B.W. Rogers Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for b.w. rogers

In the complex landscape of international procurement, sourcing high-quality automation solutions from B.W. Rogers can present significant challenges for B2B buyers. With a reputation for excellence in fluid power, motion control, and process equipment, B.W. Rogers stands out as a trusted distributor and integrator. This guide is designed to equip you with essential insights on the various types of products available, their applications across diverse industries, and effective strategies for supplier vetting.

Navigating the global market requires an understanding of both regional dynamics and the specific needs of your business. Whether you are operating in Nigeria’s burgeoning manufacturing sector or Saudi Arabia’s expansive energy market, knowing how to assess the cost, quality, and reliability of suppliers is crucial. This comprehensive guide empowers international B2B buyers from Africa, South America, the Middle East, and Europe to make informed purchasing decisions that align with their operational goals.

By delving into aspects such as product categories, application scenarios, and supplier evaluation criteria, this resource will help you streamline your sourcing process. As you explore the offerings of B.W. Rogers, you will gain valuable knowledge to enhance your procurement strategies and ensure that your automation systems perform flawlessly in your unique operational context.

Understanding b.w. rogers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fluid Power Distributor | Specializes in hydraulic and pneumatic components. | Manufacturing, automotive, aerospace | Pros: Wide product range, expert support. Cons: Potentially higher costs for premium products. |

| Automation Integrator | Designs and implements custom automated control systems. | Process automation, assembly lines | Pros: Tailored solutions, improved efficiency. Cons: Complexity in integration and higher initial investment. |

| Hose and Fitting Supplier | Offers a variety of hoses and custom fittings for industries. | Agriculture, construction, industrial | Pros: Versatile product offerings, local expertise. Cons: Limited to specific applications and industries. |

| Industrial Equipment Supplier | Provides a range of industrial power tools and equipment. | Construction, manufacturing, maintenance | Pros: Comprehensive solutions, reliable brands. Cons: May require extensive product knowledge for optimal selection. |

| Technical Account Management | Personalized service with dedicated account managers. | All sectors requiring ongoing support | Pros: Enhanced customer relationship, tailored service. Cons: Availability may vary by region. |

What Are the Key Characteristics of Fluid Power Distributors?

Fluid power distributors like B.W. Rogers specialize in hydraulic and pneumatic components, serving industries such as manufacturing, automotive, and aerospace. These distributors typically carry products from leading manufacturers, ensuring quality and reliability. B2B buyers should consider factors like product availability, technical support, and pricing structures when selecting a distributor. While they offer a comprehensive range of components, buyers may face higher costs for premium products.

How Do Automation Integrators Enhance Operational Efficiency?

Automation integrators focus on designing and implementing custom automated control systems tailored to specific business needs. They are crucial in sectors like process automation and assembly lines, where efficiency and precision are paramount. B2B buyers should assess the integrator’s expertise, previous projects, and post-installation support. Although these solutions can significantly enhance productivity, the complexity of integration and higher initial investments may be a consideration for some businesses.

What Should Buyers Know About Hose and Fitting Suppliers?

Hose and fitting suppliers provide essential products for various industries, including agriculture, construction, and industrial applications. They offer a wide selection of hoses and custom fittings, ensuring optimal performance and reliability. When purchasing, B2B buyers should evaluate the supplier’s expertise, product range, and customer service. While these suppliers can meet diverse needs, they may be limited to specific applications, which could impact broader project requirements.

What Are the Benefits of Working with Industrial Equipment Suppliers?

Industrial equipment suppliers, such as B.W. Rogers, offer a comprehensive range of power tools and equipment crucial for construction, manufacturing, and maintenance sectors. These suppliers often feature reliable brands and provide solutions that enhance operational effectiveness. B2B buyers should consider the supplier’s reputation, product quality, and after-sales service. However, selecting the right equipment may require extensive product knowledge, which could be a barrier for some organizations.

Why Is Technical Account Management Important in B2B Relationships?

Technical account management involves personalized service provided by dedicated account managers who understand the specific needs of their clients. This approach is beneficial across all sectors requiring ongoing support and tailored solutions. B2B buyers should look for suppliers who offer this level of service, as it can enhance customer relationships and ensure that products and services align with business goals. However, the availability of such services may vary by region, which can influence purchasing decisions.

Key Industrial Applications of b.w. rogers

| Industry/Sector | Specific Application of b.w. rogers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Automated Control Systems | Enhanced productivity and efficiency in operations | Reliability of components, customization options, lead times |

| Food and Beverage | Fluid Power Solutions for Processing Equipment | Improved consistency and quality in production | Compliance with hygiene standards, compatibility with existing systems |

| Steel and Metal Fabrication | Hydraulic and Pneumatic Components for Machinery | Increased operational uptime and reduced maintenance costs | Durability of materials, availability of technical support |

| Automotive | Motion Control Systems for Assembly Lines | Streamlined production processes and reduced labor costs | Precision engineering, scalability of solutions, after-sales service |

| Energy and Power Generation | Fluid Connectors and Process Equipment | Optimized energy efficiency and reduced downtime | Product certifications, reliability under extreme conditions, local support availability |

How Does B.W. Rogers Enhance Manufacturing Operations?

B.W. Rogers specializes in creating custom automated control systems that streamline manufacturing processes. By evaluating existing systems, they design tailored solutions that enhance productivity and operational efficiency. For international B2B buyers, particularly in regions like Africa and South America, the ability to source reliable automation components that can be customized for local manufacturing needs is crucial. Ensuring these systems are compatible with existing infrastructure can significantly reduce implementation time and costs.

What Role Does B.W. Rogers Play in the Food and Beverage Sector?

