C13 To C13 Power Cable Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for c13 to c13 power cable

In today’s rapidly evolving technological landscape, sourcing reliable c13 to c13 power cables is essential for businesses looking to maintain operational efficiency and connectivity. Whether you’re managing a data center in Nigeria or powering servers in Vietnam, the quality and specifications of your power cords can significantly impact equipment performance and longevity. This comprehensive guide serves as a critical resource for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, by addressing key challenges such as supplier vetting, cable specifications, and cost considerations.

Throughout this guide, you will discover an extensive range of IEC C13 power cables, including various types, applications, and lengths tailored to meet diverse business needs. We will delve into essential factors to consider when selecting power cords, from understanding the importance of connector compatibility to evaluating manufacturers based on ISO certifications. Additionally, we will provide insights on pricing strategies to help you make informed purchasing decisions that align with your budget and operational requirements.

By equipping yourself with the knowledge contained in this guide, you will be empowered to navigate the global market with confidence, ensuring that your business is supported by high-quality power solutions that enhance productivity and reduce downtime.

Understanding c13 to c13 power cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard C13 to C14 | Basic configuration, typically 10A/250V, various lengths | Data centers, servers, and networking gear | Pros: Cost-effective, widely available. Cons: Limited to standard applications. |

| C13 to C13 Angled | Angled connectors to save space, ideal for tight setups | Rack-mounted servers, compact equipment | Pros: Space-saving design, easier cable management. Cons: May not fit all configurations. |

| C13 to C13 Splitter | Allows multiple devices to connect from a single outlet | Power distribution in data centers | Pros: Efficient power usage, reduces outlet clutter. Cons: Potential for overloading. |

| C13 to C13 Extension | Longer length options for flexible setups | Remote equipment, extended reach applications | Pros: Versatile length choices, enhances accessibility. Cons: Bulkier and may require more storage. |

| C13 to C13 Hospital Grade | Enhanced safety features, built for sensitive environments | Hospitals, labs, and critical systems | Pros: High reliability, meets stringent safety standards. Cons: Higher cost compared to standard cables. |

What Are the Characteristics of Standard C13 to C14 Power Cables?

Standard C13 to C14 power cables are the most commonly used type in various B2B settings. They typically support a current of 10A at 250V, making them suitable for powering a wide range of equipment, including servers and networking devices. Buyers should consider the length options available, as these cables come in various sizes to accommodate different setups. Their universal compatibility makes them a go-to choice, but businesses should be aware that they are limited to standard applications and may not meet specialized needs.

How Do Angled C13 to C13 Cables Benefit B2B Buyers?

Angled C13 to C13 cables are designed with connectors that bend at a 90-degree angle, which helps save space in environments where equipment is tightly packed. This design is particularly beneficial for rack-mounted servers and compact equipment setups, allowing for better cable management and airflow. When purchasing, businesses should assess the compatibility of these cables with their existing equipment, as the angled design may not fit all configurations. While they provide a space-efficient solution, their specialized nature may limit options for some users.

What Advantages Do C13 to C13 Splitter Cables Offer?

C13 to C13 splitter cables allow multiple devices to connect to a single power outlet, making them ideal for power distribution in data centers. They enhance efficiency by reducing the number of outlets required and minimizing clutter. However, buyers should be cautious about the potential for overloading the circuit, as using splitters can lead to power management challenges. When purchasing, it’s essential to consider the power requirements of connected devices to ensure safe and effective use.

Why Choose C13 to C13 Extension Cables?

C13 to C13 extension cables are ideal for scenarios requiring longer reach, such as remote equipment setups or when devices are positioned far from power sources. These cables come in various lengths, offering flexibility for different configurations. However, businesses should be mindful that longer cables can be bulkier and may require more storage space. When selecting extension cables, it’s crucial to ensure they meet the necessary electrical specifications for the equipment being used.

What Makes C13 to C13 Hospital Grade Cables Essential?

C13 to C13 hospital-grade cables are engineered with enhanced safety features to meet the stringent requirements of healthcare environments. These cables are built for reliability and are essential for powering critical systems and sensitive medical equipment. While they provide high levels of safety and durability, they tend to be more expensive than standard cables. Buyers in the healthcare sector should prioritize these cables for their quality assurance, ensuring compliance with safety standards while investing in long-term reliability.

Key Industrial Applications of c13 to c13 power cable

| Industry/Sector | Specific Application of c13 to c13 power cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Data Centers | Connecting servers and networking equipment to PDUs | Ensures stable power supply, reducing downtime and enhancing performance | Compliance with local electrical standards and certifications |

| Telecommunications | Powering telecom equipment and routers | Supports uninterrupted communication services | Length options and cable durability for various installations |

| Healthcare | Connecting medical devices and diagnostic equipment | Guarantees reliable operation of critical healthcare devices | Compatibility with medical-grade standards and safety regulations |

| Manufacturing | Powering machinery and automated systems | Increases operational efficiency and minimizes equipment failure | Custom lengths and robustness to withstand industrial environments |

| Retail and Commercial | Powering displays, POS systems, and kiosks | Enhances customer experience through reliable service availability | Versatile cable lengths and adaptability to various setups |

How is C13 to C13 Power Cable Used in Data Centers?

In data centers, C13 to C13 power cables are vital for connecting servers and other networking equipment to Power Distribution Units (PDUs). These cables ensure a stable power supply, which is crucial for maintaining uptime and optimizing performance. Data centers often require cables that comply with local electrical standards, so international buyers should prioritize sourcing from ISO-certified manufacturers that guarantee quality and reliability.

What Role Does C13 to C13 Power Cable Play in Telecommunications?

Telecommunications companies utilize C13 to C13 power cables to power critical equipment such as routers and switches. The reliability of power connections directly impacts communication services, making these cables indispensable. For businesses in regions like Africa and South America, sourcing cables that can endure fluctuating voltage levels and environmental conditions is essential for maintaining service continuity.

