Central Pneumatic Air Compressor Parts: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for central pneumatic air compressor parts

In today’s competitive landscape, sourcing central pneumatic air compressor parts can pose significant challenges for international B2B buyers. With varying quality standards, fluctuating prices, and an array of suppliers across continents—from Africa to Europe and South America—making informed purchasing decisions is critical for maintaining operational efficiency. This guide aims to demystify the complexities involved in procuring these essential components, offering insights into the types of parts available, their applications in various industries, and best practices for supplier vetting.

Navigating the global market for central pneumatic air compressor parts requires a comprehensive understanding of the components that ensure optimal performance, including pressure switches, air regulators, and compressor pumps. Buyers will benefit from a detailed analysis of pricing structures, shipping considerations, and warranty policies that can impact their bottom line. By equipping B2B buyers with actionable insights, this guide empowers them to make informed decisions that not only enhance their operational capabilities but also foster long-term partnerships with reliable suppliers.

Whether you are based in Brazil, Vietnam, or the Middle East, this resource will serve as your go-to reference for successfully sourcing high-quality central pneumatic air compressor parts that meet your business needs.

Understanding central pneumatic air compressor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pressure Switches | Controls compressor operation based on pressure levels. | Automotive repair, manufacturing. | Pros: Reliable pressure control. Cons: May require calibration. |

| Air Regulators | Regulates airflow and pressure to tools and machinery. | Construction, metalworking. | Pros: Enhances tool efficiency. Cons: Can be sensitive to contaminants. |

| Compressor Pumps | Converts electrical energy into compressed air. | Heavy-duty industrial applications. | Pros: Essential for high-performance. Cons: Higher replacement costs. |

| Air Filters | Removes contaminants from air supply. | Food processing, pharmaceuticals. | Pros: Improves air quality. Cons: Regular maintenance needed. |

| Drain Valves | Allows moisture removal from compressor tanks. | All air compressor applications. | Pros: Prevents rust and damage. Cons: Can be overlooked in maintenance. |

What Are the Characteristics of Pressure Switches in Central Pneumatic Air Compressors?

Pressure switches are crucial components that manage the compressor’s operational cycle by turning it on or off based on the pressure level in the tank. They are typically designed to handle various pressure ranges, making them suitable for different applications, including automotive repair and manufacturing. When purchasing pressure switches, B2B buyers should consider compatibility with existing systems, reliability, and ease of installation, as improper selection can lead to operational inefficiencies.

How Do Air Regulators Enhance Tool Performance?

Air regulators are designed to control the pressure and flow of air supplied to pneumatic tools, ensuring optimal performance. These components are essential in industries like construction and metalworking, where precision and consistent airflow are critical. B2B buyers should assess the regulator’s pressure range, durability, and ease of installation. Investing in high-quality air regulators can significantly enhance the efficiency and longevity of pneumatic tools.

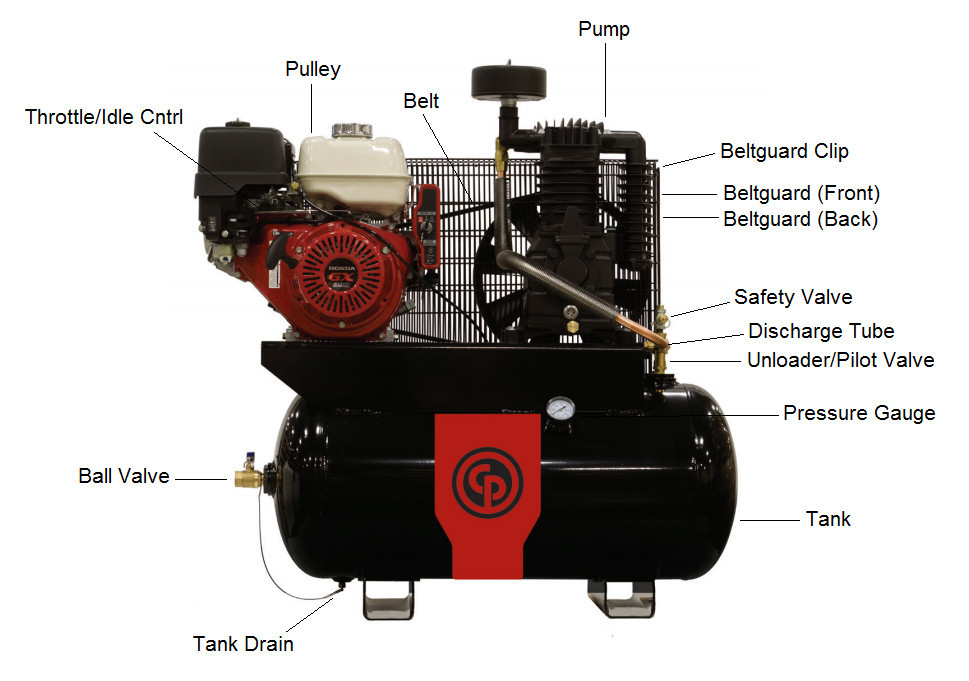

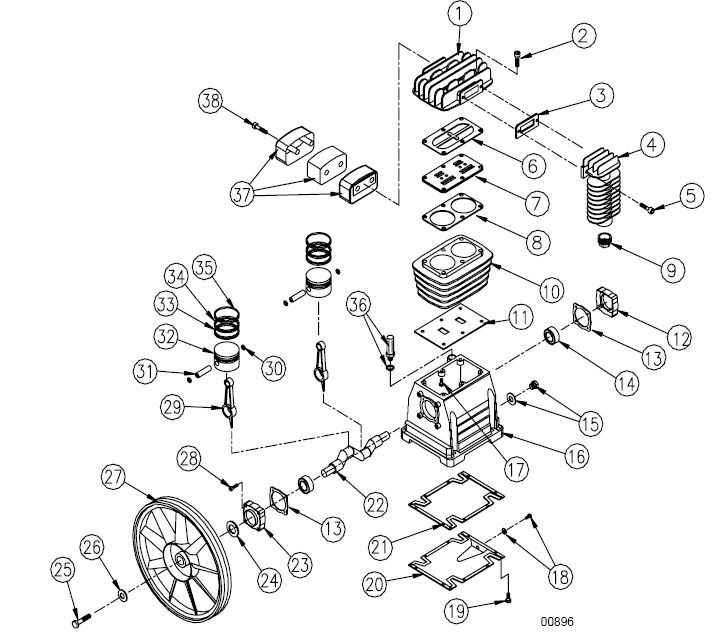

What Should Buyers Know About Compressor Pumps?

