Cable Aircraft Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for cable aircraft

In today’s dynamic global market, sourcing high-quality cable aircraft poses a significant challenge for international B2B buyers. Whether you are in Brazil, Nigeria, or any other region, understanding the nuances of aircraft cable types, their applications, and the suppliers that offer them is crucial for making informed purchasing decisions. This comprehensive guide aims to equip you with the essential insights needed to navigate the complexities of the aircraft cable market.

Within these pages, you will explore various types of aircraft cables, including galvanized and stainless steel options, along with their respective strengths and applications. We will delve into critical factors such as supplier vetting processes, pricing structures, and compliance with international safety standards. Each section is designed to empower you with the knowledge necessary to select products that meet your operational needs while adhering to budgetary constraints.

Moreover, by focusing on regional considerations and market trends, this guide addresses the unique challenges faced by buyers in Africa, South America, the Middle East, and Europe. With actionable insights and expert recommendations, you will be well-prepared to make strategic decisions that enhance your supply chain efficiency and product reliability in the competitive landscape of cable aircraft.

Understanding cable aircraft Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 7×19 Galvanized Aircraft Cable | Made of 7 strands of wire with 19 wires each, high flexibility and strength | Rigging, winch lines, fencing | Pros: High tensile strength, corrosion-resistant. Cons: Limited lifespan in harsh environments. |

| 7×19 Stainless Steel Aircraft Cable | Enhanced durability and resistance to corrosion, ideal for marine applications | Marine rigging, architectural applications | Pros: Long-lasting, aesthetic appeal. Cons: Higher cost compared to galvanized options. |

| Rotation-Resistant Wire Rope | Designed to minimize torque and rotation, available in various constructions | Lifting applications, cranes, and hoists | Pros: Reduces twisting during use. Cons: More complex installation requirements. |

| Swaged Wire Rope | Terminals are swaged for added strength, available in various sizes | Heavy lifting, suspension systems | Pros: Customizable lengths, high load capacity. Cons: Requires specialized fittings. |

| Cable Laid Wire Rope | Constructed with a unique cable-laying process, offers flexibility and strength | Elevators, cranes, and other heavy machinery | Pros: Excellent fatigue resistance. Cons: May require more maintenance than standard wire ropes. |

What are the Characteristics of 7×19 Galvanized Aircraft Cable?

7×19 Galvanized Aircraft Cable is composed of 7 strands, each containing 19 wires, resulting in a flexible yet strong cable. Its galvanized finish provides a level of corrosion resistance, making it suitable for various outdoor applications. This cable is widely used in rigging and winch lines, particularly in industries that require reliable and durable lifting solutions. Buyers should consider its tensile strength and flexibility, but be aware that its lifespan may be reduced in extreme environments.

How Does 7×19 Stainless Steel Aircraft Cable Compare?

7×19 Stainless Steel Aircraft Cable offers similar construction to its galvanized counterpart but with superior corrosion resistance, making it ideal for marine and architectural applications. The aesthetic appeal of stainless steel is another advantage, as it can enhance the visual quality of installations. While the initial investment is higher, the long-term durability and reduced maintenance needs can justify the cost for many B2B buyers.

Why Choose Rotation-Resistant Wire Rope?

Rotation-Resistant Wire Rope is engineered to reduce torque during lifting, making it a preferred choice for cranes and hoists. This type of wire rope is available in various constructions and is particularly beneficial in applications where stability is crucial. B2B buyers should weigh the benefits of reduced twisting against the complexity of installation, which may require specialized knowledge or equipment.

What Makes Swaged Wire Rope a Viable Option?

Swaged Wire Rope features terminals that are swaged onto the cable, enhancing its overall strength. This type is often used in heavy lifting and suspension systems. Its customizability in lengths and high load capacity are significant advantages for B2B buyers. However, the need for specialized fittings and installation techniques can pose challenges, making it essential to evaluate the specific requirements of each project.

When Should You Consider Cable Laid Wire Rope?

Cable Laid Wire Rope is constructed through a unique process that enhances its flexibility and strength. It is commonly used in elevators and cranes, where fatigue resistance is a critical factor. For B2B buyers, the choice of this wire rope should be based on its application demands, as it may require more maintenance than standard wire ropes. Understanding the operational environment and load conditions is key to making an informed purchasing decision.

Key Industrial Applications of cable aircraft

| Industry/Sector | Specific Application of cable aircraft | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Rigging and hoisting systems | Enhanced safety and efficiency in lifting operations | Ensure compliance with local safety standards and load ratings. |

| Maritime | Sailboat rigging and mooring systems | Improved durability and performance in marine environments | Select corrosion-resistant materials for longevity in saltwater. |

| Telecommunications | Support structures for antennas and towers | Reliable stability and strength for critical infrastructure | Consider tensile strength and weather resistance for longevity. |

| Entertainment | Stage rigging for concerts and events | Safe and effective support for heavy equipment and lighting | Look for custom lengths and fittings to meet specific design needs. |

| Agriculture | Crop support systems for greenhouses | Increased yield through effective plant support | Verify compatibility with environmental conditions and load capacities. |

How is cable aircraft utilized in the construction industry?

In the construction sector, cable aircraft is primarily used for rigging and hoisting systems. These cables facilitate the lifting of heavy materials and equipment, ensuring that operations are conducted safely and efficiently. The use of high-tensile strength aircraft cables helps mitigate risks associated with lifting operations, as they are designed to handle substantial loads without compromising safety. Buyers should ensure that the cables comply with local regulations and safety standards, particularly in regions like Africa and South America where construction practices may vary significantly.

What role does cable aircraft play in maritime applications?

In maritime settings, cable aircraft is essential for rigging sailboats and securing mooring systems. Its corrosion-resistant properties, particularly when made from stainless steel, make it ideal for use in harsh marine environments. This application not only enhances the performance and durability of sailing vessels but also ensures safety during operations. Buyers in the Middle East and Europe should prioritize sourcing cables that meet specific marine standards to ensure reliability and longevity against saltwater exposure.

Why is cable aircraft important in telecommunications?

The telecommunications industry utilizes cable aircraft for support structures in antennas and towers. These cables provide the necessary strength and stability to withstand environmental pressures, ensuring uninterrupted service. The reliability of these cables is crucial for maintaining the integrity of communication infrastructure, especially in regions prone to extreme weather. B2B buyers must consider the tensile strength and weather resistance of cables when sourcing for telecommunications applications, ensuring they meet the demands of the local environment.