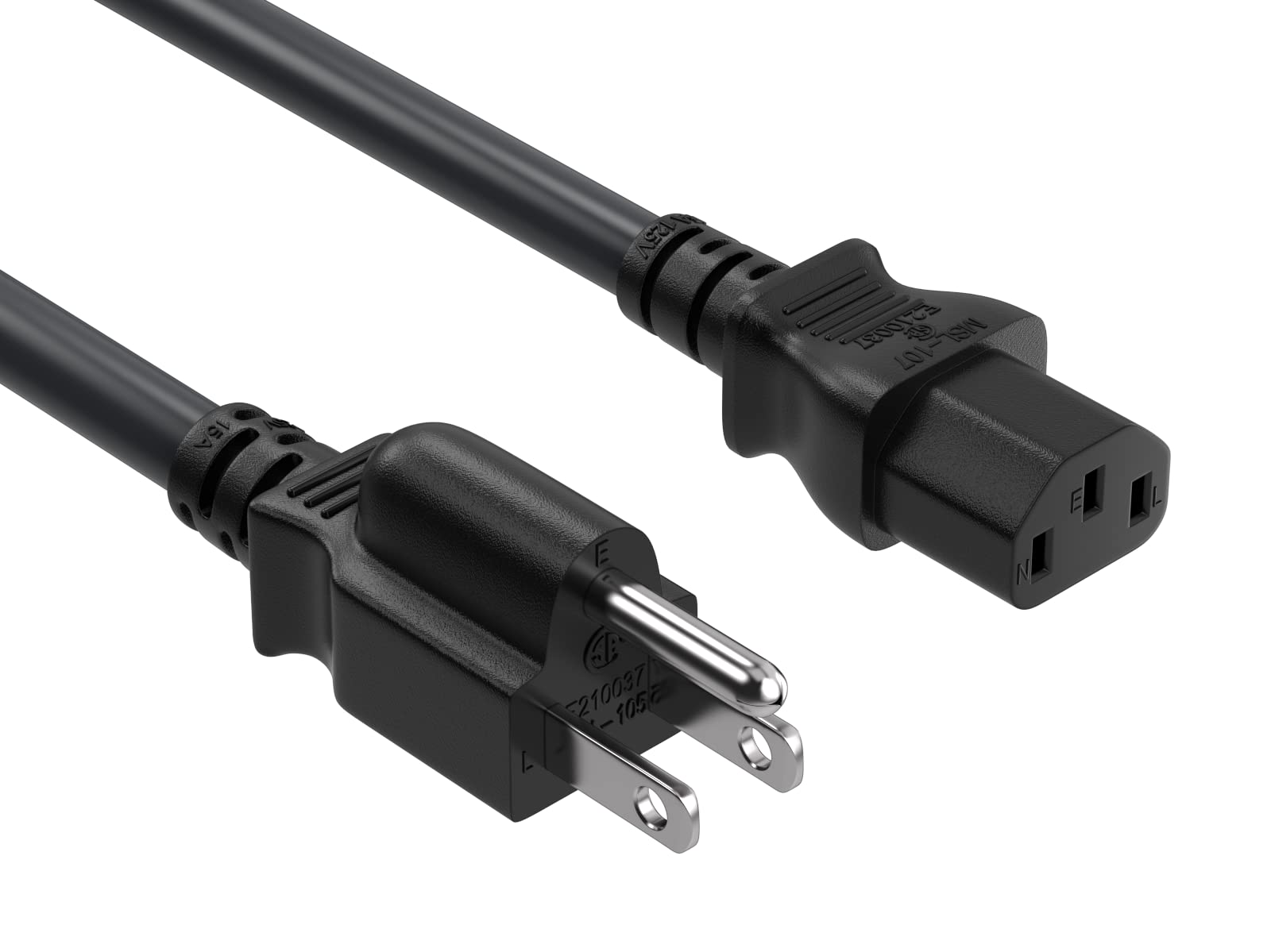

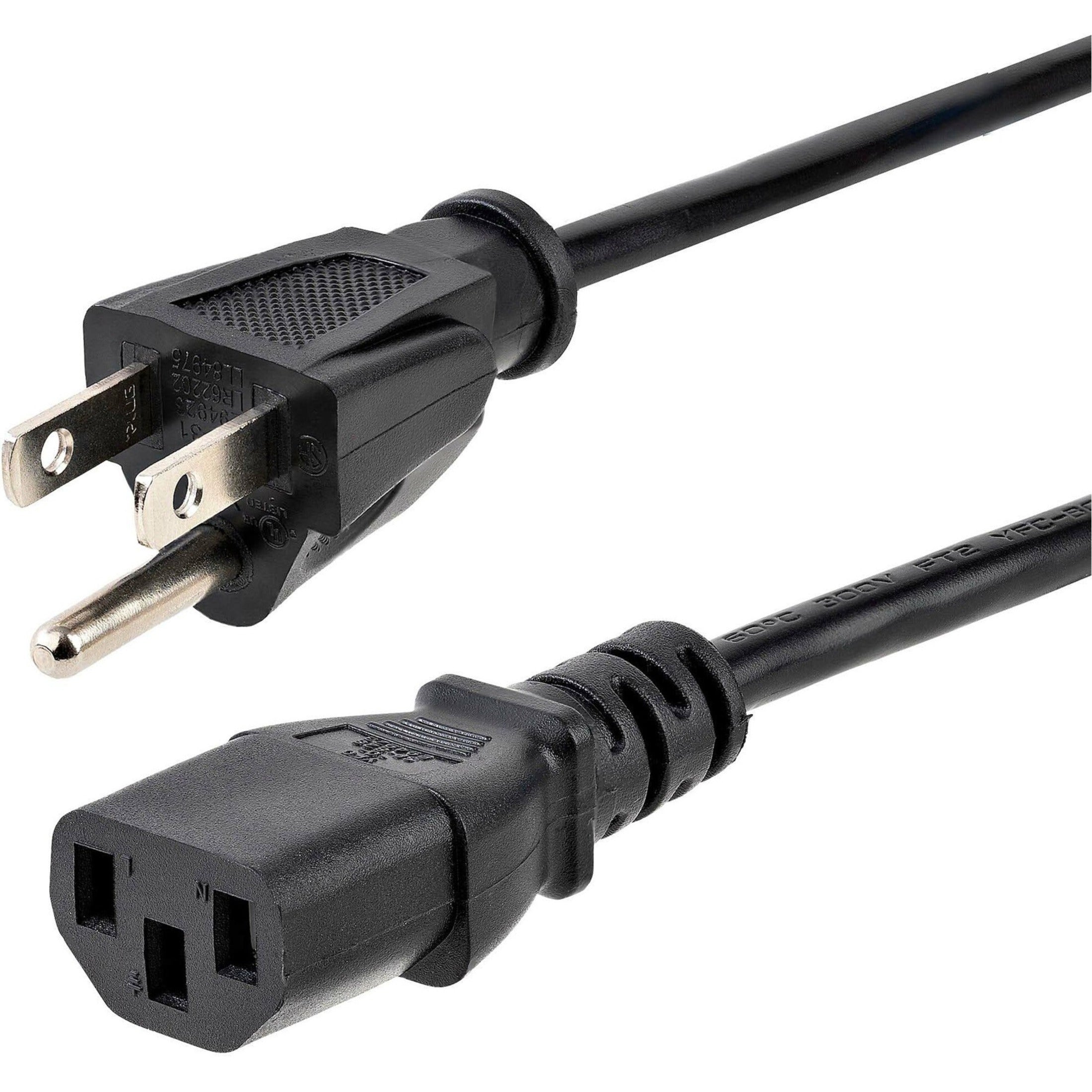

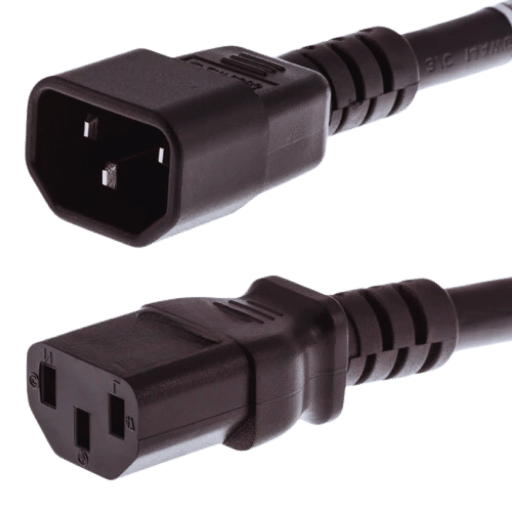

Illustrative image related to c13 to c13 power cable

Why is C13 to C13 Power Cable Important in Healthcare?

In healthcare settings, C13 to C13 power cables connect essential medical devices, including diagnostic tools and life-support systems. The reliability of these power connections can have life-or-death implications, making it crucial for healthcare facilities to use high-quality cables that meet medical-grade standards. Buyers from the Middle East and Europe should ensure that their suppliers provide cables that comply with stringent safety regulations.

How Does C13 to C13 Power Cable Enhance Manufacturing Operations?

Manufacturers leverage C13 to C13 power cables to power various machinery and automated systems, ensuring efficient operations and minimizing potential equipment failures. The durability of these cables is critical in industrial environments where wear and tear are common. Buyers should consider sourcing custom lengths and robust cables that can withstand harsh conditions, particularly in regions with diverse operational challenges.

What Benefits Does C13 to C13 Power Cable Provide in Retail and Commercial Settings?

In retail and commercial environments, C13 to C13 power cables are used to power displays, point-of-sale (POS) systems, and kiosks. These cables support seamless customer interactions and service availability, enhancing the overall shopping experience. For international buyers, flexibility in cable lengths and adaptability to various setups are key considerations, ensuring that they can meet the diverse needs of their retail operations.

3 Common User Pain Points for ‘c13 to c13 power cable’ & Their Solutions

Scenario 1: Incompatibility Issues with Power Distribution Units (PDUs)

The Problem:

B2B buyers often encounter challenges when integrating C13 to C13 power cables with their existing power distribution units (PDUs). For instance, a company upgrading its server room may find that the new PDUs use different connector types or require specific amperage ratings. This mismatch can lead to operational delays and increased costs due to the need for additional adapters or replacements. Such situations not only hinder the deployment of new equipment but can also cause frustration among IT teams who are under pressure to maintain uptime.

The Solution:

