Check Valve Diagram: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for check valve diagram

In today’s global marketplace, sourcing a reliable check valve diagram is essential for ensuring the integrity and efficiency of fluid systems. B2B buyers face the challenge of navigating a myriad of options, each with its own specifications, applications, and compliance standards. This comprehensive guide delves into the intricacies of check valves, providing detailed insights into various types, their operational mechanisms, and applications across industries—from water treatment to HVAC systems.

Understanding the nuances of check valve diagrams is vital for making informed purchasing decisions, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. This guide empowers you to effectively vet suppliers, evaluate costs, and align your procurement strategies with your operational needs. By offering actionable insights and best practices, it equips you with the knowledge necessary to mitigate risks associated with backflow, contamination, and equipment failure.

Whether you’re a seasoned engineer or a procurement specialist, this resource will enhance your understanding of check valve systems, enabling you to make strategic decisions that drive efficiency and reliability in your projects.

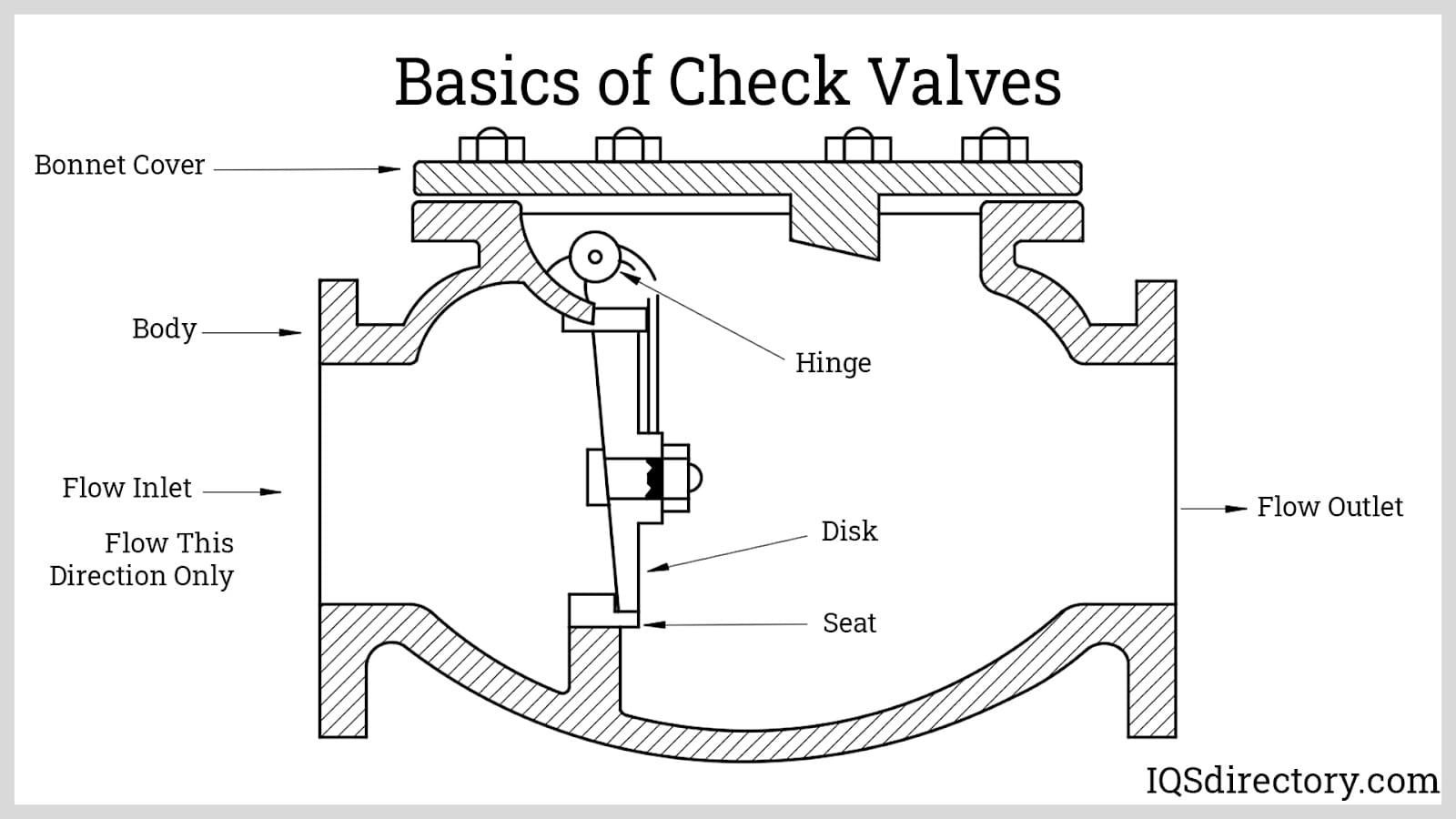

Understanding check valve diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

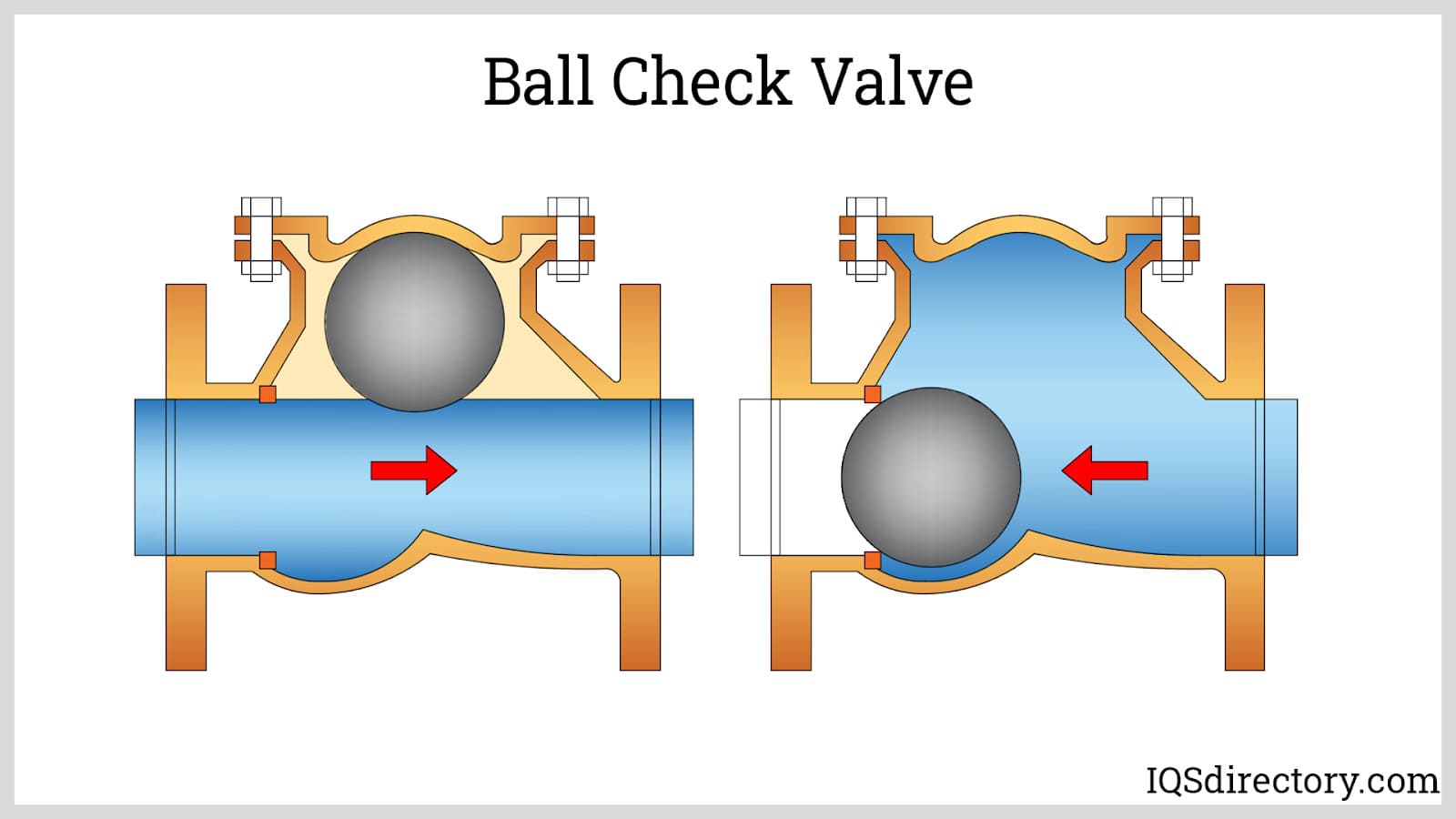

| Ball Check Valves | Utilizes a ball bearing on a spring to prevent backflow. | Water and gas pipelines, HVAC systems | Pros: Reliable, simple design. Cons: May require higher pressure to operate effectively. |

