Calefaccion Electrica: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for calefaccion electrica

In today’s global market, sourcing the right calefaccion electrica (electric heating) solutions can be a daunting task for international B2B buyers. With diverse climatic conditions, varying energy regulations, and unique consumer preferences across regions such as Africa, South America, the Middle East, and Europe, decision-makers face the challenge of balancing comfort, efficiency, and cost-effectiveness. This guide is designed to address these complexities by offering an in-depth analysis of electric heating systems, including their types, applications, and the latest technological advancements.

The comprehensive scope of this guide will empower buyers by providing insights into the different electric heating options available, such as central heating systems, electric boilers, and individual room heaters. Additionally, we will cover essential topics like supplier vetting processes, cost considerations, and energy efficiency ratings. By equipping B2B buyers with actionable information, this guide aims to facilitate informed purchasing decisions that align with their operational needs and budget constraints.

Whether you’re based in Nigeria, Germany, or any other region, understanding the nuances of calefaccion electrica is crucial for ensuring that your heating solutions are not only effective but also sustainable and compliant with local regulations. Join us as we navigate the intricacies of the electric heating market and help you find the ideal solutions for your business.

Understanding calefaccion electrica Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Central Electric Heating Systems | Utilizes a network of radiators or underfloor heating | Large commercial buildings, hotels | Pros: Efficient for large spaces; centralized control. Cons: Higher initial installation costs. |

| Aerothermal Systems | Extracts heat from the air; offers heating, cooling, and hot water | Residential and commercial properties | Pros: Eco-friendly, low operating costs. Cons: Performance can decrease in extreme cold. |

| Electric Boilers | Heats water for heating systems; compatible with radiators | Industrial applications, residential | Pros: Quick installation, no emissions. Cons: Higher energy costs compared to other systems. |

| Individual Electric Heaters | Portable units for room-specific heating | Small offices, workshops | Pros: Flexible and easy to install. Cons: Less efficient for large spaces. |

| Heat Accumulators | Stores heat for later use; operates during off-peak hours | Warehouses, factories | Pros: Cost-effective in areas with variable energy pricing. Cons: Requires space for installation. |

What Are Central Electric Heating Systems and Their Applications?

Central electric heating systems are designed to provide uniform heating throughout large spaces, making them ideal for commercial buildings, hotels, and educational institutions. These systems typically use a network of radiators or underfloor heating, which can be controlled centrally for efficient energy use. When considering this option, B2B buyers should evaluate the initial installation costs against long-term energy savings, as well as the system’s scalability for future expansions.

How Do Aerothermal Systems Work and Who Can Benefit?

Aerothermal systems leverage renewable energy by extracting heat from the air, providing heating, cooling, and hot water. They are particularly suitable for residential buildings and commercial properties seeking eco-friendly solutions. B2B buyers should consider the system’s efficiency ratings, installation requirements, and potential integration with existing infrastructure. While they offer significant energy savings and environmental benefits, performance may decline in very low temperatures, which is crucial for regions with extreme climates.

What Are the Advantages of Electric Boilers for B2B Buyers?

Electric boilers are a straightforward heating solution that quickly heats water for various heating applications, including radiators and underfloor systems. They are commonly used in industrial settings and residential buildings where gas options are limited. B2B buyers should assess the energy costs associated with electric boilers compared to other heating methods, as they can be higher. However, their installation is typically faster, and they produce no emissions, making them a safe choice for many environments.

Why Choose Individual Electric Heaters for Small Spaces?

Individual electric heaters are portable units designed for localized heating, making them suitable for small offices, workshops, or temporary spaces. Their flexibility allows businesses to heat only occupied areas, reducing overall energy consumption. Buyers should weigh the convenience and ease of installation against the potential for higher energy costs in larger environments, as these units may not efficiently heat extensive areas.

How Do Heat Accumulators Function and What Are Their Benefits?

Heat accumulators store thermal energy generated during off-peak hours, providing a steady supply of heat when needed. This feature is particularly advantageous for warehouses and factories that operate on fluctuating energy rates. When considering heat accumulators, B2B buyers should evaluate the space requirements for installation and the potential for cost savings in energy pricing. While they can be cost-effective, their bulkiness may pose a challenge in constrained environments.

Key Industrial Applications of calefaccion electrica

| Industry/Sector | Specific Application of calefaccion electrica | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Residential Construction | Central heating systems using electric boilers | Energy-efficient heating solutions that reduce costs | Energy efficiency ratings, installation requirements, and maintenance support |

| Agriculture | Greenhouse heating for crop production | Enhanced growth conditions, extending growing seasons | Temperature control technology and energy consumption efficiency |

| Hospitality | Electric heating for hotels and resorts | Improved guest comfort and satisfaction | Scalability, energy management systems, and integration with existing infrastructure |

| Manufacturing | Industrial heating in production processes | Consistent temperature control, improving product quality | Compliance with safety standards and energy efficiency requirements |

| Healthcare | Heating systems in hospitals and clinics | Ensures patient comfort and supports medical equipment | Reliability, safety certifications, and energy efficiency |

How is calefaccion electrica utilized in residential construction?

In residential construction, calefaccion electrica is increasingly adopted through central heating systems that utilize electric boilers. These systems provide a reliable and energy-efficient heating solution, which is crucial for maintaining comfort in homes. Buyers in this sector must consider energy efficiency ratings and installation requirements to ensure compliance with local regulations, especially in regions like Europe where sustainability is a priority. Additionally, maintenance support is vital to guarantee long-term operational efficiency.

What role does calefaccion electrica play in agriculture?

In the agricultural sector, calefaccion electrica is essential for heating greenhouses, creating optimal growth conditions for crops. By maintaining a stable temperature, electric heating systems can extend the growing season and enhance yield quality. Buyers from regions like Africa and South America should focus on sourcing systems that offer precise temperature control technology and energy consumption efficiency to maximize productivity while minimizing operational costs.

