Can I Install Cr125 Carb On 1974 Yamaha Dt100 Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for can i install cr125 carb on 1974 yamaha dt100

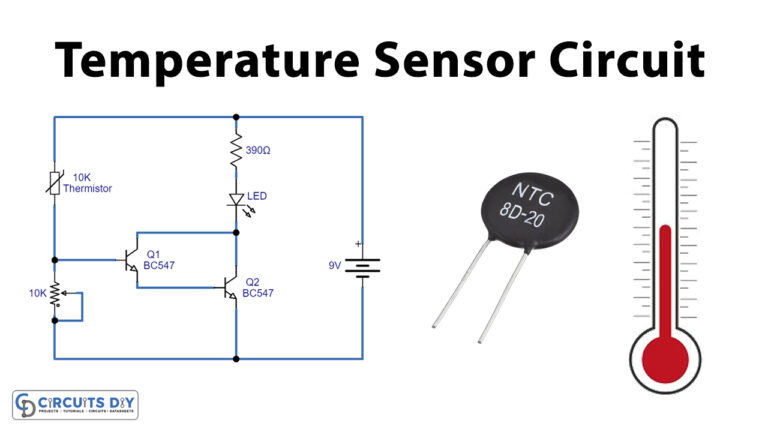

In the ever-evolving landscape of motorcycle maintenance and upgrades, one pressing question that many B2B buyers face is: “Can I install a CR125 carburetor on a 1974 Yamaha DT100?” This inquiry highlights a common challenge among international buyers—navigating the compatibility and performance implications of aftermarket parts. As the demand for vintage motorcycle restoration and performance enhancement grows across markets in Africa, South America, the Middle East, and Europe, understanding the nuances of carburetor swaps becomes crucial.

This comprehensive guide delves into various aspects of sourcing the right carburetor for the Yamaha DT100, including compatibility considerations, performance enhancements, and potential pitfalls. It addresses the types of carburetors available, their specific applications, and the importance of vetting suppliers to ensure quality and reliability. Additionally, the guide provides insights into cost factors, helping buyers make informed decisions that align with their budget and performance goals.

By equipping B2B buyers with actionable insights and expert recommendations, this guide empowers them to navigate the global market effectively. Whether you are looking to enhance performance or restore a classic bike to its former glory, understanding the dynamics of carburetor selection will ensure you make the right choices that drive success in your business ventures.

Understanding can i install cr125 carb on 1974 yamaha dt100 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CR125 Standard Carb | Designed for optimal performance in CR125 models; larger bore size | High-performance aftermarket upgrades | Pros: Increased throttle response; improved power. Cons: May require additional tuning; potential compatibility issues. |

| PWK28 Flat Slide Carb | Flat slide design for enhanced airflow; 28mm diameter | Performance tuning for vintage bikes | Pros: Better fuel atomization; responsive throttle. Cons: Installation complexity; may need custom intake modifications. |

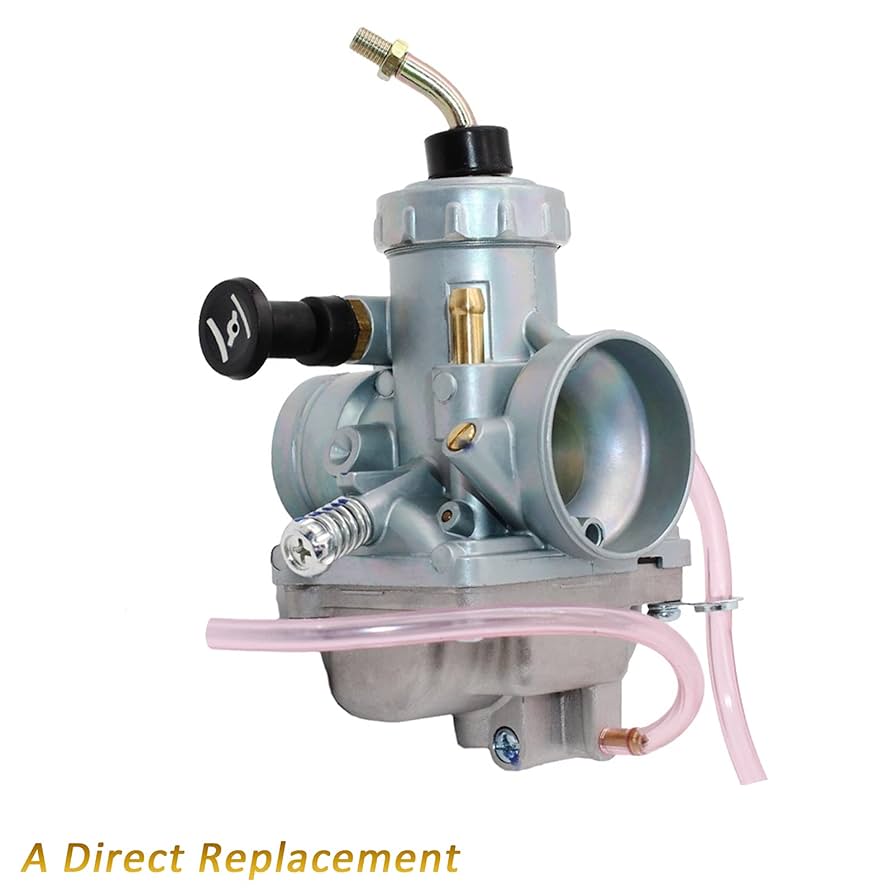

| OEM DT100 Replacement Carb | Direct fit for DT100; 23mm throttle for stock performance | Restoration projects for vintage models | Pros: Easy installation; reliable performance. Cons: Limited performance gains compared to aftermarket options. |

| V-Force Reed Block Combo | Upgraded reed block for improved airflow and performance | Enhancements for DT100 and similar models | Pros: Boosts engine efficiency; compatible with various carb setups. Cons: Requires intake modifications; additional cost. |

| Nibbi PE Clone Carb | Affordable alternative; available in multiple sizes (24-28mm) | Budget-friendly performance upgrades | Pros: Easy tuning; cost-effective. Cons: Quality may vary; potential for less durability. |

What Are the Key Characteristics of the CR125 Standard Carb?