In the food and beverage industry, B.W. Rogers provides fluid power solutions that are essential for processing equipment. These solutions help maintain product consistency and quality, which are critical in a competitive market. For buyers in the Middle East and Europe, sourcing components that comply with strict hygiene standards while ensuring compatibility with existing systems is vital. B.W. Rogers’s experience in this sector allows them to offer tailored solutions that meet these specific requirements.

How Are Hydraulic and Pneumatic Components Beneficial in Steel and Metal Fabrication?

In steel and metal fabrication, B.W. Rogers supplies hydraulic and pneumatic components that enhance the efficiency of machinery. These components are designed to increase operational uptime and lower maintenance costs, providing significant value to manufacturers. Buyers from Europe and Africa should consider the durability of materials and the availability of technical support when sourcing these components, as they operate in demanding environments that require reliable performance.

Why Are Motion Control Systems Important for Automotive Production?

B.W. Rogers offers advanced motion control systems that streamline assembly line processes in the automotive industry. These systems can significantly reduce labor costs while improving production speed and accuracy. For B2B buyers in regions like Saudi Arabia and South America, selecting precision-engineered solutions that can scale with production demands is essential. The after-sales service and support provided by B.W. Rogers further enhance the value of these systems.

How Does B.W. Rogers Support Energy and Power Generation Industries?

In the energy and power generation sectors, B.W. Rogers provides fluid connectors and process equipment that optimize energy efficiency and reduce downtime. For international buyers, sourcing reliable and certified products that can withstand extreme conditions is critical. B.W. Rogers’s commitment to quality and local support availability ensures that businesses can maintain operational integrity and efficiency, making them a trusted partner in these industries.

3 Common User Pain Points for ‘b.w. rogers’ & Their Solutions

Scenario 1: Delays in Supply Chain for Critical Components

The Problem: B2B buyers often face the challenge of delays in the supply chain, especially when sourcing critical components such as hydraulic hoses and pneumatic systems from B.W. Rogers. These delays can stem from various factors, including production backlogs or international shipping issues. Such interruptions not only halt production lines but can also lead to significant financial losses and strain relationships with clients who depend on timely deliveries.

The Solution: To mitigate supply chain delays, buyers should establish a proactive communication strategy with B.W. Rogers. This involves maintaining regular contact with account managers to receive updates on stock levels and anticipated delivery times. Additionally, buyers can consider leveraging B.W. Rogers’ extensive network of locations to source products from the nearest office, reducing shipping time. It may also be beneficial to order in bulk or set up automatic reordering for essential components to ensure inventory levels remain consistent and to avoid last-minute rush orders.

Scenario 2: Difficulty in Customizing Automation Solutions

The Problem: Many B2B buyers struggle with the customization of automation solutions to meet specific operational requirements. This is particularly true for industries such as food and beverage, where precise control over processes is crucial. Buyers may find it challenging to communicate their unique needs and may not be aware of the full range of customization options available from B.W. Rogers.

The Solution: To effectively customize automation solutions, buyers should engage in a thorough needs assessment with B.W. Rogers’ technical account managers. This collaborative approach allows buyers to articulate their requirements clearly, enabling B.W. Rogers to design tailored solutions. Buyers should also consider requesting a site evaluation, where B.W. Rogers can assess current systems and recommend enhancements. Utilizing B.W. Rogers’ engineering capabilities ensures that the solutions not only fit current needs but are also scalable for future growth.

Scenario 3: Navigating Complex Product Offerings

The Problem: The vast array of products offered by B.W. Rogers can be overwhelming for B2B buyers, particularly those new to the automation and fluid power industries. Buyers may find it difficult to select the right components that align with their operational needs, leading to potential mispurchases and wasted resources.

The Solution: To navigate B.W. Rogers’ product offerings effectively, buyers should take advantage of the company’s educational resources and consultative services. Engaging in training sessions or product demos can provide insights into the functionality and application of various products. Buyers should also create a checklist of specific requirements before consulting with B.W. Rogers, allowing for a more focused discussion. Additionally, utilizing B.W. Rogers’ online resources, such as product catalogs and technical specifications, can empower buyers to make informed decisions that suit their operational needs.

By addressing these common pain points with tailored solutions, B2B buyers can enhance their purchasing experience with B.W. Rogers, ensuring smoother operations and stronger business outcomes.

Strategic Material Selection Guide for b.w. rogers

What Are the Key Properties of Common Materials Used by B.W. Rogers?

B.W. Rogers leverages various materials to meet the diverse needs of its clients in fluid power, motion control, and automation sectors. Understanding the properties and applications of these materials is crucial for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Industrial Applications?

Steel is a staple material in the manufacturing of hydraulic and pneumatic components due to its exceptional strength and durability. Key properties include high tensile strength, good temperature resistance (up to 300°C), and moderate corrosion resistance, especially when treated with coatings.

Pros: Steel’s durability makes it ideal for high-pressure applications, ensuring long-term performance. Its cost-effectiveness in bulk manufacturing also appeals to buyers.

Cons: However, steel can be prone to rust if not properly coated, which limits its use in corrosive environments. Additionally, its weight can be a disadvantage in applications where weight reduction is critical.

Impact on Application: Steel is compatible with a variety of media, including hydraulic fluids and gases, making it versatile for various industrial applications.

Considerations for International Buyers: Buyers must ensure compliance with international standards such as ASTM A36 or DIN EN 10025. In regions like Nigeria and Saudi Arabia, local sourcing and treatment standards may also apply.

