Butn Barrel Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for butn barrel

In today’s competitive landscape, sourcing the right burn barrel can present a unique challenge for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe, understanding the nuances of burn barrels—including their types, applications, and safety features—is critical for making informed purchasing decisions. This guide serves as an essential resource, addressing key considerations such as material selection, design efficiency, and compliance with local regulations.

As you navigate the global market for burn barrels, you will discover various models tailored for specific applications, from waste incineration to backyard burning needs. We’ll delve into the importance of supplier vetting, ensuring that you partner with reputable manufacturers who prioritize quality and safety in their products. Additionally, the guide covers cost factors, enabling you to budget effectively while maximizing value.

By providing a comprehensive overview of the burn barrel market, this guide empowers you to make strategic choices that align with your operational goals. Whether you’re in Saudi Arabia seeking durable solutions or in Vietnam looking for environmentally friendly options, the insights offered here will help you secure the best products to meet your business needs. Equip yourself with the knowledge to confidently navigate the complexities of sourcing burn barrels in a globalized economy.

Understanding butn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Steel Barrel | Typically made of heavy-gauge steel, 55-gallon capacity, robust design | Waste management, outdoor burning, agricultural waste disposal | Pros: Durable, cost-effective; Cons: Can rust over time, may require modifications for optimal airflow |

| Stainless Steel Barrel | Corrosion-resistant, high-temperature tolerance, often custom designs | High-end waste incineration, chemical disposal, food processing | Pros: Long-lasting, easy to clean; Cons: Higher upfront cost, limited availability |

| Vortex Burn Barrel | Features enhanced airflow design, multiple ventilation holes, cylindrical shape | Efficient burning of yard waste, industrial waste management | Pros: Improved combustion efficiency, reduced smoke; Cons: Requires assembly, may need maintenance for airflow optimization |

| Incinerator Barrel | Advanced technology for high-temperature burning, often includes accessories | Document destruction, hazardous waste management, medical waste disposal | Pros: Cleaner burn, reduces environmental impact; Cons: Higher investment, requires specific operational knowledge |

| Plastic Burn Barrel | Made from high-density polyethylene, lightweight, resistant to chemicals | Safe burning of non-toxic materials, portable waste management solutions | Pros: Lightweight, resistant to rust; Cons: Less durable than metal barrels, may not withstand high heat |

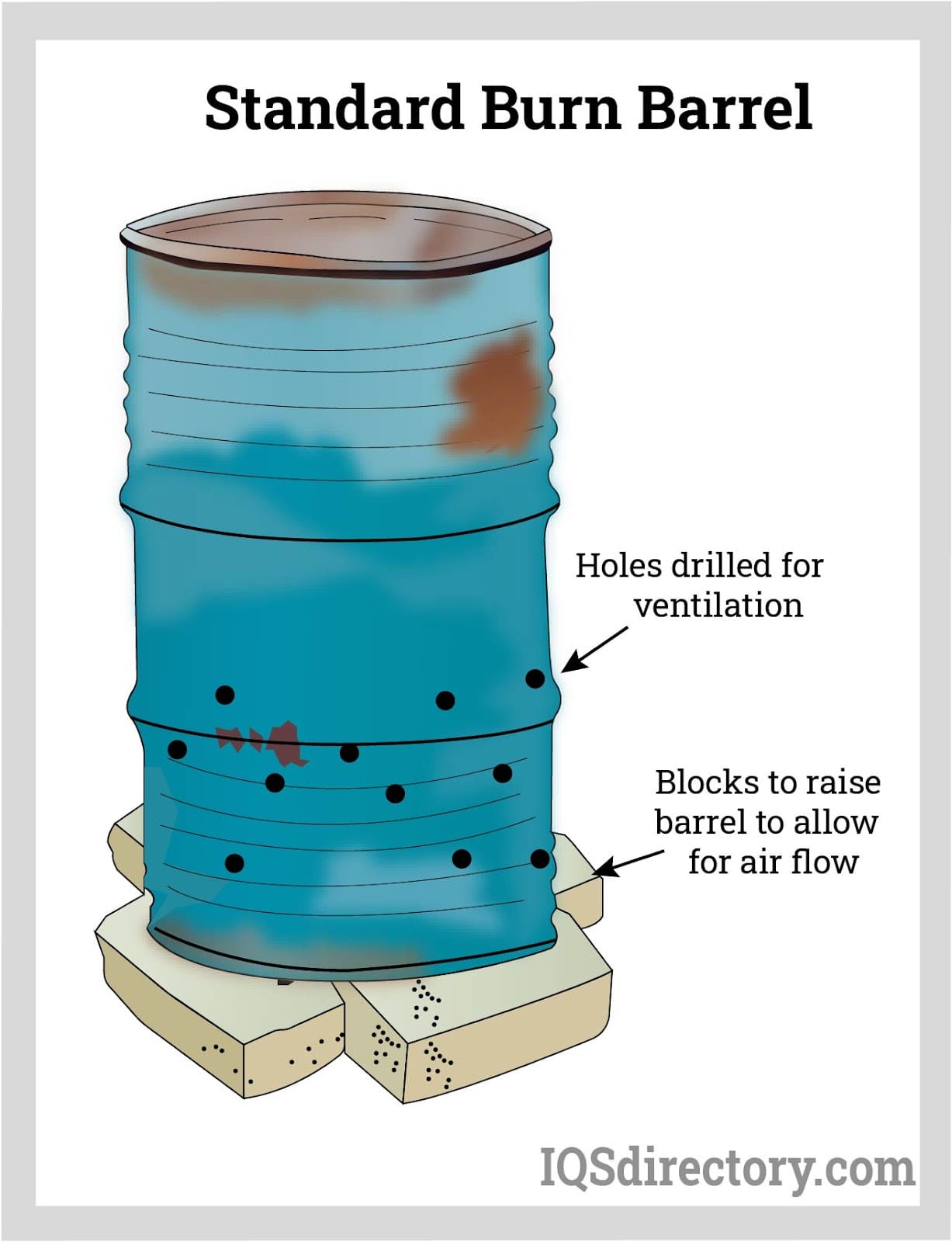

What are the characteristics of a Standard Steel Barrel?