Compressor pumps are vital for converting electrical energy into compressed air, serving as the heart of any air compressor system. They come in various sizes and capacities, making them suitable for heavy-duty industrial applications. When sourcing compressor pumps, buyers must consider the pump type (single-stage vs. two-stage), power requirements, and maintenance needs. A high-quality pump ensures reliable operation, but it may come with a higher initial investment.

Why Are Air Filters Important for B2B Applications?

Air filters play a critical role in maintaining the quality of compressed air by removing contaminants that could damage tools and machinery. Industries such as food processing and pharmaceuticals rely heavily on clean air, making air filters indispensable. B2B buyers should focus on the filter’s efficiency ratings, maintenance requirements, and compatibility with existing systems. Regular replacement and maintenance of air filters are essential to avoid costly downtime and equipment damage.

What Role Do Drain Valves Play in Air Compressor Maintenance?

Drain valves are essential for removing moisture from air compressor tanks, preventing rust and damage to the compressor system. They are applicable across all industries using air compressors. Buyers should consider the valve’s ease of use, durability, and compatibility with their systems. Neglecting to maintain drain valves can lead to significant operational issues, making them a critical component in the overall maintenance strategy for air compressors.

Key Industrial Applications of central pneumatic air compressor parts

| Industry/Sector | Specific Application of central pneumatic air compressor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering pneumatic tools for assembly lines | Increased efficiency and productivity in production | Availability of durable parts and fast shipping |

| Automotive Repair | Operating air tools for vehicle maintenance | Enhanced service speed and reduced labor costs | Compatibility with various air tool brands |

| Construction | Supplying compressed air for nail guns and spray equipment | Improved project timelines and reduced manual effort | Quality assurance and compliance with local standards |

| Oil & Gas | Providing air for drilling and refining operations | Reliable operation under harsh conditions | Resistance to corrosion and extreme temperatures |

| Agriculture | Driving equipment for irrigation and crop processing | Increased yield and efficiency in operations | Availability of parts suited for outdoor environments |

How Are Central Pneumatic Air Compressor Parts Used in Manufacturing?

In the manufacturing sector, central pneumatic air compressor parts are essential for powering pneumatic tools used in assembly lines. These tools, such as nail guns and impact wrenches, enhance operational efficiency and productivity. By ensuring a reliable supply of compressed air, manufacturers can minimize downtime and maintain a steady workflow. International buyers, particularly from regions like Africa and South America, should prioritize sourcing durable components that can withstand continuous use and ensure fast shipping to avoid production interruptions.

What Role Do Central Pneumatic Air Compressor Parts Play in Automotive Repair?

In automotive repair shops, central pneumatic air compressor parts are crucial for operating air tools like ratchets, sanders, and paint sprayers. These tools significantly speed up vehicle maintenance and repair processes, reducing labor costs and enhancing service delivery. B2B buyers in the automotive sector must consider the compatibility of parts with various air tool brands and ensure a steady supply chain to maintain operational efficiency.

How Are Central Pneumatic Air Compressor Parts Utilized in Construction?

The construction industry heavily relies on central pneumatic air compressor parts to power nail guns, spray equipment, and other pneumatic tools. This reliance facilitates faster project completion and reduces the manual effort required for tasks like framing and painting. For international buyers, particularly in the Middle East and Europe, sourcing high-quality parts that comply with local safety standards is paramount to ensure reliable performance on-site.

Why Are Central Pneumatic Air Compressor Parts Important in Oil & Gas?

In the oil and gas industry, central pneumatic air compressor parts are used to provide compressed air for drilling and refining operations. These components must operate reliably under harsh conditions, including exposure to corrosive substances and extreme temperatures. Buyers from regions with significant oil reserves, like the Middle East, should prioritize sourcing parts that offer high resistance to wear and corrosion, ensuring longevity and efficiency in their operations.

How Do Central Pneumatic Air Compressor Parts Benefit Agriculture?

In agriculture, central pneumatic air compressor parts are utilized to drive equipment for irrigation systems and crop processing machinery. The efficient use of compressed air can significantly increase yield and operational efficiency. For B2B buyers in regions like Brazil and Vietnam, it’s crucial to source parts that are designed for outdoor environments and can withstand varying weather conditions, ensuring optimal performance throughout the agricultural season.

3 Common User Pain Points for ‘central pneumatic air compressor parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Replacement Parts Quickly

The Problem: Many B2B buyers experience significant delays when trying to source replacement parts for Central Pneumatic air compressors. This often stems from limited availability in their region, leading to prolonged downtime and potential loss of revenue. In industries where air compressors are essential for production or service delivery, any disruption can severely impact operations. Buyers may struggle with locating the right part, understanding compatibility with existing equipment, and navigating the logistics of international shipping, especially in regions with less robust supply chains.

The Solution: To mitigate sourcing delays, B2B buyers should establish relationships with multiple suppliers that specialize in Central Pneumatic parts. Utilizing online marketplaces and specialized industrial parts suppliers can enhance access to a wider inventory. Moreover, leveraging local distributors who maintain stock can facilitate quicker delivery. It’s crucial to maintain a well-documented list of required parts, including model numbers and specifications, to ensure accurate ordering. Buyers should also consider investing in a comprehensive inventory management system to track usage and anticipate future needs, minimizing the risk of sudden shortages.