How does cable aircraft enhance safety in entertainment?

In the entertainment sector, cable aircraft is widely used for stage rigging, providing safe support for heavy lighting and equipment during concerts and events. This application is critical for ensuring the safety of performers and audiences alike. The ability to customize lengths and fittings allows for tailored solutions that fit specific stage designs. Buyers in this industry should focus on sourcing cables that can handle dynamic loads and comply with safety regulations, which is especially important in large-scale events across Europe and Africa.

What benefits does cable aircraft offer in agricultural applications?

In agriculture, cable aircraft is used in crop support systems, particularly in greenhouses, where it helps support plants as they grow. This application not only maximizes space but also increases yield by ensuring that plants are adequately supported and exposed to sunlight. Buyers must consider the environmental conditions of their specific agricultural setting and ensure that the cables can withstand factors such as humidity and temperature variations. Sourcing cables that are durable and reliable will contribute to better crop management and productivity.

3 Common User Pain Points for ‘cable aircraft’ & Their Solutions

Scenario 1: Inconsistent Load Ratings Cause Safety Concerns

The Problem: B2B buyers often struggle with the inconsistency in load ratings for aircraft cables, which can lead to safety issues. When sourcing cables, buyers may find that the specifications provided do not align with the actual performance during use. This discrepancy can result from factors such as improper installation, mismatched terminal fittings, or inadequate understanding of the cable’s break strength when used with different accessories. Such uncertainties can lead to catastrophic failures, putting personnel and equipment at risk.

The Solution: To mitigate this risk, B2B buyers should prioritize sourcing cables from reputable manufacturers who provide clear and comprehensive load rating information. It’s crucial to understand that the break strength of aircraft cables can vary significantly based on the type of fittings and installation methods used. Buyers should request detailed installation guidelines and weight load guidelines from suppliers. Additionally, conducting thorough training for installation personnel can ensure that cables are used correctly, thus maintaining their load ratings. Regular inspections and testing of the installed cables can help identify any potential weaknesses before they lead to failure.

Scenario 2: Corrosion and Environmental Degradation

The Problem: In regions with high humidity or corrosive environments, such as coastal areas or industrial zones, B2B buyers face the challenge of cable corrosion. Standard galvanized cables may deteriorate quickly, leading to unexpected failures and costly downtime. This issue is particularly pressing for companies in industries such as construction, shipping, and outdoor installations, where equipment is exposed to the elements.

The Solution: To combat corrosion, buyers should opt for stainless steel aircraft cables, which offer superior resistance to rust and degradation. When selecting cables, look for options that specify marine-grade stainless steel, particularly Type 316, which is known for its excellent corrosion resistance. Additionally, implementing regular maintenance protocols, including the application of protective coatings or lubricants, can extend the life of the cables. Investing in storage solutions that minimize exposure to corrosive elements can also help maintain cable integrity over time.

Illustrative image related to cable aircraft

Scenario 3: Difficulty in Finding the Right Specifications

The Problem: B2B buyers often encounter challenges in sourcing the right specifications for their aircraft cables, especially when dealing with unique project requirements. This can lead to delays in project timelines and frustration as teams scramble to find appropriate products that meet specific engineering standards or load requirements.

The Solution: To streamline the sourcing process, buyers should create a comprehensive specification checklist that includes diameter, construction type (e.g., 7×19 or 7×7), material (galvanized vs. stainless steel), and any special treatments (such as vinyl coating). Engaging with suppliers who offer customization options can also be beneficial, as this allows for tailored solutions that meet project demands. Establishing a strong relationship with a trusted supplier can facilitate quicker access to necessary specifications and expert guidance. Furthermore, utilizing online resources and product comparison tools can help buyers easily identify and evaluate suitable options, reducing the time spent on sourcing and ensuring that the right products are procured efficiently.

Strategic Material Selection Guide for cable aircraft

What Are the Key Properties of Common Materials Used in Cable Aircraft?

When selecting materials for cable aircraft, understanding the properties and performance characteristics of each option is essential. Here are four common materials used in the industry:

1. Galvanized Steel

Galvanized steel is a popular choice for aircraft cable due to its excellent strength-to-weight ratio and corrosion resistance. The galvanization process involves coating the steel with zinc, which protects it from rust and degradation, making it suitable for outdoor applications.

Pros: Galvanized steel offers high tensile strength and is relatively cost-effective, making it a go-to for many applications. It is durable under various environmental conditions, including moisture and temperature fluctuations.

Cons: While galvanized steel is resistant to rust, it can still corrode over time, especially in highly saline or acidic environments. Additionally, the manufacturing process can be complex, leading to higher costs in some regions.

Impact on Application: This material is suitable for applications exposed to the elements, such as rigging and suspension systems. However, buyers in regions with high humidity or saltwater exposure may need to consider additional protective measures.

Considerations for International Buyers: Compliance with local standards such as ASTM or DIN is crucial. Buyers from Africa and South America should verify that suppliers can meet these standards to ensure product reliability.

2. Stainless Steel

Stainless steel, particularly types 304 and 316, is favored for its superior corrosion resistance and aesthetic appeal. Type 316 is especially recommended for marine environments due to its enhanced resistance to chlorides.

Pros: The durability and longevity of stainless steel make it ideal for critical applications. It maintains its strength and appearance over time, reducing the need for frequent replacements.

Illustrative image related to cable aircraft

Cons: The primary drawback is the higher cost compared to galvanized steel. Additionally, while stainless steel is resistant to corrosion, it is not entirely immune, particularly in harsh environments.

Impact on Application: Stainless steel is suitable for applications requiring high strength and corrosion resistance, such as in marine or chemical processing environments.

Considerations for International Buyers: Buyers should ensure that the stainless steel meets international standards for quality and corrosion resistance. Countries in the Middle East often prefer materials that can withstand extreme temperatures and humidity.

Illustrative image related to cable aircraft

3. Vinyl-Coated Cable

Vinyl-coated aircraft cable combines the strength of steel with a protective vinyl layer, enhancing its durability and resistance to environmental factors.

Pros: The vinyl coating provides additional protection against abrasion and corrosion, making it ideal for outdoor applications. It also offers aesthetic benefits, as the coating can be colored to match specific design requirements.

Cons: The coating can wear off over time, especially in high-friction applications, which may expose the steel underneath to corrosion. Additionally, the manufacturing process can be more complex, potentially increasing costs.