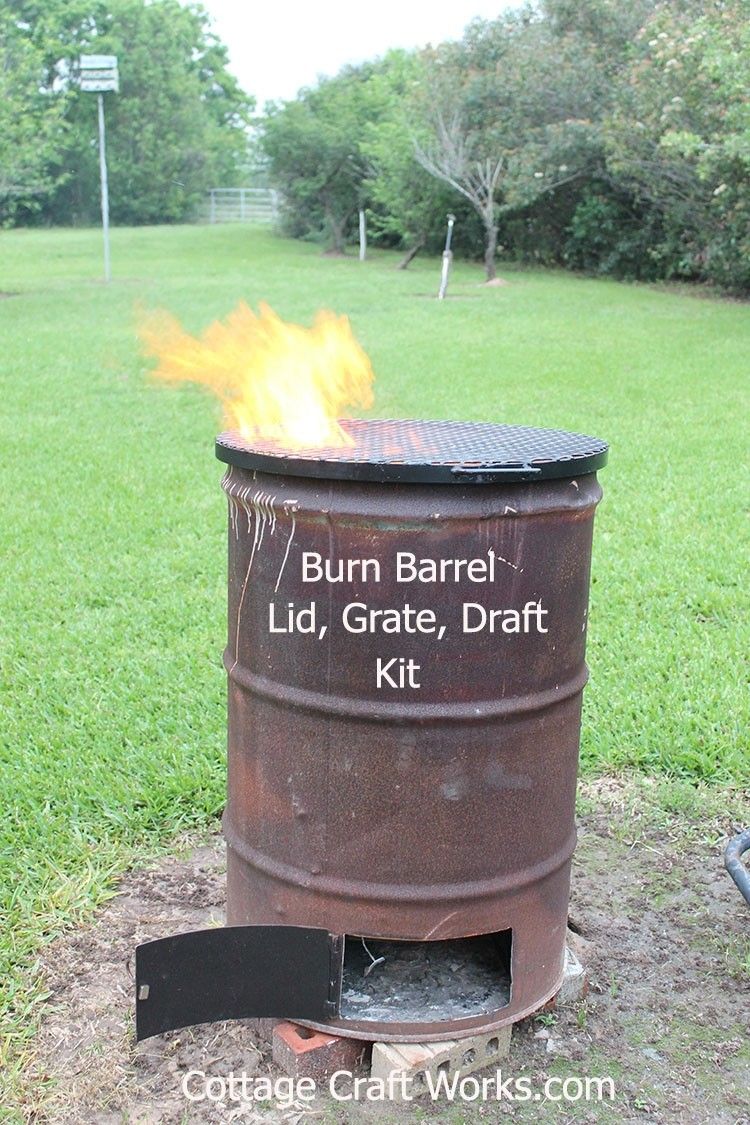

Standard steel barrels are the most commonly used type for burning waste. Typically constructed from heavy-gauge steel, these barrels have a capacity of 55 gallons, making them suitable for various waste management applications, particularly in agricultural settings. Buyers should consider their durability and cost-effectiveness; however, they may require modifications, such as drilling air holes, to enhance burning efficiency. Over time, they can rust, which might necessitate periodic replacements or maintenance.

How does a Stainless Steel Barrel compare to other options?

Stainless steel barrels are designed to withstand corrosion and high temperatures, making them ideal for demanding applications like chemical disposal and food processing. Their longevity and ease of cleaning make them a preferred choice for businesses looking for a reliable waste management solution. While the initial investment may be higher compared to standard steel barrels, their durability and performance can lead to cost savings in the long run, especially in environments where rust and wear are concerns.

What makes the Vortex Burn Barrel an efficient choice?

The Vortex burn barrel is engineered with an innovative airflow design that maximizes combustion efficiency. With multiple ventilation holes and a cylindrical shape, it significantly reduces smoke emissions, making it an environmentally friendly option for burning yard and industrial waste. While this design enhances burning performance, it may require assembly and ongoing maintenance to ensure optimal airflow. B2B buyers should evaluate their waste types and burning needs to determine if this model aligns with their operational goals.

Illustrative image related to butn barrel

When should you consider an Incinerator Barrel?

Incinerator barrels are equipped with advanced technology that allows for high-temperature burning, making them suitable for sensitive waste types, including medical and hazardous materials. They often come with accessories that enhance their functionality, such as ash catchers and covers. Although they involve a higher upfront investment, the cleaner burn and reduced environmental impact can justify the cost for businesses handling regulated waste. It’s crucial for potential buyers to have the necessary operational knowledge to use these barrels effectively.

What are the advantages and limitations of a Plastic Burn Barrel?

Plastic burn barrels, made from high-density polyethylene, offer a lightweight and rust-resistant alternative for burning non-toxic materials. Their portability makes them ideal for businesses requiring flexible waste management solutions. However, they are generally less durable than metal barrels and may not withstand high heat as effectively. B2B buyers should weigh the convenience of transport and storage against the potential for reduced longevity when considering plastic options for their waste disposal needs.

Key Industrial Applications of butn barrel

| Industry/Sector | Specific Application of butn barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Waste Management | Incineration of Non-Recyclable Waste | Reduces landfill use and complies with environmental regulations | Sourcing durable materials; ensuring compliance with local regulations |

| Agriculture | Burning of Crop Residue and Debris | Improves soil health by returning nutrients; reduces pest populations | Need for high-temperature resistance; availability of parts for maintenance |

| Construction | Disposal of Construction Debris | Efficient waste management on-site; reduces transportation costs | Sourcing barrels with adequate capacity; ensuring safety features |

| Food Processing | Safe disposal of Organic Waste | Minimizes health hazards and pest issues; complies with food safety standards | Sourcing from certified suppliers; ensuring proper design for organic materials |

| Oil and Gas | Incineration of Hazardous Materials | Ensures safe disposal of waste; mitigates environmental risks | Need for barrels designed for hazardous waste; compliance with safety regulations |

How is the butn barrel utilized in waste management?