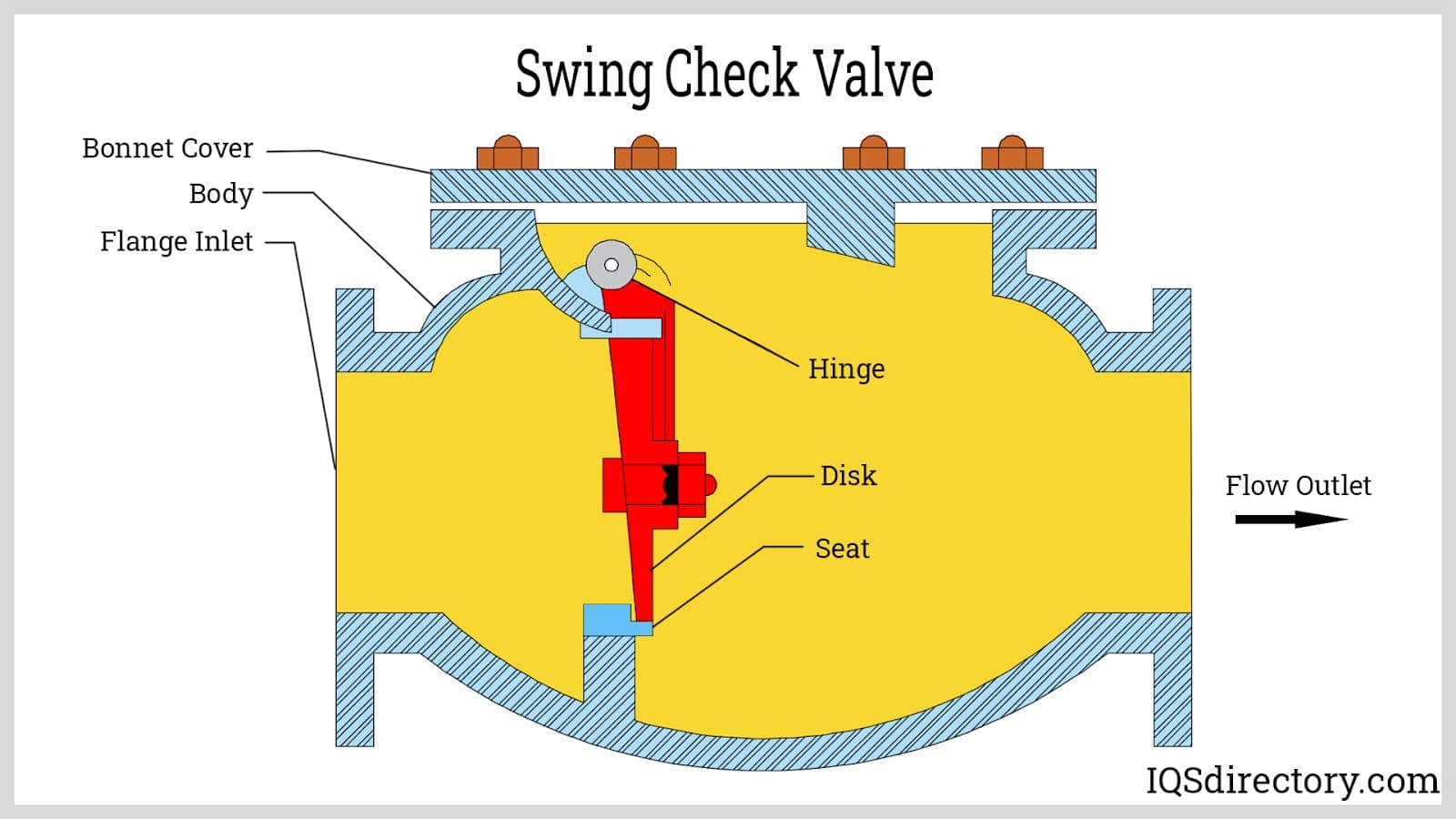

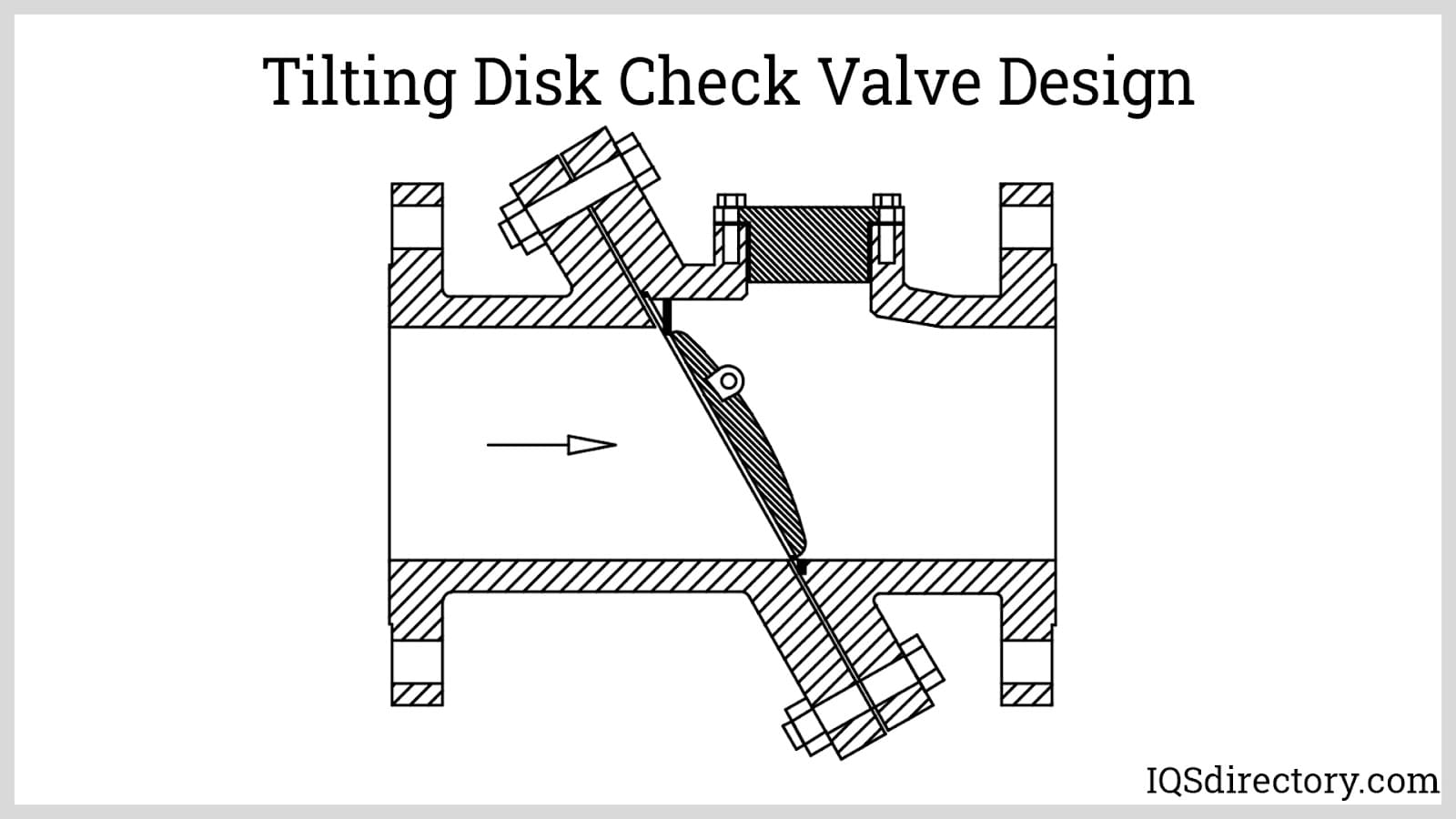

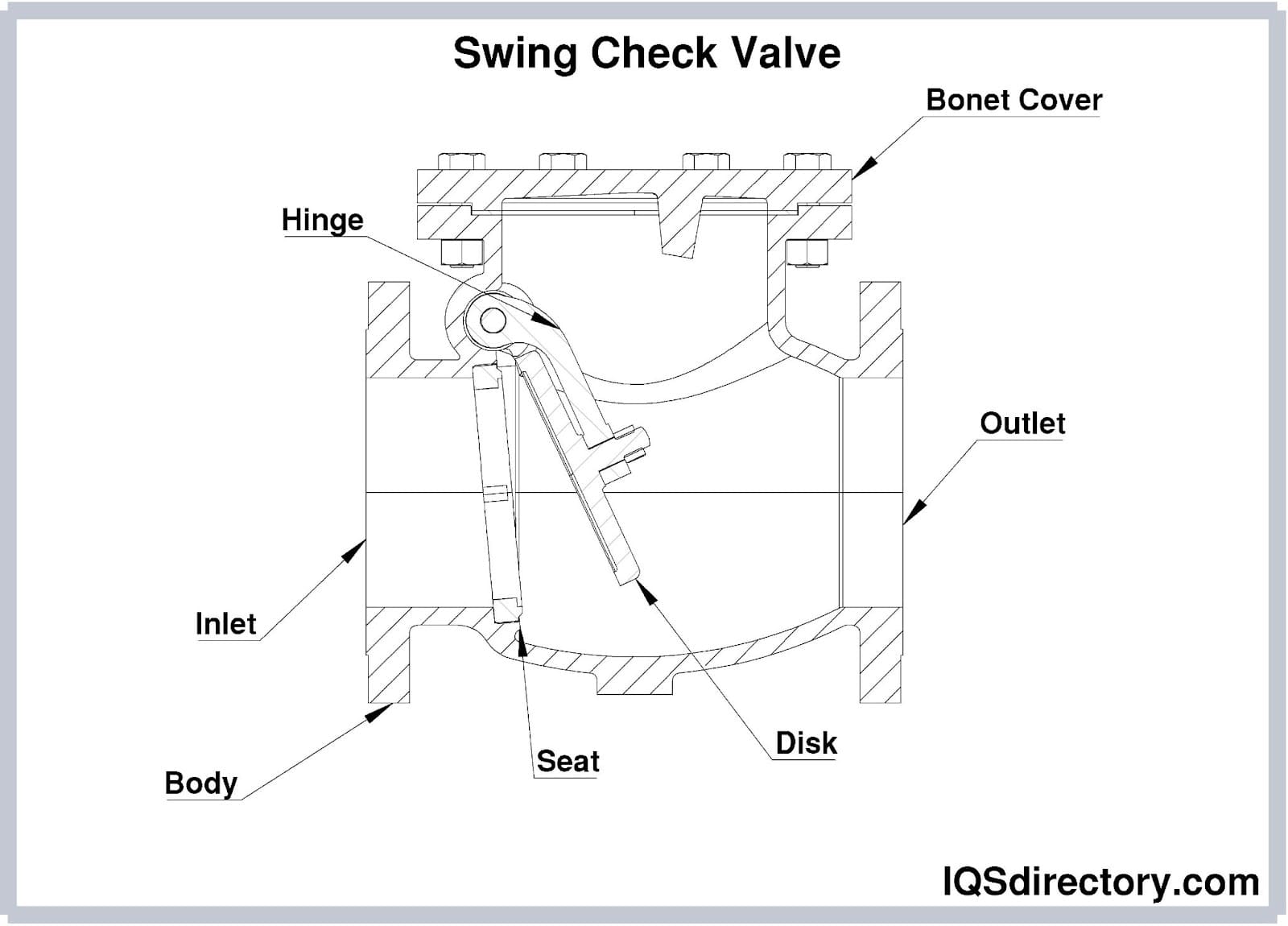

| Swing Check Valves | Features a hinged disk that swings open to allow flow. | Fire protection systems, drainage applications | Pros: Effective against surges. Cons: Can be prone to slamming, leading to wear. |

