Car Wash Business Equipment List Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for car wash business equipment list

In the fast-evolving landscape of the car wash industry, sourcing the right car wash business equipment list is crucial for success. International B2B buyers face the challenge of navigating a diverse market filled with varying standards and expectations, particularly in regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide serves as a valuable resource, offering an in-depth exploration of essential equipment types, their applications, supplier vetting processes, and cost considerations.

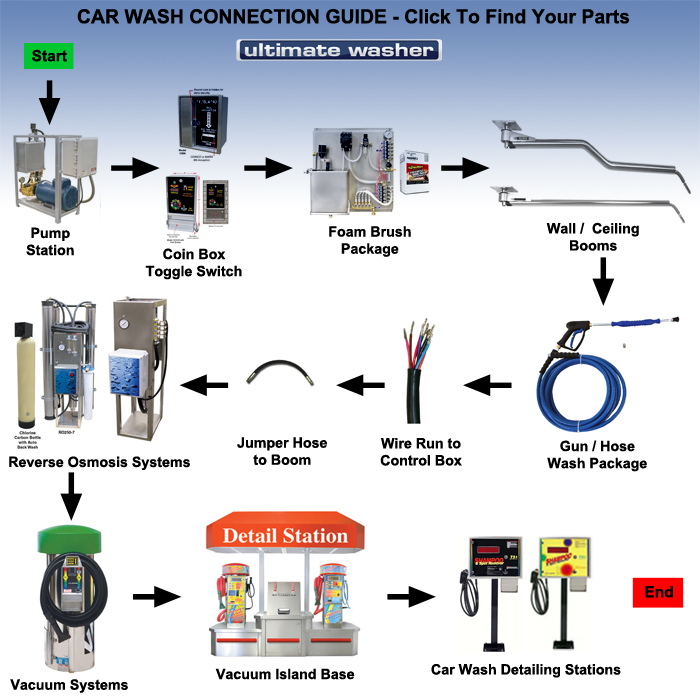

By delving into the specifics of high-pressure washers, vacuum systems, and water treatment technologies, this guide empowers buyers to make informed purchasing decisions tailored to their unique operational needs. Additionally, it highlights the importance of understanding regional market dynamics and regulatory requirements, ensuring compliance and optimal performance.

With actionable insights and expert recommendations, this guide equips international buyers with the knowledge needed to enhance their car wash operations, improve service quality, and ultimately drive profitability. Whether you are a new entrant looking to establish your business or an experienced operator seeking to upgrade your equipment, this resource will help you navigate the complexities of sourcing and investing in car wash equipment effectively.

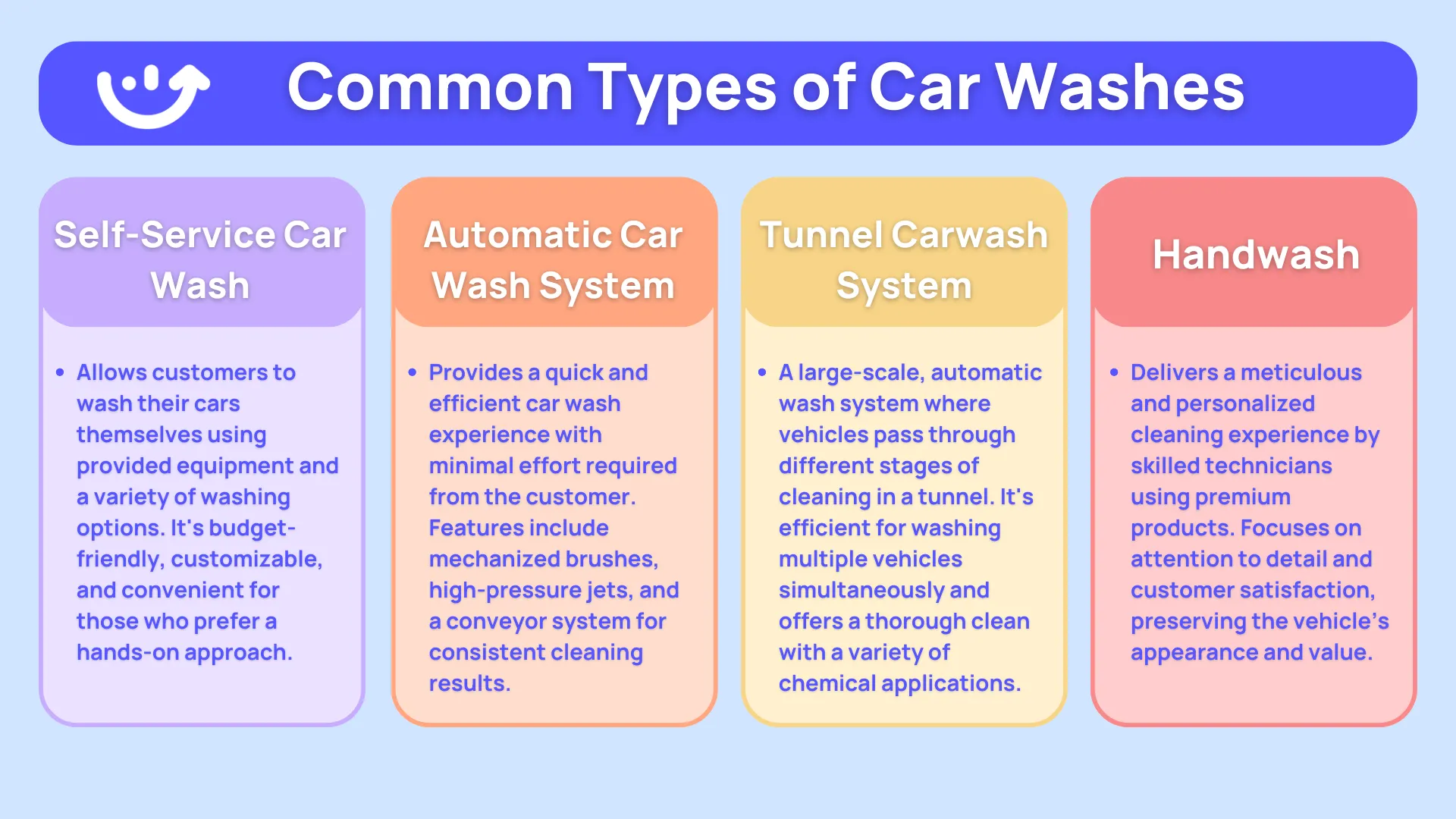

Understanding car wash business equipment list Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Pressure Washers | Adjustable pressure settings, robust cleaning capability | Exterior car washing, fleet maintenance | Pros: Effective dirt removal; Cons: High cost and maintenance requirements. |

| Vacuum Systems | Strong suction, specialized attachments | Interior cleaning, detailing services | Pros: Efficient cleaning; Cons: Can be bulky and require dedicated space. |

| Water Filtration Systems | Removes impurities, protects equipment | Environmental compliance, water quality control | Pros: Prolongs equipment life; Cons: Initial investment can be significant. |

| Car Wash POS Systems | Integrated sales and inventory management | Business operations, customer engagement | Pros: Streamlines processes; Cons: Learning curve for new users. |

| Detailing Equipment | Specialized tools for polishing and waxing | High-end detailing services | Pros: Enhances finish quality; Cons: Requires skilled operators. |

What Are High-Pressure Washers and Why Are They Essential for Car Wash Businesses?