In the waste management sector, butn barrels serve as effective incinerators for non-recyclable waste. They facilitate the reduction of landfill dependency and help companies comply with stringent environmental regulations. International buyers, particularly in Africa and South America, should focus on sourcing durable materials that can withstand high temperatures and ensure compliance with local waste disposal laws. Additionally, understanding the local regulatory framework is crucial to avoid penalties.

What role does the butn barrel play in agriculture?

In agriculture, butn barrels are used for burning crop residue and debris, a practice that enriches soil health by returning nutrients and controlling pest populations. This method is particularly beneficial in regions like the Middle East, where water scarcity makes traditional composting impractical. B2B buyers in this sector should prioritize sourcing barrels that can withstand high temperatures and have features that allow for efficient airflow, optimizing the burning process and minimizing smoke emissions.

Illustrative image related to butn barrel

How can construction companies benefit from using butn barrels?

Construction companies utilize butn barrels for the on-site disposal of construction debris, streamlining waste management processes and reducing transportation costs. This is particularly important in Europe, where regulations around construction waste are stringent. When sourcing butn barrels for construction purposes, buyers should consider the barrel’s capacity and safety features, ensuring they meet the demands of high-volume waste disposal while adhering to safety standards.

In what ways do food processors use butn barrels?

Food processing facilities often rely on butn barrels for the safe disposal of organic waste, minimizing health hazards and pest issues associated with decomposing materials. This is critical for compliance with food safety standards, especially in regions like Europe where regulations are stringent. Buyers in the food sector should source barrels from certified suppliers and ensure that the design accommodates organic materials, promoting effective and safe waste disposal.

How do oil and gas industries utilize butn barrels for hazardous materials?

In the oil and gas sector, butn barrels are essential for the incineration of hazardous materials, ensuring safe and environmentally responsible waste disposal. This application is vital in mitigating environmental risks associated with hazardous waste. International buyers in this industry must ensure that the barrels they source are specifically designed for hazardous waste, adhering to stringent safety regulations to prevent accidents and ensure compliance with environmental standards.

3 Common User Pain Points for ‘butn barrel’ & Their Solutions

Scenario 1: Inefficient Burning Leading to Increased Waste Management Costs

The Problem: Many B2B buyers, particularly in waste management and environmental services, face the challenge of using traditional burn barrels that do not facilitate efficient burning. This inefficiency often results in unburned waste, leading to increased disposal costs and environmental compliance issues. For instance, companies burning wet or bulky materials may find that their current barrels produce excessive smoke and leave behind a substantial amount of residual waste, complicating their operations and costing them more in waste management fees.

The Solution: To address this issue, companies should invest in advanced burn barrels designed for optimal airflow and combustion efficiency. For example, choosing burn barrels with enhanced ventilation systems allows for better airflow, resulting in hotter and cleaner burns. Buyers should look for features like adjustable air holes and insulated materials that can withstand high temperatures. Furthermore, when sourcing these barrels, consider the material quality—stainless steel options are preferable as they resist warping and last longer. Implementing these solutions not only reduces waste but also aligns operations with environmental regulations, ultimately cutting costs in waste disposal.

Scenario 2: Regulatory Compliance and Safety Concerns

The Problem: B2B buyers in industries such as agriculture and construction often face stringent regulations surrounding waste disposal and open burning. Non-compliance can lead to significant fines and reputational damage. Many burn barrels do not meet regulatory standards for emissions, and businesses can find themselves at risk of penalties if their burning practices are deemed unsafe or harmful to the environment. This is especially concerning in regions where environmental laws are becoming increasingly stringent.

The Solution: To mitigate this risk, buyers should prioritize sourcing burn barrels that are specifically designed to comply with local regulations. This means looking for products that have been certified for safety and emissions standards. For instance, investing in incinerators with patented designs that minimize smoke output and maximize combustion efficiency can help ensure compliance. Additionally, businesses should stay updated on local regulations regarding waste burning and seek guidance from suppliers who can provide documentation and support in meeting these requirements. This proactive approach not only ensures compliance but also enhances the company’s reputation as a responsible waste manager.

Scenario 3: Difficulty in Sourcing Durable and Cost-Effective Burn Barrels

The Problem: B2B buyers often struggle with sourcing burn barrels that are both durable and cost-effective. Many available options on the market are either too expensive for bulk purchases or fail to withstand regular use, leading to frequent replacements and increased operational costs. This challenge is particularly pertinent for businesses with high-volume waste disposal needs, such as those in the construction or agricultural sectors, where durability and reliability are paramount.

The Solution: To tackle this sourcing challenge, businesses should engage with reputable suppliers that offer customizable burn barrels tailored to specific operational needs. It’s beneficial to request samples or conduct pilot tests to evaluate the durability of products before making bulk purchases. Buyers should also consider long-term investments in high-quality materials, such as stainless steel or heavy-duty galvanized options, which may have a higher upfront cost but provide significant savings over time through reduced replacement frequency. Finally, establishing a strong relationship with suppliers can lead to better pricing and exclusive deals, further alleviating sourcing challenges while ensuring that the business is equipped with reliable burn barrels.

Illustrative image related to butn barrel

Strategic Material Selection Guide for butn barrel

What Are the Key Properties of Common Materials for Burn Barrels?

When selecting materials for burn barrels, several options are commonly considered, each with distinct properties that influence performance and suitability for specific applications. Here, we analyze four prevalent materials: steel, stainless steel, plastic, and aluminum.

Steel: The Traditional Choice

Steel is a widely used material for burn barrels due to its robustness and high-temperature resistance. It typically has a temperature rating of up to 1,200°F (649°C), making it suitable for incineration processes. The primary advantage of steel is its durability; however, it is prone to rust and corrosion when exposed to moisture unless properly coated or treated. This makes it less suitable for regions with high humidity or frequent rain.