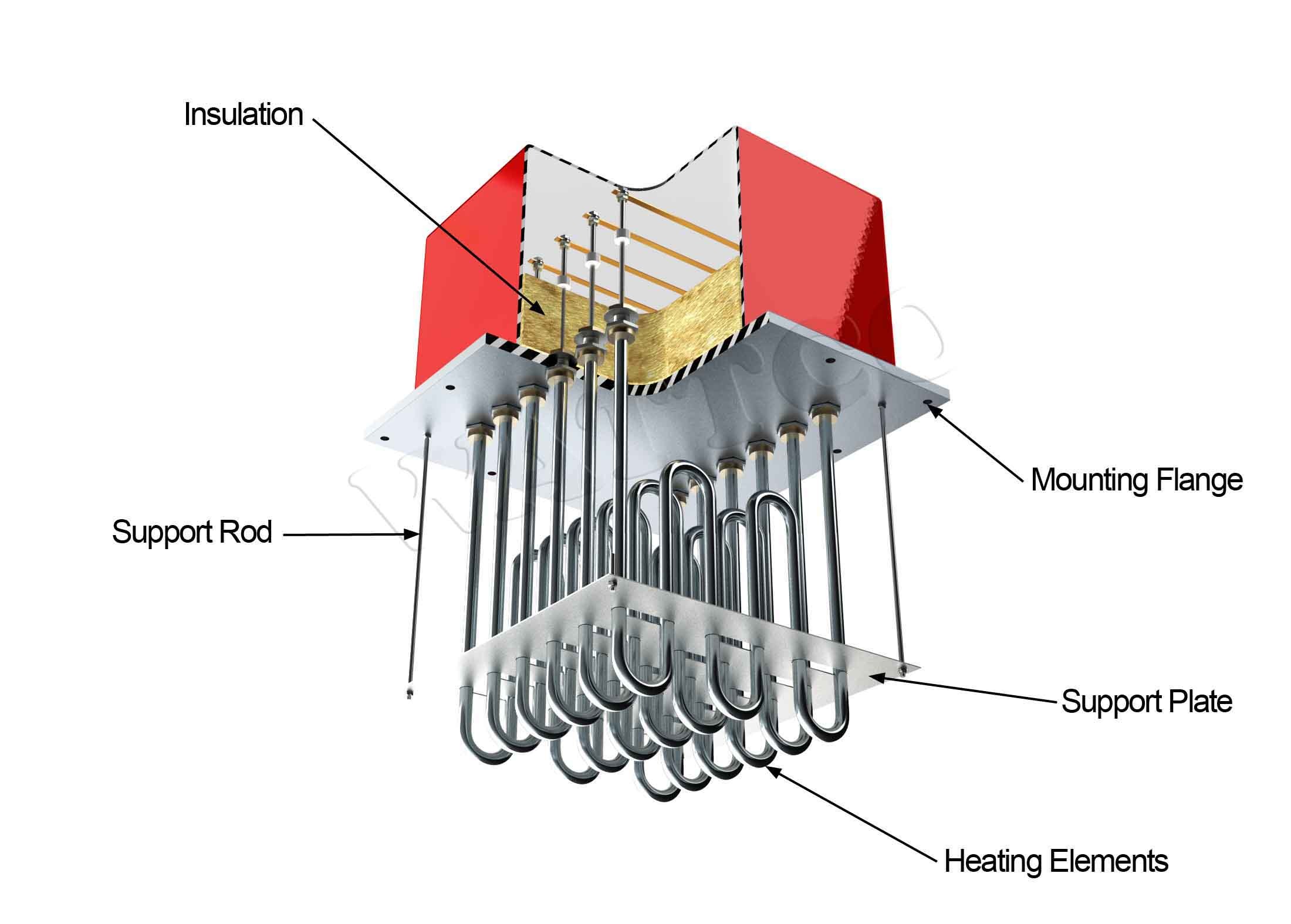

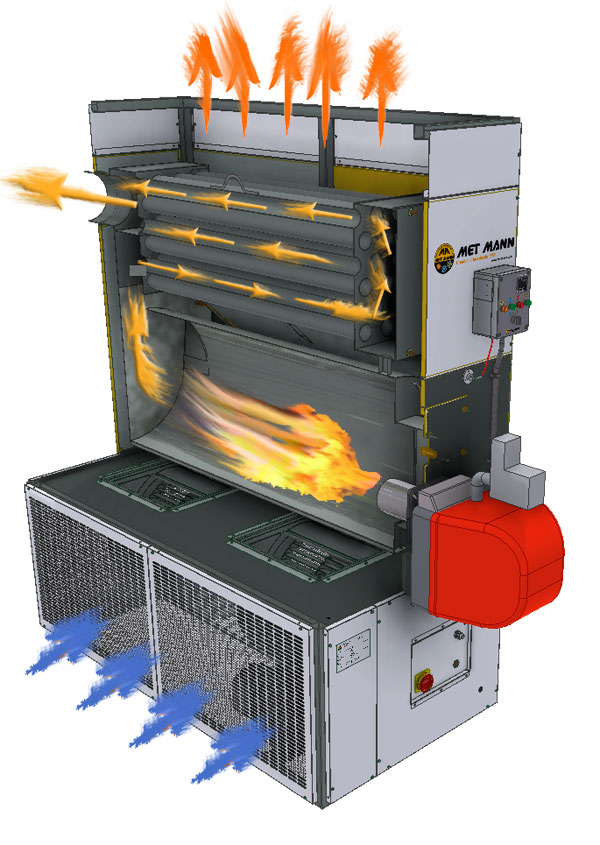

Illustrative image related to calefaccion electrica

How does calefaccion electrica enhance the hospitality industry?

For the hospitality industry, electric heating systems are critical in hotels and resorts to ensure guest comfort. Providing consistent heating enhances guest satisfaction, which is vital for repeat business. B2B buyers in this sector should look for scalable solutions that can accommodate varying guest capacities and integrate with existing infrastructure. Additionally, energy management systems can help optimize energy usage, reducing costs while maintaining high service standards.

In what ways is calefaccion electrica applied in manufacturing?