Scenario 2: Misalignment Between Parts and Equipment Specifications

The Problem: A common issue for buyers is the misalignment between the specifications of replacement parts and the actual requirements of their Central Pneumatic compressors. This often results from insufficient product knowledge or unclear specifications provided by suppliers. Misordering parts can lead to wasted time and resources, as well as further operational disruptions when the incorrect components fail to fit or function as intended.

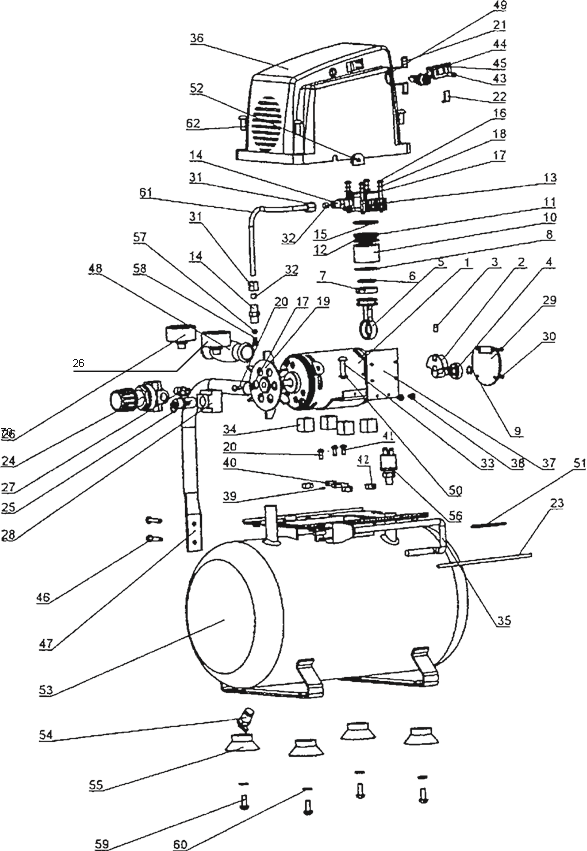

The Solution: To avoid misalignment, buyers should prioritize understanding the specifications of their equipment. This includes consulting the compressor’s manual, which typically contains detailed information about compatible parts and replacement guidelines. Engaging with knowledgeable suppliers who can provide expert advice on part compatibility is also essential. Furthermore, establishing a standardized process for ordering parts, including verification steps for specifications, can help ensure that the correct components are procured. Training staff on how to read and interpret specifications can empower teams to make more informed purchasing decisions.

Scenario 3: Navigating Warranty Claims and Defective Parts

The Problem: When faced with defective parts or equipment, B2B buyers often encounter challenges in navigating warranty claims for Central Pneumatic products. Complications arise from a lack of clear communication with suppliers or manufacturers, leading to frustration and extended periods of equipment inoperability. Additionally, understanding the warranty terms and the proper documentation required can be daunting, especially for buyers unfamiliar with the claims process.

The Solution: To streamline the warranty claims process, buyers should familiarize themselves with the warranty terms associated with their Central Pneumatic air compressors. Maintaining thorough records of purchases, including receipts and serial numbers, is vital for a successful claim. Buyers should establish direct communication channels with customer support teams of their suppliers or manufacturers for quick assistance. It’s also beneficial to document any issues with parts, including photographs and descriptions, to support claims effectively. Regularly reviewing warranty policies and ensuring that all team members are aware of the procedures can significantly enhance the efficiency of managing defective parts.

Strategic Material Selection Guide for central pneumatic air compressor parts

What Are the Key Materials Used in Central Pneumatic Air Compressor Parts?

When selecting materials for central pneumatic air compressor parts, it is crucial to consider their properties and suitability for specific applications. This analysis focuses on four common materials: aluminum, steel, brass, and plastic. Each material has unique characteristics that can significantly impact performance, durability, and cost-effectiveness.

How Does Aluminum Perform in Air Compressor Parts?

Aluminum is widely used for various components in air compressors due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressures, making it suitable for parts like housings and brackets.

Pros: Aluminum’s lightweight property reduces the overall weight of the compressor, enhancing portability. It is also resistant to rust, which is particularly advantageous in humid climates common in regions like Africa and South America.

Cons: While aluminum is durable, it may not withstand high-pressure applications as effectively as other materials. It is also more expensive than some alternatives, which could be a consideration for budget-sensitive buyers.

Impact on Application: Aluminum is compatible with various media, including air and oil, but may not be suitable for corrosive gases. Buyers should ensure that the application environment aligns with aluminum’s limitations.

