Braid Electrical Wire Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for braid electrical wire

In today’s interconnected marketplace, sourcing high-quality braid electrical wire poses significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The growing demand for braided wire—known for its durability and flexibility—underscores the necessity for comprehensive knowledge about the types, applications, and sourcing strategies that can streamline the procurement process. This guide serves as an essential resource for navigating the complexities of the braid electrical wire market, providing insights into various wire types, their specific applications across industries, and the critical factors to consider when vetting suppliers.

Understanding the nuances of braid electrical wire is vital for making informed purchasing decisions that meet regulatory standards and operational requirements. From the specifications of materials used to the intricacies of pricing models, this guide empowers buyers by equipping them with actionable insights. It also addresses common concerns such as supplier reliability, quality assurance, and cost-effectiveness, ensuring that businesses in regions like Nigeria and Saudi Arabia can secure the best products for their unique needs. By leveraging this comprehensive resource, international buyers can confidently navigate the global market, ultimately enhancing their operational efficiency and product quality.

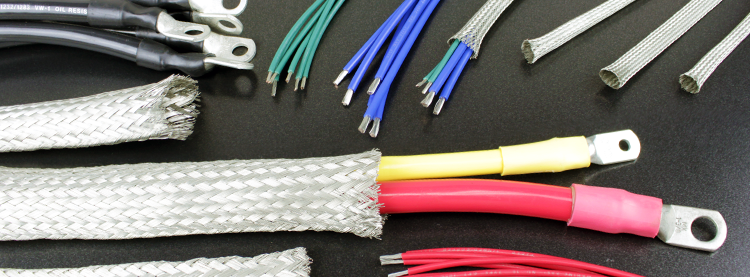

Understanding braid electrical wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Copper Braided Wire | High conductivity, flexible, corrosion-resistant | Electrical wiring, grounding systems | Pros: Excellent conductivity; Cons: Higher cost |

| Steel Braided Wire | Durable, lightweight, good tensile strength | Industrial applications, lighting | Pros: Strong and resistant to wear; Cons: Limited flexibility |

| Aluminum Braided Wire | Lightweight, cost-effective, lower conductivity than copper | Power transmission, overhead lines | Pros: Cost-effective; Cons: Less conductive than copper |

| Metal Braided Cable | Aesthetic appeal, available in various metals like brass | Decorative lighting, custom fixtures | Pros: Unique look; Cons: Not suitable for heavy loads |

| Shielded Braided Wire | Enhanced protection against electromagnetic interference | Data transmission, sensitive electronics | Pros: Reduces signal interference; Cons: More expensive than unshielded |

What Are the Characteristics of Copper Braided Wire?

Copper braided wire is renowned for its high electrical conductivity and flexibility, making it an ideal choice for applications requiring reliable electrical connections. Its corrosion-resistant properties enhance longevity, particularly in harsh environments. B2B buyers should consider the higher initial investment, which is often justified by the performance benefits and reduced maintenance costs over time.

How Does Steel Braided Wire Compare in Durability?

Steel braided wire offers exceptional durability and tensile strength, making it suitable for industrial applications and environments where wear and tear are prevalent. Its lightweight nature allows for easier handling and installation. However, buyers should note its limited flexibility, which can impact installation in tight spaces. The strength of steel makes it a preferred option for applications requiring robust support.

Why Choose Aluminum Braided Wire for Cost-Effectiveness?

Aluminum braided wire is a lightweight, cost-effective alternative to copper, making it a popular choice for power transmission and overhead lines. While it provides adequate conductivity for many applications, it falls short compared to copper in performance. Buyers should evaluate their specific needs against the benefits of lower costs, especially for large-scale projects where budget constraints are a priority.

What Are the Aesthetic Benefits of Metal Braided Cables?

Metal braided cables, available in materials such as brass and copper, offer a unique aesthetic appeal that is particularly valued in decorative lighting and custom fixture applications. These cables can enhance the visual aspect of installations, making them attractive to designers and architects. However, they are not intended for heavy electrical loads, so buyers must ensure suitability for their specific applications.

How Does Shielded Braided Wire Enhance Performance?

Shielded braided wire is specifically designed to protect against electromagnetic interference (EMI), making it essential for data transmission and sensitive electronic applications. This type of wire ensures signal integrity, which is crucial in high-performance environments. While it tends to be more expensive than unshielded options, the investment is often warranted for applications where reliable data transmission is critical. Buyers should assess their operational needs when considering shielded options.

Key Industrial Applications of braid electrical wire

| Industry/Sector | Specific Application of braid electrical wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Lighting and Fixtures | Custom lighting designs for residential and commercial spaces | Enhances aesthetic appeal while ensuring safety and durability | Compliance with local electrical standards and voltage ratings |

| Automotive | Wiring for electric vehicles and charging stations | Supports efficient energy transfer and reliability | Temperature resistance and flexibility for varied environments |

| Telecommunications | Data transmission in networking equipment | High-performance connectivity and reduced signal interference | Compatibility with existing systems and shielding requirements |

| Industrial Machinery | Electrical connections in manufacturing equipment | Increases equipment lifespan and reduces maintenance costs | Durability under extreme conditions and load-bearing capacity |

| Construction | Electrical installations in buildings and infrastructures | Ensures safety and compliance with building codes | Availability of various gauges and materials for specific needs |

How is Braid Electrical Wire Used in Lighting and Fixtures?