Illustrative image related to cable aircraft

Impact on Application: Vinyl-coated cables are excellent for applications where appearance matters, such as decorative railings or signage. However, they may not be suitable for high-load or high-friction environments.

Considerations for International Buyers: Buyers should verify that the coating adheres to local regulations regarding environmental safety and material usage. In Europe, compliance with REACH regulations may be necessary.

4. Aluminum

Aluminum aircraft cables are lightweight and resistant to corrosion, making them suitable for applications where weight is a critical factor.

Pros: The primary advantage of aluminum is its lightweight nature, which can significantly reduce overall system weight. It also has good corrosion resistance, particularly when anodized.

Cons: Aluminum has lower tensile strength compared to steel, which may limit its applications. It is also more expensive than galvanized steel, which can be a consideration for budget-conscious buyers.

Impact on Application: Aluminum is ideal for applications in aviation and aerospace where weight savings are crucial. However, it may not be suitable for high-load applications.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum available and their corresponding strength ratings. Compliance with international standards for aerospace materials is essential, particularly for buyers in Europe.

Summary Table of Material Selection for Cable Aircraft

| Material | Typical Use Case for cable aircraft | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Rigging, suspension systems | High strength and cost-effective | Corrosion over time | Medium |

| Stainless Steel | Marine applications, chemical processing | Superior corrosion resistance | Higher cost | High |

| Vinyl-Coated Cable | Decorative railings, signage | Aesthetic appeal and abrasion resistance | Coating wear over time | Medium |

| Aluminum | Aviation, aerospace applications | Lightweight and corrosion-resistant | Lower tensile strength | High |

This guide provides a comprehensive overview of the materials used in cable aircraft, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cable aircraft

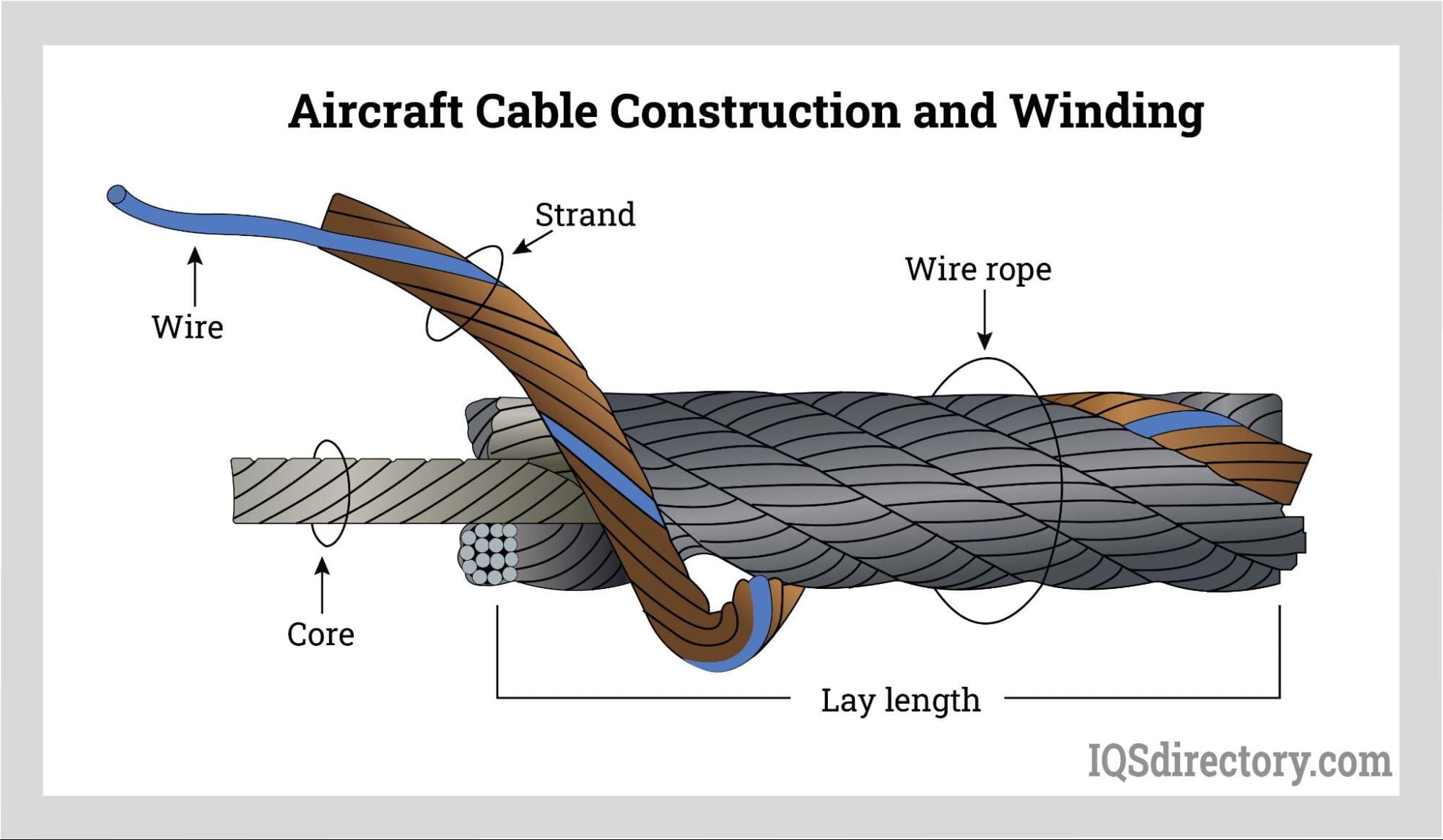

What Are the Key Stages in the Manufacturing Process of Aircraft Cable?

The manufacturing of aircraft cable involves several critical stages that ensure the final product meets industry standards and customer specifications. Understanding these stages can help B2B buyers make informed decisions regarding their suppliers.

Illustrative image related to cable aircraft

1. Material Preparation

The first step in manufacturing aircraft cable is the selection and preparation of raw materials. Typically, high-strength steel or stainless steel is chosen for its durability and resistance to corrosion. The raw materials are subjected to rigorous quality checks to ensure they meet specified mechanical properties and chemical compositions. Suppliers should provide material certifications that verify compliance with international standards such as ASTM or ISO.

2. Forming Processes

Once the materials are prepared, they undergo various forming processes, which include wire drawing, stranding, and rope laying.