The CR125 Standard Carb is primarily designed for improved performance in CR125 motorcycles. It features a larger bore size that enhances airflow, making it suitable for high-performance applications. B2B buyers looking to upgrade their vintage motorcycles for racing or off-road use may find this carburetor particularly appealing. However, it is essential to consider that installation may require additional tuning to achieve optimal performance.

How Does the PWK28 Flat Slide Carb Enhance Performance?

The PWK28 Flat Slide Carb offers a flat slide design that significantly improves airflow and fuel atomization, resulting in better throttle response and overall engine performance. This carburetor is particularly suitable for vintage bikes that require a performance boost. B2B buyers should be aware that while this option provides enhanced performance, it may necessitate custom modifications to the intake system, increasing installation complexity.

What Advantages Does the OEM DT100 Replacement Carb Provide?

The OEM DT100 Replacement Carb is designed for a direct fit on Yamaha DT100 models, maintaining the original specifications with a 23mm throttle. This carburetor is ideal for restoration projects where maintaining authenticity is crucial. For B2B buyers, the ease of installation and reliable performance make it a practical choice, although it may not deliver the performance enhancements that aftermarket options provide.

Why Opt for a V-Force Reed Block Combo?

The V-Force Reed Block Combo is an excellent upgrade for those looking to improve airflow and engine efficiency in their DT100 or similar models. This upgrade is compatible with various carburetor setups and can significantly enhance performance. However, B2B buyers should consider the need for intake modifications and the associated costs, as these factors can impact overall project budgets.

What Makes Nibbi PE Clone Carbs a Budget-Friendly Option?

Nibbi PE Clone Carbs are an affordable alternative for those seeking performance upgrades without breaking the bank. Available in sizes ranging from 24mm to 28mm, these carburetors are easy to tune and can fit a variety of models. However, buyers should be cautious about the variability in quality and durability, which may affect long-term performance.

Key Industrial Applications of can i install cr125 carb on 1974 yamaha dt100

| Industry/Sector | Specific Application of can i install cr125 carb on 1974 yamaha dt100 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Upgrading vintage motorcycle models for enhanced performance | Improved engine efficiency and power output | Quality of carburetor, compatibility with existing components |

| Motorcycle Repair Services | Customizing older models for enthusiasts and collectors | Increased customer satisfaction and repeat business | Availability of aftermarket parts, expertise in installation |

| Racing and Performance Tuning | Enhancing performance of classic bikes for competitive racing | Competitive edge in racing events | Proven performance metrics, tuning capabilities, and reliability |

| Spare Parts Distribution | Providing components for vintage motorcycle restoration | Access to a niche market with high demand | Sourcing from reputable manufacturers, ensuring authenticity |

| Export and Import Businesses | Facilitating international trade of motorcycle parts | Expanding market reach and diversifying product lines | Compliance with international regulations, quality assurance |

How is the CR125 Carburetor Installed on a 1974 Yamaha DT100 in Motorcycle Manufacturing?

In the motorcycle manufacturing sector, the installation of a CR125 carburetor on a 1974 Yamaha DT100 is a popular modification aimed at enhancing performance. This upgrade can significantly improve engine efficiency and power output, appealing to manufacturers looking to revive vintage models. Businesses in this sector must consider the quality and compatibility of the carburetor to ensure seamless integration with existing components.

What Role Does the CR125 Carburetor Play in Motorcycle Repair Services?

For motorcycle repair services, the ability to customize older models, such as the Yamaha DT100, is crucial for meeting the demands of enthusiasts and collectors. Installing a CR125 carburetor can lead to better throttle response and overall performance, which increases customer satisfaction and fosters repeat business. Repair shops should focus on sourcing high-quality aftermarket carburetors and ensuring their technicians are skilled in installation and tuning.

How Can Racing and Performance Tuning Benefit from the CR125 Carburetor?

In the racing and performance tuning industry, the installation of a CR125 carburetor on a 1974 Yamaha DT100 allows for enhanced performance tailored for competitive racing. This modification can provide a significant competitive edge, attracting racers who seek to optimize their machines. Businesses in this sector should prioritize proven performance metrics and the reliability of the carburetor, ensuring it meets the rigorous demands of racing environments.

Why is the CR125 Carburetor Important for Spare Parts Distribution?

Spare parts distribution businesses can leverage the growing interest in vintage motorcycle restoration by offering components like the CR125 carburetor. This niche market often sees high demand, as collectors and restorers seek authentic parts to maintain or enhance their motorcycles. Distributors must ensure they source from reputable manufacturers to guarantee the authenticity and quality of the parts they provide.

How Does the CR125 Carburetor Affect Export and Import Businesses?

For export and import businesses, facilitating the trade of motorcycle parts, including the CR125 carburetor, opens avenues to expand market reach. The international demand for vintage motorcycle parts is significant, particularly in regions such as Africa and South America. Ensuring compliance with international regulations and maintaining quality assurance is essential for businesses looking to thrive in this competitive landscape.