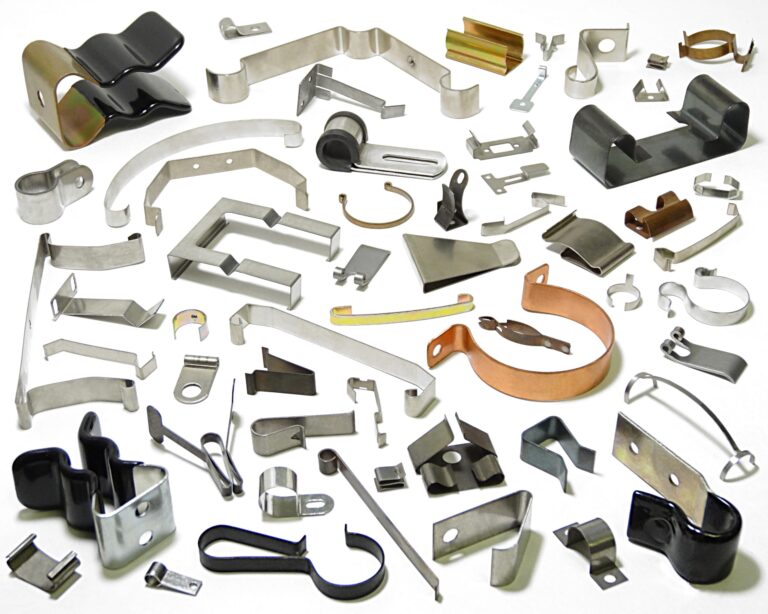

Illustrative image related to b.w. rogers

What Advantages Does Aluminum Offer for Automation Systems?

Aluminum is increasingly favored in automation systems due to its lightweight nature and excellent corrosion resistance. It typically performs well in temperatures up to 150°C and is non-magnetic, which is beneficial in certain applications.

Pros: The lightweight characteristic of aluminum allows for easier handling and installation, reducing overall project costs. Its corrosion resistance makes it suitable for humid and coastal environments.

Cons: While aluminum is strong, it is not as robust as steel, which may limit its use in high-stress applications. Additionally, its higher cost compared to steel can be a factor for budget-conscious buyers.

Impact on Application: Aluminum is compatible with various media, including water and air, but may not be suitable for highly abrasive substances.

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM B221 for aluminum extrusions. In Europe, EN standards may also apply, and buyers should be aware of local preferences for aluminum grades.

Why is Polyurethane a Preferred Material in Hose Manufacturing?

Polyurethane is commonly used in hoses and tubing due to its flexibility and resistance to abrasion and chemicals. It can withstand temperatures ranging from -40°C to 80°C, making it suitable for various environments.

Pros: The flexibility and lightweight nature of polyurethane hoses make them easy to install and maneuver. They also exhibit excellent resistance to wear and tear, extending their lifespan.

Cons: However, polyurethane may not perform well under extreme temperatures or in applications involving high-pressure steam. Additionally, its cost can be higher than traditional rubber hoses.

Impact on Application: Polyurethane hoses are compatible with a wide range of media, including oils, fuels, and air, making them ideal for diverse industrial applications.

Considerations for International Buyers: Compliance with standards like ASTM D412 for rubber properties is essential. Buyers from regions like South America should also consider local regulations regarding chemical compatibility.

What Role Does Stainless Steel Play in Food and Beverage Applications?

Stainless steel is a critical material in the food and beverage industry due to its hygienic properties and resistance to corrosion. It typically withstands temperatures up to 500°C and offers excellent resistance to a variety of chemicals.

Pros: Its non-reactive nature ensures that it does not contaminate food products, making it ideal for food processing applications. Additionally, stainless steel’s durability leads to lower maintenance costs over time.

Cons: The primary drawback is its higher cost compared to carbon steel and other materials. Fabrication can also be more complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with food-grade media, ensuring safety and compliance with health regulations.

Considerations for International Buyers: Buyers must ensure compliance with food safety standards such as FDA regulations in the U.S. or EFSA standards in Europe. Additionally, understanding local preferences for specific grades, such as 304 or 316 stainless steel, is crucial.

Summary Table of Material Selection for B.W. Rogers

| Material | Typical Use Case for b.w. rogers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Hydraulic and pneumatic components | High strength and durability | Prone to rust if untreated | Medium |

| Aluminum | Automation systems | Lightweight and corrosion-resistant | Less robust than steel | High |

| Polyurethane | Hoses and tubing | Flexible and abrasion-resistant | Not suitable for high-temperature | Medium |

| Stainless Steel | Food and beverage applications | Hygienic and non-reactive | Higher cost and complex fabrication | High |

This strategic material selection guide provides actionable insights for international B2B buyers, ensuring they make informed decisions based on material properties, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for b.w. rogers

What Are the Main Stages in the Manufacturing Process at B.W. Rogers?

B.W. Rogers employs a comprehensive manufacturing process that ensures high-quality products tailored to various industrial applications. The process can be divided into several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials that meet industry standards. B.W. Rogers focuses on materials that are durable and suitable for the intended application, such as hydraulic and pneumatic components. Proper inventory management ensures that materials are readily available, minimizing delays in production.

-

Forming: During the forming stage, raw materials are shaped into components using techniques such as machining, molding, or extrusion. B.W. Rogers utilizes advanced machinery and technology to enhance precision and efficiency. This stage is crucial as it determines the structural integrity and functionality of the components produced.

-

Assembly: In the assembly phase, individual components are put together to create complete systems. B.W. Rogers emphasizes meticulous assembly processes to ensure that every product meets rigorous performance standards. Skilled technicians oversee this stage, employing both automated systems and manual labor to achieve the desired results.

-

Finishing: The final stage involves surface treatments and quality checks to enhance durability and aesthetics. Finishing processes may include painting, coating, or polishing, depending on the product requirements. This stage not only improves the product’s appearance but also adds a layer of protection against environmental factors.

