Bonded Rubber: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for bonded rubber

In an increasingly competitive landscape, sourcing bonded rubber surfacing presents a unique challenge for B2B buyers focused on safety, durability, and aesthetics. As international markets expand, particularly in regions such as Africa, South America, the Middle East, and Europe—including key players like Germany and Nigeria—understanding the nuances of bonded rubber becomes paramount. This guide serves as a comprehensive resource, addressing various types of bonded rubber products, their diverse applications in playgrounds and sports facilities, and the critical factors for supplier vetting.

International buyers will benefit from insights into installation costs, maintenance requirements, and compliance with safety standards, ensuring that they make informed purchasing decisions tailored to their specific regional needs. Additionally, we explore the environmental benefits and longevity of bonded rubber, highlighting its growing popularity as a sustainable choice for public and private sectors alike. By equipping B2B buyers with essential knowledge and actionable strategies, this guide aims to simplify the sourcing process, enabling stakeholders to navigate the complexities of the global bonded rubber market effectively. Whether you are a contractor, facility manager, or procurement officer, understanding the landscape of bonded rubber will empower you to choose solutions that align with your organizational goals and community safety standards.

Understanding bonded rubber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bonded Rubber Mulch | Made from shredded rubber with a binding agent, resembles wood mulch | Playgrounds, parks, residential areas | Pros: Aesthetic appeal, low maintenance; Cons: Higher initial cost, requires professional installation. |

| Poured-in-Place Rubber | Seamless surface poured on-site, customizable thickness | Sports facilities, commercial playgrounds | Pros: Highly durable, customizable; Cons: More expensive, longer installation time. |

| Rubber Tile Flooring | Interlocking tiles, easy to install, available in various colors | Gyms, fitness centers, commercial spaces | Pros: Easy installation, versatile design; Cons: May require periodic replacement, less impact absorption than bonded options. |

| Bonded Rubber Pathways | Designed for walkways, offers slip resistance and durability | Parks, nature trails, outdoor recreation areas | Pros: Enhances accessibility, low maintenance; Cons: Installation complexity, initial cost considerations. |

| Decorative Rubber Mulch | Available in various colors, used for landscaping and aesthetics | Landscaping, garden paths, playgrounds | Pros: Enhances visual appeal, eco-friendly; Cons: May not provide the same safety ratings as other types. |

What Are the Key Characteristics of Bonded Rubber Mulch?

Bonded rubber mulch is a popular choice for playgrounds and parks, combining aesthetic appeal with safety. This type consists of shredded rubber mixed with a binding agent, creating a surface that mimics natural wood mulch. It offers excellent impact absorption, making it suitable for areas where children play. When purchasing, consider the installation costs and the need for professional services to ensure a proper setup. The long-term benefits, such as low maintenance and durability, can outweigh the initial investment.

How Does Poured-in-Place Rubber Differ from Other Types?

Poured-in-place rubber is a seamless, custom-fit surface ideal for high-traffic areas like sports facilities and commercial playgrounds. This type allows for various thicknesses to meet specific safety standards. While it offers exceptional durability and a high degree of customization, its installation can be time-consuming and costly. B2B buyers should evaluate the long-term cost-effectiveness against the initial investment, as its longevity often compensates for the upfront expenses.

What Are the Benefits of Rubber Tile Flooring?

Rubber tile flooring is an interlocking system that provides an easy installation process, making it ideal for gyms and commercial spaces. Available in a variety of colors and designs, this flooring option allows businesses to customize their environments. However, while it is simple to install, it may not absorb impacts as well as bonded rubber options, making it less suitable for playgrounds. Buyers should weigh the versatility and ease of maintenance against the potential need for replacement.

Why Choose Bonded Rubber Pathways for Outdoor Areas?

Bonded rubber pathways are designed to provide a durable, slip-resistant surface that enhances accessibility in parks and outdoor recreation areas. This type is particularly beneficial for ensuring safe movement for individuals with mobility challenges. The installation process can be complex, requiring skilled labor, but the low maintenance and long lifespan make it an attractive option for municipalities and businesses. Evaluating the initial costs against the benefits of accessibility and safety is crucial for B2B buyers.

What Makes Decorative Rubber Mulch an Attractive Option?

Decorative rubber mulch is primarily used for landscaping and aesthetic purposes, available in various colors to enhance visual appeal. While it provides some safety benefits, it may not meet the same safety ratings as other bonded rubber types. B2B buyers should consider its environmental benefits, as it is made from recycled materials, and its ability to reduce maintenance compared to traditional mulch. However, assessing its suitability for safety-critical applications is essential before making a purchase decision.

Key Industrial Applications of bonded rubber

| Industry/Sector | Specific Application of Bonded Rubber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Playground and Recreational Facilities | Safety surfacing for playgrounds and sports areas | Provides superior impact absorption, ensuring child safety and reducing liability for operators | Ensure compliance with ASTM safety standards; consider local installation expertise |

| Landscaping and Urban Development | Pathways and trails in parks and public spaces | Enhances aesthetics while providing a durable, low-maintenance surface that withstands various weather conditions | Evaluate sourcing of eco-friendly materials; focus on durability and design flexibility |

| Sports Facilities | Flooring for indoor sports courts and gyms | Offers excellent traction and shock absorption, improving athlete performance and safety | Assess customization options for color and design; ensure proper installation techniques are available |

| Equestrian and Agricultural | Stable flooring and riding arenas | Provides a non-slip, cushioned surface that reduces injury risks for horses and riders | Source materials that are resistant to weathering and provide easy drainage solutions |

| Educational Institutions | Surfaces for outdoor classrooms and activity areas | Promotes active learning environments while ensuring safety and accessibility for all students | Verify ADA compliance and consider local climate impacts on material longevity |

How is Bonded Rubber Used in Playground and Recreational Facilities?