In the lighting industry, braid electrical wire is commonly used for custom lighting designs in both residential and commercial settings. Its flexible nature allows designers to create intricate and aesthetically pleasing installations. Additionally, the wire’s durability ensures longevity, reducing the need for frequent replacements. Buyers in regions like Africa and the Middle East must ensure that the wire complies with local electrical standards, particularly regarding voltage ratings and safety certifications.

What Role Does Braid Electrical Wire Play in the Automotive Sector?

Braid electrical wire is increasingly utilized in the automotive industry, especially for electric vehicles (EVs) and charging stations. Its lightweight and flexible characteristics facilitate efficient wiring solutions, which are crucial for enhancing energy transfer and overall vehicle performance. International buyers should prioritize sourcing wires that can withstand high temperatures and varying environmental conditions, ensuring safety and reliability in diverse climates.

How is Braid Electrical Wire Essential for Telecommunications?

In telecommunications, braid electrical wire is vital for data transmission in networking equipment. Its ability to minimize signal interference makes it an ideal choice for high-speed applications, ensuring robust connectivity. For businesses in South America and Europe, compatibility with existing systems and adherence to shielding requirements are critical factors to consider when sourcing braid electrical wire.

Why is Braid Electrical Wire Important in Industrial Machinery?

Braid electrical wire finds significant application in the industrial machinery sector, where it is used for electrical connections in manufacturing equipment. Its durability under extreme conditions contributes to the efficiency and longevity of machinery, ultimately reducing maintenance costs for businesses. Buyers should look for wires that can handle high loads and are resistant to wear and tear, especially in heavy-duty applications prevalent in regions like Nigeria and Saudi Arabia.

How Does Braid Electrical Wire Contribute to Construction Projects?

In construction, braid electrical wire is essential for safe electrical installations in buildings and infrastructure projects. It ensures compliance with local building codes and enhances safety for end-users. International buyers must consider the availability of various gauges and materials to meet specific project needs, ensuring that the wire can handle the intended electrical load and environmental conditions.

3 Common User Pain Points for ‘braid electrical wire’ & Their Solutions

Scenario 1: Sourcing Quality Braided Electrical Wire for Industrial Applications

The Problem: A B2B buyer in the manufacturing sector is tasked with sourcing braided electrical wire for an upcoming project. They face challenges in ensuring the wire meets the necessary specifications for safety and durability, especially in high-stress environments. With numerous suppliers and varying quality standards, it can be overwhelming to differentiate between products that are genuinely reliable and those that might fail under operational pressure. This uncertainty can lead to delays and increased costs if the wrong materials are selected.

The Solution: To effectively source high-quality braided electrical wire, buyers should start by establishing clear specifications based on their project requirements. This includes understanding the wire gauge, insulation type, and voltage rating needed for their specific application. Engaging with reputable suppliers who provide certification and testing results can significantly mitigate risks. Look for suppliers that adhere to international standards such as UL or IEC, which can assure product reliability. Additionally, consider requesting samples to conduct in-house testing before making large purchases. Establishing a relationship with suppliers who offer consistent quality and support can streamline procurement processes and build trust over time.

Scenario 2: Navigating Compliance and Safety Standards

The Problem: A company in the electrical installation sector faces difficulties ensuring that their use of braided electrical wire complies with local and international safety standards. With constantly evolving regulations, there is a risk of non-compliance, which could lead to legal issues, project delays, and potential hazards for end-users. The buyer needs to stay informed about these regulations while also ensuring their workforce is adequately trained on compliance requirements.

The Solution: To navigate compliance effectively, buyers should invest in continuous education and training programs for their teams regarding the latest electrical standards. Regularly consulting with compliance experts or industry associations can provide invaluable insights into changing regulations. Additionally, when selecting braided electrical wire, ensure that the products are marked with relevant certifications indicating compliance with applicable standards. Keeping comprehensive documentation of all materials used, including their certification and compliance history, can aid in demonstrating adherence to regulations during audits or inspections. A proactive approach to compliance not only protects the company legally but also enhances its reputation in the market.

Scenario 3: Installation Challenges with Braided Electrical Wire

The Problem: An electrical contractor encounters difficulties during the installation of braided electrical wire, particularly in residential and commercial settings where aesthetics and functionality must be balanced. The challenge lies in managing the wire’s flexibility and ensuring secure connections while maintaining a clean and professional appearance. Missteps during installation can lead to electrical failures or unsafe conditions, ultimately affecting client satisfaction and project reputation.

The Solution: To tackle installation challenges, contractors should adopt best practices specific to braided electrical wire. First, proper tools for cutting and stripping the wire are essential; using the right equipment can prevent fraying and ensure clean cuts. Additionally, employing techniques such as using heat shrink tubing can provide insulation and a polished look. It’s also beneficial to develop a standardized installation process that includes visual aids or checklists to ensure consistency across projects. Training staff on the unique characteristics of braided wire—such as its flexibility and potential for kinking—can lead to more efficient installations. Moreover, encouraging open communication with clients about the installation process and potential challenges can foster trust and satisfaction.