3 Common User Pain Points for ‘can i install cr125 carb on 1974 yamaha dt100’ & Their Solutions

Scenario 1: Compatibility Concerns with CR125 Carburetor Installation

The Problem: B2B buyers often face significant uncertainty regarding the compatibility of the CR125 carburetor with the 1974 Yamaha DT100. This stems from differences in mounting configurations, throttle response, and tuning requirements. Buyers may fear that the new carburetor will not fit properly or, worse, cause performance issues, leading to wasted resources and time. This concern is especially acute for international buyers who may have limited access to local expertise or parts.

The Solution: To effectively address compatibility concerns, buyers should conduct thorough research on the specifications of both the CR125 carburetor and the Yamaha DT100 engine. It is advisable to consult detailed service manuals or forums that specialize in vintage motorcycles, where experienced users often share their modifications and outcomes. When sourcing the CR125 carburetor, verify that it comes with the necessary mounting hardware and gaskets to facilitate installation. Additionally, consider engaging a professional mechanic with experience in two-stroke engines for proper alignment and tuning post-installation, ensuring optimal performance without compromising the bike’s integrity.

Scenario 2: Performance Optimization Challenges Post-Installation

The Problem: After installing the CR125 carburetor, buyers frequently encounter performance optimization challenges. The new carburetor may not deliver the expected improvements in throttle response or power, leading to frustration and dissatisfaction. Issues such as bogging, poor fuel efficiency, or excessive smoke may arise, which can be particularly troublesome for businesses that rely on these bikes for commercial use in demanding environments.

The Solution: To optimize performance following the carburetor installation, buyers should focus on tuning the carburetor to match the unique characteristics of the Yamaha DT100. This includes adjusting the needle position, jet sizes, and air-fuel mixture settings. Utilizing a dynamometer can provide precise measurements to fine-tune these parameters for maximum efficiency. Additionally, consider upgrading the intake and exhaust systems to enhance airflow, which can significantly improve performance. Collaborating with local suppliers who understand the specific needs of two-stroke engines will also provide valuable insights and components that can aid in achieving desired performance levels.

Scenario 3: Sourcing Quality Parts and Avoiding Counterfeits

The Problem: In international markets, especially in regions like Africa and South America, sourcing quality carburetors and parts can be challenging. Buyers often face the risk of acquiring counterfeit or substandard components that do not perform as expected or, worse, damage the engine. This situation can lead to costly repairs and hinder operational efficiency, particularly for businesses relying on motorcycles for transportation or delivery services.

The Solution: To mitigate the risk of purchasing counterfeit parts, B2B buyers should establish relationships with reputable suppliers and manufacturers known for their quality standards. Researching suppliers through online reviews, industry forums, and recommendations from fellow motorcycle enthusiasts can lead to more reliable sourcing. Additionally, consider purchasing carburetors and components from well-known brands or authorized distributors who offer warranties and customer support. It is also beneficial to familiarize oneself with the common signs of counterfeit products, such as unusual packaging or pricing that seems too good to be true. By prioritizing quality sourcing, buyers can ensure the longevity and performance of their motorcycles, ultimately leading to better business outcomes.

Strategic Material Selection Guide for can i install cr125 carb on 1974 yamaha dt100

When considering the installation of a CR125 carburetor on a 1974 Yamaha DT100, the selection of materials used in the carburetor and its components is crucial for ensuring optimal performance and compatibility. Here, we analyze several common materials relevant to this application, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Analyzing Common Materials for Carburetor Components

Aluminum

Key Properties: Aluminum is lightweight and exhibits good corrosion resistance, particularly when anodized. It can withstand moderate temperatures and pressures, making it suitable for carburetor applications.

Pros & Cons: The primary advantage of aluminum is its low weight, which reduces the overall mass of the carburetor, enhancing performance. It is also relatively cost-effective and easy to machine. However, aluminum can be prone to wear and may not hold up well under extreme conditions without proper treatment.

Impact on Application: Aluminum’s compatibility with various fuel types and its resistance to corrosion make it a popular choice for carburetors. However, it may require coatings or treatments to enhance its durability against fuel additives.

International Considerations: Buyers in regions like Africa and South America should ensure that aluminum components meet local standards for automotive parts. Compliance with ASTM standards is often expected, and sourcing from reputable manufacturers is crucial to avoid quality issues.

Plastic (Nylon or Polypropylene)

Key Properties: Plastics like nylon and polypropylene are lightweight, resistant to chemical corrosion, and can handle a range of temperatures.

Pros & Cons: The use of plastic can significantly reduce weight and manufacturing costs. It is also resistant to many chemicals found in fuels. However, plastics may not withstand high temperatures as well as metals and can degrade over time with exposure to UV light.

Impact on Application: Plastic carburetor components can effectively manage fuel flow and resist corrosion from various fuel types. However, their performance can be affected by temperature fluctuations, which is critical in varying climates.

International Considerations: For buyers in the Middle East and Europe, it is essential to confirm that plastic materials comply with relevant safety and environmental regulations, such as REACH in Europe. Understanding local preferences for material durability is also vital.

Zinc Die-Cast

Key Properties: Zinc die-casting provides excellent dimensional accuracy and surface finish. It has good corrosion resistance and can withstand moderate pressures.

Pros & Cons: A significant advantage of zinc die-cast components is their ability to be produced in complex shapes, which can reduce assembly time. They are generally more durable than plastics but can be heavier and more expensive.

Impact on Application: Zinc die-cast carburetor components can enhance performance due to their strength and precision. However, they may require additional treatments to improve corrosion resistance, especially in humid environments.

