C Channel Platform Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for c channel platform

In the rapidly evolving global market, sourcing a reliable C-channel platform can present significant challenges for international B2B buyers. As companies strive to optimize their construction and manufacturing processes, understanding the nuances of C-channel steel becomes essential. This guide delves into the multifaceted world of C-channel platforms, exploring various types, their diverse applications, and the intricacies of supplier vetting. Buyers will gain insights into cost considerations, quality assurance practices, and the importance of selecting materials that meet specific project requirements.

With a keen focus on the needs of B2B buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Vietnam and Germany—this comprehensive resource empowers decision-makers to navigate the complexities of international procurement. By equipping readers with actionable strategies and in-depth knowledge about C-channel platforms, this guide aims to streamline the purchasing process, ensuring that companies can confidently select products that enhance their operational efficiency and project outcomes.

Ultimately, whether you are involved in construction, manufacturing, or industrial applications, understanding the dynamics of the C-channel market will enable you to make informed purchasing decisions that align with your business goals. Join us as we explore the essential elements of sourcing C-channel platforms in today’s competitive landscape.

Understanding c channel platform Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard C-Channel | Straight, uniform dimensions; made from various steels | General construction, framing, and support systems | Pros: Versatile, widely available; Cons: May require additional finishing for corrosion resistance. |

| Galvanized C-Channel | Coated with zinc for enhanced corrosion resistance | Outdoor structures, scaffolding, and marine uses | Pros: Long-lasting, low maintenance; Cons: Higher initial cost compared to non-galvanized options. |

| Custom C-Channel | Tailored dimensions and thickness for specific projects | Specialized frameworks in manufacturing and transport | Pros: Meets unique project requirements; Cons: Longer lead times and potential higher costs. |

| C-Channel Toeboards | Designed to prevent falling debris; various lengths available | Scaffolding and temporary work platforms | Pros: Increases safety on job sites; Cons: Limited to specific applications. |

| Heavy-Duty C-Channel | Thicker walls for enhanced load-bearing capacity | Industrial machinery, heavy construction | Pros: Excellent strength-to-weight ratio; Cons: Heavier, which may complicate handling and installation. |

What Are the Characteristics of Standard C-Channel Platforms?

Standard C-channel platforms are characterized by their consistent dimensions and structural integrity, making them a staple in construction and framing applications. Typically made from carbon steel, they provide a balance of strength and weight, ideal for general use. When considering a purchase, buyers should evaluate the specific weight requirements and ensure compatibility with existing structures, as these channels can vary in thickness and width.

How Do Galvanized C-Channel Platforms Enhance Durability?

Galvanized C-channel platforms are coated with zinc, significantly improving their resistance to corrosion. This feature is particularly beneficial for outdoor applications or environments with high humidity, such as coastal areas. Buyers should consider the initial investment against the long-term savings from reduced maintenance and replacement costs. Selecting galvanized options is advisable for projects requiring longevity and durability in harsh conditions.

Why Choose Custom C-Channel Platforms for Specialized Needs?

Custom C-channel platforms offer tailored dimensions and specifications, allowing businesses to meet unique project requirements. These platforms are particularly useful in specialized frameworks within manufacturing or transportation sectors. However, buyers must be prepared for potentially longer lead times and higher costs associated with custom orders. It is essential to clearly communicate specifications to manufacturers to ensure product accuracy.

What Are the Benefits of C-Channel Toeboards in Safety?

C-channel toeboards are specifically designed to prevent tools and materials from falling off work platforms, enhancing safety on job sites. Available in various lengths, these toeboards can be easily integrated into scaffolding systems. Buyers should assess their safety protocols and consider the installation requirements, as these products are crucial for maintaining compliance with safety regulations.

When Should Heavy-Duty C-Channel Platforms Be Used?

Heavy-duty C-channel platforms feature thicker walls that provide superior load-bearing capacity, making them ideal for industrial machinery and heavy construction projects. These platforms are designed to withstand significant stress and weight, ensuring structural integrity in demanding environments. Buyers should consider the handling and installation implications of heavier materials, as they may require additional equipment or labor for transport and setup.