To avoid compatibility issues, it is crucial for buyers to conduct a thorough assessment of their current and future power needs before purchasing C13 to C13 cables. Start by verifying the specifications of both the PDUs and the devices that will be connected. Ensure that the C13 cables you source are rated for the appropriate voltage and amperage, typically 10A at 250V for standard C13 configurations. Additionally, look for cables from reputable suppliers who offer detailed specifications and compatibility charts. If necessary, consider consulting with a cable specialist to tailor a solution that meets the unique demands of your infrastructure, ensuring seamless integration and minimizing the risk of downtime.

Scenario 2: Cable Length and Management Challenges

The Problem:

Another common pain point for B2B buyers is the challenge of managing cable lengths in data centers or office environments. Buyers may find that standard-length C13 to C13 cables either fall short or are excessively long, leading to clutter and potential trip hazards. Inadequate cable management can also result in inefficiencies, as teams may struggle to identify and access specific cables, leading to wasted time during maintenance or troubleshooting.

The Solution:

To effectively address cable length and management issues, opt for customizable C13 to C13 cables that allow you to specify the exact length needed for your setup. Many suppliers offer custom cable building services, which can help you avoid the pitfalls of standard lengths. Furthermore, implementing a structured cable management system, such as cable ties, trays, or racks, can significantly enhance organization and accessibility. Ensure that each cable is clearly labeled, indicating its function and connection points, to facilitate easy identification. This proactive approach not only streamlines operations but also enhances safety within your workspace.

Scenario 3: Quality Assurance and Reliability Concerns

The Problem:

Quality assurance is a critical concern for B2B buyers sourcing C13 to C13 power cables, particularly in regions with fluctuating power supply stability. Inferior-quality cables can lead to overheating, potential equipment damage, and increased risk of failure, which can be costly for organizations relying on consistent power delivery for their operations. Buyers may find it challenging to determine which manufacturers meet international safety and quality standards, leading to uncertainty about the reliability of their purchases.