International Considerations: When sourcing zinc components, buyers should ensure compliance with international standards such as ISO and ASTM. Additionally, understanding local market preferences for weight versus durability can influence purchasing decisions.

Stainless Steel

Key Properties: Stainless steel offers exceptional corrosion resistance and strength, withstanding high temperatures and pressures.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, making it ideal for high-performance applications. However, it is heavier and more expensive than other materials, which can impact overall carburetor weight.

Impact on Application: Stainless steel components can significantly enhance the performance and lifespan of the carburetor, particularly in harsh environments. They are compatible with a wide range of fuels and additives.

International Considerations: Buyers in Europe and the Middle East should ensure that stainless steel parts meet standards such as ASTM A240 for corrosion resistance. Additionally, the cost factor may be a consideration for budget-conscious buyers.

Summary Table of Material Selection

| Material | Typical Use Case for can i install cr125 carb on 1974 yamaha dt100 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Carburetor body and components | Lightweight and cost-effective | Prone to wear without treatment | Medium |

| Plastic | Float bowls and fuel lines | Chemical resistance and lightweight | Limited temperature tolerance | Low |

| Zinc Die-Cast | Carburetor housing and intricate components | Excellent dimensional accuracy | Heavier and potentially more expensive | Medium |

| Stainless Steel | Fasteners and critical wear components | Exceptional durability and corrosion resistance | Higher weight and cost | High |

This strategic material selection guide provides valuable insights for international B2B buyers considering the installation of a CR125 carburetor on a 1974 Yamaha DT100. Understanding the properties, advantages, and limitations of each material is essential for making informed purchasing decisions that align with performance expectations and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for can i install cr125 carb on 1974 yamaha dt100

What Are the Key Manufacturing Processes for Installing a CR125 Carburetor on a 1974 Yamaha DT100?

When considering the installation of a CR125 carburetor on a 1974 Yamaha DT100, understanding the manufacturing processes of the components involved is essential for ensuring compatibility and performance. The typical manufacturing process for carburetors includes several stages: material preparation, forming, assembly, and finishing.

How is Material Prepared for Carburetor Manufacturing?

Material preparation begins with selecting high-quality aluminum alloys or plastic composites that can withstand the rigors of engine operation. These materials are often sourced from reputable suppliers that meet international standards for quality and consistency. In this stage, materials are cleaned, cut, and shaped into the necessary components using precision machining techniques.

What Forming Techniques Are Used in Carburetor Production?

The forming stage involves various techniques, including die casting and CNC machining. Die casting is commonly used for creating the main body of the carburetor, allowing for intricate designs and high dimensional accuracy. CNC machining is employed for finer components, such as the throttle body and jets, ensuring that they meet precise specifications. These processes contribute to the overall performance and reliability of the carburetor, which is crucial when retrofitting to a vintage motorcycle.

How Are Carburetors Assembled and Finished?

Once all components are manufactured, the assembly process begins. This typically involves carefully fitting the parts together, ensuring that all seals and gaskets are correctly placed to prevent leaks. After assembly, the carburetor undergoes a finishing process that may include anodizing or painting to enhance durability and aesthetics. This stage is critical in protecting the components from corrosion and wear, especially in diverse environmental conditions encountered by international buyers.

What Quality Assurance Measures Are Essential in Carburetor Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, particularly for components that will be used in high-performance applications. Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This ensures that processes are consistently monitored and improved.

What Are the Key QC Checkpoints in Carburetor Production?

In the context of carburetor production, several key QC checkpoints are implemented:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor dimensions, tolerances, and overall quality of the components.

- Final Quality Control (FQC): Before shipment, finished carburetors undergo a comprehensive inspection to verify that they meet all performance and aesthetic standards.

Which Testing Methods Are Commonly Used for Carburetors?

Testing methods for carburetors include flow testing, pressure testing, and performance testing. Flow testing assesses the carburetor’s ability to deliver the correct air-fuel mixture, while pressure testing ensures that there are no leaks. Performance testing typically involves installing the carburetor on a test engine to evaluate its operational efficiency and responsiveness. These tests are crucial for ensuring that the carburetor will perform reliably when installed on a Yamaha DT100.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those sourcing components internationally from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are several strategies to consider:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s adherence to quality standards. This may involve on-site visits to evaluate production processes, quality control measures, and overall operational efficiency. Buyers should request audits that include detailed reports on compliance with international standards such as ISO 9001.

How Can Buyers Access Quality Assurance Reports?

Buyers should request quality assurance reports from suppliers that document the results of IQC, IPQC, and FQC processes. These reports should detail any non-conformities and corrective actions taken to address them. Regularly reviewing these documents helps ensure that the supplier maintains consistent quality over time.

Are Third-Party Inspections Recommended for International Buyers?

Engaging third-party inspection services can provide an added layer of confidence for international buyers. These services can conduct independent evaluations of the manufacturing processes and final products, ensuring that they meet the specified quality standards. This is particularly important in regions where buyers may be unfamiliar with local manufacturing practices.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and certifications, which can impact the sourcing process. For instance, while ISO certifications are widely recognized, buyers should also consider local certifications that may be relevant to their specific market.

How Can Buyers Navigate Regional Regulations?

Buyers should familiarize themselves with the regulatory landscape in their target markets. This includes understanding any specific requirements related to emissions, safety, and performance standards that may apply to carburetors. Engaging with local experts or industry associations can provide valuable insights into these regulations.

What Should Buyers Consider When Selecting Suppliers?