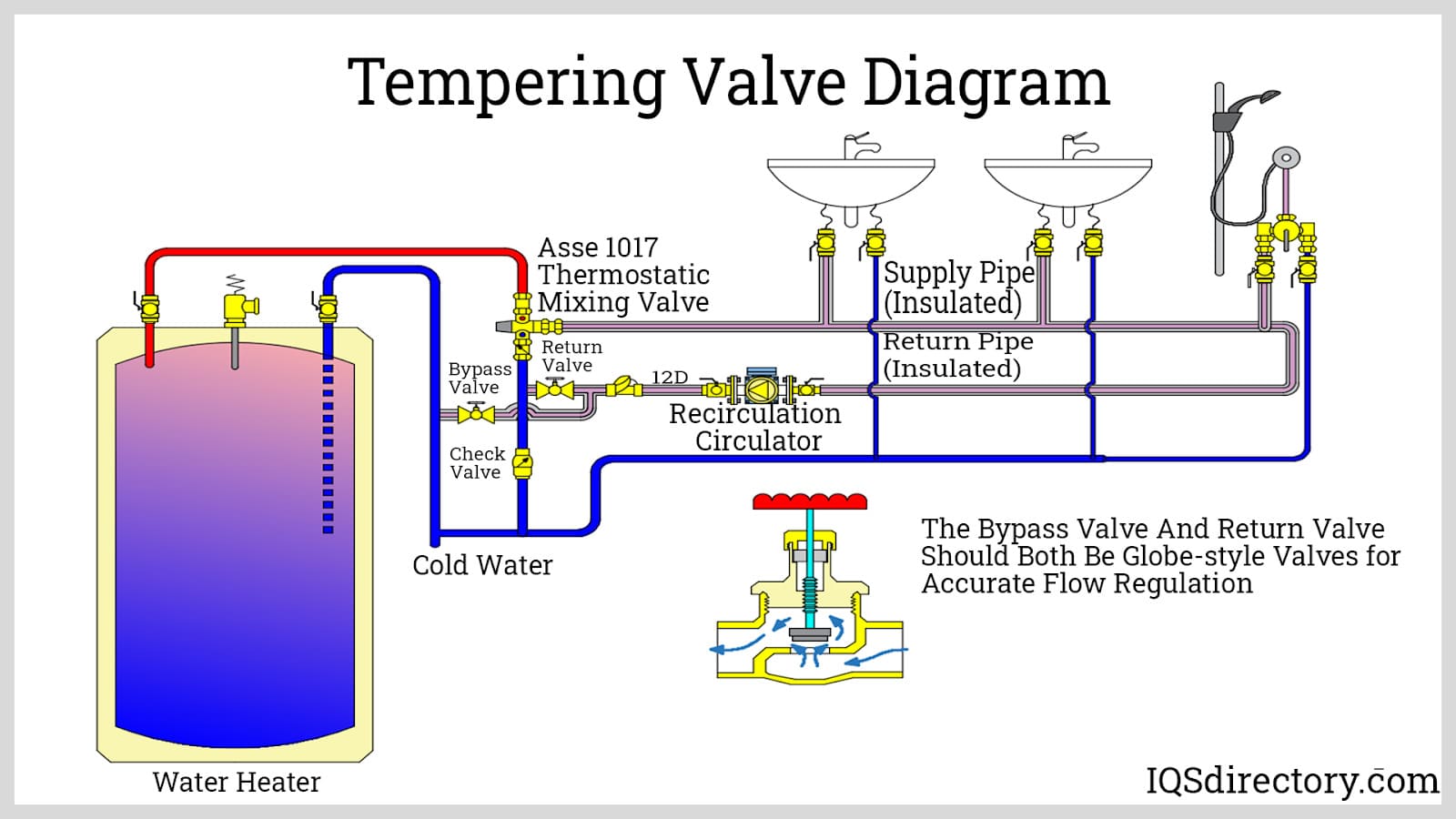

| Double Check Valves | Comprises two check valves for enhanced backflow prevention. | Drinking water systems, irrigation systems | Pros: Increased safety, redundancy. Cons: More complex and potentially higher cost. |