Illustrative image related to c13 to c13 power cable

The Solution:

To ensure the procurement of high-quality C13 to C13 cables, prioritize sourcing from manufacturers who adhere to international standards, such as ISO 9001 certifications. Look for products that are UL listed and RoHS compliant, which indicate adherence to safety and environmental regulations. Conducting a supplier audit or requesting samples for testing can further help in assessing quality before making bulk purchases. Additionally, consider establishing long-term relationships with trusted suppliers who can provide ongoing support and warranty options, ensuring peace of mind regarding product reliability and performance. This diligence in sourcing can significantly reduce the risk of operational disruptions caused by power cable failures.

Strategic Material Selection Guide for c13 to c13 power cable

What Are the Common Materials Used in C13 to C13 Power Cables?

When selecting materials for C13 to C13 power cables, it’s essential to consider the properties and suitability of each material for specific applications. Here, we analyze four common materials used in the construction of these power cables: PVC, rubber, TPE (Thermoplastic Elastomer), and silicone. Each material has distinct advantages and limitations that can significantly affect performance, durability, and compliance with international standards.

How Does PVC Perform in C13 to C13 Power Cables?

Polyvinyl Chloride (PVC) is one of the most widely used materials for insulation and jackets in power cables. It offers good electrical insulation properties and is resistant to moisture, chemicals, and UV light. PVC can typically operate at temperatures up to 70°C, making it suitable for standard indoor applications.

Pros: PVC is cost-effective and easy to manufacture, allowing for high-volume production. Its durability makes it ideal for a variety of environments, including data centers and office settings.

Cons: However, PVC is less flexible than other materials, which can limit its use in applications requiring frequent movement or bending. Additionally, it has a lower temperature tolerance compared to other materials, which may not be suitable for high-performance applications.

Impact on Application: PVC is compatible with most media, including standard electrical systems. International buyers should ensure that the PVC used complies with local standards such as ASTM or DIN.

What Advantages Does Rubber Offer for C13 to C13 Power Cables?

Rubber is another common material used in power cables, particularly in environments where flexibility and durability are paramount. It can withstand a wide temperature range, typically from -40°C to 90°C, making it suitable for both indoor and outdoor applications.

Pros: Rubber’s excellent flexibility allows for easy handling and installation, especially in tight spaces. It also has superior abrasion and cut resistance, providing enhanced durability.

Cons: The primary drawback is the higher cost compared to PVC, which may impact budget-sensitive projects. Rubber can also degrade over time when exposed to certain chemicals or oils, necessitating careful consideration of its application environment.

Impact on Application: Rubber is particularly beneficial for outdoor or industrial applications where exposure to harsh conditions is expected. Buyers should verify that the rubber meets international safety and environmental standards.

Illustrative image related to c13 to c13 power cable

Why Choose TPE for C13 to C13 Power Cables?

Thermoplastic Elastomer (TPE) is gaining popularity due to its combination of rubber-like flexibility and plastic-like processability. TPE cables can typically operate within a temperature range of -40°C to 105°C.

Pros: TPE offers excellent flexibility and resilience, which is ideal for applications requiring frequent movement. It is also resistant to oil, chemicals, and UV light, making it suitable for various environments.

Cons: The main limitation of TPE is its relatively higher cost compared to PVC and rubber. Additionally, TPE may not be as widely available in all regions, which could affect supply chains.

Impact on Application: TPE is an excellent choice for applications in data centers and outdoor environments where flexibility and durability are critical. International buyers should ensure compliance with relevant standards like JIS or IEC.

What Role Does Silicone Play in C13 to C13 Power Cables?

Silicone is often used in high-temperature applications due to its ability to withstand extreme temperatures (up to 200°C). It is also highly resistant to environmental factors such as moisture and ozone.

Pros: Silicone’s high-temperature resistance makes it suitable for specialized applications, including industrial and high-performance environments. Its flexibility remains intact even at extreme temperatures, ensuring reliable performance.

Cons: The primary disadvantage of silicone is its cost, which is significantly higher than PVC and rubber. Additionally, silicone may not provide the same level of mechanical protection as other materials.

Impact on Application: Silicone is ideal for applications where high temperatures and harsh environmental conditions are prevalent. Buyers should confirm that silicone cables meet international compliance standards.

Summary Table of Material Properties

| Material | Typical Use Case for c13 to c13 power cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor office and data center applications | Cost-effective and durable | Less flexible, lower temperature tolerance | Low |

| Rubber | Outdoor and industrial applications | Excellent flexibility and abrasion resistance | Higher cost, potential chemical degradation | Med |

| TPE | Data centers and outdoor environments | High flexibility and chemical resistance | Higher cost, limited availability | Med |

| Silicone | High-temperature industrial applications | Extreme temperature resistance | High cost, lower mechanical protection | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of different materials used in C13 to C13 power cables. By understanding these factors, buyers can make informed decisions that align with their operational requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for c13 to c13 power cable

What Are the Main Stages in the Manufacturing Process of C13 to C13 Power Cables?

The manufacturing of C13 to C13 power cables involves several critical stages that ensure the final product meets the required specifications and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in manufacturing C13 power cables is sourcing high-quality raw materials. This includes copper wire for the conductors, insulation materials like PVC or rubber, and the plastic for the connectors. Suppliers often undergo stringent vetting to ensure they meet international standards. Material testing is conducted to verify electrical conductivity, insulation resistance, and environmental resistance. -

Forming

In this stage, the copper wire is drawn to the required gauge, typically 18 AWG for C13 cables, and then coated with insulation. The insulation process is crucial as it protects against electrical faults and external damage. Techniques such as extrusion are commonly used, where the insulated wire is continuously formed into the desired shape. -

Assembly

Once the individual components are prepared, the assembly process begins. The connectors (C14 male and C13 female) are attached to the cable ends. This is typically done using automated machinery that ensures precision and consistency in the connections. The assembly process is closely monitored to minimize human error. -

Finishing

The final stage involves several tasks, including cutting the cables to specified lengths, applying strain relief, and quality checks. The cables are labeled and packaged for distribution. Quality control is particularly stringent at this stage to ensure that the cables meet all regulatory requirements.