High-pressure washers are a cornerstone of any car wash operation, designed to deliver powerful streams of water that effectively remove dirt and grime from vehicle exteriors. These machines typically feature adjustable pressure settings, allowing operators to tailor the cleaning process based on the vehicle type and surface sensitivity. B2B buyers should consider factors such as PSI ratings, durability, and ease of maintenance when selecting high-pressure washers, as these aspects can significantly affect operational efficiency and cost over time.

How Do Vacuum Systems Enhance Interior Cleaning in Car Wash Operations?

Vacuum systems play a critical role in maintaining the cleanliness of a vehicle’s interior. Equipped with strong suction power and various attachments, these systems can efficiently remove debris from hard-to-reach areas, such as under seats and in corners. B2B buyers should evaluate the vacuum’s capacity, suction strength, and ease of use, as these features influence the speed and effectiveness of cleaning operations. Additionally, considering the space required for installation is essential for optimizing workflow in the car wash facility.

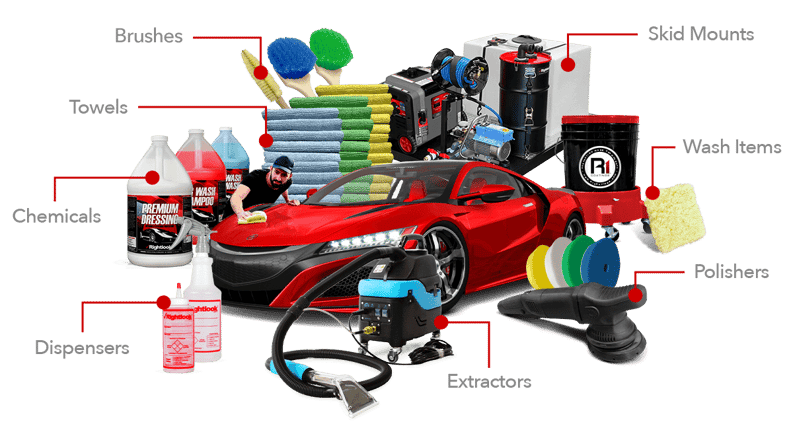

Illustrative image related to car wash business equipment list

Why Are Water Filtration Systems Important for Car Wash Businesses?

Water filtration systems are vital for ensuring the quality of water used in car washing, protecting both the environment and the vehicles being serviced. These systems effectively remove minerals and impurities, which can damage vehicle finishes and lead to equipment wear. For B2B buyers, key considerations include the system’s capacity to handle the volume of water used and its maintenance requirements. Investing in a reliable water filtration system can yield long-term savings and compliance with environmental regulations.

What Role Do Car Wash POS Systems Play in Business Operations?

Car wash POS systems are essential for modernizing business operations by integrating sales processing with inventory management and customer engagement tools. These systems streamline transactions, track sales data, and enhance customer service, making them invaluable for any car wash business. B2B buyers should assess the system’s compatibility with existing operations, ease of use, and the range of features offered. While the initial learning curve may pose a challenge, the long-term benefits of improved efficiency and customer satisfaction are significant.

How Does Detailing Equipment Contribute to High-Quality Car Care?

Detailing equipment, including polishers and wax applicators, is crucial for delivering high-end car care services. These tools are designed to enhance the vehicle’s finish, providing a polished and professional appearance that can attract discerning customers. When purchasing detailing equipment, B2B buyers should focus on the quality of materials, ease of use, and the skill level required for operation. Investing in high-quality detailing tools can differentiate a car wash business from competitors and elevate the overall customer experience.

Key Industrial Applications of car wash business equipment list

| Industry/Sector | Specific Application of car wash business equipment list | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Dealerships | Regular car cleaning and detailing services | Enhances vehicle presentation, boosts customer satisfaction, and increases sales opportunities. | Look for high-capacity equipment that can handle multiple vehicles efficiently. Reliability and ease of maintenance are critical. |

| Fleet Management | Cleaning and maintenance of company vehicles | Reduces operational costs by maintaining vehicle aesthetics and longevity, ensuring compliance with company standards. | Consider equipment that is durable and capable of high-volume cleaning to minimize downtime. |

| Car Rental Services | Pre-rental cleaning and post-rental detailing | Ensures vehicles are in pristine condition, enhancing customer experience and retention rates. | Focus on versatile equipment that can handle various vehicle types and sizes quickly. |

| Transportation Services | Regular washing of buses, trucks, and vans | Improves fleet appearance and safety, which can enhance brand reputation and customer trust. | Prioritize robust equipment that can withstand heavy usage and environmental conditions. |

| Car Wash Franchises | Standardized cleaning processes across multiple locations | Streamlines operations, ensuring consistent service quality and customer satisfaction. | Look for scalable equipment solutions and comprehensive training support for staff. |

How Are Automotive Dealerships Utilizing Car Wash Business Equipment?

Automotive dealerships frequently employ car wash equipment to maintain their inventory’s visual appeal. Regular cleaning and detailing not only enhance the presentation of vehicles but also play a crucial role in customer satisfaction, leading to increased sales. Dealerships require high-capacity equipment that can efficiently service multiple vehicles in a short timeframe. Reliability and ease of maintenance are essential, as any downtime can directly impact sales.

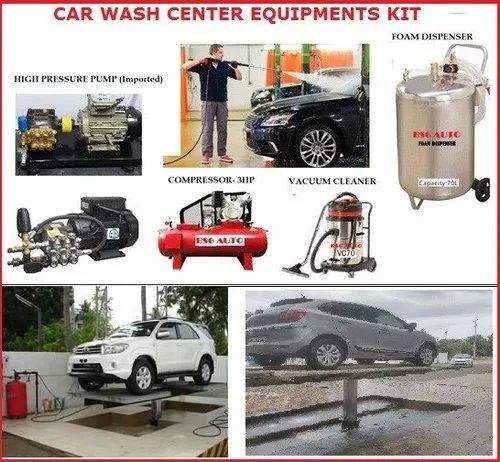

Illustrative image related to car wash business equipment list

What Role Does Fleet Management Play in Car Wash Equipment Applications?