When selecting suppliers for carburetors, buyers should prioritize those with a proven track record of quality and reliability. Evaluating customer reviews, seeking references, and considering the supplier’s experience in exporting to international markets can help mitigate risks associated with sourcing.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with the installation of a CR125 carburetor on a 1974 Yamaha DT100 is essential for B2B buyers. By focusing on quality control, verifying supplier capabilities, and navigating regional regulations, buyers can ensure that they procure reliable and high-performing components for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘can i install cr125 carb on 1974 yamaha dt100’

This guide provides a practical checklist for B2B buyers interested in sourcing components for installing a CR125 carburetor on a 1974 Yamaha DT100. Understanding the technical requirements and supplier capabilities is essential for ensuring successful procurement and installation.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the CR125 carburetor installation on the DT100. This includes dimensions, compatibility with existing parts, and performance expectations. Having a detailed specification helps in communicating your needs effectively to suppliers and ensures that the components sourced will meet your operational standards.

Step 2: Research Compatible Components

Investigate the compatibility of the CR125 carburetor with the DT100. Check forums, technical documents, and user experiences to understand the nuances of this swap. Look for recommendations on necessary modifications, such as intake boot adjustments or additional parts like reed blocks, to ensure optimal performance.

- Considerations:

- Compatibility with existing fuel systems.

- Potential need for tuning or additional modifications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, assess suppliers thoroughly. Request detailed company profiles, product catalogs, and case studies demonstrating their experience in similar projects. It’s important to gauge their reliability and track record in delivering quality components that meet specific technical requirements.

- Key Questions:

- What is their experience with motorcycle carburetors?

- Can they provide references from previous clients in your region?

Step 4: Check Supplier Certifications and Standards

Ensure that potential suppliers adhere to relevant industry standards and certifications. This guarantees that the components meet safety and performance regulations. Compliance with international standards can also facilitate smoother importation processes, especially for B2B transactions across different regions.

Step 5: Request Samples or Prototypes

Whenever possible, ask suppliers for samples or prototypes of the CR125 carburetor. This allows you to physically assess the quality and compatibility before making a bulk order. Testing samples can also help identify any potential issues early in the procurement process.

Step 6: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers, engage in negotiations regarding pricing, delivery times, and payment terms. Ensure that you are getting a fair deal, taking into account the quality of the components and the supplier’s reputation. Clear terms help prevent misunderstandings and ensure a smooth transaction.

Step 7: Plan for After-Sales Support

Inquire about the after-sales support provided by the supplier. This includes warranty terms, return policies, and technical assistance. Reliable after-sales support can be crucial, especially if installation issues arise or if there are compatibility concerns post-purchase.

By following this checklist, B2B buyers can effectively navigate the sourcing process for installing a CR125 carburetor on a 1974 Yamaha DT100, ensuring a successful outcome that meets both technical and operational needs.

Comprehensive Cost and Pricing Analysis for can i install cr125 carb on 1974 yamaha dt100 Sourcing

What Are the Key Cost Components for Sourcing CR125 Carbs for a 1974 Yamaha DT100?

When considering the installation of a CR125 carburetor on a 1974 Yamaha DT100, it’s essential to understand the cost structure involved. The key components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary cost driver will be the carburetor itself, which can range from $27.57 to $100 or more depending on brand and specifications. Additional materials, such as gaskets, hoses, and possible modifications to the intake system, should also be factored in. The choice of high-quality materials will enhance performance but will increase costs.

-

Labor: Installation labor can vary significantly based on the complexity of the job and local labor rates. In regions like Africa or South America, labor costs may be lower, but specialized skills may be needed for proper installation, which can drive up costs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Depending on the supplier’s efficiency and location, these costs can fluctuate, impacting the final pricing of the carburetor.

-

Tooling: If modifications to the existing setup are necessary, costs for tools and equipment may arise. This is particularly relevant if specialized tools are needed for installation or tuning, which can add to the overall investment.

-

Quality Control: Ensuring that the carburetor meets performance specifications will involve QC processes that can increase costs. Certifications and quality assurance testing add an additional layer of expense, particularly for international buyers who require compliance with specific standards.

-

Logistics: Shipping and handling costs can vary widely based on the origin of the carburetor and destination. Incoterms will play a crucial role in determining who bears the costs and risks associated with transportation.

-

Margin: Suppliers will typically add a profit margin to cover their costs and generate profit. Understanding the typical margins in the motorcycle parts industry will help buyers negotiate better prices.

How Do Price Influencers Impact the Cost of CR125 Carbs?

Several factors can influence the pricing of carburetors for the Yamaha DT100. These include:

-

Volume/MOQ: Ordering in bulk can significantly reduce the unit price due to economies of scale. For B2B buyers, negotiating a minimum order quantity (MOQ) can lead to substantial savings.

-

Specifications/Customization: Customized carburetors may come at a premium. If you require specific adjustments to fit the DT100, be prepared for higher costs associated with bespoke manufacturing.

-

Materials: The choice of materials directly affects both performance and price. High-performance carburetors made from premium materials will generally cost more but offer better longevity and efficiency.

-

Quality/Certifications: Products with recognized quality certifications may command higher prices. However, investing in quality often leads to lower total cost of ownership due to reduced failure rates and maintenance needs.

-

Supplier Factors: The reputation, reliability, and location of suppliers can impact pricing. Established suppliers may charge more but offer better service and support.

-

Incoterms: Understanding the shipping terms is crucial for international buyers. Different Incoterms can affect the final price based on who is responsible for shipping costs, duties, and insurance.