What Quality Assurance Practices Are Essential for C13 to C13 Power Cables?

Quality assurance (QA) is integral to the manufacturing of C13 to C13 power cables, ensuring that products are safe, reliable, and compliant with international standards. Here are the key aspects of QA in this context:

-

International Standards Compliance

Manufacturers typically adhere to ISO 9001, which outlines criteria for a quality management system. This certification indicates that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, compliance with CE marking ensures that products meet European safety standards. -

Industry-Specific Standards

Beyond general ISO standards, industry-specific certifications such as UL (Underwriters Laboratories) and RoHS (Restriction of Hazardous Substances) are critical. These certifications verify that the cables are safe for use in electrical installations and do not contain harmful materials. -

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

– Final Quality Control (FQC): A comprehensive inspection of the finished product, including electrical testing, mechanical strength, and insulation resistance tests. -

Common Testing Methods for Quality Assurance

Various testing methods are employed to verify the quality of C13 power cables, including:

– Electrical Testing: Measures the voltage withstand and insulation resistance to ensure safe operation.

– Mechanical Testing: Assesses the tensile strength and flexibility of the cable.

– Environmental Testing: Evaluates the cable’s performance under different temperature and humidity conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are actionable steps:

-

Conduct Supplier Audits

Performing on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. This allows buyers to assess compliance with international standards and the effectiveness of the supplier’s QA protocols. -

Request Quality Assurance Documentation

Suppliers should provide documentation of their quality management systems, including certifications like ISO 9001 and test reports. These documents should detail the testing methods used and the results from recent batches of cables. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspectors can conduct tests and audits, offering an additional layer of assurance. -

Understand Regional Compliance Nuances

Different regions may have specific compliance requirements. For instance, products sold in Europe must meet CE standards, while those in the U.S. may require UL certification. Buyers should be aware of these nuances to ensure compliance and avoid potential legal issues.

What Are the Challenges in Quality Assurance for International B2B Buyers?

B2B buyers, especially those in emerging markets, may face unique challenges in ensuring quality assurance for C13 to C13 power cables. These include:

-

Variability in Supplier Standards

Suppliers in different regions may have varying quality standards and practices. Buyers must thoroughly assess potential suppliers to ensure they meet consistent quality levels. -

Logistical Issues

Shipping cables internationally can introduce risks such as damage during transit or delays that might affect the quality of the product. Buyers should work with suppliers who have robust logistics and packaging solutions. -

Communication Barriers

Language and cultural differences can create misunderstandings regarding specifications and quality expectations. Clear communication and well-defined contracts can mitigate these risks. -

Regulatory Compliance

Navigating the regulatory landscape can be complex, especially for buyers who may not be familiar with the standards required in different regions. Collaborating with legal experts or consultants can help ensure compliance.

By understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing C13 to C13 power cables, ensuring that they receive reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘c13 to c13 power cable’

To effectively procure C13 to C13 power cables for your business needs, it is essential to follow a structured sourcing approach. This guide provides a step-by-step checklist to ensure you make informed decisions and select the best products that meet your requirements.

Illustrative image related to c13 to c13 power cable

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the first step in sourcing C13 to C13 power cables. Consider factors such as voltage ratings, amperage capacity (typically 10A), and cable lengths that suit your operational needs. This clarity will streamline your search and help you communicate effectively with suppliers.

Step 2: Research Supplier Reputation

Investigate potential suppliers to gauge their reliability and quality. Look for reviews, testimonials, and case studies from businesses similar to yours. A reputable supplier will have a track record of delivering high-quality products and excellent customer service.

- Check Industry Certifications: Ensure that the suppliers adhere to international standards (e.g., ISO 9001) and certifications relevant to your region.

- Evaluate Customer Support: Good suppliers provide responsive customer service and technical support, which is crucial for addressing any issues post-purchase.

Step 3: Verify Product Compliance and Quality

Before making a purchase, confirm that the power cables comply with local and international safety standards. This is particularly important in regions with stringent electrical regulations.

Illustrative image related to c13 to c13 power cable

- Request Test Reports: Ask for compliance documentation, such as UL or RoHS certifications, to ensure the products are safe and environmentally friendly.

- Inspect Material Quality: Look for cables made from high-quality materials (like 18 AWG wire) that ensure durability and optimal performance.

Step 4: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and terms of sale. Look beyond just the base price to understand the total cost of ownership, including shipping, taxes, and potential tariffs.

- Explore Volume Discounts: Many suppliers offer tiered pricing based on order quantity, which can significantly reduce costs.

- Consider Payment Terms: Evaluate payment options and terms to ensure they align with your cash flow management.

Step 5: Request Samples

Before finalizing your order, request samples of the C13 to C13 power cables. This allows you to assess the product quality firsthand and ensure it meets your specifications.

- Conduct Performance Testing: Test the cables in your operational environment to validate compatibility and performance.

- Evaluate Packaging and Documentation: Ensure that the cables come with proper labeling and documentation, which is vital for inventory management.

Step 6: Negotiate and Finalize Contracts

Once you are satisfied with the product samples and supplier terms, enter negotiations to finalize your contract. Ensure all agreed-upon terms, including delivery timelines, warranties, and after-sales support, are documented.

- Clarify Return Policies: Understand the procedures for returns or exchanges in case the products do not meet your expectations.

- Establish Communication Channels: Set up clear lines of communication for ongoing support and future orders.

Step 7: Plan for Future Needs

As you complete your initial procurement, consider establishing a relationship with your chosen supplier for future needs. Discuss potential customizations or bulk orders to streamline future purchases.

- Keep Track of Inventory Levels: Regularly monitor your cable inventory to anticipate future orders and avoid supply chain disruptions.

- Stay Updated on Product Innovations: Suppliers often release new products or improvements; staying in touch can benefit your operations.

By following this checklist, you will be well-equipped to source high-quality C13 to C13 power cables that meet your business’s specific needs, ensuring reliability and efficiency in your operations.