In manufacturing, calefaccion electrica is used for industrial heating in various production processes. Maintaining consistent temperatures is vital for product quality and operational efficiency. Buyers in this industry must ensure compliance with safety standards and consider energy efficiency requirements, as industrial operations can significantly impact energy consumption. Investing in advanced electric heating solutions can lead to improved product consistency and reduced waste.

Why is calefaccion electrica important in healthcare facilities?

In healthcare, calefaccion electrica plays a crucial role in providing a comfortable environment for patients and ensuring the functionality of medical equipment. Hospitals and clinics require reliable heating systems to maintain optimal conditions for patient care. Buyers should prioritize sourcing systems that offer reliability and safety certifications, as well as energy efficiency, to meet the demanding needs of healthcare environments while managing operational costs effectively.

Illustrative image related to calefaccion electrica

3 Common User Pain Points for ‘calefaccion electrica’ & Their Solutions

Scenario 1: High Energy Costs During Winter Months

The Problem: Many B2B buyers, particularly in regions with harsh winters, struggle with the high operational costs associated with electric heating systems. This challenge is compounded by fluctuating energy prices, which can significantly impact budgets and profitability. Businesses often find themselves at a crossroads, needing efficient heating solutions that do not break the bank while ensuring the comfort of their employees or clients.

The Solution: To mitigate high energy costs, businesses should consider investing in modern, energy-efficient electric heating solutions, such as inverter-driven heat pumps or smart thermostats. These systems are designed to optimize energy consumption by adjusting output based on real-time temperature and occupancy data. Additionally, buyers should explore bulk purchasing options from reputable suppliers to secure better pricing on electric heating units. Conducting a thorough energy audit can also help identify inefficiencies in existing heating systems and inform decisions on upgrading to more efficient solutions.

Scenario 2: Difficulty in Selecting the Right Heating System

The Problem: Choosing the appropriate electric heating system can be a daunting task for B2B buyers, especially for those managing properties or facilities with varying heating needs. Factors such as building size, insulation quality, and specific usage patterns create complexities that can lead to suboptimal heating solutions if not addressed properly. Inadequate heating can result in discomfort for occupants and increased energy usage, further complicating operational efficiency.

The Solution: To streamline the selection process, businesses should utilize comprehensive heating calculators and consult with HVAC professionals who specialize in electric heating systems. These tools can assess specific requirements based on square footage, insulation quality, and heating needs, guiding buyers toward the most suitable options—be it electric boilers, radiant floor heating, or individual room heaters. Additionally, implementing a phased approach to installation allows businesses to test different systems in various areas before committing to a full rollout, ensuring the best fit for their operational demands.

Scenario 3: Maintenance and Downtime Challenges

The Problem: B2B buyers often face unexpected maintenance issues with electric heating systems, leading to downtime that can affect productivity and comfort. Regular maintenance is essential, yet many businesses either overlook it due to resource constraints or lack the knowledge to perform it effectively. This oversight can result in costly repairs and prolonged periods without adequate heating, which can negatively impact employee morale and customer satisfaction.

The Solution: Establishing a proactive maintenance schedule is crucial for minimizing downtime and ensuring the longevity of electric heating systems. Businesses should collaborate with experienced service providers to create a tailored maintenance plan that includes regular inspections and timely repairs. Investing in smart heating technology that offers predictive maintenance capabilities can also alert businesses to potential issues before they escalate. Furthermore, training staff on basic troubleshooting techniques can empower them to address minor issues immediately, reducing reliance on external support and minimizing heating disruptions.

Strategic Material Selection Guide for calefaccion electrica

What Are the Key Materials Used in Electric Heating Systems?

When selecting materials for electric heating systems (calefacción eléctrica), it is essential to consider properties that affect performance, durability, and compatibility with various applications. Below, we analyze four common materials used in electric heating systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Copper Perform in Electric Heating Applications?

Key Properties: Copper is renowned for its excellent thermal conductivity, high melting point (approximately 1,984°F or 1,085°C), and corrosion resistance. These properties make it an ideal choice for heating elements and wiring.

Illustrative image related to calefaccion electrica

Pros & Cons: The primary advantage of copper is its high efficiency in heat transfer, which leads to lower energy consumption. However, copper is relatively expensive compared to alternatives like aluminum, which can impact overall project budgets. Additionally, its manufacturing complexity is moderate, requiring specialized techniques to ensure durability.

Impact on Application: Copper’s compatibility with various media, including water and air, makes it suitable for both central and individual heating systems. However, it may not be the best choice for environments with highly corrosive substances.

Considerations for International Buyers: Compliance with international standards such as ASTM B75 for copper tubes is crucial. Buyers in regions like Germany and Nigeria should ensure that suppliers adhere to these standards to maintain quality and safety.

Illustrative image related to calefaccion electrica

What Role Does Aluminum Play in Electric Heating Systems?

Key Properties: Aluminum is lightweight, has a melting point of approximately 1,221°F (660.3°C), and offers good thermal conductivity, albeit lower than copper.

Pros & Cons: The main advantages of aluminum include its lower cost and ease of manufacturing, making it a popular choice for budget-sensitive projects. However, its lower thermal efficiency compared to copper can lead to higher energy costs in the long run. Additionally, aluminum can be prone to oxidation, which may affect its performance over time.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable heaters. However, its compatibility with certain media, particularly those that are corrosive, should be carefully evaluated.

Considerations for International Buyers: Buyers should be aware of compliance with standards like DIN 17615 for aluminum products. In regions like South America, where corrosion can be an issue, selecting anodized aluminum may be beneficial.

Illustrative image related to calefaccion electrica

How Does Stainless Steel Enhance Electric Heating Systems?

Key Properties: Stainless steel offers excellent corrosion resistance, a melting point of around 2,500°F (1,370°C), and good mechanical strength, making it suitable for high-pressure applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which extends the lifespan of heating elements. However, its higher cost and complexity in manufacturing can be a drawback for budget-conscious projects.

Impact on Application: Stainless steel is ideal for applications involving water heating and high-pressure systems, ensuring safety and reliability. Its compatibility with a wide range of media makes it versatile for various heating solutions.