Strategic Material Selection Guide for braid electrical wire

What Are the Key Materials Used in Braid Electrical Wire?

When selecting braid electrical wire, understanding the materials used is crucial for ensuring optimal performance and compliance with international standards. Below, we analyze four common materials utilized in the production of braid electrical wire, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Copper

Key Properties:

Copper is renowned for its excellent electrical conductivity, making it a preferred choice for electrical wiring. It can withstand temperatures up to 200°C and has a high resistance to corrosion, especially when coated.

Pros & Cons:

Copper wires are highly durable and flexible, allowing for easy installation in various applications. However, they are more expensive than alternatives like aluminum and can be prone to oxidation if not properly insulated.

Impact on Application:

Copper is suitable for high-performance applications, including power distribution and data transmission. Its compatibility with various media makes it versatile for different environments.

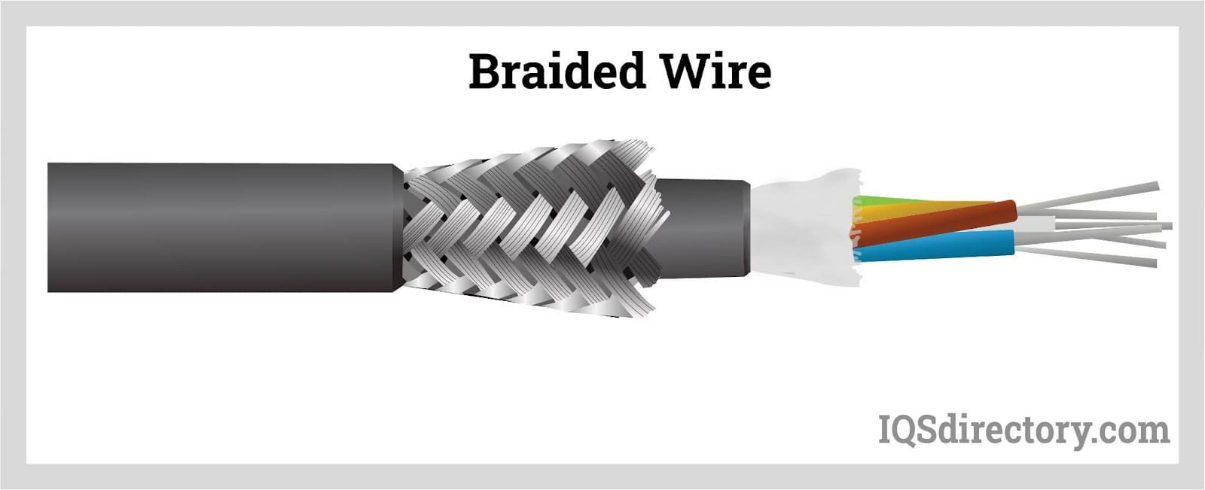

Illustrative image related to braid electrical wire

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should ensure compliance with local standards such as IEC and ASTM. The demand for copper wiring may be influenced by the availability of raw materials and market fluctuations.

2. Aluminum

Key Properties:

Aluminum is lightweight and has a lower conductivity than copper, but it can still perform adequately in many applications. It typically operates well up to 80°C and is resistant to corrosion when properly treated.

Pros & Cons:

Aluminum is cost-effective and easier to handle due to its lightweight nature. However, its lower conductivity means larger gauge wires are required for the same performance level as copper, which can complicate installation.

Impact on Application:

Aluminum wires are often used in overhead power lines and large-scale applications where weight is a concern. They are less suitable for high-frequency applications due to their higher resistance.

Considerations for International Buyers:

In regions like South America, where aluminum is commonly used, buyers should verify compliance with local electrical codes and standards. Additionally, the cost-effectiveness of aluminum can be a significant advantage in budget-sensitive projects.

Illustrative image related to braid electrical wire

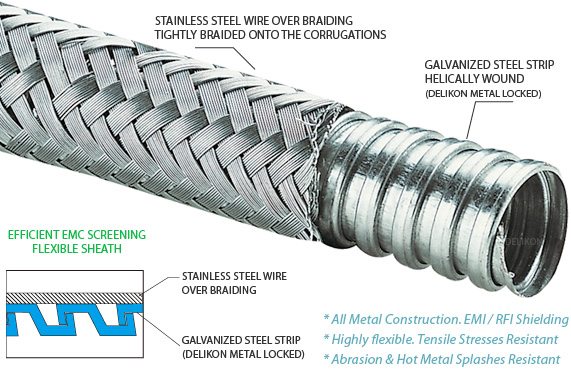

3. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can withstand high temperatures, typically up to 300°C. It is known for its strength and durability.

Pros & Cons:

The primary advantage of stainless steel is its resistance to rust and corrosion, making it ideal for harsh environments. However, it is more expensive than copper and aluminum and has lower electrical conductivity.

Impact on Application:

Stainless steel is often used in applications requiring high strength and corrosion resistance, such as marine or industrial settings. However, its lower conductivity limits its use in traditional electrical applications.