From a B2B perspective, steel burn barrels are often more cost-effective, making them appealing for bulk purchases. However, buyers must consider their maintenance needs and the potential for reduced lifespan due to corrosion. Compliance with local environmental regulations is also crucial, as improper burning can lead to air quality issues.

Illustrative image related to butn barrel

Stainless Steel: Enhanced Durability and Performance

Stainless steel offers superior corrosion resistance compared to regular steel, withstanding high temperatures (up to 1,800°F or 982°C) without warping. This material is ideal for burn barrels intended for frequent use, as it can handle the rigors of incineration without degrading. The primary disadvantage is the higher cost associated with stainless steel, which may deter some budget-conscious buyers.

For international buyers, particularly in regions like the Middle East and Europe, stainless steel burn barrels often align with stringent environmental standards, ensuring compliance with regulations like ASTM and DIN. This makes them a preferred choice for businesses focused on sustainability and long-term investment.

Plastic: Lightweight and Cost-Effective

Plastic burn barrels, typically made from high-density polyethylene (HDPE), are lightweight and resistant to corrosion, making them suitable for various applications. They can withstand temperatures up to 200°F (93°C), which limits their use for high-heat applications. However, they are more cost-effective and easier to handle than metal options.

Illustrative image related to butn barrel

The primary downside is their lower durability under extreme conditions, which can lead to deformation or melting when exposed to high temperatures. For B2B buyers in warmer climates, such as parts of Africa and South America, understanding the limitations of plastic barrels is crucial. Additionally, compliance with local waste disposal regulations is essential to avoid penalties.

Aluminum: A Lightweight Alternative

Aluminum is another material option for burn barrels, known for its lightweight properties and resistance to rust. It can withstand temperatures similar to stainless steel but is generally less durable under extreme heat due to its lower melting point. The main advantage of aluminum is its ease of transport and handling, making it ideal for businesses that require mobility.

However, the cost of aluminum can be high, and its susceptibility to deformation under high heat can limit its application. International buyers should consider the local market demand for aluminum products and their compliance with environmental standards, especially in regions with strict waste management regulations.

Illustrative image related to butn barrel

Summary of Material Selection for Burn Barrels

| Material | Typical Use Case for burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste incineration | Cost-effective and durable | Prone to rust and corrosion | Low |

| Stainless Steel | Frequent use and high-temperature applications | Superior corrosion resistance | Higher initial investment | High |

| Plastic | Lightweight waste disposal | Lightweight and easy to handle | Limited temperature resistance | Medium |

| Aluminum | Mobile waste management solutions | Lightweight and rust-resistant | Susceptible to deformation under heat | Medium |

This guide provides actionable insights for B2B buyers in selecting the appropriate material for burn barrels, considering both performance characteristics and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for butn barrel

What Are the Key Stages in the Manufacturing Process of Burn Barrels?

The manufacturing process for burn barrels involves several critical stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

-

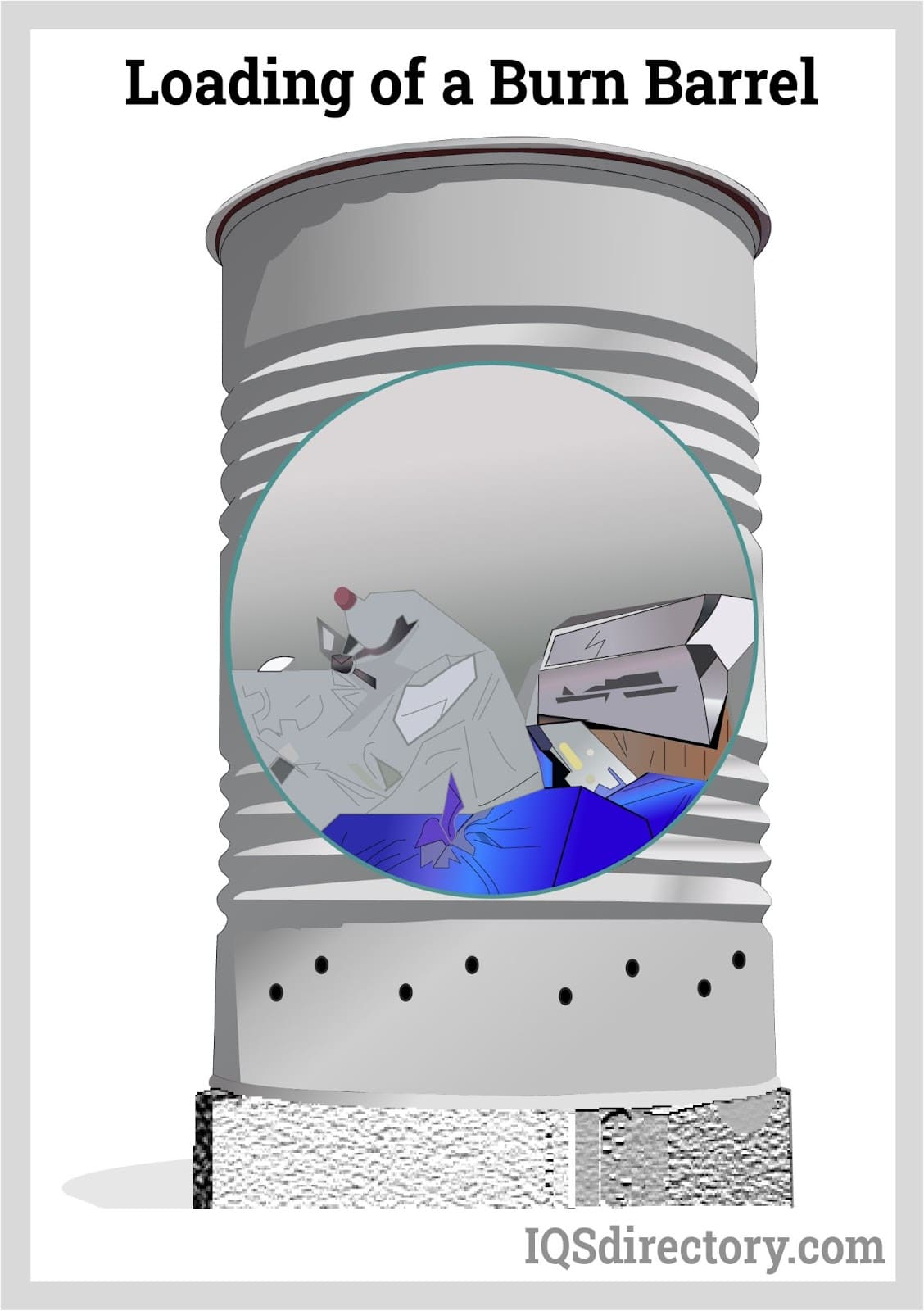

Material Preparation: The primary materials for burn barrels are typically steel or durable plastics. For steel barrels, high-quality carbon steel is often sourced to ensure strength and longevity. The material is cut to size, and any necessary treatments, such as rust prevention coatings, are applied to enhance durability.