Considerations for International Buyers: Compliance with standards such as ASTM A312 for stainless steel pipes is essential. Buyers in the Middle East, where high humidity can accelerate corrosion, should prioritize high-grade stainless steel.

Illustrative image related to calefaccion electrica

What About Thermoplastic Materials in Electric Heating Systems?

Key Properties: Thermoplastics, such as polyamide and polyethylene, are lightweight and have a melting point ranging from 300°F to 500°F (150°C to 260°C). They offer good electrical insulation properties.

Pros & Cons: The advantages of thermoplastics include their low cost and ease of manufacturing, making them suitable for various applications. However, their lower thermal resistance compared to metals can limit their use in high-temperature scenarios.

Impact on Application: Thermoplastics are often used in insulation and casing for heating elements, providing safety and protection. However, they may not be suitable for direct contact with high-temperature media.

Illustrative image related to calefaccion electrica

Considerations for International Buyers: Compliance with international standards such as ISO 9001 for quality management systems is important. Buyers in Africa should ensure that thermoplastics used meet local safety regulations.

Summary Table of Material Selection

| Material | Typical Use Case for calefaccion electrica | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Heating elements, wiring | Excellent thermal conductivity | High cost | High |

| Aluminum | Portable heaters, lightweight applications | Lower cost, easy to manufacture | Lower thermal efficiency | Medium |

| Stainless Steel | High-pressure water heating systems | Corrosion resistance, durability | Higher cost, complex manufacturing | High |

| Thermoplastic | Insulation and casing for heating elements | Low cost, lightweight | Lower thermal resistance | Low |

This analysis provides a comprehensive overview of materials commonly used in electric heating systems, equipping international B2B buyers with the insights needed to make informed decisions based on their specific requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for calefaccion electrica

What Are the Main Stages in the Manufacturing Process of Calefacción Eléctrica?

The manufacturing process of calefacción eléctrica involves several key stages, each critical to ensuring the final product meets performance and quality standards. Understanding these stages will help B2B buyers evaluate potential suppliers more effectively.

1. Material Preparation: How Are Raw Materials Selected and Processed?

The initial phase of manufacturing calefacción eléctrica begins with sourcing high-quality raw materials. Manufacturers typically utilize metals such as aluminum and steel for structural components, along with specialized thermal fluids for heating systems. The materials undergo rigorous testing for thermal conductivity and durability to ensure they can withstand operational demands.

Illustrative image related to calefaccion electrica

Once selected, the materials are prepared through cutting, shaping, and cleaning processes to eliminate impurities that could affect performance. This preparation stage is crucial, as the quality of the raw materials directly influences the efficiency and longevity of the heating systems.

2. Forming: What Techniques Are Used to Shape Heating Elements?

After material preparation, the forming process shapes the components into functional parts. Techniques such as stamping, extrusion, and die-casting are commonly employed to create elements like heating coils, radiators, and control panels.

For instance, heating elements may be formed using wire winding techniques to create coils that maximize surface area for heat distribution. Advanced manufacturing technologies, such as CNC machining, ensure precision and consistency across all components, which is vital for achieving optimal performance.

3. Assembly: How Are Components Integrated into Finished Products?

The assembly stage is where all manufactured components come together. Automated assembly lines are often used to streamline this process, enhancing efficiency and reducing labor costs. Key components like heating elements, control units, and safety features are integrated in a systematic manner.

Illustrative image related to calefaccion electrica

During assembly, quality control checks are frequently performed to identify any defects early in the process. This may include verifying the correct installation of components and conducting preliminary functional tests to ensure that the product meets design specifications.

4. Finishing: What Processes Ensure the Final Product Meets Quality Standards?

The finishing stage encompasses various processes aimed at enhancing the product’s aesthetic appeal and functionality. This may involve surface treatments such as painting, anodizing, or powder coating to improve corrosion resistance and visual appearance.

Additionally, final inspections are conducted to ensure that the products meet all specifications and regulatory standards. This includes checking for dimensional accuracy and overall quality before packaging for shipment.

Illustrative image related to calefaccion electrica

What Quality Assurance Measures Are Commonly Used in the Calefacción Eléctrica Industry?

Quality assurance (QA) is paramount in the manufacturing of calefacción eléctrica, ensuring that products are safe, reliable, and efficient. B2B buyers should be familiar with various QA measures and international standards that suppliers adhere to.

1. What International Standards Should Buyers Look For?

Manufacturers of calefacción eléctrica typically comply with international quality standards such as ISO 9001, which outlines requirements for a quality management system. This standard emphasizes continuous improvement and customer satisfaction.

In addition, industry-specific certifications such as CE marking for products sold in Europe and API standards for safety and performance are crucial. These certifications provide assurance that the products have undergone rigorous testing and meet safety regulations.

2. How Are Quality Control Checkpoints Integrated Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process, ensuring products meet established standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials before they are used in production. Suppliers are assessed based on material specifications and compliance with industry standards.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring production parameters and conducting tests to identify defects early. This stage may include functional tests of heating elements and safety checks on electrical components.

-

Final Quality Control (FQC): This final stage involves comprehensive testing of the finished products. Common tests include performance evaluations, safety inspections, and compliance checks with relevant certifications.

3. What Testing Methods Are Used to Ensure Product Safety and Performance?

Various testing methods are employed to validate the performance and safety of calefacción eléctrica products. These include:

-

Thermal Testing: Evaluating the efficiency and heat output of heating elements under various conditions.

-

Electrical Testing: Ensuring that electrical components function correctly and safely under load conditions, including tests for insulation resistance and continuity.

-

Durability Testing: Assessing how products perform under extreme conditions, such as high temperatures or prolonged use, to determine longevity and reliability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of potential suppliers is crucial to ensuring they receive high-quality products. Here are some effective methods:

1. What Should Buyers Look for in Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers should request access to audit reports that outline the supplier’s compliance with relevant standards and the effectiveness of their quality management systems.

Audits should evaluate:

- Quality management practices

- Compliance with international standards

- Records of past performance and defect rates

2. How Can Buyers Use Third-Party Inspections to Ensure Quality?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can evaluate production practices, perform random sampling of products, and verify compliance with safety standards.