Which Key Techniques Are Utilized in B.W. Rogers’ Manufacturing?

B.W. Rogers employs various advanced manufacturing techniques to optimize efficiency and product quality. Key techniques include:

-

Lean Manufacturing: This approach minimizes waste and maximizes productivity by streamlining processes. It involves continuous improvement practices that enhance operational efficiency.

-

Automation: The use of automated systems in material handling and assembly reduces human error and increases production speed. B.W. Rogers integrates automation to ensure precision and consistency across its product lines.

-

Computer-Aided Design (CAD): CAD software is used for designing components and systems, enabling accurate modeling and simulation before production. This technique allows for quick adjustments and optimizations in design, ensuring that products meet client specifications.

What International Standards Guide Quality Assurance at B.W. Rogers?

B.W. Rogers is committed to maintaining high standards of quality assurance, adhering to both international and industry-specific standards. Key standards include:

-

ISO 9001: This internationally recognized standard focuses on quality management systems, ensuring that B.W. Rogers consistently meets customer expectations and regulatory requirements. Compliance with ISO 9001 indicates a commitment to continuous improvement and customer satisfaction.

-

CE Marking: For products marketed in the European Union, CE marking demonstrates compliance with health, safety, and environmental protection standards. This is crucial for international buyers in Europe, as it assures that products meet stringent EU requirements.

-

API Standards: The American Petroleum Institute (API) sets standards for equipment used in the oil and gas industry. B.W. Rogers ensures that its products align with API standards, making them suitable for demanding applications in this sector.

How Does B.W. Rogers Implement Quality Control Throughout the Manufacturing Process?

B.W. Rogers employs a robust quality control (QC) framework that includes multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial QC stage involves inspecting raw materials upon arrival. B.W. Rogers conducts tests and assessments to ensure that all materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are carried out at various stages to identify and rectify any deviations from quality standards. This proactive approach minimizes defects and ensures that the final product meets quality expectations.

-

Final Quality Control (FQC): Once production is complete, the final QC stage involves thorough testing and inspection of finished products. This includes functional testing, dimensional checks, and any additional assessments based on the specific application of the product.

What Common Testing Methods Are Used to Ensure Product Quality?

B.W. Rogers employs a variety of testing methods to validate the quality and performance of its products:

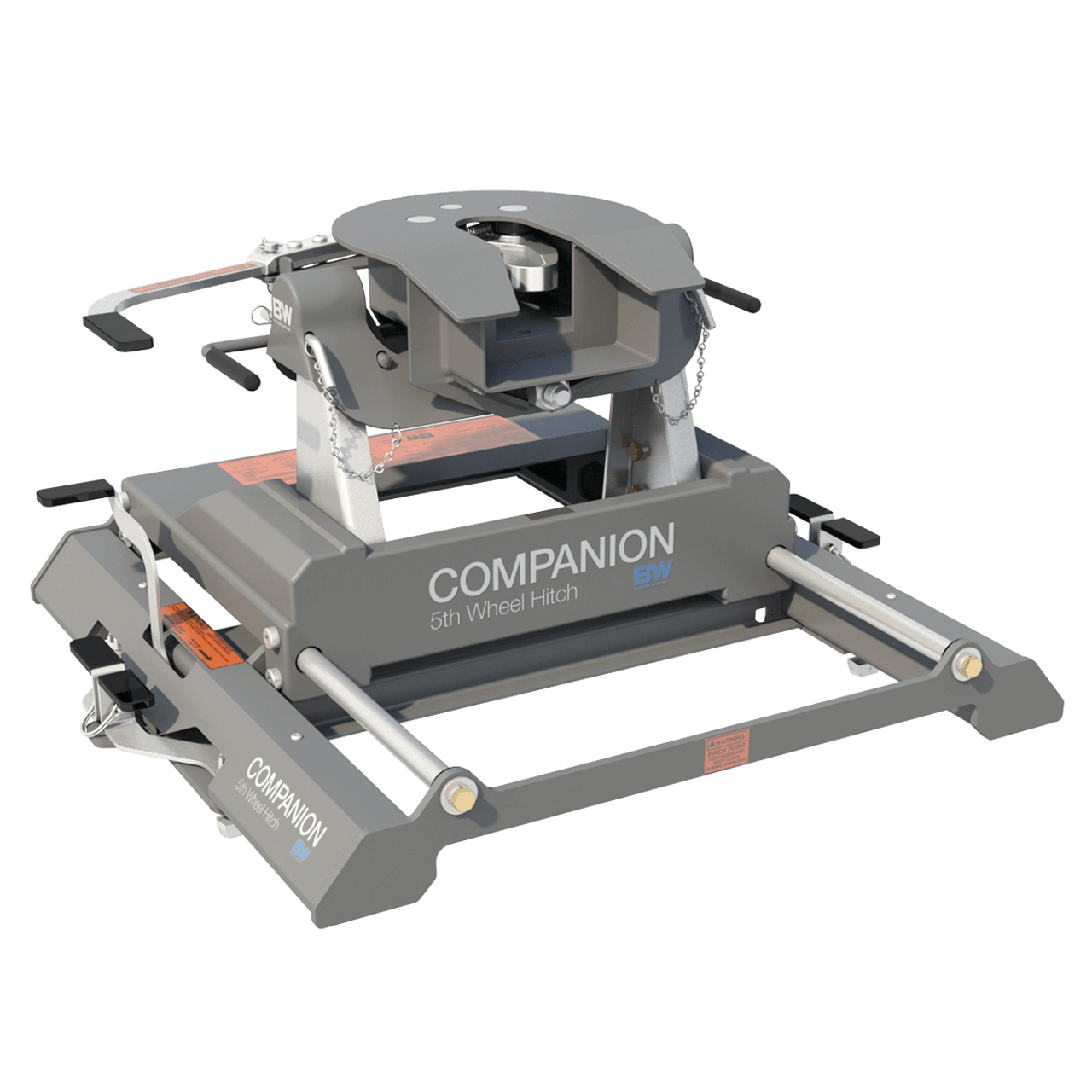

Illustrative image related to b.w. rogers

-

Hydraulic Testing: This method assesses the integrity and performance of hydraulic components under pressure, ensuring they can withstand operational demands.