What Buyer Tips Can Enhance Cost Efficiency for CR125 Carb Sourcing?

To maximize cost efficiency in sourcing carburetors, international buyers should consider the following tips:

-

Negotiation: Always negotiate prices and terms. Establishing a good relationship with suppliers can lead to better pricing and terms in the future.

-

Total Cost of Ownership: Look beyond the initial purchase price. Consider factors like maintenance, expected lifespan, and performance to determine the true cost of ownership.

-

Pricing Nuances for International Buyers: Be aware of additional costs such as tariffs, import duties, and local taxes that can affect overall pricing. Understanding local regulations can help avoid unexpected expenses.

-

Supplier Research: Take the time to research and compare multiple suppliers. Look for customer reviews and testimonials to gauge reliability and performance.

-

Standardization: If possible, standardize components across different models to reduce complexity and cost in sourcing parts.

By considering these factors, B2B buyers can make informed decisions that lead to effective sourcing strategies for installing a CR125 carb on a 1974 Yamaha DT100.

Alternatives Analysis: Comparing can i install cr125 carb on 1974 yamaha dt100 With Other Solutions

Introduction: Exploring Alternatives to the CR125 Carburetor Installation

When considering modifications for a 1974 Yamaha DT100, one popular question arises: “Can I install a CR125 carburetor?” While this solution may enhance performance, it’s crucial for B2B buyers to evaluate alternative approaches that could offer similar benefits. This analysis compares the proposed carburetor swap with other viable options, allowing buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Can I Install CR125 Carb on 1974 Yamaha DT100 | PWK28 Carb Swap | OEM Carburetor Replacement |

|---|---|---|---|

| Performance | Moderate improvement in throttle response, but potential tuning issues | Significant performance gains with proper tuning | Reliable performance, consistent output |

| Cost | Moderate initial investment, additional tuning costs | Generally lower cost, easy to find | Higher upfront cost for OEM parts |

| Ease of Implementation | Complex installation and tuning required | Easier installation, straightforward tuning process | Simple swap with no tuning needed |

| Maintenance | Requires ongoing tuning and adjustments | Minimal maintenance with stable performance | Low maintenance with standardized parts |

| Best Use Case | Enthusiasts seeking high performance | Riders wanting a balance of performance and cost | Casual riders needing reliability |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of the PWK28 Carb Swap?

The PWK28 carburetor is a popular choice among enthusiasts due to its significant performance gains. It provides improved throttle response and acceleration when installed correctly. The ease of installation and tuning makes it an attractive alternative for those looking to enhance their Yamaha DT100 without extensive modifications. However, the performance improvements can vary based on the rider’s experience with tuning, and incorrect setups may lead to suboptimal performance. Additionally, while the PWK28 is generally affordable, the need for proper tuning can add to the overall cost.

Why Consider an OEM Carburetor Replacement?

Opting for an OEM carburetor replacement is a straightforward solution that ensures reliability and consistency. This option is particularly appealing for casual riders or those prioritizing maintenance-free performance. The OEM parts are designed to fit perfectly, reducing the need for additional modifications. However, the downside includes a potentially higher upfront cost compared to aftermarket options, and the performance may not meet the expectations of enthusiasts looking for significant enhancements. This route is best for those who value reliability over performance upgrades.

Conclusion: Making the Right Choice for Your Yamaha DT100

Selecting the right carburetor solution for a 1974 Yamaha DT100 involves weighing the benefits of performance enhancements against cost and maintenance considerations. While installing a CR125 carburetor might appeal to performance-focused riders, alternatives like the PWK28 carb and OEM replacements offer distinct advantages in terms of ease of use and reliability. B2B buyers should assess their specific needs—whether they prioritize performance, budget constraints, or maintenance capabilities—before making a decision. Understanding these alternatives can lead to a more satisfactory and informed purchase, ultimately enhancing the riding experience for various user segments.

Essential Technical Properties and Trade Terminology for can i install cr125 carb on 1974 yamaha dt100

What Are the Key Technical Properties Relevant to Installing a CR125 Carb on a 1974 Yamaha DT100?

When considering the installation of a CR125 carburetor on a 1974 Yamaha DT100, several technical properties must be assessed to ensure compatibility and optimal performance. Understanding these specifications can guide B2B buyers in making informed decisions.

1. Carburetor Diameter (Venturi Size)

The diameter of the carburetor’s venturi significantly affects the airflow and fuel mixture entering the engine. For example, the CR125 typically features a larger venturi (e.g., 28mm) compared to the stock DT100 carburetor (around 23mm). A larger diameter can increase power but may require additional modifications to the intake system to prevent bogging or inefficient combustion.

2. Material Composition

The materials used in the carburetor construction impact durability and performance. Common materials include aluminum and plastic. Aluminum carburetors are generally preferred for their strength and heat resistance, while plastic options might be lighter and less expensive. B2B buyers should prioritize materials that offer longevity and resistance to wear, especially in harsh environments typical in regions like Africa and the Middle East.

3. Jetting Specifications

Jetting refers to the selection of jets that control the fuel-air mixture. Each carburetor comes with specific jetting settings that must be adjusted when swapping parts. For instance, the CR125 carb may require different main and pilot jets to achieve optimal performance on the DT100 engine. Understanding jetting is crucial for ensuring the engine runs smoothly and efficiently.

4. Throttle Response and Adjustment

Throttle response is a critical performance metric influenced by the carburetor’s design and configuration. The CR125 carburetor may provide quicker throttle response, but it requires careful tuning to avoid issues such as flooding or stalling. Proper adjustment is vital for performance, particularly for B2B buyers looking to enhance riding experiences.