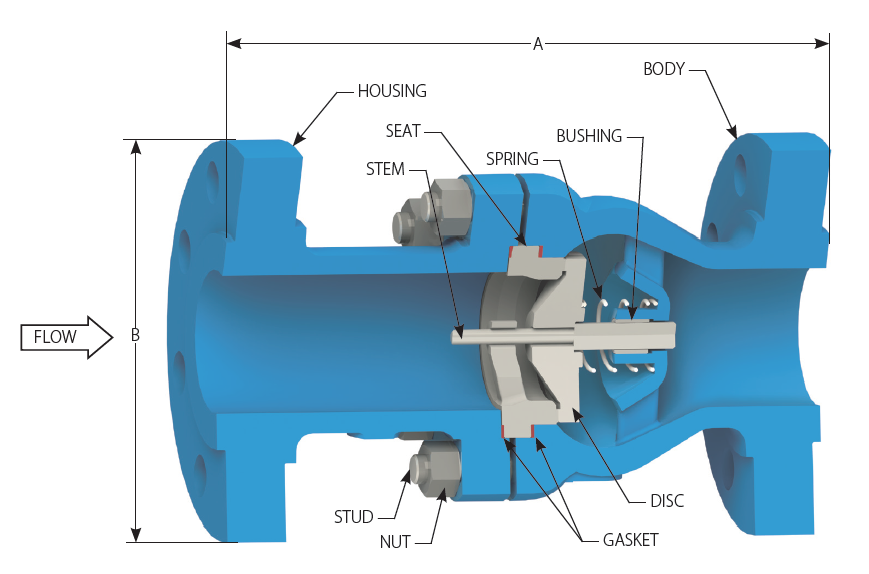

| Lift Check Valves | Disc moves vertically in response to fluid pressure. | Oil and gas applications, chemical processing | Pros: Effective for high-pressure systems. Cons: Requires sufficient pressure to operate. |

| Non-Slam Check Valves | Designed to prevent slamming by using a pressure-sensitive spring. | Pumping stations, water treatment facilities | Pros: Reduces noise and wear. Cons: More expensive than standard swing check valves. |

What Are the Characteristics of Ball Check Valves?

Ball check valves are characterized by their simple design, which includes a ball bearing that moves up and down on a spring. They are widely used in various B2B applications, particularly in water and gas pipelines, as well as HVAC systems. When selecting ball check valves, buyers should consider the required cracking pressure, as these valves may not perform effectively at lower pressures. Their reliability and straightforward mechanism make them a preferred choice for many industries.

How Do Swing Check Valves Function?

Swing check valves utilize a hinged disk that swings open to allow fluid flow and closes under backflow conditions. This design is particularly effective in fire protection systems and drainage applications, where pressure surges may occur. Buyers should be aware of potential slamming issues, which can lead to wear over time. While they are effective in many scenarios, the operational environment should be considered to ensure longevity and reliability.

What Advantages Do Double Check Valves Offer?

Double check valves consist of two check valves in tandem, providing an extra layer of protection against backflow. They are commonly used in drinking water systems and irrigation applications to prevent contamination. While they offer enhanced safety and redundancy, buyers should note that they may come at a higher cost and require more complex installation. Evaluating the necessity for additional protection can help justify the investment.

What Are the Key Features of Lift Check Valves?

Lift check valves feature a disc that lifts vertically in response to fluid pressure, making them suitable for high-pressure applications such as oil and gas processing. Their design allows for efficient operation in systems where pressure fluctuations are common. However, buyers should ensure that the system’s pressure is sufficient to operate these valves effectively. Their ability to handle high pressures makes them ideal for demanding industrial settings.

How Do Non-Slam Check Valves Reduce Wear and Noise?

Non-slam check valves are designed to minimize slamming effects by incorporating a pressure-sensitive spring that controls the closing motion. This feature is particularly beneficial in pumping stations and water treatment facilities, where noise reduction and reduced wear are critical. Although they may come at a higher price point compared to standard swing check valves, the long-term benefits of decreased maintenance and operational noise can provide significant value for B2B buyers in sensitive applications.

Illustrative image related to check valve diagram

Key Industrial Applications of check valve diagram

| Industry/Sector | Specific Application of check valve diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Preventing backflow in filtration systems | Ensures water quality and safety by preventing contamination | Compliance with local regulations, material durability, and maintenance needs |

| Oil & Gas | Flow control in pipelines | Maintains system integrity and prevents costly leaks or spills | Pressure ratings, corrosion resistance, and compatibility with fluids |

| HVAC | Maintaining coolant flow in multi-story buildings | Enhances energy efficiency and system reliability | Size specifications, pressure ratings, and ease of installation |

| Fire Protection Systems | Ensuring proper flow direction in firefighting systems | Critical for emergency response and safety compliance | Certification standards, valve response time, and maintenance requirements |

| Pharmaceutical Manufacturing | Preventing contamination in liquid transfer systems | Protects product integrity and ensures compliance with health standards | Material compatibility, precision in flow control, and regulatory compliance |

How Are Check Valve Diagrams Used in Water Treatment Systems?

In water treatment facilities, check valves are critical components in filtration systems to prevent backflow, ensuring that treated water does not mix with untreated water. The check valve diagram illustrates the flow direction and operational mechanics, enabling operators to maintain water quality and safety. For international buyers, especially in regions like Africa and South America, understanding local regulations regarding water safety is essential when sourcing these valves. Buyers should consider materials that resist corrosion and ensure easy maintenance to cope with varying water qualities.

What Role Do Check Valves Play in Oil & Gas Pipelines?

In the oil and gas industry, check valve diagrams are essential for understanding flow control within pipelines. These valves prevent backflow, which can lead to leaks and environmental hazards. The diagram provides clarity on the valve’s operational parameters, helping engineers ensure pipeline integrity. Buyers in the Middle East and Europe, where oil and gas operations are prevalent, must focus on sourcing valves that meet high-pressure ratings and corrosion resistance standards, given the harsh operating conditions.

How Do Check Valves Enhance HVAC Systems?

In HVAC systems, particularly in multi-story buildings, check valves are employed to maintain coolant flow and prevent backflow. The check valve diagram showcases how these valves operate under varying pressure conditions, which is vital for system efficiency. For B2B buyers in Europe and the Middle East, sourcing check valves that are appropriately sized for specific HVAC applications is crucial, along with ensuring compatibility with existing system components to avoid operational disruptions.

Why Are Check Valves Essential in Fire Protection Systems?

Check valves in fire protection systems are vital for ensuring that water flows in the correct direction during an emergency. The check valve diagram helps fire safety engineers understand how these valves function, particularly in maintaining pressure and preventing backflow. Buyers from Africa and South America should prioritize sourcing valves that meet international safety certification standards and ensure quick response times to enhance overall safety compliance in fire protection systems.

How Do Check Valves Prevent Contamination in Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, check valves are used in liquid transfer systems to prevent contamination and ensure product integrity. The check valve diagram provides insight into the flow mechanisms, which is crucial for maintaining the stringent quality standards required in this industry. Buyers in Europe and other regions must focus on sourcing valves made from materials compatible with various pharmaceuticals, while also ensuring compliance with health regulations to safeguard product quality.