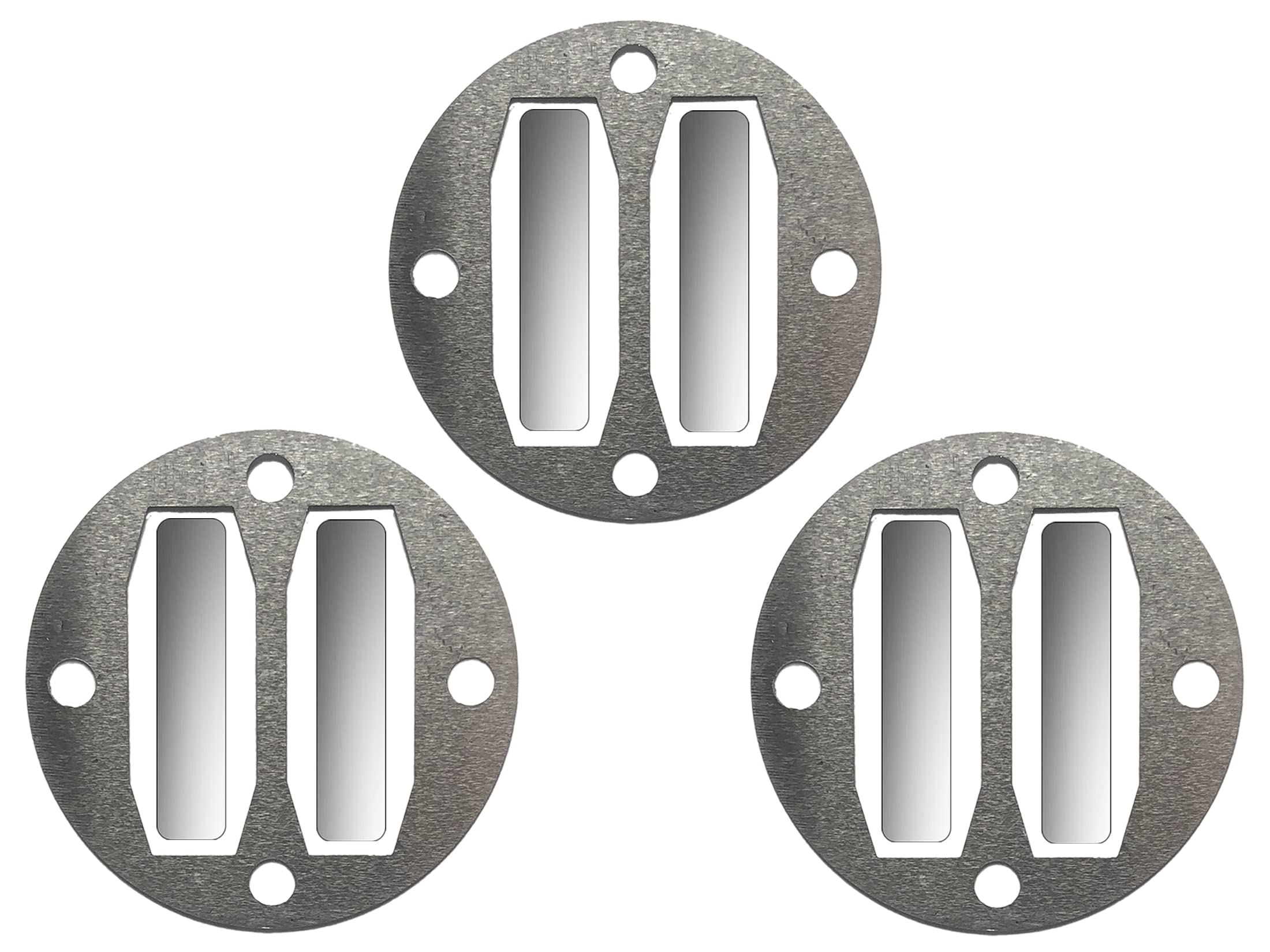

Illustrative image related to central pneumatic air compressor parts

International Considerations: Buyers from Europe and the Middle East should ensure compliance with relevant standards such as EN 573 for aluminum alloys.

What Advantages Does Steel Offer for Compressor Components?

Steel is another common material used in air compressor parts, particularly for components that require high strength and durability, such as tanks and frames. Steel can handle higher temperatures and pressures, often rated above 200°C.

Pros: Steel’s strength makes it ideal for high-stress applications, and it generally has a lower cost compared to aluminum. Its durability ensures a longer lifespan, which is appealing for businesses looking to minimize replacement costs.

Cons: Steel is heavier than aluminum, which may affect the portability of the compressor. Additionally, it is prone to corrosion if not properly treated, which can be a significant drawback in humid or corrosive environments.

Impact on Application: Steel is suitable for various media, including air and oil, but may require protective coatings to prevent rust.

Illustrative image related to central pneumatic air compressor parts

International Considerations: Compliance with ASTM A36 or similar standards is essential for steel components, especially for buyers in Africa and South America, where local regulations may vary.

Why is Brass a Preferred Material for Specific Parts?

Brass is often used for fittings, valves, and connectors in air compressors due to its excellent corrosion resistance and machinability. It can withstand moderate pressures and temperatures, typically rated up to 120°C.

Pros: Brass’s corrosion resistance makes it ideal for applications involving moisture or oil, ensuring longevity. Its ease of machining allows for precise fittings, which is crucial for maintaining system integrity.

Cons: Brass is generally more expensive than both aluminum and steel, which may deter cost-conscious buyers. It is also less suitable for high-pressure applications.

Impact on Application: Brass is compatible with air and oil, making it a reliable choice for various compressor parts.

International Considerations: Buyers should be aware of standards such as ASTM B16 for brass components, especially in regions like Europe where compliance is heavily regulated.

How Does Plastic Fit into the Material Selection for Compressors?

Plastic is increasingly being used in air compressor parts, particularly for non-structural components like covers and insulation. It is lightweight and can handle temperatures up to 80°C.

Pros: Plastic is cost-effective and lightweight, which can significantly reduce manufacturing and shipping costs. It also offers good insulation properties, which can enhance safety.

Cons: Plastic generally has lower strength and durability compared to metals, making it less suitable for high-stress applications. It may also degrade over time when exposed to certain chemicals.

Illustrative image related to central pneumatic air compressor parts

Impact on Application: Plastic is suitable for air and non-corrosive media but should be avoided in high-pressure or high-temperature environments.

International Considerations: Compliance with standards such as ISO 9001 for quality management is essential for plastic components, particularly for buyers in the Middle East and Europe.

Summary Table of Material Selection for Central Pneumatic Air Compressor Parts

| Material | Typical Use Case for central pneumatic air compressor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings, brackets | Lightweight and corrosion-resistant | Limited high-pressure capability | Medium |

| Steel | Tanks, frames | High strength and durability | Prone to corrosion without treatment | Low |

| Brass | Fittings, valves | Excellent corrosion resistance | Higher cost, limited high-pressure use | High |

| Plastic | Covers, insulation | Cost-effective and lightweight | Lower strength, chemical degradation | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for central pneumatic air compressor parts

What Are the Key Stages in the Manufacturing Process of Central Pneumatic Air Compressor Parts?

The manufacturing process for Central Pneumatic air compressor parts typically involves several critical stages, ensuring high-quality output that meets industry standards. Understanding these stages can help B2B buyers make informed decisions when sourcing parts.

Illustrative image related to central pneumatic air compressor parts

1. Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. Common materials used in air compressor parts include aluminum, steel, and various plastics. These materials are chosen for their durability and resistance to wear and corrosion.