- Wire Drawing: In this phase, large diameter steel rods are drawn through a series of dies to achieve the desired wire diameter. This process enhances the tensile strength of the wire.

- Stranding: The drawn wires are then twisted together to form strands. Common configurations include 7×7 and 7×19, where the first number indicates the number of wires in each strand and the second indicates the total number of strands.

- Rope Laying: The strands are further twisted together to create the final cable. The quality of stranding and laying is crucial for the cable’s performance, as any inconsistencies can lead to weaknesses.

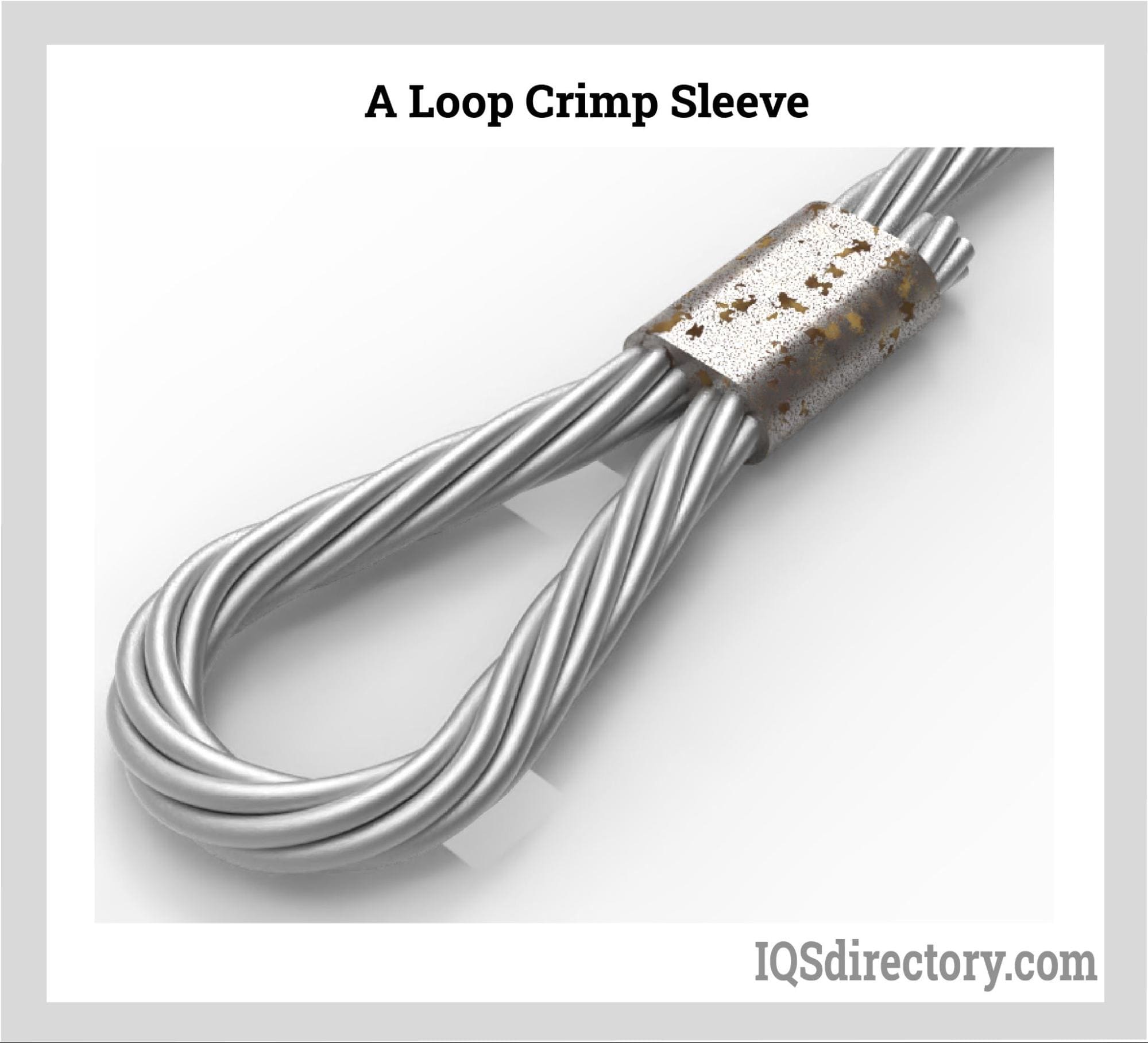

3. Assembly Techniques

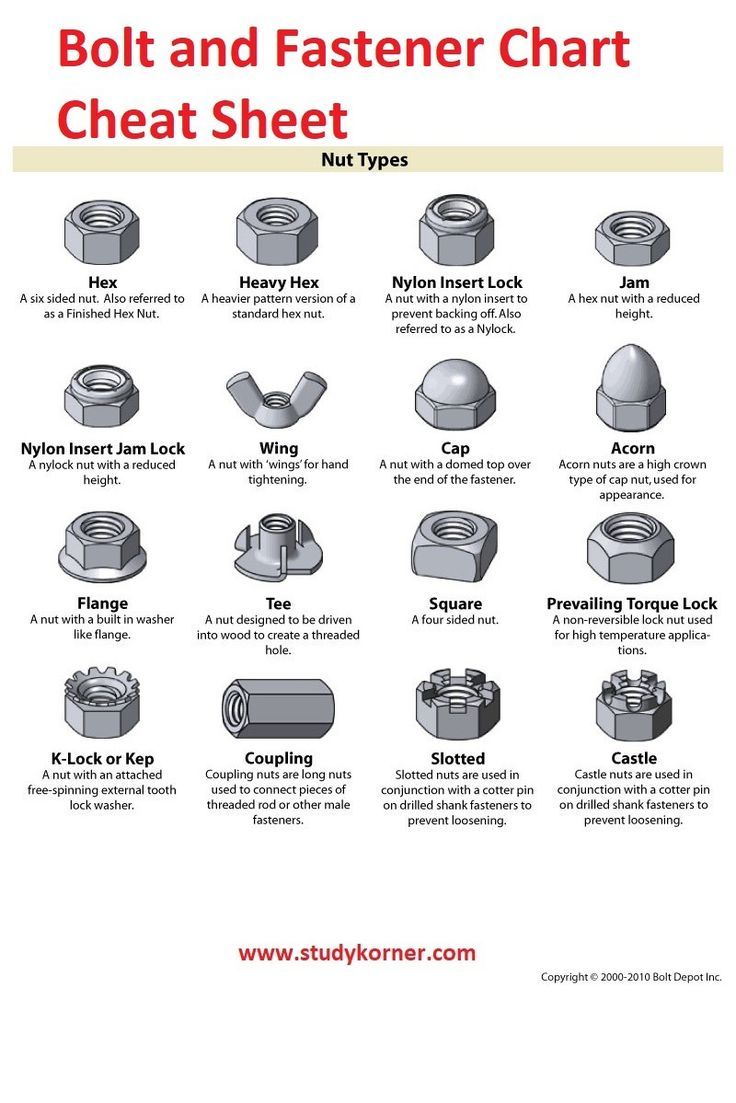

Assembly involves attaching various fittings and terminals to the cable. This stage may include swaging, where terminals are mechanically compressed onto the cable ends to create a secure connection. Different types of terminals, such as die-cast zinc or swaged aluminum, may be used depending on the application requirements. B2B buyers should ensure that the assembly process adheres to recommended installation and weight load guidelines.

4. Finishing Processes

The finishing stage typically includes surface treatment and coating. Common treatments involve galvanization or the application of vinyl coatings to enhance corrosion resistance. This is especially important for cables used in harsh environments, such as marine applications or outdoor installations. Proper finishing not only extends the life of the cable but also ensures compliance with safety standards.

How Is Quality Assurance Implemented in Aircraft Cable Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each batch of aircraft cable meets stringent safety and performance standards.

Illustrative image related to cable aircraft

International Standards and Certifications

B2B buyers should look for manufacturers that comply with international quality standards such as ISO 9001, which focuses on maintaining a quality management system. Additional certifications may be industry-specific, such as CE marking in Europe or API specifications for oil and gas applications. These certifications indicate that the manufacturer adheres to rigorous testing and quality control protocols.

Key Quality Control Checkpoints

Quality control involves multiple checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. Materials that do not meet specifications are rejected.

- In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to ensure that each process is performed correctly. This includes monitoring wire drawing, stranding, and assembly.

- Final Quality Control (FQC): Once the aircraft cable is assembled and finished, a final inspection is conducted. This includes testing for tensile strength, diameter consistency, and visual inspections for defects.

Common Testing Methods for Aircraft Cable

Various testing methods are employed to ensure the performance and safety of aircraft cables:

- Tensile Testing: Measures the maximum load the cable can withstand before breaking.

- Fatigue Testing: Assesses how the cable performs under repeated loading and unloading cycles.

- Corrosion Resistance Testing: Evaluates the cable’s ability to resist environmental factors that can lead to corrosion.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensure product reliability.

Conducting Supplier Audits

One effective method is to conduct supplier audits. These audits should assess the manufacturer’s adherence to established quality standards and their overall production processes. Buyers can request access to quality management documentation, including procedure manuals and previous audit reports.

Requesting Quality Control Reports

Buyers should also request detailed quality control reports that outline the results of various tests conducted on the aircraft cable. This documentation should include information on material certifications, inspection results, and compliance with international standards.

Engaging Third-Party Inspectors