-

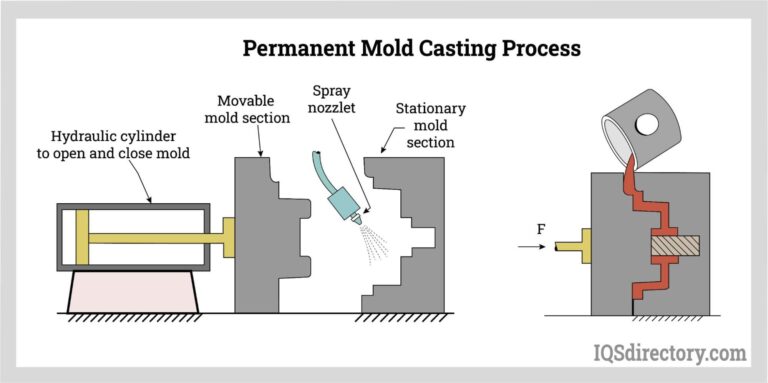

Forming: In this stage, the prepared materials are shaped into the cylindrical form characteristic of burn barrels. Techniques such as deep drawing or spinning are commonly used for metal barrels, where sheets of steel are formed into cylindrical shapes under high pressure. For plastic barrels, rotational molding may be employed, allowing for uniform thickness and strength.

-

Assembly: After forming, components such as lids, handles, and air vents are attached. This process may involve welding for metal barrels or mechanical fastening for plastic versions. Attention to detail is critical here, as proper assembly impacts the barrel’s functionality and safety.

-

Finishing: The final stage involves surface treatments, which may include painting, powder coating, or additional rust-proofing. This not only enhances aesthetics but also ensures that the barrel can withstand outdoor elements, extending its life span.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the manufacturing of burn barrels, particularly for international buyers. Understanding relevant quality standards can help ensure that the products meet safety and performance expectations.

Illustrative image related to butn barrel

-

International Standards: ISO 9001 is a widely recognized standard that outlines requirements for quality management systems. Manufacturers adhering to this standard demonstrate their commitment to consistent quality and customer satisfaction.

-

Industry-Specific Certifications: Depending on the market, additional certifications may apply. For example, CE marking is crucial for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards. In the oil and gas industry, API (American Petroleum Institute) certification may be relevant for barrels used in hazardous material handling.

What Are the Key Quality Control Checkpoints in Burn Barrel Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process to ensure that the burn barrels meet established specifications. Here are the key QC stages:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival at the manufacturing facility. Materials are checked for compliance with specifications and any defects that could affect product quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted at various stages, particularly after forming and assembly. This ensures that any deviations from standards are detected early, preventing defective products from moving forward in the production line.

-

Final Quality Control (FQC): Once the barrels are finished, a comprehensive inspection is performed. This includes checking for structural integrity, surface finishes, and functionality of all components. Testing methods such as pressure testing or burn tests may be employed to ensure performance under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those sourcing internationally, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are several strategies to consider:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control systems, and overall operational practices. This firsthand observation can provide insights into the supplier’s commitment to quality.

-

Reviewing QC Reports: Requesting detailed QC reports from the supplier can help buyers understand their quality management processes. These reports should outline testing methods, results, and any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be scheduled at various points in the manufacturing process, offering assurance that the products meet required standards before shipment.

What Are the Specific QC Considerations for International B2B Buyers?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider regarding quality control and compliance:

Illustrative image related to butn barrel

-

Understanding Regional Standards: Different regions may have specific regulations and standards that must be adhered to. Familiarizing oneself with these requirements is essential to ensure compliance and avoid potential legal issues.

-

Language and Communication Barriers: When dealing with suppliers from different countries, language barriers can complicate quality assurance processes. Ensuring clear communication and documentation can help mitigate misunderstandings regarding quality expectations.

-

Cultural Differences in Business Practices: Understanding cultural differences can play a significant role in quality assurance. Business practices and attitudes towards quality may vary significantly, impacting how quality control is prioritized and executed.

Conclusion

The manufacturing processes and quality assurance measures for burn barrels are integral to ensuring that these products meet the demands of B2B buyers. By understanding the key stages of manufacturing, relevant quality standards, and effective verification strategies, international buyers can make informed decisions when sourcing burn barrels. Emphasizing quality not only protects your investment but also enhances your reputation in the marketplace, ensuring customer satisfaction and long-term success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘butn barrel’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure burn barrels. Understanding the nuances of sourcing these products is essential for ensuring compliance, efficiency, and cost-effectiveness in your operations. From identifying specifications to evaluating suppliers, each step is designed to streamline your purchasing process.

Step 1: Define Your Technical Specifications

Clearly outline the specifications you require for the burn barrels. This includes size, material (such as steel or stainless steel), and any specific design features like airflow holes or safety mechanisms. Having defined specifications will help you communicate effectively with suppliers and ensure you receive products that meet your operational needs.

Step 2: Research Regulatory Compliance

Investigate local and international regulations regarding the use of burn barrels in your region. Different countries may have specific environmental regulations or safety standards that need to be adhered to. Ensure that your selected burn barrels comply with these regulations to avoid potential legal issues or fines.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of reliability and quality, as well as those who can provide certifications that verify their compliance with industry standards.