During the preparation stage, materials undergo inspections to verify their quality and suitability for production. This may involve checking for impurities, verifying chemical compositions, and ensuring that materials meet specified thickness and hardness requirements.

2. Forming Techniques: How Are Parts Shaped?

Once the materials are prepared, they enter the forming stage. This involves various techniques such as casting, machining, and forging, depending on the specific part being produced.

- Casting: This technique is often used for complex shapes like compressor housings. Molten metal is poured into molds and allowed to cool, forming the desired shape.

- Machining: Parts that require high precision, such as pistons and valves, are typically machined from solid blocks of metal. This process includes turning, milling, and drilling.

- Forging: This technique is employed for components that need to withstand high stress, such as crankshafts. Metal is heated and shaped under pressure, enhancing its strength.

3. Assembly Process: How Are Parts Joined Together?

After individual components are manufactured, they proceed to the assembly stage. This is where parts such as compressors, motors, and tanks are assembled into a complete unit.

The assembly process often incorporates both manual and automated techniques. Automated assembly lines can enhance efficiency and reduce human error, while skilled technicians ensure that each component is correctly fitted and aligned.

Quality checks during assembly are critical, including torque checks and alignment verifications, to ensure that the assembled compressor meets performance specifications.

4. Finishing: What Are the Final Touches Applied?

The finishing stage adds the final touches to the parts. This can involve surface treatments such as painting, anodizing, or powder coating to enhance aesthetics and protect against corrosion.

In addition, parts may undergo polishing or deburring to eliminate sharp edges and improve surface smoothness, which is crucial for optimal performance and safety.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is vital in ensuring that Central Pneumatic air compressor parts meet specific performance and safety standards. Buyers should be familiar with international and industry-specific standards to assess supplier capabilities effectively.

Illustrative image related to central pneumatic air compressor parts

ISO 9001: What Does It Mean for Quality Management?

ISO 9001 is a globally recognized standard for quality management systems (QMS). Suppliers adhering to this standard demonstrate a commitment to continuous improvement and customer satisfaction.

B2B buyers should verify that their suppliers are certified to ISO 9001, as this indicates systematic processes for quality control, from material procurement through to production and delivery.

What Are Other Relevant Industry Standards?

In addition to ISO 9001, buyers should consider industry-specific certifications such as:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards. Essential for products sold in the European market.

- API Standards: For parts used in oil and gas applications, API (American Petroleum Institute) standards ensure that components can withstand harsh conditions.

How Is Quality Controlled Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integral at various stages of manufacturing to ensure that parts meet the required specifications.

Incoming Quality Control (IQC)

The first line of defense in quality assurance is Incoming Quality Control (IQC). This involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Non-compliant materials are rejected, preventing defects from entering the production line.

In-Process Quality Control (IPQC)

During the manufacturing process, In-Process Quality Control (IPQC) measures are taken to monitor production. This may involve regular inspections, sampling, and testing of parts at various stages to catch any issues early.

Final Quality Control (FQC)

Final Quality Control (FQC) takes place before products are shipped. This includes comprehensive testing of finished parts to ensure they meet performance standards. Common tests may include pressure tests, operational tests, and dimensional inspections.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality assurance processes is crucial.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control practices. Buyers can request to visit manufacturing facilities or conduct virtual audits to evaluate production processes, quality systems, and compliance with standards.

What Documentation Should Buyers Request?

Buyers should request documentation such as:

- Quality assurance reports

- Certificates of compliance (e.g., ISO 9001, CE)

- Testing and inspection reports

These documents provide insights into the supplier’s commitment to quality and help ensure that they meet international standards.

How Important Are Third-Party Inspections?

Engaging third-party inspection services adds an extra layer of assurance. Independent inspectors can validate the quality of materials, production processes, and final products, offering unbiased assessments that enhance buyer confidence.

Conclusion: Ensuring Quality in Sourcing Central Pneumatic Air Compressor Parts

Understanding the manufacturing processes and quality assurance measures for Central Pneumatic air compressor parts is essential for B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, and effective verification methods, international buyers can make informed sourcing decisions that ensure reliability and performance in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘central pneumatic air compressor parts’

Introduction

Sourcing Central Pneumatic air compressor parts can be a critical task for B2B buyers seeking to maintain efficiency and reliability in their operations. This guide provides a structured checklist to streamline your procurement process, ensuring you make informed decisions that align with your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Understanding the specific technical requirements of the air compressor parts you need is essential. This includes identifying the model number, type of part (e.g., pressure switches, filters, pumps), and any unique features that may be required for compatibility. Clear specifications prevent costly errors and delays in the procurement process.

Step 2: Research Reputable Suppliers

Begin by researching suppliers known for their quality and reliability in providing Central Pneumatic parts. Look for suppliers with a strong online presence, positive customer reviews, and industry certifications. Consider reaching out to other businesses in your region or sector for recommendations to ensure you engage with trustworthy vendors.

Step 3: Evaluate Potential Suppliers

Before making a purchase, conduct a thorough evaluation of your shortlisted suppliers. Request detailed company profiles, including their experience with Central Pneumatic products, case studies, and references from clients in similar industries. This step helps mitigate risks associated with quality and service delivery.

Illustrative image related to central pneumatic air compressor parts

Step 4: Check Availability of Parts

Confirm that the suppliers have the specific parts you need in stock. Inquire about lead times for backordered items and their ability to fulfill bulk orders. Having reliable inventory is crucial for maintaining your operational uptime and preventing delays in your projects.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers meet necessary quality standards and certifications relevant to your industry. This may include ISO certifications or specific safety standards for air compressor components. Certification verification is vital to ensure that the parts you procure will meet safety and performance expectations.

Step 6: Request Quotes and Compare Pricing

Once you have identified potential suppliers, request detailed quotes that outline pricing, shipping costs, and payment terms. Comparing multiple quotes allows you to assess the market rate and negotiate better terms, ensuring you receive the best value for your investment.