3 Common User Pain Points for ‘check valve diagram’ & Their Solutions

Scenario 1: Misinterpretation of Check Valve Diagrams Leading to Installation Errors

The Problem:

B2B buyers often encounter difficulties in interpreting check valve diagrams, particularly when they are not familiar with the specific symbols used in hydraulic and pneumatic systems. For instance, a buyer may misread the flow direction indicated in the diagram, leading to the installation of the check valve in reverse. This not only compromises the functionality of the system but can also result in costly downtime and repairs. Such errors can be particularly detrimental in critical applications, like water treatment facilities or oil pipelines, where backflow prevention is essential for operational safety.

The Solution:

To mitigate this issue, it is crucial for buyers to invest time in understanding the standardized symbols used in check valve diagrams. Familiarizing themselves with resources like the International Organization for Standardization (ISO) symbols can provide clarity. Additionally, buyers should engage with suppliers who offer comprehensive installation guides that include clear diagrams and explanations of the symbols. When sourcing check valves, requesting detailed technical documentation alongside the product can further ensure accurate installation. Conducting a pre-installation review with technical staff to confirm that everyone interprets the diagrams consistently can also be beneficial.

Scenario 2: Inadequate Specifications Resulting in Performance Issues

The Problem:

B2B buyers frequently face challenges when it comes to specifying the right check valve for their application. Insufficiently detailed specifications can lead to the procurement of a check valve that does not meet the pressure and flow requirements of the system, resulting in performance issues such as valve chatter or premature failure. For example, a buyer in the HVAC sector may choose a standard check valve without considering the specific environmental conditions, leading to inefficiencies and potential system failures.

The Solution:

To overcome this challenge, buyers should conduct a thorough analysis of their system requirements before selecting a check valve. This includes understanding the maximum flow rates, pressure conditions, and the nature of the fluids being handled. Utilizing check valve diagrams that specify pressure ratings and material compatibility can guide buyers in making informed decisions. Additionally, consulting with manufacturers to receive tailored advice based on their operational needs can ensure that the chosen valve will perform effectively. Buyers should also consider implementing a trial period for new valve types to assess their performance under real operating conditions.

Scenario 3: Lack of Standardization Across Suppliers Causing Compatibility Issues

The Problem:

In international markets, especially across diverse regions like Africa, South America, and Europe, B2B buyers often encounter compatibility issues due to a lack of standardization in check valve diagrams and specifications among different suppliers. This inconsistency can lead to difficulties in integrating new valves into existing systems, resulting in increased costs and delays. For example, a buyer in the Middle East might find that the check valve sourced from a European supplier does not align with the existing piping systems designed using different standards.

The Solution:

To address compatibility concerns, buyers should prioritize working with suppliers who adhere to international standards such as those set by the ISO or the American National Standards Institute (ANSI). When reviewing check valve diagrams, buyers should ensure that the specifications align with their existing systems. Furthermore, leveraging modular designs can provide greater flexibility, allowing for easier integration across different systems. Establishing long-term relationships with a select group of suppliers who understand the specific needs of their industry can also foster better communication and standardization, ultimately reducing compatibility issues. Regular training sessions on the latest standards and technologies can help the procurement teams remain informed and adept at navigating these complexities.

Strategic Material Selection Guide for check valve diagram

What Are the Key Properties of Common Materials Used in Check Valve Diagrams?

When selecting materials for check valves, several factors influence their performance, including temperature and pressure ratings, as well as corrosion resistance. Understanding these properties is essential for ensuring the longevity and reliability of check valves in various applications.

Stainless Steel: A Versatile Choice for Check Valves

Stainless steel is widely used in check valves due to its excellent corrosion resistance and high-temperature tolerance. It typically withstands temperatures up to 400°F (204°C) and pressures exceeding 1500 psi, making it suitable for a variety of applications, including water, oil, and gas systems.

Pros: Stainless steel offers durability and strength, making it ideal for high-pressure environments. It also has a relatively low maintenance requirement, which is beneficial for long-term use.

Cons: The primary drawback is its cost, as stainless steel is more expensive than other materials. Additionally, manufacturing processes can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including aggressive fluids, which is crucial for industries such as oil and gas.

Illustrative image related to check valve diagram

Considerations for International Buyers: Compliance with standards such as ASTM A312 or DIN 17440 is essential. Buyers in regions like Europe may prefer stainless steel valves that meet stringent EU regulations, while those in Africa and South America should consider local standards.

PVC: Cost-Effective for Low-Pressure Applications

Polyvinyl chloride (PVC) is a popular choice for check valves, particularly in water and wastewater applications. It is lightweight, resistant to corrosion, and can handle temperatures up to 140°F (60°C) and pressures around 150 psi.

Pros: PVC is cost-effective and easy to install due to its lightweight nature. It also resists chemical corrosion, making it suitable for a variety of fluids.

Cons: Its temperature and pressure ratings are lower than those of metals, limiting its use in high-stress environments. PVC can also become brittle over time when exposed to UV light.

Impact on Application: PVC is ideal for non-aggressive media, such as water and certain chemicals, but is not suitable for high-temperature or high-pressure applications.

Considerations for International Buyers: Buyers should ensure compliance with local standards like ASTM D1784. In regions like the Middle East, where temperatures can be high, UV-resistant coatings may be necessary.

Brass: A Reliable Option for Smaller Systems

Brass is often used in smaller check valves due to its good corrosion resistance and ability to handle moderate temperatures and pressures, typically around 200°F (93°C) and 300 psi.

Pros: Brass offers excellent machinability and is relatively affordable compared to stainless steel. It also has good antimicrobial properties, making it suitable for potable water applications.

Cons: Brass can be susceptible to dezincification in certain environments, which can compromise its integrity over time.

Impact on Application: Brass check valves are commonly used in plumbing and HVAC systems, where they can effectively manage water flow without backflow.

Considerations for International Buyers: Compliance with standards such as ASTM B16 and DIN 50930 is crucial. Buyers should also consider local regulations regarding the use of brass in drinking water systems, especially in Europe.

Ductile Iron: Strength for Heavy-Duty Applications

Ductile iron is a robust material often used in larger check valves designed for heavy-duty applications, such as municipal water systems and industrial processes. It can handle high pressures and temperatures, typically around 250°F (121°C) and up to 300 psi.

Pros: Ductile iron offers exceptional strength and durability, making it ideal for high-stress applications. It also has good wear resistance.

Cons: The weight of ductile iron can make installation more challenging, and it is generally more expensive than PVC or brass.

Impact on Application: Ductile iron is well-suited for high-flow applications, such as in municipal water distribution systems, where reliability is critical.

Considerations for International Buyers: Compliance with standards like ASTM A536 and ISO 1083 is essential. Buyers in regions with extreme weather conditions should ensure that ductile iron valves are treated for corrosion resistance.

Summary Table of Material Selection for Check Valves

| Material | Typical Use Case for check valve diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas systems | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| PVC | Water and wastewater applications | Cost-effective and lightweight | Limited temperature and pressure ratings | Low |

| Brass | Plumbing and HVAC systems | Good machinability and affordability | Susceptible to dezincification | Med |

| Ductile Iron | Municipal water systems | Exceptional strength and durability | Heavy and more expensive | Med |

This guide provides a comprehensive overview of material selection for check valves, ensuring that international B2B buyers can make informed decisions tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for check valve diagram

What Are the Main Stages in the Manufacturing Process of Check Valves?

The manufacturing process for check valves typically involves several critical stages that ensure the final product meets industry standards and customer expectations. Each stage is essential for creating a reliable, high-quality valve capable of preventing backflow in various applications.

How is Material Prepared for Check Valve Production?

Material preparation is the first step in the manufacturing process. High-grade materials such as stainless steel, brass, and PVC are commonly used, depending on the valve’s application. Suppliers must ensure that the raw materials meet specific chemical and mechanical properties. This can include testing for tensile strength, corrosion resistance, and thermal stability.

Once materials are sourced, they undergo a thorough inspection (Incoming Quality Control, IQC) to verify compliance with specifications. This inspection may involve checking the dimensions, surface finish, and the presence of any defects. Proper documentation of material certifications is crucial for traceability, especially for international buyers who may require specific compliance reports.

What Key Techniques Are Used in Forming Check Valves?