Illustrative image related to butn barrel

Step 4: Request Samples and Conduct Quality Checks

Ask for samples or visit the supplier’s facility to assess the quality of their burn barrels. Inspect the materials used, workmanship, and design features to ensure they align with your specifications. This step is crucial as it allows you to verify the durability and efficiency of the products before making a bulk purchase.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Look for transparency in pricing, including shipping and handling fees. Additionally, consider the payment terms offered, such as upfront payments or credit options, to manage your cash flow effectively.

Step 6: Assess After-Sales Support and Warranty Options

Evaluate the after-sales support provided by the supplier, including warranty options and customer service availability. A strong warranty can protect your investment and provide peace of mind regarding product longevity. Good after-sales support can also assist with any operational issues that may arise post-purchase.

Step 7: Finalize the Contract and Place Your Order

Once you have selected a supplier, finalize the contract by clearly outlining all terms, including delivery timelines, payment schedules, and quality expectations. Ensure both parties agree on the terms before placing your order. A well-defined contract minimizes misunderstandings and sets clear expectations for both sides, paving the way for a successful procurement process.

By following these steps, B2B buyers can confidently navigate the procurement of burn barrels, ensuring they meet their operational needs while adhering to regulatory standards.

Illustrative image related to butn barrel

Comprehensive Cost and Pricing Analysis for butn barrel Sourcing

What Are the Key Cost Components in Sourcing Burn Barrels?

When sourcing burn barrels, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Steel and stainless steel are common for burn barrels due to their durability, but they come at a higher cost compared to plastic options. The thickness of the material also affects pricing, as thicker materials offer better longevity but increase costs.

-

Labor: Labor costs vary by region and can include wages for skilled workers involved in manufacturing, welding, and assembly. Countries with lower labor costs may offer competitive pricing, but this should be balanced against quality and compliance with safety standards.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial tooling costs for custom designs can be significant. If a buyer requires specific dimensions or features, these costs need to be factored into the total price. Tooling costs can be amortized over larger orders, making higher volume purchases more cost-effective.

-

Quality Control (QC): Implementing stringent quality control measures ensures product reliability but adds to the cost. Buyers should inquire about the QC processes in place and any associated costs.

-

Logistics: Transportation costs depend on the distance, mode of transport, and the size of the shipment. Buyers should consider both domestic and international shipping logistics, as these can substantially influence total costs.

-

Margin: The supplier’s profit margin varies based on competition, market demand, and the supplier’s positioning. Understanding the market dynamics can help buyers negotiate better pricing.

What Influences Burn Barrel Pricing in the B2B Market?

Several factors influence the pricing of burn barrels, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract discounts due to economies of scale. Understanding the MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom designs or specific features (like additional air holes or specialized coatings) can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Quality and Certifications: Products that meet international safety standards or have certifications may command higher prices. Buyers should assess whether these certifications are necessary for their intended use.

-

Supplier Factors: The supplier’s reputation, reliability, and history of delivering quality products can affect pricing. Established suppliers may charge a premium but offer greater assurance of quality.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping and logistics. Understanding these terms can help buyers avoid hidden costs and ensure clarity on who bears the risk during transport.

What Are Effective Tips for Buyers to Ensure Cost-Efficiency?

-

Negotiate Wisely: Leverage your purchasing power, especially when dealing with larger volumes. Establishing a strong relationship with suppliers can lead to better pricing and terms.

-

Consider Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, operational efficiency, and lifespan when evaluating costs. A slightly higher initial investment in a durable barrel may yield savings over time.

-

Be Aware of Pricing Nuances for International Purchases: Currency fluctuations, import duties, and local taxes can significantly impact the final cost. Buyers should factor these into their budgeting to avoid surprises.

-

Research Local Market Conditions: Understanding regional market dynamics can provide insights into fair pricing and help identify potential suppliers offering competitive rates.

-

Request Samples: Before committing to large orders, request samples to assess quality. This ensures the product meets your specifications and can prevent costly returns or reorders.

By understanding the complex landscape of costs and pricing in burn barrel sourcing, international B2B buyers can make informed decisions that align with their operational needs and budgetary constraints.

Alternatives Analysis: Comparing butn barrel With Other Solutions

Understanding Alternatives to Butn Barrel Solutions

In the realm of waste management and incineration, the choice of equipment can significantly impact efficiency, cost-effectiveness, and environmental compliance. While the butn barrel serves as a popular option for burning waste, various alternatives exist that may better suit specific needs based on factors such as performance, cost, and maintenance. This analysis will compare the butn barrel with two viable alternatives: Incinerators and Burn Cages.

Illustrative image related to butn barrel

Comparison Table

| Comparison Aspect | Butn Barrel | Incinerators | Burn Cages |

|---|---|---|---|

| Performance | Moderate burn efficiency; can smolder without proper airflow | High burn efficiency; burns at over 1800°F for complete incineration | Good for yard waste; may not handle larger debris efficiently |

| Cost | Generally low-cost | Higher initial investment; long-term savings on waste disposal | Moderate cost; affordable for smaller operations |

| Ease of Implementation | Simple setup; requires minimal tools | Requires installation; may need permits | Easy to set up; portable options available |

| Maintenance | Low maintenance; occasional cleaning needed | Regular maintenance required; parts may need replacement | Low maintenance; generally durable |

| Best Use Case | Household waste and small debris | Industrial waste, medical waste, and larger volumes | Yard waste, leaves, and small branches |

Detailed Breakdown of Alternatives

Incinerators

Incinerators present a robust alternative to butn barrels, particularly for businesses that handle larger volumes or hazardous waste. With the ability to achieve higher temperatures (over 1800°F), incinerators ensure complete combustion, minimizing smoke and residue. However, they often come with a higher initial investment and may require specific permits and regular maintenance to ensure compliance with environmental regulations. For companies focused on sustainability and efficiency, incinerators can be a worthwhile investment in the long run, as they reduce waste volume significantly.