In playgrounds and recreational facilities, bonded rubber serves as a safety surfacing option that significantly reduces the risk of injury from falls. Its unique composition provides superior impact absorption, making it compliant with ASTM safety standards. For international buyers, especially in regions like Africa and South America, it’s crucial to ensure that local suppliers can provide certified materials and experienced installation services. Additionally, the long lifespan and low maintenance requirements of bonded rubber make it an economically viable choice for municipalities and private operators alike.

What Role Does Bonded Rubber Play in Landscaping and Urban Development?

Bonded rubber is increasingly used in landscaping and urban development for creating aesthetically pleasing pathways and trails in parks and public spaces. Its natural appearance mimics wood mulch while offering durability and weather resistance. For buyers in Europe, particularly in Germany, sourcing eco-friendly materials is vital, as sustainability is a growing concern. The product’s design flexibility allows for various colors and textures, enhancing the visual appeal of urban landscapes while minimizing maintenance efforts.

How is Bonded Rubber Beneficial in Sports Facilities?

In sports facilities, bonded rubber flooring provides an ideal surface for indoor courts and gyms, offering excellent traction and shock absorption. This not only enhances athlete performance but also minimizes the risk of injuries during play. For international buyers, particularly in competitive sports markets, ensuring that the flooring meets specific performance standards and can be customized for different sports is essential. Additionally, sourcing from reputable suppliers who understand local regulations will streamline the procurement process.

What Are the Applications of Bonded Rubber in Equestrian and Agricultural Settings?

In equestrian and agricultural environments, bonded rubber is used for stable flooring and riding arenas, providing a non-slip, cushioned surface. This significantly reduces the risk of injuries for both horses and riders, making it a preferred choice among equestrian facilities. Buyers from regions with varying climates, such as the Middle East, should consider sourcing materials that are weather-resistant and facilitate easy drainage to maintain a safe environment year-round.

How Does Bonded Rubber Enhance Educational Institutions?

Bonded rubber surfaces in educational institutions are used for outdoor classrooms and activity areas, promoting active learning while ensuring safety for students. Its ADA compliance makes it accessible for all students, including those with disabilities. For buyers in diverse regions, it’s important to assess local climate impacts on material longevity and sourcing options that align with educational budgets. The combination of safety, accessibility, and aesthetic appeal makes bonded rubber a valuable investment for schools looking to enhance their outdoor learning environments.

3 Common User Pain Points for ‘bonded rubber’ & Their Solutions

Scenario 1: Navigating High Installation Costs for Bonded Rubber Surfaces

The Problem:

Many B2B buyers, particularly those in emerging markets, often face the challenge of high initial costs associated with installing bonded rubber surfaces. This can be especially daunting for municipalities or organizations with limited budgets, as the upfront investment can be significantly higher than alternatives like loose-fill materials. Furthermore, the need for professional installation adds to the overall expense, leading to concerns about whether the investment is justified.

The Solution:

To mitigate these costs, buyers should consider a multi-pronged approach. First, sourcing materials locally can significantly reduce shipping expenses and expedite delivery times. Establishing relationships with local suppliers who provide high-quality bonded rubber can also lead to favorable pricing. Additionally, buyers can engage in community partnerships or funding initiatives to share the installation costs. For instance, collaborating with local schools or recreational organizations to enhance community spaces can attract funding or grants. Finally, investing in training for in-house staff to perform the installation can cut costs in the long run, as it reduces reliance on external contractors. By weighing these options, buyers can make a financially sound decision while still achieving a safe and durable playground surface.

Scenario 2: Ensuring Safety Compliance and Standards for Bonded Rubber

The Problem:

B2B buyers in the playground and recreational sectors are increasingly concerned about meeting safety regulations and compliance standards. Bonded rubber surfaces must meet ASTM critical fall height requirements to ensure child safety. However, many buyers are unsure how to verify that their chosen material meets these standards, leading to anxiety about potential liabilities and compliance issues.

The Solution:

To ensure compliance, buyers should prioritize sourcing bonded rubber from reputable manufacturers who provide clear documentation of safety certifications. Requesting detailed product specifications, including test results from recognized testing laboratories, is essential. Buyers can also engage with industry experts or consultants who specialize in playground safety to audit their installations and recommend best practices. Additionally, implementing a regular maintenance schedule, including periodic inspections of the surface integrity, will help maintain compliance over time. Establishing a clear record of safety checks and maintenance can also serve as a defense against potential liability claims.

Scenario 3: Addressing Maintenance Concerns for Long-Term Durability

The Problem:

Despite the durability of bonded rubber, some buyers express concerns about its long-term maintenance and upkeep. Issues such as debris accumulation, surface wear, and aesthetic degradation can arise, leading to frustration among facility managers who want to maintain a safe and visually appealing environment for users.

Illustrative image related to bonded rubber

The Solution:

To effectively manage maintenance, buyers should develop a comprehensive maintenance plan tailored to their specific environment. Regular cleaning schedules, including blowing or sweeping away debris, can be established to keep the surface looking pristine. Buyers should also consider using specialized maintenance tools designed for bonded rubber surfaces to prevent damage during cleaning. Additionally, training staff on how to identify and address minor wear issues before they escalate can prolong the lifespan of the surface. Implementing a proactive approach to maintenance not only enhances user safety but also ensures that the playground or recreational area remains inviting and functional for years to come. By investing time and resources into maintenance, buyers can protect their initial investment and ensure ongoing satisfaction with their bonded rubber surfacing.

Strategic Material Selection Guide for bonded rubber

What Are the Key Materials Used in Bonded Rubber Production?

When selecting materials for bonded rubber applications, it is essential to consider the properties, advantages, and limitations of each option. Here, we analyze four common materials used in the production of bonded rubber: recycled rubber, binding agents, color additives, and fillers.

How Does Recycled Rubber Contribute to Bonded Rubber Performance?