In fleet management, car wash equipment is vital for the cleaning and maintenance of company vehicles. Regular washing helps maintain vehicle aesthetics and longevity, which is essential for compliance with corporate standards. For fleet managers, sourcing durable and high-volume cleaning equipment is crucial to minimize operational downtime. The equipment must also accommodate various vehicle types and sizes to ensure comprehensive service.

How Do Car Rental Services Benefit from Car Wash Equipment?

Car rental services leverage car wash equipment for pre-rental cleaning and post-rental detailing. Ensuring that vehicles are in pristine condition enhances customer experience and retention rates. Rental companies require versatile equipment capable of handling different vehicle types quickly and efficiently. This flexibility is key to maintaining a competitive edge in the market, particularly in regions with diverse vehicle models.

Why Is Regular Washing Important for Transportation Services?

Transportation services, including bus and truck operations, utilize car wash equipment to maintain the cleanliness and safety of their fleets. Regular washing improves the fleet’s appearance, which can enhance brand reputation and customer trust. For this sector, sourcing robust equipment that can withstand heavy usage and environmental conditions is crucial. Additionally, efficiency in operation can lead to reduced labor costs and improved service delivery.

How Do Car Wash Franchises Standardize Operations with Equipment?

Car wash franchises use standardized cleaning equipment across multiple locations to streamline operations and ensure consistent service quality. This consistency is vital for customer satisfaction and brand integrity. Franchises should focus on scalable equipment solutions that can adapt to varying business sizes and include comprehensive training support for staff. This approach helps maintain service standards and operational efficiency across all franchise locations.

3 Common User Pain Points for ‘car wash business equipment list’ & Their Solutions

Scenario 1: Navigating Limited Local Supply Chains for Equipment

The Problem: Many B2B buyers in regions such as Africa and South America often encounter significant challenges when sourcing car wash equipment locally. Limited availability of specialized items like high-pressure washers and foam cannons can lead to delays in starting operations or fulfilling customer demand. Additionally, logistical issues may arise when attempting to import equipment, including high shipping costs and customs delays, which can strain budgets and timelines.

Illustrative image related to car wash business equipment list

The Solution: To tackle these sourcing challenges, buyers should consider establishing relationships with multiple suppliers both locally and internationally. Conduct thorough research to identify reputable suppliers who specialize in car wash equipment. Utilize platforms such as Alibaba or local trade shows to connect with manufacturers directly, which can help reduce costs and improve availability. Furthermore, consider forming purchasing cooperatives with other car wash owners in your area. This approach can enable bulk purchasing, which often results in discounted rates and improved shipping terms. Finally, invest time in understanding local regulations regarding imports to streamline the customs process, ensuring that any international purchases reach you in a timely manner.

Scenario 2: Maintaining Equipment Performance and Longevity

The Problem: Car wash businesses heavily rely on equipment performance to maintain service quality. However, many owners face issues with equipment breakdowns and maintenance, leading to costly downtimes and unsatisfied customers. Without a proper maintenance schedule or understanding of the equipment needs, businesses can find themselves overwhelmed, especially when trying to balance operational demands with equipment upkeep.

The Solution: Implementing a proactive maintenance plan is essential for extending the life of car wash equipment. Begin by creating a detailed maintenance schedule that aligns with each piece of equipment’s operational demands. For instance, high-pressure washers should be serviced regularly to avoid performance drops. Utilize the manufacturer’s guidelines for maintenance and consider investing in training for staff on routine checks and basic repairs. Additionally, keep an inventory of essential spare parts on hand to minimize downtime during repairs. Establishing a relationship with a local equipment technician or service provider can also be beneficial for more complex issues, ensuring that your car wash remains operational and your customers remain satisfied.

Scenario 3: Adapting to Technological Advancements

The Problem: As the car wash industry evolves, many B2B buyers struggle to keep up with technological advancements such as automated systems and eco-friendly solutions. This gap can lead to inefficiencies and missed opportunities, particularly in regions where competitors are adopting modern technologies to attract customers. Buyers may feel overwhelmed by the pace of change and uncertain about which technologies will provide the best return on investment.

The Solution: To effectively adapt to technological changes, buyers should prioritize education and research. Attend industry conferences and workshops focused on the latest innovations in car wash technology. Networking with other car wash owners can also provide insights into successful technology implementations. Begin by evaluating your current operations to identify areas where technology could drive efficiency—this might include investing in a robust POS system that integrates with inventory management and customer relationship management tools. Consider starting with a pilot program to test new technologies in your car wash before a full rollout, allowing you to measure effectiveness and customer feedback. Additionally, explore government incentives or grants that promote eco-friendly practices, which can help offset initial costs and enhance your business’s sustainability profile.

Strategic Material Selection Guide for car wash business equipment list

What Are the Key Materials for Car Wash Business Equipment?

When selecting materials for car wash business equipment, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. The following analysis focuses on common materials used in car wash equipment, providing insights for international B2B buyers.

How Do Different Materials Affect Equipment Performance?

1. Stainless Steel

Key Properties: Stainless steel is known for its exceptional corrosion resistance and strength, making it ideal for high-pressure applications. It can withstand temperatures up to 1,500°F (815°C) and pressures exceeding 3,000 PSI.