5. Air-Fuel Mixture Ratio

The air-fuel mixture ratio is crucial for engine performance and efficiency. An incorrect ratio can lead to poor combustion, reduced power, and increased emissions. Buyers need to understand how the CR125 carburetor affects this ratio compared to the stock DT100 setup and adjust accordingly to maintain optimal engine health.

What Are the Common Trade Terms in the Context of Carburetor Swaps?

Familiarity with industry terminology can enhance communication and streamline procurement processes for B2B buyers.

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. Using OEM parts ensures compatibility and maintains the vehicle’s integrity. For buyers, opting for OEM carburetors or components can reduce the risk of performance issues.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it affects inventory management and cost-effectiveness. Buyers should negotiate MOQs that align with their sales forecasts to optimize purchasing strategies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When considering carburetor options, submitting RFQs can help buyers compare costs and features across different suppliers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs and risks. Knowledge of Incoterms is critical for B2B transactions, particularly for international buyers from diverse regions, as it clarifies obligations and helps avoid disputes.

5. Aftermarket Parts

Aftermarket parts are components made by manufacturers other than the original equipment manufacturer. While often less expensive, their quality can vary. Buyers should weigh the potential cost savings against the risk of compatibility and performance issues when considering aftermarket carburetors.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions about carburetor swaps, ensuring compatibility and enhancing performance for motorcycles like the Yamaha DT100.

Navigating Market Dynamics and Sourcing Trends in the can i install cr125 carb on 1974 yamaha dt100 Sector

Market Overview & Key Trends in the Carburetor Replacement Sector for Yamaha Motorcycles

The global market for motorcycle carburetors, particularly for models like the 1974 Yamaha DT100, is experiencing significant transformation driven by various factors. One of the primary drivers is the growing interest in vintage motorcycles, which has spurred demand for compatible replacement parts. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, seek to restore and maintain these classic models, they are increasingly exploring options like carburetor swaps. The trend toward customizing and upgrading motorcycles to improve performance is also on the rise, with aftermarket solutions like the CR125 carb gaining traction due to their potential performance benefits.

Emerging technologies such as e-commerce platforms and digital supply chain management tools are reshaping how buyers source parts. B2B buyers now have access to a wider range of suppliers, including those offering high-quality aftermarket products from China and Europe. This shift allows for comparative analysis of prices, quality, and shipping options, enabling better-informed purchasing decisions. Furthermore, the integration of customer feedback and product reviews on digital platforms enhances transparency and supports buyers in selecting the best products for their needs.

Another notable trend is the increasing focus on performance enhancement through carburetor modifications. For instance, swapping to a PWK28mm carburetor, often recommended for compatibility with various Yamaha models, can yield performance improvements when combined with other upgrades such as reed block modifications. As the market evolves, international buyers must stay abreast of these trends to optimize their sourcing strategies effectively.

How Does Sustainability & Ethical Sourcing Impact Carburetor Sourcing Decisions?

In the context of sourcing carburetors for the Yamaha DT100, sustainability and ethical sourcing are becoming paramount considerations for B2B buyers. The environmental impact of manufacturing processes, including those involved in producing carburetors, cannot be overlooked. As global consumers increasingly prioritize eco-friendly products, suppliers are responding by adopting more sustainable practices. This includes using recyclable materials, minimizing waste, and ensuring responsible sourcing of raw materials.

Ethical supply chains are gaining importance as buyers seek to align their procurement strategies with broader corporate social responsibility goals. B2B buyers are encouraged to engage with suppliers who demonstrate transparency in their production processes and hold relevant certifications. Green certifications, such as ISO 14001 for environmental management, can serve as indicators of a supplier’s commitment to sustainability.

Moreover, sourcing from manufacturers who utilize environmentally friendly materials or processes can enhance a company’s brand reputation and appeal to a more conscientious customer base. For instance, choosing carburetors that are designed for longevity and efficiency can lead to reduced emissions and lower overall environmental impact. As the market continues to evolve, integrating sustainability into sourcing strategies will not only meet regulatory requirements but also resonate with increasingly eco-aware consumers.

What Is the Evolution of Carburetor Technology for Vintage Yamaha Models?

The evolution of carburetor technology has significantly impacted the performance and maintenance of vintage Yamaha models like the DT100. Initially, these motorcycles were equipped with simple, mechanically operated carburetors that provided basic fuel metering capabilities. Over the years, advancements in carburetor design have introduced features such as adjustable jetting and improved air-fuel mixture control, enhancing overall engine performance and efficiency.

In the context of B2B sourcing, understanding the historical development of carburetor technology is essential. Modern aftermarket options, like the PWK series, offer enhanced performance characteristics compared to original equipment. These advancements allow for greater customization and tuning capabilities, aligning with the growing demand for performance upgrades among vintage motorcycle enthusiasts.

As international buyers navigate the market for replacement carburetors, awareness of these technological advancements can inform their purchasing decisions, ensuring they choose products that not only fit their motorcycles but also enhance performance and reliability. This historical perspective on carburetor technology underscores the importance of sourcing parts that meet contemporary standards while still honoring the legacy of classic models.

Frequently Asked Questions (FAQs) for B2B Buyers of can i install cr125 carb on 1974 yamaha dt100

-

How do I determine if a CR125 carburetor is compatible with my 1974 Yamaha DT100?