-

Leak Testing: For pneumatic and fluid power components, leak testing is crucial to verify that there are no leaks, ensuring reliability in performance.

-

Performance Testing: Products are subjected to various operational tests to ensure they meet performance specifications under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps:

-

Conduct Audits: Buyers can request on-site audits to review the manufacturing and QC processes. This provides firsthand insight into the supplier’s operations and adherence to quality standards.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including results from IQC, IPQC, and FQC stages. Regular reports can help buyers assess ongoing compliance.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an objective evaluation of the supplier’s quality practices. These inspectors can verify compliance with industry standards and regulations.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from different regions may encounter various nuances when it comes to quality control:

-

Regulatory Compliance: Understanding the specific regulatory requirements in their region is crucial. For instance, products supplied to the EU must meet CE marking requirements, while buyers in other regions may have different standards.

-

Cultural Expectations: Different cultures may have varying expectations regarding product quality and supplier relationships. Buyers should communicate clearly about their quality requirements and ensure that suppliers understand these expectations.

-

Logistics and Supply Chain Considerations: Ensuring product quality during transportation is vital. Buyers should discuss packaging and handling procedures with suppliers to minimize the risk of damage during shipping.

In conclusion, B.W. Rogers exemplifies a commitment to quality through its meticulous manufacturing processes and robust quality assurance framework. For international B2B buyers, understanding these processes and standards is critical for making informed purchasing decisions and ensuring product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘b.w. rogers’

To assist international B2B buyers in effectively sourcing products and services from B.W. Rogers, this practical guide outlines essential steps to ensure a successful procurement process. By following this checklist, buyers can streamline their sourcing efforts while mitigating risks associated with international transactions.

Step 1: Define Your Technical Specifications

Before engaging with B.W. Rogers, it’s critical to outline your specific technical requirements. This includes identifying the types of automation, fluid power systems, or motion control solutions you need. Clear specifications help in communicating your needs effectively and ensure that the products you procure align with your operational goals.

- Consider application requirements: Are you in need of hydraulic components, pneumatic systems, or custom automation solutions?

- Determine compatibility: Ensure that the specifications align with your existing systems to avoid integration issues.

Step 2: Conduct Market Research on B.W. Rogers

Gain a comprehensive understanding of B.W. Rogers and its offerings by researching the company and its market position. Look into their product range, industry reputation, and customer feedback.

- Explore their website: Review the available product catalogs and technical documentation.

- Evaluate case studies: Assess previous projects to understand their capabilities and industry expertise.

Step 3: Evaluate Supplier Certifications

Verification of certifications is essential to ensure compliance with industry standards. B.W. Rogers should hold relevant certifications that reflect their quality and safety standards.

- Request documentation: Ask for copies of certifications such as ISO or industry-specific qualifications.

- Understand their partners: Familiarize yourself with the manufacturers they represent, such as Parker Hannifin, to gauge product quality.

Step 4: Engage with Technical Account Managers

B.W. Rogers employs technical account managers who can provide valuable insights into product selection and system integration. Engaging with these professionals can clarify technical doubts and enhance your sourcing strategy.

- Schedule a consultation: Discuss your project requirements and seek tailored recommendations.

- Inquire about support services: Understand the after-sales support and warranty options available for the products.

Step 5: Request Samples and Prototypes

Before making bulk purchases, it’s prudent to request samples or prototypes of the products. This allows you to assess quality and performance firsthand.

- Evaluate performance: Test the products in your operational environment to ensure they meet your expectations.

- Gather feedback: Involve your technical team in the evaluation process to gain diverse insights.

Step 6: Negotiate Pricing and Terms

Once you are satisfied with the product quality, engage in negotiations regarding pricing, delivery timelines, and payment terms. Effective negotiation can lead to better pricing structures and favorable terms.

- Compare quotes: Analyze offers from B.W. Rogers and other suppliers to ensure competitive pricing.

- Discuss bulk discounts: If you plan to purchase large volumes, inquire about potential discounts or loyalty programs.

Step 7: Finalize the Purchase Agreement

After negotiations, ensure that all terms are documented in a formal purchase agreement. This should include product specifications, pricing, delivery schedules, and payment terms.

Illustrative image related to b.w. rogers

- Review the contract: Ensure that all agreed-upon terms are included and that there are no hidden clauses.

- Confirm delivery logistics: Coordinate the shipping details, especially if you are importing products internationally.

By adhering to this checklist, B2B buyers can streamline their sourcing process with B.W. Rogers, ensuring they procure high-quality products that meet their operational needs while fostering a strong supplier relationship.

Comprehensive Cost and Pricing Analysis for b.w. rogers Sourcing

What Are the Key Cost Components for Sourcing from B.W. Rogers?

When considering sourcing from B.W. Rogers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The cost of raw materials is a significant factor, especially since B.W. Rogers sources from leading manufacturers in various industries such as hydraulic and pneumatic components. Prices may vary based on material quality, market demand, and supplier relationships.

-

Labor: Labor costs encompass the wages paid to skilled technicians and engineers involved in the design and assembly of custom automated control systems. This cost can fluctuate based on regional labor rates and the complexity of the required solutions.