Another option is to engage third-party inspection services. These organizations can provide independent verification of a supplier’s quality practices and product compliance. This is particularly beneficial for buyers unfamiliar with local manufacturing standards or those looking to mitigate risks in international transactions.

Illustrative image related to cable aircraft

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances in quality control that may vary by region. For instance, in Africa and South America, local standards may not always align with international benchmarks. Buyers should ensure that the supplier is familiar with both local regulations and international standards, as this can significantly impact product quality and safety.

Furthermore, language barriers and differences in business practices may pose challenges during quality verification. Establishing clear communication channels and leveraging local representatives can help mitigate these issues.

In conclusion, understanding the manufacturing processes and quality assurance practices for aircraft cable is essential for B2B buyers. By focusing on these critical aspects, businesses can select reliable suppliers that meet their quality and performance requirements, ensuring the safety and effectiveness of their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cable aircraft’

The following practical sourcing guide provides a detailed checklist for B2B buyers looking to procure aircraft cable. This guide will help ensure that your purchasing process is efficient, cost-effective, and aligned with your specific operational needs.

Step 1: Define Your Technical Specifications

Before initiating your procurement process, it’s essential to clearly define your technical requirements. This includes specifying the type of aircraft cable you need—such as galvanized or stainless steel—as well as the diameter, construction (e.g., 7×7 or 7×19), and length.

- Consider load capacities: Determine the necessary break strength based on your application to ensure safety and reliability.

- Assess environmental factors: Identify whether the cable will be exposed to corrosive environments, which may necessitate the use of stainless steel.

Step 2: Research Reputable Suppliers

Invest time in identifying and researching potential suppliers. Look for manufacturers or distributors with established reputations in the industry.

- Check industry certifications: Ensure the suppliers comply with relevant international standards and certifications.

- Seek reviews and testimonials: Explore feedback from other businesses, particularly those in your region, to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Offerings

Once you have a list of potential suppliers, evaluate their product offerings in detail.

- Compare specifications: Verify that the cables meet your defined technical specifications.

- Look for product variations: Some suppliers may offer specialized cables that could better suit your needs, such as rotation-resistant or swaged options.

Step 4: Request Samples and Specifications

Before making a bulk purchase, request samples or detailed product specifications.

- Assess material quality: Inspect the samples for durability and compliance with your specifications.

- Review technical documentation: Ensure that the supplier can provide installation guidelines and load capacity charts.

Step 5: Negotiate Pricing and Terms

Engage in discussions about pricing, delivery timelines, and payment terms with your shortlisted suppliers.

- Consider bulk purchase discounts: Many suppliers offer cost savings for larger orders, which can significantly impact your budget.

- Clarify warranty and return policies: Understanding these terms can protect your investment and mitigate risks associated with defective products.

Step 6: Finalize Logistics and Delivery Plans

Once you’ve settled on a supplier, coordinate the logistics of your order to ensure timely delivery.

- Confirm shipping methods: Depending on your location, choose a shipping option that balances speed and cost.

- Plan for customs clearance: If sourcing internationally, ensure that all customs requirements are met to avoid delays.

Step 7: Implement Quality Control Measures

After receiving your order, conduct a thorough inspection to ensure that the cables meet your specifications and quality standards.