Buyers should ensure that third-party inspectors are accredited and have experience in the calefacción eléctrica industry. This external validation can help mitigate risks associated with supplier quality.

Illustrative image related to calefaccion electrica

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing calefacción eléctrica products from different regions. Understanding regional regulations, cultural factors, and logistical challenges can influence procurement decisions.

1. How Do Regional Standards Impact Quality Assurance?

Different regions may have distinct regulatory requirements and quality standards. For example, products intended for the European market must adhere to CE marking requirements, while those for the Middle Eastern market may need to comply with local safety regulations.

Buyers should familiarize themselves with these standards and ensure that suppliers can provide the necessary documentation and certifications for their products.

Illustrative image related to calefaccion electrica

2. What Logistical Considerations Should Buyers Keep in Mind?

Logistics play a significant role in the quality assurance process. Buyers should consider factors such as shipping times, customs regulations, and potential delays that could impact product quality. Ensuring proper handling during transportation and storage is essential to maintaining product integrity.

In conclusion, understanding the manufacturing processes and quality assurance measures for calefacción eléctrica is crucial for B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘calefaccion electrica’

The purpose of this guide is to provide B2B buyers with a structured approach to sourcing electric heating systems (calefacción eléctrica). This checklist will help ensure that you make informed decisions that align with your organization’s specific needs and preferences, ultimately enhancing comfort while optimizing energy consumption.

Step 1: Define Your Technical Specifications

Begin by identifying the specific requirements for your electric heating system. Consider factors such as the size of the area to be heated, insulation quality, and the local climate.

– Heating Capacity: Calculate the necessary heating capacity in kilowatts (kW) based on the square footage and insulation level of your space.

– System Type: Decide whether you need central heating solutions, individual room units, or a combination of both.

Step 2: Research and Understand Available Technologies

Familiarize yourself with the various technologies available in electric heating. Each system has unique benefits and applications, which can significantly affect your decision.

– Types of Systems: Look into options like radiators, convectors, and heat pumps. Aerothermal systems, for instance, are efficient and eco-friendly.

– Energy Efficiency Ratings: Pay attention to energy efficiency ratings (A+++ to D), which indicate the system’s performance and potential cost savings over time.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure they can meet your needs. This step is critical for establishing a reliable supply chain.

– Request Documentation: Ask for company profiles, case studies, and references from previous clients in similar sectors or regions.

– Certifications and Standards: Verify that suppliers comply with local and international standards for safety and quality.

Step 4: Assess Installation Requirements

Understanding the installation process can save time and costs in the long run. Evaluate whether the installation can be completed without significant renovations.

– Installation Complexity: Check if the system requires extensive modifications to existing infrastructure.

– Support Services: Inquire about installation support or partnerships that suppliers may offer.

Step 5: Consider Maintenance and Support

Select systems that provide long-term reliability and minimal maintenance requirements. This consideration can significantly impact operational costs.

– Warranty and Service Agreements: Ensure that the supplier offers comprehensive warranties and service agreements that cover potential repairs or replacements.

– User-Friendly Features: Look for systems with smart technology that simplifies monitoring and maintenance, such as programmable thermostats and remote access.

Step 6: Analyze Cost Implications

Conduct a thorough cost analysis, including initial investment, operational costs, and potential savings from energy efficiency.

– Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and energy consumption over the system’s lifespan.

– Financing Options: Explore financing plans that may be available, especially for larger installations, to manage upfront costs.

Step 7: Finalize Your Decision and Place Orders

After careful evaluation, finalize your supplier choice and place your orders. Ensure you have all necessary documentation and agreements in place.

– Order Confirmation: Confirm the details of your order, including delivery timelines and installation dates.

– Follow-Up: Set up a follow-up schedule with your supplier to ensure timely delivery and address any potential issues.

By following this structured checklist, B2B buyers can effectively source electric heating systems that meet their operational needs while ensuring energy efficiency and comfort for their environments.

Comprehensive Cost and Pricing Analysis for calefaccion electrica Sourcing

What Are the Key Cost Components in Calefaccion Electrica Sourcing?

When sourcing calefaccion electrica, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as metals, plastics, and electronic components significantly influences pricing. High-quality materials can enhance durability and efficiency but also increase costs.

-

Labor: Labor costs vary by region and can be affected by local wage standards and availability of skilled workers. In countries like Germany, labor costs may be higher compared to regions in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: Specialized tools and molds are often needed for production, particularly for customized solutions. The initial investment in tooling can be substantial but is amortized over production volumes.

-

Quality Control (QC): Ensuring that products meet specific standards incurs costs associated with testing and inspection. Buyers should consider suppliers with robust QC processes to minimize defects.

-

Logistics: Shipping and handling costs vary significantly based on distance, mode of transport, and Incoterms. Effective logistics management can reduce overall costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary widely based on market competition and the supplier’s positioning.

How Do Price Influencers Affect Calefaccion Electrica Costs?

Several factors influence the pricing of calefaccion electrica:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Understanding the supplier’s minimum order quantities (MOQ) can aid in negotiating better prices.

-

Specifications/Customization: Custom specifications may incur additional costs. It’s essential to communicate specific requirements early to avoid unexpected expenses.

-

Materials: The choice of materials can drastically affect cost. For example, using environmentally-friendly materials may increase upfront costs but can lead to long-term savings in energy efficiency.

-

Quality/Certifications: Products that meet international quality standards or have specific certifications may command higher prices. Buyers should evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record but can offer better service and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery can significantly affect total costs. Buyers should clarify responsibilities for costs and risks associated with transportation.

What Are the Best Buyer Tips for Cost-Efficiency in Calefaccion Electrica Sourcing?

To enhance cost efficiency when sourcing calefaccion electrica, consider the following strategies:

-

Negotiate Wisely: Don’t hesitate to negotiate prices, especially if you can commit to larger volumes. Suppliers often have room for price adjustments.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider installation, maintenance, and operational costs over the product’s lifespan. Products with higher upfront costs may offer better long-term savings.