-

Manufacturing Overhead: This includes utilities, rent, and other indirect costs associated with maintaining operational facilities. B.W. Rogers operates multiple locations, which can impact overhead allocation depending on regional operational efficiencies.

-

Tooling: The investment in specialized tools and equipment necessary for production can influence pricing. Custom tooling may incur additional costs, particularly for specialized projects.

-

Quality Control (QC): Ensuring product reliability and compliance with industry standards necessitates robust QC processes, which can add to the overall cost. Certifications and testing may also be required, impacting pricing structures.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. These expenses can vary based on shipment size, distance, and chosen Incoterms, affecting the final cost to the buyer.

-

Margin: B.W. Rogers typically applies a markup to cover operational costs and profit margins. Understanding their pricing strategy can help buyers assess the value received relative to costs.

How Do Price Influencers Affect Sourcing Decisions with B.W. Rogers?

Several factors can influence the pricing structure for B.W. Rogers products:

-

Volume and Minimum Order Quantity (MOQ): Larger orders may qualify for volume discounts. Understanding the MOQ can help buyers optimize costs, especially in regions where bulk purchasing is feasible.

-

Specifications and Customization: Custom solutions often come at a premium. Buyers should clearly define their specifications to avoid unexpected costs associated with changes or custom tooling.

-

Material Quality and Certifications: Higher-quality materials typically demand higher prices. Buyers should assess the importance of certifications relevant to their industries, which may also influence costs.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Long-term partnerships may yield better pricing due to established trust and reduced risk.

-

Incoterms: The chosen Incoterms dictate responsibility for shipping, insurance, and tariffs. Understanding these terms can help buyers manage total costs effectively.

What Are Essential Buyer Tips for Cost-Efficiency in International Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are key strategies to enhance cost-efficiency:

-

Negotiation Strategies: Engage in open discussions with B.W. Rogers to negotiate pricing based on your specific needs and order volumes. Demonstrating a willingness to establish a long-term relationship may yield better terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost associated with sourcing, including logistics, maintenance, and potential downtime. A lower initial cost may not always equate to a better value.

-

Understanding Pricing Nuances: Be aware that international pricing may include tariffs and taxes that can affect overall costs. Ensure to factor these into your budget when sourcing from B.W. Rogers.

-

Leverage Local Knowledge: Collaborate with local distributors or representatives familiar with regional market conditions. They can provide insights into cost-saving opportunities and help navigate the complexities of international trade.

-

Requesting Quotes: Regularly solicit quotes to keep abreast of market trends and price changes. This practice will empower buyers to make timely decisions and negotiate effectively.

Disclaimer

The prices and cost structures mentioned are indicative and subject to change based on market conditions, exchange rates, and specific buyer requirements. Always consult directly with B.W. Rogers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing b.w. rogers With Other Solutions

When considering automation and fluid power solutions, it’s essential for B2B buyers to explore various options to determine which best suits their specific operational needs. B.W. Rogers Co. is a well-regarded supplier in this space, but several alternatives may offer competitive advantages based on different criteria such as performance, cost, and maintenance requirements.

Illustrative image related to b.w. rogers

Comparison Table

| Comparison Aspect | B.W. Rogers | Parker Hannifin | SMC Corporation |

|---|---|---|---|

| Performance | High-quality fluid power systems | Industry-leading solutions | Strong in pneumatic applications |

| Cost | Moderate pricing | Higher due to brand value | Competitive pricing |

| Ease of Implementation | Requires skilled integration | User-friendly solutions | Quick setup and installation |

| Maintenance | Regular service needed | Low maintenance required | Moderate maintenance needs |

| Best Use Case | Custom automation systems | Comprehensive fluid power applications | Efficient pneumatic control systems |

Detailed Breakdown of Alternatives

Parker Hannifin

Parker Hannifin is a premier provider of motion and control technologies, offering a broad range of hydraulic, pneumatic, and electromechanical components. One of its significant advantages is its strong reputation for reliability and performance across multiple industries, including aerospace, automotive, and manufacturing. However, their products often come at a premium price, which could be a deterrent for budget-conscious buyers. Additionally, while Parker solutions are generally user-friendly, the integration of complex systems may still require specialized knowledge.

SMC Corporation

SMC Corporation specializes in pneumatic technology and offers a wide array of products designed for efficient automation. Their solutions are known for quick setup and ease of integration, making them an excellent choice for businesses looking to streamline operations rapidly. The competitive pricing of SMC products also appeals to a diverse range of industries. However, while SMC excels in pneumatic applications, they may not provide as comprehensive a solution for fluid power systems as B.W. Rogers, potentially limiting their effectiveness in certain applications.

Conclusion: How to Choose the Right Solution for Your Business Needs

Selecting the right solution among B.W. Rogers and its alternatives requires a careful assessment of your specific operational demands and budget constraints. B2B buyers should consider factors such as the primary application (fluid power vs. pneumatic control), the importance of brand reputation, and the availability of technical support for implementation. Additionally, understanding the total cost of ownership, including maintenance and potential downtime, will help inform a more strategic purchasing decision. By weighing these elements, buyers can find a solution that not only meets their immediate needs but also supports their long-term business goals.

Essential Technical Properties and Trade Terminology for b.w. rogers

What Are the Key Technical Properties Relevant to B.W. Rogers Products?

Understanding the technical specifications of products offered by B.W. Rogers is crucial for B2B buyers in industries such as fluid power, automation, and motion control. Here are some essential properties that influence decision-making:

Illustrative image related to b.w. rogers

-

Material Grade: This refers to the quality and type of materials used in manufacturing components, such as hydraulic hoses or pneumatic fittings. High-grade materials ensure durability and reliability, which are vital for systems operating under high pressure or in demanding environments. For B2B buyers, selecting products with appropriate material grades can minimize maintenance costs and enhance system longevity.