Burn Cages

Burn cages are another viable alternative, particularly suited for smaller operations dealing primarily with yard debris. These structures allow for efficient burning while promoting airflow, reducing the chance of smoldering. They are typically more portable than incinerators and easier to set up, making them appealing for businesses with limited space or those that need a mobile solution. However, burn cages may not be ideal for larger volumes or more complex waste types, as they are primarily designed for organic material.

Making the Right Choice for Your Business

When selecting the appropriate waste management solution, B2B buyers should assess their specific operational needs, including the type and volume of waste generated, budget constraints, and compliance requirements. The butn barrel may be suitable for small-scale operations or residential use, while incinerators are better for industries with stringent disposal needs and higher waste volumes. Burn cages can serve as a practical middle ground for those managing organic waste in a more controlled manner. Ultimately, understanding the unique advantages and limitations of each option will enable buyers to make informed decisions that align with their business goals and sustainability objectives.

Illustrative image related to butn barrel

Essential Technical Properties and Trade Terminology for butn barrel

What Are the Key Technical Properties of a Burn Barrel for B2B Buyers?

Understanding the technical properties of burn barrels is essential for B2B buyers, especially when making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

– Definition: The material grade refers to the type of material used to manufacture the burn barrel, typically stainless steel or heavy-duty galvanized steel.

– Importance: Higher-grade materials ensure durability and resistance to corrosion, which is vital for longevity, especially in harsh environments. Stainless steel options are particularly beneficial for buyers looking for products that withstand extreme temperatures and resist warping. -

Capacity

– Definition: This refers to the volume the barrel can hold, commonly available in sizes like 55 gallons.

– Importance: Knowing the capacity helps businesses choose a burn barrel that meets their waste disposal needs. Larger capacities may be ideal for industrial or agricultural applications, while smaller sizes may suit residential or light commercial use. -

Airflow Design

– Definition: This involves the design features that facilitate air circulation within the barrel, often achieved through strategically placed holes or vents.

– Importance: An effective airflow design is crucial for efficient burning, reducing smoke production and improving combustion efficiency. B2B buyers should assess airflow designs to ensure compliance with environmental regulations and to minimize smoke-related complaints. -

Burn Temperature

– Definition: This indicates the maximum temperature the barrel can achieve during operation, typically measured in Fahrenheit.

– Importance: Higher burn temperatures result in more complete combustion, which is essential for reducing harmful emissions. Buyers should prioritize barrels that can reach temperatures above 1800°F for optimal performance and compliance with local emissions standards. -

Safety Features

– Definition: Safety features include design elements that prevent accidents, such as spark arrestors, covers, and sturdy handles.

– Importance: These features are crucial for minimizing fire hazards, particularly in areas prone to wildfires. B2B buyers must ensure that the barrels they purchase include robust safety features to protect their operations and comply with safety regulations. -

Portability

– Definition: This refers to the ease with which a burn barrel can be moved, often determined by its weight and design.

– Importance: For businesses that require mobility, such as landscaping or construction firms, portable burn barrels can significantly enhance operational efficiency. Buyers should consider options with handles or wheels for easier transport.

What Trade Terms Should B2B Buyers Understand When Purchasing Burn Barrels?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify reliable suppliers that provide quality products tailored to specific applications. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest number of units a supplier is willing to sell in a single order.

– Importance: Knowing the MOQ is essential for budget planning and inventory management. Buyers must ensure that their order quantities align with their operational needs and financial constraints. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

– Importance: Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they secure the best deal for their burn barrel needs. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, which is crucial for effective logistics planning. -

Lead Time

– Definition: Lead time is the amount of time from placing an order to receiving the product.

– Importance: Understanding lead times is vital for inventory management and ensuring that operations run smoothly without delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing burn barrels, ensuring they meet their operational and regulatory needs effectively.

Navigating Market Dynamics and Sourcing Trends in the butn barrel Sector

What are the Current Market Dynamics and Key Trends Affecting the Butn Barrel Sector?

The butn barrel sector is witnessing significant transformation driven by global environmental awareness and evolving regulatory standards. Key trends include the increasing demand for efficient waste management solutions, particularly in regions facing rapid urbanization and industrialization, such as Africa and South America. The rise of e-commerce has also amplified the need for reliable and sustainable packaging options, positioning butn barrels as an essential component in various supply chains.

Technological advancements are enhancing the manufacturing processes of butn barrels, with innovations in materials and design leading to products that are not only more durable but also easier to recycle. For international B2B buyers, particularly from Europe, the Middle East, and Asia, the focus is shifting towards sourcing barrels that meet both functional and environmental standards. This includes the adoption of digital platforms for procurement, enabling buyers to access a broader range of suppliers and streamline their sourcing processes.

Emerging markets, particularly in the Middle East and Africa, are also experiencing increased investment in infrastructure, which is likely to boost the demand for butn barrels in construction and waste management applications. Buyers must remain agile and informed about these market dynamics to capitalize on opportunities and mitigate risks associated with fluctuations in supply and demand.

How Can Sustainability and Ethical Sourcing Impact the Butn Barrel Sector?

Sustainability has become a cornerstone of modern supply chains, and the butn barrel sector is no exception. The environmental impact of traditional waste disposal methods has prompted a shift towards more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through innovative manufacturing processes and sustainable materials.

Ethical sourcing is also gaining traction, with buyers seeking out suppliers who comply with environmental regulations and labor standards. Certifications such as ISO 14001 for environmental management systems and FSC (Forest Stewardship Council) certification for sustainably sourced wood products are becoming essential for suppliers aiming to attract conscientious buyers. Additionally, the use of recycled materials in the production of butn barrels not only reduces waste but also appeals to a growing segment of eco-conscious consumers.

Illustrative image related to butn barrel

Incorporating sustainability into sourcing decisions is not merely a compliance issue; it has become a competitive advantage. Buyers who prioritize ethical sourcing can enhance their brand reputation, attract new customers, and ultimately drive sales growth while contributing positively to the environment.

What is the Brief Evolution of the Butn Barrel Sector?