Recycled rubber, often sourced from scrap tires, is the primary component in bonded rubber formulations. Its key properties include excellent durability, impact absorption, and resistance to various weather conditions. This material can withstand extreme temperatures without significant degradation, making it suitable for diverse climates, from the humid conditions in Nigeria to the colder environments in Germany.

Pros: Recycled rubber is environmentally friendly and cost-effective, providing a sustainable solution for playground and pathway surfacing. Its durability ensures a long lifespan, reducing the need for frequent replacements.

Illustrative image related to bonded rubber

Cons: The initial sourcing of high-quality recycled rubber can be complex due to variations in material quality. Additionally, the presence of contaminants can affect the final product’s performance.

Impact on Application: The use of recycled rubber enhances safety in playgrounds by providing a cushioning effect that meets ASTM critical fall height requirements.

What Role Do Binding Agents Play in Bonded Rubber?

Binding agents, such as polyurethane or aromatic binders, are crucial for ensuring the integrity and longevity of bonded rubber surfaces. These agents provide adhesion between rubber particles, allowing the material to form a solid, stable layer.

Pros: Binding agents improve the overall strength and durability of the bonded rubber surface, making it resistant to displacement and wear. They also enhance the surface’s resistance to microbial growth, which is essential for maintaining hygiene in playgrounds.

Cons: The cost of high-quality binding agents can increase the overall installation expense. Moreover, the curing time required for these agents can delay the usability of the surface.

Impact on Application: The choice of binding agent affects the surface’s compliance with international standards, such as ASTM and DIN, which are crucial for safety certifications.

How Do Color Additives Enhance Aesthetic Appeal?

Color additives, typically in the form of EPDM granules, are used to enhance the visual appeal of bonded rubber surfaces. These additives allow for a wide range of color options, catering to aesthetic preferences in various regions.

Pros: The inclusion of color additives can significantly increase the aesthetic appeal of playgrounds and recreational areas, making them more inviting. They also offer UV resistance, preventing fading over time.

Cons: The cost of color additives can add to the overall material expense. Additionally, the quality of color additives can vary, impacting the long-term appearance of the surface.

Impact on Application: Aesthetically pleasing surfaces can influence community acceptance and usage rates, particularly in regions where visual appeal is a significant factor in design.

What Are the Benefits of Using Fillers in Bonded Rubber?

Fillers, such as silica or clay, can be added to bonded rubber formulations to enhance specific properties, including density and cost-effectiveness.

Pros: Fillers can improve the mechanical properties of bonded rubber, making it more robust and cost-efficient. They can also help in reducing the overall material cost by replacing a portion of the more expensive rubber.

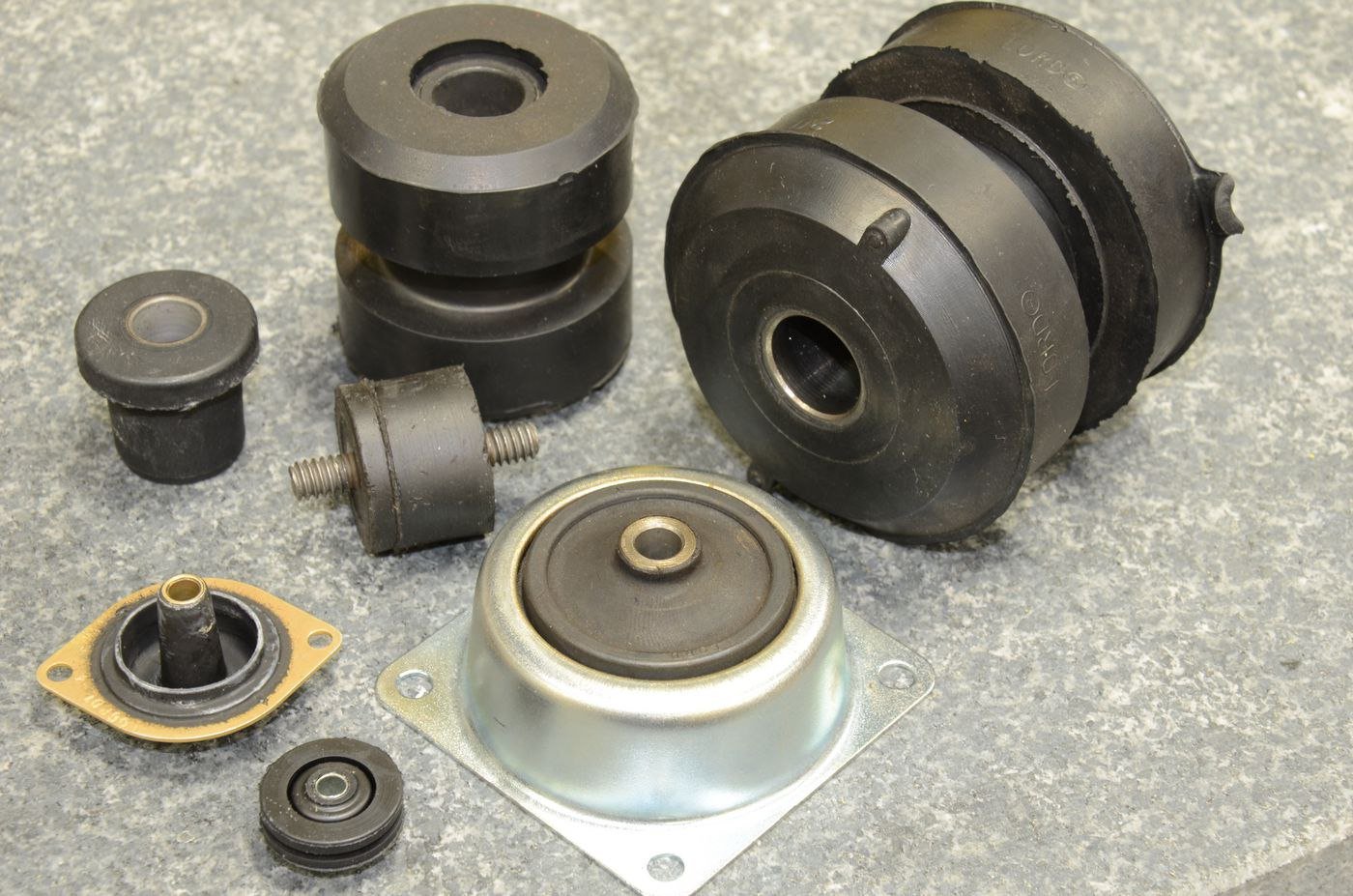

Illustrative image related to bonded rubber

Cons: The addition of fillers can sometimes compromise the elasticity and impact absorption capabilities of the final product. Careful selection and testing are necessary to ensure that performance standards are met.