Illustrative image related to cable aircraft

- Perform load tests: If applicable, conduct tests to verify the cable’s performance under expected loads.

- Document findings: Keep records of inspections and tests for future reference and compliance.

By following this checklist, B2B buyers can confidently navigate the procurement process for aircraft cable, ensuring that their operational needs are met while minimizing risks associated with sourcing.

Comprehensive Cost and Pricing Analysis for cable aircraft Sourcing

What Are the Key Cost Components in Aircraft Cable Sourcing?

When evaluating the cost structure of aircraft cables, several components come into play. Materials represent a significant portion of the total cost, with options such as galvanized or stainless steel affecting pricing. The choice between 7×7 or 7×19 constructions also impacts material costs due to differences in tensile strength and manufacturing processes.

Labor costs are influenced by the complexity of manufacturing processes, including the assembly of terminals and quality checks. Manufacturing overhead encompasses expenses related to facility maintenance and operational costs that support production. Additionally, tooling costs should not be overlooked, as specialized machinery may be required for custom specifications.

Quality Control (QC) is essential in ensuring the reliability and safety of aircraft cables, contributing to overall costs. Finally, logistics—including transportation, warehousing, and customs duties—can significantly impact the final price, particularly for international buyers.

Illustrative image related to cable aircraft

How Do Price Influencers Impact Aircraft Cable Costs?

Several factors can influence pricing in the aircraft cable market. Volume and Minimum Order Quantity (MOQ) are critical; larger orders often lead to reduced per-unit costs. Custom specifications and unique requirements may also increase costs, as they necessitate specialized production methods.

The choice of materials plays a crucial role as well. For instance, stainless steel cables typically command a higher price due to their durability and resistance to corrosion compared to galvanized options. Furthermore, certifications and quality assurance measures can add to costs but are essential for ensuring compliance with international standards.

Supplier factors—such as the supplier’s reputation, location, and relationship with buyers—can also influence pricing. Finally, understanding Incoterms is vital for buyers to anticipate additional costs related to shipping and delivery terms.

What Are Effective Buyer Tips for Negotiating Aircraft Cable Prices?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, negotiating favorable pricing requires a strategic approach. Negotiation tactics should focus on leveraging volume discounts, exploring alternative suppliers, and being open to flexible terms that can reduce costs.

Illustrative image related to cable aircraft

To maximize cost-efficiency, buyers should conduct a Total Cost of Ownership (TCO) analysis, considering not just the purchase price but also long-term costs related to maintenance, replacement, and operational efficiency. Understanding the nuances of pricing—such as the impact of currency fluctuations and local market conditions—can provide a competitive edge in negotiations.

International buyers should be aware of pricing nuances that may arise from varying tariffs, import duties, and logistics costs. Establishing a clear understanding of these factors can help mitigate unexpected expenses and foster better relationships with suppliers.

What Should Buyers Remember About Indicative Pricing?

It is important to note that the prices for aircraft cables can vary significantly based on the aforementioned factors. Thus, while indicative prices may provide a starting point for negotiations, buyers should always seek tailored quotes based on their specific requirements. Engaging multiple suppliers and requesting detailed breakdowns of costs can lead to more informed purchasing decisions, ultimately resulting in better value for their investment.

Alternatives Analysis: Comparing cable aircraft With Other Solutions

When evaluating solutions for rigging and suspension systems, it’s crucial to consider various alternatives to cable aircraft. Each alternative presents unique advantages and challenges that can significantly impact operational efficiency and cost-effectiveness. Below, we compare cable aircraft with two viable alternatives: synthetic ropes and chain systems.

Illustrative image related to cable aircraft

| Comparison Aspect | Cable Aircraft | Synthetic Ropes | Chain Systems |

|---|---|---|---|

| Performance | High tensile strength; suitable for various applications; limited to smaller diameters (up to 3/8″). | Strong and lightweight; excellent for dynamic loads; more flexible than cable. | Extremely strong and durable; ideal for heavy loads; rigid with less flexibility. |

| Cost | Generally moderate; prices vary based on material (galvanized vs. stainless steel). | Often lower initial cost; may require more frequent replacement depending on usage. | Higher upfront cost; long-term investment due to durability. |

| Ease of Implementation | Requires specific fittings and knowledge for installation; straightforward for experienced users. | Easier to handle and install; lightweight nature simplifies deployment. | Heavier and requires more robust mounting systems; installation can be complex. |

| Maintenance | Regular inspections needed to ensure integrity; corrosion protection essential. | Minimal maintenance; however, UV exposure can degrade materials over time. | Low maintenance once installed; rust protection may be needed in certain environments. |

| Best Use Case | Ideal for general-purpose applications, winch lines, and rigging in constrained spaces. | Best suited for applications requiring lightweight and flexible solutions, such as sailing. | Optimal for heavy-duty lifting and securing applications, such as construction or industrial settings. |

What Are the Advantages and Disadvantages of Synthetic Ropes Compared to Cable Aircraft?

Synthetic ropes, such as those made from nylon or polyester, offer several benefits over cable aircraft. They are lighter and more flexible, which enhances maneuverability and ease of use, particularly in applications involving dynamic loads. Their lower initial cost can also be appealing for budget-conscious projects. However, synthetic materials may have a shorter lifespan in harsh environments and require more frequent replacements, especially if subjected to UV exposure or abrasion.

How Do Chain Systems Compare to Cable Aircraft in Terms of Performance?

Chain systems excel in applications requiring substantial load-bearing capacity and durability. They can handle heavier weights and are less prone to failure under extreme conditions. While they provide excellent security for heavy loads, their rigidity can limit flexibility in certain applications. Additionally, installation can be more complex, often necessitating specialized hardware and expertise, making it less accessible for casual users compared to cable aircraft.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate rigging or suspension solution, B2B buyers should consider the specific requirements of their applications, including load capacity, environmental factors, and budget constraints. Cable aircraft is a versatile option suitable for many general-purpose applications, while synthetic ropes may offer advantages in weight and flexibility for dynamic uses. Chain systems, on the other hand, are ideal for heavy-duty scenarios where maximum strength is essential. By carefully evaluating these aspects, buyers can make informed decisions that align with their operational needs and long-term goals.

Essential Technical Properties and Trade Terminology for cable aircraft

What Are the Key Technical Properties of Aircraft Cable?