Step 7: Review Warranty and Return Policies

Before finalizing your purchase, review the warranty and return policies provided by the supplier. Understanding these policies is crucial for protecting your investment and ensuring you have recourse should any parts fail to meet quality standards. Look for suppliers who offer clear, fair policies that support your business needs.

By following this structured checklist, B2B buyers can confidently source Central Pneumatic air compressor parts, ensuring operational efficiency and long-term reliability.

Comprehensive Cost and Pricing Analysis for central pneumatic air compressor parts Sourcing

What Are the Key Cost Components in Sourcing Central Pneumatic Air Compressor Parts?

Understanding the cost structure for sourcing Central Pneumatic air compressor parts is essential for B2B buyers aiming to optimize their purchasing strategy. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials directly impacts the cost. High-quality, durable materials tend to increase the price but can lead to lower failure rates and longer product lifespans. Buyers should consider the balance between upfront costs and long-term durability.

-

Labor: Labor costs vary significantly based on the region of production. For instance, manufacturing in countries with lower labor costs can reduce overall expenses. However, it’s crucial to assess the skill level of the workforce, as this can affect the quality of the parts produced.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient production processes can minimize overhead, allowing suppliers to offer competitive pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. These costs are often amortized over the production run, making high-volume orders more cost-effective.

-

Quality Control (QC): Rigorous QC processes ensure that parts meet specified standards, but they also add to the overall cost. Buyers should inquire about the supplier’s QC protocols to ensure they align with their quality expectations.

-

Logistics: Transportation and shipping costs are critical, particularly for international transactions. Factors such as distance, shipping method, and import tariffs can significantly influence total costs.

-

Margin: Suppliers typically add a profit margin to cover risks and business expenses. Understanding typical margins in the industry can help buyers gauge whether they are receiving fair pricing.

How Do Price Influencers Affect the Cost of Air Compressor Parts?

Several factors can influence the pricing of Central Pneumatic air compressor parts, impacting both initial costs and long-term value.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often come with volume discounts. Buyers should assess their needs and consider ordering in bulk to reduce per-unit costs.

-

Specifications/Customization: Customized parts may incur additional costs due to unique tooling or materials required. Clear communication with suppliers regarding specifications can help avoid unexpected charges.

-

Materials and Quality Certifications: Parts made from premium materials or those certified by recognized standards (e.g., ISO) may carry higher prices but provide assurance of quality and reliability.

-

Supplier Factors: Reputation, reliability, and customer service of suppliers can also influence pricing. Established suppliers with a history of quality service may charge more but offer peace of mind.

-

Incoterms: The choice of Incoterms affects the distribution of costs and risks in international shipping. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for accurate cost assessments.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Air Compressor Parts?

To maximize value when sourcing Central Pneumatic air compressor parts, buyers should consider the following strategies:

Illustrative image related to central pneumatic air compressor parts

-

Negotiation: Engage in negotiations with suppliers to explore pricing flexibility, especially for large orders. Building a long-term relationship can also lead to better terms and discounts.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the purchase price. This includes maintenance, operational efficiency, and potential downtime costs. Investing in higher-quality parts may yield lower overall costs.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations and their impact on pricing. Additionally, understanding local regulations and tariffs can prevent unexpected expenses.

-

Market Research: Conducting thorough market research can help buyers identify competitive pricing and alternatives. Comparing multiple suppliers can provide leverage during negotiations.

-

Stay Updated on Trends: Keeping abreast of industry trends, such as advancements in materials or manufacturing processes, can lead to informed purchasing decisions and potential cost savings.

In summary, a comprehensive understanding of cost structures and price influencers, combined with strategic buying practices, can significantly enhance the efficiency and effectiveness of sourcing Central Pneumatic air compressor parts for international B2B buyers.

Alternatives Analysis: Comparing central pneumatic air compressor parts With Other Solutions

Exploring Alternatives to Central Pneumatic Air Compressor Parts

When considering air compressor parts for industrial applications, it’s vital to evaluate alternatives that can meet specific operational needs. Central Pneumatic air compressor parts are widely recognized for their affordability and compatibility, but other options may provide enhanced performance, cost savings, or specialized features. This analysis will compare Central Pneumatic parts against two viable alternatives: Ingersoll Rand air compressor parts and rotary screw compressors.

| Comparison Aspect | Central Pneumatic Air Compressor Parts | Ingersoll Rand Air Compressor Parts | Rotary Screw Compressors |

|---|---|---|---|

| Performance | Reliable for light to moderate tasks | High performance for industrial applications | Continuous operation, high efficiency |

| Cost | Lower initial investment | Higher upfront costs, but durable | Higher initial investment, long-term savings |

| Ease of Implementation | User-friendly, accessible parts | Requires specialized knowledge for installation | Complex installation, may need professional setup |

| Maintenance | Moderate maintenance requirements | Low maintenance, high durability | Generally low maintenance, but parts can be costly |

| Best Use Case | Hobbyists, small businesses | Large-scale industrial operations | Continuous production environments |

What Are the Advantages of Ingersoll Rand Air Compressor Parts?

Ingersoll Rand parts are known for their robust construction and high-performance capabilities, making them ideal for industrial settings. They offer excellent reliability and longevity, which can lead to lower total costs over time due to reduced downtime and maintenance needs. However, the initial investment is significantly higher than Central Pneumatic parts, which may deter smaller businesses or those with limited budgets. Additionally, installation may require specialized knowledge or trained technicians, which can add to the overall project costs.

Why Consider Rotary Screw Compressors?

Rotary screw compressors are designed for continuous operation and are highly efficient, making them suitable for environments where air supply is critical. They generally have lower noise levels and offer better energy efficiency compared to piston-based compressors. However, the upfront costs can be a barrier, and their installation complexity often necessitates professional assistance. While they may require a higher investment initially, their low maintenance needs and long service life can make them a cost-effective solution for larger operations.

Making the Right Choice for Your Air Compressor Needs

Choosing the right air compressor parts or systems depends on several factors, including budget, operational demands, and maintenance capabilities. Central Pneumatic parts offer an economical solution for light to moderate tasks, making them suitable for hobbyists and small businesses. In contrast, Ingersoll Rand parts cater to high-demand industrial environments, while rotary screw compressors excel in continuous operation scenarios.