Considerations for International Buyers:

For buyers in Europe and the Middle East, ensuring compliance with standards such as EN and ISO is critical. The aesthetic appeal of stainless steel also makes it popular in design-oriented applications.

Illustrative image related to braid electrical wire

4. Tinned Copper

Key Properties:

Tinned copper is copper wire coated with a thin layer of tin, enhancing its corrosion resistance and solderability. It can typically handle temperatures up to 150°C.

Pros & Cons:

The primary advantage of tinned copper is its enhanced durability in humid or corrosive environments. However, it is more expensive than standard copper due to the additional processing.

Impact on Application:

Tinned copper is ideal for marine applications, automotive wiring, and environments where moisture is prevalent. Its solderability makes it a preferred choice for electronic connections.

Considerations for International Buyers:

Buyers in regions with high humidity, such as parts of Africa and South America, should consider tinned copper for its durability. Compliance with relevant standards is essential for ensuring safety and performance.

Summary Table

| Material | Typical Use Case for braid electrical wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Power distribution, data transmission | Excellent conductivity | Higher cost, prone to oxidation | High |

| Aluminum | Overhead power lines, large-scale wiring | Cost-effective, lightweight | Lower conductivity, larger gauge | Medium |

| Stainless Steel | Marine, industrial applications | Corrosion resistance, strength | Lower conductivity, higher cost | High |

| Tinned Copper | Marine, automotive, humid environments | Enhanced durability, solderability | Higher processing cost | Medium |

This strategic material selection guide provides essential insights for B2B buyers, enabling informed decisions that align with both performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for braid electrical wire

What Are the Main Stages in the Manufacturing Process of Braided Electrical Wire?

The manufacturing process of braided electrical wire involves several critical stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with sourcing high-quality raw materials, typically copper or aluminum strands for the conductors, and various insulating materials. Suppliers should ensure that the metals used are of a specific gauge, which affects conductivity and overall performance. Pre-testing of raw materials, such as checking for impurities and measuring conductivity, is essential to guarantee quality from the outset. -

Forming

In this stage, the raw materials are shaped into the desired configuration. For braided electrical wires, strands of metal are twisted together to form a braid, which enhances flexibility and durability. The braiding process typically employs machines that can achieve precise braiding patterns and densities. This is crucial as the braid must provide adequate shielding while also maintaining the required electrical properties. -

Assembly

Once the braiding is complete, the wire undergoes assembly, where insulation is applied. This may involve extruding a plastic or rubber jacket around the braided wire, ensuring it meets electrical safety standards. The assembly process may also include adding features such as connectors or terminals, depending on the intended application of the wire. -

Finishing

The final stage of manufacturing involves testing and finishing touches. This can include applying protective coatings, marking the wire for identification, and conducting final inspections. Each of these steps is designed to enhance the product’s longevity and usability, ensuring it meets the specifications required by international standards.

Which Quality Control Standards Are Relevant for Braided Electrical Wire?

Quality control (QC) is a crucial aspect of the manufacturing process, especially for products like braided electrical wire that are used in various applications, including construction, automotive, and consumer electronics. Adhering to recognized standards helps ensure that the products are safe and reliable.

-

International Standards

ISO 9001 is one of the most widely recognized quality management standards. Manufacturers should implement ISO 9001 practices to maintain a systematic approach to managing their processes, improving quality, and enhancing customer satisfaction. This standard emphasizes continuous improvement and customer feedback, which are essential for maintaining quality in production. -

Industry-Specific Certifications

In addition to ISO 9001, there are other industry-specific standards that manufacturers may comply with, such as CE marking for products sold in Europe, which indicates conformity with health, safety, and environmental protection standards. Additionally, certifications from organizations like the American Petroleum Institute (API) may be relevant for wires used in oil and gas applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is integrated throughout the manufacturing process, with specific checkpoints designed to catch potential issues before they escalate. The main checkpoints include:

-

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials upon delivery to ensure they meet the required specifications. Tests may include visual inspections, dimensional checks, and material property tests. -

In-Process Quality Control (IPQC)

During production, continuous monitoring is essential. Manufacturers should conduct routine checks to ensure that the braiding and assembly processes are adhering to set standards. This may involve using statistical process control (SPC) techniques to monitor variations in production. -

Final Quality Control (FQC)

Once the manufacturing process is complete, a final inspection is performed. This includes testing the finished products for electrical conductivity, insulation integrity, and compliance with international standards. Random sampling methods may be used to ensure a representative quality check.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable strategies:

-

Conduct Supplier Audits

Periodic audits can help assess a supplier’s adherence to quality standards. Buyers should request access to quality management documentation and audit reports to evaluate the supplier’s compliance with international standards. -

Request Quality Assurance Reports

Suppliers should provide detailed reports on their quality assurance processes, including results from IQC, IPQC, and FQC. This transparency allows buyers to gauge the reliability of the manufacturing process. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspectors can conduct on-site evaluations and provide certification that the products meet specific standards.

What Are the Nuances of Quality Control for International B2B Buyers?