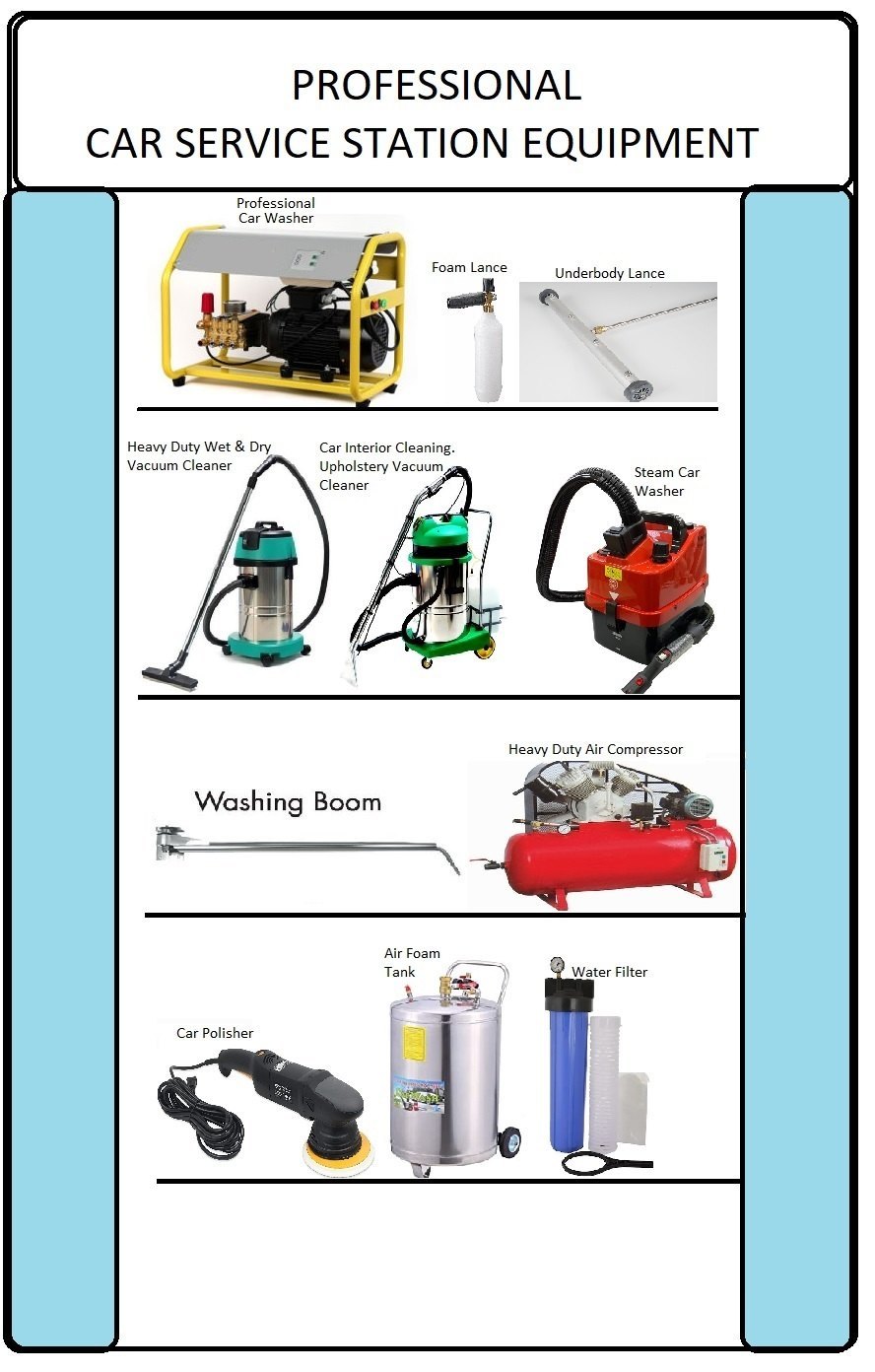

Illustrative image related to car wash business equipment list

Pros & Cons: The durability of stainless steel ensures a long lifespan, reducing replacement costs. However, it is more expensive than alternatives like aluminum or plastic, which may deter budget-conscious buyers. Manufacturing complexity is moderate, as it requires specialized processes for cutting and welding.

Impact on Application: Stainless steel is particularly suitable for components exposed to harsh cleaning chemicals and high-pressure water, such as nozzles and tanks.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards regarding corrosion resistance and safety. Familiarity with ASTM and ISO standards can guide material selection.

Illustrative image related to car wash business equipment list

2. Polyethylene

Key Properties: Polyethylene is a lightweight, flexible plastic that has excellent chemical resistance and can operate effectively at temperatures ranging from -100°F to 120°F (-73°C to 49°C).

Pros & Cons: The low cost and ease of manufacturing make polyethylene a popular choice for components like buckets and hoses. However, its lower durability compared to metals may result in more frequent replacements, impacting long-term costs.

Impact on Application: Ideal for non-structural components, polyethylene is commonly used in water storage tanks and spray nozzles, where flexibility and chemical resistance are essential.

Illustrative image related to car wash business equipment list

Considerations for International Buyers: Buyers should verify that polyethylene products meet relevant safety and environmental regulations, as well as compatibility with local cleaning agents.

3. Rubber

Key Properties: Rubber is known for its elasticity and resilience, making it a suitable material for seals and gaskets. It can withstand temperatures from -40°F to 200°F (-40°C to 93°C) and offers good abrasion resistance.

Pros & Cons: The flexibility of rubber allows for a tight seal, reducing leaks in hoses and pumps. However, it can degrade over time when exposed to UV light or harsh chemicals, necessitating regular inspections and replacements.

Illustrative image related to car wash business equipment list

Impact on Application: Rubber is essential for components that require flexibility and sealing capabilities, such as hoses, gaskets, and vacuum attachments.

Considerations for International Buyers: Buyers should consider the local climate and environmental conditions that may affect rubber durability. Compliance with international standards for material safety is also vital.

4. Aluminum

Key Properties: Aluminum is lightweight and corrosion-resistant, with a melting point of around 1,220°F (660°C). It has good strength-to-weight ratio, making it suitable for various applications.

Illustrative image related to car wash business equipment list

Pros & Cons: The low weight of aluminum facilitates easier handling and installation, while its resistance to corrosion extends the product life. However, it is more expensive than plastic and less durable than stainless steel under extreme conditions.

Impact on Application: Aluminum is commonly used for structural components, frames, and fittings in car wash equipment, where strength and weight savings are crucial.

Considerations for International Buyers: Buyers should ensure that aluminum products meet local standards for structural integrity and corrosion resistance, particularly in coastal regions.

Summary of Material Selection for Car Wash Equipment

| Material | Typical Use Case for car wash business equipment list | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure nozzles, tanks | Exceptional durability and corrosion resistance | Higher cost than alternatives | High |

| Polyethylene | Buckets, hoses | Low cost and chemical resistance | Lower durability compared to metals | Low |

| Rubber | Seals, gaskets | Flexibility and resilience | Degrades under UV and chemicals | Medium |

| Aluminum | Structural components, frames | Lightweight and corrosion-resistant | Less durable than stainless steel | Medium |

This analysis provides a comprehensive overview of material selection for car wash equipment, assisting international B2B buyers in making informed decisions that align with their operational needs and regional requirements.

Illustrative image related to car wash business equipment list

In-depth Look: Manufacturing Processes and Quality Assurance for car wash business equipment list

What Are the Main Stages in the Manufacturing Process of Car Wash Equipment?

The manufacturing of car wash equipment involves several critical stages, each ensuring that the final product meets the high standards required for effective and reliable operation. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing car wash equipment is selecting high-quality materials that can withstand the rigors of daily use. Common materials include stainless steel for durability, high-density plastics for lightweight components, and rubber for hoses and seals. Each material undergoes thorough inspection for quality before moving to the next stage.