The forming stage involves shaping the prepared materials into the components of the check valve. Common techniques include:

-

Casting: This involves pouring molten metal into a mold to create the valve body. Precision casting methods such as investment casting can achieve complex shapes with tight tolerances.

-

Machining: Components may be further refined through machining processes like turning, milling, and grinding to achieve the desired dimensions and surface finish.

-

Stamping and Forging: For some parts, particularly discs and seats, stamping or forging can be utilized for enhanced strength and durability.

After forming, components are subjected to Intermediate Quality Control (IPQC) checks, which involve measuring dimensions and inspecting surface finishes to ensure they meet specified tolerances.

How is Assembly Conducted in Check Valve Manufacturing?

The assembly stage is where individual components are brought together to create the final check valve. This process can vary based on the valve design but typically includes:

-

Component Alignment: Ensuring that all parts fit correctly, including seats, springs, and any seals.

-

Joining Techniques: This may involve welding, threading, or using adhesives, depending on the materials and design requirements.

-

Functional Testing: After assembly, each valve is tested to confirm that it operates correctly under expected conditions. This may include checking the opening and closing actions and ensuring there are no leaks.

Final assembly is also subject to Full Quality Control (FQC) checks, which may include pressure testing and operational tests to simulate real-world conditions.

What Finishing Processes Are Applied to Check Valves?

Finishing processes enhance the valve’s performance and aesthetic appeal. Common finishing techniques include:

-

Surface Treatment: Coatings such as galvanization or powder coating can be applied to improve corrosion resistance and extend the valve’s lifespan.

-

Polishing: This step improves the surface finish, reducing friction and enhancing flow characteristics.

-

Inspection and Packaging: The final inspection ensures that the valves meet all specifications before they are packaged for shipment. Proper packaging is vital to prevent damage during transportation.

What International Standards and Quality Assurance Practices Are Relevant?

Quality assurance is crucial in the manufacturing of check valves, particularly for international B2B buyers. Compliance with international standards such as ISO 9001 ensures that manufacturers maintain a quality management system that consistently meets customer requirements.

How Do International Standards Like ISO 9001 Impact Check Valve Manufacturing?

ISO 9001 provides a framework for quality management, emphasizing continuous improvement and customer satisfaction. Manufacturers must document their processes, conduct regular audits, and implement corrective actions when necessary. This structured approach reassures buyers about the reliability and consistency of the products they purchase.

Illustrative image related to check valve diagram

What Industry-Specific Certifications Should B2B Buyers Look For?

Beyond ISO certifications, certain industry-specific certifications may be relevant, depending on the application:

-

CE Marking: Indicates compliance with European safety standards, particularly important for valves used in the EU market.

-

API Standards: The American Petroleum Institute (API) provides standards for valves used in the oil and gas industry, ensuring they can withstand harsh conditions.

-

ASME Compliance: For valves used in pressure systems, adherence to the American Society of Mechanical Engineers (ASME) standards is critical.

What Are the Common Testing Methods for Check Valves?

Testing methods are integral to quality assurance and can vary based on the valve’s application. Common testing methods include:

-

Hydrostatic Testing: This method checks for leaks by subjecting the valve to high-pressure water.

-

Pneumatic Testing: For valves that operate with gases, this test evaluates the integrity of the valve under air pressure.

-

Cycle Testing: Valves are operated through multiple opening and closing cycles to ensure durability and proper function over time.

-

Visual Inspection: A thorough visual examination for surface defects, proper assembly, and overall finish is essential before the product leaves the factory.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must conduct due diligence to ensure that their suppliers maintain high-quality standards. Here are effective strategies to verify supplier QC processes:

What Role Do Audits and Reports Play in Supplier Quality Verification?

-

Supplier Audits: Regular audits of the manufacturing facility can provide insights into the quality management system and production processes. Buyers should look for comprehensive audit reports that detail findings and corrective actions.

-

Quality Control Reports: Requesting detailed QC reports, including test results and compliance certifications, can help buyers understand the quality assurance measures in place.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and products. These inspections can include:

-

Pre-shipment Inspections: Verifying product quality before shipment ensures that the valves meet specified standards.

-

Random Sampling: Inspectors can conduct random sampling of products to evaluate quality and adherence to specifications.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances when it comes to quality control. Factors to consider include:

-

Cultural Differences: Understanding the local manufacturing culture can help buyers navigate expectations and standards.

-

Regulatory Compliance: Different regions may have varying regulatory requirements, making it essential to ensure that suppliers comply with both local and international standards.

-

Logistical Considerations: Buyers should factor in the impact of logistics on quality assurance, including the potential for damage during transportation and the importance of proper packaging.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for check valves is essential for B2B buyers. By focusing on these critical aspects, companies can ensure they source reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘check valve diagram’

Introduction

This practical sourcing guide serves as a step-by-step checklist for B2B buyers looking to procure check valve diagrams. Understanding the intricacies of check valves is essential for ensuring the integrity and efficiency of fluid systems. By following this checklist, buyers can streamline their procurement process and make informed decisions that align with their operational needs.

Illustrative image related to check valve diagram

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical specifications for the check valves you need. This includes understanding the application, required materials, pressure ratings, and flow directions. Specific details, such as the type of check valve (ball, swing, or double check), will significantly influence your purchasing decisions.

Step 2: Research Regulatory Standards

Ensure that the check valves and their diagrams comply with international and local regulatory standards. These standards may vary by region, especially in markets like Europe and the Middle East, where regulations can be stringent. Familiarize yourself with standards such as ISO or API, as compliance is crucial for quality assurance and safety.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record in providing high-quality check valve diagrams and ensure they have the technical expertise to meet your specifications.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers hold relevant certifications that validate their quality control processes. Certifications such as ISO 9001 or industry-specific accreditations indicate a commitment to quality and reliability. This step is essential to mitigate risks associated with subpar products, especially in critical applications.

Step 5: Request Customization Options

Inquire about customization options for check valve diagrams that cater to your specific operational needs. Suppliers may offer tailored diagrams that reflect unique configurations or integrate seamlessly with existing systems. Custom solutions can enhance operational efficiency and reduce the risk of errors in installation.

Step 6: Review Sample Diagrams and Documentation

Request sample diagrams and associated documentation from potential suppliers. This allows you to assess the clarity and accuracy of the diagrams, ensuring they meet your operational requirements. Pay attention to details such as flow direction, pressure ratings, and any annotations that facilitate understanding.

Step 7: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms and conditions that align with your budget and timeline. Discuss pricing, delivery schedules, and after-sales support, as these factors can significantly impact your procurement experience. Establishing clear expectations upfront can lead to a smoother transaction and a stronger supplier relationship.

By adhering to this checklist, B2B buyers can navigate the complexities of sourcing check valve diagrams effectively, ensuring they make well-informed decisions that contribute to the success of their projects.

Comprehensive Cost and Pricing Analysis for check valve diagram Sourcing

What Are the Key Cost Components in Check Valve Diagram Sourcing?

Understanding the cost structure associated with sourcing check valve diagrams is essential for B2B buyers aiming to optimize their procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts the price. Common materials for check valves include brass, stainless steel, and plastic. Each material has its own cost implications based on availability, quality, and performance characteristics.

-

Labor: Labor costs encompass wages for skilled workers involved in the design, manufacturing, and assembly of check valves. Regions with higher labor costs, such as Western Europe, may see increased prices compared to countries in Africa or South America, where labor might be cheaper.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance necessary for production. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Tooling costs are associated with the machinery and equipment needed to produce the check valves. Custom tooling for unique designs can significantly increase initial costs.

-

Quality Control: Implementing rigorous quality control processes is vital for ensuring that the check valves meet industry standards. This may involve testing and certification, adding to the overall cost.

-

Logistics: Transporting materials and finished products adds another layer of cost. International shipping, customs duties, and local distribution should be factored into the total expenditure.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. This margin can vary based on the supplier’s market position and competitiveness.

How Do Price Influencers Affect Check Valve Diagram Procurement?

Several factors influence the pricing of check valves, which can vary significantly across different markets.