When sourcing braided electrical wire from international suppliers, buyers must be aware of specific nuances that can affect quality control:

-

Regulatory Compliance

Different countries have varying regulations regarding electrical products. Buyers should ensure that the products comply with local regulations in their markets, such as UL certification in the United States or CE marking in Europe. -

Cultural Differences in Quality Standards

Understanding the cultural context of suppliers can provide insights into their quality assurance practices. Some regions may prioritize cost over quality, while others may have stringent quality control measures in place. -

Logistics and Supply Chain Considerations

The logistics involved in international shipping can impact product quality. Buyers should be aware of how products are packaged and transported, as poor handling can lead to damage, affecting the product’s performance.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing braided electrical wire, ensuring they partner with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘braid electrical wire’

Introduction

In the ever-evolving electrical supply industry, sourcing braided electrical wire requires a strategic approach. This guide serves as a practical checklist for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and meets your specific requirements.

Step 1: Define Your Technical Specifications

Understanding the technical specifications of braided electrical wire is paramount for a successful purchase. Determine the wire gauge, material type (copper or stainless steel), and insulation requirements based on your application. This clarity helps avoid compatibility issues and ensures you select a product that meets safety and performance standards.

Illustrative image related to braid electrical wire

- Gauge: Common sizes include 18/3 or 22 AWG, which cater to different load capacities.

- Material: Choose between copper for conductivity or stainless steel for durability based on the intended use.

Step 2: Research Market Trends

Stay informed about current market trends and pricing fluctuations in the braided electrical wire sector. Understanding these dynamics allows you to make timely purchasing decisions and negotiate better terms with suppliers.

- Price Variability: Monitor international pricing trends, especially in regions where you plan to source.

- Emerging Technologies: Be aware of advancements in braided wire technology that could impact your product selection.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, conducting thorough evaluations is essential. Request company profiles, product catalogs, and references from other buyers in similar industries. This diligence helps ensure that the supplier has a proven track record of reliability and quality.

- Certifications: Verify certifications such as UL or CE to ensure compliance with safety standards.

- Experience: Look for suppliers with experience in your specific market region to navigate local regulations effectively.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality of the braided electrical wire firsthand. Evaluate the samples for flexibility, durability, and insulation quality to ensure they meet your specifications.

- Testing: Conduct necessary tests to check for conductivity and insulation integrity.

- Appearance: Inspect the physical attributes, such as braid tightness and finish, which can indicate overall quality.

Step 5: Negotiate Terms and Conditions

Once you have selected a supplier, focus on negotiating favorable terms. This includes pricing, payment terms, delivery schedules, and after-sales support. Clear communication at this stage can prevent future misunderstandings and enhance your purchasing experience.

- Volume Discounts: Inquire about pricing breaks for larger orders.

- Lead Times: Confirm delivery timelines to align with your project schedules.

Step 6: Confirm Shipping and Compliance

Ensure that all shipping and compliance details are clearly outlined before finalizing the transaction. This includes understanding import/export regulations, shipping costs, and delivery logistics specific to your region.

- Documentation: Verify that all necessary documentation for customs clearance is provided.

- Insurance: Consider shipping insurance to protect against potential damages during transit.

Step 7: Monitor and Evaluate Post-Purchase

After receiving your braided electrical wire, monitor its performance and evaluate the overall supplier experience. Gather feedback from your team on the product’s quality and reliability. This assessment can inform future purchasing decisions and supplier relationships.

- Performance Metrics: Track how well the wire performs in various applications over time.

- Supplier Feedback: Provide constructive feedback to suppliers to help improve their offerings.

By following this comprehensive checklist, you can streamline your sourcing process for braided electrical wire, ensuring that you acquire products that meet your business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for braid electrical wire Sourcing

When sourcing braided electrical wire, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis aims to break down the various cost components, identify key price influencers, and provide actionable tips for effective negotiations.

Illustrative image related to braid electrical wire

What Are the Key Cost Components in Braided Electrical Wire Production?

The total cost of braided electrical wire comprises several components:

-

Materials: The primary costs originate from the raw materials, which can include copper, aluminum, and various insulating materials. The choice of material greatly impacts the overall price; for instance, copper is generally more expensive than aluminum but offers superior conductivity.

-

Labor: Labor costs can vary significantly based on the geographical location of the manufacturer. Regions with lower labor costs may offer competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Specialized tooling for production can be a significant upfront investment. These costs are often amortized over large production runs, making it essential for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring the quality of braided electrical wire involves rigorous testing and inspection, which can add to the overall cost. Certification standards (like UL or ISO) further influence pricing as they require compliance with specific manufacturing practices.

-

Logistics: Shipping costs can fluctuate based on the origin and destination, mode of transport, and current freight rates. For international buyers, understanding Incoterms is essential for determining who bears these costs.

-

Margin: Suppliers typically add a profit margin on top of their total costs. This margin can vary based on competition, market demand, and the perceived value of the product.

What Influences the Pricing of Braided Electrical Wire?

Several factors can influence the pricing structure of braided electrical wire:

-

Volume/MOQ: Suppliers often provide better pricing for larger orders. Understanding the MOQ can help buyers negotiate more favorable terms.

-

Specifications and Customization: Custom specifications, such as specific gauge sizes, lengths, or insulation types, can lead to price adjustments. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher quality materials and certifications can increase costs but also enhance reliability and safety, which are critical in electrical applications.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge a premium, but this often translates into better service and quality assurance.