Comprehensive Cost and Pricing Analysis for c13 to c13 power cable Sourcing

When considering the sourcing of C13 to C13 power cables, a comprehensive understanding of the cost structure and pricing dynamics is essential for B2B buyers, especially those operating in diverse international markets like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for C13 to C13 Power Cables?

The cost of C13 to C13 power cables comprises several critical components:

-

Materials: The primary materials include copper for the conductors, PVC or rubber for insulation, and other components like connectors. The quality of these materials significantly affects the overall cost.

-

Labor: Labor costs vary based on the manufacturing location. Regions with higher labor costs may influence the final pricing, while countries with lower labor expenses can provide more competitive rates.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, impacting pricing favorably.

-

Tooling: The initial investment in tooling and machinery is a factor, especially for custom specifications. High tooling costs may be amortized over larger production runs, making unit costs lower for bulk orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. While this adds to the upfront cost, it can prevent costly returns and warranty claims.

-

Logistics: Shipping and handling costs vary based on the distance from the manufacturer to the buyer, as well as the chosen Incoterms. These terms dictate who is responsible for shipping costs and risks, influencing the overall budget.

-

Margin: Suppliers typically apply a markup on production costs to maintain profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect C13 to C13 Power Cable Costs?

Several factors can influence the pricing of C13 to C13 power cables:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs due to economies of scale. Negotiating for lower MOQs can be beneficial for smaller businesses looking to keep inventory costs low.

-

Specifications and Customization: Custom lengths, colors, or specialized connectors can increase costs. Buyers should evaluate whether these custom features are necessary for their applications.

-

Material Quality and Certifications: Cables that meet higher safety and performance standards (like UL, CE, RoHS) may come at a premium. However, investing in certified products can enhance reliability and safety in critical applications.

-

Supplier Factors: Supplier reliability, reputation, and service offerings (like after-sales support) can justify higher prices. It’s essential to assess the total value provided by suppliers beyond just the product cost.

-

Incoterms: Understanding the implications of various Incoterms (like FOB, CIF) can help buyers manage costs effectively. Choosing the right Incoterm can influence shipping expenses and risk management.

What Tips Can Help Buyers Optimize Their Sourcing Strategy?

B2B buyers can employ several strategies to enhance their sourcing efficiency:

-

Negotiate Wisely: Leverage volume purchases to negotiate better pricing. Establishing long-term relationships with suppliers can also lead to favorable terms and discounts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the entire lifecycle cost, including shipping, storage, and potential replacement costs. A cheaper cable may lead to higher TCO if it fails prematurely.

-

Understand Pricing Nuances for International Purchases: Currency fluctuations, tariffs, and import duties can significantly impact costs for international buyers. It’s advisable to factor these into the budget when sourcing cables from different regions.

-

Research Suppliers Thoroughly: Look for suppliers with a proven track record, positive reviews, and comprehensive warranties. This can mitigate risks associated with product quality and service reliability.

Conclusion

In summary, a well-rounded understanding of the cost structure, pricing influencers, and strategic sourcing tips is vital for B2B buyers of C13 to C13 power cables. By considering these factors, buyers can make informed decisions that align with their business objectives while ensuring product reliability and cost efficiency. Keep in mind that prices can vary significantly based on numerous factors, so always seek indicative pricing tailored to your specific needs.

Alternatives Analysis: Comparing c13 to c13 power cable With Other Solutions

Introduction: Exploring Alternatives to C13 to C13 Power Cables

When evaluating power solutions for devices and systems, it is essential to consider various alternatives to the C13 to C13 power cable. This analysis will help B2B buyers make informed decisions by comparing the C13 to C13 power cable with other viable options. Understanding the performance, cost, ease of implementation, maintenance, and best use cases of these alternatives can significantly influence purchasing choices, especially in diverse markets like Africa, South America, the Middle East, and Europe.

Illustrative image related to c13 to c13 power cable

Comparison Table

| Comparison Aspect | C13 To C13 Power Cable | C14 to C13 Power Cable | NEMA 5-15P to C13 Power Cable |

|---|---|---|---|

| Performance | Reliable for devices up to 10A/250V | Suitable for high-performance equipment | Supports standard electronics with up to 15A/125V |

| Cost | Competitive pricing | Generally higher due to specialized use | Typically lower, widely available |

| Ease of Implementation | Simple plug-and-play | Requires compatible PDU | Easy installation, universal compatibility |

| Maintenance | Low maintenance required | Moderate, depends on usage | Minimal, standard wear and tear |

| Best Use Case | Data centers, servers | High-performance servers, networking | General electronics, home/office use |

Detailed Breakdown of Alternatives

C14 to C13 Power Cable

The C14 to C13 power cable is a robust alternative, particularly suited for high-performance equipment such as servers and networking devices. With a rating of up to 10A/250V, it is ideal for environments where power demands are high. However, this cable often comes at a higher price point due to its specialized design and functionality. While it provides excellent performance, compatibility with specific power distribution units (PDUs) is necessary, which could complicate implementation in environments with diverse equipment.

NEMA 5-15P to C13 Power Cable

The NEMA 5-15P to C13 power cable serves as a versatile solution for connecting standard electronic devices to power sources. It supports up to 15A/125V, making it suitable for a broad range of applications, from office equipment to home electronics. One of its main advantages is its cost-effectiveness and widespread availability, making it an attractive option for businesses looking to minimize expenses. However, its performance may be limited compared to C13 to C13 and C14 to C13 cables in high-demand scenarios, such as data centers.

Conclusion: Making the Right Choice for Your Power Needs

When selecting the appropriate power cable solution, B2B buyers must consider their specific operational requirements. The C13 to C13 power cable remains an excellent choice for data centers and server environments due to its reliability and simplicity. Alternatively, the C14 to C13 cable is optimal for high-performance equipment, while the NEMA 5-15P to C13 cable offers a budget-friendly option for general electronics. Assessing factors such as performance needs, cost considerations, and ease of implementation will guide buyers toward the best solution tailored to their operational demands. By understanding these alternatives, businesses can ensure they choose a power solution that aligns with their requirements and optimizes their operations.