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs. Buyers should negotiate minimum order quantities (MOQ) to achieve better pricing.

-

Specifications/Customization: Customized check valves may incur additional costs due to specialized design and manufacturing requirements. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The choice of materials not only affects the initial price but also impacts the longevity and reliability of the valves. Investing in higher-quality materials may lead to lower maintenance costs over time.

-

Quality/Certifications: Valves that meet specific industry certifications may command higher prices due to their reliability and safety. Buyers should weigh the importance of certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge a premium, but this can often lead to lower long-term costs due to reduced failures and warranty claims.

-

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect overall costs.

What Tips Can Buyers Use to Optimize Costs in Check Valve Diagram Sourcing?

International B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, can employ several strategies to enhance cost-efficiency in sourcing check valves.

-

Negotiate Terms: Establishing strong relationships with suppliers can lead to better negotiation outcomes. Always discuss pricing, payment terms, and delivery schedules to find mutually beneficial agreements.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider factors such as maintenance, operational efficiency, and potential downtime. Investing in higher-quality valves may lead to lower costs in the long run.

-

Consider Local Suppliers: Local suppliers may offer better rates due to lower logistics costs and more straightforward customs processes. They can also provide faster turnaround times.

-

Stay Informed on Market Trends: Keeping abreast of market trends, including material prices and technological advancements, can help buyers make informed decisions and time their purchases effectively.

Disclaimer on Indicative Prices

It is essential to note that prices for check valve diagrams can vary widely based on the aforementioned factors. Buyers are encouraged to obtain multiple quotes and conduct thorough research to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing check valve diagram With Other Solutions

Exploring Alternatives to Check Valve Diagrams for Fluid Control Solutions

In the world of fluid control, the check valve diagram serves as a fundamental reference for understanding how check valves operate and their applications. However, various alternative technologies and methods exist that can also manage fluid flow effectively. This section compares the check valve diagram with two prominent alternatives: ball valves and gate valves. This analysis will help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Check Valve Diagram | Ball Valve | Gate Valve |

|---|---|---|---|

| Performance | Prevents backflow, operates automatically | Provides excellent flow control | Ideal for on/off control |

| Cost | Moderate initial investment | Generally low to moderate cost | Typically higher due to complexity |

| Ease of Implementation | Simple installation in most systems | Easy installation and operation | Requires more space and precise alignment |

| Maintenance | Low maintenance, robust design | Low maintenance, but requires periodic checks | Requires regular maintenance checks |

| Best Use Case | Pump systems, HVAC applications | Ideal for systems requiring frequent operation | Suitable for high-pressure applications |

What are the Advantages and Disadvantages of Ball Valves?

Ball valves are popular for their simplicity and effectiveness in controlling flow. The spherical disc allows for quick opening and closing, making them suitable for applications requiring frequent operation. Their design minimizes pressure loss, ensuring efficient fluid handling. However, they may not be ideal for throttling applications since partially open ball valves can create turbulence and wear. Additionally, while they tend to be cost-effective, the need for periodic inspections can add to overall operational costs.

How Do Gate Valves Compare in Functionality and Use Cases?

Gate valves are primarily designed for full flow applications, where the goal is to either fully open or fully close the valve. They excel in high-pressure situations and are often used in large pipelines. While they provide minimal resistance when fully opened, gate valves can be slower to operate compared to check valves and ball valves. Their maintenance requirements are higher, as they need regular inspections to ensure proper sealing and function. Although they are effective in certain applications, their complexity and higher costs can deter some buyers.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a fluid control solution, B2B buyers should consider specific operational requirements, including the nature of the fluid, pressure levels, and the frequency of valve operation. For applications that require reliable backflow prevention with minimal maintenance, the check valve diagram remains an excellent choice. However, if the need for precise flow control is paramount, ball valves could be more suitable. Conversely, for systems operating under high pressure where full flow is critical, gate valves may be the best option. Ultimately, understanding the unique demands of your application will lead to the most effective valve selection.

Essential Technical Properties and Trade Terminology for check valve diagram

What Are the Essential Technical Properties of Check Valves?

Understanding the critical specifications of check valves is vital for ensuring the reliability and efficiency of fluid systems in various industries. Here are key technical properties to consider:

1. Material Grade

The material grade of a check valve directly affects its durability, corrosion resistance, and overall performance. Common materials include stainless steel, brass, and PVC. For B2B buyers, selecting the right material is crucial for applications exposed to specific chemicals or high temperatures, as it can prevent premature failure and reduce maintenance costs.

2. Cracking Pressure

Cracking pressure is the minimum pressure required to open a check valve and allow fluid flow. This specification is vital for ensuring that the valve operates effectively in specific applications, such as in pump systems where maintaining a certain pressure is critical. Understanding cracking pressure helps B2B buyers ensure compatibility with their systems and prevents issues like backflow that could lead to equipment damage.

3. Flow Rate

The flow rate, often measured in gallons per minute (GPM) or liters per second (L/s), indicates the maximum capacity of a check valve to allow fluid flow without causing pressure loss. For B2B buyers, knowing the required flow rate is essential for selecting a valve that meets operational demands and maintains system efficiency.

4. Size and Threading

Check valves come in various sizes and threading configurations, which are essential for ensuring a proper fit within pipeline systems. Common thread sizes include ½ inch to 2 inches. B2B buyers must consider these dimensions to ensure compatibility with existing infrastructure, preventing installation challenges and potential leaks.

5. End Connections

End connections refer to how a check valve is attached to piping systems, such as threaded, flanged, or welded connections. Understanding these options is vital for B2B buyers to ensure ease of installation and the ability to integrate with different piping systems.

6. Temperature and Pressure Ratings

Temperature and pressure ratings indicate the maximum limits under which a check valve can operate effectively. These ratings are crucial for B2B buyers to avoid operational failures in high-stress environments, ensuring long-term reliability and safety in fluid transport systems.

What Are Common Trade Terms Related to Check Valves?

Familiarizing yourself with industry terminology can enhance communication and decision-making. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. In the context of check valves, understanding OEM specifications is crucial for B2B buyers looking to ensure quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, ensuring that they order sufficient quantities to meet operational needs without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. B2B buyers use RFQs to compare costs and negotiate favorable terms when sourcing check valves, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping, insurance, and customs responsibilities, thereby facilitating smoother transactions in the global market.

5. P&ID (Piping and Instrumentation Diagram)

P&ID is a schematic representation of a piping system, showing the piping and the equipment in the system. Understanding P&ID symbols for check valves is crucial for B2B buyers involved in system design and maintenance, as it helps visualize the flow and integration of various components.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their check valve selections align with operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the check valve diagram Sector

What Are the Key Market Dynamics and Trends Affecting the Check Valve Diagram Sector?

The global check valve market is witnessing significant growth, driven by increasing industrial activities, urbanization, and the need for efficient fluid control in various applications. The rise of the oil and gas, water treatment, and HVAC industries particularly fuels demand for check valves, as these components are crucial in preventing backflow and ensuring system integrity. Emerging markets in Africa and South America are showing a notable uptick in infrastructure projects, which in turn increases the need for reliable check valve solutions.

Technological advancements are shaping the sourcing landscape, with automation and IoT integration becoming prevalent. Smart check valves that can monitor flow and pressure in real-time are gaining traction among international B2B buyers. Additionally, the adoption of digital platforms for procurement and supply chain management is facilitating smoother transactions and enhancing supplier relationships.

Illustrative image related to check valve diagram

For buyers in Europe, particularly in Germany and the Middle East, there is a growing emphasis on quality and compliance with international standards. This trend necessitates a keen focus on sourcing from manufacturers who can provide detailed check valve diagrams and certifications that guarantee performance and safety.

How Are Sustainability and Ethical Sourcing Impacting the Check Valve Diagram Market?

Sustainability is increasingly becoming a priority for B2B buyers, particularly in regions like Europe and the Middle East, where regulatory pressures are mounting. The environmental impact of manufacturing processes for check valves is under scrutiny, prompting suppliers to adopt greener practices. This includes using recyclable materials and reducing waste during production.