How Can International Buyers Optimize Their Sourcing Strategy?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several tips can enhance cost-efficiency:

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices based on volume and long-term contracts. Establishing relationships with suppliers can also lead to better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with installation, maintenance, and potential failures. Choosing higher-quality products may result in lower TCO.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local demand, currency fluctuations, and trade tariffs. Awareness of these factors can aid in making informed sourcing decisions.

-

Stay Informed on Market Trends: Regularly monitor market trends and forecasts related to raw material prices and supply chain dynamics. This knowledge can provide leverage during negotiations.

Conclusion

When sourcing braided electrical wire, a comprehensive understanding of the cost structure, pricing influencers, and negotiation strategies is essential for B2B buyers. By considering these factors, international buyers can make informed decisions that enhance their sourcing efficiency and overall profitability. As prices can vary widely, it is advisable to consult multiple suppliers and request indicative pricing before committing to any purchase.

Alternatives Analysis: Comparing braid electrical wire With Other Solutions

Exploring Alternatives to Braid Electrical Wire

In the world of electrical wiring, braid electrical wire is known for its flexibility and durability, making it a popular choice for various applications. However, there are several alternatives that may suit different needs and preferences. Understanding these options can help B2B buyers make informed decisions based on performance, cost, and specific use cases.

Illustrative image related to braid electrical wire

| Comparison Aspect | Braid Electrical Wire | Steel Braided Cord | PVC Insulated Wire |

|---|---|---|---|

| Performance | High flexibility, good conductivity | Aesthetic appeal, moderate flexibility | Excellent insulation, higher current capacity |

| Cost | Moderate | Higher | Lower |

| Ease of Implementation | Requires specialized connectors | Easy to handle, DIY-friendly | Simple installation with standard fittings |

| Maintenance | Minimal, but check for frays | Moderate, may need replacements | Low maintenance, durable |

| Best Use Case | Automotive, aerospace, high-vibration environments | Decorative lighting, DIY projects | Residential wiring, general electrical needs |

What Are the Advantages and Disadvantages of Steel Braided Cord?

Steel braided cords provide a unique aesthetic appeal that makes them a popular choice for design-oriented applications, such as pendant lighting and home decor. They are typically easy to handle, making them suitable for DIY projects. However, while they look impressive, they may not be as efficient in carrying heavy electrical loads compared to braid electrical wire. Their maximum current capacity is lower, which can limit their application in high-power environments.

How Does PVC Insulated Wire Compare to Braid Electrical Wire?

PVC insulated wire is a cost-effective alternative that offers excellent insulation and is widely used in residential settings. Its ability to handle higher current loads makes it suitable for general electrical needs. However, PVC wire lacks the flexibility and durability of braid electrical wire, making it less ideal for applications that involve movement or vibration. Furthermore, PVC can be less aesthetically pleasing, which may be a consideration in design-sensitive projects.

Conclusion: How to Choose the Right Electrical Wire Solution for Your Needs

When selecting between braid electrical wire and its alternatives, B2B buyers should assess their specific requirements, including performance, cost, and application. If flexibility and durability are paramount, braid electrical wire may be the optimal choice, particularly for demanding environments. Conversely, for decorative or lower-power applications, steel braided cords or PVC insulated wire may be more appropriate and economical. Ultimately, understanding the distinct advantages and limitations of each option will empower buyers to make choices that best align with their project goals and operational needs.

Illustrative image related to braid electrical wire

Essential Technical Properties and Trade Terminology for braid electrical wire

What Are the Key Technical Properties of Braid Electrical Wire?

Understanding the essential technical specifications of braid electrical wire is crucial for B2B buyers, especially when making informed purchasing decisions. Here are some of the critical properties to consider:

1. Material Composition

Braid electrical wires are commonly made from copper, aluminum, or stainless steel. Copper is preferred for its excellent conductivity and durability, making it ideal for high-performance applications. Stainless steel offers corrosion resistance, suitable for harsh environments. B2B buyers should evaluate the material based on the specific electrical requirements and environmental conditions of their projects.

2. Gauge Size (AWG)

The American Wire Gauge (AWG) system indicates the wire’s diameter and current-carrying capacity. A lower AWG number signifies a thicker wire, which can handle higher currents without overheating. For instance, a 12 AWG wire can carry more current than a 20 AWG wire. Understanding gauge sizes helps buyers select the right wire for their electrical load requirements, ensuring safety and efficiency.

3. Voltage Rating

Each braid electrical wire has a specified voltage rating, indicating the maximum voltage it can safely carry. Common ratings include 300V, 600V, and even higher for specialized applications. This specification is critical for ensuring the wire’s suitability for the intended electrical systems and preventing potential failures or hazards.

4. Temperature Rating

Temperature ratings denote the maximum operating temperature for the wire. Common ratings are 60°C, 75°C, and 90°C. For example, a wire rated at 90°C can be used in environments where heat generation is a concern. Buyers should consider these ratings to ensure the wire can withstand the thermal conditions of their specific applications.