-

Understand Pricing Nuances for International Markets: Prices can vary significantly across regions due to local economic conditions, tariffs, and shipping costs. Researching market conditions in target regions like Nigeria or Germany can provide insights into reasonable pricing.

-

Stay Informed on Trends: Keep up with market trends, such as shifts towards energy-efficient systems. Being informed can help you make better purchasing decisions and negotiate from a position of strength.

-

Request Samples: Before committing to large orders, request samples to assess quality and suitability. This can prevent costly mistakes in large-scale purchases.

Disclaimer on Indicative Prices

Prices for calefaccion electrica products can fluctuate based on various factors, including market demand and supplier conditions. It’s recommended that buyers obtain multiple quotes and conduct thorough market research to ensure they receive competitive pricing.

Alternatives Analysis: Comparing calefaccion electrica With Other Solutions

When considering heating solutions for commercial or industrial applications, it is essential to evaluate various alternatives to calefaccion electrica. Each heating method has its unique advantages and disadvantages that can significantly impact operational efficiency, cost-effectiveness, and comfort levels. This section presents a comparative analysis of calefaccion electrica against two alternative heating solutions: aerothermal systems and gas boilers.

| Comparison Aspect | Calefaccion Electrica | Aerothermal Systems | Gas Boilers |

|---|---|---|---|

| Performance | Provides consistent and controllable heat. Ideal for various spaces. | Highly efficient, offering up to 5 times more energy output than input. | Rapid heating, good for large spaces but can be less efficient. |

| Cost | Higher operational costs; installation can be low-cost but varies by setup. | Higher initial investment but lower long-term energy costs. | Moderate initial cost; fluctuating fuel prices affect long-term costs. |

| Ease of Implementation | Generally easy to install; no need for ventilation. | More complex installation; requires space for outdoor units. | Installation can be labor-intensive; requires proper venting. |

| Maintenance | Low maintenance; no moving parts to service regularly. | Moderate maintenance; periodic checks needed for efficiency. | Higher maintenance; requires regular servicing to ensure safety and efficiency. |

| Best Use Case | Suitable for residential and smaller commercial applications. | Best for larger facilities needing both heating and cooling solutions. | Effective for industrial applications or where high heat output is required. |

Aerothermal Systems: What Are Their Advantages and Disadvantages?

Aerothermal systems, utilizing heat pumps, extract thermal energy from the air and can be used for both heating and cooling. The primary advantage is their energy efficiency, as they can convert one unit of electricity into multiple units of heat. This makes them environmentally friendly and cost-effective over time. However, their initial installation can be quite costly, and they require sufficient outdoor space for the heat pump units, which may not be feasible in all settings.

Illustrative image related to calefaccion electrica

Gas Boilers: Are They Still a Viable Option?

Gas boilers are a traditional heating solution that provides quick and effective heating. They are particularly well-suited for larger facilities requiring substantial heat output. The initial investment is moderate, but ongoing fuel costs can fluctuate significantly based on market conditions. Additionally, gas boilers require proper venting systems, which can complicate installation and increase maintenance needs. Safety is also a concern, necessitating regular inspections to avoid potential hazards.

Making the Right Choice: What Should B2B Buyers Consider?

When choosing the right heating solution, B2B buyers should carefully assess their specific needs, including the scale of the operation, available space for installation, and budget constraints. While calefaccion electrica offers a straightforward and low-maintenance option, aerothermal systems provide excellent energy efficiency, and gas boilers deliver high output for large spaces. Conducting a thorough cost-benefit analysis that includes initial investment, operational costs, and long-term sustainability will guide buyers toward the best solution tailored to their operational requirements. Ultimately, aligning the heating solution with the organization’s energy goals and operational demands will ensure a successful investment.

Essential Technical Properties and Trade Terminology for calefaccion electrica

What Are the Key Technical Properties of Calefacción Eléctrica?

Understanding the essential technical properties of calefacción eléctrica is crucial for B2B buyers who wish to make informed decisions regarding heating solutions. Here are some critical specifications to consider:

1. Energy Efficiency Rating

The energy efficiency rating indicates how effectively a heating system converts energy into heat. Systems with a higher rating (e.g., A+++) consume less electricity while providing the same level of heating. This is vital for reducing operational costs and minimizing environmental impact, which is particularly important for businesses operating in regions with high energy prices.

2. Power Output (kW)

Power output, measured in kilowatts (kW), determines the heating capacity of the system. Selecting the appropriate power output is crucial for ensuring adequate heating in the intended space. Under-specifying can lead to insufficient heating, while over-specifying can result in wasted energy and higher costs. Accurate assessment of heating requirements is essential for optimal performance.

3. Installation Type

Different calefacción eléctrica systems can be categorized based on installation type—centralized versus decentralized. Centralized systems heat water that is circulated through radiators, while decentralized systems, like electric radiators, provide localized heating. Understanding the installation type affects both the upfront costs and the long-term efficiency of the heating solution.

4. Thermal Inertia

Thermal inertia refers to the ability of a heating system to retain and release heat over time. Systems with high thermal inertia, such as accumulators, store heat generated during off-peak hours and distribute it when needed. This can lead to significant energy savings and is particularly beneficial in regions with fluctuating energy costs.

5. Control Mechanisms

Modern calefacción eléctrica systems often come equipped with advanced control mechanisms, including programmable thermostats and Wi-Fi connectivity. These features allow users to customize heating schedules and monitor energy usage remotely, leading to improved comfort and reduced energy bills. For B2B buyers, these controls can be a selling point when evaluating systems based on operational efficiency.

What Are the Common Trade Terms in Calefacción Eléctrica?

Familiarity with industry terminology can enhance communication and negotiation processes for B2B buyers. Here are some common jargon terms used in the calefacción eléctrica sector:

Illustrative image related to calefaccion electrica

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of calefacción eléctrica, buyers may work with OEMs to procure specific components or complete systems tailored to their needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory and cost effectively, especially when considering large-scale installations or projects.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. By issuing an RFQ, B2B buyers can compare pricing, features, and terms from multiple vendors, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping responsibilities, risk transfer, and cost allocation, which are critical when importing calefacción eléctrica systems from other countries.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is received. Understanding lead time is crucial for project planning and ensuring that heating solutions are available when needed, especially in regions with seasonal demands.