-

Forming: This stage involves shaping the prepared materials into the required components. Techniques such as welding, injection molding, and CNC machining are commonly used. For example, high-pressure washers may be fabricated using precision machining to ensure that parts fit perfectly and function effectively. The forming process is critical as any defects at this stage can lead to equipment failure later.

-

Assembly: Once individual components are formed, they are assembled into the final product. This may involve manual labor or automated systems, depending on the complexity of the equipment. Quality checks are performed at this stage to ensure that each part fits correctly and operates as intended. For instance, the assembly of a foam cannon requires careful attention to the seals and connections to prevent leaks.

-

Finishing: The final stage of manufacturing includes painting, coating, or polishing the equipment. Finishing not only enhances the aesthetic appeal but also provides protection against corrosion and wear. Techniques such as powder coating are often used for durability. Additionally, final inspections are conducted to verify that the equipment meets specifications and quality standards.

How Is Quality Assurance Implemented in the Manufacturing of Car Wash Equipment?

Quality assurance (QA) is paramount in the manufacturing of car wash equipment to ensure reliability and safety. Various international and industry-specific standards guide QA practices, including ISO 9001, CE marking, and API standards.

-

International Standards Compliance: ISO 9001 is the most recognized quality management standard globally. It emphasizes a process-oriented approach and continual improvement. Manufacturers aiming to export their products often seek ISO 9001 certification, which assures B2B buyers of consistent quality and adherence to international norms.

-

Industry-Specific Standards: In addition to ISO, certain equipment may require compliance with specific standards. For example, CE marking indicates that products meet European health, safety, and environmental protection standards. For equipment intended for use in hazardous environments, API standards may apply, ensuring that products are safe and reliable.

-

Quality Control Checkpoints: Throughout the manufacturing process, various quality control (QC) checkpoints are established:

-

Incoming Quality Control (IQC): This occurs at the beginning of the production process when raw materials are received. Materials are inspected for compliance with specifications and quality before they are used.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC ensures that each step meets the required quality standards. This might involve sampling and testing components after forming and before assembly.

-

Final Quality Control (FQC): After assembly and finishing, the final product undergoes rigorous testing to ensure it meets all specifications. This includes functional tests, safety assessments, and performance evaluations.

What Common Testing Methods Are Used in Car Wash Equipment Manufacturing?

Testing is an integral part of the QA process in car wash equipment manufacturing. Several testing methods are commonly employed to ensure that products perform as expected.

Illustrative image related to car wash business equipment list

-

Hydraulic Testing: For equipment like high-pressure washers, hydraulic testing is essential. This involves pressurizing the equipment to check for leaks and structural integrity under operational conditions.

-

Performance Testing: Equipment is evaluated for its performance capabilities, such as the effectiveness of foam cannons in generating foam or the suction power of vacuum cleaners. These tests help ensure that the equipment meets the promised specifications.

-

Durability Testing: To simulate long-term use, manufacturers may subject products to accelerated wear tests. This helps identify potential failure points and ensures that the equipment can withstand heavy use over time.

-

Safety Testing: Safety is a top priority, especially when dealing with electrical components. Equipment is tested for electrical safety, ensuring that it meets international safety standards and poses no risk to users.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensuring the reliability of their investments.

-

Supplier Audits: Conducting audits of suppliers’ manufacturing facilities can provide insights into their quality control processes. Buyers should look for compliance with international standards like ISO 9001 and review the supplier’s quality management system.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the testing and inspection processes that the supplier employs. These reports should include data on past performance, failure rates, and corrective actions taken in response to any issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices. These agencies can conduct inspections and provide certifications that validate the supplier’s claims.

-

Certifications and Compliance Documentation: Buyers should request copies of relevant certifications, such as ISO 9001 or CE marks, and ensure that they are current. This documentation serves as proof of the supplier’s commitment to quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances when it comes to quality control in car wash equipment procurement. Understanding these factors can help mitigate risks and ensure successful transactions.

-

Cultural Differences: Different regions may have varying approaches to quality control. Buyers should be aware of cultural norms and practices that might affect supplier reliability, such as communication styles and business ethics.

-

Import Regulations: Each country has specific import regulations that may include additional quality standards. Buyers should familiarize themselves with these requirements to avoid complications during customs clearance.

-

Language Barriers: Language differences can pose challenges in understanding quality assurance documentation and specifications. It’s advisable to work with suppliers who can provide clear and accurate information in a language the buyer understands.

-

Logistics and Supply Chain Considerations: The geographical distance between suppliers and buyers can affect the quality control processes. Buyers should consider the logistics involved in transporting equipment and ensure that suppliers have robust quality checks at every stage of the supply chain.

By understanding the manufacturing processes and quality assurance protocols in the car wash equipment industry, B2B buyers can make informed decisions, ensuring they procure reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car wash business equipment list’

Introduction

Procuring the right equipment for a car wash business is a critical step towards ensuring operational efficiency and customer satisfaction. This guide serves as a practical checklist for B2B buyers looking to source essential car wash equipment, providing actionable insights to facilitate informed purchasing decisions.

Step 1: Assess Your Business Needs

Understanding the specific requirements of your car wash operation is essential. Consider the scale of your business, the types of services offered (e.g., exterior wash, interior detailing), and target customer demographics. This will help you identify which equipment is necessary and avoid over-investing in unnecessary tools.

- Evaluate the volume of vehicles you expect to service.

- Identify any unique service offerings that may require specialized equipment.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications for each piece of equipment you intend to procure. This includes capacity, power requirements, and any necessary certifications. Defining these specifications early on will streamline the selection process and ensure compatibility with your existing systems.

- For example, high-pressure washers should have a minimum of 1500 PSI.

- Consider water filtration and treatment systems that meet local environmental regulations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and customer testimonials to gauge reliability and performance. It’s beneficial to seek references from other businesses in your region or industry.

- Look for suppliers with experience in the car wash sector.

- Verify their capacity to provide after-sales support and maintenance services.

Step 4: Request Quotes and Compare Pricing

Obtain quotes from multiple suppliers to compare pricing and terms. This will not only help you secure competitive pricing but also provide insight into each supplier’s service levels and responsiveness. Be sure to evaluate the total cost of ownership, including maintenance and operational costs.

Illustrative image related to car wash business equipment list

- Pay attention to warranty offerings and service agreements.

- Check for any hidden fees or charges that may impact the total cost.

Step 5: Verify Compliance and Certifications

Ensure that the equipment complies with local and international safety and environmental regulations. Certifications can indicate adherence to industry standards, which is crucial for maintaining your business’s reputation and operational legality.

- Look for equipment with certifications such as ISO or CE.

- Confirm that suppliers provide documentation proving compliance.