Understanding the essential technical properties of aircraft cable is crucial for making informed purchasing decisions. Here are several key specifications that every B2B buyer should consider:

Illustrative image related to cable aircraft

-

Material Grade

Aircraft cables are typically made from either galvanized steel or stainless steel. Galvanized steel offers excellent corrosion resistance at a lower cost, making it suitable for outdoor applications. Stainless steel, particularly grades 304 and 316, provide superior corrosion resistance and are often used in marine environments or where aesthetics are important. Selecting the appropriate material grade affects the cable’s longevity and overall performance. -

Construction Type

The construction of aircraft cable can significantly influence its strength and flexibility. Common constructions include 7×7 and 7×19 configurations. The 7×7 configuration consists of seven strands with seven wires each, offering good flexibility and moderate strength, while the 7×19 configuration provides enhanced strength and is suitable for applications requiring greater load-bearing capacity. Understanding construction types helps buyers select cables that meet their specific operational needs. -

Diameter

The diameter of aircraft cable typically ranges from 1/32 inch to 3/8 inch. The diameter directly correlates with the cable’s load capacity; larger diameters can handle heavier loads. Knowing the required diameter is essential for ensuring the cable can support the intended application without risk of failure. -

Break Strength

Break strength refers to the maximum load that a cable can bear before failing. This is a critical specification for safety and reliability in applications such as rigging, lifting, and suspension. Buyers should always consider the break strength in relation to the intended load to prevent accidents and equipment damage. -

Coating Options

Coatings such as vinyl or nylon can enhance the cable’s resistance to abrasion and corrosion. Vinyl-coated cables, for example, provide additional protection and can be more aesthetically pleasing. The choice of coating can affect both durability and suitability for specific environments. -

Tolerance

Tolerance indicates the allowable deviation from the nominal diameter of the cable. This specification is important for ensuring compatibility with fittings and other hardware. A tighter tolerance is often preferable for applications requiring precision and reliability.

What Are Common Trade Terms Used in the Aircraft Cable Industry?

Familiarity with industry jargon can streamline communication and negotiations. Here are several common trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify the quality and compatibility of aircraft cables with their existing systems. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. It is crucial for buyers to understand MOQ as it can affect inventory management and procurement strategies, especially in regions with varying demand. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. Submitting an RFQ can help buyers compare offers and secure the best pricing and service terms for their aircraft cable needs. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. Understanding these terms helps in determining who bears shipping costs, insurance, and risks during transport. -

Lead Time

This term refers to the time between placing an order and receiving the goods. Knowing the lead time is vital for planning project timelines and ensuring that materials are available when needed. -

Certification Standards

Certification standards, such as ISO or ASTM, provide assurance of quality and performance. Buyers should inquire about the relevant certifications for aircraft cables to ensure compliance with industry standards and safety regulations.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing aircraft cables, ultimately enhancing operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the cable aircraft Sector

What Are the Current Market Trends in the Cable Aircraft Sector?

The global cable aircraft market is witnessing significant growth, driven by various factors such as increased demand for lightweight materials, advancements in manufacturing technology, and a growing focus on safety regulations in aviation and industrial applications. Emerging markets in Africa, South America, the Middle East, and Europe are particularly noteworthy, as they are expanding their infrastructure and aviation sectors, resulting in increased demand for high-quality aircraft cables. For B2B buyers from regions like Brazil and Nigeria, understanding these dynamics is crucial for making informed sourcing decisions.

Recent technological advancements in cable manufacturing, such as the use of high-tensile materials and corrosion-resistant coatings, are shaping the market landscape. Innovations like automated production processes and smart inventory management systems are also enhancing operational efficiencies. Additionally, the trend toward customization is gaining traction, with suppliers offering tailored solutions to meet specific industry requirements. This move toward bespoke offerings allows B2B buyers to ensure that their sourcing aligns closely with their operational needs.

How Is Sustainability Shaping Sourcing in the Cable Aircraft Sector?

Sustainability has emerged as a critical factor in the sourcing strategies of B2B buyers in the cable aircraft sector. Companies are increasingly aware of their environmental impact and are prioritizing ethical supply chains that minimize ecological footprints. This shift is particularly relevant for international buyers, as regulatory pressures and consumer expectations for sustainability are on the rise.

Illustrative image related to cable aircraft

To address these challenges, many manufacturers are adopting green certifications and utilizing eco-friendly materials in their production processes. For example, sourcing galvanized or stainless steel cables, which offer durability and recyclability, is becoming more common. Suppliers that demonstrate a commitment to sustainable practices not only enhance their reputations but also attract forward-thinking buyers. By prioritizing suppliers who adhere to environmental standards, B2B buyers can align their procurement strategies with broader sustainability goals.

What Is the Historical Context of Cable Aircraft Development?

The evolution of cable aircraft can be traced back to the early 20th century when the aviation industry began to adopt wire ropes for various applications, including rigging and suspension systems. The development of lightweight materials and innovative manufacturing techniques paved the way for the modern aircraft cables we see today. Over the decades, the industry has experienced significant advancements, particularly in terms of strength-to-weight ratios and corrosion resistance.

Today, cable aircraft is utilized in a wide range of applications beyond aviation, including construction, marine, and industrial sectors. This diversification reflects the adaptability of cable technology to meet the evolving needs of various industries. For B2B buyers, understanding this historical context is essential for recognizing the long-term reliability and performance of cable aircraft in their operations.

Conclusion

In summary, the cable aircraft sector is characterized by dynamic market trends driven by technological advancements and sustainability initiatives. International B2B buyers must navigate these evolving dynamics, focusing on ethical sourcing and innovative solutions to meet their operational needs. By understanding the historical context and current trends, buyers can make informed decisions that align with both their business objectives and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of cable aircraft

-

How do I choose the right type of aircraft cable for my project?

When selecting aircraft cable, consider the specific application and required strength. Aircraft cable typically comes in 7×7 or 7×19 constructions, with sizes ranging from 1/32″ to 3/8″. Assess the tensile strength needed for your application and choose between galvanized or stainless steel options based on environmental factors. For outdoor or corrosive environments, stainless steel is advisable. Always refer to the manufacturer’s specifications and guidelines to ensure compatibility with your rigging system. -

What is the best supplier for sourcing aircraft cable internationally?