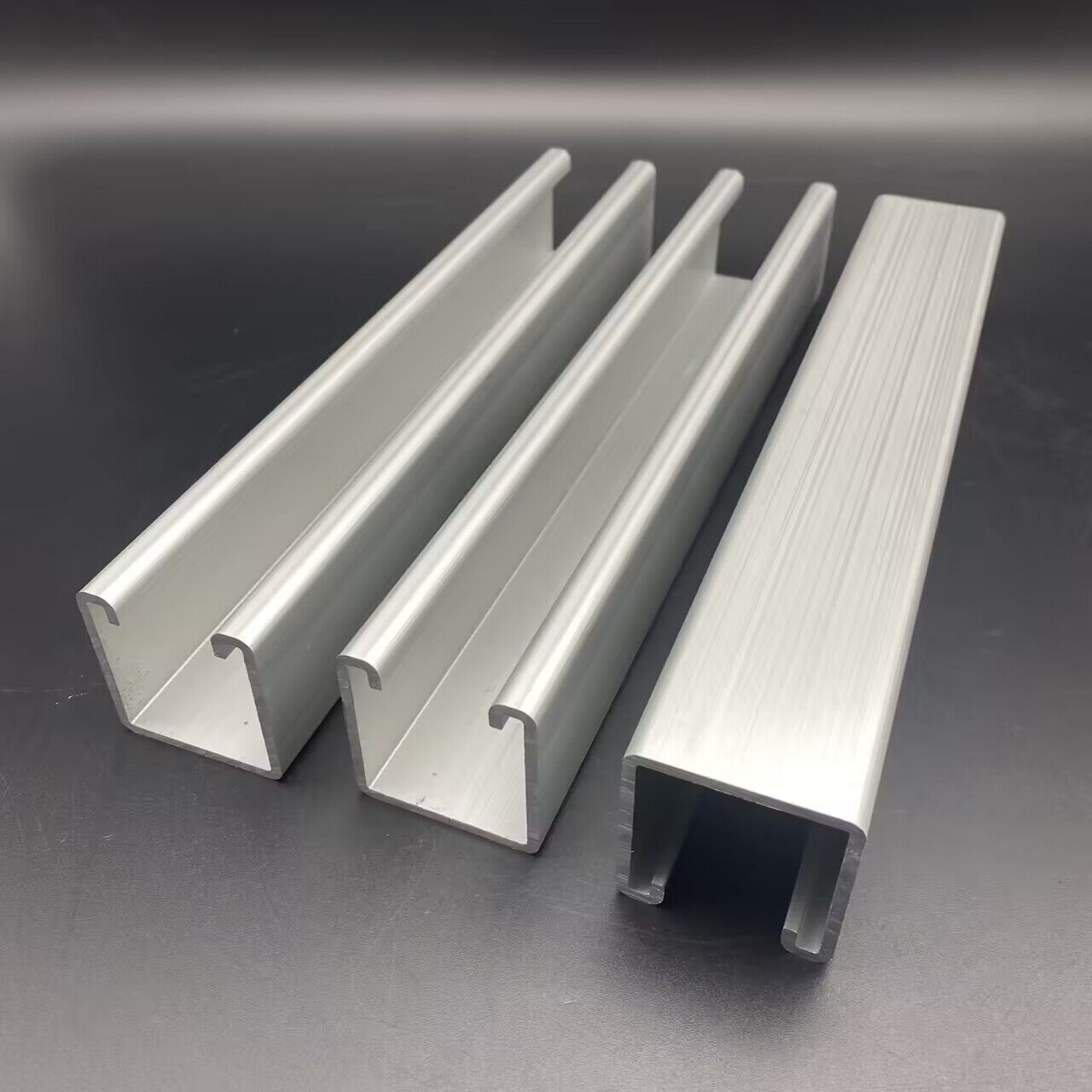

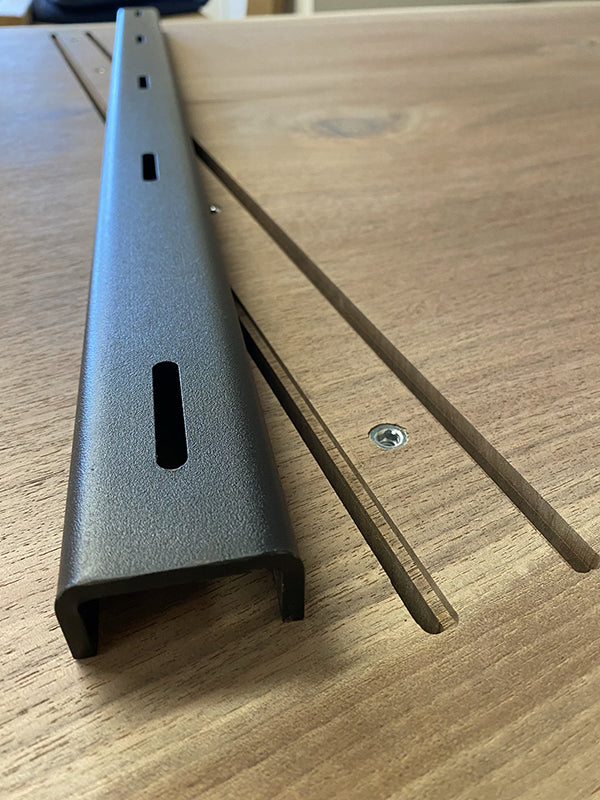

Illustrative image related to c channel platform

Key Industrial Applications of c channel platform

| Industry/Sector | Specific Application of c channel platform | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Scaffold Frameworks | Provides a sturdy and safe platform for workers | Ensure compliance with local safety standards and regulations |

| Transportation | Vehicle Chassis and Frames | Enhances structural integrity while minimizing weight | Look for materials with high corrosion resistance |

| Manufacturing | Industrial Machinery Supports | Offers a reliable foundation for heavy machinery | Consider custom sizes and load-bearing capacities |

| Energy | Wind Turbine Towers | Supports vertical structures in harsh environments | Evaluate durability and weather resistance |

| Mining | Support Structures for Equipment | Ensures stability and safety in rugged terrains | Source from suppliers with experience in extreme conditions |

How is the C Channel Platform Used in Construction?

In the construction industry, the c channel platform is primarily utilized in scaffold frameworks. It acts as a robust support system, ensuring the safety of workers at various heights. The unique C-shaped design allows for optimal load distribution, which is crucial in high-rise projects. International buyers should prioritize suppliers who adhere to local safety standards and regulations, ensuring that the scaffolding systems can withstand the demands of construction environments, particularly in regions with varying climates.

What Role Does C Channel Play in Transportation?

C channel platforms are pivotal in the manufacturing of vehicle chassis and frames, providing the necessary strength and flexibility to withstand dynamic forces. Their lightweight nature contributes to improved fuel efficiency in vehicles. For B2B buyers, especially in developing markets, sourcing high-quality, corrosion-resistant materials is essential to ensure longevity and performance in diverse operating conditions.

How is C Channel Utilized in Manufacturing?

In manufacturing, c channel platforms serve as support structures for heavy machinery, enhancing stability and operational efficiency. The ability to customize dimensions allows manufacturers to tailor solutions to specific machinery needs, optimizing space and functionality. Buyers should focus on suppliers that offer a range of thicknesses and materials to meet their unique requirements, including those for high-load applications.

What is the Significance of C Channel in Energy Sector Applications?

In the energy sector, particularly for wind turbine towers, c channel platforms provide the necessary structural support to withstand harsh environmental conditions. Their durability is critical for the longevity of energy installations. Buyers should evaluate the weather resistance and load-bearing capabilities of c channel products, ensuring they meet the rigorous demands of outdoor installations, especially in regions prone to extreme weather.

How Does C Channel Support Mining Operations?

In mining, c channel platforms are employed to create support structures for heavy equipment, ensuring stability in rugged terrains. This application is vital for maintaining operational safety and efficiency in challenging environments. Buyers in the mining sector should prioritize sourcing from manufacturers who understand the unique stresses of mining operations and can provide tailored solutions that meet industry-specific requirements.