Step 6: Assess Delivery and Installation Support

Evaluate the logistics of delivery and installation. Confirm that the supplier can meet your timeline and provide assistance during the installation process. Proper setup is critical for ensuring equipment operates efficiently from day one.

- Ask about installation services and any associated costs.

- Inquire about training for your staff on using the equipment.

Step 7: Plan for Ongoing Maintenance and Support

Establish a plan for ongoing maintenance and support after your equipment is installed. Reliable suppliers should offer maintenance contracts or service packages that ensure your equipment remains in optimal condition, minimizing downtime.

- Discuss the availability of spare parts and service response times.

- Consider establishing a relationship with suppliers for long-term support.

By following this structured checklist, B2B buyers can make informed decisions that will enhance their car wash operations and drive business success.

Illustrative image related to car wash business equipment list

Comprehensive Cost and Pricing Analysis for car wash business equipment list Sourcing

What Are the Key Cost Components in Sourcing Car Wash Business Equipment?

When sourcing equipment for a car wash business, understanding the cost structure is vital for budget planning and long-term profitability. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Materials: The quality and type of materials used in manufacturing car wash equipment significantly affect costs. For instance, high-pressure washers and foam cannons made from durable materials will generally incur higher upfront costs but may reduce maintenance and replacement expenses over time.

-

Labor: Labor costs encompass both direct labor involved in manufacturing and indirect labor related to management and support functions. In regions with higher labor costs, manufacturers may seek to optimize efficiency to maintain competitiveness.

-

Manufacturing Overhead: This includes expenses not directly tied to production, such as utilities, rent, and administrative costs. Efficient management of these overheads can lead to cost savings that can be passed on to buyers.

-

Tooling: Custom tooling for specialized equipment can increase initial costs. However, manufacturers may offer lower prices for standard tools, allowing buyers to negotiate based on their specific needs.

-

Quality Control (QC): Investing in rigorous QC processes ensures that equipment meets safety and performance standards. While this may increase costs, it ultimately leads to greater customer satisfaction and reduced warranty claims.

-

Logistics: Shipping and handling are crucial, especially for international buyers. Costs can vary based on shipping methods, distances, and the nature of the equipment. Buyers should consider logistics when calculating the total cost.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding industry standards for margins can assist buyers in negotiating better deals.

What Influences Pricing for Car Wash Equipment?

Several factors influence the pricing of car wash equipment, making it essential for buyers to consider these elements when negotiating.

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to discounted pricing. Suppliers may offer better rates for bulk purchases, which is advantageous for businesses planning to scale.

-

Specifications and Customization: Equipment with customized features often comes at a premium. Buyers should balance their needs for specialized equipment against their budget constraints.

-

Materials and Quality Certifications: Equipment made with high-quality materials and certified for safety and performance will typically cost more. However, investing in certified equipment can enhance reliability and customer trust.

-

Supplier Factors: The reputation and location of the supplier can impact costs. Established suppliers may charge more due to their brand value and reliability, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The agreed-upon Incoterms define the responsibilities of buyers and sellers in international trade, affecting the overall cost. Understanding these terms can help buyers anticipate additional expenses related to shipping, insurance, and customs.

What Tips Can Help International Buyers Optimize Their Sourcing Costs?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to ensure cost efficiency:

-

Negotiate Effectively: Leverage volume purchases and long-term relationships to negotiate better prices. Transparency about your budget can encourage suppliers to offer more competitive rates.

-

Focus on Total Cost of Ownership (TCO): Instead of only considering the initial purchase price, evaluate the total cost of ownership, including maintenance, operational costs, and potential savings from using high-quality equipment.

-

Understand Pricing Nuances: Prices can fluctuate based on currency exchange rates and local market conditions. Buyers should stay informed about economic trends that could impact costs.

-

Consider Local Suppliers: Sourcing equipment locally can reduce shipping costs and lead times. Additionally, local suppliers may better understand regional market demands and provide tailored solutions.

Disclaimer on Indicative Prices

Prices for car wash equipment can vary widely based on specifications, suppliers, and market conditions. Buyers are encouraged to conduct thorough market research and consult multiple suppliers to obtain accurate pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing car wash business equipment list With Other Solutions

Exploring Alternatives to Traditional Car Wash Business Equipment

When considering the establishment or upgrade of a car wash business, the selection of equipment is crucial. However, there are viable alternatives to the traditional car wash business equipment list that can achieve similar results. These alternatives may offer unique advantages, depending on the specific needs and operational contexts of businesses in diverse markets such as Africa, South America, the Middle East, and Europe.

Comparison Table of Car Wash Solutions

| Comparison Aspect | Car Wash Business Equipment List | Mobile Car Wash Solutions | DIY Car Wash Kits |

|---|---|---|---|

| Performance | High efficiency with professional results | Moderate; dependent on manpower | Variable; depends on user technique |

| Cost | High initial investment | Lower startup costs | Minimal cost; pay for supplies only |

| Ease of Implementation | Requires planning and setup | Quick to set up; minimal infrastructure | Simple; can start with basic supplies |

| Maintenance | Regular maintenance required | Low maintenance; equipment can be mobile | Low maintenance; equipment is minimal |

| Best Use Case | Established businesses targeting high volume | Entrepreneurs targeting convenience | Budget-conscious individuals or small businesses |

In-Depth Analysis of Alternative Solutions

Mobile Car Wash Solutions

Mobile car wash services have gained popularity due to their convenience and flexibility. These operations typically require less infrastructure than a traditional car wash, allowing entrepreneurs to start with lower initial investments. The performance can vary significantly based on the skill level of the personnel involved, leading to inconsistent results. Maintenance is low, as the equipment is often portable and easy to store. This model is best for urban areas where convenience is prioritized, making it an attractive option for busy consumers.

DIY Car Wash Kits

DIY car wash kits present a budget-friendly alternative for individuals or small businesses looking to minimize upfront costs. These kits typically include basic cleaning supplies and tools, allowing users to wash their vehicles at their convenience. The performance largely depends on the user’s skills and knowledge of effective washing techniques, which can lead to inconsistent results. Maintenance is minimal since these kits generally consist of simple tools that don’t require extensive upkeep. This solution is ideal for cost-conscious buyers who may not need high-volume operations or professional-grade results.

Conclusion: Choosing the Right Solution for Your Car Wash Business

In determining the best solution for a car wash business, B2B buyers should consider their operational context, budget, and desired level of service. While a comprehensive car wash equipment list offers high performance and professional results, alternatives like mobile car wash solutions and DIY kits can provide flexibility and lower costs. Each option has distinct advantages and drawbacks, making it essential for buyers to evaluate their specific needs and market conditions before making a decision. By aligning the chosen solution with their business objectives, buyers can maximize efficiency and customer satisfaction in their car wash operations.