The best supplier for aircraft cable will depend on your specific needs and location. Look for suppliers with a strong reputation in the industry, quality certifications, and positive customer reviews. It’s beneficial to choose suppliers who specialize in international shipping, offer a variety of products, and provide customization options. Additionally, ensure they have experience in your region to navigate local regulations and logistics effectively. -

What are the minimum order quantities (MOQs) for aircraft cable?

Minimum order quantities can vary significantly between suppliers. Some may offer flexible MOQs, especially for standard items, while others may require larger quantities for custom orders. Generally, MOQs can range from 100 feet to several thousand feet, depending on the product type and supplier. When negotiating, inquire about sample orders or trial runs to assess quality before committing to larger purchases. -

What payment terms should I expect when sourcing aircraft cable?

Payment terms will largely depend on the supplier’s policies and your business relationship. Common terms include upfront payment, 30% deposit with the balance upon shipment, or net 30/60 days post-delivery for established clients. It’s essential to clarify payment methods accepted, such as bank transfers or letters of credit, especially for international transactions. Ensure that all terms are documented in the purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance (QA) for the aircraft cable I purchase?

To ensure quality assurance, request documentation such as certificates of compliance and test reports from your supplier. Reputable manufacturers will conduct rigorous testing on their cables, including tensile strength and durability tests. If possible, consider visiting the manufacturing facility or requesting third-party inspections. Establishing a clear QA process, including regular audits and inspections, can further safeguard the quality of the products received. -

What are the logistics considerations for importing aircraft cable?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling bulk materials like aircraft cable. Ensure all documentation, such as import permits and compliance certificates, is in order to facilitate smooth customs clearance. Additionally, factor in potential delays caused by regulations in your country, especially in regions like Africa and South America, where customs processes may vary. -

Can I customize aircraft cable to meet specific project requirements?

Yes, many suppliers offer customization options for aircraft cable, allowing you to specify length, diameter, material, and terminal types. Discuss your specific requirements with the supplier to understand their capabilities. Custom orders may have longer lead times and higher MOQs, so plan accordingly. Ensure that all specifications are documented clearly to avoid issues during production. -

How do I handle issues with defective aircraft cable after purchase?

If you encounter defective aircraft cable, promptly contact the supplier with detailed information about the issue. Most reputable suppliers will have a return or exchange policy for defective items. Document the defects with photos and provide any relevant order information to expedite the process. It’s advisable to review the warranty terms before purchasing to understand your rights and the supplier’s obligations regarding defective products.

Top 5 Cable Aircraft Manufacturers & Suppliers List

1. US Cargo Control – Aircraft Cable Options

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Aircraft Cable options include: 7×19 Galvanized Aircraft Cable, 7×19 304 Stainless Steel Aircraft Cable, 7×19 316 Stainless Steel Aircraft Cable, 7×19 Galvanized Aircraft Cable – Vinyl-Coated, 7×19 304 Stainless Steel Aircraft Cable – Vinyl-Coated, and Custom Wire Rope. Break Strengths range from 920 lbs to 14400 lbs.

2. Rose Brand – Aircraft Cable & Rigging Supplies

Domain: rosebrand.com

Registered: 1995 (30 years)

Introduction: Aircraft Cable / Wire Rope, Fittings and Accessories from Rose Brand. Call for Sales Support 1-800-223-1624. Categories include: Hardware & Rigging, ADC Winches & Theatrical Automation, Personal Protective Equipment (PPE), Pipe & Base, Scenic, Shop & Studio Supplies, and more. Specific products mentioned include Fiber Rope, Pulleys and Blocks, Kabuki Drop Systems, Carabiners & Connectors, Harnesse…

3. e-Rigging – Aircraft Cable & Steel Cable Solutions

Domain: e-rigging.com

Registered: 2004 (21 years)

Introduction: Aircraft Cable and Steel Cable are both types of wire ropes used for various applications. Aircraft Cable is typically made from stainless steel and is designed for high strength and flexibility, making it suitable for applications like cable railing systems. Steel Cable, on the other hand, can be galvanized or stainless steel and is often used in rigging and heavy lifting applications. Key featur…

4. Stagerigging Warehouse – Aircraft Cable Solutions

Domain: stageriggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Key Product Details:

– Product Types: Galvanized Aircraft Cable, Black Galvanized Aircraft Cable, Stainless Steel Aircraft Cable, Vinyl Coated Aircraft Cable

– Sizes Available: 1/16 in, 1/8 in, 3/16 in, 1/4 in, 3/32 in, 5/16 in, 7/32 in, etc.

– Length Options: Per Foot, 100 ft, 250 ft, 500 ft, 1000 ft, 2500 ft, 5000 ft, 10000 ft, 15000 ft

– Breaking Strength: Ranges from 270 lbs to 9800 lbs depend…

5. Spartan Tool – 3/64 x 9.5 Long Aircraft Cable

Domain: spartantool.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Spartan Tool 3/64″ x 9.5″ Long Aircraft Cable”, “SKU”: “63030350”, “MSRP”: “$7.41”, “Condition”: “New”, “Availability”: “In Stock”, “Weight”: “0.01 LBS”, “Key Features”: {“High-Strength Material”: “Manufactured from aircraft-grade steel”, “Optimal Length”: “9.5 inches”, “Superior Flexibility”: “Allows navigation through tight spaces”, “Corrosion Resistant”: “Coated to prevent rus…

Strategic Sourcing Conclusion and Outlook for cable aircraft

How Can Strategic Sourcing Enhance Your Aircraft Cable Procurement?

In the rapidly evolving landscape of cable aircraft procurement, strategic sourcing emerges as a pivotal approach for international buyers. Companies in regions such as Africa, South America, the Middle East, and Europe can significantly benefit from understanding the distinctions between various aircraft cable types—such as galvanized versus stainless steel—and their specific applications across industries. Leveraging reliable suppliers who provide high-quality, compliant products ensures safety and durability, thereby minimizing operational risks.

Illustrative image related to cable aircraft

The market offers a wide variety of aircraft cables, including options tailored for high tensile strength and custom requirements. By focusing on strategic sourcing, buyers can optimize their supply chains, negotiate better terms, and ultimately reduce costs. This proactive stance not only fosters long-term partnerships but also enhances product availability in local markets.

As you consider your sourcing strategies, engage with suppliers who demonstrate a commitment to quality and innovation. The future of aircraft cable procurement is bright, and by aligning with the right partners, you can position your business for success in a competitive global market. Start your strategic sourcing journey today to unlock new opportunities and drive growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to cable aircraft