6. Warranty Period

The warranty period is the duration during which a manufacturer guarantees that a product will function correctly. For calefacción eléctrica systems, a longer warranty period can indicate confidence in product quality and can provide peace of mind for buyers investing in larger installations.

By grasping these essential technical properties and industry terms, B2B buyers can navigate the complexities of calefacción eléctrica with greater confidence, ensuring that they select the best solutions for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the calefaccion electrica Sector

What Are the Key Trends Driving the Global Calefaccion Electrica Market?

The global calefaccion electrica market is experiencing significant transformation, driven by a confluence of factors. A primary driver is the increasing demand for energy-efficient heating solutions, particularly in regions facing rising energy costs. Countries in Africa, South America, the Middle East, and Europe are prioritizing energy efficiency, leading to a surge in the adoption of innovative heating technologies such as electric boilers, infrared radiators, and heat pumps. These technologies not only offer lower operational costs but also align with environmental sustainability goals.

Emerging B2B trends include the integration of smart technology into heating systems. Buyers are increasingly looking for solutions that allow remote monitoring and control, enhancing energy management. Smart thermostats and IoT-enabled devices are becoming essential for businesses aiming to optimize energy consumption and reduce waste. Additionally, the rise of renewable energy sources is propelling the adoption of electric heating systems that can leverage solar and wind energy, particularly in markets like Germany and parts of Africa.

Market dynamics are also influenced by regulatory frameworks promoting renewable energy and energy-efficient solutions. International buyers should stay informed about local regulations and incentives that support the installation of electric heating systems. Moreover, businesses are increasingly focusing on local sourcing and partnerships to mitigate supply chain disruptions, a trend that has gained momentum post-pandemic.

How Is Sustainability Shaping Sourcing Practices in the Calefaccion Electrica Sector?

Sustainability is at the forefront of sourcing practices in the calefaccion electrica sector. The environmental impact of heating solutions is a major concern, prompting B2B buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and technologies that minimize carbon footprints.

Ethical sourcing is becoming increasingly important, as buyers seek to ensure that their supply chains adhere to environmental and social governance (ESG) criteria. Suppliers offering ‘green’ certifications, such as Energy Star or ISO 14001, provide assurance that their products meet rigorous environmental standards. Furthermore, manufacturers that utilize recyclable materials and low-impact production processes are gaining favor among conscientious buyers.

As businesses pivot towards sustainable operations, the demand for products that not only heat efficiently but also contribute to energy savings is rising. This trend is particularly relevant in regions like Europe, where consumers are more environmentally conscious and willing to invest in high-quality, sustainable heating solutions.

How Has the Calefaccion Electrica Sector Evolved Over Time?

The calefaccion electrica sector has evolved significantly from traditional heating methods to modern, energy-efficient systems. Initially dominated by fossil fuel-based heating solutions, the market has shifted towards electric systems due to advancements in technology and growing environmental awareness.

The introduction of electric heat pumps and smart thermostats revolutionized how consumers approach heating, allowing for greater control and efficiency. The transition is further supported by government policies aimed at reducing carbon emissions and promoting renewable energy sources. As a result, B2B buyers are now presented with a wide array of innovative and sustainable heating options that were not available in the past, making it essential for them to stay informed about the latest developments and trends in the industry.

In conclusion, understanding these dynamics is crucial for international B2B buyers in the calefaccion electrica sector, particularly as they navigate sourcing decisions that align with both economic and environmental goals.

Frequently Asked Questions (FAQs) for B2B Buyers of calefaccion electrica

-

How do I choose the right calefacción eléctrica system for my business?

Choosing the right calefacción eléctrica system involves assessing your specific heating needs, including the size of the space, insulation quality, and local climate conditions. Evaluate the different types of systems available, such as central heating, individual room heaters, or renewable options like aerothermal systems. Consider factors such as energy efficiency, installation requirements, and long-term operational costs. Consulting with a heating specialist can also provide valuable insights tailored to your business’s unique requirements. -

What is the best calefacción eléctrica solution for large commercial spaces?

For large commercial spaces, central heating systems or high-capacity electric boilers are often the best options. These systems can efficiently distribute heat throughout extensive areas and adapt to varying heating demands. Look for solutions that offer zoning capabilities, allowing different areas to be heated independently based on usage. Additionally, consider energy-efficient models that can help reduce operational costs while maintaining a comfortable environment for employees and customers. -

What factors should I consider when vetting suppliers for calefacción eléctrica?

When vetting suppliers, evaluate their experience in the industry, product range, and customer reviews. It’s essential to check their compliance with international quality standards and certifications, particularly for electrical appliances. Request samples or case studies to assess product performance and reliability. Also, consider the supplier’s capacity for customization, lead times, and their ability to provide after-sales support and warranty services. -

What are the typical minimum order quantities (MOQ) for calefacción eléctrica products?

Minimum order quantities (MOQ) can vary significantly depending on the supplier and the specific products being ordered. Generally, MOQs for calefacción eléctrica products can range from a few units for smaller items like individual heaters to larger quantities for bulk orders of central heating systems. Always clarify MOQs with potential suppliers and consider negotiating terms that align with your purchasing capabilities and business needs. -

What payment terms are commonly offered by suppliers of calefacción eléctrica?

Payment terms can differ widely among suppliers, but common practices include upfront payments, payment upon delivery, or payment terms extending to 30, 60, or even 90 days post-delivery. Some suppliers may offer discounts for early payments or bulk orders. It’s crucial to understand the financial implications of these terms, especially in international transactions, and to establish a clear agreement before finalizing any orders. -

How can I ensure quality assurance (QA) for calefacción eléctrica products?

To ensure quality assurance, request documentation that verifies compliance with relevant industry standards and certifications. Conduct factory audits if possible, or request third-party inspection services to evaluate product quality before shipment. Establish clear specifications and testing protocols for the products you order, and consider implementing a quality control plan that includes regular checks during the production process and upon receipt of goods. -

What logistics considerations should I keep in mind when importing calefacción eléctrica?