Illustrative image related to car wash business equipment list

Essential Technical Properties and Trade Terminology for car wash business equipment list

What Are the Key Technical Specifications for Car Wash Equipment?

When investing in car wash equipment, understanding its technical specifications is crucial for ensuring efficiency, durability, and customer satisfaction. Here are some essential properties to consider:

-

Pressure Rating (PSI)

Pressure rating, measured in pounds per square inch (PSI), is vital for high-pressure washers. A minimum of 1500 PSI is recommended for effective dirt and grime removal. Higher pressure ratings enable faster cleaning, reducing labor time and enhancing service speed, which is essential for customer retention in competitive markets. -

Material Grade

The material grade of equipment components determines their durability and resistance to wear and corrosion. Stainless steel and high-density polyethylene are common materials for car wash equipment due to their resistance to rust and chemical damage. Selecting high-grade materials ensures longevity and minimizes replacement costs, which is critical for maintaining profitability. -

Flow Rate (GPM)

The flow rate, measured in gallons per minute (GPM), indicates how much water is used during washing. An optimal flow rate balances water usage with cleaning efficiency, ensuring that cars are cleaned effectively without excessive water waste. This is especially important in regions with water scarcity, as it supports sustainability practices and compliance with local regulations. -

Voltage and Power Consumption

Understanding the voltage requirements and power consumption of electric equipment is crucial for ensuring compatibility with local electrical systems. High-efficiency models can significantly reduce operational costs, making them a smart investment for long-term profitability. Buyers should evaluate energy ratings to choose equipment that aligns with their budget and energy conservation goals. -

Filtration Capability

Water filtration systems must effectively remove impurities to prevent damage to vehicles and equipment. Systems with multi-stage filtration capabilities are preferable as they enhance water quality and prolong the lifespan of washing equipment. This not only protects the investment but also ensures high-quality service, contributing to customer satisfaction. -

Maintenance Requirements

Equipment that is easy to maintain reduces downtime and service disruptions. Buyers should consider the frequency and type of maintenance required, including the availability of spare parts and technical support. Choosing equipment with straightforward maintenance protocols can significantly enhance operational efficiency.

What Are Common Trade Terms in the Car Wash Equipment Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that are used in another company’s end products. When sourcing car wash equipment, understanding the OEM can help buyers identify quality and compatibility, ensuring that they are getting reliable products that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory planning, especially for businesses just starting or looking to expand. It allows buyers to assess whether a supplier’s terms align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products. This process is vital for comparing costs and securing the best deals. Buyers should include detailed specifications in their RFQ to ensure accurate responses from suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, risk management, and delivery responsibilities, especially for international buyers from regions like Africa and South America. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for planning operations and managing customer expectations. Buyers should factor in lead times when sourcing equipment to ensure timely service delivery. -

Warranty Period

The warranty period indicates how long a manufacturer will cover repairs or replacements for defective products. A longer warranty period can signify confidence in the product’s durability and reliability. Buyers should consider warranty terms when evaluating equipment to mitigate risks associated with equipment failure.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their car wash business operations and profitability.

Navigating Market Dynamics and Sourcing Trends in the car wash business equipment list Sector

What Are the Key Trends Influencing the Car Wash Business Equipment Market?

The global car wash business is experiencing significant growth, driven by urbanization, increased vehicle ownership, and a growing demand for convenience services. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the current and emerging trends in sourcing car wash equipment is crucial.

One of the most notable trends is the integration of technology into car wash operations. Advanced point-of-sale (POS) systems, mobile payment options, and customer relationship management (CRM) tools are becoming essential for streamlining operations and enhancing customer experience. Moreover, the emergence of automated and self-service car wash systems is transforming traditional models, making them more efficient and appealing to a tech-savvy customer base.

Sourcing trends are also shifting towards suppliers who can offer customized solutions and scalable equipment. With the global supply chain facing disruptions, buyers are increasingly looking for local suppliers who can ensure timely delivery and support. Additionally, the demand for eco-friendly and water-efficient equipment is on the rise, influenced by stricter environmental regulations and consumer preferences for sustainable practices.

How Can Sustainability and Ethical Sourcing Impact the Car Wash Equipment Sector?

Sustainability is becoming a cornerstone of B2B operations in the car wash industry. Buyers are increasingly focused on the environmental impact of their equipment choices, seeking suppliers who prioritize ethical sourcing and sustainable practices. This trend is particularly relevant in regions like Africa and South America, where environmental concerns are intertwined with economic development.

Ethical supply chains are essential not only for compliance with regulations but also for enhancing brand reputation. Buyers should prioritize suppliers that provide transparency in their sourcing processes, ensuring that materials are obtained responsibly and that labor practices meet ethical standards.

In terms of equipment, the adoption of ‘green’ certifications and eco-friendly materials is gaining traction. Equipment designed to minimize water usage, such as low-flow washing systems or recycling water treatment solutions, is increasingly in demand. Buyers should look for suppliers that can demonstrate their commitment to sustainability through certifications and environmental impact assessments, thereby aligning their business practices with global sustainability goals.

How Has the Car Wash Equipment Industry Evolved Over Time?

The evolution of the car wash equipment sector reflects broader technological advancements and changing consumer preferences. Initially, car washes were manual operations relying heavily on human labor and basic equipment. Over the decades, innovations such as automated washing systems, high-pressure washers, and advanced cleaning chemicals have transformed the landscape.

The shift towards automation began in the late 20th century, driven by the need for efficiency and the desire to reduce labor costs. Today, modern car wash businesses often incorporate sophisticated technologies, including digital payment systems, automated equipment, and real-time inventory management, to enhance service delivery. This evolution not only improves operational efficiency but also meets the growing consumer expectation for fast and high-quality service.

Illustrative image related to car wash business equipment list

For B2B buyers, understanding this historical context is vital for making informed sourcing decisions. As the industry continues to evolve, keeping an eye on emerging technologies and market dynamics will be crucial for staying competitive in the car wash business landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of car wash business equipment list

-

How do I choose the right car wash equipment supplier for my business?

Selecting the right supplier for car wash equipment involves thorough research and vetting. Look for suppliers with a proven track record in the industry, preferably those who specialize in the type of equipment you need. Check customer reviews and case studies, request references, and assess their responsiveness to inquiries. Ensure they have a robust warranty and after-sales support. Additionally, consider suppliers who can provide local service and support, particularly if you’re in regions like Africa or South America where access to parts and maintenance can be critical. -

What types of car wash equipment should I prioritize for a successful operation?