B2B buyers should carefully assess their unique requirements and long-term operational goals when selecting air compressor solutions. Prioritizing factors such as performance needs, budget constraints, and maintenance capabilities can help ensure that the chosen solution aligns with both immediate and future demands.

Essential Technical Properties and Trade Terminology for central pneumatic air compressor parts

What Are the Key Technical Properties of Central Pneumatic Air Compressor Parts?

Understanding the essential technical properties of central pneumatic air compressor parts is crucial for international B2B buyers. Here are some critical specifications to consider:

-

Material Grade

The material grade refers to the quality and type of materials used in manufacturing air compressor parts, such as aluminum, steel, or plastic. Higher-grade materials often enhance durability and performance, leading to lower maintenance costs and longer service life. For B2B buyers, selecting parts made from high-grade materials can result in better reliability, especially in demanding environments. -

Tolerance

Tolerance is the allowable variation in dimensions of a part. For air compressor components, precise tolerances are vital to ensure proper fit and function. Parts that do not meet specified tolerances can lead to inefficiencies, increased wear, and potential system failures. Understanding tolerances helps buyers ensure compatibility with existing systems, minimizing the risk of operational disruptions. -

Pressure Rating

This specification indicates the maximum pressure that a component can safely withstand. Pressure ratings are critical for parts like pressure switches and valves, as exceeding them can result in catastrophic failure. B2B buyers must ensure that the parts they purchase can handle the operational pressures of their compressors to maintain safety and efficiency. -

Flow Rate

The flow rate measures the volume of air that a compressor can deliver, typically expressed in cubic feet per minute (CFM). This property is essential for matching the compressor to its intended application. Buyers need to evaluate the required flow rates for their tools and equipment to ensure optimal performance and avoid underperformance. -

Operating Temperature

Each component has a specified operating temperature range, indicating the extremes of temperature at which it can function effectively. Parts that exceed these temperatures may degrade or fail prematurely. Understanding these limits helps buyers select components that will operate reliably in their specific environmental conditions.

What Are Common Trade Terms Related to Central Pneumatic Air Compressor Parts?

Familiarity with industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold to another company to be included in their products. For air compressor parts, purchasing OEM components ensures compatibility and reliability, as they are designed specifically for a particular model. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it can impact inventory costs and purchasing decisions. Suppliers may set MOQs to ensure profitability, especially for specialized components. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific parts. It’s a critical step in the procurement process, allowing buyers to compare offers and negotiate better deals. Crafting a detailed RFQ can help buyers ensure they receive accurate and competitive quotes. -

Incoterms

Incoterms, short for International Commercial Terms, are a series of pre-defined commercial terms published by the International Chamber of Commerce. These terms clarify the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding Incoterms is crucial for minimizing risks associated with international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the context of air compressor parts, shorter lead times can enhance operational efficiency and reduce downtime. Buyers should inquire about lead times when negotiating contracts to ensure timely delivery. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary within a specified period. Understanding warranty terms is vital for buyers, as it provides insight into the manufacturer’s confidence in their products and can influence purchasing decisions.

By comprehending these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing central pneumatic air compressor parts, ultimately enhancing their operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the central pneumatic air compressor parts Sector

What Are the Current Market Dynamics and Sourcing Trends for Central Pneumatic Air Compressor Parts?

The market for central pneumatic air compressor parts is shaped by several global drivers, including increased industrialization, a growing emphasis on efficient energy use, and an expanding manufacturing sector in developing regions like Africa and South America. International B2B buyers are increasingly seeking reliable suppliers that offer high-quality replacement parts to maintain their operational efficiency. Key trends include the digital transformation of supply chains, where e-commerce platforms and online marketplaces facilitate faster procurement processes, particularly for parts that may not be readily available locally.

Moreover, the rise of predictive maintenance technologies is leading to a shift from reactive to proactive sourcing strategies. This trend is particularly relevant in regions such as the Middle East and Europe, where businesses are investing in IoT-enabled equipment that can signal the need for parts before failures occur. Buyers are also focusing on suppliers that provide comprehensive catalogs of parts, ensuring that they can source everything from pressure switches to air filters from a single platform, thus reducing lead times and logistical complexities.

How Are Sustainability and Ethical Sourcing Influencing the Central Pneumatic Air Compressor Parts Sector?

Sustainability is becoming a critical factor in the sourcing of central pneumatic air compressor parts. Buyers are increasingly aware of the environmental impact of their procurement choices, prompting them to seek suppliers who prioritize eco-friendly practices. This includes the use of recyclable materials and the implementation of sustainable manufacturing processes.

Illustrative image related to central pneumatic air compressor parts

Ethical sourcing is also gaining traction, with companies looking for suppliers that adhere to social responsibility standards. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can enhance a supplier’s appeal to conscientious buyers. Moreover, there is a growing trend toward the use of ‘green’ lubricants and oils in air compressor maintenance, which not only reduces environmental harm but also improves operational efficiency. By aligning with suppliers that prioritize sustainability, B2B buyers can enhance their own brand reputation while contributing to a more sustainable industrial ecosystem.

How Has the Central Pneumatic Air Compressor Parts Market Evolved Over Time?

The evolution of the central pneumatic air compressor parts market can be traced back to the early days of industrial machinery. Initially, air compressors were simplistic in design, primarily serving basic functions. However, as industries advanced, the demand for more sophisticated and reliable air compressor systems surged, leading to the development of specialized parts designed for enhanced performance and longevity.

Over the years, the market has witnessed significant innovations, including advancements in materials and manufacturing techniques that have improved the durability and efficiency of compressor components. The advent of online platforms has transformed how businesses source these parts, allowing for greater accessibility and convenience. Today, international buyers can easily compare prices, quality, and supplier reliability, making the procurement process more efficient than ever before. This evolution reflects a broader trend towards increased specialization and technological integration within the industrial sector, setting the stage for future growth and innovation in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of central pneumatic air compressor parts

-

How do I solve issues with my Central Pneumatic air compressor not starting?