-

Pressure Rating: This specification indicates the maximum pressure a component can withstand without failure. For example, hydraulic hoses often have pressure ratings that vary based on their application. Understanding these ratings helps buyers ensure that components will perform safely and effectively in their specific operational settings.

-

Tolerance Levels: Tolerance refers to the allowable deviation from specified dimensions in components. High tolerance levels are critical in automation systems where precision is essential for performance. B2B buyers must consider tolerance when selecting parts to avoid issues in assembly and functionality, which can lead to costly downtime.

-

Flow Rate: This metric measures the volume of fluid that can pass through a component within a certain timeframe. In hydraulic and pneumatic systems, flow rates directly affect performance efficiency. Buyers need to match flow rates with system requirements to optimize operations and reduce energy consumption.

-

Temperature Range: The operational temperature range defines the conditions under which a product can function effectively. For industries dealing with extreme temperatures, selecting components that can withstand these conditions is essential to prevent failures. B2B buyers should always verify that products meet their specific environmental requirements.

What Are Common Trade Terms in the B.W. Rogers Industry?

Familiarity with industry terminology can enhance communication and negotiation between B2B buyers and suppliers. Here are several essential trade terms relevant to B.W. Rogers:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For B.W. Rogers, this means they may supply components that are integrated into larger systems made by other companies. Understanding OEM relationships can help buyers evaluate product reliability and support.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases and avoid overstocking or stockouts.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is a strategic step in the procurement process, enabling them to compare offers and negotiate better deals.

-

Incoterms (International Commercial Terms): These are a set of predefined rules published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers engaged in cross-border trade, as they define who bears the risks and costs associated with shipping.

-

Lead Time: This term refers to the time it takes from placing an order to receiving it. For B2B buyers, understanding lead times is essential for planning production schedules and managing project timelines. Efficient lead time management can significantly impact a company’s operational efficiency.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing products from B.W. Rogers, ensuring that they select components that meet their specific operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the b.w. rogers Sector

What Are the Current Market Dynamics and Key Trends Affecting the B.W. Rogers Sector?

In the rapidly evolving landscape of industrial automation and fluid power, several global drivers are shaping the market dynamics for B.W. Rogers and its international clientele. Key among these is the increasing demand for automation solutions across various sectors, including manufacturing, food and beverage, and automotive industries. With the global push towards smart factories, international B2B buyers are seeking advanced automation technologies that enhance operational efficiency and reduce costs.

Emerging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics are becoming central to sourcing decisions. These technologies enable real-time data analytics and predictive maintenance, allowing businesses to optimize their systems and workflows. For buyers in regions like Africa and South America, where industrial growth is on the rise, leveraging these technologies can lead to significant competitive advantages.

Moreover, sustainability is becoming a non-negotiable aspect of sourcing strategies. As regulations tighten and consumers demand greener solutions, companies are increasingly prioritizing suppliers that demonstrate environmental responsibility. For B.W. Rogers, this means focusing on the development of eco-friendly products and processes, aligning with the global trend toward sustainable industrial practices.

How Important Is Sustainability and Ethical Sourcing in the B.W. Rogers Sector?

Sustainability and ethical sourcing are critical considerations for B.W. Rogers and its international B2B buyers. The environmental impact of industrial operations is under scrutiny, making it essential for companies to adopt sustainable practices. Buyers from regions like the Middle East and Europe are particularly keen on sourcing from suppliers that prioritize eco-friendly materials and processes.

B.W. Rogers can enhance its market position by obtaining relevant sustainability certifications and utilizing green materials in its product offerings. Certifications such as ISO 14001 for environmental management systems can serve as a strong selling point, reassuring buyers of the company’s commitment to reducing its ecological footprint.

Furthermore, ethical supply chains are gaining traction. Buyers are increasingly interested in understanding the origin of materials and the ethical practices of suppliers. This demand not only reflects consumer preferences but also aligns with global trends toward corporate social responsibility. B.W. Rogers has the opportunity to differentiate itself by ensuring transparency in its supply chain and by collaborating with manufacturers who uphold high ethical standards.

What Is the Evolution and History of B.W. Rogers in the B2B Market?

B.W. Rogers has a storied history in the fluid power and automation sectors, evolving to meet the changing needs of industry since its inception. Established in Akron, Ohio, the company has expanded its reach significantly, now serving clients across various sectors with a robust portfolio of hydraulic, pneumatic, and automation products.

The acquisition of B.W. Rogers by Kaman in 2014 marked a significant milestone, enhancing its capabilities and market presence. This strategic move allowed B.W. Rogers to leverage Kaman’s extensive distribution network and technological resources, positioning it to better meet the demands of a global clientele. Today, B.W. Rogers continues to innovate, focusing on custom automation solutions that address the specific needs of its customers, making it a trusted partner for international B2B buyers seeking quality and reliability in their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of b.w. rogers

-

How do I source high-quality automation products from B.W. Rogers?

To source high-quality automation products from B.W. Rogers, begin by visiting their official website to explore their extensive catalog of products, including motion control and fluid power solutions. Connect with a technical account manager who can provide tailored recommendations based on your specific industry needs. Additionally, consider scheduling a consultation to discuss your project requirements in detail, ensuring you receive the most suitable solutions for your operations. -

What types of industries does B.W. Rogers serve?