5. Stranding and Flexibility

Braid electrical wires can be either solid or stranded. Stranded wires consist of multiple smaller strands, providing flexibility and ease of installation, especially in tight spaces. In contrast, solid wires are less flexible but can offer better conductivity over short distances. Buyers should assess the installation environment to determine the best option for their needs.

6. Shielding

Some braid electrical wires come with shielding, which protects against electromagnetic interference (EMI). Shielded cables are essential in applications requiring signal integrity, such as data transmission or sensitive electronics. Buyers should consider whether shielding is necessary for their applications to maintain performance and reliability.

What Common Trade Terminology Should B2B Buyers Know?

Familiarizing oneself with trade terminology is essential for effective communication and negotiation in the electrical wire market. Here are some key terms:

Illustrative image related to braid electrical wire

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of braid electrical wire, it indicates the supplier of the wire that is integrated into final products. Understanding OEM relationships can help buyers identify reliable sources for high-quality components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it influences purchasing decisions and inventory management. Understanding MOQs helps companies assess whether a supplier aligns with their volume needs.

3. RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers requesting pricing and other details for specific products or services. For braid electrical wire, submitting an RFQ can help buyers compare offers and negotiate better terms, ensuring they get the best value for their investment.

Illustrative image related to braid electrical wire

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery obligations, which are vital in global procurement of braid electrical wire.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for project planning and inventory management. Buyers should inquire about lead times to align their procurement schedules with project timelines.

6. Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product meets specific safety and quality benchmarks. For braid electrical wire, these certifications are essential for ensuring compliance with local regulations and industry standards, which can affect marketability and safety.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions regarding braid electrical wire, ensuring they select the right products for their specific applications while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the braid electrical wire Sector

What Are the Current Market Dynamics and Key Trends Affecting Braid Electrical Wire?

The global market for braid electrical wire is experiencing substantial growth, driven by increasing demands across multiple sectors, including construction, automotive, and consumer electronics. In regions like Africa, South America, the Middle East, and Europe, the growing emphasis on infrastructure development and modernization has intensified the need for reliable electrical solutions. Notably, the adoption of smart technologies and the Internet of Things (IoT) is influencing the design and specifications of braid electrical wire, as manufacturers focus on enhanced conductivity and durability.

Illustrative image related to braid electrical wire

Emerging sourcing trends highlight a shift towards digital platforms, where international B2B buyers can streamline procurement processes through e-commerce solutions. This digital transformation allows for real-time inventory management, competitive pricing, and greater transparency in supplier relationships. Additionally, the rise of automation and robotics in manufacturing is leading to improved production efficiencies, reducing lead times, and enhancing product quality.

International buyers are also becoming increasingly conscious of regional market dynamics. For instance, the Middle East is witnessing a surge in demand for high-voltage braid electrical wire due to extensive energy projects, while Africa’s growing urbanization is driving the need for reliable wiring solutions in residential and commercial buildings. Understanding these regional nuances is crucial for B2B buyers to make informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Impacting Braid Electrical Wire Procurement?

The environmental impact of manufacturing processes and materials used in braid electrical wire is under scrutiny as global awareness of sustainability issues rises. B2B buyers are now prioritizing suppliers that adhere to ethical sourcing practices and demonstrate a commitment to reducing their carbon footprint. This trend is particularly pronounced in Europe, where strict regulations on environmental standards mandate transparency in supply chains.

As part of this shift, many manufacturers are investing in ‘green’ certifications and utilizing eco-friendly materials. Buyers can look for certifications such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) to ensure that the braid electrical wire they procure is compliant with environmental standards. Furthermore, suppliers that engage in recycling initiatives or use renewable energy sources during production are becoming more attractive to environmentally-conscious buyers.

The focus on ethical sourcing not only helps mitigate environmental risks but also enhances brand reputation. B2B companies that align their procurement strategies with sustainable practices are likely to build stronger relationships with stakeholders and appeal to a broader customer base, particularly in regions where sustainability is a key purchasing factor.

What Is the Historical Context of Braid Electrical Wire in the B2B Landscape?

The evolution of braid electrical wire can be traced back to the early 20th century when electrical systems began to gain widespread adoption. Initially, wire was primarily made from solid copper, but the demand for flexibility and durability led to the development of braided wire designs. This innovation allowed for better conductivity while accommodating the physical demands of various applications, from household wiring to industrial machinery.

Throughout the decades, advancements in materials science and manufacturing processes have further refined braid electrical wire. The introduction of synthetic materials and coatings has improved insulation properties, making these wires suitable for a broader range of environmental conditions. Today, braid electrical wire is recognized not only for its functional attributes but also for its aesthetic appeal in applications such as architectural lighting and interior design.

Understanding this historical context equips B2B buyers with insights into the product’s evolution, allowing them to make informed decisions about sourcing and application based on past innovations and market developments.

Illustrative image related to braid electrical wire

Frequently Asked Questions (FAQs) for B2B Buyers of braid electrical wire

-

How do I choose the right braid electrical wire for my application?

Selecting the right braid electrical wire depends on several factors including the voltage requirements, current capacity, and environmental conditions. Consider the wire’s gauge, as thicker wires handle more current but are less flexible. Additionally, evaluate the material; copper offers excellent conductivity, while stainless steel provides durability in harsh environments. Always check the wire’s specifications against your application needs to ensure compliance with local electrical standards and safety regulations. -

What is the best type of braid electrical wire for outdoor use?