The butn barrel has evolved significantly since its inception, originally designed for the storage and transport of liquids and solids. Historically, these barrels were made from wood and metal, primarily serving agricultural and industrial purposes. Over the decades, advancements in materials science have led to the introduction of high-density polyethylene and stainless steel options, enhancing durability and safety.

In recent years, the evolution has been influenced by changing regulations and increased environmental awareness. The focus has shifted from mere functionality to sustainability, prompting manufacturers to innovate and create barrels that not only perform effectively but also minimize environmental impact. As the sector continues to adapt to modern demands, the future of butn barrels looks promising, with ongoing innovations likely to redefine their applications and sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of butn barrel

-

1. How do I ensure my burn barrel burns efficiently?

To achieve optimal burning efficiency, consider the design and airflow of your burn barrel. Ensure it has sufficient air holes drilled around the base and halfway up the sides to facilitate airflow. A well-ventilated barrel promotes complete combustion and reduces smoke. Additionally, avoid burning wet or damp materials, as they hinder burning performance. Regular maintenance, such as cleaning out ash and debris, will also enhance burning efficiency. -

2. What is the best material for a burn barrel?

The best material for a burn barrel is typically heavy-duty steel or stainless steel. These materials can withstand high temperatures and resist warping over time. Stainless steel, in particular, offers durability and corrosion resistance, making it a preferred choice for long-term use. When sourcing burn barrels, ensure that they meet industry standards and are designed to handle the specific types of waste you intend to incinerate. -

3. What customization options are available for burn barrels?

Many suppliers offer customization options for burn barrels, including size, material, and design features. You can request specific dimensions to fit your operational needs, and choose from various finishes or coatings for added durability. Some manufacturers may also provide additional features such as improved airflow systems, lids, or safety mechanisms. Be sure to discuss your requirements with potential suppliers to find the best fit for your needs. -

4. What is the minimum order quantity (MOQ) for burn barrels?

Minimum order quantities (MOQ) for burn barrels can vary significantly between suppliers. Generally, MOQs can range from a single unit for smaller manufacturers to several hundred units for larger operations. When negotiating with suppliers, clarify their MOQ policies early in the discussions to ensure they align with your purchasing capabilities and operational needs. -

5. What payment terms should I expect when sourcing burn barrels internationally?

Payment terms for international purchases of burn barrels can vary based on the supplier and your negotiation. Common terms include a deposit upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer payment via letters of credit, wire transfers, or trade credit options. Always ensure that payment terms are clearly defined in your contract to avoid misunderstandings. -

6. How do I vet suppliers for burn barrels effectively?

To vet suppliers for burn barrels, conduct thorough research by reviewing their business credentials, customer testimonials, and product certifications. Request samples to assess product quality and inspect their manufacturing processes if possible. Additionally, consider their experience in the industry and their ability to meet your specific needs. Networking with other businesses in your sector can also provide valuable insights into reliable suppliers. -

7. What logistics considerations should I be aware of when importing burn barrels?

When importing burn barrels, consider logistics aspects such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling industrial equipment to navigate potential challenges. Additionally, familiarize yourself with import duties and taxes applicable in your country. Proper planning and communication with your supplier can help ensure a smooth shipping process. -

8. How can I ensure quality assurance (QA) for my burn barrel order?

To ensure quality assurance for your burn barrel order, establish clear quality standards and specifications with your supplier before production begins. Request regular updates and photos during the manufacturing process to monitor progress. Additionally, consider third-party inspections before shipment to verify that the products meet your quality criteria. Having a solid agreement on quality expectations will help mitigate risks and ensure you receive the intended product.

Top 4 Butn Barrel Manufacturers & Suppliers List

1. Proud Pyro – The Pyro Cage

Domain: proudpyro.com

Registered: 2017 (8 years)

Introduction: The Pyro Cage is a burn cage designed as a replacement for traditional burn barrels. It is ideal for burning yard debris, cardboard boxes, and sensitive documents. Key features include:

– Engineered for excellent airflow, resulting in hotter flames and thorough burns.

– Composed of 4 panels that easily assemble without tools, forming a strong self-supporting structure.

– Made from strong 14 gauge …

2. Reddit – Burn Barrels Discussion

3. Hearth – 55 Gallon Steel Drum with Airflow Holes

Domain: hearth.com

Registered: 1995 (30 years)

Introduction: 55 gallon steel drum, drilled a dozen 3/8″ holes around the base (6″ from the bottom) for air flow.

4. Innovative Ag – Large Burn Barrel

Domain: innovativeagsd.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Large Burn Barrel”, “sku”: “Medium Burn Large Burn Barrel”, “regular_price”: “$2,250.00”, “sale_price”: “$2,250.00”, “shipping_info”: “Shipping calculated at checkout.”, “description”: “Great for burning items on windy days and containing it. Features a door on the bottom for easy emptying and a filter on the top to keep loose debris in the unit.”, “availability”: “Pre-order item…

Strategic Sourcing Conclusion and Outlook for butn barrel

How Can Strategic Sourcing Enhance Your Procurement of Burn Barrels?

In the dynamic landscape of burn barrel sourcing, strategic procurement is essential for maximizing value and ensuring compliance with evolving environmental regulations. By engaging with reliable suppliers, buyers can access innovative designs that promote efficient burning and reduce emissions, such as those made from durable stainless steel. Understanding the various applications and types of burn barrels—from standard models to specialized incinerators—enables businesses to make informed decisions tailored to their specific needs.

Illustrative image related to butn barrel

Investing in high-quality burn barrels not only improves operational efficiency but also enhances safety standards, particularly in regions where waste management practices are under scrutiny. As international buyers from Africa, South America, the Middle East, and Europe seek reliable waste disposal solutions, focusing on quality and supplier reliability will be paramount.

Looking ahead, fostering strong relationships with suppliers will be key to navigating market fluctuations and securing competitive pricing. We encourage you to explore diverse sourcing options and consider the long-term benefits of integrating advanced burn barrel technologies into your operations. Take action now to optimize your procurement strategy and position your business for success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.