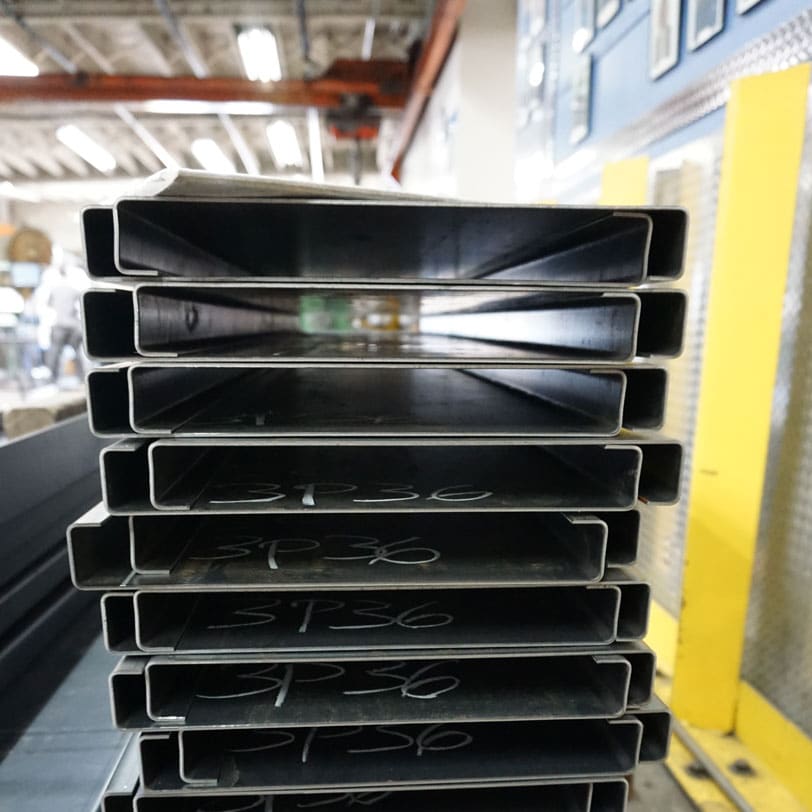

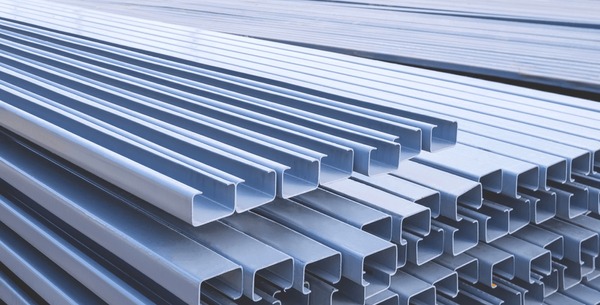

Illustrative image related to c channel platform

3 Common User Pain Points for ‘c channel platform’ & Their Solutions

Scenario 1: Ensuring Structural Integrity in Diverse Environments

The Problem: B2B buyers often face challenges related to the structural integrity of C-channel platforms, especially in harsh environments like coastal areas or regions with high humidity. Corrosion can compromise the durability and safety of the material, leading to costly repairs and potential project delays. Buyers may struggle to select the right type of C-channel steel that balances cost, weight, and resistance to environmental factors, leaving them vulnerable to unforeseen failures.

The Solution: To address this issue, it is crucial for buyers to opt for galvanized or stainless-steel C-channel options. Galvanization provides a protective zinc coating that significantly enhances corrosion resistance, while stainless steel offers both strength and durability in extreme conditions. When sourcing C-channel platforms, buyers should consult with manufacturers to specify the environmental conditions they will face and request appropriate certifications for corrosion resistance. Additionally, leveraging local suppliers familiar with regional conditions can help ensure that the selected materials meet both performance standards and local building codes. Conducting regular inspections and maintenance of the platforms will also help catch any potential issues early, ensuring the longevity of the investment.

Scenario 2: Navigating Complex Sizing and Customization Needs

The Problem: International B2B buyers often encounter difficulties in sourcing C-channel platforms that fit unique project specifications. Construction projects may require custom dimensions or specific weight capacities that standard products do not meet. This challenge can lead to project delays, increased costs, and frustration as buyers attempt to navigate the complexities of customizing orders from overseas suppliers.

The Solution: To overcome sizing and customization challenges, buyers should establish clear specifications before approaching manufacturers. Detailed drawings and structural requirements should be communicated upfront to ensure that the supplier fully understands the project needs. Working with manufacturers that offer flexible production capabilities is essential; buyers should seek out companies that can provide rapid prototyping or short lead times for custom orders. Additionally, leveraging technology such as 3D modeling can help visualize the final product and streamline the customization process. Engaging in open dialogue with suppliers about potential design modifications can also foster a collaborative approach to problem-solving, leading to more tailored solutions that meet the specific needs of the project.

Scenario 3: Understanding Compliance and Safety Regulations

The Problem: B2B buyers must navigate a myriad of compliance and safety regulations that govern the use of C-channel platforms across different regions. Failure to adhere to these regulations can result in legal repercussions, project shutdowns, and reputational damage. Buyers often find it challenging to keep up with varying standards, especially when dealing with international suppliers who may not fully understand local requirements.

The Solution: To ensure compliance, buyers should familiarize themselves with the relevant industry standards and regulations specific to their region. This may include codes from organizations such as the International Organization for Standardization (ISO) or local building authorities. Before finalizing orders, buyers should request documentation that verifies compliance with these standards from their suppliers. Additionally, establishing a relationship with a compliance consultant can provide valuable insights into navigating complex regulatory environments. Implementing a robust quality assurance process that includes regular audits and supplier evaluations can further mitigate risks associated with compliance, ensuring that all platforms meet the necessary safety standards before they are deployed in the field.