When importing calefacción eléctrica, consider shipping methods, customs regulations, and potential tariffs that may apply to your products. Work with logistics partners who have experience in handling electrical goods and understand the specific requirements for safe transport. Additionally, ensure you have a clear understanding of delivery timelines and any documentation needed for customs clearance to avoid delays. -

Can calefacción eléctrica systems be customized to meet specific business needs?

Yes, many suppliers offer customization options for calefacción eléctrica systems, allowing you to tailor the product specifications to meet your business needs. This may include variations in size, heating capacity, control systems, or additional features such as smart technology integration. Discuss your requirements with potential suppliers to explore available customization options and ensure that the final products align with your operational goals.

Top 8 Calefaccion Electrica Manufacturers & Suppliers List

1. Elnur – Calefacción Eléctrica Eficiente

Domain: elnur.es

Introduction: Tipos de calefacción eléctrica: 1. Aerotermia: Energía renovable que extrae calor del aire exterior, proporciona calefacción, refrigeración y agua caliente. Sistema de alta eficiencia energética (hasta 80% de energía gratuita). 2. Calderas eléctricas: Sustituyen calderas de gas o gasoil, utilizan un sistema hidráulico similar. Disponibles en modelos para solo calefacción, mixtas y de alta potencia…

2. Hudson Reed – Radiadores Eléctricos de Diseño

Domain: es.hudsonreed.com

Registered: 2000 (25 years)

Introduction: Radiadores eléctricos de diseño para el hogar, conectados directamente a la red eléctrica, controlables de manera independiente, sin necesidad de calefacción central. Instalación sencilla sin obras, solución económica para calefacción eléctrica, reducción de costes energéticos y control individual de cada estancia.

3. Mr. Heater – Calentadores Portátiles

Domain: hn.ebay.com

Registered: 1995 (30 years)

Introduction: Los aparatos de calefacción eléctrica de casa incluyen diversas opciones como calentadores portátiles, calefactores de cerámica, y calefactores de panel. Las marcas destacadas son Mr. Heater, Honeywell, Pelonis, y De’Longhi. Las capacidades de calefacción varían desde menos de 2000 BTU hasta más de 30,000 BTU. Se ofrecen tanto productos nuevos como usados, con precios que oscilan desde menos de L …

4. CALELEC – Heating and Humidity Control Solutions

Domain: calelec.com

Registered: 2008 (17 years)

Introduction: CALELEC manufactures electric and gas heaters, water heating solutions (boilers), and humidity control systems (humidifiers and dehumidifiers). They offer a wide variety of products tailored to industrial, residential, and commercial needs. Key offerings include:

– Residential heating solutions: electric and gas heating, instant and storage boilers, sauna equipment, steam generators.

– Industria…

5. Ovacen – Calefacción Eléctrica

Domain: ovacen.com

Registered: 2012 (13 years)

Introduction: Calefacción eléctrica: Tipos y características generales. Tipos de calefacción eléctrica incluyen: 1. Radiadores eléctricos 2. Chimeneas eléctricas 3. Suelo radiante eléctrico 4. Aire acondicionado reversible 5. Bomba de calor aerotérmica 6. Calderas eléctricas. Ventajas: dispositivos económicos, fácil instalación, ocupan poco espacio, suministro constante de energía. Desventajas: menor distribuci…

6. DUCASA – Acumulador de Calor Dinámico 5.000W

Domain: materialelectricoyclimatizacion.com

Registered: 2018 (7 years)

Introduction: [{‘name’: ‘Acumulador de calor dinámico Serie 15/265 de 5.000W – DUCASA’, ‘price’: ‘1.095,23 €’, ‘original_price’: ‘1.894,86 €’, ‘discount’: ‘-42,2%’, ‘features’: ‘Potencia térmica 5000 W, sensor para ventana abierta, control de carga, adaptable a 8 o 14 horas de carga, ventilador silencioso (31 dB), fácil montaje.’}, {‘name’: ‘Acumulador de calor estático i-817/14 T de 950W – DUCASA’, ‘price’: ‘5…

7. Schlüter – DITRA-HEAT-E

Domain: eu.schluter.com

Registered: 1996 (29 years)

Introduction: Calefacción eléctrica Schlüter-DITRA-HEAT-E; garantiza pies calientes; control del tiempo con precisión; calentamiento rápido; sistemas de calefacción eléctrica de suelo y paneles murales.

8. Obramat – Calefacción Eléctrica

Domain: obramat.es

Introduction: Calefacción eléctrica en Obramat incluye calderas eléctricas, radiadores y calefactores eléctricos de las mejores marcas. Categorías de productos: emisores térmicos secos, emisores térmicos cerámicos, radiadores eléctricos, toalleros eléctricos, calefactores y termostatos. Ofrecen entrega en 24 horas y recogida en 2 horas.

Strategic Sourcing Conclusion and Outlook for calefaccion electrica

As international B2B buyers navigate the complex landscape of calefacción eléctrica, the importance of strategic sourcing cannot be overstated. By understanding the diverse systems available—ranging from central electric heating to individual solutions like radiators and accumulators—buyers can make informed decisions that align with their specific needs and energy efficiency goals. The shift towards sustainable options, such as aerotermia, offers significant cost savings and environmental benefits, making it an attractive choice for modern installations.

Incorporating smart technology in heating systems not only enhances comfort but also optimizes energy consumption, a crucial factor in regions with fluctuating energy costs. For buyers in Africa, South America, the Middle East, and Europe, this presents an opportunity to invest in systems that not only meet current demands but also anticipate future trends in energy consumption and sustainability.

Looking ahead, it is imperative for B2B buyers to engage with suppliers who prioritize innovation and efficiency in their offerings. By doing so, they can ensure they are well-positioned to meet the challenges of a rapidly evolving market while contributing to a more sustainable future in heating solutions. Embrace the shift towards strategic sourcing and explore the potential that calefacción eléctrica holds for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.