Impact on Application: The use of fillers must be balanced with performance requirements, particularly in safety-critical applications like playgrounds.

Summary Table of Material Selection for Bonded Rubber

| Material | Typical Use Case for Bonded Rubber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Recycled Rubber | Playground surfacing | Environmentally friendly and durable | Sourcing quality can be complex | Medium |

| Binding Agents | Adhesion in bonded rubber | Enhances strength and durability | Increases installation costs | High |

| Color Additives | Aesthetic enhancement | Wide range of colors and UV resistance | Adds to overall material expense | Medium |

| Fillers | Cost-effective formulations | Improves mechanical properties | May compromise elasticity and impact absorption | Low |

This strategic material selection guide provides actionable insights for international B2B buyers, ensuring informed decisions that align with regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bonded rubber

What Are the Key Stages in the Manufacturing Process of Bonded Rubber?

The manufacturing process for bonded rubber involves several critical stages, each designed to ensure the final product meets safety, durability, and aesthetic standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Processing Raw Materials

The first step in manufacturing bonded rubber is sourcing high-quality raw materials. Typically, recycled rubber from tires or other industrial sources is used. This rubber is processed into small shreds or granules, which are then screened to ensure uniformity in size. The binding agents, often polyurethane or similar compounds, are also prepared during this stage. The quality of these materials is essential as they directly influence the performance and longevity of the bonded rubber surface.

Forming: Mixing and Application Techniques

Once the materials are prepared, they are mixed in a controlled environment. The rubber shreds are combined with the binding agents in specific ratios, ensuring an optimal blend for adhesion and durability. This mixture is then spread onto the prepared surface area. Key techniques include hand-troweling or using specialized equipment for uniform application. The goal is to achieve a consistent thickness that meets safety standards, such as ASTM critical fall height requirements.

Assembly: Curing and Setting

After the bonded rubber is applied, it undergoes a curing process. This is crucial for the binding agent to set properly, ensuring the rubber adheres firmly to the substrate. The curing time can vary based on environmental conditions, but it typically ranges from 24 to 48 hours. During this phase, it’s essential to monitor temperature and humidity levels to prevent defects in the final product.

Finishing: Quality Checks and Surface Treatment

Once cured, the bonded rubber surface is subjected to finishing treatments. This may include additional texture treatments to enhance slip resistance or aesthetic considerations, such as dyeing the rubber. Final inspections are conducted to ensure that the surface is free from defects and meets the required specifications.

What Quality Assurance Measures Are Implemented in Bonded Rubber Manufacturing?

Quality assurance (QA) is a vital aspect of bonded rubber production, ensuring that the final product adheres to international standards and customer expectations. Several QA measures are typically implemented throughout the manufacturing process.

Which International Standards Govern Bonded Rubber Quality?

Manufacturers of bonded rubber should comply with several international standards, such as ISO 9001, which outlines quality management systems. Additionally, industry-specific certifications like CE marking (for products sold in Europe) and compliance with ASTM standards are crucial for validating product safety and performance.

Illustrative image related to bonded rubber

What Are the Key Quality Control Checkpoints in Bonded Rubber Production?

Quality control (QC) is integrated into various stages of the manufacturing process, typically including:

-

Incoming Quality Control (IQC): This checkpoint involves the inspection of raw materials upon arrival. Rubber granules and binding agents are tested for quality, consistency, and compliance with specifications.

-

In-Process Quality Control (IPQC): During the mixing and application phases, samples are taken at regular intervals to ensure that the mixing ratios are correct and that the application techniques meet operational standards.

-

Final Quality Control (FQC): After curing, the finished product undergoes a comprehensive inspection. This includes visual assessments, adhesion tests, and impact resistance evaluations to ensure compliance with safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks and ensure product reliability.

What Methods Can Buyers Use to Evaluate Supplier Quality?

-

Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and QA practices. Buyers should assess the supplier’s compliance with international standards and the effectiveness of their quality management systems.

-

Reports and Documentation: Suppliers should provide comprehensive documentation, including test results, certification copies, and quality assurance reports. This transparency can help buyers confirm that the products meet specified standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturer’s processes and product quality. These agencies can conduct pre-shipment inspections to ensure that the products meet the agreed specifications.

What QC Nuances Should International B2B Buyers Be Aware Of?

International buyers should be aware that quality assurance practices can vary significantly by region. For instance, European suppliers may adhere to stricter environmental and safety regulations compared to those in other regions. Understanding these nuances is critical for ensuring compliance and quality.

How Do Regional Regulations Affect Quality Assurance?

In Europe, for example, the CE marking signifies that a product meets EU safety and environmental requirements, which may not be as stringent in other regions. Buyers in Africa and South America should ensure that their suppliers are compliant with local regulations, which may differ significantly from international standards.

What Are the Challenges in Quality Control for International Transactions?

Language barriers, differing quality expectations, and logistical issues can complicate quality assurance in international transactions. Buyers should establish clear communication channels and set explicit quality expectations from the outset to mitigate these challenges.

