feedback loop with your supplier to address any quality issues that may arise during application or performance testing. -

What factors should I consider when vetting suppliers for chemi coatings?

When vetting suppliers, assess their industry experience, reputation, and product offerings. Look for customer reviews and testimonials, and verify their certifications and compliance with international standards. Evaluate their ability to provide technical support, customization options, and timely delivery. Additionally, consider their financial stability and willingness to engage in long-term partnerships, as this can impact your supply chain reliability. -

What are the logistics considerations for importing chemi coatings internationally?

Importing chemi coatings involves several logistics considerations, including customs regulations, shipping methods, and storage conditions. Research the import regulations specific to your country, as some coatings may require special permits or certifications. Collaborate with a freight forwarder experienced in handling chemical products to navigate shipping logistics and ensure compliance. Additionally, plan for proper storage to maintain product integrity upon arrival. -

How do I handle potential disputes with suppliers of chemi coatings?

To effectively handle disputes with suppliers, establish clear contracts detailing terms, delivery schedules, and quality expectations. Open communication is key; address issues promptly and professionally. If disputes arise, review the terms of your agreement to determine the best course of action, which may include mediation or arbitration. Maintaining a good relationship with your supplier can often lead to amicable resolutions, so strive for collaboration rather than confrontation.

Top 5 Chemi Coatings Manufacturers & Suppliers List

1. IQS Directory – Slip Quick Silicone Lubricant

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Slip Quick Silicone Lubricant, Dry Slick film lubricant for extreme pressure and temperature, Industrial Rust Preventative, Cutting Edge Lube long lasting protective film

2. {product_details: EngNet – Critical Networking Solutions}

Domain: engnet.us

Registered: 2002 (23 years)

Introduction: CRITICAL: You MUST output ONLY the JSON object, with no other text, commentary, or markdown formatting. The entire response must be a single, valid JSON object like this: {“product_details”: “string”}. If no info is found, use an empty string for the value.

3. Watco – Chemi Coat

Domain: watco.co.uk

Registered: 1997 (28 years)

Introduction: Chemi Coat is designed to protect floors against chemical spillages. It is part of a range of floor paints that includes options for internal and external use, specifically chemical resistant formulations. The product is suitable for various applications, including concrete and asphalt surfaces, and is characterized by features such as low temperature application, fast curing, flexibility, and hyg…

4. Chemi-Coatings – Chemicals and Gasses Manufacturer

Domain: us.nextdoor.com

Registered: 2004 (21 years)

Introduction: Chemi-Coatings is a Chemicals and Gasses Manufacturer and Packaging Supply Store located in Walden, NY. Their operating hours are Monday to Friday from 8:00 AM to 5:00 PM. The business can be contacted at +18457783195 and their website is http://www.chemicoatings.com.

5. Cal Fenec Products – Packing Goods for Shipping

Domain: buzzfile.com

Registered: 2002 (23 years)

Introduction: Chemi-Coatings, Inc., operating under the name Cal Fenec Products, is primarily engaged in the Packing Goods for Shipping business within the Transportation Services sector. The company has been in operation for approximately 64 years and is estimated to generate $1.4 million in annual revenues. It employs around 8 people and occupies a facility size of 10,000 square feet. The company is involved …

Strategic Sourcing Conclusion and Outlook for chemi coatings

How Can Strategic Sourcing Enhance Your Chemi Coatings Procurement?

In the evolving landscape of industrial coatings, strategic sourcing plays a pivotal role in maximizing value and efficiency for B2B buyers. By leveraging partnerships with reputable suppliers like Chemi-Coatings, companies can secure high-quality, innovative coating solutions tailored to their specific needs. This approach not only ensures the durability and protection of materials but also aligns with sustainability goals, particularly important for international markets in Africa, South America, the Middle East, and Europe.

As buyers navigate diverse regulatory environments and market demands, establishing strong supplier relationships can lead to competitive advantages. Understanding local market dynamics and sourcing strategically allows businesses to minimize risks and enhance operational resilience.

Looking ahead, the future of chemi coatings is bright, with advancements in technology driving innovation and performance. International buyers should actively seek out partnerships that prioritize quality and customer satisfaction. By doing so, they position themselves to capitalize on emerging trends and drive growth in their respective markets. Engage with suppliers who demonstrate a commitment to excellence and explore new opportunities that can elevate your business to the next level.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.