Moreover, ethical sourcing practices are vital in establishing a trustworthy supply chain. Buyers are now more inclined to partner with suppliers who demonstrate transparency and commitment to social responsibility. Certifications like ISO 14001 for environmental management and the use of eco-friendly materials are becoming key factors in the decision-making process.

Investing in “green” check valves—those made from sustainable materials or designed for energy efficiency—can enhance brand reputation and appeal to environmentally conscious customers. B2B buyers should prioritize suppliers who can provide comprehensive check valve diagrams that illustrate the environmental benefits of their products.

What Is the Historical Context of Check Valves in the B2B Sector?

The evolution of check valves dates back to the early days of industrialization when the need for efficient fluid management became paramount. Initially, simple mechanical designs like swing check and ball check valves were developed to prevent backflow in piping systems. Over the decades, advancements in materials and technology led to the introduction of more sophisticated designs, such as pilot-operated and non-slam check valves.

The introduction of digital technologies in recent years has further transformed the check valve landscape, making it easier for manufacturers to produce high-quality diagrams that facilitate better understanding among B2B buyers. Today, the focus is not only on functionality but also on sustainable practices and ethical sourcing, reflecting the changing dynamics of the global market.

In conclusion, as the check valve market continues to evolve, international B2B buyers must stay informed about emerging trends, sustainability practices, and historical advancements to make informed sourcing decisions.

Illustrative image related to check valve diagram

Frequently Asked Questions (FAQs) for B2B Buyers of check valve diagram

-

How do I select the right check valve for my application?

Selecting the right check valve involves understanding your specific application requirements, such as flow direction, pressure ratings, and the type of fluid being transported. Consider factors like the valve’s cracking pressure, size, and material compatibility with the medium. It’s also vital to evaluate the installation environment, as some valves may perform better in high-pressure systems while others are designed for low-pressure applications. Consulting with suppliers who specialize in check valves can also provide valuable insights tailored to your needs. -

What are the key specifications to look for in a check valve diagram?

When reviewing a check valve diagram, focus on several key specifications: the flow direction, valve type (e.g., swing, ball, or lift), cracking pressure, and connection sizes. Ensure the diagram includes details on the materials used, as this impacts durability and compatibility with your system. Additionally, check for any unique features such as pilot lines or pressure relief options, which could affect performance and maintenance. A comprehensive diagram provides a clear visual representation of the valve’s operation and integration into your system. -

What are the common international standards for check valves?

International standards for check valves vary by region and application. Common standards include the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) standards. For Europe, the European Norm (EN) standards may apply, particularly in the context of safety and performance. Ensure that any supplier you consider adheres to these standards, as compliance guarantees quality and reliability. Additionally, request certification documents to confirm adherence to these standards during the purchasing process. -

What should I consider when vetting suppliers for check valves?

When vetting suppliers for check valves, assess their reputation, certifications, and experience in the industry. Look for suppliers with a proven track record of delivering quality products that comply with relevant standards. It’s also beneficial to check customer reviews and request references to gauge reliability. Evaluate their customer service, responsiveness, and willingness to provide technical support. Finally, consider their production capacity and lead times to ensure they can meet your demands efficiently. -

What customization options are available for check valves?

Customization options for check valves may include variations in size, materials, pressure ratings, and specific features like flanged or threaded connections. Many manufacturers offer tailored solutions to meet unique operational needs, such as specific cracking pressures or enhanced sealing mechanisms. Discuss your requirements with potential suppliers to explore available customization options. Keep in mind that custom solutions may involve longer lead times and potentially higher costs, so factor this into your decision-making process. -

What are typical minimum order quantities (MOQs) for check valves?

Minimum order quantities (MOQs) for check valves can vary widely depending on the supplier and the specific product. Generally, MOQs may range from a few units for standard products to larger quantities for customized or specialized valves. It’s essential to clarify MOQs upfront with suppliers, especially if you are testing a new product or entering a new market. Some suppliers may offer flexibility in MOQs for first-time customers or bulk orders, so don’t hesitate to negotiate terms that suit your purchasing strategy. -

What payment terms should I expect when purchasing check valves internationally?

Payment terms for international purchases of check valves typically include options such as advance payment, letters of credit, or payment on delivery. Common practices may require a deposit upfront, especially for custom orders, with the balance due upon delivery or before shipment. It’s crucial to discuss and agree upon payment terms with your supplier prior to placing an order. Ensure that the terms are documented in the contract, and consider any additional costs such as tariffs or shipping fees that may affect the overall price. -

How can I ensure quality assurance (QA) in my check valve purchases?

To ensure quality assurance in your check valve purchases, request documentation of the supplier’s QA processes, including testing and inspection protocols. Look for suppliers that follow industry standards and certifications, such as ISO 9001, which demonstrates a commitment to quality management. Additionally, consider requesting samples for testing or conducting site visits to evaluate their manufacturing processes. Establishing clear quality expectations in your contract can also help mitigate risks associated with defects or non-compliance.

Top 6 Check Valve Diagram Manufacturers & Suppliers List

1. E4 Training – Check Valves

Domain: e4training.com

Registered: 2000 (25 years)

Introduction: Check valves allow flow in one direction only. The symbol indicates flow from the bottom pipe to the top pipe without backflow. There are two types: one relies on gravity to remain closed, while the other uses a spring mechanism. Pilot operated check valves feature a dashed pilot line to open the valve when pressure is applied. Shuttle valves are used in load sensing systems to direct the highest …

2. RS Components – Check Valves

Domain: my.rs-online.com

Registered: 2001 (24 years)

Introduction: Check valves are designed to prevent backflow of fluids or gases in a piping system. They operate automatically without human intervention, using pressure differences to open and close. Common types include: 1. Ball Check Valves – use a ball bearing on a spring. 2. Swing Check Valves – use a disk or flapper. 3. Double Check Valves – consist of two units for enhanced protection. 4. Lift Check Valve…

3. Direct Material – Swing Check Valve Diagram

Domain: directmaterial.com

Registered: 2005 (20 years)

Introduction: This company, Direct Material – Swing Check Valve Diagram, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Pinterest – Check Valve Types

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Types of Check Valve, Types of NRV, Types of Non-return Valve

5. Dombor – Check Valves

Domain: dombor.com

Registered: 2021 (4 years)

Introduction: Check valves are crucial devices used in pump outlets, pipelines, and compressors to prevent backflow of fluid. They operate based on pressure differentials between inlet and outlet areas. Key types of check valves include: 1. Swing Check Valve – operates with a disc that swings on a hinge; 2. Lift Check Valve – uses a disc that lifts to allow flow; 3. Dual Plate Check Valve – compact and handles …

6. AFT – Check Valve Junction Type

Domain: docs.aft.com

Registered: 1996 (29 years)

Introduction: Check Valve junction type requires two connecting pipes; models effect of a check valve that closes to prevent back flow; no explicit flow direction; adopts flow direction from connecting pipes for loss calculation; user can define base area for loss model (default is upstream flow area); initially assumed open unless modeled as closed; can close during steady-state or transient simulation; modeli…

Strategic Sourcing Conclusion and Outlook for check valve diagram

In conclusion, the strategic sourcing of check valves is essential for ensuring the efficiency and reliability of fluid control systems across various industries. By understanding the different types of check valves, their operational mechanisms, and the specific applications they serve, B2B buyers can make informed decisions that minimize risks associated with backflow and system contamination. Emphasizing the importance of quality and compliance with industry standards will further enhance operational performance and safety.

For international buyers from Africa, South America, the Middle East, and Europe, the opportunity to source high-quality check valves tailored to your unique operational needs is significant. Engaging with reputable suppliers who offer a range of options, including pilot-operated and non-slam check valves, can lead to optimized system performance and reduced maintenance costs.

As the global market continues to evolve, embracing innovative sourcing strategies and staying abreast of technological advancements will be crucial. Take proactive steps now to evaluate your check valve needs and connect with trusted suppliers to secure a competitive advantage in your sector. Your investment in quality components today will pave the way for sustainable success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.