By understanding the manufacturing processes and quality assurance measures associated with bonded rubber, B2B buyers can make informed decisions that ensure they receive a product that meets their specific requirements and complies with international standards. This knowledge is vital for establishing long-term partnerships with reliable suppliers and ensuring the safety and satisfaction of end-users.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bonded rubber’

This guide provides a structured approach for B2B buyers looking to procure bonded rubber, ensuring that you make informed decisions based on safety, cost, and supplier reliability. Follow these steps to streamline your sourcing process and secure the best options for your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the bonded rubber meets your project requirements. Consider factors such as thickness, color options, and compliance with safety standards like ASTM F1951. This step will help you communicate effectively with suppliers and avoid potential issues during installation.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of bonded rubber. Look for companies with a strong track record in the industry, preferably with experience in your region, such as Africa, South America, or Europe. Use online platforms, industry forums, and trade shows to gather information about potential suppliers and their offerings.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it’s crucial to verify that your chosen suppliers have the necessary certifications. Check for ISO certifications, environmental compliance (like recycled content), and safety certifications relevant to playground equipment. Valid certifications indicate a commitment to quality and safety, which is essential for minimizing liability.

Step 4: Request Samples and Test Products

Always request samples of the bonded rubber before placing a bulk order. Testing samples will help you evaluate the material’s durability, texture, and overall suitability for your intended use. Pay attention to how the rubber performs under different conditions, such as varying temperatures and moisture levels.

Step 5: Assess Installation Requirements

Understanding the installation process is key to managing costs and timelines. Inquire whether the supplier provides installation services or if you will need to hire a contractor. If opting for self-installation, ensure you have access to detailed installation instructions and the necessary tools.

Step 6: Review Maintenance and Longevity

Discuss the maintenance requirements and expected lifespan of the bonded rubber with potential suppliers. High-quality bonded rubber should be low-maintenance and durable, offering long-term cost-effectiveness despite a potentially higher initial investment. Ask about warranties or guarantees that cover wear and tear over time.

Step 7: Negotiate Terms and Finalize the Purchase

Once you’ve selected a supplier, negotiate the terms of your purchase, including pricing, delivery timelines, and payment options. Clear communication is essential to avoid misunderstandings. Ensure that you have a written agreement detailing all terms to protect both parties involved.

By following these steps, you can ensure that your procurement process for bonded rubber is thorough, strategic, and ultimately successful. This approach will help you secure a high-quality product that meets your safety and aesthetic needs while also being cost-effective.

Comprehensive Cost and Pricing Analysis for bonded rubber Sourcing

What Are the Key Cost Components in Bonded Rubber Sourcing?

When evaluating the costs associated with sourcing bonded rubber, several key components must be considered. These include:

-

Materials: The primary component of bonded rubber is shredded rubber, often sourced from recycled materials. The quality and type of rubber, such as SBR (Styrene-Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer), will significantly influence costs. Additionally, the binding agents used in the installation process can vary in price based on their quality and supplier.

-

Labor: Installation of bonded rubber surfaces is labor-intensive. It typically requires skilled labor for proper site preparation, mixing of materials, and hand-troweling to achieve a smooth finish. Labor costs will vary depending on local wage rates and the complexity of the project.

-

Manufacturing Overhead: This includes costs related to the production process, including utilities, equipment maintenance, and facility costs. Efficient manufacturing can help reduce overhead, impacting the final price.

-

Tooling: The tools necessary for installation, such as trowels and mixers, represent an additional cost factor. Some suppliers may include rental or purchase options for these tools in their pricing.

-

Quality Control (QC): Ensuring that the bonded rubber meets safety standards (e.g., ASTM) incurs additional costs related to testing and certification. Buyers should verify that their suppliers adhere to these quality benchmarks.

-

Logistics: Shipping costs can fluctuate significantly based on the distance from the supplier to the buyer, the weight of the materials, and the chosen shipping method. International buyers should be particularly aware of potential customs duties and import taxes.

-

Margin: Suppliers will typically apply a markup to cover operational costs and profit. Understanding the supplier’s margin can aid in negotiations.

How Do Price Influencers Affect Bonded Rubber Costs?

Several factors can influence the pricing of bonded rubber, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs. Buyers should consider negotiating higher volumes to benefit from price breaks.

-

Specifications and Customization: Custom colors or specific formulations can increase costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials that meet stringent safety standards will command higher prices. Buyers should prioritize certified products, especially in regions with strict regulations.

-

Supplier Factors: Supplier reputation, reliability, and past performance can impact pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer lower prices to build market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects who bears costs and risks during shipping. Understanding these terms is crucial for accurately calculating total landed costs.

What Tips Can Help Buyers Negotiate Better Prices for Bonded Rubber?

-

Understand Total Cost of Ownership (TCO): While initial costs are important, consider the long-term savings associated with maintenance and durability. Bonded rubber surfaces typically require less upkeep than alternatives, making them cost-effective over time.

-

Leverage Local Suppliers: For international buyers, sourcing materials locally can reduce shipping costs significantly. Collaborate with suppliers who offer local sourcing options to maximize savings.

-

Negotiate Terms: Don’t hesitate to negotiate on price, payment terms, and delivery schedules. Suppliers may be willing to adjust their pricing based on the buyer’s commitment level or payment terms.

-

Research and Compare: Obtain quotes from multiple suppliers to benchmark pricing and understand market rates. This can empower buyers during negotiations and may reveal potential cost-saving opportunities.

-

Stay Informed on Market Trends: Awareness of fluctuations in raw material prices, global supply chain issues, and industry trends can provide leverage in negotiations and assist in making informed purchasing decisions.

Conclusion

While the initial investment in bonded rubber can be higher than other materials, understanding the cost structure and pricing influencers is crucial for B2B buyers. By focusing on TCO, negotiating effectively, and considering local sourcing options, businesses can maximize value in their bonded rubber purchases. Always remember that prices can vary widely based on numerous factors, so it’s advisable to seek multiple quotes and verify supplier credentials.