B.W. Rogers caters to a diverse range of industries, including automotive, food and beverage, life sciences, power generation, and steel manufacturing. Their expertise in fluid power and automation solutions makes them a preferred partner for companies looking to enhance production efficiency and system reliability. If your industry is not listed, it’s worth reaching out directly to discuss how their products can be adapted for your specific needs. -

What is the minimum order quantity (MOQ) for B.W. Rogers products?

The minimum order quantity (MOQ) for products from B.W. Rogers can vary based on the specific item and application. It is advisable to contact their sales team directly to inquire about MOQs for the products you are interested in. They can provide detailed information tailored to your order size, ensuring you can plan your procurement effectively while meeting any project deadlines. -

What payment terms does B.W. Rogers offer for international buyers?

B.W. Rogers typically provides flexible payment terms for international buyers, which may include options such as credit terms, wire transfers, or letters of credit. The exact terms can depend on the size of the order and the buyer’s creditworthiness. To ensure a smooth transaction, it is recommended to discuss payment options upfront with their sales department to establish terms that work for both parties. -

How does B.W. Rogers ensure quality assurance in their products?

B.W. Rogers implements rigorous quality assurance protocols throughout their supply chain. They work exclusively with leading manufacturers known for their high standards in hydraulic, pneumatic, and automation components. Regular audits and testing of products ensure compliance with industry standards, providing clients with confidence in the reliability and performance of their systems. -

What logistics solutions does B.W. Rogers provide for international shipping?

B.W. Rogers partners with reputable logistics companies to facilitate international shipping, ensuring timely delivery of products worldwide. They can assist in navigating customs regulations and provide guidance on shipping methods that best suit your needs, whether air or sea freight. For specific shipping inquiries, it is best to contact their logistics team to discuss your requirements and get detailed shipping estimates. -

Can B.W. Rogers customize products for specific applications?

Yes, B.W. Rogers offers customization options for various products to meet specific application needs. Their engineering team can collaborate with you to design solutions tailored to your operational requirements, whether it involves modifying existing products or creating entirely new systems. This flexibility allows businesses to optimize their processes and achieve better efficiency. -

How can I vet B.W. Rogers as a reliable supplier?

To vet B.W. Rogers as a reliable supplier, consider their industry reputation, years of experience, and customer testimonials. Additionally, request references from other businesses in your sector who have worked with them. Engaging in direct communication with their team can also provide insights into their customer service and responsiveness, helping you assess their capability to meet your needs effectively.

Top 6 B.W. Rogers Manufacturers & Suppliers List

1. B.W. Rogers Co. – Motion Control & Automation Solutions

Domain: localautomation.com

Registered: 2005 (20 years)

Introduction: B.W. Rogers Co. is a premier regional supplier of products used in motion control, fluid power, process equipment, fluid connectors, and industrial power tools. They evaluate existing industrial systems and engineer, design, and build custom automated control systems for cost-effective production solutions. They utilize leading manufacturers in hydraulic, pneumatic, electromechanical, lubrication,…

2. B.W. Rogers Jr. CPA – Comprehensive Accounting & Tax Services

Domain: bwrogerscpa.com

Registered: 2017 (8 years)

Introduction: B.W. Rogers Jr. CPA, LLC offers a range of accounting and tax services including Tax Planning & Return Preparation, Payroll, Financial Planning, Estates & Trusts, Accounting & Bookkeeping, Business Entity Selection, Corporate & Partnership Returns, Management Advisory Services, and Electronic Tax Filing. They provide personalized service with a one-on-one approach and have over 30 years of experie…

3. BW Rogers – Automation Products

Domain: directory.designnews.com

Registered: 1995 (30 years)

Introduction: BW Rogers is a distributor of automation products including robotics, electromechanical devices, motion controllers, pneumatics, hydraulics, process equipment, fluid connectors, and assembly tools.

4. B.W. Rogers Company – Fluid Power Products

Domain: cbinsights.com

Registered: 2009 (16 years)

Introduction: B.W. Rogers Company is a broad line distributor of fluid power products, including hydraulic hoses, fittings, pumps, motors, cylinders, valves, pneumatics, machine control, and automation products. They are one of the largest distributors of Parker Hannifin motion and control products and also market products from other premium manufacturers such as Advantech, Phoenix Contact, and Wooster Hydrosta…

5. BW ROGERS – Air Filters

Domain: voomisupply.com

Registered: 2019 (6 years)

Introduction: This company, BW ROGERS – Air Filters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. B.W. Rogers – Centrifugal and Submersible Pumps

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: B.W. Rogers is a distributor of centrifugal pumps and submersible pumps, representing a number of high-quality pump manufacturers.

Strategic Sourcing Conclusion and Outlook for b.w. rogers

B.W. Rogers stands as a pivotal player in the automation and fluid power sectors, providing tailored solutions that enhance operational efficiency across diverse industries. Their commitment to quality, coupled with an extensive portfolio of products from leading manufacturers, positions them as a reliable partner for businesses looking to optimize their processes. By leveraging strategic sourcing, companies can access high-quality components and innovative automation solutions that drive productivity while minimizing costs.

For international B2B buyers, particularly from emerging markets such as Nigeria, Saudi Arabia, and across South America and Europe, engaging with B.W. Rogers offers a unique opportunity to tap into advanced technologies and expertise. Their local presence combined with a robust support network ensures that clients receive personalized service and expert guidance in sourcing the right solutions for their specific needs.

As industries worldwide continue to evolve, the importance of strategic sourcing cannot be overstated. By partnering with B.W. Rogers, businesses can stay ahead of the curve, ensuring they are equipped with the best tools and systems to thrive in a competitive landscape. Don’t miss the chance to enhance your operations—connect with B.W. Rogers today and explore the potential of innovative automation solutions tailored to your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.