To troubleshoot a Central Pneumatic air compressor that won’t start, check the power supply and ensure that the unit is plugged in and the outlet is functional. Inspect the pressure switch and reset it if necessary. Verify that the compressor’s safety features, such as thermal overload or circuit breakers, are not triggered. If the problem persists, consider replacing worn-out components like capacitors or pressure switches, which are commonly available as replacement parts. Always consult the user manual for specific troubleshooting steps. -

What is the best replacement part for a malfunctioning pressure switch in Central Pneumatic air compressors?

The best replacement part for a malfunctioning pressure switch is typically the OEM (Original Equipment Manufacturer) part designed specifically for your compressor model. This ensures compatibility and reliability. Many suppliers offer a range of pressure switches compatible with Central Pneumatic models, such as the Central Pneumatic 47065 or 68067. When sourcing, ensure you check the specifications and compatibility with your air compressor to avoid installation issues. -

How can I ensure quality when sourcing Central Pneumatic air compressor parts internationally?

To ensure quality when sourcing parts internationally, conduct thorough due diligence on potential suppliers. Look for suppliers with a proven track record and positive reviews from other B2B buyers. Request samples or certifications to verify product quality. Consider suppliers that offer warranties or guarantees on their parts. Additionally, engage in direct communication to assess their responsiveness and reliability, which can be indicative of overall service quality. -

What are the typical minimum order quantities (MOQs) for Central Pneumatic air compressor parts?

Minimum order quantities (MOQs) for Central Pneumatic air compressor parts can vary significantly depending on the supplier and part type. Generally, MOQs can range from a single unit for commonly used parts to hundreds for bulk orders. It’s crucial to negotiate MOQs directly with suppliers, especially when sourcing for international markets, as they may be flexible based on your purchasing needs and relationship with the supplier. -

What payment terms should I consider when purchasing from international suppliers?

When purchasing from international suppliers, consider payment terms that mitigate risk while ensuring smooth transactions. Common terms include partial payment upfront (20-30%) with the balance due upon shipment or delivery. Using secure payment methods such as letters of credit or escrow services can protect both parties. Always clarify currency exchanges, fees, and payment timelines before finalizing any agreement to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing air compressor parts?

When importing air compressor parts, consider logistics factors such as shipping methods, transit times, and customs regulations. Choose between air freight for faster delivery or sea freight for cost-effective bulk shipping. Understand the customs duties and taxes applicable in your country, and ensure proper documentation to avoid delays. Partnering with a reliable freight forwarder can help streamline the import process and manage any potential logistical challenges. -

How can I customize air compressor parts to fit my specific needs?

Customization of air compressor parts can often be arranged through direct communication with suppliers. Discuss your specific requirements, such as dimensions, materials, or performance specifications, and inquire if the supplier can accommodate custom orders. Some manufacturers offer tailored solutions for unique applications, but be prepared for potentially higher costs and longer lead times. Always request prototypes or samples before finalizing custom orders to ensure they meet your specifications. -

What is the warranty process for defective Central Pneumatic air compressor parts?

The warranty process for defective Central Pneumatic air compressor parts typically involves contacting the supplier or manufacturer directly. Most reputable suppliers will require proof of purchase and may ask for details about the defect. Depending on the warranty policy, you might receive a replacement part at no cost or a repair service. Familiarize yourself with the warranty terms before purchasing to understand your rights and the claims process in case of defective parts.

Top 3 Central Pneumatic Air Compressor Parts Manufacturers & Suppliers List

1. Liberty Industrial Lubricants – Central Pneumatic Air Compressor Parts

Domain: libertyindustriallubricants.com

Registered: 2022 (3 years)

Introduction: Central Pneumatic Air Compressor Parts and Oil includes various components such as air filter assemblies, pressure switches, oil filters, separator filters, and lubricants. Key products include:

– Air filter assembly for Powermate

– Inlet air filter assembly for Powermate

– Pressure switches for Sanborn and Craftsman

– Oil filter replacements for Ingersoll Rand and Sullair

– Quincy compressor…

2. Central Pneumatic – Air Tools and Compressors

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Central Pneumatic products include a variety of air tools and compressors such as air nailers, staplers, cut-off tools, paint sprayers, air compressors, sanders, polishers, grinders, hammers, ratchets, and wrenches. They also offer automotive tools like vehicle spray guns, impact wrenches, and air tools. The products are categorized under Home & Garden, Business & Industrial, and Toys & Hobbies, w…

3. Central Pneumatic – Parts Order Information

Domain: mastertoolrepair.com

Registered: 1999 (26 years)

Introduction: Master Tool Repair no longer carries parts for Central Pneumatic air compressor units. Please call Harbor Freight at 1-800-444-3353 to order parts. There are no products listed under this category.

Strategic Sourcing Conclusion and Outlook for central pneumatic air compressor parts

As we conclude this comprehensive guide on central pneumatic air compressor parts, it is essential to recognize the critical role that strategic sourcing plays in optimizing operational efficiency. By focusing on acquiring high-quality replacement parts, businesses can significantly reduce downtime and extend the lifespan of their equipment. The availability of a diverse range of components—such as pressure switches, compressors, and air filters—ensures that international buyers can tailor their sourcing strategies to meet specific operational needs.

For B2B buyers in Africa, South America, the Middle East, and Europe, leveraging reliable suppliers is key to maintaining a competitive edge. Engaging with trusted distributors not only guarantees access to quality parts but also fosters strong supplier relationships that can lead to better pricing and service. As the global market evolves, staying informed about the latest developments in air compressor technology and parts availability will be crucial.

Looking ahead, we encourage buyers to actively explore partnerships that enhance their sourcing capabilities. By prioritizing strategic sourcing, companies can ensure they are well-prepared to meet future demands while optimizing their operational performance. Invest in quality today to secure a more efficient tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.