Strategic Material Selection Guide for c channel platform

When selecting materials for C-channel platforms, it is crucial to consider the specific requirements of your application, including structural integrity, environmental conditions, and compliance with international standards. Below, we analyze four common materials used in C-channel platforms, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

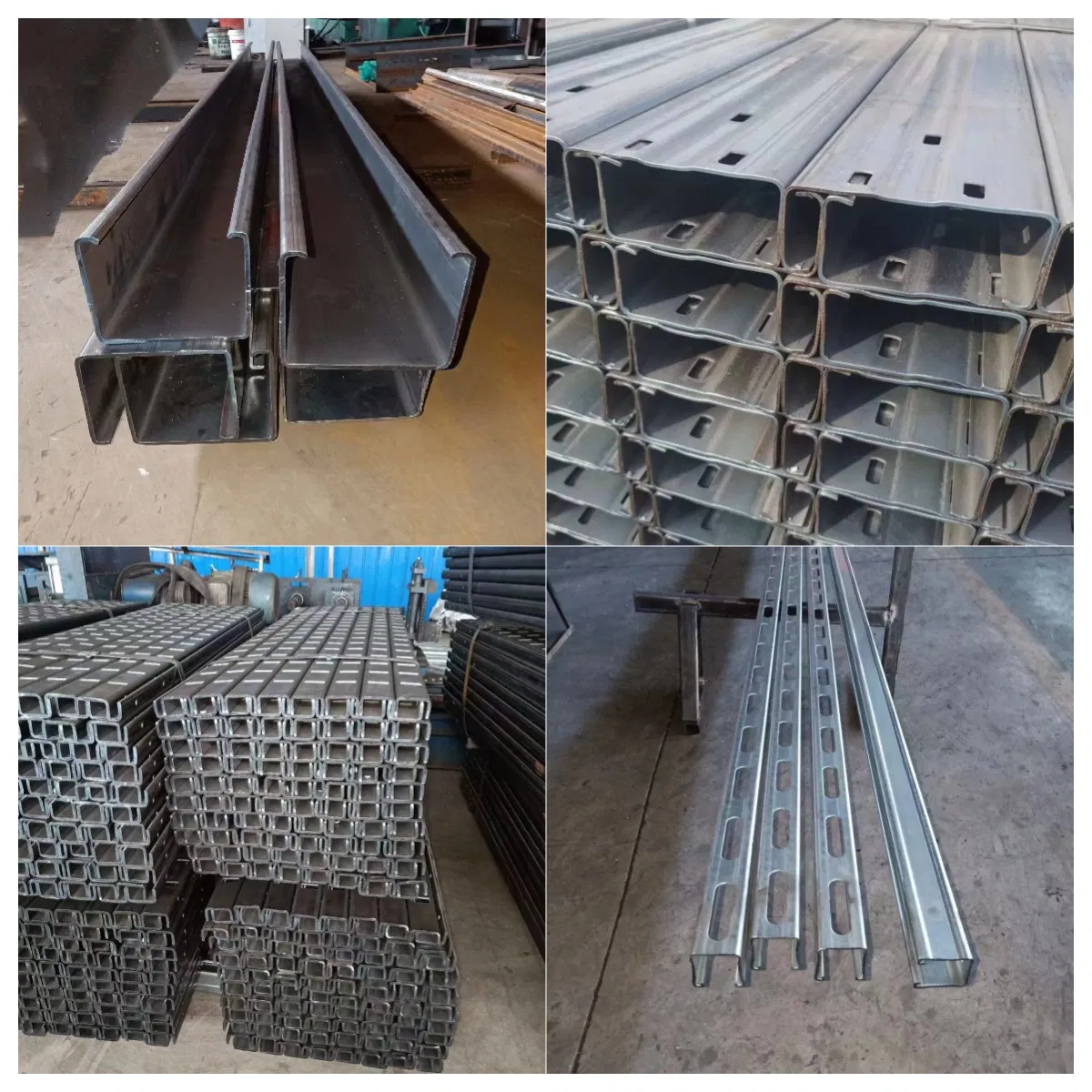

Illustrative image related to c channel platform

What are the Key Properties of Galvanized Steel for C-Channel Platforms?

Galvanized steel is a popular choice for C-channel platforms due to its corrosion resistance and durability. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and environmental degradation. This material typically exhibits a high strength-to-weight ratio, making it suitable for heavy-duty applications. Galvanized steel can withstand various temperature and pressure conditions, making it versatile for different industries.

Pros: Its resistance to corrosion extends the lifespan of the platform, reducing maintenance costs. Additionally, it is readily available and easy to fabricate.

Cons: The initial cost can be higher than non-galvanized options, and the manufacturing process may require specific techniques to ensure the coating adheres properly.

Impact on Application: Galvanized steel is ideal for outdoor applications and environments with high moisture levels, ensuring that the platform remains structurally sound over time.

Illustrative image related to c channel platform

Considerations for International Buyers: Compliance with standards like ASTM A123 for galvanization is essential. Buyers from regions like Europe may also need to consider EN standards for structural steel.

How Does Stainless Steel Perform as a Material for C-Channel Platforms?

Stainless steel is known for its exceptional corrosion resistance and aesthetic appeal. It is particularly advantageous in environments where hygiene is crucial, such as food processing or pharmaceutical industries. Stainless steel C-channels can handle high temperatures and pressures, making them suitable for various industrial applications.

Pros: The longevity and low maintenance requirements of stainless steel make it a cost-effective choice in the long run. Its strength allows for reduced material usage without compromising structural integrity.

Cons: The initial investment is significantly higher compared to other materials, and it can be more challenging to fabricate due to its hardness.

Impact on Application: Stainless steel is compatible with a wide range of media, including chemicals and food products, making it a versatile choice for specialized applications.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel and the European EN 10088 standard is crucial. Buyers should also consider local availability and the associated costs of stainless steel.

What are the Benefits and Drawbacks of Carbon Steel for C-Channel Platforms?

Carbon steel is another widely used material for C-channel platforms. It is known for its strength and affordability, making it an attractive option for many construction projects. Carbon steel C-channels can be treated with coatings to enhance their corrosion resistance, although they are inherently less resistant than galvanized or stainless steel.

Pros: The lower cost of carbon steel makes it accessible for projects with budget constraints. Its strength allows for heavy load-bearing capabilities.

Cons: Without proper treatment, carbon steel is prone to rust and corrosion, which can lead to increased maintenance costs over time.

Impact on Application: Carbon steel is suitable for indoor applications or environments where moisture is controlled, but it may not be ideal for outdoor use without protective coatings.

Considerations for International Buyers: Buyers should ensure compliance with ASTM A36 or equivalent standards, particularly in regions like South America and Africa, where structural integrity is paramount.

What Role Does Aluminum Play in C-Channel Platforms?

Aluminum C-channels are becoming increasingly popular due to their lightweight nature and excellent corrosion resistance. This material is ideal for applications where weight reduction is critical, such as in transportation or aerospace industries.

Pros: The lightweight nature of aluminum allows for easier handling and installation. It also does not require additional coatings for corrosion resistance.

Cons: Aluminum is generally less strong than steel, which may limit its use in heavy-duty applications. The cost can also be higher compared to carbon steel.