To assess compatibility, start by comparing the mounting dimensions and throttle size of the CR125 carburetor with those of the original DT100 carb. Consult technical manuals or online forums dedicated to Yamaha motorcycles for insights from other users who have attempted similar modifications. Ensure that the carburetor’s air-fuel mixture can be adequately adjusted for optimal performance on the DT100, as mismatched components can lead to poor engine performance or damage. -

What modifications might be necessary when installing a CR125 carb on a 1974 Yamaha DT100?

Installing a CR125 carb may require modifications to the intake manifold and possibly the airbox to accommodate the new carb’s dimensions and airflow characteristics. You may also need to adjust the jetting to ensure the engine receives the correct air-fuel mixture. Additionally, consider upgrading other components like the reed block to enhance performance, as the original DT100 setup may restrict airflow. -

What are the potential performance benefits of installing a CR125 carburetor on a Yamaha DT100?

A properly installed CR125 carburetor can enhance throttle response and increase power output due to its larger diameter and improved airflow design. However, performance gains depend on various factors, including the overall condition of the engine and whether other modifications, like exhaust upgrades or porting, have been made. It’s important to manage expectations, as the benefits may vary significantly based on the bike’s specific setup and tuning. -

How can I find reliable suppliers for motorcycle carburetors in international markets?

To locate trustworthy suppliers, start by researching online directories and industry trade shows specific to motorcycle parts. Look for suppliers with positive reviews and a solid reputation within the motorcycle community. Additionally, consider reaching out to manufacturers directly for recommendations or verifying supplier credentials through trade associations or local chambers of commerce. -

What are the typical minimum order quantities (MOQs) for motorcycle carburetors?

MOQs for motorcycle carburetors can vary significantly based on the supplier and the specific product. Generally, you may encounter MOQs ranging from 10 to 100 units, especially for aftermarket parts. It’s advisable to discuss your needs with the supplier and see if they offer flexibility for smaller orders, particularly if you are testing the market or launching a new product line. -

What payment terms should I expect when sourcing motorcycle parts internationally?

Payment terms can differ among suppliers but typically include options such as upfront payment, partial payment with balance upon delivery, or open account terms for established relationships. Be sure to negotiate terms that align with your cash flow and risk management strategies. Using secure payment methods, like letters of credit or escrow services, can also help mitigate risks in international transactions. -

How can I ensure quality assurance (QA) when sourcing carburetors from foreign suppliers?

To ensure quality, request samples before placing large orders and conduct thorough inspections upon receipt. Establish clear specifications and standards for the carburetors, including performance metrics and materials used. Additionally, consider implementing regular audits of your suppliers or partnering with third-party quality inspection services to verify product quality before shipment. -

What logistical considerations should I keep in mind when importing motorcycle parts?

When importing, factor in shipping costs, customs duties, and delivery timelines. Work with logistics providers experienced in international shipping to navigate customs clearance and ensure compliance with local regulations. Establish a reliable supply chain to minimize delays, and consider utilizing warehousing solutions to manage inventory effectively in your target markets, especially in regions like Africa and South America where logistics can be more complex.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Can I Install Cr125 Carb On 1974 Yamaha Dt100 Manufacturers & Suppliers List

1. Jokers Clays – Yamaha DT Carburetor

Domain: jokersclays.com

Registered: 2017 (8 years)

Introduction: Carburetor fit for Yamaha DT100, DT175 models from 1974, 1975, 1976, and 1983; also compatible with Suzuki.

2. Yamaha – Vintage 1978 DT100

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Vintage Yamaha 2 Stroke, 1978 DT100, saved from the landfill

3. Yamaha – Carburetor for DT Series

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Carburetor for Yamaha DT100 (1974-1983), DT125 (1976-1981), DT175 (1974-1981). Condition: New. Price: $23.27 each or Best Offer. Free shipping. Estimated delivery: Wed, Sep 10 – Sat, Sep 13. Bulk savings available for multiple purchases.

4. Yamaha – DT Engine Performance Modifications

Domain: yamaha-enduros.com

Registered: 2014 (11 years)

Introduction: This company, Yamaha – DT Engine Performance Modifications, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Power Dynamo – Yamaha Solid State Ignition

Domain: hvccycle.net

Registered: 2013 (12 years)

Introduction: Yamaha DT100, DT125, DT175, RT180, IT175 Solid State Ignition. Model: 70-98 -799-00. Manufacturer: Power Dynamo. Features: 12V /100W rotor replacement magneto with integrated fully electronic ignition. Output: 12V/100W DC. Replaces stock 6V Mitsubishi magneto. No engine casing modifications required. All parts are new. Benefits: Increased light output, stable ignition with solid spark, improved st…

Strategic Sourcing Conclusion and Outlook for can i install cr125 carb on 1974 yamaha dt100

In conclusion, the prospect of installing a CR125 carburetor on a 1974 Yamaha DT100 presents both opportunities and challenges for B2B buyers in the motorcycle parts sector. Key considerations include the compatibility of the carburetor with the existing engine setup, the potential need for modifications to the intake system, and the importance of selecting the right aftermarket components, such as reed blocks. Strategic sourcing of high-quality parts, whether from local suppliers or international manufacturers, can significantly enhance performance and reliability.

B2B buyers should prioritize partnerships with reputable suppliers who can provide not only the necessary components but also expert advice on installations and modifications. This approach will ensure that investments yield optimal results in terms of performance and customer satisfaction.

Looking ahead, the demand for customized solutions in the vintage motorcycle market is expected to grow, particularly in regions like Africa, South America, the Middle East, and Europe. Now is the ideal time to engage with suppliers who understand the intricacies of these modifications and can support your business in meeting customer needs effectively. Embrace the opportunity to innovate and expand your offerings in this niche market.