Illustrative image related to bonded rubber

Alternatives Analysis: Comparing bonded rubber With Other Solutions

Understanding Alternatives to Bonded Rubber for Playground Surfacing

When selecting the ideal surfacing solution for playgrounds, it is essential to consider alternatives to bonded rubber that fulfill similar safety and aesthetic functions. Various options exist in the market, each with distinct advantages and disadvantages. This analysis compares bonded rubber against two viable alternatives: poured-in-place rubber and wood mulch.

Comparison of Bonded Rubber and Alternatives

| Comparison Aspect | Bonded Rubber | Poured-in-Place Rubber | Wood Mulch |

|---|---|---|---|

| Performance | Excellent impact absorption; meets ASTM standards | Superior safety, customizable thickness; seamless surface | Moderate impact absorption; may displace easily |

| Cost | Higher initial cost, low lifetime cost | Moderate to high initial cost, variable lifetime cost | Low initial cost, higher replenishment costs |

| Ease of Implementation | Requires skilled installation; manual troweling necessary | Professional installation recommended; can be complex | Easy to install; DIY-friendly |

| Maintenance | Low maintenance; no raking required | Moderate maintenance; may require periodic resurfacing | High maintenance; frequent replenishment needed |

| Best Use Case | Ideal for playgrounds needing safety and aesthetics | Suitable for high-traffic areas and customized designs | Best for natural, rustic settings |

Exploring Poured-in-Place Rubber as an Alternative

Poured-in-place rubber is a popular alternative to bonded rubber, providing a seamless surface that is highly customizable in thickness and color. This option excels in performance, particularly in high-traffic areas where safety is paramount. However, its installation can be complex and often requires professional contractors, which can increase initial costs. Maintenance is moderate; while it does not require frequent replenishment, it may need periodic resurfacing to maintain its integrity.

Evaluating Wood Mulch for Playground Surfacing

Wood mulch is a traditional playground surfacing choice that offers a natural aesthetic and is generally the most cost-effective option upfront. It provides decent impact absorption but lacks the stability of unitary surfaces like bonded rubber and poured-in-place rubber. Wood mulch requires significant ongoing maintenance, including regular raking and replenishment, which can lead to higher long-term costs. Additionally, it is susceptible to displacement, especially in high-traffic areas, making it less reliable for safety compared to rubber options.

Illustrative image related to bonded rubber

Conclusion: Choosing the Right Surfacing Solution for Your Needs

When deciding on the best playground surfacing solution, B2B buyers must consider the specific needs of their project, including safety standards, budget constraints, and maintenance capabilities. Bonded rubber offers a balance of safety and aesthetics, making it ideal for high-quality playgrounds. Poured-in-place rubber provides flexibility and a seamless finish, while wood mulch is a budget-friendly option but requires ongoing maintenance. By assessing these factors, buyers can make an informed choice that aligns with their project goals and long-term operational efficiency.

Essential Technical Properties and Trade Terminology for bonded rubber

What Are the Key Technical Properties of Bonded Rubber?

When considering bonded rubber for commercial applications, several technical properties are critical for ensuring safety, durability, and cost-effectiveness. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

1. Material Composition

Bonded rubber is typically made from recycled rubber materials, which are combined with a binding agent to create a unitary surface. The quality of the rubber used affects the overall performance, including durability and safety. High-quality rubber ensures better impact absorption, which is crucial for playground surfaces. B2B buyers should verify that the materials meet industry standards to ensure a reliable product.

Illustrative image related to bonded rubber

2. ASTM Safety Ratings

ASTM (American Society for Testing and Materials) ratings are vital in assessing the safety characteristics of bonded rubber surfaces. Specifically, ASTM F1951 tests measure the surface’s impact attenuation, ensuring it meets critical fall height requirements. For buyers, understanding these ratings helps in selecting surfaces that provide optimal safety for end-users, particularly in playgrounds and recreational areas.

3. Surface Texture and Slip Resistance

The textured surface of bonded rubber enhances slip resistance, making it a safer option for environments where falls may occur. This property is particularly beneficial in playgrounds, sports facilities, and other high-traffic areas. Buyers should inquire about the surface texture to ensure it meets safety regulations and provides adequate grip, especially in wet conditions.

4. Installation Requirements

Bonded rubber installation requires precise preparation and skilled labor. It is typically a one-layer system, which can reduce installation complexity compared to multi-layer systems. However, the requirement for professional installation means that buyers must factor in labor costs and select qualified contractors. Understanding the installation process can help buyers anticipate timelines and budget accordingly.

5. Maintenance and Lifespan

One of the significant advantages of bonded rubber is its low maintenance needs and long lifespan. Unlike loose fill materials, bonded rubber does not require constant raking or replenishing. Its durability and resistance to wear make it a cost-effective choice over time. Buyers should consider the total cost of ownership, including maintenance and replacement intervals, when evaluating options.

6. Environmental Impact

Since bonded rubber is made from recycled materials, it offers an eco-friendly alternative to traditional surfacing options. Buyers focusing on sustainability will find bonded rubber appealing as it reduces waste and supports recycling initiatives. Understanding the environmental benefits can enhance a company’s corporate responsibility profile.

What Are Common Trade Terminology and Acronyms Related to Bonded Rubber?

Familiarity with trade terminology is essential for B2B transactions, as it facilitates clear communication and negotiation.

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bonded rubber, OEMs may provide the raw materials or components that make up the final product. Buyers should identify reliable OEMs to ensure quality and consistency.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding the MOQ is crucial for buyers to manage inventory and costs effectively. Suppliers may set MOQs based on production capacities, so negotiating this term can be beneficial, especially for smaller buyers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For bonded rubber, issuing an RFQ allows buyers to compare prices, delivery times, and terms from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities when sourcing bonded rubber from international suppliers.

5. ASTM (American Society for Testing and Materials)

As mentioned earlier, ASTM standards are crucial for ensuring the quality and safety of materials. Buyers should look for products that meet relevant ASTM standards to guarantee compliance and safety.

6. Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times for bonded rubber products is essential for project planning and avoiding delays in installation. Buyers should discuss lead times with suppliers upfront to ensure timely delivery.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing bonded rubber, ensuring that their investments are safe, durable, and cost-effective.

Navigating Market Dynamics and Sourcing Trends in the bonded rubber Sector

What Are the Current Trends and Market Dynamics in the Bonded Rubber Sector?

The bonded rubber sector is experiencing robust growth driven by increased demand for safe and sustainable playground surfaces, as well as a rise in eco-consciousness among consumers and businesses alike. Globally, cities and municipalities are investing in public recreational spaces, spurred by an emphasis on child safety and community wellness. In regions such as Africa and South America, urbanization is accelerating the need for durable, low-maintenance surfacing solutions. Meanwhile, European markets, particularly in Germany, are focusing on compliance with stringent safety and environmental regulations, which favor bonded rubber products due to their superior impact absorption and cleanliness.

Emerging B2B tech trends include the use of online platforms for sourcing materials, allowing buyers to connect directly with manufacturers and suppliers, thereby streamlining procurement processes. Additionally, advancements in materials science are leading to the development of more innovative, durable, and aesthetically pleasing bonded rubber products. As international buyers navigate these dynamics, they should consider the importance of certifications such as ASTM compliance, which enhances product credibility and safety assurance.

How Is Sustainability Shaping the Sourcing of Bonded Rubber Products?

Sustainability is a key driver in the bonded rubber industry, influencing sourcing decisions and product development. The environmental impact of bonded rubber is significantly lower than traditional materials, as it is primarily produced from recycled rubber, reducing landfill waste and promoting circular economy principles. For B2B buyers, sourcing bonded rubber from suppliers who adhere to ethical practices is crucial. This includes ensuring that the rubber is sourced responsibly, with minimal environmental footprint and adherence to fair labor practices.

Illustrative image related to bonded rubber

Certification plays a vital role in this aspect, with various ‘green’ certifications available for bonded rubber products. These certifications not only validate the sustainability claims of manufacturers but also provide buyers with peace of mind regarding the materials they are investing in. By prioritizing suppliers with these certifications, businesses can enhance their corporate social responsibility initiatives while meeting growing consumer demands for environmentally friendly products.

What Is the Historical Context of Bonded Rubber in the B2B Market?

The evolution of bonded rubber began in the late 20th century as an innovative solution to address safety concerns associated with traditional playground surfacing materials, such as wood chips and sand. The need for safer, more durable, and low-maintenance options led to the development of bonded rubber, which combines shredded rubber with a binding agent to create a uniform surface that meets safety standards.

Initially adopted in North America, the technology has since spread globally, with increasing acceptance in emerging markets. As regulations surrounding playground safety and environmental sustainability have tightened, bonded rubber has positioned itself as a preferred choice for public and private installations. This historical context not only highlights the product’s adaptability but also underscores its relevance in today’s market, particularly for international buyers looking for reliable and sustainable surfacing solutions.

By understanding these trends and dynamics, B2B buyers can make informed decisions that align with their operational needs and sustainability goals, ensuring they remain competitive in an evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of bonded rubber

1. How do I choose the right bonded rubber supplier for my business needs?

Selecting a reliable bonded rubber supplier requires thorough research and consideration of several factors. Start by evaluating their industry experience and reputation through customer testimonials and case studies. Ensure they offer quality products that meet international safety standards, such as ASTM certifications. Inquire about their production capacity and whether they can accommodate your specific needs, including custom colors or textures. Additionally, assess their communication responsiveness and willingness to support your queries during the procurement process.

2. What is the minimum order quantity (MOQ) for bonded rubber products?

Minimum order quantities for bonded rubber can vary significantly between suppliers, typically ranging from 500 kg to several tons. It’s important to discuss your specific needs with potential suppliers to find one that aligns with your order size. Some suppliers may offer flexible MOQs for first-time buyers or smaller businesses, while others might require higher quantities for cost-effectiveness. Always confirm the MOQ before finalizing a supplier to ensure it fits within your budget and project requirements.

3. What are the payment terms I should expect when purchasing bonded rubber internationally?

Payment terms for international purchases of bonded rubber often include options like advance payment, letters of credit, or net terms (e.g., 30, 60, or 90 days). It’s crucial to negotiate favorable terms that balance risk and cash flow for your business. Most suppliers will require a deposit upfront, especially for custom orders, with the remaining balance due upon shipment or delivery. Always clarify payment methods accepted and any fees associated with international transactions.

4. How can I ensure quality assurance (QA) for bonded rubber products?

To ensure quality assurance for bonded rubber, request certifications and test results that demonstrate compliance with industry standards. A reputable supplier should provide documentation for material safety, durability, and performance, including ASTM testing results. Consider visiting the manufacturing facility if feasible, or request samples to evaluate material quality firsthand. Establishing a clear QA protocol with your supplier can help maintain consistent quality across your orders.

5. What are the logistics considerations for shipping bonded rubber internationally?

When shipping bonded rubber internationally, consider the mode of transport, delivery times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but may take longer. Ensure that your supplier is experienced in international shipping and can handle the necessary documentation, including bills of lading and customs declarations. Additionally, clarify responsibilities for duties and taxes to avoid unexpected costs upon arrival.

6. How does bonded rubber compare to other playground surfacing materials?

Bonded rubber offers several advantages over traditional playground surfacing materials like wood mulch or poured-in-place rubber. It provides superior impact absorption, is easier to maintain, and remains in place during adverse weather conditions. Additionally, bonded rubber does not harbor pests or require regular raking, making it a cleaner option. Its aesthetic versatility allows for color customization, giving playgrounds a more natural look while ensuring safety and compliance with standards.