When starting a car wash business, prioritize equipment that will enhance both the efficiency and quality of your services. Essential items include high-pressure washers, foam cannons, vacuum cleaners, and drying equipment. Consider investing in specialized tools like water filtration systems and detailing machines to improve service quality. Additionally, technology such as a point-of-sale system can streamline operations and enhance customer experience. Assess your target market’s needs to tailor your equipment list accordingly. -

What are the common minimum order quantities (MOQs) for car wash equipment?

Minimum order quantities (MOQs) for car wash equipment can vary significantly based on the supplier and the type of equipment. Generally, larger suppliers may have higher MOQs, while smaller or local manufacturers might offer more flexibility. It’s advisable to negotiate MOQs based on your initial budget and operational scale. Always inquire if the supplier can accommodate smaller orders, especially if you are just starting and want to test the market before committing to larger purchases. -

How can I ensure the quality of the car wash equipment I purchase?

To ensure the quality of car wash equipment, source from reputable suppliers known for their high standards. Request product samples or demonstrations before making a purchase. Additionally, look for certifications that indicate compliance with international safety and performance standards. Engaging in third-party quality assessments can also provide assurance. Establish a solid return policy with your supplier, allowing you to address any quality issues post-purchase. -

What payment terms are typically offered for international orders of car wash equipment?

Payment terms for international orders can vary widely depending on the supplier and the nature of the transaction. Common options include advance payment, letter of credit, or staggered payments based on shipment milestones. Always clarify payment methods accepted, and consider using escrow services to protect your investment. Make sure to understand the currency exchange implications and any additional fees that may arise from cross-border transactions, particularly in regions with volatile currencies. -

What logistics considerations should I keep in mind when importing car wash equipment?

Logistics for importing car wash equipment involve several critical factors. First, understand the shipping methods available, such as sea or air freight, and choose based on urgency and budget. Be aware of customs regulations and import duties in your country, as they can significantly affect your total cost. Additionally, partner with a reliable freight forwarder who can navigate the complexities of international shipping and ensure timely delivery. Planning for potential delays and having contingency measures in place will also help mitigate risks. -

How can I customize car wash equipment to better suit my business needs?

Customization options for car wash equipment often depend on the supplier’s capabilities. Communicate your specific requirements, such as equipment size, features, or branding options. Many suppliers are willing to work with you to modify existing products or create custom solutions that fit your operational needs. Be prepared to discuss the implications of customization on costs and lead times, and ensure that any modifications align with your service goals and customer expectations. -

What are the best practices for maintaining car wash equipment?

Regular maintenance is crucial for the longevity and performance of car wash equipment. Establish a routine inspection schedule to check for wear and tear, particularly on high-use items like pressure washers and vacuums. Implement cleaning protocols to remove debris and prevent build-up that can lead to malfunctions. Keep detailed maintenance logs to track repairs and servicing. Additionally, train your staff on proper equipment use and care to minimize damage and ensure efficient operation.

Top 6 Car Wash Business Equipment List Manufacturers & Suppliers List

1. NCS Wash – Premium Car Wash Solutions

Domain: ncswash.com

Registered: 2018 (7 years)

Introduction: 1. High-Quality Car Wash Soap: Tough on stains like bird droppings, bugs, and tree sap; protects paintwork and wax coat; leaves a beautiful coat and shine.

2. Microfiber Towels, Mitts or Sponge: Designed to pick up dirt gently; available in various sizes; microfiber wash mitts for cleaning nooks and crannies.

3. Soft-Bristle Brushes: For deep cleaning; soft bristles remove dirt without damaging pa…

2. Dultmeier – Car Wash Equipment Supplies

Domain: dultmeier.com

Registered: 1996 (29 years)

Introduction: Commercial & Industrial Car Wash Equipment Supplies for Sale. Equipment, supplies, and parts for self-serve, automatic, touch-free, soft wash & mobile cleaning operations. Includes pressure washer parts, high-pressure pumps, and cleaning accessories. Featured products include car wash pumps, wash stations, mobile cleaning equipment, soaps/detergents, spray guns/wands, spray nozzles, car care vendi…

3. CarWash – Essential Equipment

Domain: carwash.com

Registered: 1995 (30 years)

Introduction: 1. Water tank: Portable tanks starting at 60 gallons, with options up to 300 gallons for growing businesses. 2. Pressure washer: Recommended around 1000 psi for safe cleaning without damaging paint. 3. Generator: Requires at least 2000W to power tools, with 2500W or 3000W recommended for extra capacity. 4. Vacuum cleaner: Options for corded or cordless, with considerations for size and weight affe…

4. Reddit – Car Detailing Essentials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Microfiber towels (color-coded for different uses), interior cleaner, interior protectant, shop vacuum, car wash soap, polisher, detailer for clay bar & drying, compound/aggressive polish, one-step polish, finishing polish, at least two polishing pads, assortment of brushes (large and small), tire dressing, trim restorer, hot water extractor, steamer.

5. GetJobber – Exterior Car Detailing Tools

Domain: getjobber.com

Registered: 2011 (14 years)

Introduction: Exterior car detailing tools: Pressure washer ($100-$400), Foam cannon ($20-$150), Hose ($20-$70), Wash mitts ($5-$30), Buckets with grit guards ($20-$100), Washer bucket ($5-$15), Sponges ($3-$10), Car wash soap ($10-$40), Clay bars ($8-$25), Degreaser ($10-$30), Waterless wash ($10-$60), Drying towels.

6. IQS Directory – Car Wash Equipment

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Car wash equipment includes various components designed for vehicle cleaning, such as water reclamation units, detergents, sprayers, brushes, and cleaning cloths. Types of car wash equipment include automatic, touchless, tunnel, and self-service systems, each with unique components and technology. Key features include water conservation, advanced filtration systems, and customization options for d…

Strategic Sourcing Conclusion and Outlook for car wash business equipment list

As you embark on your car wash business journey, understanding the importance of strategic sourcing for essential equipment cannot be overstated. By investing in high-quality tools—from high-pressure washers and vacuum systems to advanced POS technology—you position your business for success. Prioritize suppliers that not only provide reliable products but also offer ongoing support and training, ensuring you maximize the potential of your investments.

In a competitive landscape across Africa, South America, the Middle East, and Europe, the right equipment can differentiate your service offerings and enhance customer satisfaction. Consider the long-term benefits of sourcing from reputable manufacturers who adhere to international standards. This approach not only ensures quality but also supports sustainable practices, which are increasingly valued by consumers.

Looking ahead, the car wash industry is ripe with opportunities for growth and innovation. Embrace technological advancements and environmentally friendly practices to stay ahead of the curve. Engage with local and international suppliers who share your vision for quality and sustainability. Now is the time to take action—secure your equipment and prepare to drive your car wash business towards a successful future.

Illustrative image related to car wash business equipment list

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.