Illustrative image related to c13 to c13 power cable

Essential Technical Properties and Trade Terminology for c13 to c13 power cable

What Are the Key Technical Properties of C13 to C13 Power Cables?

When sourcing C13 to C13 power cables, understanding the essential technical properties can significantly impact purchasing decisions. Here are some critical specifications to consider:

-

Connector Type

C13 to C13 cables utilize the IEC 60320 standard, with the C14 connector (male) on one end and the C13 connector (female) on the other. This specification is crucial for ensuring compatibility with various devices like computers, servers, and power distribution units (PDUs). Selecting the correct connector type guarantees seamless integration into existing setups. -

Current Rating

Typically rated at 10A and 250V, the current rating indicates the maximum electrical load the cable can safely carry. This rating is essential for B2B buyers to avoid overheating or electrical failures, particularly in high-demand environments like data centers or industrial settings. Ensuring the cable meets the required current rating helps in maintaining operational efficiency and safety. -

Cable Gauge (AWG)

The American Wire Gauge (AWG) measures the thickness of the wire. Commonly, C13 to C13 cables are 18 AWG, which balances flexibility and conductivity. A thicker gauge can handle higher currents and reduces resistance, making it vital for high-power applications. Understanding AWG helps buyers assess cable performance and durability. -

Jacket Material

The outer jacket is often made from SJT (service Junior Thermoplastic) or similar materials, providing insulation and protection. The choice of material affects durability, flexibility, and resistance to environmental factors like heat and moisture. Buyers should consider the operational environment to select cables that will withstand specific conditions. -

Length Variations

C13 to C13 cables are available in various lengths, typically ranging from 1 to 15 feet. Choosing the right length is critical for minimizing clutter and ensuring efficient setup in server racks or workstations. Custom lengths may also be available, allowing businesses to tailor solutions to their specific layouts. -

Compliance and Certifications

Look for cables that are UL Listed and RoHS compliant. These certifications indicate adherence to safety and environmental regulations, providing assurance of quality. For B2B buyers, these certifications can be pivotal in avoiding legal liabilities and ensuring reliable product performance.

What Are Common Trade Terms Related to C13 to C13 Power Cables?

Familiarity with industry jargon can streamline procurement processes and enhance communication with suppliers. Here are key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to companies that produce components that are used in another company’s product. In the context of power cables, understanding OEM relationships can help buyers identify reliable sources for high-quality cables that meet specific technical standards. -

MOQ (Minimum Order Quantity)

This term indicates the minimum number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, particularly for businesses that require bulk purchases to meet operational needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This process is crucial for comparing costs and negotiating better pricing, especially when sourcing large quantities of cables. -

Incoterms (International Commercial Terms)

These are predefined commercial terms that dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international transactions to avoid misunderstandings and ensure compliance with trade regulations. -

PDU (Power Distribution Unit)

A PDU is a device that distributes electrical power to multiple devices, often used in data centers. Recognizing the role of PDUs helps buyers understand how C13 to C13 cables fit into their overall power management strategy. -

Cable Management

This term refers to the organization and containment of cables to enhance aesthetics and prevent tangling. Effective cable management is essential for operational efficiency, especially in environments with numerous connections like server rooms or offices.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing C13 to C13 power cables, ultimately enhancing their procurement strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the c13 to c13 power cable Sector

What Are the Key Drivers Shaping the C13 to C13 Power Cable Market?

The global market for C13 to C13 power cables is experiencing robust growth, driven by the increasing demand for reliable power connectivity in data centers, telecommunications, and industrial applications. As businesses worldwide digitalize, the necessity for efficient power distribution systems has surged, particularly in regions like Africa, South America, the Middle East, and Europe. This surge is further fueled by the expansion of cloud computing and the Internet of Things (IoT), which require consistent power supply solutions.

Emerging trends in the B2B sourcing landscape include the customization of cable lengths and specifications to meet specific operational needs. Buyers are increasingly seeking suppliers who offer flexible solutions, such as custom cable builders, to accommodate unique installations. Additionally, the rise of e-commerce platforms has made it easier for international buyers to source high-quality power cables from diverse manufacturers, enhancing competition and driving down prices.

Illustrative image related to c13 to c13 power cable

Another significant trend is the integration of smart technology into power cables, enabling monitoring and management of power consumption. This innovation is particularly appealing to businesses focused on optimizing their energy usage and reducing operational costs. For international buyers, understanding regional compliance standards and certifications is essential to ensure product reliability and safety.

How Does Sustainability Impact the Sourcing of C13 to C13 Power Cables?

Sustainability is becoming a crucial consideration in the B2B sourcing of C13 to C13 power cables. The environmental impact of manufacturing processes and the materials used in power cables are under increasing scrutiny. Buyers are now prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint through eco-friendly practices.

Ethical sourcing is also gaining traction, with businesses seeking to establish supply chains that adhere to social responsibility standards. This includes transparency in sourcing materials, fair labor practices, and compliance with environmental regulations. Power cables that are certified green or made from recyclable materials can enhance a company’s sustainability profile and resonate with eco-conscious clients.

Illustrative image related to c13 to c13 power cable

Moreover, as international regulations tighten around environmental standards, B2B buyers must be proactive in ensuring that their suppliers possess the necessary certifications. This not only mitigates risks associated with non-compliance but also positions businesses as leaders in sustainability within their industries.

What Is the Historical Context of C13 to C13 Power Cables in B2B?

The evolution of C13 to C13 power cables traces back to the standardization of electrical connections in computing and networking equipment. The C13 connector, designed under the IEC 60320 standard, became widely adopted in the late 20th century, aligning with the rise of personal computers and server technology. This standardization facilitated interoperability across different devices, simplifying the procurement process for B2B buyers.

Over the years, advancements in materials and manufacturing processes have improved the durability and efficiency of these cables. With the advent of data centers and the exponential growth of digital infrastructure, the demand for reliable C13 to C13 power cables has increased significantly. Today, these cables are integral to power distribution systems in a variety of settings, from large-scale data centers to small office environments, reflecting their essential role in modern business operations.

Frequently Asked Questions (FAQs) for B2B Buyers of c13 to c13 power cable

-

How do I ensure the quality of C13 to C13 power cables before purchasing?