Impact on Application: Aluminum is suitable for environments where weight savings are essential, but it may not be ideal for applications requiring high load-bearing capacities.

Illustrative image related to c channel platform

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum is necessary. Buyers should also consider the availability of aluminum in their region, as it may not be as widely stocked as steel.

Summary Table of Material Selection for C-Channel Platforms

| Material | Typical Use Case for C Channel Platform | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Outdoor construction, scaffolding | Excellent corrosion resistance | Higher initial cost | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Exceptional durability | High fabrication complexity | High |

| Carbon Steel | Indoor structures, general construction | Cost-effective | Prone to rust without treatment | Low |

| Aluminum | Lightweight applications, transport | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering C-channel platforms. By evaluating the properties, advantages, and international compliance requirements for each material, buyers can make informed decisions that align with their project needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for c channel platform

What Are the Main Stages of the Manufacturing Process for C-Channel Platforms?

The manufacturing process for C-channel platforms involves several critical stages that ensure the final product meets industry standards and customer requirements. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, typically carbon steel or galvanized steel. These materials are sourced from reputable suppliers to guarantee strength and durability. After procurement, the materials undergo inspection to verify compliance with specifications.

-

Forming: This stage involves shaping the raw steel into the characteristic C-channel profile. Techniques such as roll forming or hot rolling are commonly employed. Roll forming allows for continuous production and precise control over dimensions, while hot rolling is beneficial for producing thicker sections. The formed channels are then cut to the required lengths.

-

Assembly: After forming, the components may require assembly, especially when the C-channel platforms are part of a more extensive system, such as scaffolding. This stage often involves welding or bolting various parts together. Quality checks are essential at this stage to ensure that joints are secure and meet load-bearing requirements.

-

Finishing: The final stage includes surface treatments to enhance corrosion resistance and aesthetics. Common finishing processes include galvanization, powder coating, or painting. These treatments not only improve durability but also ensure compliance with international standards, making the products suitable for various environments, including those in humid or corrosive climates.

How Is Quality Assurance Integrated into C-Channel Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for C-channel platforms, ensuring that products are safe, reliable, and meet the necessary regulatory standards.

Illustrative image related to c channel platform

-

International Standards: Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards helps ensure consistent quality throughout the manufacturing process. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for oil and gas applications may apply.

-

Quality Control Checkpoints: Effective QA involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to verify compliance with specifications.

– In-Process Quality Control (IPQC): Quality checks are conducted during the manufacturing process to monitor compliance with defined standards. This includes dimensional checks, weld inspections, and material integrity tests.

– Final Quality Control (FQC): Before shipment, finished products undergo thorough inspections to ensure they meet all specifications and quality standards. This includes load testing and visual inspections for defects. -

Common Testing Methods: Various testing methods are employed to ensure quality. These may include:

– Tensile Testing: To measure the strength and ductility of the steel.

– Ultrasonic Testing: To detect internal defects within the metal.

– Visual Inspections: To identify surface defects and ensure proper finishing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies to ensure that a supplier meets quality standards:

-

Supplier Audits: Conducting on-site audits of the manufacturing facilities allows buyers to assess the quality management systems in place. This includes reviewing documentation related to quality control processes, training records, and compliance with relevant standards.

-

Requesting Quality Assurance Reports: Buyers should ask suppliers for detailed quality assurance reports, which should outline the testing methods used, inspection results, and any corrective actions taken for non-conformities. These reports provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can perform independent checks and provide unbiased assessments of the manufacturer’s quality control processes and product conformity.

-

Certifications and Compliance Documentation: Buyers should request copies of relevant certifications, such as ISO 9001 or CE markings, and verify their validity. This documentation serves as a testament to the supplier’s commitment to maintaining high-quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the quality control landscape as an international B2B buyer requires an understanding of regional nuances and compliance requirements.

-

Cultural Differences: Different regions may have varying expectations regarding quality and compliance. For instance, European buyers may prioritize environmental sustainability and certifications more than counterparts in other regions. Understanding these cultural expectations can guide negotiations and quality requirements.

-

Regulatory Compliance: Different countries may impose specific regulations that affect product standards. For instance, products sold in the European Union must adhere to CE marking requirements, while those sold in North America may need to meet ASTM standards. Buyers should be aware of these requirements to ensure that products are compliant in their respective markets.

-

Supply Chain Considerations: The complexity of international supply chains can affect quality assurance. Buyers should consider the entire supply chain when evaluating suppliers, including the sourcing of raw materials, transportation logistics, and the potential for delays that could impact product integrity.

By understanding the manufacturing processes and quality assurance measures for C-channel platforms, B2B buyers can make informed decisions, ensuring they partner with suppliers who prioritize quality and compliance, ultimately leading to successful project outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘c channel platform’

Introduction

Sourcing a C-channel platform requires a methodical approach to ensure you select the right materials and suppliers for your project. This guide provides a step-by-step checklist designed for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By following these steps, you can make informed decisions that align with your technical needs and budget constraints.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline your project requirements. Specify the dimensions, weight capacity, and material preferences (e.g., galvanized steel for corrosion resistance). This clarity helps suppliers provide accurate quotes and ensures the products meet your specific needs.

- Considerations:

- Load-bearing requirements

- Environmental factors (e.g., exposure to moisture)

Step 2: Research and Identify Suppliers

Start by compiling a list of potential suppliers who specialize in C-channel products. Utilize online directories, industry associations, and referrals from industry peers to find credible manufacturers. A diverse supplier pool allows for competitive pricing and options.

- Key Resources:

- Industry trade shows

- Online B2B marketplaces

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; seek feedback on product quality and customer service.

- What to Look For:

- Years of experience in the industry

- Certifications and compliance with international standards

Step 4: Request Samples for Quality Assessment

Once you’ve narrowed down your supplier list, request samples of the C-channel products. Assess the quality, finish, and structural integrity of the samples to ensure they meet your expectations. This step is vital for avoiding costly mistakes later.

- Sample Evaluation:

- Check for uniformity in dimensions

- Evaluate the corrosion resistance of galvanized options

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers possess relevant certifications that validate their manufacturing processes and product quality. This is especially important in international transactions, where standards may vary significantly.