7. Can bonded rubber be customized for specific projects?

Yes, bonded rubber can often be customized to meet the specific needs of your project. Suppliers typically offer various color options and textures to create visually appealing surfaces that fit your design vision. Additionally, you can specify the depth and thickness of the application to meet safety standards for specific equipment or usage scenarios. Always discuss customization options with your supplier to ensure they can accommodate your requests within your timeline and budget.

8. What are the environmental benefits of using bonded rubber?

Bonded rubber is an environmentally friendly choice for playground and landscaping surfaces. Made from 100% recycled rubber, it reduces waste by repurposing materials that would otherwise end up in landfills. The longevity and durability of bonded rubber also mean less frequent replacements, minimizing resource consumption over time. Furthermore, its non-toxic nature ensures a safe play environment for children, making it a sustainable option for both commercial and residential applications.

Top 7 Bonded Rubber Manufacturers & Suppliers List

1. XGrass – Bonded Rubber Surfacing

Domain: xgrass.com

Registered: 2004 (21 years)

Introduction: Bonded rubber surfacing is a playground surfacing option that combines shredded rubber mulch with a binding agent, providing a natural appearance similar to wood mulch while ensuring safety and low maintenance. Key features include:

– Safety: Excellent safety rating with superior impact absorption, meeting ASTM critical fall height requirements, textured surface for slip-resistance, and does not …

2. Trassig – Bonded Rubber

Domain: trassig.com

Registered: 2010 (15 years)

Introduction: Product Name: Bonded Rubber

SKU: Bonded Rubber

Price: $95.00

Packaging: Sold in 50 lb bags

Description: Bonded Rubber is a safety surfacing option for residential jungle gyms and play equipment. It is easy to install, requiring only aromatic binders and a solid base of compacted crushed stone. The product is made from 100% recycled rubber, coated with a fade-resistant color, and does not attract i…

3. Rubber Designs – Bonded Rubber Mulch

Domain: rubberdesigns.com

Registered: 2009 (16 years)

Introduction: Bonded Rubber Mulch is a safety surfacing option that provides a natural trail or path system and playground safety surface. It is a one-step pour, cost-effective, long-lasting, safe, and durable, suitable for playgrounds, parks, zoos, horse walking/training facilities, and themed water play areas. The product allows for piling and sloping, offers anti-fatigue qualities, and meets ASTM F-1292-96 a…

4. FlexGround – FlexBond

Domain: flexground.com

Registered: 2006 (19 years)

Introduction: FlexBond is a versatile single layer unitary surfacing system for playgrounds, walking trails, and landscaping. Key features include: 100% colored recycled shredded rubber and a single component polyurethane; meets ASTM F-1292 Standard Specification for Impact Attenuation when properly installed; meets ASTM F-1951 Standard Specification for Accessibility when properly installed with playground equ…

5. Gametime – Recycled Bonded Rubber

Domain: gametime.com

Registered: 1994 (31 years)

Introduction: Bonded Rubber – Model Number: RecycledBonded1. Description: A single layer system made from recycled materials and binder poured and spread over sub-base. Best for natural look and walking paths. Advantages include low maintenance, easy to clean, good shock absorbency, and material stability against play or weather-related events. Required Sub-Base: Concrete, Asphalt, Compacted Aggregate. Maintena…

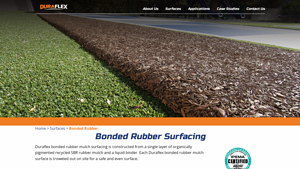

6. Duraflex – Bonded Rubber Mulch Surfacing

Domain: duraflexsurfacing.com

Registered: 2021 (4 years)

Introduction: Duraflex bonded rubber mulch surfacing is constructed from a single layer of organically pigmented recycled SBR rubber mulch and a liquid binder. Each surface is troweled out on site for a safe and even surface. It is ASTM approved and ADA compliant, more affordable than traditional poured-in-place surfaces, clean and non-toxic, with a seamless, natural appearance. The porous surface drains and dr…

7. Robertson Surfaces – Bonded Rubber

Domain: robertsonsurfaces.com

Registered: 2022 (3 years)

Introduction: Bonded Rubber is a seamless surface made from shredded rubber pieces, poured on-site in a single-layer system. It resembles bonded rubber mulch, providing a natural appearance for outdoor facilities. Key features include:

– Available in six natural colors and three colorful mixes.

– Suitable for playgrounds, trails, and landscaping applications.

– Made from 100% recycled rubber, ensuring an eco…

Strategic Sourcing Conclusion and Outlook for bonded rubber

Why Should B2B Buyers Consider Bonded Rubber for Their Projects?

In today’s competitive landscape, strategic sourcing of bonded rubber presents an opportunity for international B2B buyers to enhance safety, aesthetics, and cost-efficiency in playground and recreational surface applications. This versatile material not only meets rigorous safety standards but also offers low maintenance and durability, making it a superior choice over traditional surfacing options. By prioritizing suppliers who can provide high-quality, sustainable products, businesses can ensure compliance with local regulations while also appealing to environmentally conscious consumers.

Illustrative image related to bonded rubber

How Can Strategic Sourcing of Bonded Rubber Benefit Your Business?

Investing in bonded rubber solutions can significantly reduce long-term operational costs, despite higher initial installation expenses. Its longevity and minimal upkeep requirements contribute to lower lifetime costs, making it an economically sound choice for various applications, from playgrounds to commercial spaces. Buyers should engage with reputable suppliers who offer tailored solutions, ensuring the materials meet specific regional needs and preferences.

What is the Future Outlook for Bonded Rubber in Global Markets?

Looking ahead, the demand for bonded rubber is expected to grow, driven by increasing awareness of safety standards and environmental sustainability. As markets in Africa, South America, the Middle East, and Europe continue to evolve, businesses that leverage strategic sourcing to integrate bonded rubber into their offerings will gain a competitive edge. Now is the time to partner with experienced suppliers to explore innovative applications and secure your place in this expanding market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to bonded rubber

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.