For outdoor applications, look for braid electrical wire that is specifically labeled as UV resistant and weatherproof. These wires typically have protective jackets that can withstand exposure to sunlight, moisture, and temperature fluctuations. Copper braided wires are often recommended due to their conductivity, but ensure they are coated or insulated to prevent corrosion. Always verify that the wire meets local codes for outdoor electrical installations. -

How can I verify the quality of braid electrical wire from suppliers?

To ensure quality, request certification documents such as UL (Underwriters Laboratories) or CE (Conformité Européenne) marks from suppliers. Conduct a factory audit if possible, and request samples to evaluate performance. Additionally, check for customer reviews and testimonials regarding the supplier’s reliability and product quality. Establishing a relationship with suppliers who have a proven track record can also help mitigate risks associated with poor quality. -

What are the common payment terms for purchasing braid electrical wire internationally?

Payment terms can vary widely among suppliers, but common practices include advance payment, letters of credit, or payment upon delivery. It’s essential to negotiate terms that protect your interests while ensuring supplier confidence. For larger orders, consider using escrow services or trade finance options to safeguard transactions. Always clarify currency exchange rates and fees to avoid unexpected costs. -

What is the minimum order quantity (MOQ) for braid electrical wire?

Minimum order quantities can differ based on the supplier and specific wire types. Typically, MOQs may range from 100 meters to several kilometers for bulk purchases. Suppliers often set these limits to cover production costs and ensure profitability. If your needs are below the MOQ, discuss options for smaller orders or seek suppliers who specialize in lower volume transactions. -

How do I handle logistics and shipping for international orders of braid electrical wire?

When ordering braid electrical wire internationally, coordinate closely with suppliers to arrange shipping logistics. Consider freight forwarders who can navigate customs regulations and optimize shipping routes. It’s crucial to clarify delivery timelines, shipping methods (air, sea, or land), and associated costs upfront. Additionally, ensure all paperwork, including bills of lading and customs declarations, is accurate to avoid delays. -

What customization options are available for braid electrical wire?

Many suppliers offer customization options for braid electrical wire, including length, gauge, and material type. You may also request specific insulation colors or additional features such as shielding for electromagnetic interference. Discuss your requirements with suppliers early in the process to ensure they can meet your specifications. Custom orders may have longer lead times, so factor this into your project timelines. -

What should I do if I encounter issues with my braid electrical wire order?

If you experience issues such as delays, quality problems, or incorrect specifications, contact your supplier immediately to resolve the matter. Document all communications and maintain records of your order details. Most reputable suppliers will have a return or exchange policy. If necessary, escalate the issue to higher management within the company or seek mediation through trade associations if the problem persists.

Top 3 Braid Electrical Wire Manufacturers & Suppliers List

1. AWC Wire – Braided Wire Solutions

Domain: awcwire.com

Registered: 1997 (28 years)

Introduction: This company, AWC Wire – Braided Wire Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Ton’s Performance – Cloth Braided Primary Wire & Looms

Domain: tonsperformance.com

Registered: 2018 (7 years)

Introduction: Cloth Braided Primary Wire & Looms – Ton’s Performance

Product Types:

– Asphalt Coated Cloth Wire Loom [5 feet length] – From $4.50

– Woven Split Wire Loom [5 feet length] – From $5.50

– 18 Gauge Cloth Braided Primary Wire [Sold By The Foot] – Regular price $0.53

– 16 Gauge Cloth Braided Primary Wire [Sold By The Foot] – Regular price $0.69

– 14 Gauge Cloth Braided Primary Wire [Sold By The Foot]…

3. SparkFun – Wire Management Techniques

Domain: learn.sparkfun.com

Registered: 2002 (23 years)

Introduction: Wire management techniques including braiding wires for organization, preventing wires from being pulled from moving parts, and strengthening connections. Suggested methods include twisting pairs of wires together and using a power drill for longer wires. Additional tools mentioned are sleeves and cable carriers for protection, as well as labeling wires with sticky notes, tape, or markers for easi…

Strategic Sourcing Conclusion and Outlook for braid electrical wire

In conclusion, strategic sourcing of braided electrical wire offers significant advantages for international B2B buyers, especially in emerging markets such as Africa, South America, the Middle East, and Europe. Understanding the diverse applications and benefits of braided wire—ranging from enhanced durability and flexibility to aesthetic appeal—can empower businesses to make informed purchasing decisions.

As global supply chains continue to evolve, prioritizing quality suppliers and sustainable sourcing practices will be crucial in maintaining competitive advantage. Buyers should focus on establishing relationships with manufacturers who not only meet regulatory standards but also align with their long-term strategic goals.

Looking ahead, the demand for innovative and reliable electrical solutions is expected to grow, driven by advancements in technology and increasing infrastructure projects worldwide. Now is the ideal time for businesses to reassess their supply chains and explore new opportunities in braided electrical wire sourcing. Engage with trusted suppliers and industry experts to ensure you remain at the forefront of this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.