- Important Certifications:

- ISO certification

- Compliance with regional safety standards

Step 6: Negotiate Terms and Conditions

After selecting a supplier, it’s time to negotiate the terms of the contract. Discuss pricing, delivery schedules, and payment terms. Clarity on these aspects helps prevent misunderstandings and ensures a smooth transaction.

- Negotiation Points:

- Minimum order quantities

- Shipping and handling costs

Step 7: Plan for Logistics and Delivery

Finally, coordinate the logistics of your order. Discuss shipping options, lead times, and customs requirements, especially if importing from overseas. Proper planning ensures timely delivery and minimizes disruptions to your project timeline.

Illustrative image related to c channel platform

- Logistics Considerations:

- Freight forwarder selection

- Customs documentation preparation

By following this checklist, B2B buyers can effectively navigate the sourcing process for C-channel platforms, ensuring that they obtain high-quality materials that meet their project needs while fostering beneficial supplier relationships.

Comprehensive Cost and Pricing Analysis for c channel platform Sourcing

What Are the Key Cost Components for C-Channel Platform Sourcing?

When evaluating the costs associated with sourcing C-channel platforms, several critical components contribute to the overall price structure. These include:

-

Materials: The type of steel used—whether carbon, stainless, or galvanized—significantly affects pricing. Galvanized steel, while more expensive, offers superior corrosion resistance, making it a preferred choice for projects exposed to harsh environments.

-

Labor: Labor costs can vary based on the region and the complexity of manufacturing processes. For instance, skilled labor is often required for the precise fabrication of custom dimensions and specifications.

-

Manufacturing Overhead: This includes costs related to running machinery, utilities, and facility maintenance. Efficient manufacturing processes can help reduce overhead costs, ultimately impacting the price offered to buyers.

-

Tooling: Initial setup costs for tooling can be substantial, particularly for customized products. Buyers should consider these costs when negotiating prices, especially for lower volume orders.

-

Quality Control (QC): Ensuring that products meet industry standards is crucial. The costs associated with quality assurance can be a significant factor in the pricing of C-channel platforms, particularly when certifications are required for international projects.

-

Logistics: Shipping costs can vary greatly depending on the destination, shipping method, and Incoterms. For international buyers, understanding these logistics costs is essential for accurate budgeting.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business viability. This margin can fluctuate based on market demand, competition, and the supplier’s operational efficiencies.

How Do Price Influencers Impact C-Channel Platform Sourcing?

Several factors influence the pricing of C-channel platforms, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often yield lower per-unit costs, making it beneficial for buyers to consolidate orders when possible.

-

Specifications and Customization: Customized dimensions or specifications can lead to higher costs due to additional labor and tooling expenses. Buyers should weigh the necessity of customization against the potential cost implications.

-

Materials Quality and Certifications: High-quality materials and certifications (e.g., ISO standards) can increase costs. Buyers should consider the long-term value of investing in quality that meets industry regulations, especially in safety-critical applications.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may command higher prices due to their proven track record and quality assurance processes.

-

Incoterms: Understanding the terms of delivery and responsibility for costs (e.g., shipping, insurance) can impact the total landed cost of C-channel platforms. Buyers should negotiate favorable Incoterms to avoid unexpected expenses.

What Are the Best Negotiation Tips for International B2B Buyers?

Navigating the complexities of C-channel platform pricing requires strategic negotiation techniques:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, durability, and potential downtime. This holistic view can justify higher upfront costs for better quality.

-

Leverage Volume for Discounts: If feasible, consolidate orders to achieve higher volumes. Suppliers are often more willing to negotiate better pricing for larger orders.

-

Request Transparency: Ask suppliers to break down their pricing structure. Understanding the cost components can provide insights into areas where you might negotiate for better terms.

-

Consider Local Suppliers: For international buyers, sourcing from local suppliers can reduce shipping costs and lead times. Evaluate the trade-offs between quality, price, and logistical advantages.

-

Be Aware of Currency Fluctuations: Exchange rate volatility can impact pricing for international transactions. Consider negotiating prices in a stable currency to mitigate this risk.

Conclusion

Sourcing C-channel platforms involves navigating a complex landscape of costs and pricing influencers. By understanding the underlying cost components, negotiating effectively, and evaluating the total cost of ownership, international B2B buyers can make informed decisions that align with their project needs and budget constraints. Always keep in mind that prices can fluctuate based on market conditions, so it’s prudent to seek multiple quotes and stay informed about industry trends.

Alternatives Analysis: Comparing c channel platform With Other Solutions

Understanding Alternatives in C-Channel Platform Solutions

When evaluating the best structural solutions for construction and industrial applications, it is essential to consider various alternatives to the C-channel platform. These alternatives can offer different benefits and drawbacks based on specific project requirements, such as performance, cost, and ease of implementation. This analysis will compare the C-channel platform against two prominent alternatives: I-beam structures and hollow structural sections (HSS).

Comparison Table

| Comparison Aspect | C Channel Platform | I-Beam Structures | Hollow Structural Sections (HSS) |

|---|---|---|---|

| Performance | High strength-to-weight ratio; versatile | Excellent load-bearing capacity; ideal for beams and trusses | Strong, lightweight, and resistant to torsion |

| Cost | Generally cost-effective; varies by size and material | Higher material costs; more expensive to fabricate | Moderate costs; depends on thickness and material |

| Ease of Implementation | Simple to install; requires standard tools | Requires specialized equipment for handling and installation | May need custom fittings for specific applications |

| Maintenance | Low maintenance; corrosion-resistant options available | Moderate maintenance; susceptible to corrosion without treatment | Minimal maintenance; durable and corrosion-resistant |

| Best Use Case | Ideal for scaffolding and support structures | Best for beams and heavy load applications | Suitable for architectural and structural framing |

Detailed Breakdown of Alternatives

I-Beam Structures

I-beams, known for their distinctive “I” shape, provide exceptional load-bearing capabilities, making them a popular choice for structural applications. Their design allows for efficient distribution of weight, which is particularly beneficial in large-scale construction projects. However, the cost of I-beams can be higher due to material and fabrication expenses. Moreover, installation may require specialized equipment and expertise, which could increase labor costs. Despite these challenges, I-beams excel in scenarios where heavy loads are a primary concern.