To ensure quality, request certifications from suppliers, such as ISO 9001, which indicates adherence to international quality standards. Additionally, ask for samples to test durability and performance. Review the supplier’s history and customer feedback to gauge reliability. It’s also beneficial to inquire about their manufacturing processes and the materials used in the cables, ensuring they comply with safety regulations relevant to your region. -

What specifications should I consider when selecting C13 to C13 power cables?

Key specifications include the cable length, gauge (AWG), and voltage rating. For instance, an 18 AWG cable is standard for most applications, rated at 10A/250V. Additionally, consider the connector type (C13 female to C14 male) and whether you need features like angled connectors or specific jacket materials for durability. Compatibility with your devices is crucial, so verify the equipment’s requirements before purchasing. -

What are common applications for C13 to C13 power cables in a B2B context?

C13 to C13 power cables are widely used in data centers to connect servers and networking equipment to power distribution units (PDUs). They are also common in office environments for powering computers and peripherals. Understanding your specific application can help you choose the right cable length and specifications to ensure optimal performance and safety in your operations. -

How can I customize C13 to C13 power cables for my specific needs?

Many suppliers offer customization options, allowing you to specify lengths, colors, and connector types. Some manufacturers can even create cables tailored to your unique requirements, such as custom labeling or branding. When requesting customization, provide clear specifications and quantities to get accurate quotes and lead times from suppliers. -

What is the typical minimum order quantity (MOQ) for C13 to C13 power cables?

MOQs vary by supplier and can range from as low as 50 units to several hundred. When sourcing, it’s crucial to discuss MOQs upfront to ensure they align with your purchasing capacity. Some suppliers may offer flexibility for first-time buyers or larger contracts, so it’s beneficial to negotiate based on your projected needs and long-term partnership potential. -

What payment terms should I expect when sourcing C13 to C13 power cables internationally?

Payment terms vary but typically include options such as advance payment, 30-day net, or letter of credit. Ensure you understand the terms before finalizing the purchase to avoid any cash flow issues. Discussing payment methods (e.g., bank transfer, credit card) and any potential discounts for upfront payments can be advantageous. Be aware of currency exchange rates and transaction fees if dealing with international suppliers. -

How do I vet suppliers of C13 to C13 power cables effectively?

To vet suppliers, start by checking their business credentials, such as registration details and industry certifications. Request references from past clients and review online testimonials. Conducting a background check on their operational history and financial stability can also provide insights. Visiting the manufacturing facility, if possible, can further assure you of their capabilities and quality standards. -

What logistics considerations should I keep in mind when importing C13 to C13 power cables?

Logistics considerations include shipping methods, lead times, and customs regulations in your country. Determine whether you prefer air freight for speed or sea freight for cost-effectiveness. Familiarize yourself with import duties and taxes to avoid unexpected costs. Working with a freight forwarder can streamline the process, helping manage documentation and ensuring compliance with international shipping laws.

Top 4 C13 To C13 Power Cable Manufacturers & Suppliers List

1. SFCable – IEC C13 Power Cords

Domain: sfcable.com

Registered: 2001 (24 years)

Introduction: High-Quality IEC C13 Power Cords, Free Standard Shipping on Orders Over $50, Lifetime Warranty on Cables and Non Electronics Products, Same-Day Shipping if ordered before 1pm PST, Customer Support: 1-888-275-8755, Available for online orders only.

2. DataPro – Panel Mount C14 to C13 AC Power Cable

Domain: datapro.net

Registered: 1995 (30 years)

Introduction: Panel Mount C14 to C13 AC Power Cable 125V

– Connector Type: C14 (panel-mount) to C13

– Voltage: 125V

– Current Rating: 10A

– Wire Specifications: 3×18 AWG, 300V, 75C, UL VW-1, CSA

– Includes mounting hardware

– Available Lengths and Prices:

– 1 ft: $13.95 (398 in stock)

– 2 ft: $14.95 (344 in stock)

– 3 ft: $15.95 (3 in stock)

– 4 ft: $16.95 (163 in stock)

– 6 ft: $19.95 (215 in stock)

…

3. AndCable – C13 C14 10A 250V Power Cord

Domain: andcable.com

Registered: 1996 (29 years)

Introduction: {“name”: “C13 C14 10A 250V Power Cord – Black”, “sku”: “52-10/C13-C14-xxB”, “price”: “$3.00”, “type”: “C14 to C13 power cord”, “current_rating”: “10A”, “voltage_rating”: “250V”, “compliance”: “IEC 60320”, “usage”: “Commonly used in data centers or enterprise networking rooms to connect a Rack Mount PDU to equipment like servers, routers, or switches.”, “available_lengths”: [“1.5 Feet”, “2.5 Feet”,…

4. StarTech – 2ft Power Extension Cord

Domain: startech.com

Registered: 1998 (27 years)

Introduction: {“length”:”2ft (60cm)”, “type”:”Power Extension Cord”, “connector_1″:”C14”, “connector_2″:”C13”, “current_rating”:”10A”, “voltage_rating”:”250V”, “gauge”:”18AWG”, “color”:”Black”}

Strategic Sourcing Conclusion and Outlook for c13 to c13 power cable

In navigating the global market for C13 to C13 power cables, B2B buyers must prioritize strategic sourcing to enhance their supply chain efficiency. With diverse applications ranging from data centers to industrial settings, the demand for reliable, high-quality power cords is on the rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Buyers are encouraged to evaluate suppliers based on ISO certifications, product variety, and post-sale support, ensuring they receive not only competitive pricing but also superior quality and service.

Moreover, understanding local market requirements and compliance regulations can significantly impact procurement success. Leveraging partnerships with suppliers who offer customization options, such as varying lengths and specifications, allows businesses to meet specific operational needs effectively.

As we look toward the future, the potential for innovation in power cord technology and sustainability practices presents exciting opportunities for growth. B2B buyers are urged to stay informed about market trends and emerging technologies that can drive efficiency and reliability in their operations. By making informed sourcing decisions today, businesses can secure a competitive edge in an increasingly interconnected global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.