Illustrative image related to c channel platform

Hollow Structural Sections (HSS)

Hollow structural sections, including square and rectangular tubing, offer a unique combination of strength and aesthetic appeal. Their enclosed shape provides excellent resistance to torsion, making them suitable for dynamic loads. HSS can be more cost-effective than I-beams in certain applications, particularly when considering their strength-to-weight ratio. However, they may require custom fittings and connectors, complicating the installation process. HSS is often used in modern architectural designs where both form and function are critical.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right structural solution, whether it be a C-channel platform, I-beam, or hollow structural section, depends on various project-specific factors. B2B buyers should consider the performance requirements, budget constraints, and installation capabilities when making their decision. It is crucial to evaluate the long-term maintenance implications and the intended application of the structure. By understanding the strengths and weaknesses of each alternative, buyers can make informed choices that align with their operational needs and project goals.

Essential Technical Properties and Trade Terminology for c channel platform

What Are the Key Technical Properties of C-Channel Platforms That B2B Buyers Should Know?

Understanding the essential technical properties of C-channel platforms is crucial for B2B buyers in various industries, especially in construction and manufacturing. Here are some critical specifications to consider:

1. Material Grade

C-channel platforms are often made from materials like carbon steel, stainless steel, or galvanized steel. The material grade determines the strength, weight, and corrosion resistance of the product. For example, galvanized steel is often preferred for outdoor applications due to its resistance to rust. Selecting the right material grade can enhance durability and reduce maintenance costs, making it a vital consideration for long-term projects.

2. Tolerance

Tolerance refers to the allowable variation in dimensions and shapes of the C-channel components. For instance, a tolerance of ±1mm means the actual size can vary by one millimeter from the specified measurement. High tolerance levels ensure that components fit together correctly, leading to improved structural integrity and safety. In B2B transactions, understanding tolerance helps buyers ensure compatibility with other components in their projects.

3. Load Capacity

Load capacity indicates how much weight a C-channel platform can support without compromising its structural integrity. This property is essential in applications like scaffolding, where safety is paramount. Buyers should assess the load capacity based on their specific use case, ensuring the chosen C-channel can handle expected loads without failure.

4. Coating Finish

The coating finish, such as electro-galvanization or powder coating, impacts the C-channel’s resistance to environmental factors. A good coating can prevent corrosion and extend the lifespan of the platform. For international buyers, especially in regions with harsh climates, understanding the benefits of different finishes can inform better purchasing decisions, ensuring longevity and reliability.

Illustrative image related to c channel platform

5. Dimensions and Customization Options

C-channel platforms come in various sizes and thicknesses to meet specific project requirements. Customization options allow buyers to specify dimensions that fit their unique applications, whether for scaffolding, machinery, or construction frameworks. Knowing the available sizes can help buyers avoid delays and additional costs associated with modifications after purchase.

6. Weight

The weight of the C-channel affects not only the ease of handling during installation but also the overall structural design of the project. Lighter options may be easier to transport and assemble, while heavier options might provide greater stability. Buyers must balance the need for strength with practical considerations such as transportation and installation logistics.

What Are the Common Trade Terms Related to C-Channel Platforms?

Familiarizing yourself with industry jargon can enhance communication and negotiation in B2B transactions. Here are several key terms relevant to C-channel platforms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality, as well as gauge compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can help in budgeting and inventory planning. It also affects purchasing decisions, especially for smaller companies that may not require large volumes.

Illustrative image related to c channel platform

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This process is vital for comparing offers and ensuring that buyers receive competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international transactions to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers manage logistics and costs effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for project planning and can influence supplier selection, especially for projects with tight deadlines.

Illustrative image related to c channel platform

6. Certification

Certification indicates that a product meets specific industry standards or regulations. For C-channel platforms, certifications may include safety and quality standards, which are essential for compliance and assurance of product performance.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their project needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the c channel platform Sector

What Are the Current Market Dynamics and Key Trends in the C-Channel Platform Sector?

The global market for C-channel platforms is experiencing significant growth driven by various factors, including rapid urbanization, infrastructure development, and an increasing demand for lightweight yet durable construction materials. In regions like Africa, South America, the Middle East, and Europe, the need for efficient building solutions has led to a surge in the adoption of C-channel steel for diverse applications ranging from scaffolding to structural frameworks. Key trends shaping this market include the integration of advanced manufacturing technologies such as automation and precision engineering, which enhance product quality and reduce lead times.

Moreover, the growing emphasis on safety in construction practices is pushing companies to source high-quality C-channel products that meet international standards. Buyers are increasingly looking for suppliers who can provide not only competitive pricing but also innovative solutions that can be customized to specific project requirements. Furthermore, digital transformation is reshaping the sourcing landscape; B2B buyers are leveraging e-commerce platforms and digital tools to streamline procurement processes and improve decision-making.

How Is Sustainability Influencing Sourcing Trends in the C-Channel Sector?

Sustainability has emerged as a critical consideration in the sourcing of C-channel platforms. The construction industry is under increasing pressure to minimize its environmental impact, and ethical sourcing practices are becoming essential for B2B buyers. Companies are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as utilizing recycled materials and implementing energy-efficient manufacturing processes.

The use of galvanized or stainless steel in C-channel products enhances their durability and resistance to corrosion, thereby extending the lifespan of construction projects and reducing the need for frequent replacements. Additionally, B2B buyers are seeking materials that are certified by recognized green standards, which can not only improve project sustainability but also enhance brand reputation in the eyes of environmentally conscious clients. Implementing these sustainable sourcing strategies not only aligns with global efforts to combat climate change but also provides a competitive advantage in an increasingly eco-aware market.

What Is the Brief Evolution of the C-Channel Platform and Its Relevance to B2B Buyers?

The C-channel platform has evolved significantly since its inception in the early 20th century. Initially used primarily in heavy construction and industrial applications, advancements in steel manufacturing and design have expanded its utility across various sectors, including residential construction and transportation. The introduction of high-strength, lightweight materials has further enhanced the versatility of C-channel products, allowing for innovative applications that cater to modern engineering demands.

For B2B buyers, understanding the historical context of C-channel platforms is essential. It highlights the material’s enduring reliability and adaptability, reinforcing its relevance in today’s market. As buyers navigate an increasingly competitive landscape, recognizing the evolution of C-channel solutions will aid in making informed purchasing decisions that align with both current needs and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of c channel platform

-

How do I ensure the quality of C-channel platforms from suppliers?

To ensure the quality of C-channel platforms, start by vetting suppliers through their certifications and quality assurance processes. Look for ISO certifications or industry-specific standards that indicate adherence to quality control. Request samples to assess material quality and manufacturing precision. Additionally, inquire about their testing protocols for structural integrity and durability, especially if you’re sourcing from regions with different manufacturing standards. Regular audits and third-party inspections can also help maintain quality across shipments. -

What is the best C-channel steel for construction projects?

The best C-channel steel for construction depends on the specific application and environmental conditions. Galvanized steel is ideal for projects exposed to moisture, as it offers corrosion resistance, while carbon steel provides excellent strength for structural support. For projects requiring flexibility and durability, stainless steel is a good choice, although it may come at a higher cost. Always consider the load requirements, environmental factors, and any applicable building codes when selecting the appropriate C-channel steel. -

What are the typical minimum order quantities (MOQ) for C-channel platforms?

Minimum order quantities (MOQ) for C-channel platforms can vary significantly by supplier and region. Typically, MOQs range from 100 to 500 units, depending on the size, material, and customization options. For larger suppliers, higher MOQs may be required to ensure production efficiency. However, some manufacturers may offer flexibility for smaller projects or initial orders. Always discuss MOQs upfront to avoid unexpected costs or delays in your procurement process. -

How can I customize C-channel platforms for my specific needs?

Customizing C-channel platforms often involves adjusting dimensions, coatings, or additional features such as pre-drilled holes for easy assembly. Most manufacturers are equipped to handle customization requests; however, it’s essential to communicate your specifications clearly. Provide detailed drawings or examples of what you need, and inquire about the lead times for custom orders. Be aware that customization may impact pricing and MOQs, so factor these into your planning. -

What payment terms should I expect when sourcing C-channel platforms internationally?

Payment terms for international purchases of C-channel platforms can vary widely based on the supplier’s policies and your relationship with them. Common practices include a deposit (often 30% to 50%) upon order confirmation, with the balance due prior to shipping. Some suppliers may offer net 30 or net 60 terms for established customers. Always negotiate terms that protect your interests, and consider using escrow services or letters of credit for larger transactions to mitigate risk. -

What are the logistics considerations for importing C-channel platforms?

When importing C-channel platforms, consider freight options, shipping costs, and customs regulations in your country. Ensure your supplier has experience with international shipping and can provide the necessary documentation, such as bills of lading and customs declarations. Additionally, factor in the lead time for production and shipping, as international orders may take longer than domestic ones. Collaborating with a freight forwarder can help streamline logistics and ensure compliance with import regulations. -

How do I verify the credibility of a C-channel platform supplier?

To verify a supplier’s credibility, start by checking their online presence, including customer reviews and case studies. Look for certifications and industry affiliations that demonstrate their commitment to quality. Request references from previous clients and follow up to gauge their satisfaction. Additionally, consider visiting the supplier’s facility if possible, or request a virtual tour. Engaging in direct communication to assess responsiveness and transparency can also provide valuable insights into their reliability. -

What are the common applications for C-channel platforms in various industries?

C-channel platforms are widely used in construction, manufacturing, and transportation industries. They serve as structural supports in scaffolding, frameworks for machinery, and components in transport vehicles. Their versatility allows them to be employed in applications requiring strength and flexibility, such as bridges, industrial shelving, and support beams. Understanding the specific needs of your industry will help you select the right type of C-channel platform to optimize performance and safety.

Top 3 C Channel Platform Manufacturers & Suppliers List

1. Fractal Designs – Steel C Channel Bar

Domain: fractaldesigns.ca

Registered: 2019 (6 years)

Introduction: Product Name: Steel C Channel Bar

Variants:

– 24″ / 1″ – $25.00

– 24″ / 5/8″ – $25.00

– 36″ / 1″ – $29.00

– 36″ / 5/8″ – $29.00

– 40″ / 1″ – $32.00

– 40″ / 5/8″ – $32.00

– 48″ / 1″ – $34.00

– 48″ / 5/8″ – $34.00

Material: Steel, powder coated black

Features: Heavy-duty construction, designed to provide stability and support for tables

Recommended Hardware: Rampa Inserts and Bolts (M5 inserts requ…

2. Skind – C Channel Iron

Domain: skind.com.sg

Registered: 2023 (2 years)

Introduction: C channel iron, also known as C steel channel, is a type of steel profile characterized by a cross-section shaped like the letter ‘C.’ It is used in various construction applications including framing, supports, brackets, fencing, and landscaping. Key applications include:

1. Framing: Used as vertical and horizontal members in structural frameworks, wall studs, and roof trusses, particularly in op…

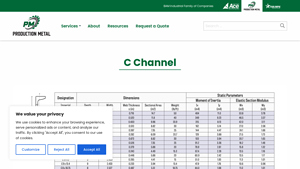

3. BAMIND Group – C Channel Steel Products

Domain: bamindgrp.com

Registered: 2024 (1 years)

Introduction: C Channel is a structural steel product characterized by a vertical web and horizontal top and bottom flanges. It is available in a wide range of sizes and web thicknesses, typically made from A36 carbon steel. This shape provides significant structural strength, making it ideal for frames, bracing, and structural support.

Strategic Sourcing Conclusion and Outlook for c channel platform

In today’s competitive landscape, strategic sourcing for C-channel platforms is essential for international B2B buyers seeking to enhance operational efficiency and ensure project success. Key takeaways emphasize the importance of selecting high-quality materials, such as galvanized steel, which offer durability and corrosion resistance—vital for long-term investments in construction and industrial applications. Understanding the unique properties of C-channel steel, including its strength-to-weight ratio and versatility, allows buyers to tailor their sourcing strategies to specific project requirements.

As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable and innovative sourcing solutions will only grow. B2B buyers are encouraged to leverage strategic partnerships with manufacturers who demonstrate a commitment to quality assurance and customer service. By adopting a proactive sourcing approach, businesses can not only mitigate risks but also capitalize on emerging opportunities in their respective markets.

Looking ahead, the integration of advanced manufacturing techniques and sustainable practices will play a pivotal role in shaping the future of C-channel platforms. Now is the time for international buyers to engage with trusted suppliers, ensuring they stay ahead in a rapidly changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.